NPN-Silizium-Fototransistor in SMT-Gehäuse mit Linse

Silicon NPN Phototransistor in SMT-Package with lens

Lead (Pb) Free Product - RoHS Compliant

SFH 3219

Wesentliche Merkmale

• TOPLED mit Linse

• Speziell geeignet für Anwendungen im Bereich

von 430

• Hohe Linearität

• Für alle Lötverfahren geeignet

• Gehäusegleich mit SFH 4209, SFH 4219,

SFH

Anwendungen

• Miniaturlichtschranken für Gleich- und

Wechsellichtbetrieb

• Industrieelektronik

• „Messen/Steuern/Regeln“

• Automobiltechnik

• Sensorik

Typ

Type

SFH 3219 Q65110A2529

nm bis 1150 nm

4289

Bestellnummer

Ordering Code

Features

• TOPLED with lens

• Especially suitable for applications from

nm to 1150 nm

430

• High linearity

• Suitable for all soldering methods

• Same package as SFH 4209, SFH 4219,

4289

SFH

Applications

• Miniature photointerrupters

• Industrial electronics

• For control and drive circuits

• Automotive technology

• Sensor technology

2005-04-29 1

Grenzwerte Maximum Ratings

SFH 3219

Bezeichnung

Parameter

Betriebs- und Lagertemperatur

Operating and storage temperature range

Kollektor-Emitterspannung

Collector-emitter voltage

Kollektorstrom

Collector current

Kollektorspitzenstrom, τ < 10 µs

Collector surge current

Verlustleistung, TA = 25 ° C

Total power dissipation

Wärmewiderstand für Montage auf PC-Board

Thermal resistance for mounting on pcb

Symbol

Symbol

T

; T

op

stg

V

CE

I

C

I

CS

P

tot

R

thJA

Wert

Value

Einheit

Unit

– 40 … + 100 ° C

35 V

15 mA

75 mA

165 mW

450 K/W

2005-04-29 2

Kennwerte (TA = 25 ° C, λ = 950 nm)

Characteristics

SFH 3219

Bezeichnung

Parameter

Wellenlänge der max. Fotoempfindlichkeit

Wavelength of max. sensitivity

Spektraler Bereich der Fotoempfindlichkeit

S = 10% von S

max

Spectral range of sensitivity

S = 10% of S

max

Bestrahlungsempfindliche Fläche (∅ 240 µm)

Radiant sensitive area

Abmessung der Chipfläche

Dimensions of chip area

Halbwinkel

Half angle

Kapazität, VCE = 0 V, f = 1 MHz, E = 0

Capacitance

Dunkelstrom

Dark current

V

= 20 V, E = 0

CE

Fotostrom

Photo current

E

= 0.1 mW/cm2, VCE = 5 V

e

Anstiegszeit/Abfallzeit

Rise and fall time

I

= 1 mA, VCC = 5 V, RL = 1 kΩ

C

Kollektor-Emitter-Sättigungsspannung

Collector-emitter saturation voltage

I

= 20 µA

C

E

= 0.1 mW/cm

e

2

Symbol

Symbol

λ

S max

Wert

Value

Einheit

Unit

990 nm

λ 430 … 1150 nm

A

L × B

0.045 mm

0.45 × 0.45 mm × mm

2

L × W

ϕ ± 25 Grad

deg.

C

I

I

t

V

CE

CEO

PCE

, t

r

CEsat

f

5.0 pF

1 (≤ 50) nA

≥ 63 µA

7 µs

150 mV

2005-04-29 3

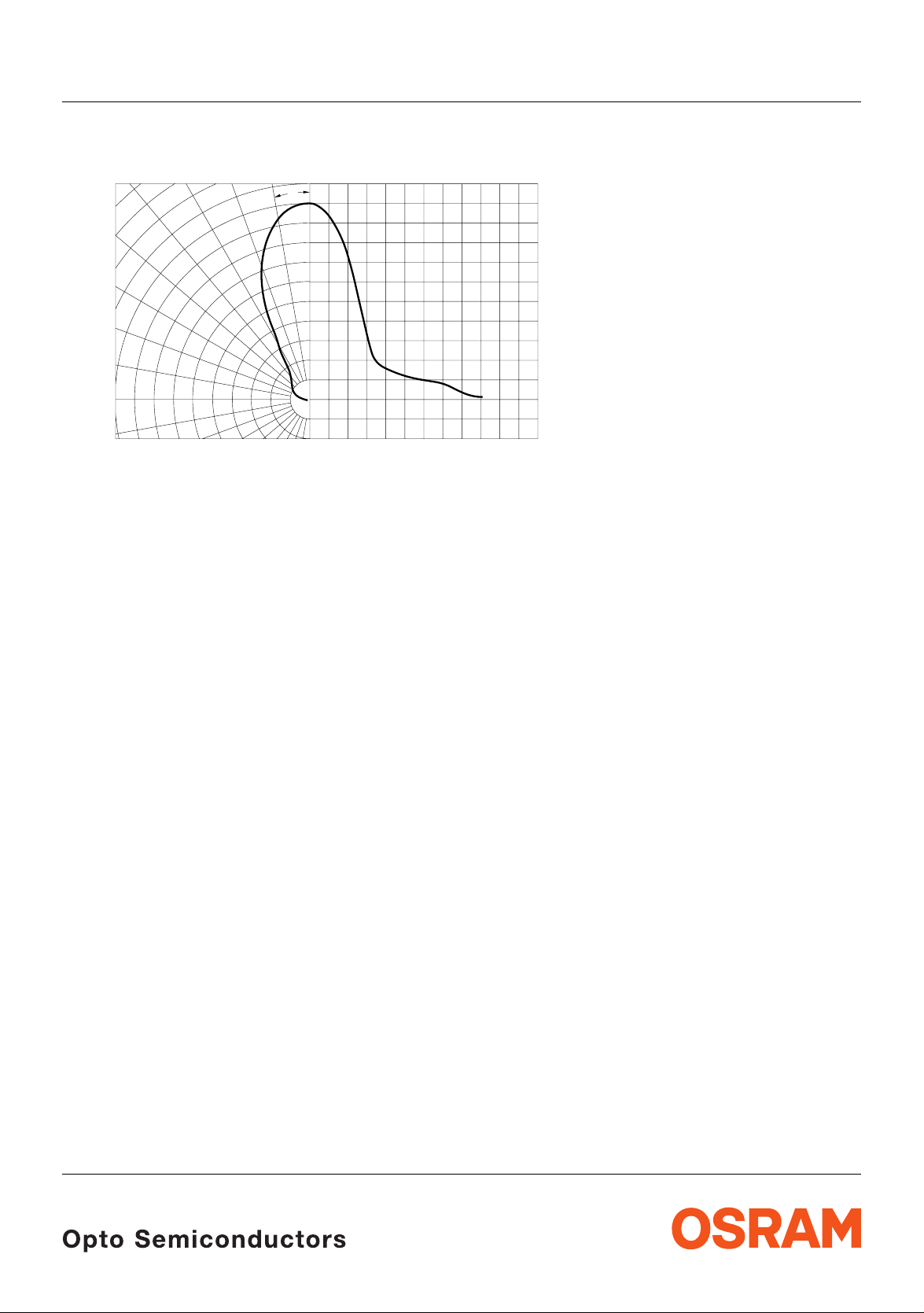

Directional Characteristics

S

= f (ϕ)

rel

SFH 3219

0˚10˚20˚40˚ 30˚

ϕ

1.0

OHF00006

50˚

60˚

70˚

80˚

90˚

100˚

1.0 0.8 0.6 0.4

0.8

0.6

0.4

0.2

0

0˚ 20˚ 40˚ 60˚

80˚

100˚ 120˚

2005-04-29 4

SFH 3219

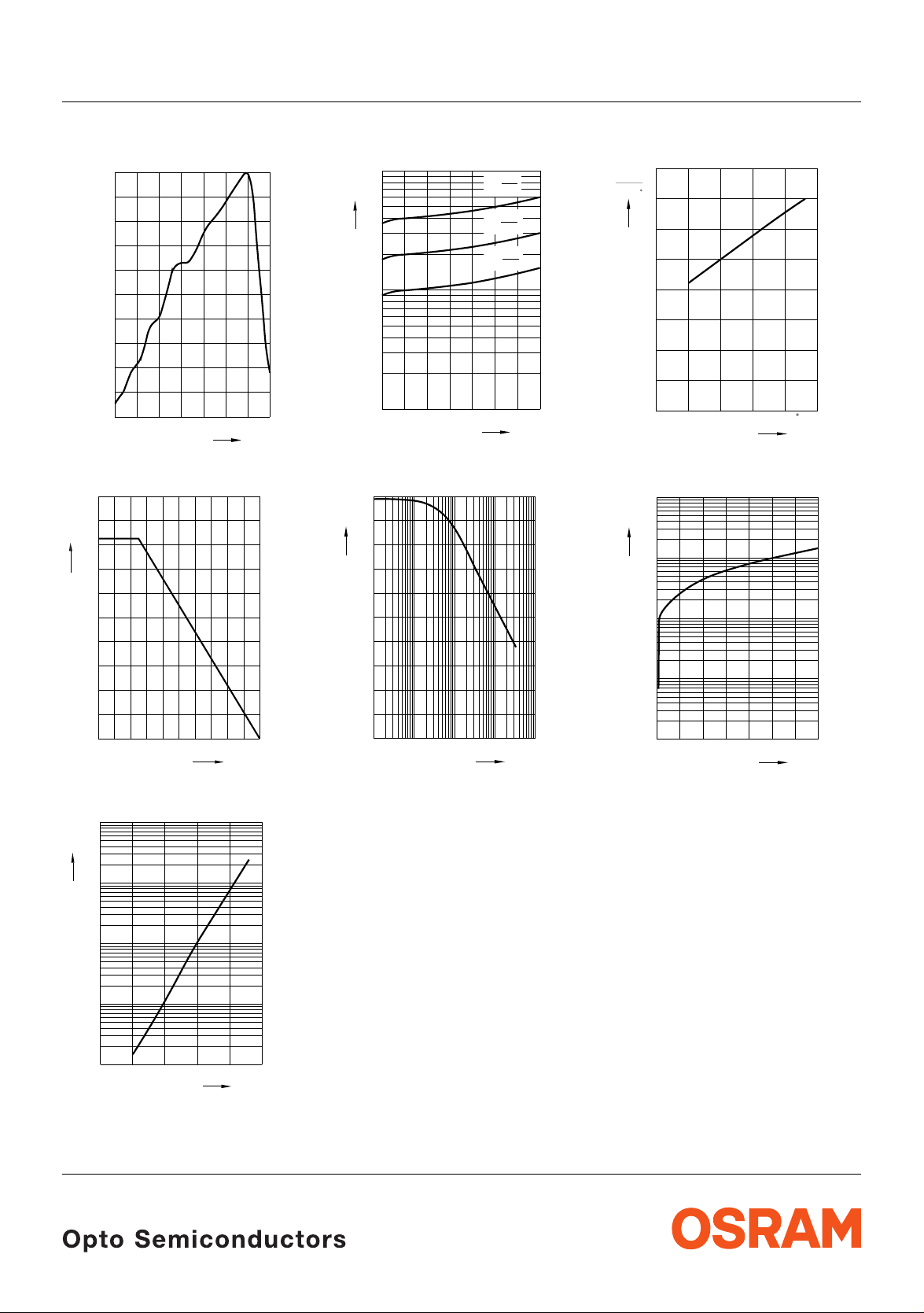

Relative Spectral Sensitivity

S

= f (λ)

rel

100

%

S

rel

80

OHF00207

70

60

50

40

30

20

10

0

400

500 600 700 800 900 1100

nm

λ

Total Power Dissipation

P

= f (TA)

tot

200

mW

P

tot

160

120

80

40

0

0

20 40 60 80 ˚C 100

OHF00871

T

A

Dark Current

I

= f (TA), VCE = 5 V, E = 0

CEO

Ι

CEO

3

10

OHF01530

Photocurrent

I

= f (VCE), Ee = Parameter

PCE

0

10

mA

Ι

PCE

-1

10

-2

10

0

5 10 15 20 25 30 35

Capacitance

C

= f (VCE), f = 1 MHz, E = 0

CE

5.0

C

pF

CE

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0

-2

10

10-110010110

0.4

0.2

0.1

OHF00007

mW

2

cm

mW

2

cm

mW

2

cm

V

CE

OHF01528

V

V

CE

Photocurrent

I

PCE /IPCE25°

1.6

Ι

PCE

Ι

PCE

25

1.4

1.0

0.8

0.6

0.4

V

= f (TA), VCE = 5 V

1.2

0.2

0

-25

0 25 50 75 100

OHF01524

C

T

A

Dark Current

I

= f (VCE), E = 0

CEO

1

10

nA

Ι

CEO

0

10

-1

10

-2

10

-3

2

10

0 5 10 15 20 25 30 35V

OHF01527

V

CE

2

10

1

10

0

10

-1

10

-25nA0 25 50 75 100

˚C

T

A

2005-04-29 5

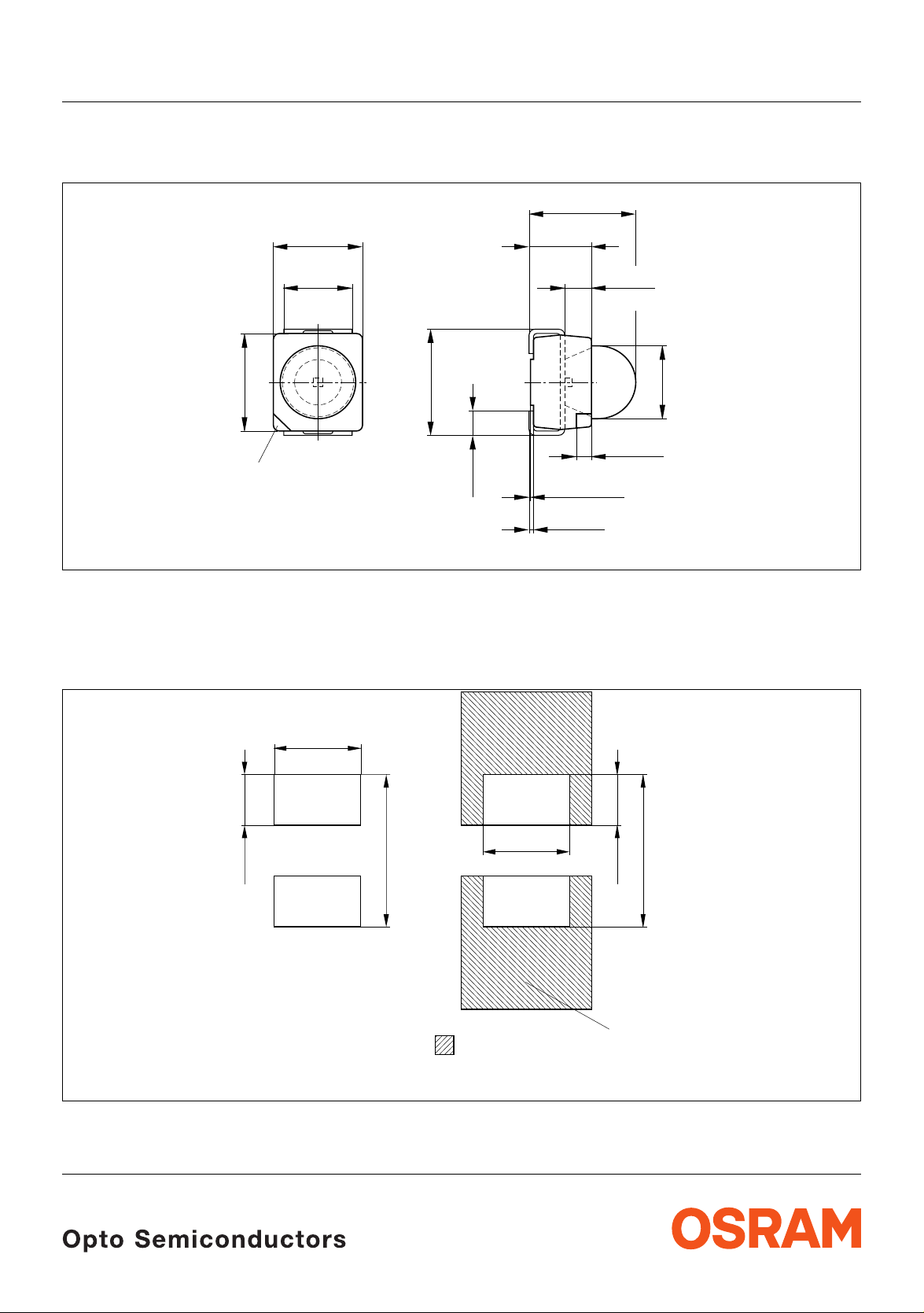

Maßzeichnung Package Outlines

SFH 3219

3.5 (0.138) max.

3.0 (0.118)

2.6 (0.102)

2.3 (0.091)

2.1 (0.083)

1

3.4 (0.134)

3.0 (0.118)

2

Package

marking

Kathodenkennung: abgeschrägte Ecke

Cathode mark: bevelled edge

Empfohlenes Lötpaddesign

Recommended Solderpad Design

3.7 (0.146)

3.3 (0.130)

1.1 (0.043)

2.1 (0.083)

1.7 (0.067)

0.1 (0.004) (typ.)

0.5 (0.020)

0.18 (0.007)

0.13 (0.005)

0.9 (0.035)

0.7 (0.028)

ø2.60 (0.102)

0.6 (0.024)

0.4 (0.016)

GEOY6956

ø2.55 (0.100)

2.6 (0.102)

2.6 (0.102)

1.5 (0.059)

Padgeometrie für

verbesserte Wärmeableitung

Paddesign for

improved heat dissipation

4.5 (0.177)

Lötstopplack

Solder resist

Cu-Fläche > 16 mm

Cu-area > 16 mm

4.5 (0.177)

1.5 (0.059)

2

2

OHLPY970

Maße werden wie folgt angegeben: mm (inch) / Dimensions are specified as follows: mm (inch).

2005-04-29 6

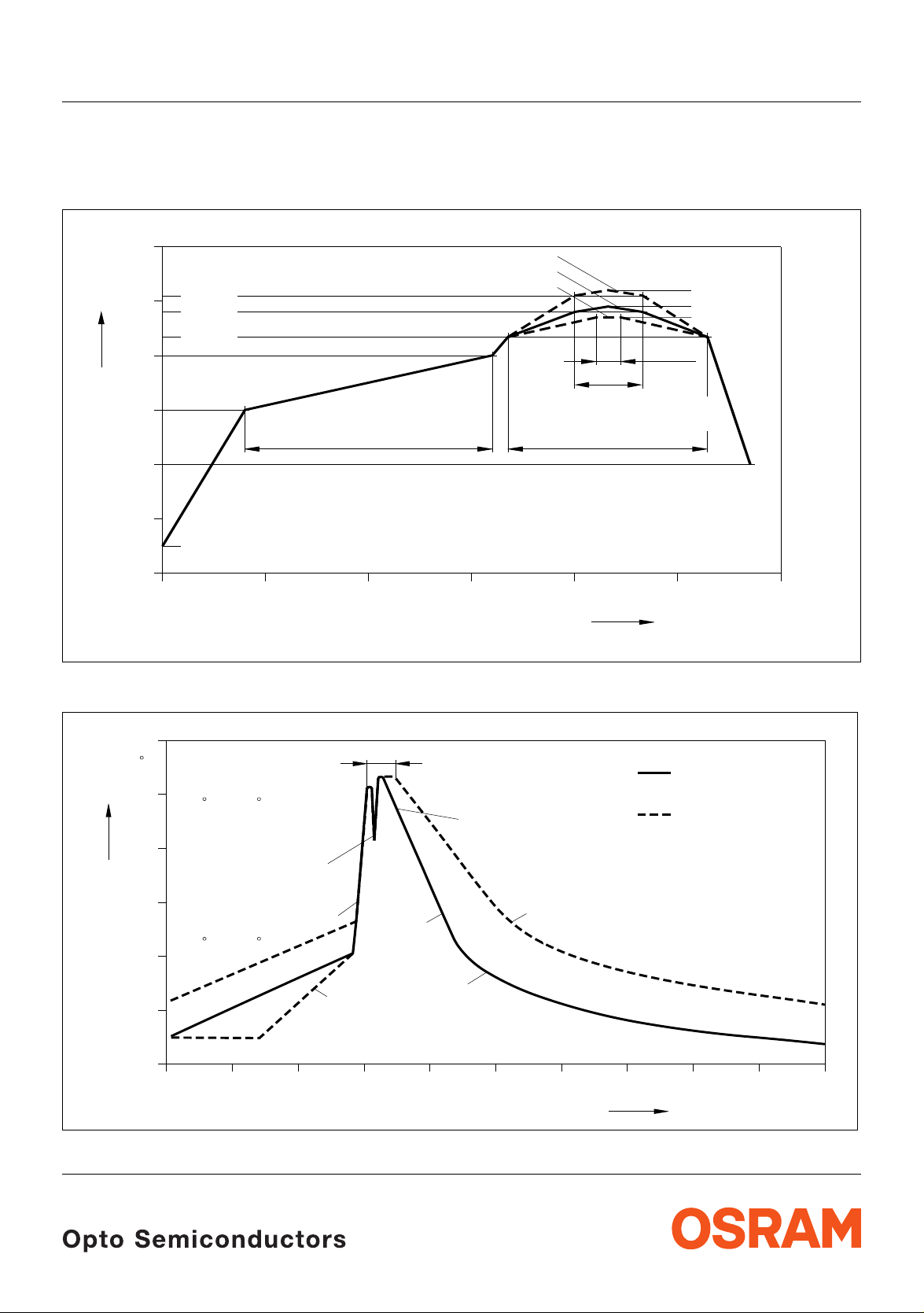

SFH 3219

Lötbedingungen Vorbehandlung nach JEDEC Level 2

Soldering Conditions Preconditioning acc. to JEDEC Level 2

IR-Reflow Lötprofil für bleifreies Löten (nach J-STD-020B)

IR Reflow Soldering Profile for lead free soldering (acc. to J-STD-020B)

300

˚C

250

T

255 ˚C

240 ˚C

Maximum Solder Profile

Recommended Solder Profile

Minimum Solder Profile

217 ˚C

200

10 s min

30 s max

150

120 s max

100 s max

Ramp Down

6 K/s (max)

100

Ramp Up

50

3 K/s (max)

25 ˚C

0

0

50 100 150 200 250 300

Wellenlöten (TTW) (nach CECC 00802)

TTW Soldering (acc. to CECC 00802)

OHLA0687

260 ˚C

245 ˚C

235 ˚C

+0 ˚C

-5 ˚C

±5 ˚C

+5 ˚C

-0 ˚C

s

t

300

C

250

T

200

150

100

235 C

CC... 130100

50

0

0

C... 260

1. Welle

1. wave

ca 200 K/s

50 100 150 200 250

10 s

2 K/s

5 K/s

Zwangskühlung

forced cooling

2005-04-29 7

2. Welle

2. wave

OHLY0598

Normalkurve

standard curve

Grenzkurven

limit curves

2 K/s

s

t

SFH 3219

Published by

OSRAM Opto Semiconductors GmbH

Wernerwerkstrasse 2, D-93049 Regensburg

www.osram-os.com

© All Rights Reserved.

The information describes the type of component and shall not be considered as assured chara cteristics.

Terms of delivery and rights to change design reserved. Due to technical requirements components may contain

dangerous substances. For information on the types in question please contact our Sales Organization.

Packing

Please use the recycling operators known to you. We can also help you – get in touch with your nearest sales office.

By agreement we will take packing material back, if it is sorted. You must bear the costs of transport. For packing

material that is returned to us unsorted or wh ich we are not obliged to accept, we shall hav e to invoice you for any costs

incurred.

Components used in life-support devices or systems must be expressly authorized for such purpose! Critical

components 1 , may only be used in life-support devices or systems 2 with the express written approval of OSRAM OS.

1

A critical component is a component used in a life-support device or sys tem whose failure can reasonably be expected

to cause the failure of that life-support device or system, or to affec t its safety or e ffectiveness of that dev ice or system.

2

Life support devices or systems are intended (a) to be implanted in the h uman body, or (b) to support and/or maintain

and sustain human life. If they fail, it is reasonable to assume that the health of the user may be endangered.

2005-04-29 8

Loading...

Loading...