Page 1

ECG for T5 fluorescent lamps

Technical Guideline

May 2005

Electronic Control

Gear to operate

T5/Ø 16 mm

fluorescent lamps

ECG to operate

T5-fluorescent lamps

Features

Product Overview

Technical Details

Instruction Manual

Tender Documents

FAQ

Page 2

Contents

1.

Introduction.......................................................................................... 6

1.1 History.....................................................................................6

1.2 T5/∅ 16 mm-Fluorescent Lamps............................................7

1.2.1 High Efficiency FH®…HE........................................................8

1.2.2 High Output FQ®…HO............................................................8

1.2.3 Fluorescent Circular FC®........................................................8

1.2.4 Comparison of Lumens between T8/∅ 26 mm- and

T5/∅ 16 mm-Fluorescent Lamps............................................8

1.3 Electronic Control Gear ..........................................................8

1.4 Different Principles, Different Behavior................................... 9

1.5 Advantages of Electronic Control Gear ..................................9

1.6 Saving Energy with Electronic Control Gear...........................9

1.7 Ignition of Fluorescent Lamps...............................................10

1.8 Costs and Safety ..................................................................10

1.9 Flexibility upon Request........................................................10

1.10 ECG bring Progress..............................................................10

1.11 The right ECG for every Application .....................................10

1.12 OSRAM ECG Milestones......................................................11

2. Product Features ...............................................................................12

2.1 Lighting Comfort ...................................................................12

2.2 Economy...............................................................................12

2.3 Safety....................................................................................12

2.4 Supply Voltage......................................................................13

2.4.1 Overvoltage and its Reason .................................................13

2.4.2 Possible Implications due to Overvoltage.............................14

2.4.3 Undervoltage and its Reason ...............................................14

2.4.4 Possible Implications due to Undervoltage........................... 14

2.4.5 Supply Voltage QT with 21 mm height ................................14

2.4.6 Supply Voltage for QT with 30 mm height ............................ 15

2.4.7 ECG for 120V / 277V Line Voltage....................................... 15

2.5 Automatic Lamp Restart .......................................................15

2.5.1 Lamp ignition for QTi ............................................................16

2.5.2 Lamp ignition for QT to operate T5-fluorescent lamps .........16

2.5.3 Off- Time for Optimum Preheat Start....................................16

2.6 Behaviour in Response to Lamp Defects .............................16

2.6.1 One-Lamp Operation with Multi-Lamp ECG ......................... 16

2.7 Noise.....................................................................................17

2.8 Power Factor λ .....................................................................18

2.9 ECG Imprint.......................................................................... 19

2.10 Reliability ..............................................................................19

2.11 Resistance to Frequent Switching ........................................19

2.12 ECG Lifetime ........................................................................19

2.13 Thermal influences of the system components ....................20

2.14 cut-off Technology ................................................................20

2.14.1 Advantages for Users ...........................................................21

2.14.2 Physical Background ............................................................21

1

Page 3

End of Life (EoL acc. to T.2)................................................22

2.15

2.16 U-OUT ..................................................................................22

2.17 Approval Marks.....................................................................23

2.17.1 ENEC-Approval Mark ...........................................................23

2.17.1.1 Safety acc. to EN 61347 ............................................23

2.17.1.2 Performance acc. to EN 60929..................................23

2.17.2 VDE EMC mark ....................................................................23

2.18 Energie Efficiency Index EEI ................................................24

2.19 CE Labelling .........................................................................24

2.20 CCC Approval.......................................................................25

3. ECG installed in Luminaire: Installations and Operation

Instructions 26

3.1 Wiring Instructions ................................................................26

3.1.1 Cable Types..........................................................................26

3.1.2 Cable Cross-Sections...........................................................26

3.1.3 Release of Contacts .............................................................27

3.1.4 Insulation ..............................................................................29

3.1.5 Terminals..............................................................................29

3.1.6 Cable routing ........................................................................29

3.2 Electromagnetic Compatibility ..............................................30

3.2.1 Harmonic Content acc. to EN 61000-3-2..............................30

3.2.2 Radio interference suppression............................................31

3.3 Permissible Cable Lengths................................................... 36

3.4 „Hot Wires“............................................................................36

3.5 Switching between Lamp and ECG...................................... 37

3.6 Master-Slave Circuit .............................................................37

3.6.1 Max. length of the connecting cable between 2 luminaries ..38

3.7 PE-Connection for Protection Class I Luminaires.................38

3.8 Functional Earth for Luminaires of Protection Class II.........39

3.8.1 General Information.............................................................. 40

3.8.2 Practical Details....................................................................40

3.9 Temperature Ranges............................................................41

3.9.1 Self heating ECG..................................................................41

3.9.2 Control Gaer Temperatures..................................................42

3.1.2.1 ECG in 30 mm height.................................................27

3.1.2.2 ECG in 21 mm height.................................................27

3.1.3.1 WAGO 250................................................................. 27

3.1.3.2 WAGO 251 – IDC.......................................................27

3.1.3.3 WAGO 251 – horizontal plug .....................................28

3.1.3.4 WAGO 251 mini – IDC...............................................28

3.1.3.5 WAGO 251 mini – horizontal plug.............................. 28

3.2.2.1 Causes of Radio Interference ....................................31

3.2.2.2 Conducted Interferences acc. to EN 55015 ...............31

3.2.2.3 Disturbances due to Fields.........................................32

3.2.2.4 Selective Shielding..................................................... 32

3.2.2.5 Installation Instructions for avoiding Disturbance....... 33

3.2.2.6 Asymmetric installation of ECG..................................34

3.2.2.7 Good wiring arrangement for 2-lamp luminaires........ 35

3.2.2.8 Luminaires with reflector and/or specular louvres...... 35

2

Page 4

3.9.2.1

3.9.2.2 Ambient Temperature ECG : ta..................................43

3.9.3 Lamp Temperature ...............................................................43

3.9.3.1 Maximum Luminous Flux for T5/∅ 16 mm-Fluorescent

3.9.4 General Recommendations for Installation...........................44

3.9.5 Measuring the Temperature .................................................44

3.10 Luminaire Wiring Test for Two-lamp Luminaires ..................45

3.10.1 Testing with a Test Adapter and Dummy Lamps.................. 45

3.11 ECG Operation for Luminaires of Protection Classes I and II48

3.12 Insulation Distances in Luminaires .......................................48

3.13 Insulation Test ......................................................................48

3.13.1 Dielectric Resistance in Lighting Systems............................49

3.13.2 Mesuring the Dielectric Resistance between N and PE or L

3.13.3 Three-Phase Operation ........................................................50

3.13.4 Resistance to Overvoltage for QUICKTRONIC for

3.14 Inrush Current / Automatic Circuit Breakers .........................50

3.15 RCDs / Fault Currents ..........................................................51

3.16 Leakage Current...................................................................51

3.17 ECGs in Three-Phase Operation..........................................51

Measuring Point Temperature tc................................42

Lamps ........................................................................43

and PE..................................................................................49

T5/∅16mm- Fluorescent Lamps...........................................50

4. Lamp Wiring.......................................................................................53

4.1 h = 21 mm............................................................................. 53

4.1.1 QUICKTRONIC® INTELLIGENT 1-lamp version ..................53

4.1.2 QUICKTRONIC ® INTELLIGENT 2-lamp version .................53

4.1.3 QT-FH MULTIWATT F/CW...................................................53

4.1.4 QT-FQ F/CW 1-lamp version................................................53

4.1.5 QT-FQ F/CW 2-lamp version................................................54

4.2 h= 30 mm.............................................................................. 54

4.2.1 QT-FH MULTIWATT 1- and 2-lamp version .........................54

4.2.2 QT-FH 3- and 4-lamp version............................................... 54

4.2.3 QT-FQ 1-lamp version.......................................................... 55

4.2.4 QT-FQ 2-lamp version.......................................................... 55

5. QUICKTRONIC INTELLIGENT...........................................................56

5.1 Definition INTELLIGENT.......................................................56

5.2 Lamp Detection as Fundamental Advantage........................56

5.3 QTi – the High-tech ECG......................................................56

5.4 QTi – Advantages................................................................. 56

5.5 QTi – Practically Applied.......................................................57

5.6 Technical Specialties for non-dimmable QTi ........................57

5.6.1 Inrush current limitation ........................................................57

5.6.2 Resistance to Overvoltage up to 400V .................................58

5.6.3 Lamp-ECG-Combination ......................................................58

5.6.3.1 Straight Fluorescent types .........................................58

5.6.3.2 Compact and Circular lamp types.............................. 59

5.6.4 Wiring ....................................................................................59

3

Page 5

Dimensions...........................................................................60

5.6.5

5.7 FAQ ......................................................................................60

6. Special Applications .........................................................................61

6.1 Outdoor Application ..............................................................61

6.1.1 Installation Instructions .........................................................61

6.1.2 OUTKIT.................................................................................62

6.2 T5-ECG in Sound Studios ....................................................62

6.2.1 Noise and how to avoid it......................................................62

6.2.2 Recommended minimum distance between lamp and

refelctor................................................................................. 63

6.3 Treatment Rooms, Operating Rooms...................................64

6.3.1 Electromagnetic Interference................................................ 64

6.3.2 Interference from Infrared Transmission Equipment ............65

6.4 Electronic Tagging................................................................65

6.5 Emergency Lighting..............................................................65

6.5.1 Different criteria for lighting................................................... 67

6.5.1.1 Switch-over time for QTi – h=21 mm .........................67

6.5.1.2 Switch-over time for QT-FH…CW – h=30 mm........... 67

6.5.1.3 Switch-over time for QT-FQ…CW – h=30 mm ..........67

6.5.1.4 Switch-over time for QT-…F/CW – h=21 mm ............67

6.5.2 Wiring diagrams for emergency lighting units.......................68

6.5.2.1 Wiring diagram QT-FH 3x14 CW with emergency

lighting component from BAG ....................................68

6.5.2.2 Wiring diagram QT-FH 4x14 CW with emergency

lighting component from BAG ....................................68

6.5.2.3 Wiring diagram QT-FH 3x14 CW with emergency

lighting component from OMNITRONIX..................... 69

6.5.2.4 Wiring diagram QT-FH 4x14 CW with emergency

lighting component from OMNITRONIX..................... 69

6.6 DC supply .............................................................................69

6.7 Portable Luminaires..............................................................70

6.8 Mix-up of FH®- and FQ®-Fluorescent Lamps........................70

7. Appendix ............................................................................................ 72

7.1 Overview of Maximum Cable Lengths..................................72

7.1.1 QUICKTRONIC® INTELLIGENT...........................................72

7.1.2 QT-FH MULTI...CW.............................................................. 72

7.1.3 QT-FQ...CW -30 mm height- ................................................72

7.1.4 QT-FH MULTI…F/CW -21 mm height- .................................72

7.1.5 QT-FQ…F/CW -21 mm height-.............................................73

7.1.6 QT-FC...................................................................................73

7.2 Terminal Types.....................................................................73

7.3 Inrush Currents.....................................................................73

7.4 Lamp/ECG Combinations..................................................... 74

7.5 OSRAM Installation Tips for T5-Systems ............................. 74

7.5.1 Recommended Minimum Distance between Lamp and

Reflector ...............................................................................75

7.5.2 Recommended Minimum Distance between two T5/∅16mm-

Fluorescent Lamps ...............................................................75

4

Page 6

Luminaire Optimisation.........................................................76

7.5.3

7.5.4 Maximum luminous flux for FH…HE fluorescent lamps .......76

7.5.5 Verticalness Operation .........................................................76

8. Troubleshooting Tips........................................................................77

8.1 General.................................................................................77

8.2 Equipment Behaviour on Overvoltage.................................. 77

8.3 Equipment Behaviour on Under Voltage ..............................78

8.4 Application faults...................................................................78

8.4.1 Wiring faults on the lamp side...............................................78

8.4.2 Short-to-ground at the output of QUICKTRONIC® ECG.......78

8.4.3 Effects of moisture................................................................78

8.4.4 Installing luminaires in draughty locations ............................78

8.5 Trouble Shooting ..................................................................79

8.5.1 Lamp does not start..............................................................79

8.5.2 Brief Glimmer........................................................................80

8.5.3 Lamp goes out during operation...........................................81

8.5.4 Different brightness levels ....................................................82

8.5.5 Fault in other electrical equipment........................................ 83

8.5.6 Problems at master-slave operation..................................... 83

8.5.7 Humingh or “chirping” from the ECG ....................................83

9. Lamp-ECG Combinations .................................................................84

9.1 FQ®...HO-Fluorescent Lamps...............................................84

9.2 FH®...HE-Fluorescent Lamps ...............................................85

9.3 FC®…Fluorescent Lamps.....................................................85

10. Tender Documents ............................................................................87

10.1 QUICKTRONIC® INTELLIGENT QTi....................................87

10.2 QUICKTRONIC® MULTIWATT for FH…HE h = 30 mm ...... 87

10.3 QUICKTRONIC® for FQ…HO h = 30 mm ............................88

11. Index ................................................................................................... 89

5

Page 7

1. Introduction

1.1 History

The development of linear fluorescent goes back to the thirties of the 20th

century. The diameter of 51mm was very voluminous. However, better

efficiency did not come up before the fifties.

1879

Kohlefaden-Glühlampe

von Thomas A. Edison

Incandescent lamps with carbon filament

by Thomas A. Edison

1910

Glühlampen mit Wolfram-Wendel

Incandescent lamps with tungsten coils

1925

BILUX®Zweidraht-Scheinwerferlampen

®

two-wire headlight lamps

BILUX

1931

Natriumdampf-Niederdrucklampen

Low-pressure sodium vapor lamps

1933

Quecksilberdampf-Hochdrucklampen

High-pressure m ercury vapor lamps

1936

Leuchtstofflampen

Fluorescent lamps

1954

XBO Xenon-Hochdrucklampen

XBO high-pressure

xenon lamps

1968

VIALOX® NAV Standard

Natriumdampf-Hochdrucklampen

®

NAV Standard

VIALOX

high-pressure sodium vapor lamps

1968

POWERSTAR HQI

Halogen-Metalldampflampen

POWERSTAR HQI

metal halide lamps

1970

HMI METALLOGEN®Lampen

HMI METALLOGEN

1971

BILUX®H4

Halogen-Zweidraht-Scheinwerferlampen

BILUX

two-wire halogen headlight lamps for auromobiles

1973

HALOSTAR Niedervolt-Halogenglühlampen

HALOSTAR low-voltage tungsten-halogen lamps

1979

LUMILUX

Leuchtstofflampen

LUMILUX

fluorescent lamps

1980

EVG QUICKTRONIC®DE LUXE / ECG

QUICKTRONIC

1982

OSRAM DULUX®L

Kompakt-Leuchtstofflampen

OSRAM DULUX

compact fluorescent lamps

1984

DECOSTAR Niedervolt-Halogenglühlampen

mit Kaltlichtreflektor

DECOSTAR low-voltage tungsten-halogen

lamps with dichroic reflectors

®

lamps

®

H4

®

®

®

DE LUXE

®

L

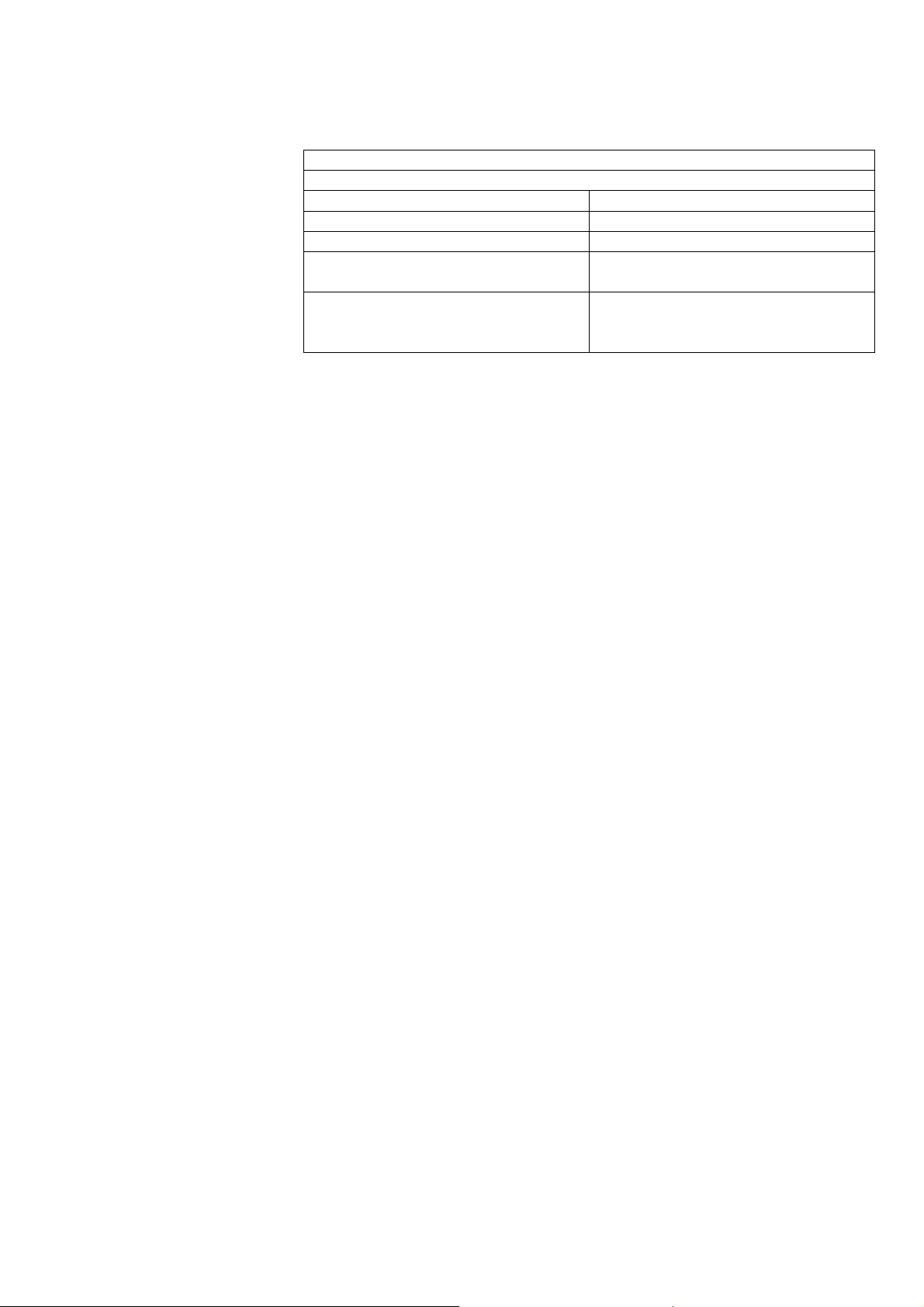

PL (W)UN (V)fN (Hz)IN (A)lta ( C)

22050600,090,95 C

1xL18 W1x16-2050

2400,0850,93 C

Anwendungsbereich: AC/DC 198 V bis 254 V

Geeignet fr Batteriespannungen 154 V bis 276 V

Zur Verwendung in Anlagen nach VDE 0108 geeignet

Range of application: AC/DC 198 V to 254 V

Temp.-Test

Range of battery voltage: 154 V to 276 V

c = 70 C max.

t

Suitable for emergency installations acc. to VDE 0108

class B

0712T201 OW2 Made in Germany

1985

OSRAM DULUX®EL Kompaktleuchtstofflampen mit elektronischem Vorschaltgerät

®

OSRAM DULUX

with electronic control gear

1987

POWERSTAR HQI-T

Halogen-Metalldampflampen

POWERSTAR HQI-T

compact metal halide lamps

1991

D1 Gasentladungslampen

D1 gas discharge lamps

1993

COLORSTAR DSX-T 80W

Natrium-Xenonlampen

COLORSTAR DSX-T 80W

sodium xenon lamps

1993

FM Mini-Leuchtstofflampen / FM mini fluorescent

lamps

1995

FH Hocheffiziente Leuchtstofflampen / FH highefficient fluorescent lamps

1

2

L

3

4

OSRAM

1996

FQ Lichtstarke Leuchtstofflampe / FQ high power

fluorescent lamps

1997

OSRAM ENDURA Die elektrodenlose

Hochleistungsleuchtstofflampe

OSRAM ENDURA The high-performance

electrodeless fluorescent lamp

EL energy-saving lamps

The improvements according to the luminous flux and lifetime with the T12

lamp (38 mm diameter) made an economic and even outdoor application

possible. There were continuous improvements for optimizations as for

example Amalgamtechnology. In this term fluorescent lamps were operated

by conventional control gears (CCG).

The decisive breakthrough was at the end of the 70s and early 80s. In the

year 1978, a new T8/∅ 26 mm- lamp generation started to replace

T12/∅38mm- fluorescent lamps. New phosphors with higher resistance

came into the market. Nowadays known under triband-phosphor (LUMILUX

light colours). The diameter of the lamps was reduced from 38mm to 26mm

however the length was kept with 59, 120 and 150 cm as the sockets G13.

The new wattage of 18, 36 and 58 W was advantageous as it was a

reduction of at least 10% compared to the T12/∅38 mm lamps in 20, 40

and 65 W.

This was also the hour of birth for the Electronic Control Gears (ECG). First

the circuits were in a instant start mode what also was called softstart up to

the programmed or preheat start. Together with modern Electronic Control

Gear QUICKTRONIC T8/∅26 mm- fluorescent lamps became even more

efficient and longer lasting. In addition, the thermal behavior of the

luminous flux was improved.

The T8-system was permanently improved as the example of the tribandphosphor shows with a very high service life of the fluorescent lamp.

In 1995, the next milestone of fluorecent lamp development saw the

introduction of new FH...HE (H

igh Efficiency) systems to the market. With

the reduced diameter of 16 mm only the lamp was designed. It is available

in 14, 21, 28 and 35 W with the G5 sockets. It is 50 mm shorter as the T8

fluorescent lamps.

T5 fluorescent lamps only can be operated by Electronic Control Gear. So

the light output and the life time of the lamp were designed from the

beginning to an optimum of up to 104 lm/W. The maximum luminous flux of

the T5 lamps is at 35 °C compared to 25 °C at T8 or T12 lamps. The

reduced lamp diameter of 16 mm as the maximum lumen output at 35 °C

are the relevant feature for a higher efficiency of the fixture.

6

Page 8

In 1996, the T5 lamp family was completed with the types of higher lumens

than volume FQ

®

…HO (High Output)-fluorescent lamps. They are available

in the wattage of 24, 39, 49, 54 and 80 W with the identical lengths as the

FH…HE types. With up to 7000 lm for FQ 80 W HO this is the lamp family

with the highest light output.

In 1999, the third member of the T5/∅ 16 mm-lamp family was introduced

to the market. Away from usual light strips, compact, efficient and

unconventional luminaires benefit from this new, circular FC

®

-lamp: 50 %

more light output than with comparable standard circular lamps.

Special Note:

Independent of the lamp diameter of the fluorescent lamp the luminous flux

is specified for an ambient temperature of 25 °C. These values are

exclusive to be used for light plannings. The value of the luminous flux is

for the T5/∅ 16 mm fluorescent lamps FH

®

...HE and FQ®...HO for 25 °C

below the values for 35 °C. The values at 35 °C ambient temperature are

only for information. The Circular lamps FC

®

only have value of luminous

flux at 25 °C. The advantages of the T5/∅ 16 mm fluorescent lamps show

their advantages in the improved efficiency of the fixture.

Detailed technical information about QUICKTRONIC

®

are shown in the

latest indoor outdoor lighting and can be downloaded under

www.osra.de/ecg

.

QUCKTRONIC

®

for the operation of the T5/∅ 16 mm fluorescent lamps

have all features of a high quality ECG.

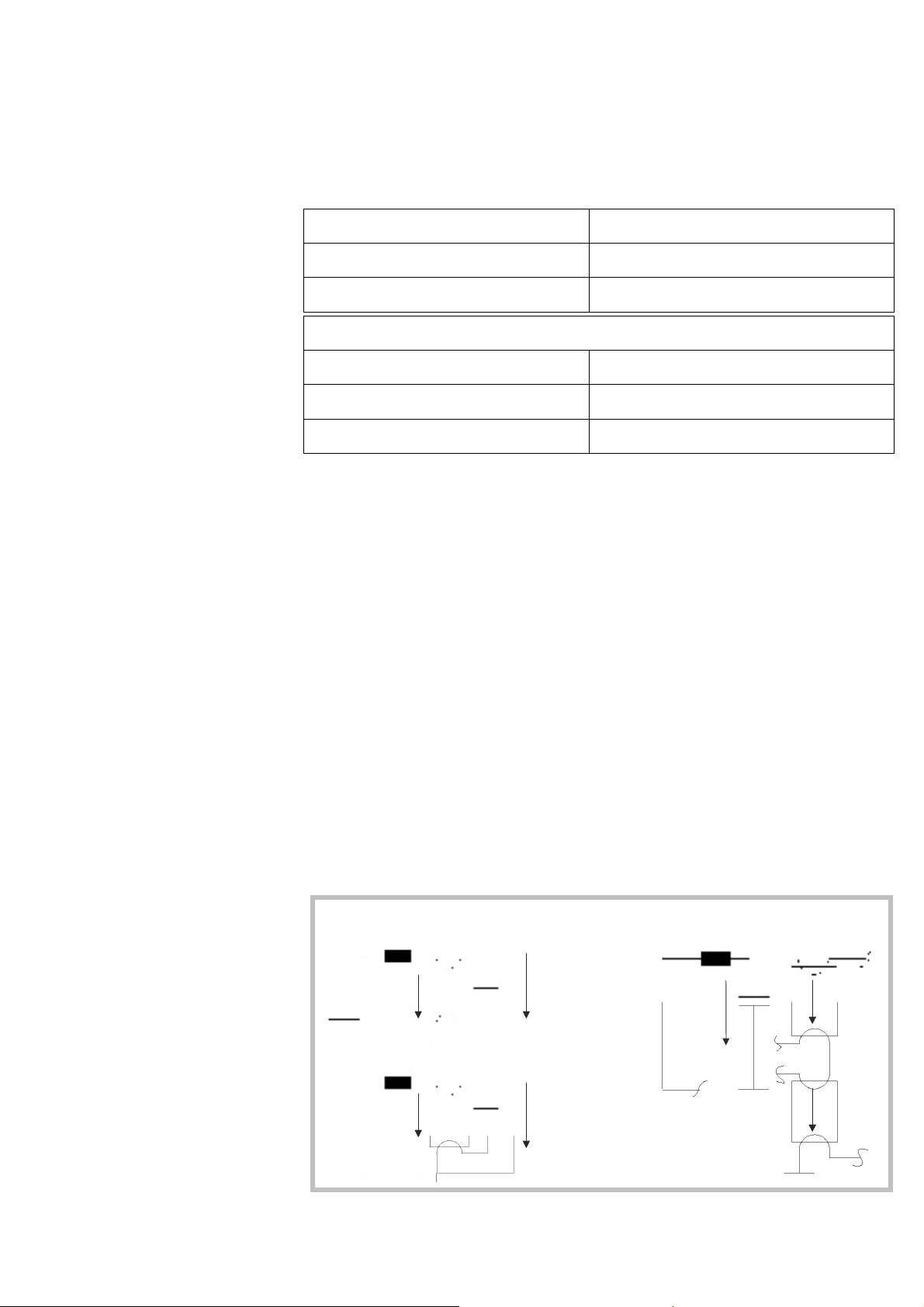

Good radio interference suppression

Good radio interference suppression

Good radio interference suppression

EN 55015

EN 55015

EN 55015

CISPR 15

CISPR 15

CISPR 15

max.Interference voltage[dB µV]

max.Interference voltage[dB µV]

max.Interference voltage[dB µV]

110

110

110

90

90

90

80

80

80

70

70

70

66

66

66

60

60

60

56

56

56

-2

-2

-2

10

10

10

110010-1

110010-1

110010-1

10210

10210

10210

Frequency [MHz]

Frequency [MHz]

Frequency [MHz]

Mains harmonics

Mains harmonics

IEC 61000-3-2

IEC 61000-3-2

EN 61000-3-2

EN 61000-3-2

Mains harmonics [%]

Mains harmonics [%]

30

30

30

25

25

25

Limit values

Limit values

Limit values

20

20

20

to IEC

to IEC

to IEC

15

15

15

10

10

10

5

5

5

0

0

0

3. 5. 7. 9. 11. 13.

3. 5. 7. 9. 11. 13.

3. 5. 7. 9. 11. 13.

Harmonics

Harmonics

Reliability of the ECG

Reliability of the ECG

IEC 61347-2-3

IEC 61347-2-3

EN 61347-2-3

EN 61347-2-3

z All insula ted

z All insula ted

z Compliance with creepage and

z Compliance with creepage and

clearance distances

clearance distances

z ECG shutdown in case of failure

z ECG shutdown in case of failure

Lamp operation to standards

Lamp operation to standards

IEC 60929

IEC 60929

EN 60929

EN 60929

rel. system luminous flux [%]

rel. system luminous flux [%]

100

100

90

90

80

80

70

70

60

60

50

50

2

2

ECG

ECG

10. 18.

10. 18.

CCG

CCG

4 6 8 1012141618 222420

4 6 8 1012141618 222420

Time of usage in hours [tsd]

Time of usage in hours [tsd]

1.2 T5/∅ 16 mm-

Fluorescent Lamps

Immunity

Immunity

IEC 61547

IEC 61547

EN 61547

EN 61547

230 V

230 V

50 Hz

50 Hz

Power regulation

Power regulation

At higher ambient temperatures

At higher ambient temperatures

P Gas [W]

P Gas [W]

50

50

40

40

30

30

20

20

0 1020304050607080

0 1020304050607080

Tube wall temperature [°C]

Tube wall temperature [°C]

Minimum ECG life

Minimum ECG life

z Long-life electrolytic capacitor

z Long-life electrolytic capacitor

(50,000h at t

(50,000h at t

z Optimised circuit

z Optimised circuit

z Low self heating

z Low self heating

Functional ECG [%]

Functional ECG [%]

100

100

100

80

80

80

60

60

60

40

40

40

20

20

20

90°C

90°C

90°C

0

0

0

0 20 40 60 80 100 120 140

0 20 40 60 80 100 120 140

0 20 40 60 80 100 120 140

)

)

c max

c max

60°C

60°C

60°C

70°C

70°C

70°C

Hours of operation [tsd]

Hours of operation [tsd]

Measuring

Measuring

point t

point t

50°C

50°C

50°C

c

c

Reliable ignition

Reliable ignition

at low temperatures

at low temperatures

-30 -25 -20 -15 -10 -5

-30 -25 -20 -15 -10 -5

Lamps starting [%]

Lamps starting [%]

EVG

EVG

KVG

KVG

Ambient temperature [°C]

Ambient temperature [°C]

100

100

80

80

60

60

40

40

20

20

0

0

0

0

The diameter and also the description of the new fluorescent lamp family is

based on American measures: (1 inch = 25.4 mm)

The value is combined with a T (tube).

5/8 of an inch = 16 mm Î T5-fluorescent lamp

Classification:

T2 tube diameter of 7 mm

T5 tube diameter of 16 mm

T8 tube diameter of 26 mm

T12 tube diameter of 38 mm

T17 tube diameter of 51 mm (1936)

7

Page 9

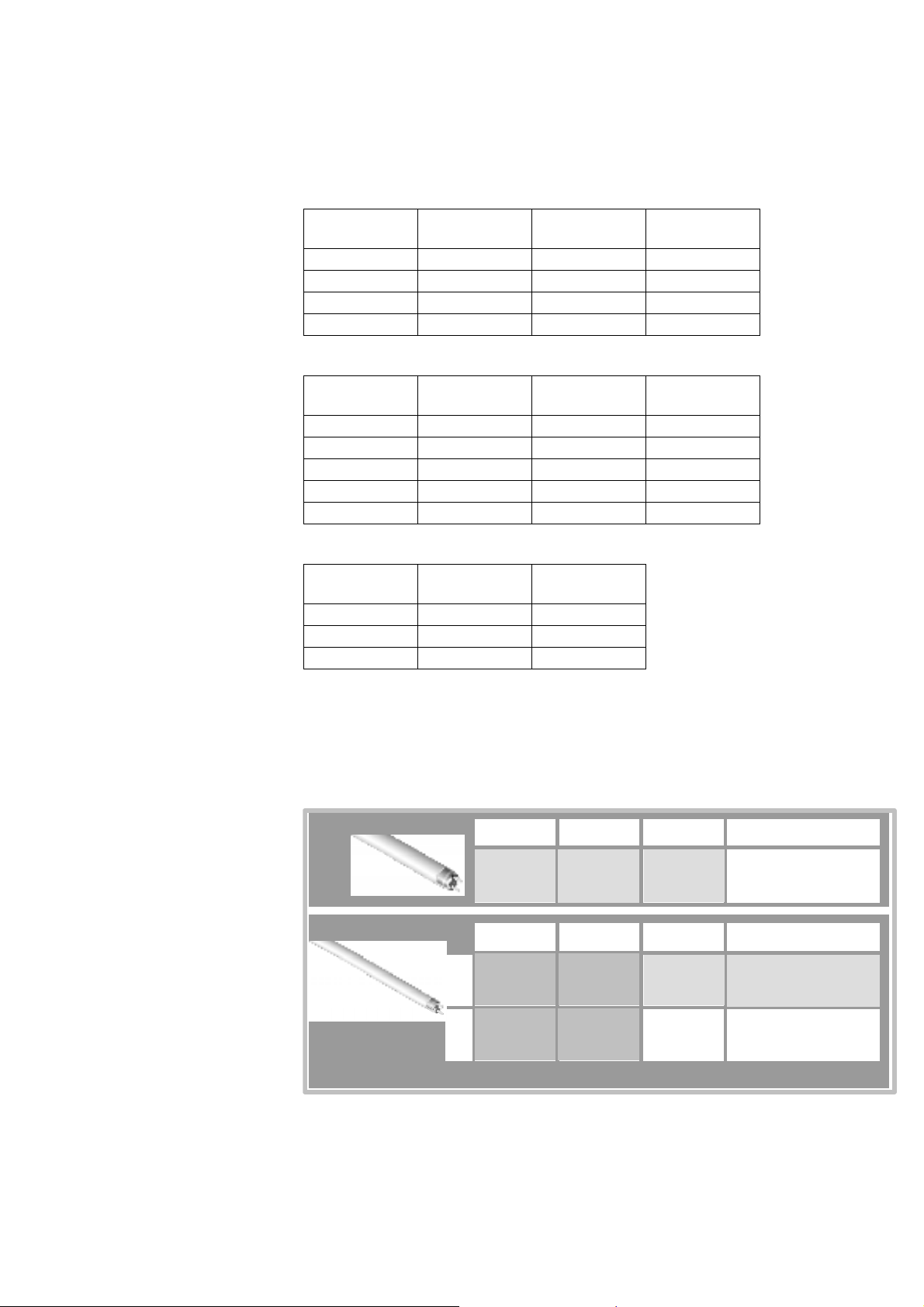

1.2.1 High Efficiency

®

FH

…HE

1.2.2 High Output FQ

®

…HO

1.2.3 Fluorescent Circular

®

FC

1.2.4 Comparison of

Lumens between

T8/∅ 26 mm- and

T5/∅ 16 mmFluorescent Lamps

Consecutively the important data of the FH…HE, FQ…HO and FC

fluorescent lamps are shown.

type length [mm] lumens at

ta=25 °C

FH® 14W HE

FH® 21W HE

FH® 28W HE

FH® 35W HE

549 1200 1350

849 1900 2100

1149 2600 2900

1449 3300 3650

lumens at

ta=35 °C

Values for light colors 827, 830, 840

type length [mm] lumens at

ta=25 °C

FQ® 24W HO

FQ® 39W HO

FQ® 54W HO

FQ® 80W HO

FQ® 49W HO

549 1750 2000

849 3100 3500

1149 4300 4900

1449 4450 5000

1449 6150 7000

lumens at

ta=35 °C

Values for light colors 827, 830, 840

type

∅ [mm]

lumens at

ta=25 °C

FC® 22W

FC® 40W

FC® 55W

225 1800

300 3200

300 4200

Values for light colors 827, 830, 840

Detailed technical data of T5/∅ 16 mm-fluorescent lamps can be found in

the OSRAM product catalogue and under www.OSRAM.com.

Fluorescent lamp innovation: T8 Î T5

T8 (Ø 26 mm)

T8 (Ø 26 mm)

Luminous flux at 25°C

Luminous flux at 25°C

600 mm 900 mm 1.200 mm 1.500 mm

600 mm 900 mm 1.200 mm 1.500 mm

18 W 30 W 36 W 58 W

18 W 30 W 36 W 58 W

1.350 lm 2.400 lm 3.350 lm 5.000 lm

1.350 lm 2.400 lm 3.350 lm 5.000 lm

1.3 Electronic Control Gear

T5 (Ø 16 mm)

T5 (Ø 16 mm)

Luminous flux at 25°C

Luminous flux at 25°C

550 mm 850 mm 1.150 mm 1.450 mm

550 mm 850 mm 1.150 mm 1.450 mm

FH 14 W 21 W 28 W 35 W

FH 14 W 21 W 28 W 35 W

1.200 lm 1.900 lm 2600 lm 3.300 lm

1.200 lm 1.900 lm 2600 lm 3.300 lm

FQ 24 W 39 W 54 W 49 W / 80 W

FQ 24 W 39 W 54 W 49 W / 80 W

1.750 lm 3.100 lm 4.450 lm 4.300 lm / 6.150 lm

1.750 lm 3.100 lm 4.450 lm 4.300 lm / 6.150 lm

Since the early seventies Electronic Control Gear have been used in

computers and consumer electronics. As this technology offers substantial

advantages, it was only natural to use it also for lighting purposes. Linear

and compact fluorescent lamps must be operated with ballasts, as the

process of gas discharge requires well defined currents and voltages. The

8

Page 10

1.4 Different Principles,

Different Behavior

1.5 Advantages of

Electronic Control Gear

ballast is responsible for preheating the lamp electrodes, for sufficient

ignition voltage and for limiting the lamp current.

The basic functions that are mentioned in chapter 1.3, can usually be

carried out with electromagnetic (inductive) ballasts. These ballasts are

classified into conventional control gear (CCG) and low loss ballasts (LLG).

The latter follow the same principle as CCG, however, due to different

engineering design they consume less energy. The much better solution is

to operate fluorescent lamps with Electronic Control Gear (ECG). Besides

the advantages of flicker-free lighting, longer lamp life and higher system

efficacy (lamp + ECG), features such as lamp ignition, limitation of the lamp

current and compensation are integrated into the ECG. Most Electronic

Control Gear are also suitable for DC operation, which means they can be

used in emergency lighting installations.

T5/ ∅ 16 mm fluorescent lamps FH

®

…HE, FQ®…HO and FC® can only be

operated by Electronic Control Gear.

If fluorescent lamps are operated with magnetic ballasts (principle of

magnetic coil, CCG and also low loss ballast), the lamp current equals the

frequency of the mains voltage. The resulting stroboscopic effect can be

dangerous in cases where people work with rotary machines. Every time,

the voltage goes through zero, the lamp current does the same until the

lamp is reignited: for every lamp ignition new carriers for the electric charge

have to be build up within the gas discharge.

CALM AND

LOWER

LOWER

ENERGY

ENERGY

CONSUMPTION

CONSUMPTION

(25 – 30%)

(25 – 30%)

CALM AND

FLICKERFREE

FLICKERFREE

LIGHT

LIGHT

OPERATION WITHOUT

OPERATION WITHOUT

NOISE

NOISE

LOW MAGNETIC

LOW MAGNETIC

STRAYFIELD

STRAYFIELD

FLICKERFREE

FLICKERFREE

START

START

1.6 Saving Energy with

Electronic Control Gear

LONGER

LONGER

LAMP LIFE

LAMP LIFE

(approx. 50%)

(approx. 50%)

LESS WASTE

LESS WASTE

DISPOSAL

DISPOSAL

(approx. 30%)

(approx. 30%)

ENERGY SAVING

ENERGY SAVING

(25 – 30%)

(25 – 30%)

LONGER LAMP LIFE

LONGER LAMP LIFE

(approx. + 50%)

(approx. + 50%)

SWITCH OFF AT END

SWITCH OFF AT END

LOW

LOW

WIRING COSTS

WIRING COSTS

DIMMABLE

DIMMABLE

(spec. version)

(spec. version)

AUTOMATIC

AUTOMATIC

OF LAMP LIFE

OF LAMP LIFE

When using Electronic Control Gear the frequency of the lamp voltage is

approx. 1000 times higher than the line voltage. The zero of the lamp

current are passed so quickly that the average of the value of the electron

density is nearly constant within the discharge plasma. The electrons don’t

have to be built up with every cycle (as it is necessary when using CCG

and low loss ballasts). So the limitation of the lamp life due to reignition

peaks for CCG operation are avoided with ECG operation. Therefore no

stroboscopic effects can occur by using high frequency control gear as

there is no longer a gap in the lamp current. Therefore, one lamp type

needs less energy to generate the same lumens when operated with high

frequency control gear compared to operation with magnetic ballasts. The

lower energy consumption reduces the lamp load and increases the lamp

9

Page 11

1.7 Ignition of Fluorescent

Lamps

1.8 Costs and Safety

1.9 Flexibility upon

Request

1.10 ECG bring Progress

1.11 The right ECG for every

Application

life. Electronic Control Gear improve the efficiency and the lamp life of

fluorescent lamps significantly.

Prior to ignition, modern ECG heat the cathode to its optimum temperature

for electron emission. After a defined period the lamp is ignited with the

required ignition voltage. Only an optimized preheat start can guarantee

that the number of switching cycles has only little effect on the lamp life.

This is another important feature of ECG which has a positive effect on the

cost of operation and which should not be neglected when looking for

alternatives to CCG.

At the end of lamp life the emitter paste applied to the lamp electrode is

used up. The complete loss of emitter results in an increase of voltage in

the vicinity of the electrode. This situation can last over a longer period of

time. As an immediate result of the accompanying temperature increase at

the lamp ends the lamp sockets may overheat. Modern ECG are able to

detect this malfunction and switch the lamps off. Unnecessary attempts to

ignite are avoided by an interrupting function and therefore, also

overheating is avoided - an important contribution to more safety.

Professional ECG control all parameters constantly. A safety shut down at

the end of the lamp life is mandatory from January 1

st

, 2007 on for all ECG

that operate T4 or T5 tubes as it is included in the IEC 61347

(Omnibusnorm for safety of Electronic Control Gear). For several years

now, all OSRAM QUICKTRONIC

®

fulfill the safety requirements acc. the

IEC 61347 already.

However as there was no Standard for this before, some ECG

manufacturer neglect this due to costs.

During past years, we see a clear increase in new, better and more energy

efficient lamp systems. Unfortunately, this resulted also in a growing

number of various ECG-types. To reduce this large number of types

manufacturers of ECG have taken a new direction and have developed

new multi-purpose ECG which can be used for a variety of fluorescent

lamps of different wattages. New integrated circuits allow the optimum

control of lamp features such as lumen output. This type reduction has, of

course, a big effect on the customer: ordering, warehousing and installation

of only a few ECG-types. The so-called MULTIWATT-ECG reduce all

relevant cost drivers.

In addition to the basic tasks of lamp operation which are also fulfilled by

magnetic ballasts, Electronic Control Gear have much more to offer: They

have better performance and are more reliable, more environmental

friendly and more practical than CCG; even more reasons to use

professional Electronic Control Gear.

OSRAM offers the right Electronic ballast for every application as shown at

the example of T8/ ∅ 26 mm fluorescent lamps.

10

Page 12

1.12 OSRAM ECG

Milestones

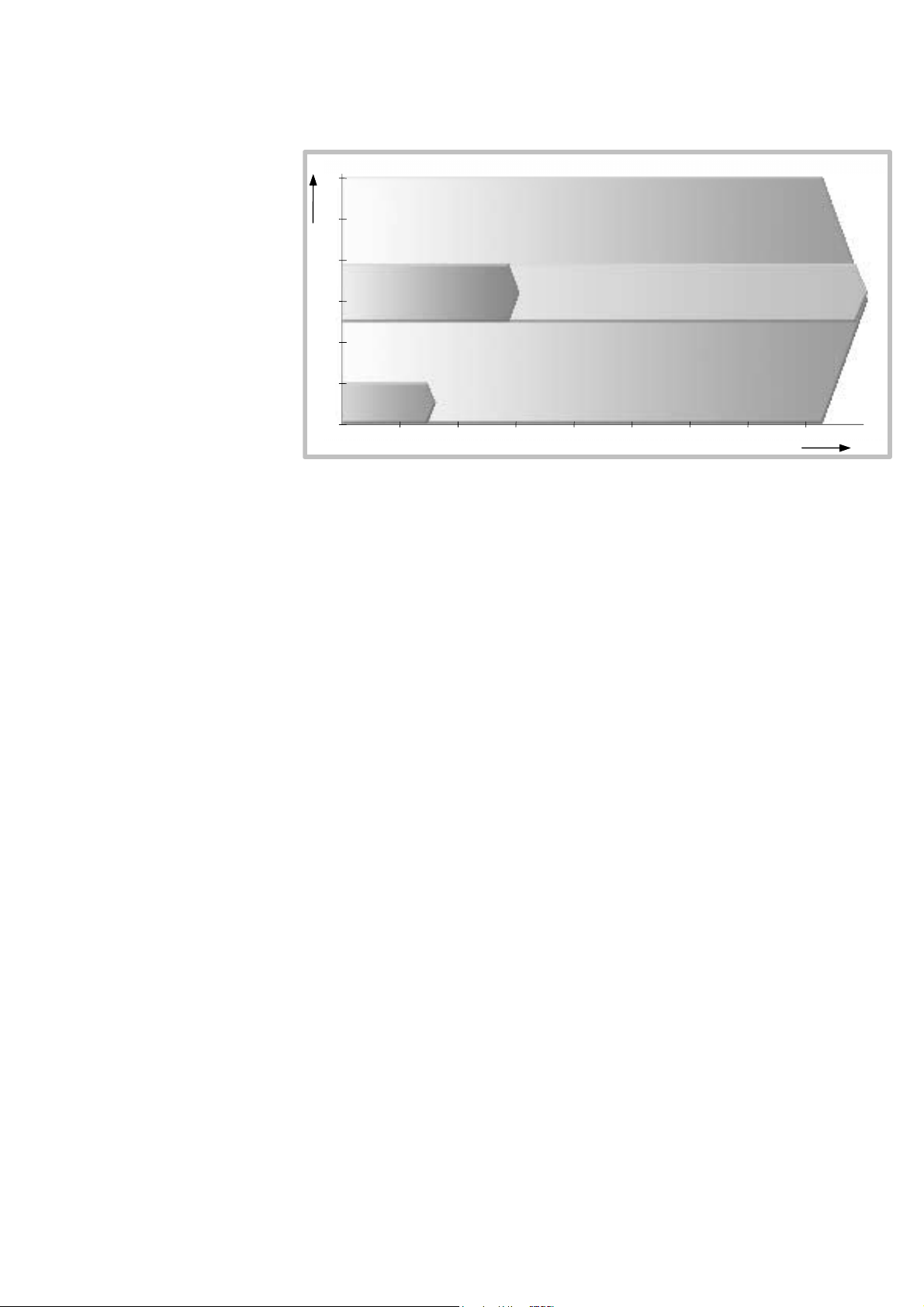

Burning hours per day

Burning hours per day

24

24

®

QUICKTRONIC

QUICKTRONIC

QUICKTRONIC

20

20

Industry,

Industry,

Open space office

Open space office

16

16

®

Railway

Railway

station,

station,

airport

airport

®

QUICKTRONIC

QUICKTRONIC

INSTANT START QTIS e

INSTANT START QTIS e

12

12

Department store,

Department store,

8

8

display

display

4

4

average

average

ECGs

ECGs

0

0

024 6 8

024 6 8

QUICKTRONIC

®

DIMMABLE

DIMMABLE

®

®

PROFESSIONAL

PROFESSIONAL

QUICKTRONIC

QUICKTRONIC

ECONOMIC

ECONOMIC

Daylight

Daylight

linked

linked

illumination

illumination

Switching cycles per day

Switching cycles per day

®

®

Daylight linked

Daylight linked

illumination with

illumination with

presence detectors

presence detectors

• For the first time in 1995, T5- fluorescent lamp systems with Cut-

off-technology have been introduced to the market.

Cut-off technology is the cut-off of the permanent filament

preheating after lamp ignition. This can be realized due to

modifications in the electronic circuit of the ECG. The result of the

Cut-off technology are less losses and optimized lamp operation.

• Four years later, in 1999, OSRAM sold the first reliable

MULTIWATT-ECG.

This operates all lamps with rated data.

• During the following years the trend of miniaturization continued and

the height of Electronic Control Gear was reduced by 30% from

30 mm to 21 mm.

In 2002, OSRAM is again the first manufacturer to introduce

MULTIWATT-ECG to operate FQ

®

…HO-fluorescent lamps High

Output in 21 mm height.

• In 2003, another novelty is brought to the T5-product segment: As

the first producer, OSRAM offers a 21 mm high 2-lamp ECG for

®

FQ

80 W HO-fluorescent lamps.

• In the beginning of 2004, the newest and most innovative member

of the T5-product family has been introduced: micro-controller

based ECG capable of operating T5-fluorescent lamps of equal

length regardless if it is a FH

®

…HE- or FQ®…HO-type. This microcontroller especially developed under the co-operation with OSRAM

is responsible for clear lamp detection and lamp operation with

nominal data.

QUICKTRONIC INTELLIGENT, QTi make one MULTIWATT-ECG

possible for all T5-fluorescent lamps from 14 to 39 W no matter if

®

FH

…HE- or FQ®…HO-types.

11

Page 13

2. Product Features

2.1 Lighting Comfort

2.2 Economy

2.3 Safety

• Flicker-free ignition

• Pleasant, flicker-free light with no stroboscopic effects due to high

frequency operation

• High comfort level with no distracting choke hum due to fully

electronic operation (see chapter 2.8 noise)

• No flickering

• No flashing or flickering, electronic defective control for

reliable safety switch-off of defective lamps

End-of-life safety shut down

• Cut-off of the permanent filament preheating after lamp

ignition

• Automatic restart after lamp replacement

• High lumen packages for T5 FQ

• Very high luminous efficacy for T5 FH

®

High Output system

®

High Efficiency system

• Long lamp life due to lamp start with optimum filament pre-heating

and operation with cut-off technology

• Low maintenance costs due to long lamp life and reduced relamping

intervals

• Lower cooling load of air-conditioning systems due to lower losses

Light engineering with T5 (Ø 16 mm) lamps

Leuchte/ 1xL58 W 1xL58 W 1xFH35 W

Luminaire

Vorschaltgerät/ VVG/ EVG/ EVG/

Control Gear LLG ECG ECG

E [lux] 539 518 500

P

gesamt/total

[W] 260 220 154

% 100 % 85 % 59 %

Büro mit 4 1-flammigen Leuchten

Office with 4 single tube luminaires

4

3

2

1

0

012344,5 m

W/m

2

15 12 9

All Electronic Control Gear QUICKTRONIC

®

for operation of T5/∅ 16 mm-

fluorescent lamp systems are developed and designed according to all

relevant national and international industry standards.

Current standard is EN 61347. For Electronic Control Gear for operation of

low pressure gas discharge lamps EN 61347-2-3 applies.

12

Page 14

2.4 Supply Voltage

2.4.1 Overvoltage and its

Reason

In detail:

• Safe shutdown of the power supply to defective lamps or

at the end-of-life due to End-of-Life detection according to Test 2

Shutdown in the event of broken filaments, no inserted lamp or air

leakage

• Compliance with European safety standards (EN 61347-2-3)

• Protection against short duration voltage surges (DIN VDE 0160)

and transient overvoltages

• Low housing temperatures allow the mechanical design of lighting

fittings with F- and FF- as well as M- and MM-approval mark

(EN 60598/DIN VDE 0710 and DIN VDE 0711)

• Can be used in emergency lighting systems according to

DIN VDE 0108

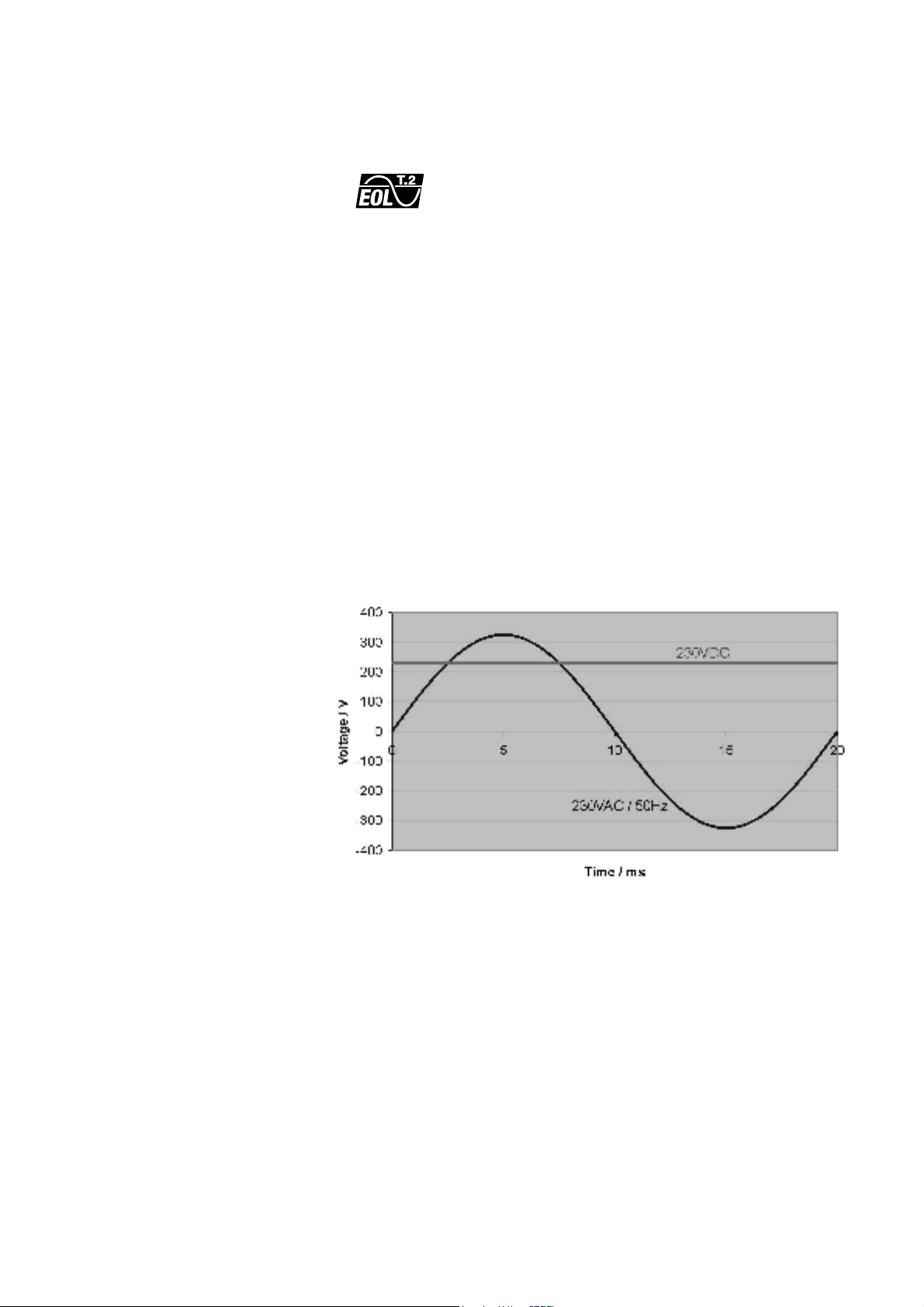

Electronic Control Gear QUICKTRONIC

lamps (FH

®

…HE, FQ®…HO and FC®) can be operated on sinusoidal AC

®

for T5/∅ 16 mm-fluorescent

voltage and DC voltage The recommended voltage intervals depend on the

design of the specific circuits.

The following chapters show the recommended voltage ranges and the

behaviour of the ECG at overvoltage and undervoltage.

It is called an overvoltage if the ingoing voltage is significantly higher

than the nominal value.

In general, we have to differentiate between two overvoltages which

also can have different reasons.

1. Transient overvoltage with a typical duration of milliseconds.

This overvoltage can be caused by:

- Switching of inductive loads such as welding machines, elevators

alternators etc.

- lightening

Quasi-stationary overvoltage with a duration from a few minutes to hours.

This overvoltage can be caused by:

- different loads on the mains side (interruption of the neutral

conductor in 3-phase installations plus an additional asymmetric

13

Page 15

2.4.2 Possible Implications

due to Overvoltage

2.4.3 Undervoltage and its

Reason

2.4.4 Possible Implications

due to Undervoltage

2.4.5 Supply Voltage

QT with 21 mm height

load distribution)

- unstable power supply (for example some countries in Far East)

It is called overvoltage, if the supply voltage exceeds the specified voltage

range of an ECG including tolerances.

In any case, overload means more stress to electronic components.

Depending on the magnitude of overvoltage the protective functions of an

ECG can come into effect and turn the ballast off.

In extreme situations overvoltages can even destroy electronic

components.

Therefore, please pay attention to the design of the mains and tolerances

of the Electronic Control Gear when using them.

Supply voltages can not only deviate to higher values but also to

lower values. If the supply voltage decreases below the value

specified in the technical data of an ECG, we have to deal with

undervoltage.

This may be true for the following points:

• Different loads on the mains side

• Incorrect electric installation

• Unstable power supply

• In some cases when used with emergency generators

Operating ECG with undervoltage is not as specified. This may result

in the following implications:

• Lamp operation not according to standards Î affecting lamp life

• No safe lamp start, a safe ignition is only guaranteed above supply

voltages of 198 V

• Unstable lamp operation meaning the discharge process of a

fluorescent lamp is not stable

• In order to keep the lamp wattage constant most ECG types are

controlled on the lamp side. In this case, reduced supply voltages

cause much higher currents which may lead to physical stress of

components and to failure of the entire ECG. If supply voltages

deviate significantly from the nominal values, high switching losses

and overload of transistors can occur finally causing ballast failures.

Valid for: QTi and QT…F/CW

Recommended voltage range for

continuous operation

AC voltage 198 V ... 264 V, 50/60 Hz

DC voltage 176 V ... 264 V

Performance at undervoltage

Lamp ignition

Voltage drop during operation

U

≥ 198 V Î reliable lamp ignition

N

U

≥ 176V Î operation possible

N

U

< 176 VÎ damage to ECG

N

possible

14

Page 16

2.4.6 Supply Voltage for QT

with 30 mm height

2.4.7 ECG for 120V / 277V

Line Voltage

2.5 Automatic Lamp

Restart

Valid for: QT-FH MULTIWATT and QT-FQ

Recommended voltage range for continuous operation

AC voltage 198V ... 264V, 50/60 Hz

DC voltage 176V ... 264V

Performance at undervoltage

Lamp ignition

U

≥ 198V Î reliable lamp start

N

Voltage drop during operation

U

≥ 176V Î operation possible

N

U

< 176V Î damage to ECG

N

possible

T5/∅ 16 mm fluorescent lamps are also getting more popular in North

America (USA, Canada). Historically in the US-market have been

established lamps in 4 ft length besides the types of 240 cm. 4 ft is also

known as 48 inch type (1 ft = 30.48 cm) and is acc. to our typical 120 cm

types. Related to the straight fluorescent types FH

this means 1,149 mm for FH

®

28 W HE and FQ® 54 W HO.

®

…HE and FQ®…HO

OSRAM SYLVANIA offers the complete range for FH

®

…HE and FQ®…HO

under PENTRON ECG. The specification there is PENTRON High

Performance T5 lamps for FH

®

and PENTRON High Output T5 for FQ®

lamps.

OSRAM SYLVANIA also offers the ECG for the North American line

voltages 120 V / 277 V und 60 Hz line frequency as shown at a glance:

MULTIWATT ECG for FH

®

fluorescent lamps: 14, 21, 28 and 35 W HE

Types: QTP 1x28T5/UNV PSN suitable for 120-277 V

QTP 2x28T5/UNV PSN suitable for 120-277 V

ECG to operate FQ

®

54 W HO

Types: QTP 1x54T5UNV/PSN suitable for 120-277 V

QTP 2x54T5UNV/PSN suitable for 120-277 V

For a large number of differnt lamp types including T8 OCTRON a variety

of dimmable and non dimmable types is available.

Information about availability under:

OSRAM LIGHT CONSULTING (OLC)

Hellabrunner Straße 1

81536 München

Tel: +49-89-6213 3076 Fax: +49-89-6213 2020

With all QUICKTRONIC

lamps FH

®

…HE, FQ®…HO and FC®, automatic restart takes place after

®

for operation of T5/∅ 16 mm-fluorescent

a change of lamp provided the power supply is maintained.

Should in the case of a twin-lamp ECG no automatic lamp restart take

place after lamp replacement and could an ECG-failure be excluded,

please proceed as follows:

15

Page 17

2.5.1 Lamp ignition for QTi

2.5.2 Lamp ignition for QT

to operate T5fluorescent lamps

2.5.3 Off- Time for

Optimum Preheat

Start

2.6 Behaviour in Response

to Lamp Defects

2.6.1 One-Lamp Operation

with Multi-Lamp ECG

Replace both lamps, take out the lamp replaced first and refit it. Provided

lamp and ECG are o.k. both lamps should then light.

Lamp start Preheat

Ignition time < 1 second

Max. number of switching cycles > 100,000 cycles

QT-FH MULTI, QT-FQ, QT…F/CW

Lamp start Preheat

Ignition time < 0.5 second

Max. number of switching cycles > 100,000 cycles

All QUICKTRONIC to operate T5/∅ 16 mm- fluorescent lamps

®

FH

…HE, FQ®…HO and FC start the lamps at any time with optimum

preheat start even after a turn-off followed by an immediate lamp

restart. OSRAM QUICKTRONIC ignite the lamp always with optimum

preheating of the electrodes. A particular off-time with regards to

lamp life is not necessary.

What do we mean by lamp defect or end-of-lamp life?

In most cases, it is not possible to see from outside which lampholders are

assigned to which ECG-terminals, so if you insert lamps and they fail to

start automatically you should take out the first lamp again and refit it. Both

lamps should then light.

Lamp replacement of 2- and multilamp luminaires proceed as follows:

Insert the lamps. If at 2- or multilamp luminaires lamp ignition doesn’t work

automatically, take out the lamp replaced first and refit it. Reignition of both

lamps works automatically.

What are the requirements?

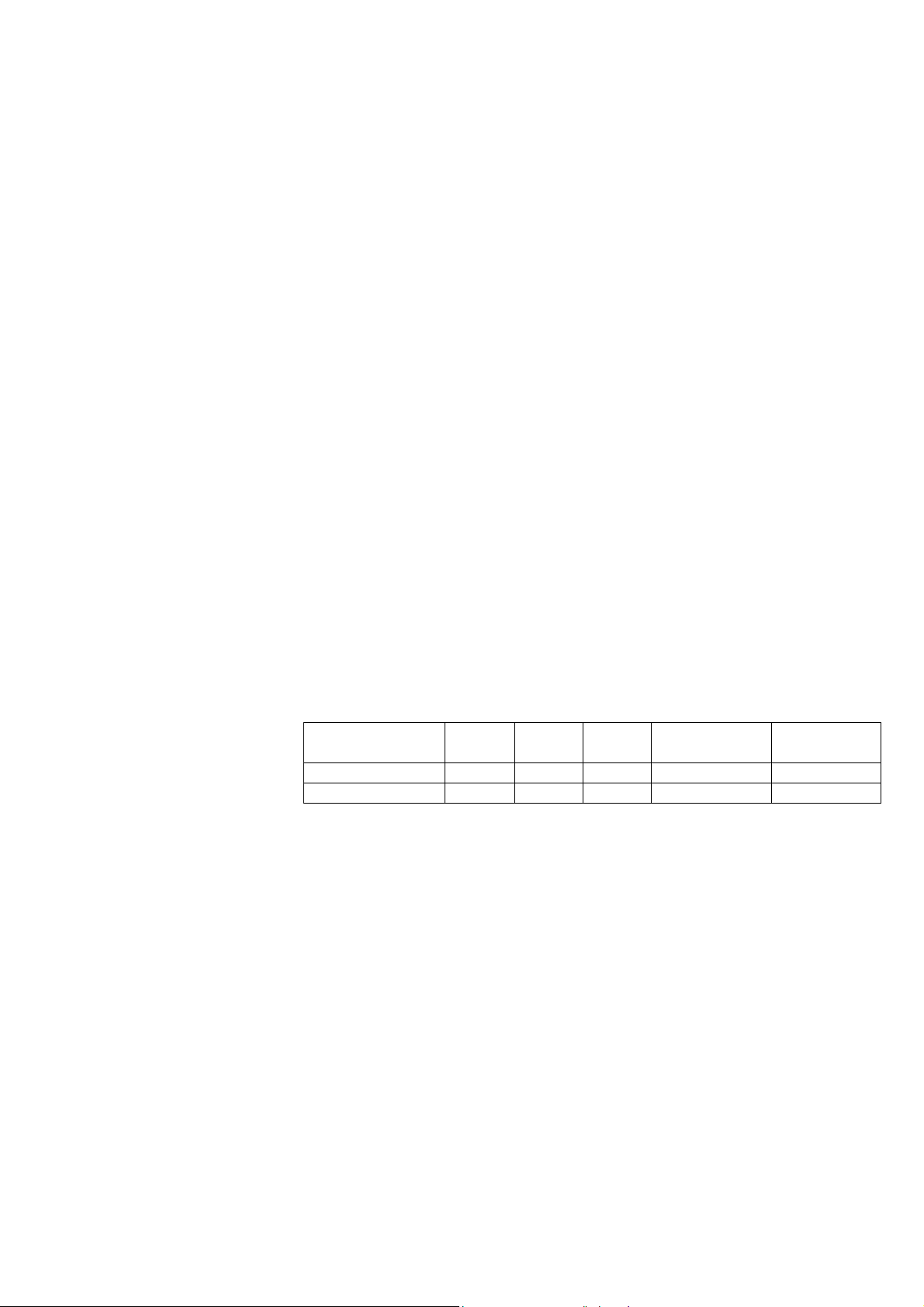

QTP 2x...

QT - FQ 2x...

QT - FQ 2x...

L

ILI

UU

Start

U

U

Zünd

Start

L

L

I

ILI

L

ILI

UU

Start

L

L

I

ILI

Parallel Circuitry Series Circuitry

16

Page 18

2.7 Noise

• Parallel circuit of lamps operated with multi-lamp ECG ≠in general

single-lamp operation possible

• Parallel circuit of lamps, but no single-lamp operation possible because

for example

- the sum of electrodes has to be recognized

For twin- and multi-lamp ECG the question is whether the remaining lamps

will continue to operate if one lamp is defect or has been removed.

In the case of twin- or multi-lamp ECG, any lamp fault that causes the safe

shutdown circuit to operate will lead to the shutdown of all lamps.

This function is called “safety shutdown”. The detection of various “out-ofrange” parameters results in a reliable shutdown of the ECG. The ECG do

not perform any lamp starts that could cause problems as described under

chapter 2.3.

In this case, one lamp or the remaining lamps will therefore never continue

to burn by itself.

What happens when one lamp is removed from a multi-lamp ECG will

depend on the type of circuit. Series circuits always exclude a single-lamp

operation. Parallel circuit is one condition for a possible single-lamp

operation, however, not the only one. Another important criterion is lamp

control during operation of circuit related as well as safety related data.

QUICKTRONIC

®

INTELLIGENT, QTi, are carried out in parallel circuits, but

cannot be operated in single-lamp mode. The reason is the sophisticated

lamp detection requiring the control of various parameters.

The following table gives a short summary of the different ECG-types:

ECG-type

height

QTi

21 mm

QT-FH

30 mm

QT-FQ

30 mm

QT-FH 3x, 4x

30 mm

QT … F/CW

21 mm

Series circuit X X X X

Parallel circuit. X

For all types shown in the table above a single-lamp operation is not

possible.

T5/∅ 16 mm-fluorescent lamps FH

at high frequency with QUICKTRONIC

®

…HE, FQ®…HO and FC® operated

®

control gear are virtually

silent.

QUICKTRONIC

®

units themselves are so quiet that even in very quiet

surroundings they cannot be heard by the human ear. They are

therefore ideal for sound-sensitive areas such as radio and recording

studios. The limit of the frequency-dependant sound pressure curve

is based on the audibility threshold (in other words, a person with

normal hearing will not be able to detect the noise generated by an

ECG in the same room).

The factors affecting the sound pressure level are the sound power level of

the ECG, the absorption properties of the room, characterised by its volume

and reverberation time, and the number of ECGs.

In mains supplies with a high level of distortion in which the mains voltage

wave form deviates significantly from a sine wave, a „chirping“ may be

heard from the reactance coils in the input section of the ECG.

17

Page 19

2.8 Power Factor λ For all electric loads, the power factor λ is the ratio of effective power (P

voltage x effective current) to apparent power (P

= voltage x apparent

app

current). This value is affected both by the phase displacement cos ϕ

between current and voltage by the current wave form distortion ε (nonsinusoidal wave form)

=

eff

λ = P

eff

/ P

= ε cos ϕ

app

In contrast to conventional control gear (CCG, inductive, 50 Hz), there is

hardly any phase displacement with Electronic Control Gear (high

frequency), which means that capacitor correction is not required. However

slight distortions in the current sine-wave curve occur during operation of

electronic control gear. In general these distortions are characterized by

integer multiples of the mains frequency (harmonics).

The harmonic content of the mains current is controlled by national and

international regulations (IEC 61000-3-2, EN 61000-3-2). OSRAM ECG

have built-in active electronic harmonic filters for this purpose which

guarantee a value for ε of more than 0.95 and hence a power factor λ

greater than 0.95.

Exemptions are ECG which apply to the international standard for system

power consumption less than 25 W. This standard requires a power factor

λ of more than 0.6. These ECG are part of the product segment ECO and

are known as QUICKTRONIC

®

ECONOMIC or QT-ECO. They are mainly

used to replace conventional control gear, but because of their

MULTIWATT-design they can partly operate FH

®

…HE- and FQ®…HO

fluorescent lamps with lower wattages:

®

FH

14W HE

®

FH

21W HE

®

FQ

24W HO

For detailed information about this combination please see

www.OSRAM.de/products/ecg

With regards to their harmonics content all QUICKTRONIC

®

have been

tested by VDE according to EN 61000-3-2 and carry the VDE-EMC

approval mark.

The confirmation of the ECG’s CE-mark by an independent testing facility

reduce the costs and the t.ime necessary for approval of luminaires

significantly.

18

Page 20

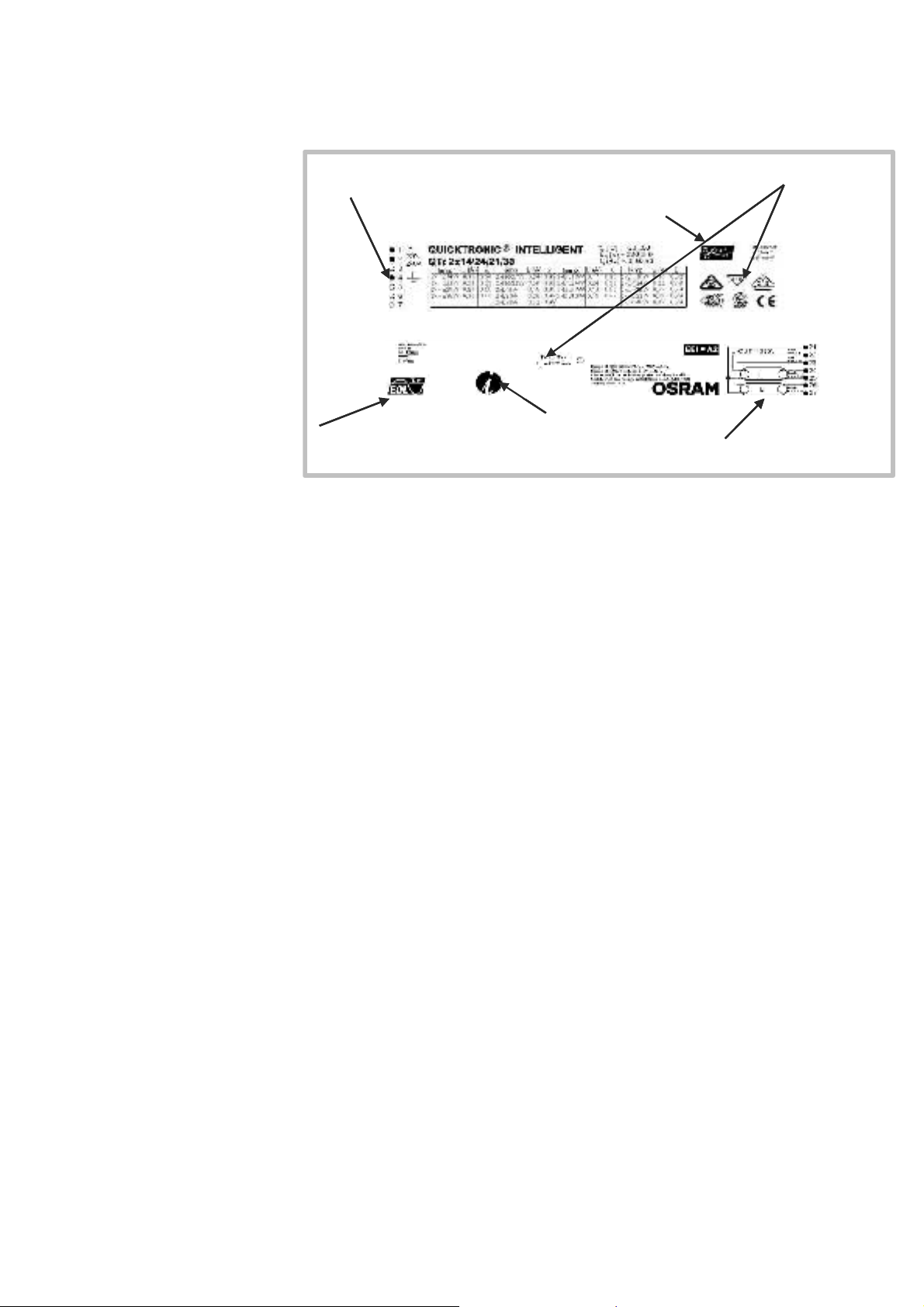

2.9 ECG Imprint

2.10 Reliability

2.11 Resistance to Frequent

Switching

2.12 ECG Lifetime

Functional Earth terminal

Functional Earth terminal

Functional Earth terminal

End-of-Life Safety-shut-

End-of-Life Safety-shut-

End-of-Life Safety-shutdown

down

down

Cut-Off-Technology

Cut-Off-Technology

Cut-Off-Technology

µProzessor inside

µProzessor inside

µProzessor inside

Thermal Behaviour

Thermal Behaviour

Lamp wiring including

Lamp wiring including

Lamp wiring including

max. cable lengths

max. cable lengths

max. cable lengths

Besides component specification and quality their failure rate is significantly

related to the operating temperature.

Electronic Control Gear of OSRAM are designed in that way, that a failure

rate of less than 2 Promille per 1,000 operating hours is expected if

operation takes place at the maximum permitted case temperatur (t

).

c

The resistance to frequent switching of Electronic control gear is based on

possible lamp starts per day. Multiplied with the lamp life professional ECG

with preheat start reach more than 100.000 switching cycles.

This information is important for combinations with occupancy sensors as

this is one of the most popular applications for frequent switching of the

lamp-ECG system.

The ECG lifetime depends on the operating temperature and failure rate of

the electronic components. Extreme overheating can destroy electronic

components in a short period of time and cause the ECG to fail. There

exists an exponential relationship between the failure rate of electronic

components and their thermal and also electrical behaviour.

An indication about the maximum recommended ambient temperature of a

luminaire is given by the imprinted measuring point tc at which each ECG

reaches its maximum recommended case temperature. The t

-temperature

c

of an OSRAM ECG is closely linked to its temperature of electronic

components. For example, when the maximum recommended tctemperature of 70 °C is reached, a QUICKTRONIC control gear for

operation of T5/∅ 16 mm-fluorescent lamps is expected to last

50,000 hours with a failure rate of max. 10 %. This value equals a failure

rate of 2 ‰ per 1,000 operating hours. Due to the exponential dependence

on temperature and failure rate of electronic components exceeding the

recommended tc-temperature reduces the ECG lifetime dramatically. On

the other hand, if the ECG temperature remains below the limit the lifetime

is extended. As a rule of thumb, every 10 °C below the imprinted

temperature value double the ECG’s lifetime and every 10 °C surpassing

the tc-value cut the service life in half.

The measuring temperature t

is an important parameter for both the safety

c

approval for a luminaire according to EN 60598 and the service life of an

19

Page 21

2.13 Thermal influences of

the system

components

2.14 cut-off Technology

ECG provided by the manufacturer under consideration of the thermal load

of electronic components.

Surviving ECGs [%]

Surviving ECGs [%]

Surviving ECGs [%]

100

100

100

80

80

80

60

60

60

90°C

90°C

40

40

40

20

20

20

90°C

0

0

0

0 20 40 60 80 100 120 140

0 20 40 60 80 100 120 140

0 20 40 60 80 100 120 140

70°C

70°C

70°C

10°C lower operating temperature at point of

10°C lower operating temperature at point of

10°C lower operating temperature at point of

measurement virtually halves ECG failure rate

measurement virtually halves ECG failure rate

measurement virtually halves ECG failure rate

The temperature must be assessed separately for the two system

components (ECG and lamp). In the case of the lamp, there are physical

laws that restrict the temperature range of an application, whereas in the

case of the ECG fixed limits must be set in order to ensure reliable

operation.

Apart from this, there are external factors such as the reciprocal influences

of ECG, lamp and luminaire and the selected installation site which have an

influence. Compliance with the specified limits and hence the guarantee of

operational reliability are the responsibility of the relevant luminaire or

system manufacturer.

There is a fixed correlation between tc-temperature, the temperatrure of

electronic components, the life of each component and hence the complete

unit. Thermal contact of an ECG to metallic parts of luminaire housings is

very positive due to good thermal conductivity.

The correlation between temperature tc of the measuring point, component

life and failure rate is crucial for an objective assessment of the reliability

and service life of an ECG. Information about tc-temperature and ECG

service life alone are not sufficient.

All QUICKTRONIC

T5/∅ 16 mm-fluorescent lamps FH

are equipped with cut-off technology.

After starting the lamp the electrode heating is being switched off. Lamp life

increases due to the reduced load of the electrodes. Therefore, cut-off

technology increases the lumen output of the luminaire and the lamp life.

And for the first time, cut-off technology is included in dimmable ECG

thanks to the new intelligent technology of QTi. Compared to Electronic

control gear without cut-off the power consumption of ECG with cut-off

technology could be reduced by another 5 to 7 %.

10 % loss at 50,000 hours

10 % loss at 50,000 hours

10 % loss at 50,000 hours

60°C

60°C

60°C

Hours of usage [thsd]

Hours of usage [thsd]

Hours of usage [thsd]

®

control gear for operation of

®

…HE and FQ®…HO

50°C

50°C

50°C

Temp. at point of

Temp. at point of

Temp. at point of

measurement t

measurement t

measurement t

c

c

c

20

Page 22

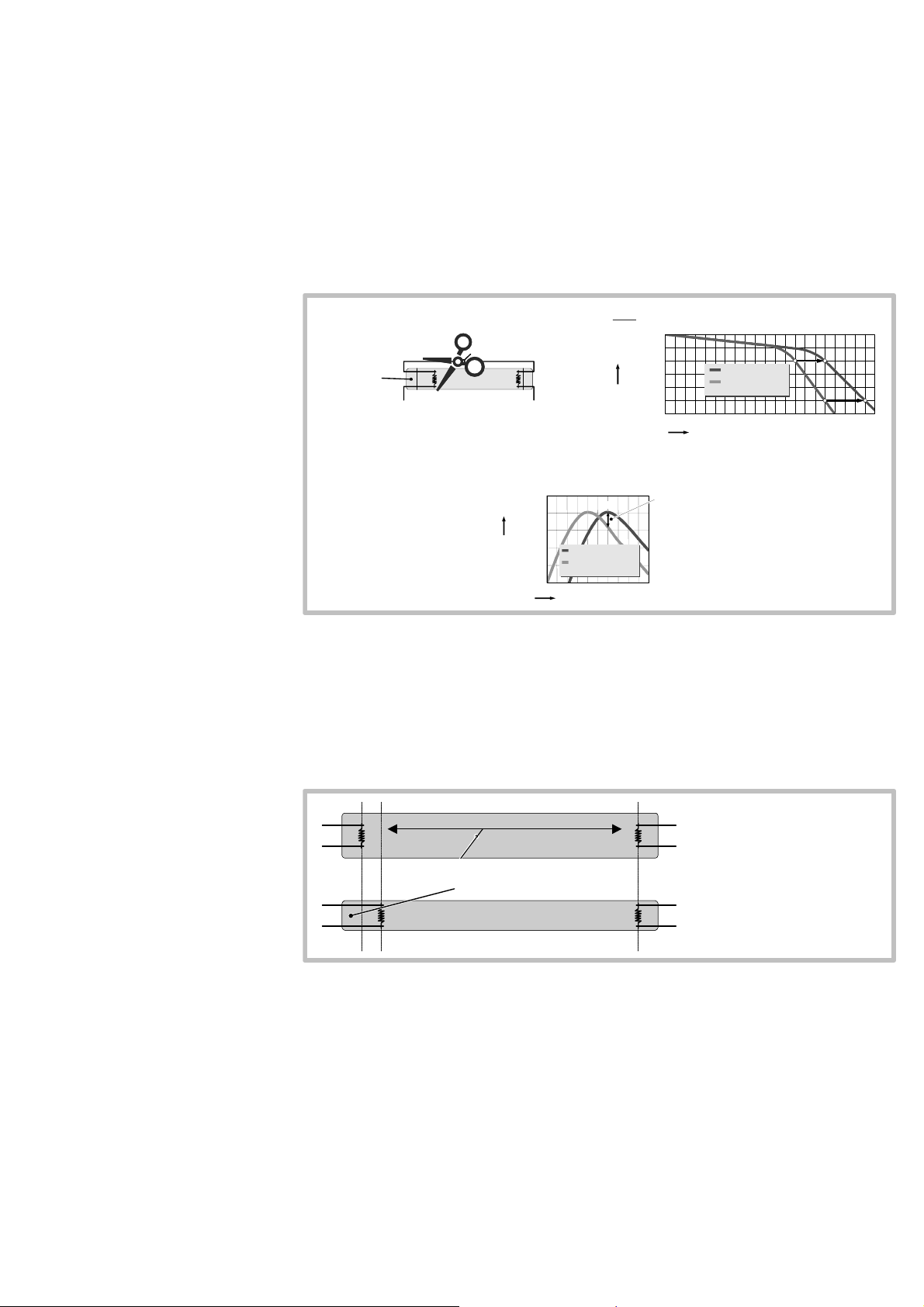

2.14.1 Advantages for Users

The following advantages for users arise from cut-off technology:

6-10 % higher luminaire efficiency

highest lamp life

2-3 W lower losses per lamp

reduced load of air condition

New circuitry wihtout permanent filament heating

New circuitry wihtout permanent filament heating

(cut-off technology)

(cut-off technology)

I

= I

I

= I

Stift

Lampe

Stift

Lampe

Cold Spot

Cold Spot

app. 40°C

app. 40°C

Significantly lower temperatures at the

Significantly lower temperatures at the

lamp electrodes

lamp electrodes

I

I

Lampe

Lampe

I

I

Stift

Stift

Cut-off advantage for the luminaire

Cut-off advantage for the luminaire

Cut-off advantage for the luminaire

110

110

110

100

100

100

90

90

90

rel.

rel.

rel.

80

80

80

Licht-

Licht-

Lichtstrom

strom

strom

70

70

70

60

60

60

10 20 30 40 50

10 20 30 40 50

10 20 30 40 50

Umgebungstemperatur (°C)

Umgebungstemperatur (°C)

Umgebungstemperatur (°C)

Only cut-off technology can fulfill lifetime

Only cut-off technology can fulfill lifetime

100%

100%

90%

90%

80%

80%

70%

70%

60%

60%

Rel.

Rel.

50%

50%

Lum-

Lum-

40%

40%

inous

35°C

35°C

35°C

Cut Offk

Cut Offk

Cut Offk

Conventional

Conventional

Conventional

ECG circuitry

ECG circuitry

ECG circuitry

inous

flux

flux

6 – 10% higher

6 – 10% higher

6 – 10% higher

luminaire efficiency for

luminaire efficiency for

luminaire efficiency for

direct lighting

direct lighting

direct lighting

5.000h

5.000h

Lifetime [hours]

Lifetime [hours]

Cut-off

Cut-off

Cut-off

Conventional

Conventional

Conventional

ECG circuitry

ECG circuitry

ECG circuitry

10.000h

10.000h

12.000h

12.000h

13. 16.

13. 16.

16.000h

16.000h

14.000h

14.000h

16. 2 0.

16. 2 0.

20.000h

20.000h

18.000h

18.000h

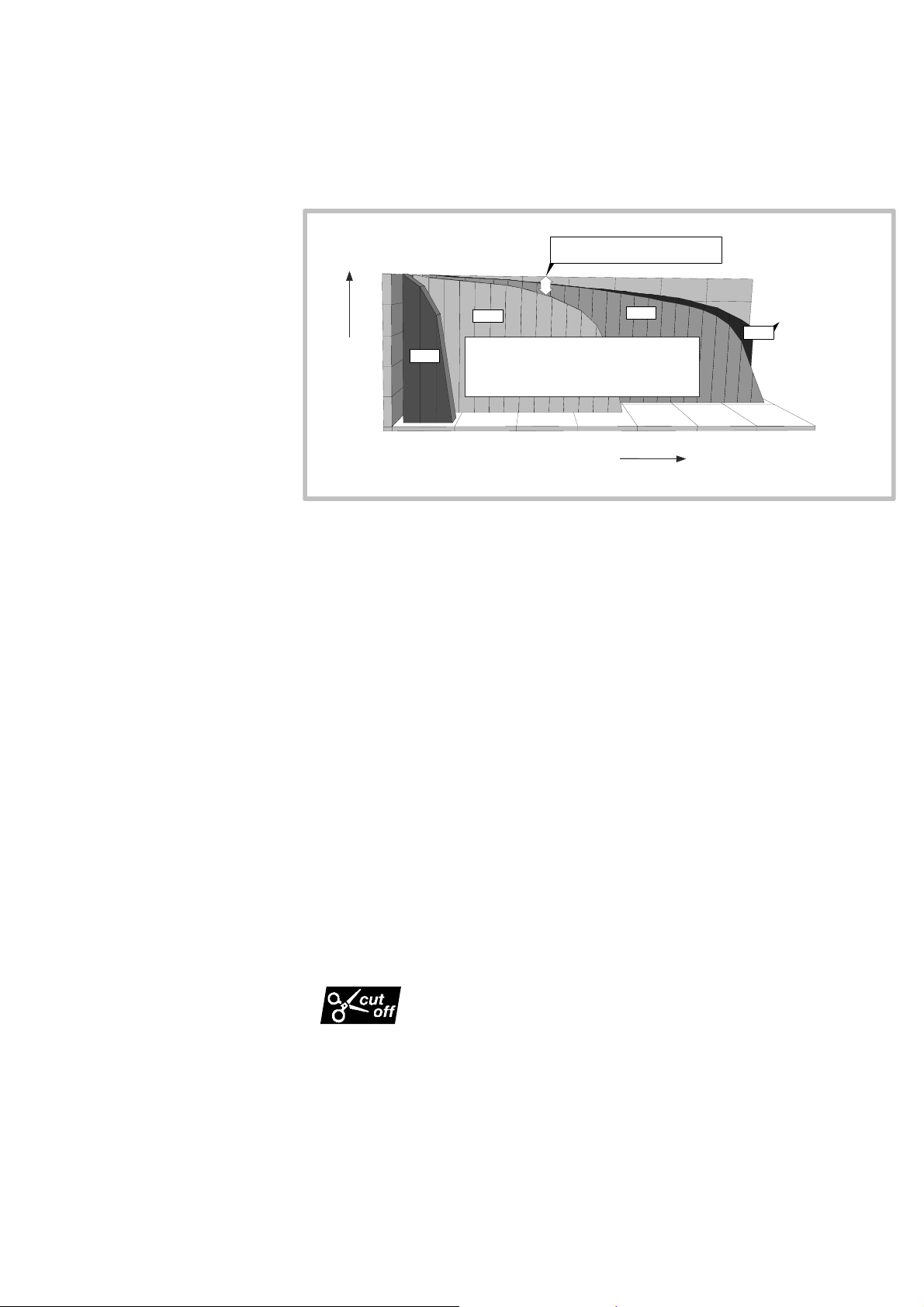

2.14.2 Physical Background

T5/∅ 16 mm-fluorescent lamps FH

®

…HE and FQ®…HO are designed to

have their maximum lumen output at 35 °C (compared to 25 °C for

T8/∅ 26 mm). For T5/∅ 16 mm-fluorescent lamps the so-called cold spot

(the point where mercury condensates in a discharge tube, stamped end of

the lamp) is located behind the electrode (see graphics) which means near

the source of heat.

T8 (Ø 26 mm)

T8 (Ø 26 mm)

T12 (Ø 38 mm)

T12 (Ø 38 mm)

Cold Spot T

Cold Spot T

The value of the luminous flux at the ambient temperature of 35 °C is only

informative for the luminaire manufacturer. Significant is the value of the

cold spot temperature. This value is measured at the socket of the stamped

side, approx. in a distance of 2 mm of the glass. For an optimized luminous

flux this value should be between 45 °C and 50 °C. This is shown at the so

called ‘Horseshoe curves’ where the luminous flux is shown in relation to

the lamp ambient temperature.

The cold spot of the T5/∅ 16 mm fluorescent lamps is influenced by

permanent filament heating. This means that higher temperatures reduce

the luminous flux. ECG with cut-off technology reduce the losses of the

system and are optimized regarding the maximum luminous flux of the

Hg opt.

Hg opt.

≈ 40°C

≈ 40°C

T5 (Ø 16 mm)

T5 (Ø 16 mm)

21

Page 23

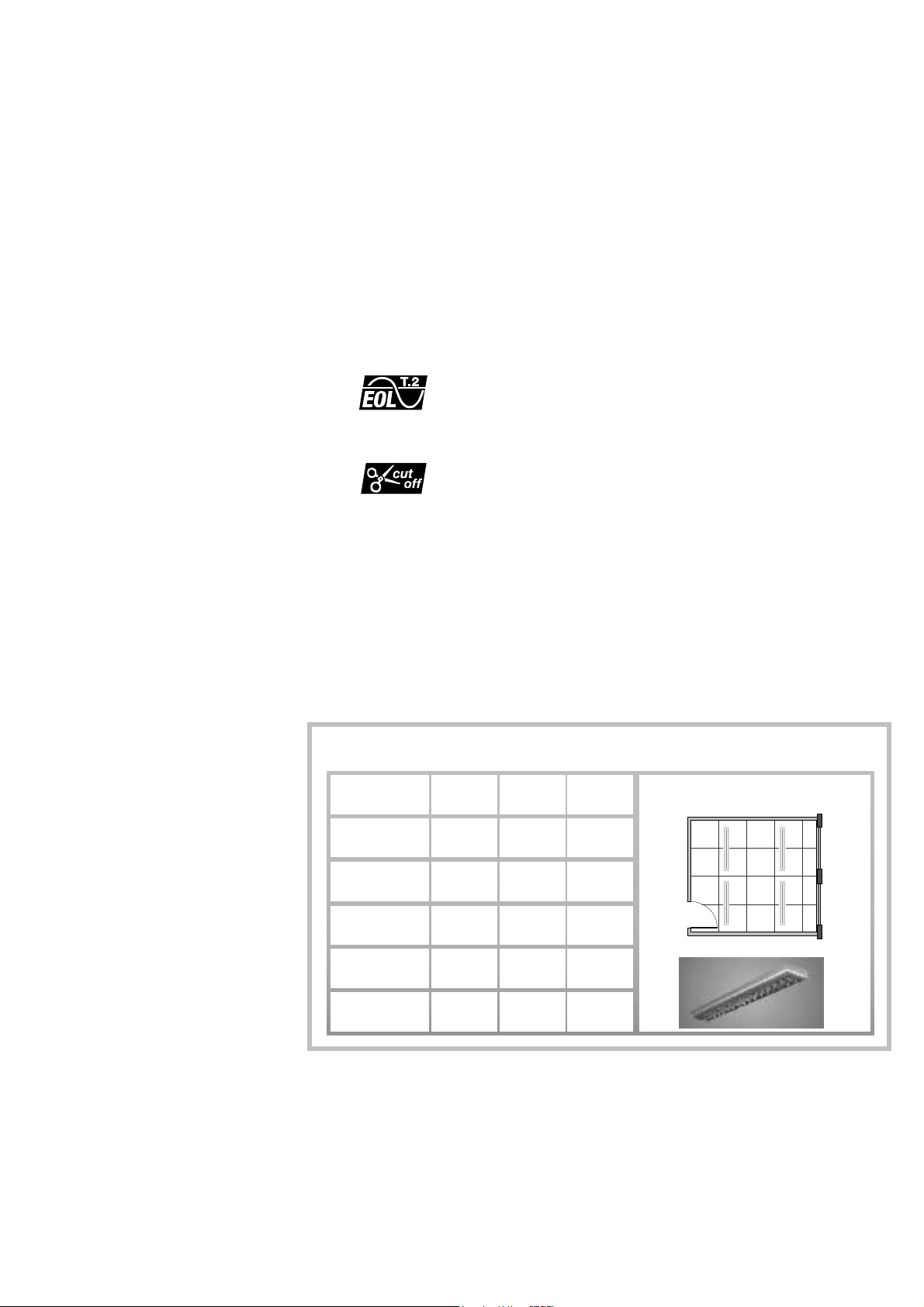

2.15 End of Life

(EoL acc. to T.2)

2.16 U-OUT

system. The cut-off of the permanent filament heating after lamp ignition is

an advantage.

Further the values of the horseshoe curves also indicate the arrangement

of the lamps within the fixture. To avoid thermal influences of the lamps

minimum distances in between have to be kept. The lamps have to be

placed that the stamp of all lamps is on the same side. For vertical

arrangement the stamp of the lamp always should be placed down. For

circular lamps FC the socket has to be placed down.

The measurement of the cold spot temperature is especially important for

the luminaire manufacturer. This temperature offers opportunities to

optimize the luminaire efficacy.

Fluorescent lamps use up their emitter during operation. The complete loss

of emitter on an electrode results in a voltage increase in the vicinity of the

electrode filament. As most Electronic control gear have no problem

providing this high asymmetric voltage and with it the required additional

power the temperature around the electrodes rises significantly.

At the moment the international ECG safety standard IEC 61347-2-3 is

under revision. In the future, all ECG must provide a “end-of-life” safety

shutdown which is continuously controlled in order to avoid overheating of

lamp sockets.

The actual status of the standard considers three different test circuits for

Electronic control gear. If an ECG complies with one of the three tests, it

offers protection against the “end-of-life” behavior of fluorescent lamps.

• Asymmetric pulse test (Test 1)

• Asymmetric power test (Test 2)

• Open filament test (Test 3)

The asymmetric power test (Test 2) is directly simulating the additional load

which results from the increased asymmetric voltage in the case of “end-oflife”. In order to pass the test the additional load may nod exceed a specific

value depending on the lamp type. Most ECG experts see test 2

(asymmetric power test) as the safest “end-of-life” control, because the

direct measurement of the asymmetric additional load mirrors the real lamp

behavior at its end of life. OSRAM does not compromise the safety of

Electronic control gear and has, for quite some time, specified Test no. 2 as

standard test.

U-OUT a binding ECG label according to safety standard EN 61347-2-

3. The former standard EN 60928, still valid until 2006, allows labeling

of U-OUT either in the product catalogue or on the ECG housing. UOUT specifies the largest effective working voltage between

- Lamp terminals

- Each lamp terminal and earth connection, if applicable

This information is important for all components electrically connected on

the lamp side of the ECG.

All components such as lamp cables, sockets (EN 60061-2), isolating

22

Page 24

2.17 Approval Marks

2.17.1 ENEC-Approval Mark

material and everything coming in contact with the ECG lamp terminals

must be layed out according to U-OUT.

OSRAM, as manufacturer, takes care that no higher voltage appears at the

lamp terminals than specified by U-OUT. Therefore no additional voltage

reserve is needed.

2.17.1.1 Safety acc. to

EN 61347

2.17.1.2 Performance acc. to

EN 60929

2.17.2 VDE EMC mark

stands for E

also a conformity mark agreed upon between the testing institutes of the

European union.

It stands for compliance with the according European standards for safety

and performance. Besides sample testing ENEC includes also a permanent

control od products and production processes. This certification is

testimony of an independent and competent institute testing the safety and

performance of Electronic control gear. The number right beside the

approval mark identifies the certifying institute. For example 10 is

representing VDE in Germany.

The ENEC approval mark for ECG to operate fluorescent lamps includes

the safety standard EN 61347 and the performance standard EN 60929.

This standard contains the safety requirements of electric units for

operation of lamps that are designed for DC- and AC-voltage at 50 or 60

Hz. It is divided into different parts.

The first part EN 61347-1 deals with general and safety requirements.

b) Electronic control gear to operate with AC-voltage at 50 or 60 Hz

This safety standard whose part EN 61347-2-3 together with the general

part EN 61347-1 succeeds the former standard EN 60928, is also called

„omnibus“ standard.

This standard specifies the performance of Electronic control gear for

fluorescent lamps. It defines the operation at AC-voltage, at 50 or 60 Hz

and with a supply frequency different from the operating frequency. It is

based on performance standards for fluorescent lamps EN 60081 and EN

60901.

uropean Norm Electrical Certification. The ENEC approval is

with an operating frequency different from the frequency of the

mains supply and to operate fluorescent lamps according to IEC

60081 and IEC 60901 and other fluorescent lamps for high

frequency operation are dealt with in part EN 61347-2-3.

The independent testing institute confirms the compliance of the ECG with

the EMC regulation regarding immunity, radio interference suppression and

harmonics. At the same time, it is also a confirmation for the CE label that

can be applied to ECGs by the manufacturer himself under compliance with

the EMC regulation. Luminaire manufacturer can significantly reduce their

costs and approval efforts with regards to EMC compliance by using

already EMC approved ECGs.

23

Page 25

2.18 Energie Efficiency

Index EEI

2.19 CE Labelling

This label helps consumers identifying the energy consumption of a

product. Usually, all Electronic control gear have the best ratings A2 …A3.

Dimmable ECG are classified as A1. Magnetic ballasts (CCG) fall under the

energy efficiency class C and D and are either already banned from the

market or are about to be banned shortly.

Low loss ballasts are usually classified in B.

Since January 1996, all products falling under the EU directive of

electromagnetic compatibility (EMC) must carry the CE label. The CE label

indicates the compliance with the requirements of this directive. From

January 1997 all products falling under the Low-Voltage directive must also

be CE labeled. There is no question that our products comply with the

specific EU directives and therefore are labeled with the CE mark.

Regarding CE labelling here the following explanations:

1. CE-label as basis to introduce product to the market

Since 01.01.1996 manufacturers and importers are obliged to apply

CE labels to products that have to comply with EMC regulations

either directly on the product, its packaging or the accompanying

documents. CE labels are obligatory for the sale of products within

the European Union. By applying the CE label manufacturers or

importers confirm that their products comply with the “basic

requirements” of specific European directives and fulfill their

protective goals (for example electromagnetic compatibility). Usually

the compliance of particular “basic requirements” is given products

are manufactured under consideration of harmonized European

standards.

2. CE label is a mark for administrative authorities

The CE label is targeted primarily at administrative authorities. It

declares to them that CE labeled products comply with European

jurisdiction at the time of sale.

3. No rights for commerce and endusers of examining declarations of

conformity issued by manufacturers.

The right to ask for and examine declarations of conformity is