Page 1

www.osram.com/prevaled-core

Technical application guide

®

PrevaLED

Core Z3

LED modules

Light is OSRAM

11/ 2013

Page 2

PrevaLED® Core Z3 LED modules | Contents

Contents

1 Introduction 03

1.1 System overview 03

1.2 No men clatu re 03

2 Optical considerations 04

2.1 Light distribution 04

2.2 Refl ector design 04

2.3 Refl ector mounting 06

2.4 Color temperature 06

2.5 Color rendering 07

2.6 Spectral distribution 07

2.7 Flux behavior 08

3 Electrical considerations 09

3.1 Forward voltage as a function of temperature 09

3.2 Electronic control gear/LED module combination 09

3.3 Wiring 10

3.4 OTi electronic control gear series 12

3.5 OT FIT electronic control gear series 12

3.6 OTe electronic control gear series 12

3.7 OT LCTS electronic control gear – LEDset GEN 1 12

3.8 Maximum allowed number of control gears

per circuit breaker 13

3.9 ESD 13

4 Thermal considerations 14

4.1 Thermal power values 14

4.2 TIM and other accessories 14

4.3 Cooling system and heat sinks 14

point location and temperature measurement 15

4.4 t

c

4.5 Thermocouple 15

5 Lifet ime and thermal behavior 17

6.1 Flux as a function of temperature 17

6.2 Lifetime 17

6 Mechanical considerations 18

6.1 Outline drawing 18

6.2 3D drawing 18

6.3 Mechanical protection of the PrevaLED

LED module 18

6.4 Mounting 18

7 Norms and standards 19

®

Core Z3

Please note:

All information in this guide has been prepared with

great care. OSRAM, however, does not accept liability

for possible errors, changes and/or omissions. Please

check www.osram.com/prevaled or contact your sales

partner for an updated copy of this guide.

2

2

Page 3

PrevaLED® Core Z3 LED modules | Introduction

1 Introduction

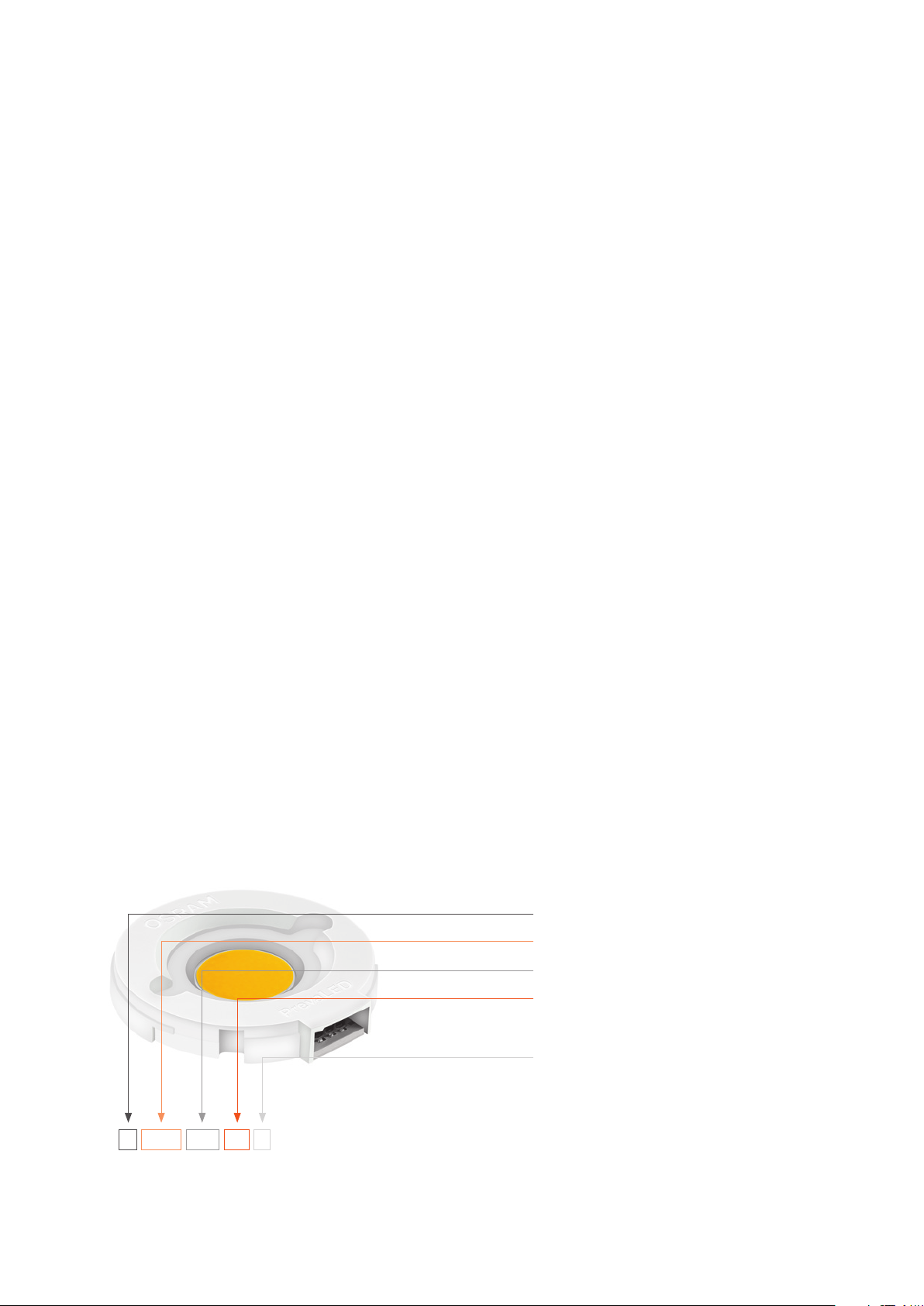

1.1 System overview

Building an LED-based luminaire poses a new set of technical challenges, among them new optical requirements,

providing adequate thermal management for stable

operation and lastly dealing with the ever-improving

performance of LEDs. Nevertheless, LED technology also

provides an unknown wealth of possibilities, opening up unprecedented levels of performance.

This technical application guide will support you in tackling

the challenges and taking full advantage of all opportunities

PrevaLED

®

Core LED modules have to offer.

Focussing on continuous improvement of performance and

costs, OSRAM has introduced its new generation

of Zhaga spotlight LED modules: PrevaLED

together with the dedicated on/off and intelligent

OPTOTRONIC

®

electronic control gear (ECG) ranges.

®

Core Z3,

Future-proof concept

To allow for a smooth transition to this new generation

of the PrevaLED

remained the same:

— System approach with OPTOTRONIC

®

Core series, crucial features have

®

ECGs

— Form factor and mechanical/optical interfaces

— Compatibility with off-the-shelf accessories

according to Zhaga book 3.

Of course, important improvements

have been realized as well:

— Effi cacy of the modules

— 5 000-lm package

— Price position

— Power supply/LED module interface – fi t to standard

cables and standard constant-current power supplies

(on/off and intelligent)

Applications

The PrevaLED

®

Core series of LED modules is ideally

suited for use in refl ector-based, rotation-symmetric

luminaires (such as tracklights, cardans, and downlights) in

shop, hospitality, decorative or offi ce applications.

1.2 Nomenclature

PL-CORE-3000-830-Z3

®

PL: PrevaLED

LED module

Core: Round shaped module

3000: 3000 lm

830: Color rendering index (CRI) + Color

temperature (CCT) = > 80 + 3000 K

Z3: Generation 3

3

Page 4

PrevaLED® Core Z3 LED modules | Optical considerations

2 Optical considerations

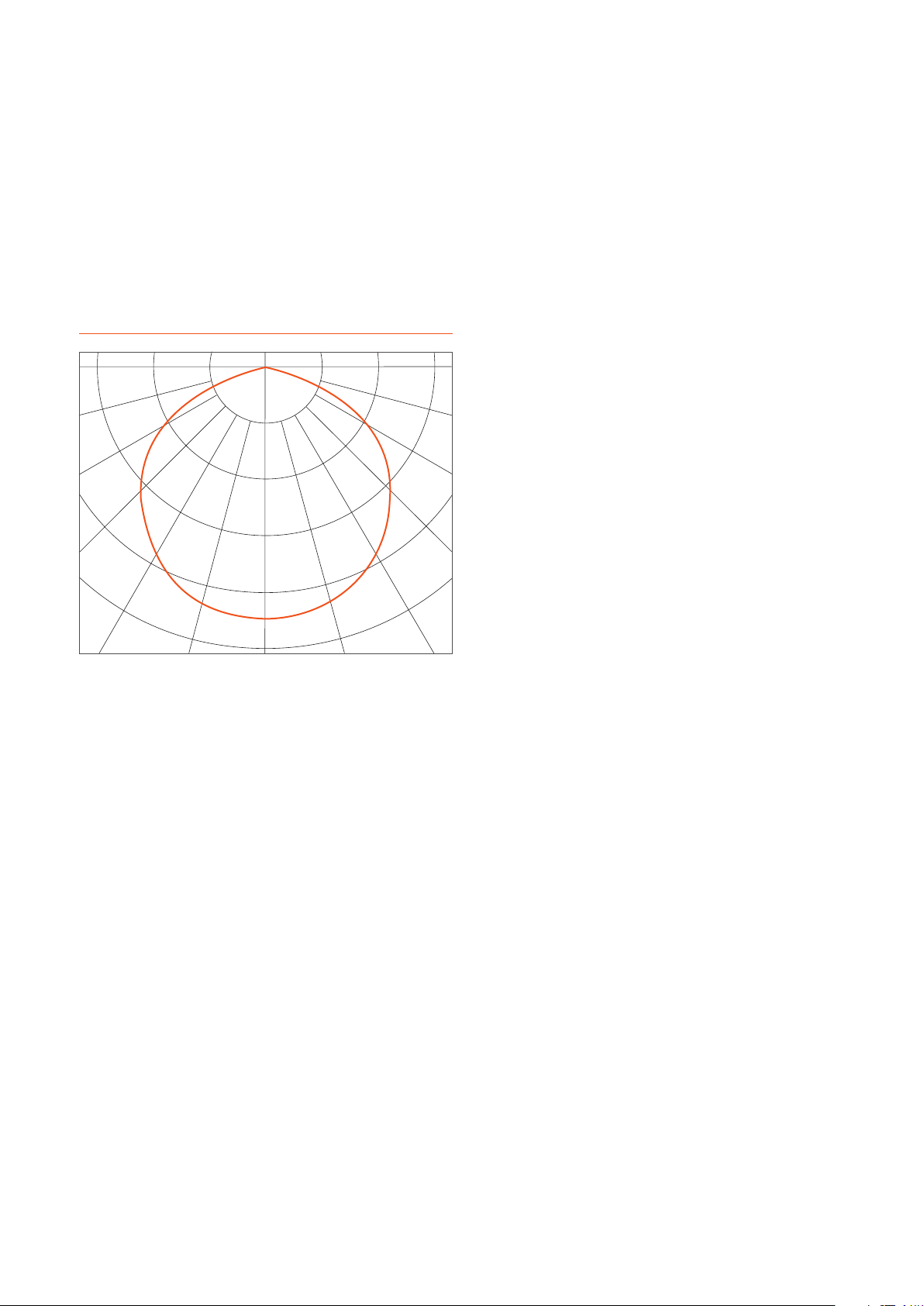

2.1 Light distribution

The light distribution of the LED module is shown in the

graph below. PrevaLED

®

Core Z3 LED modules create

a beam angle of 115° FWHM (full width at half maximum).

C 0°

75°

60°

45°

30°

15°

2.2 Refl ector design

High luminous intensities (1.5–4.5 Mcd/m2) are the key

factor for LED-based lamps and luminaires in the area of

refl ector applications such as spotlights. For this purpose,

light sources with small light-emitting surfaces and a high

luminous fl ux – as realized in the PrevaLED

®

Core Z3 – are

required, because in such combinations, the light can be

collimated especially well with refl ectors.

®

The PrevaLED

Core Z3 is equipped with a surface that

emits light evenly and makes the use of diffuser materials

unnecessary due to its high level of homogeneity. The

minimized light-emitting surface (LES) and a positioning of

the refl ector close to the LES allows for an improved optical

handling. Generally, the properties of the PrevaLED

®

Core Z3

help to avoid roughness and facets, allowing for very small

total beam angles of 10° or less.

OSRAM provides mechanical (3D fi les) and optical simulation data (ray fi les) to support customized refl ector

designs. Mechanical fi les can be downloaded at

www.osram.com/prevaled.

Ray fi le data are available upon request through your

sales partner. Available ray fi le formats are ASAP, SPEOS,

LightTools and Photopia (all bi nary).

4

Page 5

PrevaLED® Core Z3 LED modules | Optical considerations

PrevaLED® Core Z3, 1100 lm, LES 9, OCA A*

Reflector output diameter [mm]

Reflector

height [mm]

50 12°; 14000 cd;

40 14°; 10000 cd;

30 15°; 9000 cd;

20 18°; 5000 cd;

PrevaLED® Core Z3, 2000 lm, LES 19, OCA C*

Reflector

height [mm]

100 15°; 17000 cd;

80 15°; 16000 cd;

60 19°; 10000 cd;

40 19°; 8000 cd;

PrevaLED® Core Z3, 3000 lm, LES 19, OCA C*

40 50 60 70

89 %; 3400 lx;

12.5 cd/lm

12°; 13000 cd;

89 %; 2400 lx;

8.7 cd/lm

91 %; 2100 lx;

7.8 cd/lm

14°; 7000 cd;

93 %; 1300 lx;

4.7 cd/lm

Reflector output diameter [mm]

80 100 120 140

90 %; 2600 lx;

5.2 cd/lm

93 %; 2100 lx;

4.2 cd/lm

95 %; 1700 lx;

6.0 cd/lm

88 %; 4200 lx;

8.4 cd/lm

89 %; 3900 lx;

7.9 cd/lm

15°; 14000 cd;

91 %; 3500 lx;

7.0 cd/lm

14°; 11000 cd;

95 %; 2600 lx;

5.3 cd/lm

91 %; 3200 lx;

11.5 cd/lm

12°; 11000 cd;

93 %; 2700 lx;

9.9 cd/lm

11°; 7000 cd;

96 %; 1800 lx;

6.6 cd/lm

12°; 22000 cd;

89 %; 5600 lx;

11.2 cd/lm

12°; 21000 cd;

91 %; 5200 lx;

10.4 cd/lm

12°; 18000 cd;

93 %; 4400 lx;

8.9 cd/lm

11°; 12000 cd;

96 %; 3100 lx;

6.1 cd/lm

10°; 17000 cd;

90 %; 4400 lx;

15.9 cd/lm

10°; 15000 cd;

92 %; 3900 lx;

14.0 cd/lm

9°; 13000 cd;

94 %; 3100 lx;

11.4 cd/lm

9°; 7000 cd;

97 %; 1800 lx;

6.4 cd/lm

11°; 28000 cd;

90 %; 7100 lx;

14.3 cd/lm

10°; 25000 cd;

92 %; 6400 lx;

12.8 cd/lm

10°; 21000 cd;

94 %; 5200 lx;

10.5 cd/lm

8°; 13000 cd;

97 %; 3300 lx;

6.5 cd/lm

PrevaLED® Core Z3, 5000 lm, LES 23, OCA D*

Reflector output diameter [mm]

Reflector

height [mm]

100 14°; 38000 cd;

80 18°; 27000 cd;

60 18°; 24000 cd;

40 22°; 14000 cd;

*Parabolic refl ector, 85% specular refl ectance, lux in 2 m distance

80 100 120 140

12°; 48000 cd;

84 %; 3600 lx;

2.9 cd/lm

81 %; 6700 lx;

5.3 cd/lm

83 %; 6000 lx;

4.8 cd/lm

16°; 18000 cd;

85 %; 4600 lx;

3.6 cd/lm

80 %; 9500 lx;

7.6 cd/lm

15°; 35000 cd;

82 %; 8900 lx;

7.1 cd/lm

14°; 30000 cd;

84 %; 7500 lx;

6.0 cd/lm

12°; 21000 cd;

87 %; 5300 lx;

4.2 cd/lm

81 %; 12100 lx;

9.7 cd/lm

12°; 43000 cd;

83 %; 10900 lx;

8.7 cd/lm

11°; 36000 cd;

85 %; 8900 lx;

7.1 cd/lm

10°; 22000 cd;

88 %; 5600 lx;

4.5 cd/lm

— A parabolic refl ector shape is used.

— A fi ne facet structure is applied as it should always

be used for CoB LEDs. The impact on the narrowest

possible beam angle is small.

— A purly specular refl ectance of 85 % is assumed.

— The collimation strength values cd/lm refer to the

LED module fl ux.

— Data values in red correspond to a refl ector with an

extremely large diameter/height ratio D/H > 2 (cut-off

angle > 45°). This is not recommended with respect

to glare.

— Illuminance values are the maximum values in the spot

center in 2 m distance to the refl ector.

The PrevaLED® Core Z3 can be used with secondary optics.

Zhaga-compliant off-the-shelf solutions can be used with the

LED module. For optics support, you can fi nd suppliers via

OSRAM's LED Light for You network: www.ledlightforyou.com.

Moreover, off-the-shelf solutions and support for refl ector

design are available, e.g., from the following suppliers:

Reflector output diameter [mm]

Reflector

height [mm]

100 15°; 25000 cd;

80 15°; 24000 cd;

60 19°; 16000 cd;

40 19°; 13000 cd;

80 100 120 140

88 %; 6300 lx;

8.4 cd/lm

89 %; 5900 lx;

7.9 cd/lm

15°; 21000 cd;

90 %; 3900 lx;

5.2 cd/lm

93 %; 3100 lx;

4.2 cd/lm

91 %; 5200 lx;

7.0 cd/lm

14°; 16000 cd;

95 %; 4000 lx;

5.3 cd/lm

12°; 34000 cd;

89 %; 8400 lx;

11.2 cd/lm

12°; 31000 cd;

91 %; 7800 lx;

10.4 cd/lm

12°; 27000 cd;

93 %; 6600 lx;

8.9 cd/lm

11°; 18000 cd;

96 %; 4600 lx;

6.1 cd/lm

11°; 43000 cd;

90 %; 10700 lx;

14.3 cd/lm

10°; 38000 cd;

92 %; 9600 lx;

12.8 cd/lm

10°; 32000 cd;

94 %; 7900 lx;

10.5 cd/lm

8°; 20000 cd;

97 %; 4900 lx;

6.5 cd/lm

Jordan Refl ektoren GmbH & Co. KG

Schwelmer Strasse 161

42389 Wuppertal, Germany

+49 202 60720

info@jordan-refl ektoren.de

www.jordan-refl ektoren.de

ACL-Lichttechnik GmbH

Hans-Boeckler-Strasse 38 A

40764 Langenfeld, Germany

+49 2173 9753 0

info@refl ektor.com

www.refl ektor.com

5

Page 6

PrevaLED® Core Z3 LED modules | Optical considerations

Alux·Luxar GmbH & Co. KG

Schneiderstrasse 76

40764 Langenfeld, Germany

+49 2173 279 0

sales@alux-luxar.de

www.alux-luxar.de

Almeco S.p.A.

Via della Liberazione, 15

20098 San Giuliano, Milanese (Mi), Italy

+39 02 988963 1

info.it@almecogroup.com

www.almecogroup.com

Nata Lighting Co., Ltd.

380 Jinou Road, Gaoxin Zone

Jiangmen City, Guangdong, China

+86 750 377 0000

info@nata.cn

www.nata.cn

®

PrevaLED

Core Z3 3D fi les including the bayonet base for

design-in are available at:

www.osram.de/prevaled-core.

2.4 Color temperature

The PrevaLED® Core Z3 series is currently available in 2 700

K, 3 000 K, 3 500 K and 4 000 K. The color coordinates

within the CIE 1931 color space are given below.

2700 K 3000 K 3500 K 4000 K

Cx 0.4585 0.4345 0.4083 0.3828

Cy 0.4104 0.4033 0.3921 0.3803

®

Within each available color temperature, the PrevaLED

Core Z3 series provides a maximum color variation of three

threshold value units (MacAdam steps). The following diagram shows these threshold values within the CIE 1931

color space.

2.3 Refl ector mounting

The LED modules have a clearly defi ned optical contact

area (OCA), which provides a defi ned surface for attaching

the refl ector. In this confi guration, the mounting and mechanical support of the refl ector must be ensured by the luminaire body or by suitable structures for refl ector mounting.

The following has to be considered when mounting the refl ector: Due to the creepage and clearance distances specifi ed in the norm (IEC 61347-1/U935, among others), it is recommended to stay within the OCA values of the corresponding category (see PrevaLED

®

datasheet).

Additionally, a bayonet base option is provided, with the

help of which the refl ector can be attached directly to the

PrevaLED

®

Core Z3.

y

0.45

0.40

0.35

6000

0.35

3000

4000

0.40 0.45 0.50

2500

2000

x

Allowed compression: 20 N

Allowed tension: 20 N

Allowed torque: 1 Nm

6

Page 7

PrevaLED® Core Z3 LED modules | Optical considerations

2.5 Color rendering

PrevaLED® Core Z3 LED modules provide a color rendering

index (CRI) of either > 80 or >90. The table below shows the

individual R

values from R1 to R16 for the available color

a

temperatures.

R

R1 R2 R3 R4 R5 R6 R7 R8 R9 R10 R11 R12 R13 R14 R15 R16

a

2700 83 83 95 93 78 82 93 82 61 18 87 76 74 86 97 76 73

3000 85 85 96 93 80 85 93 83 65 26 89 78 73 88 97 80 77

3500 87 87 97 94 81 86 94 84 70 33 92 80 69 91 97 83 78

4000 88 89 99 93 82 88 93 84 73 41 95 81 67 93 97 86 79

3000 94 96 99 98 92 94 96 91 87 74 97 93 78 97 99 93 90

2.6 Spectral distribution

The typical spectral distribution of the PrevaLED® Core Z3

LED modules is shown in the following diagram.

Relative luminous intensity [%]

120

100

80

60

40

20

0

400

Values measured at tc = 25 °C

450 500 550

827 830 835 840 930

600 650 700 750

Wavelength [nm]

7

Page 8

PrevaLED® Core Z3 LED modules | Optical considerations

2.7 Flux behavior

The following diagrams show the luminous fl ux over

the operating current for all PrevaLED

®

Core Z3 modules.

PL-CORE-1100-8xx-Z3

PhiV typ [lm]

140 0

120 0

1000

800

600

400

100 150

PL-CORE-3000-XXX-Z3

PhiV typ [lm]

Z3 1100 lm 840 65 °C Z3 1100 lm 830 65 °C

200 250 300 350

I [mA]

Z3 3000 lm 840 65 °C Z3 3000 lm 830 65 °C

Z3 3000 lm 930 65 °C

PL-CORE-2000-XXX-Z3

PhiV typ [lm]

3000

2500

2000

150 0

1000

500

200 250 400 450350

PL-CORE-5000-XXX-Z3

PhiV typ [lm]

Z3 2000 lm 840 65 °C Z3 2000 lm 830 65 °C

Z3 2000 lm 930 65 °C

300 500 550 600

I [mA]

Z3 5000 lm 840 65 °C Z3 5000 lm 830 65 °C

Z3 5000 lm 930 65 °C

5000

4000

3000

2000

6000

5000

4000

3000

2000

1000

0

700 900 1000 1100500 600

800

I [mA]

0200

400 1200 1400 1600

800 1000600

I [mA]

8

Page 9

PrevaLED® Core Z3 LED modules | Electrical considerations

3 Electrical considerations

3.1 Forward voltage as a function of temperature

Relative forward voltage normalized at 65 °C [%]

101.5

101.0

100.5

100.0

99.5

99.0

98.5

98.0

020406080100120

110 0 l m 2000 lm 3000 lm 5000 lm

Case temperature tc [°C]

3.2 Electronic control gear/LED module combination

PrevaLED® Core Z3 LED modules can either be used with

constant-current control gears or in combination with

OSRAM OTi control gears. The OTi control gears provide a

thermal shutdown function as well as an automatic fl ux calibration. Constant- current control gears do not provide these

features. The table below shows possible combinations of

PrevaLED

®

Core Z3 LED modules and OSRAM ECGs.

Modules Drivers

Typ. current

[mA]

PL-CORE-1100-830 235

PL-CORE-1100-840 220 1210

PL-CORE-2000-830 400 2070

PL-CORE-2000-840 385 2160

PL-CORE-2000-930 490 1750 TBD

PL-CORE-3000-830 590 3035

PL-CORE-3000-840 575 3115

PL-CORE-3000-930 730 2900 2900 2900 3240 2900

PL-CORE-5000-830 950 3400 3400 TBD

PL-CORE-5000-840 885 3700 3700 TBD

PL-CORE-5000-930 1155

2300: System fi t OK nominatyp. fl ux level (lm) if deviating from nominal

: System fit OK for 1 or more current settings

Preliminary data. The fl ux levels realized with fi xed-value constant-current OTe and OT FIT drivers will change as the effi cacy of the modules evolves.

OT 35/45

LTCS

OT 45

DALI LTCS

OTe

25/CS

OTe

35/CS

OTe

50/CS

OTe 50/CS

FAN

4600 4600

OT FIT

15/CS

1160

OT FIT

25/CS

OT FIT

OTi DALI 25OTi DALI 35OTi DALI

35/CS

50 FAN

9

Page 10

PrevaLED® Core Z3 LED modules | Electrical considerations

3.3 Wiring

The input clamps used in the PrevaLED® Core Z3 can handle solid wires with a cross-section of 0.5–1.0 mm

2

(AWG 21-17).

Example: H05V-U 1x 0.5 mm2

Wire preparation

For wires with

2

(AWG17):

1 mm

5.5 mm

For wires with

0.5-0.823 mm2

(AWG21–18):

5.3 +- 0.2 mm

Please note:

— The connector is designed for three “poke-in” and

release cycles.

— The installation of LED modules needs to be carried out

in compliance with all applicable electrical and safety

standards. Only qualifi ed personnel should be allowed to

perform installations.

— If you cannot use solid wires, you can use stranded wires

with a diameter of 0.5 to 0.75 mm and tin-coat the wire

ends before inserting them into the connection clamp.

10

Page 11

PrevaLED® Core Z3 LED modules | Electrical considerations

Connect and release

Connect

Plug wire directly

Release

1 2

Use a very slim screwdriver and push gently into the release hole

Note: Push in the screwdriver below the release spring.

3

Pull out the wire and afterwards the screwdriver

11

Page 12

PrevaLED® Core Z3 LED modules | Electrical considerations

3.4 OTi electronic control gear series

If you use the PrevaLED® Core Z3 series in combination with

the OSRAM OTi control gear series, you will get the best

results and the full functionality of the LED module.

The system includes a one-wire communication interface,

using the LEDset II communication standard between the

control gear and the module. A thermal derating and a fl ux

calibration are included.

Therefore, please connect all three terminals of the module

to the control gear:

3.6 OTe electronic control gear series

If you like to use the OSRAM OTe series, please connect the

terminal LED+ to the module and select the desired current

by connecting it to only one of the output terminals 21, 22

or 23.

Select only

1 connection

terminal

3.7 OT LCTS electronic control gear – LEDset GEN 1

If you want to use PrevaLED® Core Z3 LED modules with

LCTS control gears, you need to attach a resistor to the

ECG to adjust the needed current.

3.5 OT FIT electronic control gear series

It is also possible to use the PrevaLED® Core Z3 series with

a constant-current driver. The OT FIT series offers different

available currents. To wire the module to the ECG, please

connect the ports LED+ and LED- to the module as shown

in the image below. The current is selected by a bridge

between ports 3, 4 and 5:

OT 35/220-240/700 LCTS

You can calculate the resistor using the formula:

I

out

R

1 + 9

=

set

I

set

= The value of the resistor in Ohm

R

set

= The output current desired to operate

I

out

I

[V]

nom

the LED module

= 700 mA for OT 35/700 LCTS and

I

nom

OT DALI 45/700 LCTS

= 274 μA

I

set

12

Page 13

PrevaLED® Core Z3 LED modules | Electrical considerations

The following values result for the modules which are

possible to drive with LCTS drivers:

Module I [mA] R [Ohm]

PL-CORE-2000-830 400 22419

PL-CORE-2000-840 385 21715

PL-CORE-2000-930 490 26642

PL-CORE-3000-830 590 31335

PL-CORE-3000-840 575 30631

PL-CORE-3000-930 730 Use DIP switch for 700 mA. Module is under-driven.

PL-CORE-5000-830 950 Use DIP switch for 700 mA. Module is under-driven.

PL-CORE-5000-840 885 Use DIP switch for 700 mA. Module is under-driven.

The resistor has to be placed between Vset and GNDset:

Example of wiring:

For further information on the LEDset interface, please refer

to the LEDset application note at www.osram.com.

3.8 Maximum allowed number of control gears

per circuit breaker

Please note:

To activate the LEDset interface, both DIP switches of the

LED module have to be in the “OFF” position.

DIP1 DIP2 Current

Off Off LEDset

Off On 700 mA

On Off 500 mA

On On 350 mA

B16 B10

OTe 35/700 50 30

OT 35/LCTS 84 52

OT 45 LCTS 60 40

OT 45 DALI LCTS 47 18

OTe 25/CS 50 30

OTe 35/CS S 44 28

OTe 35/CS 25 15

OTe 50/1A4 CS 25 15

OTe 50/1A0 CS 25 15

OTe 50/CS FAN 25 15

OT FIT 15CS 28 17

OT FIT 25/CS 28 17

OT FIT 35/CS 28 17

OTi DALI 25 84* 52*

OTi DALI 35 60* 40*

OTi DALI 50 FAN 13 18

* Preliminary data

3.9 ESD

It is not necessary to handle PrevaLED® Core Z3 LED

modules in electrostatic protected areas (EPAs). To protect

a PrevaLED

®

Core LED module from electrostatic damage,

do not open it. The LED module fulfi lls the requirement of

the immunity standard IEC/EN 61547.

13

Page 14

PrevaLED® Core Z3 LED modules | Thermal considerations

4 Thermal considerations

The proper thermal design of an LED luminaire is critical for

achieving the best performance and ensuring the longest

lifetime of all components. Due to the high effi cacy of Pre-

®

Core Z3 LED modules, only a partial amount of the

vaLED

introduced electrical power has to be dissipated through the

back of the LED module. The thermal power that has to be

dissipated for PrevaLED

®

Core Z3 LED modules is given

below.

4.1 Thermal power values

Max. thermal

Typ. thermal

Product

PL-CORE-1100-830-Z3 7.7 8.2 4.91

PL-CORE-1100-840-Z3 6.9 7.3 5.48

PL-CORE-2000-830-Z3 11.2 12.4 3.23

PL-CORE-2000-930-Z3 14.4 15.6 2.56

PL-CORE-2000-840-Z3 10.1 11.0 3.63

PL-CORE-3000-830-Z3 15.9 17.4 2.30

PL-CORE-3000-930-Z3 21.2 23.3 1.72

PL-CORE-3000-840-Z3 15.1 16.6 2.41

PL-CORE-5000-830-Z3 28.6 31.3 1.28

PL-CORE-5000-930-Z3 33.7 36.8 1.09

PL-CORE-5000-840-Z3 25.1 27.4 1.46

1) Value measured at the t

2) Value measured at the rear of the luminaire at an ambient temperature

of 25 °C.

power [W]

point at a reference temperature (tr) of 65 °C.

c

power [W] at

1)

nominal current1)

Max. allowable

thermal resis-

tance Rth [K/W]

2)

4.2 TIM and other accessories

When mounting a PrevaLED® Core Z3 LED module within a

luminaire, it is recommended to use thermal interface

material (TIM) between the back of the LED module and the

luminaire housing or heat sink. It is recommended to use

thermal paste, but thermal foil can also be used. In order to

balance possible unevenness, the material should be

applied as thinly as possible, but as thickly as necessary.

In this way, air inclusions, which may otherwise occur, are

replaced by TIM and the required heat conduction between

the back of the LED module and the contact surfaces of the

luminaire housing is achieved. For this purpose, the planarity

and smoothness of the surface should be optimized.

The list below is a selection of suppliers of thermal interface

materials. Additional suppliers for thermal management

support can also be found via OSRAM’s LED Light for your

network: www.ledlightforyou.com.

Thermal interface materials

Alfatec www.alfatec.de

Kerafol www.kerafol.de

Laird www.lairdtech.com

Bergquist www.bergquistcompany.com

Arctic Silver www.arcticsilver.com

Wakefield www.wakefield.com

To achieve the best possible lifetime of the module and to

save it from damage by overheating, a thermal protection

feature is added. This feature is only usable when operating

the module with an OSRAM OTi control gear.

The characteristics of the thermal protection are shown in

the following diagram:

Current [% of minimal ECG current]

100

50

0

75 105

tc [°C]

The behaviour below 50 % of the system current depends on the

nominal system current and the applied ECG.

4.3 Cooling system and heat sinks

For the selection of a suitable heat sink, several points

regarding thermal resistance have to be considered.

The selection is usually done through the following

necessary steps.

Total power dissipation of the

Defi ne boundary

conditions

Estimate heat sink

thermal resistance on

LED module level

Select heat sink

thermal resistance

Selection of a heat sink

LED module, max. ambient

temperature t

temperature t

time requirements

Rth =

tr measured at the tc point

Use the estimated Rth as a target for a possible heat sink

profi le and examine the performance curve in the heat sink

manufacturer’s catalog.

, max. reference

a

according to life-

r

t

- t

r

a

P

th

14

Page 15

PrevaLED® Core Z3 LED modules | Thermal considerations

Please note:

A thermal design must always be confi rmed by performing

a thermal measurement in steady-state condition.The whole

area of the PCB must be in contact with solid material of the

heat sink. In the following, you fi nd two examples of how to

cool a PrevaLED

®

Core Z3 LED module.

Example 1:

LED module: PL-CORE 1100-827

Heat sink: Fischer SK572 height: 37.5 mm

TIM: Kerafoil 86/82

: 25 °C

T

ambient

Temperature at the t

point: 61 °C

c

Example 2:

LED module: PL-CORE 5000-830

Heat sink: Sunon LA003-012A82DY

(active cooling solution with 12-V fan)

TIM: Kerafoil 86/82

: 25 °C

T

ambient

Temperature at the t

point: 57 °C

c

Please note that the shown solutions are just examples. A

thermal system always depends on many factors, such as

airfl ow, ambient temperature etc. Please check your entire

cooling system by performing a thermal measurement in

steady-state condition. The list below is a selection of suppliers of different cooling solutions.

Location of the tc point

tc point

2D code

To ensure a lifetime of 50000 hours (L

temperature (t

) at the tc point must not exceed 65 °C. The

r

maximum temperature reached at the t

), the reference

70B50

point must not

c

exceed 85 °C. A correct temperature measurement can,

for example, be performed with a thermocouple.

4.5 Thermocouple

Use a thermocouple that can be glued onto the LED module.

Make sure that the thermocouple is fi xed with direct contact

to the t

point. Examples of suitable thermo couples:

c

Cooling systems

Nuventix www.nuventix.com

Sunon www.sunoneurope.com

Cooler Master www.coolermaster.com

AVC www.avc-europa.de

SEPA www.sepa-europe.com

Fischer Elektronik www.fischerelektronik.de

Meccal www.meccal.com

Wakefield www.wakefield.com

R-Theta www.r-theta.com

Cool Innovations www.coolinnovations.com

K-type thermocouple with miniature connector

Different thermocouples

Illustration Description Temperature range [°C]

4.4 Tc point location and temperature measurement

The tc point is the location to check if the chosen cooling

solution (heat sink and TIM) is suffi cient to ensure the LED

module performance. The t

point is located on the back of

c

the LED module under the center of the diffuser (see image

below).

PVC-insulated

thermo couple

PFA-insulated

thermo couple

Sprung

thermo couple

-10 … +105

-75 … +260

-75 … +260

15

Page 16

PrevaLED® Core Z3 LED modules | Thermal considerations

To measure the temperature and to ensure a good thermal

coupling between the LED module and the heat sink, drill a

hole into the heat sink and push the thermocouple through

the heat sink. To ensure a direct contact between the thermocouple and the PCB, it is recommended to glue the thermocouple onto the PCB. You can, for example, use an acrylic adhesive (e.g. type Loctite 3751).

It is also possible to use a sprung thermocouple. A suitable

type is: Electronic Sensor FS TE-4-KK06/09/2m. Please note that a good thermal contact between the thermocouple

and the PCB is required. Please refer to the data sheet and

the application guideline of the manufacturer to ensure correct handling.

Note: Please keep in mind that you need a direct contact

between the thermocouple and the PCB.

Note: If you use a TIM, please cut out a small area where

the thermocouple has direct contact to the metal-core

PCB.

Another possible way is to create a small groove along the

top surface of the heat sink and run the thermocouple inside

the groove to the t

point.

c

16

Page 17

PrevaLED® Core Z3 LED modules | Lifetime and thermal behavior

5 Lifetime and thermal behavior

5.1 Flux as a function of temperature

The following diagram shows the behavior of the fl ux output

over the t

PL-CORE-2000 lm/3000 lm-Z3

Relative luminous intensity normalized at 65 °C [%]

108

106

104

102

100

98

point temperature for Prevaled Core Z3.

c

96

94

92

25 45 65 85

Case temperature tc [°C]

5.2 Lifetime

OSRAM PrevaLED® Core Z3 modules have a lifetime of

50 000 hours (L

) at a tc point temperature of 65 °C. This

70B50

means that after 50 000 hours, over 50 % of the used modules will have more than 70 % of the initial luminous fl ux. If you

operate the module at a lower t

point temperature, the life-

c

time of the module is going to rise signifi cantly.

Note: Higher t

PrevaLED

temperatures lead to a shorter lifetime of the

c

®

Core Z3 LED modules. Moreover, the failure rate

will also increase.

17

Page 18

PrevaLED® Core Z3 LED modules | Mechanical considerations

Enable 3D View

6 Mechanical considerations

The following schematic drawing provides further details on

the dimensions of PrevaLED

fi les of the LED modules, please go to: www.osram.com.

6.1 Outline drawing

1100 lm

®

Core Z3 LED modules. For 3D

2000/3000 lm

6.3 Mechanical protection of the PrevaLED® Core Z3

LED module

The housing of a PrevaLED® Core Z3 LED module should

not be exposed to strong mechanical stress. Please apply

force only to the dedicated mounting positions. Strong mechanical stress can lead to irreversible damage of

the LED module.

Note: Please do not touch or mechanically stress

the yellow chip-on-board surface. This could damage

the module.

For operation in damp, wet or dusty environments, the user

has to make sure that an adequate ingress protection is

chosen. The LED module has to be protected by a suitable

IP classifi cation of the luminaire housing. Please con sider

the luminaire standard IEC 60598-1 as well as the different

requirements.

5000 lm

6.2 3D drawing

6.4 Mounting

To fi x a PrevaLED® Core Z3 LED module to a heat sink, you

can use M3 cylinder head screws according to DIN 7984. If

you cannot use DIN screws, please use the following specifi cation: Height of head not more than 2.6 mm, diameter of

head below 5.5 mm. The allowed torque is0.4 to 0.6 Nm.

18

Page 19

PrevaLED® Core Z3 LED modules | Norms and standards

7 Norms and standards

Safety: IEC/EN 62031

IEC/EN 60598-1

Photobiological safety: IEC/EN 62471

Risk group: 1

Electromagnetic compatibility: CISPR 15

IEC/EN 61547

IEC/EN 61000-3-2

IEC/EN 61000-3-3

EN 55015

Ingress protection: IP10

Flammability of plastics: UL8750 Class 2/UL 94 850 °C glow wire test

Approvals: CE,UL

19

Page 20

www.osram.com/prevaled-core

OSRAM GmbH

Head Offi ce:

Marcel-Breuer-Strasse 6

80807 Munich, Germany

Phone +49 (0)89-6213-0

Fax +49 (0)89-6213-20 20

www.osram.com

12/13 OSRAM S-GI MK EM Subject to change without notice. Errors and omissions excepted.

Loading...

Loading...