Page 1

www.osram.dewww.osram.

de

www.osram.com/prevaled-core

Technical application guide

®

PrevaLED

Core Z2 light engines

JUNE

2013

Page 2

CONTENTS

CONTENTS

1. Introduction 3

1.1. System overview 3

1.2. System information 6

1.2.1. Nomenclature and marking 6

1.2.2. Technical data 7

1.2.3. Accessories 7

1.3. Zhaga – interchangeability of light engines 7

2. Optical considerations 8

2.1. Refl ector 8

2.1.1. Refl ector design 9

2.1.2. Refl ector mounting 10

2.1.3. Lighting design information 10

2.2. Luminous fl ux and color stability 11

2.3. Zhaga – optical interface 11

3. Electrical considerations 12

3.1. Safety requirements 12

3.2. Wiring information 12

3.3. Wiring in class I and class II luminaires 13

3.4. Optional cable clamp 13

3.5. Electrostatic safety measures 14

3.6. Inrush current limitation 14

3.7. Connection information 14

3.8. Zhaga – electrical interface 14

4. Thermal considerations 15

4.1. Thermal interface material and other accessories 15

4.2. Heat sink 16

4.3. Temperature measurement 17

4.4. Thermal simulation 18

4.5. ECG thermal considerations 19

4.6. Thermal management and lifetime 19

4.7. Zhaga – thermal interface 19

5. Mechanical considerations 21

5.1. LED module dimensions 21

5.2. Mechanical protection of the LED module 21

5.3. ECG dimensions 22

5.4. LED module attachment 22

5.5. Zhaga – mechanical interface 22

6. Assembly in a reference luminaire 23

6.1. Preparation 23

6.2. Wiring and refl ector/cover 24

6.3. Commissioning the PrevaLED

7. Norms and standards 25

7.1. Norms and standards for PrevaLED® LED modules and light engines 25

7.2. Norms and standards for control gears 25

7.3. Photobiological safety 26

®

light engine 24

Please note:

All information in this guide has been prepared with great care.

OSRAM, however, does not accept liability for possible errors,

changes and/or omissions.

Please check www.osram.com/prevaled-core or contact your

sales partner for an updated copy of this guide.

2

Page 3

INTRODUCTION

1. Introduction

1.1. System overview

Brightness levels of today’s LEDs are opening the door for

usage of LEDs in general lighting applications requiring

high lumen output levels. Building an LED-based luminaire

poses a new set of technical challenges, among them new

optical requirements, providing adequate thermal management for stable operation and lastly dealing with the everimproving performance of LEDs.

®

OSRAM’s PrevaLED

family of LED light engines addresses

the challenges of LED-based lighting while at the same

time giving the user great performance and fl exibility.

®

The PrevaLED

Core Z2 series of light engines is ideally

suited for use in refl ector-based, rotation-symmetric

applications such as downlights or spotlights. These light

engines provide several convincing benefi ts in the

application:

®

• PrevaLED

Core Z2 light engines are available as a system of matching LED modules and ECGs and deliver

maximum performance at very high levels of effi ciency.

• These light engines provide superior optical performance, both in terms of their optical effi ciency as well

as their high quality of light (color rendering).

• A wide range of lumen packages (currently available

from 800–5000 lm) allows addressing a wide range of

applications based on a single platform. This platform

allows, for example, the operation of a sequence of

spotlights – ranging from halogen-class up to HID levels

– in a row, while at the same time creating a homogeneous overall impression for the end user.

• Thanks to their high thermal and optical performance,

luminaires based on PrevaLED

®

Core Z2 light engines

can be realized with minimized size of required heat sink

and refl ector, giving the user greater design fl exibility.

• PrevaLED

®

Core Z2 light engines provide standardized

interfaces for the user, in particular by defi ning stable

lumen packages over time. Independent of future increases in LED effi cacy, the luminous fl ux of an individual

LED module will remain constant, but at lower power

consumption. In this way, a luminaire designed on the

PrevaLED

®

Core platform will automatically benefi t from

effi cacy improvements without needing a lengthy and

costly redesign of the base construction.

3

Page 4

INTRODUCTION

At present, PrevaLED® Core Z2 light engines are available

as systems in different performance grades:

• Lumen packages of 800–5000 lm are available with a

good to very good color rendering (with typ. CRI 83

and typ. CRI 93).

• The lumen packages of 800–5000 lm with CRI 83 are

especially well suited for consumer applications.

Movable 3D PrevaLED® Core Z2

(works with Adobe Acrobat 7 or higher)

The high efficacy of the light engines not only results in

minimized energy consumption of the luminaire, but also

reduces the thermal load on the luminaire, allowing for

smaller and lighter designs of the heat sink.

The PrevaLED® light engine consists of an LED module,

dedicated OTp and connection cable.

Both the CRI 90 and the CRI 80 types are available with

2700 K, 3000 K, 3500 K and 4500 K CCT; in lumen

packages of 800, 1500, 2000, 3000, 4000 and 5000 lm.

®

PrevaLED

OPTOTRONIC

Core LED modules must be operated with

®

power supplies of the “OTp” type. Available

types are detailed in the next section. All possible system

configurations are listed on the latest datasheet.

Additional details on optical, thermal, mechanical and

electrical characteristics can be found in the following

sections. Additional and updated information (as well as

updates of this guide) will be posted at www.osram.com/

prevaled-core.

OSRAM also provides an extensive range of energy-saving

light management components, such as sensors and room

controllers. By use of these products, additional energy sa vings can be realized. For an overview of these products,

please visit www.osram.com/lms.

4

Page 5

INTRODUCTION

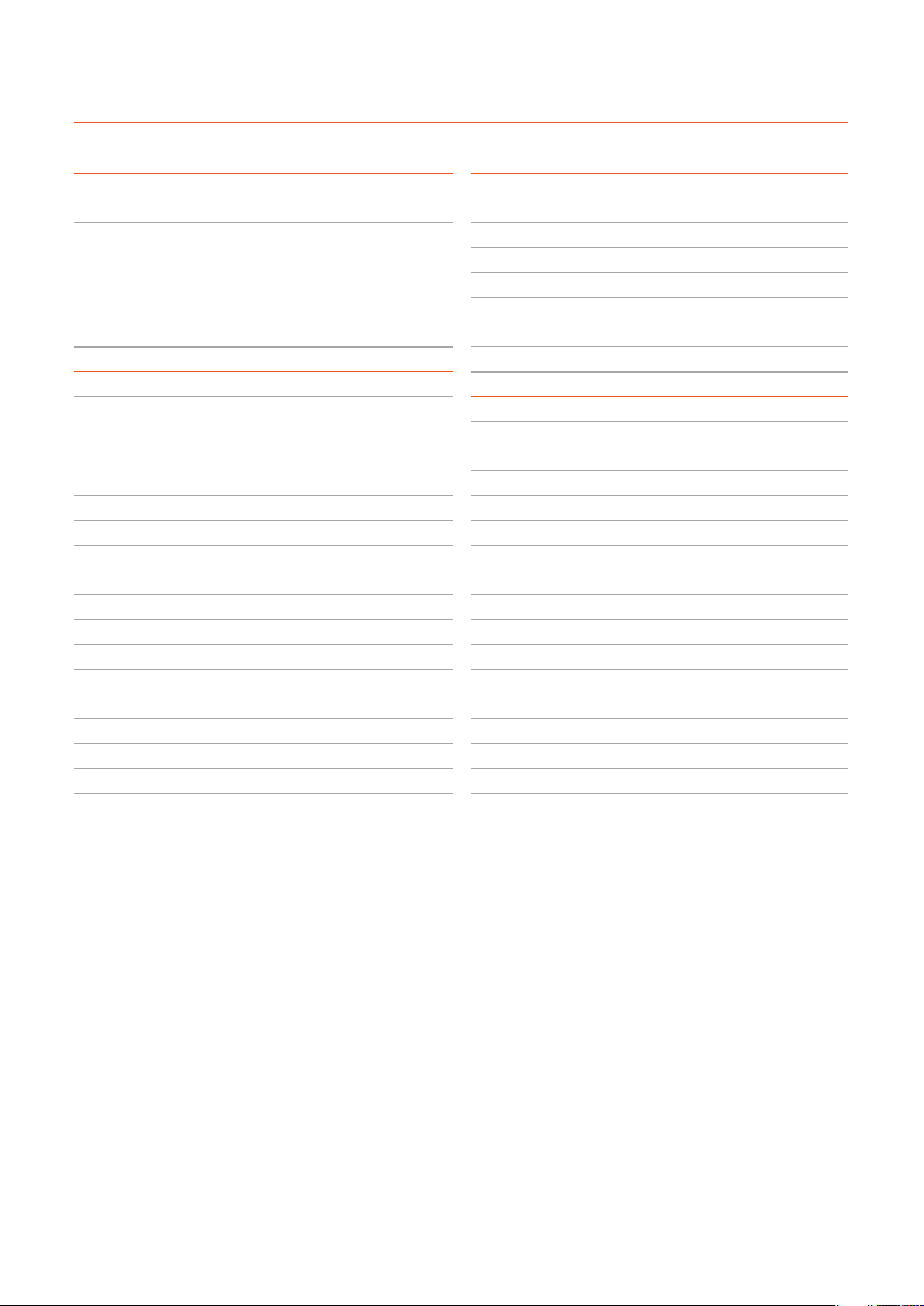

PrevaLED® Core Z2 –

CRI 90: Six lumen packages

800 lm, 1500 lm

2000 lm

3000 lm, 4000 lm, 5000 lm

PrevaLED® Core Z2 – CRI 90: Six lumen packages

2700 K 3000 K 3500 K 4000 K

800 lm LEP-800-927-C-Z2 LEP-800-930-C-Z2 LEP-800-935-C-Z2 LEP-800-940-C-Z2

1500 lm LEP-1500-927-C-Z2 LEP-1500-930-C-Z2 LEP-1500-935-C-Z2 LEP-1500-940-C-Z2

2000 lm LEP-2000-927-C-Z2 LEP-2000-930-C-Z2 LEP-2000-935-C-Z2 LEP-2000-940-C-Z2

3000 lm LEP-3000-927-C-Z2 LEP-3000-930-C-Z2 LEP-3000-935-C-Z2 LEP-3000-940-C-Z2

4000 lm LEP-4000-927-C-Z2 LEP-4000-930-C-Z2 LEP-4000-935-C-Z2 LEP-4000-940-C-Z2

5000 lm – LEP-5000-930-C-Z2 LEP-5000-935-C-Z2 LEP-5000-940-C-Z2

®

PrevaLED

Core Z2 –

CRI 80: Six lumen packages

800 lm, 1500 lm

2000 lm

(2000 lm), 3000 lm,

4000 lm, 5000 lm

PrevaLED® Core Z2 – CRI 80: Six lumen packages

2700 K 3000 K 3500 K 4000 K

800 lm LEP-800-827-C-Z2 LEP-800-830-C-Z2 LEP-800-835-C-Z2 LEP-800-840-C-Z2

1500 lm LEP-1500-827-C-Z2 LEP-1500-830-C-Z2 LEP-1500-835-C-Z2 LEP-1500-840-C-Z2

2000 lm LEP-2000-827-C-Z2 LEP-2000-830-C-Z2 LEP-2000-835-C-Z2 LEP-2000-840-C-Z2

3000 lm LEP-3000-827-C-Z2 LEP-3000-830-C-Z2 LEP-3000-835-C-Z2 LEP-3000-840-C-Z2

4000 lm LEP-4000-827-C-Z2 LEP-4000-830-C-Z2 LEP-4000-835-C-Z2 LEP-4000-840-C-Z2

5000 lm – LEP-5000-830-C-Z2 LEP-5000-835-C-Z2 LEP-5000-840-C-Z2

5

Page 6

INTRODUCTION

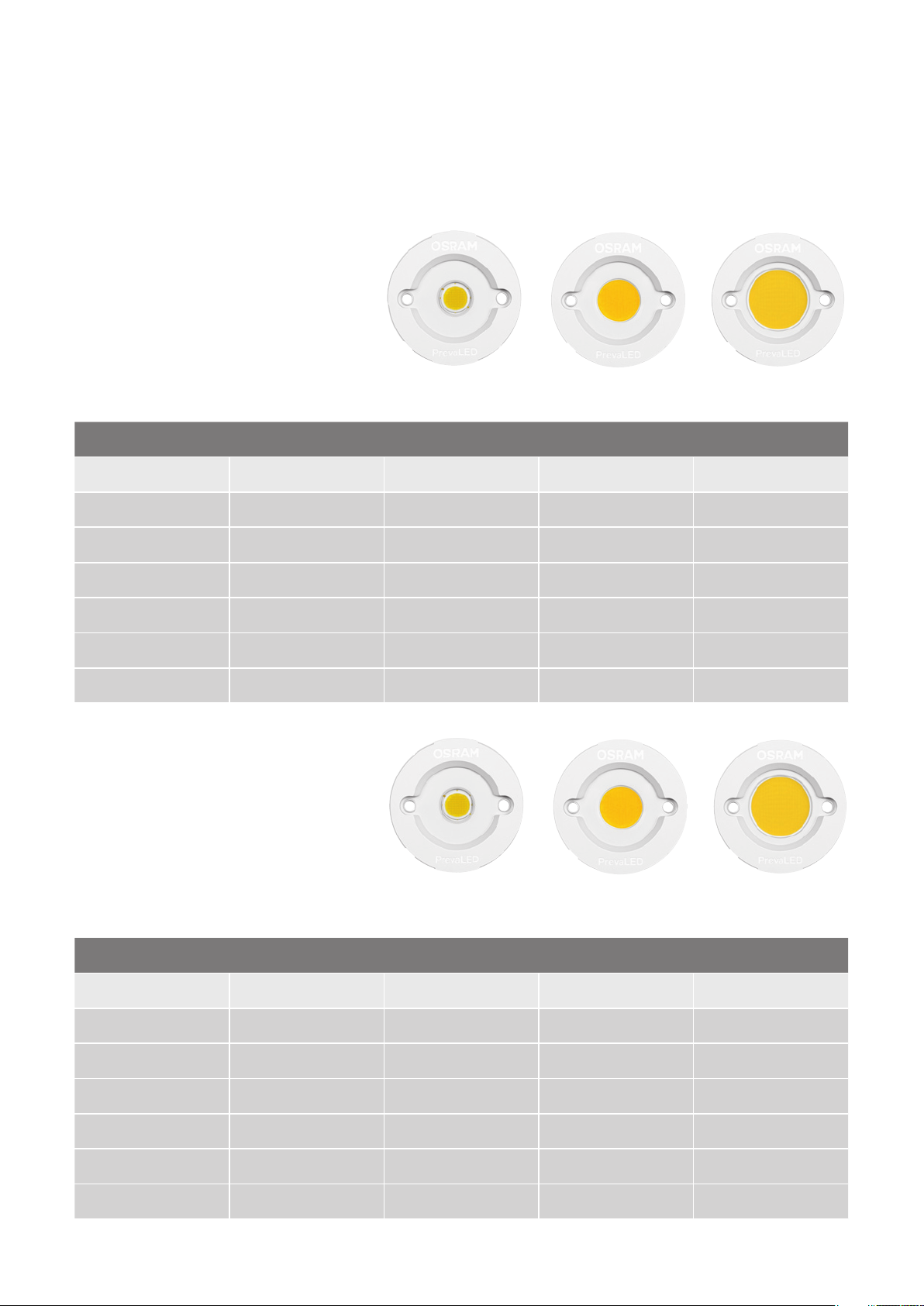

1.2. System information

1.2.1. Nomenclature and marking

The PrevaLED

®

family follows a consistent naming

convention for identifying key parameters of the LED

module and the power supply. The nomenclature of the

LED modules and OPTOTRONIC

®

ECGs is as follows:

LED module:

LEP = LED module PrevaLED

®

5000 = 5000 lm

930 = CRI + CCT = CRI > 90 + 3000 K

C = Core, round shape

Z2 = Product generation Z2

LEP - 5000 - 930 - C - Z2

Power supply:

OTp DALI 45 / 220-240 / 700 HD FAN

OTp: OPTOTRONIC

®

PrevaLED

®

Control protocol: DALI (if applicable)

Wattage: 45 W

Input voltage: 220–240 V

Maximum output current: 700 mA

HD = High Dynamic

FAN = Ventilator/auxiliary output 5 V

6

Page 7

INTRODUCTION

1.2.2. Technical data

Technical data product family PrevaLED® Core Z2:

For current data, please see the PrevaLED

®

datasheet

at www.osram.com/prevaled-core.

PrevaLED® Core Z2

Technical data electronic control gear (ECG):

For current ECG data, please see the OPTOTRONIC

(OTp) datasheet at www.osram.com/prevaled-core.

1.2.3. Accessories

Cable kit

The cable is required for contacting and connecting the

individual PrevaLED

®

Core Z2 LED module with the power

supply. It ensures a fl exible and safe connection. This

cable kit is approved according to UL (Underwriters

Laboratories).

PrevaLED® Core Z2-

cable kit 800 lm,

1500 lm, 2000 lm, 3000 lm

PrevaLED® Core Z2-

cable kit 4000 lm

and 5000 lm

Cable clamp for OTp

This cable clamp can be clamped onto the ECG, turning

it into an ECG suitable for independent installation. It is

®

available for order for all OPTOTRONIC

OTp 45 versions.

®

OTp 35 and

ECG (OPTOTRONIC®)

Combinations of LED modules and ECGs:

For current combination possibilities, please see the

PrevaLED

®

datasheet at www.osram.COM/prevaled-core.

Within rated power, LED modules and power supplies can

be fl exibly combined, e.g. according to the favored control

option or form factor. A general requirement is that each

LED module is connected to an individual ECG.

The connection between the LED module and the ECG

should be established by means of the supplied cable kit.

Available in lengths 40 cm and 80 cm, please also refer to:

3.2. Wiring information.

Well-established form factors have been utilized for the

housings of the ECGs in order to ensure that existing

luminaire housings or accessories can be adopted to

PrevaLED

®

technology.

1.3. Zhaga – interchangeability of light engines

The Zhaga Consortium for the standardization of LED light

sources (LED light engines) is a worldwide cooperation

of luminaire and lamp manufacturers, producers of LED

modules and companies that supply the lighting industry.

The interchangeability of LED light engines is achieved

by defi ning fundamental interface parameters while still

leaving room for innovation in LED and driver technologies. Zhaga interface specifi cations cover the physical

dimensions, as well as the photometric, electrical and

thermal properties of different LED light engines.

The Zhaga Consortium was established in February 2010

and includes more than 180 companies (status: April

2012). OSRAM AG is a full member. The members

meet regularly in different regions of the world in order

to jointly work out the specifi cations. Large parts of the

new PrevaLED

®

Core portfolio fulfi ll the Zhaga specifi c ation book 3 for “spotlight systems with separate electronic

control gear.”

®

An updated list of all currently certifi ed PrevaLED

light

engines is available at: www.osram.com/zhaga.

For more information, please go to: www.zhagastandard.org.

7

Page 8

OPTICAL CONSIDERATIONS

2. Optical considerations

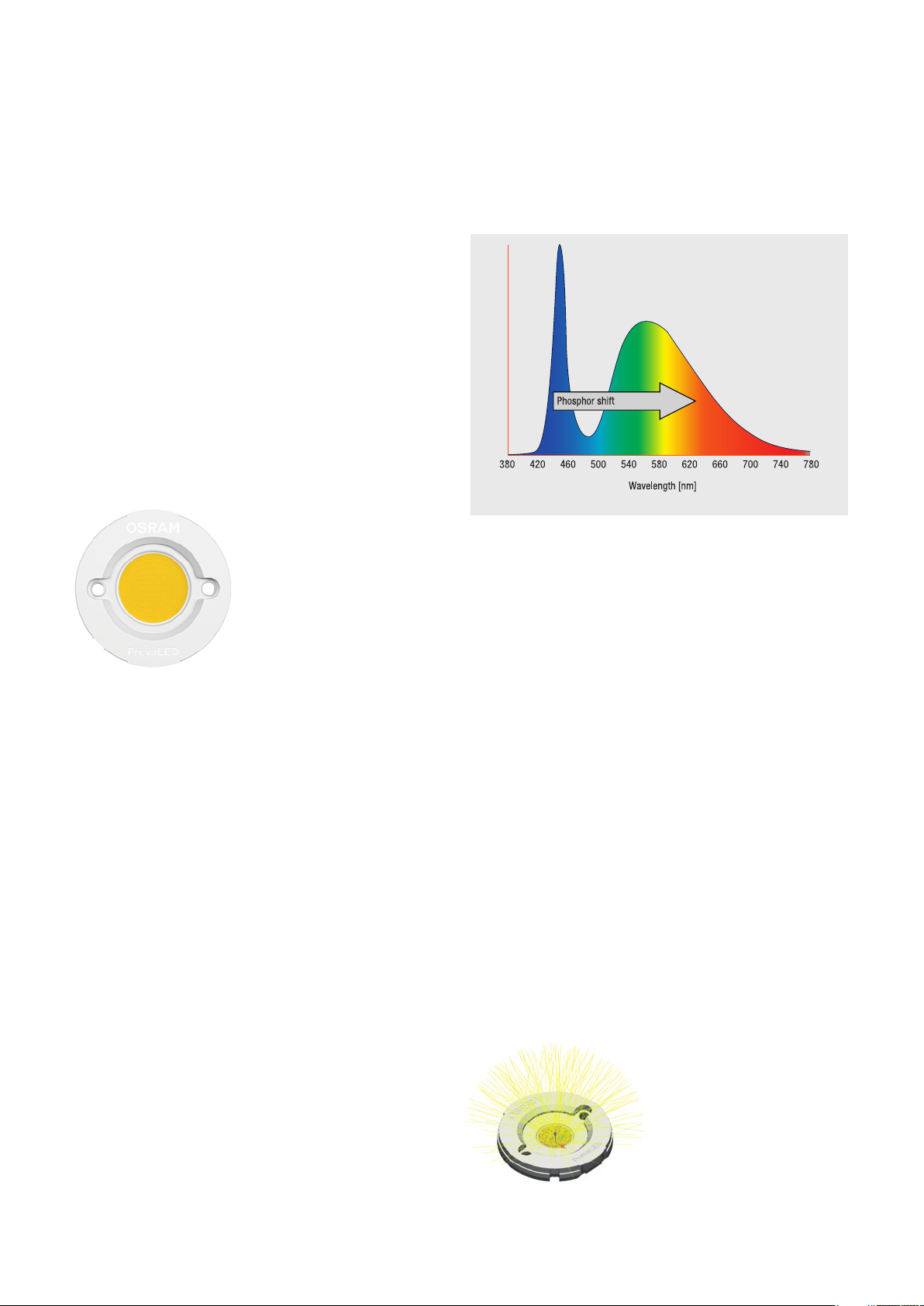

Chip-on-board-design (CoB)

So-called chip-on-board (CoB) light sources without

housing and with high-performance chips set very closely

next to each other have proven to be especially advantageous. Due to the large amount of applied chips, the size

of the light source is fl exible and scalable. In the application, the compactness, on the one hand, allows for very

high axis light and illumination levels, and, on the other

hand, a very high-contrast illumination with high brilliance.

Very good homogeneity (with a uniformity factor of 0.93) –

combined with constantly Lambertian radiation – additionally simplifi es refl ector design and facilitates the interchangeability of light sources.

PrevaLED

®

Core Z2

The CoB design is characterized by a large amount of

closely set LED chips, arranged in a certain grid which is

covered with luminescent material (cf. the image above).

One of the key advantages of this design is its very homogeneous light-emitting surface.

Pure phosphor conversion with CoB

Thanks to the use of pure phosphor conversion, the

PrevaLED

®

Core Z2 module can achieve a color rendering

quality of higher than CRI 90, while at the same time

providing a very homogeneous light output.

Phosphor conversion: By means of phosphor conversion, the blue

light of the LED chip is shifted towards the higher wavelengths of

green and red light.

2.1. Refl ector

High luminous densities (1.5–4.5 Mcd/m

2

) are the key

factor for LED-based lamps and luminaires in the area of

refl ector applications such as spotlights, for example.

For these, light sources with small light-emitting areas

and a high luminous fl ux are required (as realized with the

PrevaLED

®

Core Z2), because that way, the light can be

collimated especially well with refl ectors.

®

Thanks to CoB technology, the PrevaLED

Core Z2 has

a uniform light-emitting surface which, due to its great

homogeneity, eliminates the need to use diffuser material.

The minimized light-emitting surface (LES) and a refl ector

positioning close to the LES allows for better optical

handling. All in all, the properties of the PrevaLED

®

Core Z2

allow for the prevention of roughness and facets, which in

turn allows for minimal overall beam angles of 10° or less.

®

The high homogeneity of the PrevaLED

Core Z2 means:

• Low complexity in the surface structure of the refl ector

• Narrower beam angles <10° FWHM in combination with

minimized light-emitting surface

PrevaLED® Core Z2

8

Page 9

OPTICAL CONSIDERATIONS

2.1.1. Refl ector design

OSRAM provides mechanical (3D fi les) and optical

simulation data (ray fi les) to support customized refl ector

designs. These data are available upon request through

your sales partner or for public download at:

www.osram.com/prevaled-core.

Information on the optical calculation and simulation

for refl ector designs:

a) First estimation: Assumption of the LES ∅ as an

idealized, homogeneous, Lambertian emitter

b) Simulation via raytracing software:

• Ray fi les available upon request via OSRAM sales

department

• Photopia fi les are lodged under www.lti.com

The light distribution curve (LDC) of the module (without

further refl ectors, opt. systems) is characterized by a

universally applicable Lambertian distribution. Therefore,

it is very easy to defi ne and connect further downstream

optical systems (refl ectors, lenses, …).

More partners for support in the optics area can

be found in OSRAM’s LED Light For You network:

www.ledlightforyou.com. Moreover, standard components

and support for refl ector design and refl ector brackets are

available e.g. through the following partners:

ACL-Lichttechnik GmbH

A.A.G. STUCCHI

s.r.l.u.s. (Tool-less

+49 2173 9753 0

info@refl ektor.com

www.refl ektor.com

re fl ector brackets)

+39 0341 653111

info@aagstucchi.it

www.aagstucchi.it

Alux·Luxar

ALMECO S.p.A.

GmbH & Co. KG

+39 02 988963-1

+49 2173 279 0

sales@alux-luxar.de

info.it@almecogroup.com

www.almecogroup.com

www.alux.de

Jordan Refl ektoren

GmbH & Co. KG

Suitable and available

refl ectors can, for example,

be found on the web pages

+49 202 60720

of these partners.

info@jordan-refl ektoren.de

www.jordan-refl ektoren.de

C90

C0

LDC PrevaLED® Core Z2 –

without refl ector

LDC PrevaLED® Core Z2 –

with spot refl ector

PrevaLED® Core Z2

Please note that strong forces applied to the

housing can damage the LED module or the

housing, especially if the LED module isn’t

attached to a heat sink. Attach or remove the refl ector

only if the LED module is safely connected to a heat sink.

9

Page 10

OPTICAL CONSIDERATIONS

2.1.2. Refl ector mounting

The LED modules have a clearly defi ned optical contact

area (OCA) which provides a defi ned surface for attaching

the refl ector. In this confi guration, the mounting and

mechanical support of the refl ector must be ensured by

the luminaire body or by suitable structures for refl ector

mounting.

The following has to be considered when mounting the

refl ector: Due to the “air and creepage distances” specifi ed in the norm (IEC 61347-1/U935, among others), it is

recommended to stay within the OCA values of the corresponding category (see PrevaLED

the PrevaLED

®

Core Z2 and design support are available

®

datasheet). 3D fi les of

on the homepage www.osram.com/prevaled-core.

Design example: Conference room

The task here is to illuminate a conference room (approx.

5 x 4 m, height 2.8 m) in such a way that a medium illuminance (E

) of 500 lux is achieved on the work plane.

medium

By means of the EULUMDAT fi les provided by the refl ector

manufacturers, lighting design software and an assumed

maintenance factor of 0.69, the following example result is

achieved (calculated in DIALux with a Jordan fl ood refl ector,

article no. 113309010101): Illuminance diagram with 9

PrevaLED

®

Core Z2-based luminaires (LEP-2000-xxx-C-Z2):

2.1.3. Lighting design information

Computerized lighting design can be carried out with

free lighting design software such as DIALux and Relux

(www.dial.de or www.relux.biz).

Lighting designers can download or request the necessary

numerical luminous intensity distribution curves

(= EULUMDAT fi les in the .ldt format) for PrevaLED

®

Core

Z2 with the corresponding refl ector via the web page of

the respective refl ector manufacturer.

Ceiling height: 2800 mm,

Mounting height: 2851 mm

Figures in lux

Exemplary lighting design with 9 x PrevaLED® Core Z2 2000 lm in a

conference room

10

Page 11

OPTICAL CONSIDERATIONS

2.2. Luminous fl ux and color stability

Depending on the type of the LED module, the nominal

CCT is 2700 K, 3000 K, 3500 or 4000 K, respectively.

Depending on the variant, PrevaLED® Core Z2 modules

provide a module-to-module color variation of less than 3

threshold value units (MacAdams steps) on the Planckian

locus around this color target. These threshold value units

can be shown within the ANSI (American National Standards Institute) norm in the following way:

Measuring tolerance for color coordinates: ±0.01

2.3. Zhaga – optical interface

In order to achieve the interchangeability of refl ectors for

spot applications, Zhaga defi nes categories for the diameters of the light-emitting surfaces. PrevaLED

®

Core Z2

modules are available in the categories LES 9, LES 19 and

LES 23. With LED modules of the same category, optical

systems basically achieve the same beam angles and luminous intensities. With their homogeneity parameter U of

more than 90 % (i.e. with their very homogeneous radiation

without any additional light diffusion), the PrevaLED

®

Core

Z2 modules facilitate all further optical light shaping by

means of refl ectors or lenses. Around the light-emitting

surface, a ringshaped surface (optical contact area, OCA)

with a defi ned height is specifi ed where refl ector optics

can be attached. In addition to the surface described in

the Zhaga specifi cation, the OCA of PrevaLED

®

Core Z2

modules is positioned closer to the light-emitting surface,

so that refl ectors with smaller openings can also be used.

All PrevaLED

®

Core Z2 light engines fulfi ll the Zhagaspecifi ed requirements in terms of luminous fl ux, chromaticity coordinates and beam characteristics and partially

even exceed these requirements.

The luminous fl ux of each LED module depends on its

temperature. Therefore, 100 % of the luminous fl ux are

also achieved with the PrevaLED

®

Core Z2, i.e. until the

reference temperature (tr) is reached. When the reference

temperature is exceeded and up to maximum temperature

), the luminous fl ux is reduced to 95 %. If the maximum

(T

c

temperature is exceeded, a further luminous fl ux reduction

comes into effect until the PrevaLED

®

Core Z2 module is

fi nally switched off.

LES: Light-emitting surface

OCA (Optical contact area):

Attachment and reference

surface for optics

(e.g. refl ectors, lenses)

All fi gures in mm

11

Page 12

ELECTRICAL CONSIDERATIONS

3. Electrical considerations

3.1. Safety requirements

All OPTOTRONIC

PrevaLED

®

de vices with an output voltage of < 120 V

®

OTp devices intended for operating

Core LED modules are SELV*-equivalent

.

DC

The design of the LED modules ensures that the requirements of IEC 62031 for LED modules are met. The chips

on the LED module do not need to be covered in order to

fulfi ll the requirements of IEC 62031.

Due to its construction, the LED module can be mounted

directly on an exposed housing without further insulation.

The luminaire manufacturer is responsible for providing the

suitable and mandatory clearance and creepage distances

for the luminaire (for a light engine operating voltage of

< 120 V

*SELV = Safety extra-low voltage

).

DC

3.2. Wiring information

The recommended wire cross section on the primary side

of the OPTOTRONIC

nection between the OPTOTRONIC

®

OTp ECG is 0.5–1.5 mm2. The con-

®

ECG and the LED

module should be established by using the cable kit

available for order in lengths of 400 mm and 800 mm.

Components of the connection cable between

LED module and OTp

PrevaLED

®

cable sockets:

IN-CONNECTOR-CRIMPING SOCKET-TOP-LS2-5 RL 710

Part#: DF3-5S-2C, supplier: Hirose Electric Europe B.V.

(www.hirose.com)

• OTp-side (socket height: 4.6 mm/code#:

CL543-0006-6)

• Module-side (socket height: 4.25 mm/code#:

CL543-0193-5-00)

The Hirose crimping tool is recommended for custom izations of the connection cable.

Part#: DF3-TA22HC/550-0257-4-00

The cable material is UL-listed (UL E52653, UL E48762,

UL 10368) and fulfi lls fl ammability requirements according

to UL 94 V-0 and UL VW-1. The cables are approved for

up to 85 °C.

The maximum diameter of the cable is 5 mm, additional

details on the dimensions of the cable kit are specifi ed in

the illustrations on the next page.

For support with customizing cable lengths or construction, you can use the manual crimping tool from Hirose

Electric or contact your sales partner.

®

The cable for PrevaLED

Core Z2 has a fl at connector on

the module side and a higher connector (800 lm, 1500 lm,

3000 lm) on the OTp side, or open cable heads (4000 lm

and 5000 lm).

5-pin cable socket in

crimped condition

Pin 1 LED+

Pin 2 LED-

Pin 3 Aux. voltage

Pin 4 Sense comm.

Pin 5 Aux. gnd.

PIN assignment of connector

12

Page 13

ELECTRICAL CONSIDERATIONS

3.3. Wiring in class I and class II luminaires

Depending on the design of the luminaire according to

class I or class II requirements, a protective earth connection can be established for the OPTOTRONIC

®

ECG.

The functional earth (equipotential connection) may be

connected to the ECG to improve EMI behavior.

For these requirements, see the illustrations below.

Since the power supplies are SELV-equivalent, no

ad ditional electrical insulation has to be provided for

the LED module.

3.4. Optional cable clamp

For OPTOTRONIC

®

OTp 35 and OTp 45 types, an optional

cable clamp is available for order. This cable clamp can

be snapped onto the ECG and thus turns it into an ECG

suitable for independent installation with strain relief.

When using this cable clamp, luminaire design according

to IEC 60598-1 class I and class II is possible. In this regard,

functional earth may have to be observed as detailed above.

Please also note the installation requirements as supplied

with the cable clamp.

For more information on the cable clamp, see chapter

1.2.3. Accessories (p. 7).

Earth connection is mandatory in class I luminaires and

improves EMI compliance according to EN 55015.

In class II luminaires do not connect earthing terminal.

13

Page 14

ELECTRICAL CONSIDERATIONS

3.5. Electrostatic safety measures

In order to safely handle components susceptible to electrostatic discharge (ESD), an adjusted production environment is necessary. This is specifi ed in IEC 61340-5-1

(“Electrostatics – Part 5-1: Protection of electronic devices

from electrostatic phenomena – General requirements”).

Based on the human body model (HBM), the following

maximum voltages apply for the PrevaLED

®

Core Z2:

3.6. Inrush current limitation

Electronic drivers are subject of a certain inrush current.

For the OPTOTRONIC

®

control gears for the PrevaLED®

Core Z2, this current is very low. That is why up to 15 OTp

(35/45) can be applied at one 16-A circuit breaker.

3.7. Connection information

The energized light engine system must not be

serviced. This includes disconnecting or connect-

ing the electrical contact of the LED module

and the ECG. In exceptional cases, such as fi nal assembly, the connection cable can be disconnected from the

LED module or the OTp and then reconnected (20 times

max. with one-minute intermissions).

3.8. Zhaga – electrical interface

Zhaga defi nes no requirements for the electrical interface

between the ECG and the module. For Zhaga categories

and the dimensions of the control gears, please see the

technical datasheet.

Material HBM Class

LEP-800-xxx-C-Z2 4 kV 2

LEP-1500-xxx-C-Z2 8 kV 3B

LEP-2000-xxx-C-Z2 8 kV 3B

LEP-3000-xxx-C-Z2 8 kV 3B

LEP-4000-xxx-C-Z2 8 kV 3B

LEP-5000-xxx-C-Z2 8 kV 3B

14

Page 15

THERMAL CONSIDERATIONS

4. Thermal considerations

The proper thermal design of an LED luminaire is critical

for achieving the best performance and ensuring the long

lifetime of all components. Because the PrevaLED

®

Core

Z2 ensures high effi ciencies, only a partial amount of the

introduced electrical power still has to be dissipated

through the back of the light engine (see also: 1.2.2. Tech-

nical data (p. 7)).

Depending on the application and the chosen LED

module, passive cooling can be suffi cient. In critical applications (e.g. small available heat sink size in combination

with high-power LED modules), active cooling by means

of a ventilator may be needed. Active cooling combines a

heat sink with a fan or a similar device to maximize the

cooling power out of an existing, passive heat sink.

4.1. Thermal interface material and other accessories

When mounting a PrevaLED

®

Core Z2 within a luminaire,

it is highly recommended to use thermal interface material

(TIM) between the back of the LED module and the luminaire housing. Either heat-conductive paste or foil can be

used. In order to balance possible unevenness, the material should be applied as thinly as possible, but as thickly as

necessary. In this way, air inclusions, which may otherwise

occur, are replaced by TIM and the required heat conduction between the back of the LED module and the contact

surfaces of the luminaire housing are achieved. For this

purpose, the planarity and roughness of the surface

should be optimized.

For initial application designs, applicably pre-pierced thermal interface material (e.g. Kerafol’s Keratherm 86-82) with

a diameter of 50 mm and matching mounting holes can

be ordered through the Alfatec company (see the partner

information below). The list below shows a selection of

suppliers of passive and active cooling solutions as well

as thermal interface materials.

Additional partners for thermal management support can

also be found in OSRAM’s LED Light For You network:

www.ledlightforyou.com.

Active cooling systems:

AVC www.avc-europa.de

Cooler Master www.coolermaster.com

Nuventix www.nuventix.com

Sunon www.sunoneurope.com

Heat sinks:

Aavid Thermalloy www.aavidthermalloy.com

Cool Innovations www.coolinnovations.com

Fischer Elektronik www.fi scherelektronik.de

Meccal www.meccal.com

Pinbloc www.pinbloc.de

Radian www.radianheatsinks.com

R-Theta www.r-theta.com

Wakefi eld www.wakefi eld.com

Thermal interface materials:

Aavid Thermalloy www.aavidthermalloy.com

Alfatec www.alfatec.de

Arctic Silver www.arcticsilver.com

Bergquist www.bergquistcompany.com

Chomerics www.chomerics.com

Dow Corning www.dowcorning.com

Electrolube www.electrolube.com

Kerafol www.kerafol.de

Kester www.kester.com

Kunze Folien www.heatmanagement.com

Laird www.lairdtech.com

MG Chemicals www.mgchemicals.com

Thermafl o www.thermafl o.com

Thermagon www.thermagon.com

Wakefi eld www.wakefi eld.com

Heat pipes:

DAU www.dau-at.com

MB Electronic AG www.mb-electronic.de

Simulation software:

Comsol www.comsol.de

Flotherm www.mentor.com

SolidWorks www.solidworks.com

Thermal probes/thermocouples:

B+B Thermo-Technik www.bubthermo.de

OMEGA www.omega.de

15

Page 16

THERMAL CONSIDERATIONS

4.2. Heat sink

Basically, the heat sink has to fulfi ll two tasks:

a) Heat spreading through heat conduction

The task here is to spread the heat as uniformly as possible from the contact surface of the LED module through

the heat sink material and into the cooling fi ns. In this

respect, the thermal conductivity and the material cross

sections of the heat sink play a decisive role (cf. the thermal

conductivities table below).

b) Heat dissipation to the surrounding medium

(usually ambient air)

For this task, the heat sink design in terms of fi n and surface confi guration is decisive. By adequate geometrical

forming, heat conduction through convection and IR radiation can be signifi cantly infl uenced and improved (cf. the

table with the IR emission coeffi cients on the next page).

Thermal conductivities of selected materials

Material Specifi c heat

Copper 380–401

conductance value

[W/(m · K)]

Very good heat

conduction

Thermal conduction

resistance (R

) formula:

th

L

R

=

th

A ·

L: Length through the material in

fl ow direction [m]

A: Material cross section/surface

of the heat sink [m

A

2

]

L

Aluminium 200–220

Brass 120

Steel 42–58

Stainless steel 15

Glass 1

Wood 0.13–0.18

Air (dry at 1013 mbar,

no dissipation)

0.0256 at 20 °C

Bad/no

cooling

16

Page 17

THERMAL CONSIDERATIONS

For necessary heat transfer and good cooling, the surface

of the applied heat sink material, with regard to heat

emission, must be considered. In order to achieve very

good radiation behavior to the ambient space, it can be

advantageous to use heat sinks with a matt black fi nish.

Within typical applications such as downlights in recessed

ceilings, it can be an advantage to use black anodized

heat sinks.

For the optimization of the radiation, special lacquers

with a high emission ratio, as typically used for radiators

instead of anodization, are available.

Overview of selected materials with

different surfaces

Material Emission

ratio

Temperature *

[°C]

Low cooling

effect

Aluminium plate,

blank, rolled

Aluminium, die-cast

surface, blank

Aluminium, black

anodized

Steel, powder-coated 0.85 25

Aluminium, matt

black fi nish

*) Temperature of the material at which

the emission ratio was measured

0.022 25

0.040 170

0.4 170

0.600 40

0.970 80

High cooling

effect

4.3. Temperature measurement

Measuring the temperature helps controlling the LED module’s operating parameters. After fi xing the LED module

into the luminaire, the temperature has to be measured at

the thermal interface point (T

point), within the planned

c

ambient and operation conditions.

Thermal interface point (T

is measured in the center of the back of the LED module

T

c

The thermal interface temperature (case temperature/T

point)

c

c

) is

measured in the center of the back of the LED module, by

means of a thin milled channel (in the LED module or the

luminaire) or hole (∅ approx. 2 mm) which is drilled into

the luminaire prototype for the thermocouple.

With this temperature measurement, as applied at the measuring point of the LED module, the actual T

temperature

c

can be determined. By means of suitable cooling methods

(active or passive cooling), this temperature must be maintained under the maximum temperature specifi ed in the

datasheet.

Based on the measured interface temperature (T

ambient temperature (t

mance (P

), you can determine the necessary thermal

th,mod

resistance of the cooling system (R

) and the thermal module perfor-

a

KS).

th

) of the

c

In order to do so, a thermocouple has to be affi xed to

point, preferably by gluing (e.g. by means of a heat-

the T

c

conducting adhesive such as “Arctic Silver”).

a

th, mod

temperature

c

Formula for calculating the T

Tc-t

R

KS =

th

P

Rth KS = Thermal resistance cooling system

T

= Temperature Tc point

c

= Ambient temperature (usually air temperature of the room)

t

a

= Thermal module performance

P

th, mod

17

Page 18

THERMAL CONSIDERATIONS

Recommended thermocouples

Description Temperature [°C] Length [mm]

All figures in mm

4.4. Thermal simulation

Using a computer, matching heat sink housing forms and

occurring maximum temperatures can be calculated by

means of numerical heat simulation.

Two thermo simulation examples:

T heat sink:

46…49 °C

T ambient: 25 °C

Surface area ~ 0.25 m2

(P115 80 Meccal)

Thermal probe -10…+100

Adhesive foil probe -50…+250

Thermal model description:

PrevaLED

®

Core Z2

2000

cable

1000

wire

TC: 47 °C

T heat sink:

38…41 °C

T ambient: 25 °C

Surface area ~ 0.5 m2

(P 200 84 Meccal)

TC: 39 °C

PrevaLED

150 mm in downlight orientation

®

LEP-2100 on heat sink with extruded profi le –

3D fi les for thermal simulation can be found at:

www.osram.com/prevaled-core.

18

Page 19

THERMAL CONSIDERATIONS

4.5. ECG thermal considerations

The installation of the ECG must ensure that the maximum

temperature at the T

thermal considerations for OPTOTRONIC

found in the technical guide for OPTOTRONIC

is not exceeded. Further details on

c

®

devices can be

®

, available

at: www.osram.com/optotronic.

4.6. Thermal management and lifetime

The PrevaLED

®

Core Z2 has a lifetime of 50,000 h

(L70B50*). If the temperature is exceeded, the specifi cation is left and, after further heat-up, the LED module is

switched off. Liftetime information (see datasheet) as well

as guarantee information for LED modules combined with

ECG at: www.osram.com/prevaled-core.

**

*) L70B50 defi nition: After 50,000 h, at least 50 %

of the observed LED modules still show 70 % of

the initial luminous fl ux.

**) The guarantee conditions can be found at

www.osram.com/system-guarantee.

4.7. Zhaga – thermal interface

Verifi cation of thermal interchangeability according to Zhaga:

Determine the thermal resistance

of the luminaire

Choose an applicable module

Examples for luminaire Rth curves

19

Page 20

THERMAL CONSIDERATIONS

The thermal test engine (TTE) for the determination

of thermal resistance:

With the TTE according to Zhaga specifi cation, the introduction of the heat output into an existing luminaire can

be simulated. To do so, the following work steps need to

be taken:

1. Installation of the TTE with thermal interface material

(TIM) into the luminaire prototype to be measured

2. Introduction of different heat outputs P

TTE

(e.g. in 10-W steps)

3. Measurement of the reference temperature t

r, TTE

after temperature stabilization, by means of the

thermo couple attached in the TTE

4. Thermal resistance calculation

t

=

r, TTE-ta

P

TTE

dependent on P

th, lum

, as shown in

TTE

R

th, lum

5. Draw the graph of R

the diagram

Choosing the suitable module:

The datasheet shows heat output values of the module

) for all versions of the PrevaLED® Core Z2 as well as

(P

th, mod

the maximum permissible thermal resistances (R

th, mod, max

).

Two examples are shown in the diagram. The datasheet

values are specifi ed for t

ambient temperature ta’, the corresponding R

= 25 °C, in case of a differing

a

th, mod, max

can

be calculated according to the following formula:

Additionally, a simple thermal ECG dummy can be used

for the simulation of the thermal power loss in the application (simulation of additional heat input, e.g. in case of

suspended ceilings).

Thermal OTp tester

'- 25 °C

t

R

th, mod, max (ta')

= R

th, mod, max (25 °C)

a

P

th, mod

All modules of which the data points are located on or

above the curve are suitable for application in the luminaire.

In the example shown in the illustration above, LEP-1500835-Z2 is suitable for application in both luminaires,

whereas LEP-2000-835-Z2 is suitable for luminaire 2 only.

Although suitable modules can be easily and clearly

determined with this method, we nevertheless recommend

verifying the thermal design by means of measurements

with real modules, as outlined in chapter 4.3.

The TTE serves the thermal measurement of an existing

cooling method or housing.

By means of their maximum cooling performance [W] as

based on T

max. [°C], it is therefore easily possible even

c

in the future to equip once thermally measured luminaires

with standardized light engines.

TTE engineering drawing at: www.osram.com/prevaled-core

20

Page 21

MECHANICAL CONSIDERATIONS

5. Mechanical considerations

5.1. LED module dimensions

This schematic drawing contains further details on the

dimensions of available PrevaLED

For 3D fi les, LES and OCA categories, see the datasheet

at: www.osram.com/prevaled-core. These 3D fi les in differ-

ent formats may be used for the construction of luminaires.

®

Core Z2 LED modules.

5.2. Mechanical protection of the LED module

The pressure-sensitive LES (light-emitting surface) of the

LED module is protected against mechanical infl uence by

a protective foil. The LED module must not be switched

on if the protective foil is still in place because it could

be destroyed. Please do not apply pressure on the LES,

neither before nor after installation and removal of the

protective foil.

For operation in damp, wet or dusty environments, the

user has to make sure that an adequate ingress protection

and the protection of the LED module and the ECG is

warranted by means of a suitable IP classifi cation of the

luminaire housing (in due consideration of the luminaire

standard IEC 60598-1, irrespective of the different requirements in indoor and outdoor areas).

LES: Light-emitting surface

OCA (Optical contact area): Attachment and reference

surface for optics (e.g. refl ectors, lenses)

All fi gures in mm

kg

21

Page 22

MECHANICAL CONSIDERATIONS

5.3. ECG dimensions

Detailed mechanical drawings and 3D fi les are available

at our website.

OTp 15

(acc. to Zhaga: Driver category CS1)

All fi gures in mm

Depending on the thermal interface material and contact

surface conditions, the recommended screwing torque

can be between 0.4 and 0.6 Nm. A higher torque level

does not necessarily lead to signifi cantly better heat

transfer, but may lead to damage of the LED module.

The recommended counter sink diameter of the mounting

holes for good thermal performance should be 3.5 mm

max. A bigger counter sink can lead to mechanical deformation of the PCB and thus to a deterioration of the

thermal connection to the heat sink. When mounting the

module with self-cutting screws, an additional torque

may be required to prepare the thread.

Due to a large number of possible combinations when

choosing thermal interface material, heat sinks and screws,

any chosen combination should be carefully checked and

tested in order to maximize the heat transfer between the

LED module and the heat sink. Optimal mounting can lead

to a lower operating temperature of the LED module and

thus to an improved performance of the system.

All OTp 35 and OTp 45 types

(acc. to Zhaga: Driver category AM3)

OTp 60

• The housing material of these devices (OTp 15/35/45)

is PBT and complies with UL 94 V-0.

• For input wiring on the network side, the housing

provides push-in terminals.

• It is recommended to use screws with washers when

attaching the ECGs to the luminaire.

5.4. LED module attachment

PrevaLED

®

Core Z2 modules are attached to a heat sink

with two M3 screws through the mounting holes within

the LED module. The mounting holes are reinforced with

metal. Only in this way can a suffi cient thermal contact be

ensured throughout the lifetime of the module, because

synthetics will, due to the infl uence of pressure and temperature, give way after some time.

PrevaLED ® Core Z2

All fi gures in mm

(except where noted otherwise)

5.5. Zhaga – mechanical interface

In order to ensure the interchangeability of spot LED light

engines, Zhaga has defi ned maximum dimensions as well

as the screw positions for mounting the module. The

planarity of the luminaire side of the mounting surface, for

example, is not defi ned. For a fairly good heat transfer to

the heat sink, we recommend a planarity of < 0.1 mm and

a roughness of < 3.2 μm, as usually achieved by surfaces

with a milling fi nish.

22

Page 23

ASSEMBLY IN A REFERENCE LUMINAIRE

6. Assembly in a reference luminaire

To demonstrate the light engine concept and the design

of a luminaire, the following pages will lead you through

an exemplary assembly of a reference luminaire, using

the 2000-lm PrevaLED

The fi rst picture shows the different components

of the complete system:

• Housing (acts as a heat sink)

• Refl ector

• Cover

• Decorative ring

• Mounting ring

• Main connection wire

• Cable kit

• Thermal interface material

• Light engine

As a fi rst step, the thermal interface material has to be

applied within the light fi xture housing and/or the heat

sink.

®

light engine.

1

3

2

4

6.1. Preparation

After applying the thermal interface material, the LED

module has to be attached to the surface. For mounting

instructions and screw selection, please see the instruction in chapter 5.4. LED module attachment.

To ease the centering of the LED module, small plastic

sticks or pins can be inserted into the screw holes in the

heat sink to guide the LED module into the right place.

After centering, these guiding pins can be removed and

replaced by the screws.

5

7

6

8

23

Page 24

ASSEMBLY IN A REFERENCE LUMINAIRE

6.2. Wiring and refl ector/cover

The corresponding cable kit can be used to connect the

LED module to the power supply. To get the connector

easily into the housing, we recommend a through hole

with a minimum diameter of 10 mm.

Once the LED module is connected, the refl ector can

be attached to the housing and the diffuse cover can be

placed on top of the luminaire.

Both components have to be properly centered above the

LED module.

9

10

®

6.3. Commissioning the PrevaLED

light engine

After the fi xation of the mounting ring, the optional

decorative ring can be attached.

As an example for an electrical connection within a class II

installation, the two wires for the main connection have to

be connected to the OPTOTRONIC

®

power supply.

In a class I installation, the protective earth has to be

connected additionally.

Finally, the complete system can be connected to the

mains and powered up.

11

13

15

12

14

16

17

19

18

24

Page 25

NORMS AND STANDARDS

7. Norms and standards

7.1. Norms and standards for PrevaLED® LED modules and light engines

®

PrevaLED

Zhaga-specifi cation book 3: Spotlight systems with separate

electronic control gear

Core Z2 complies with the following standards:

According to the EC declarations (European directive: 2006/95/EC, European

directive: 2004/108/EC), PrevaLED

Safety of LED modules: IEC 62031

Photobiological safety: IEC/TR 62471-2 (typenabhängig)

Electromagnetic compatibility: DIN EN 55015

DIN EN 61547

DIN EN 61000-3-2

DIN EN 61000-3-3

Ingress protection: IP 20

Vibration, shocks, tensile strength: IEC 60068-2-6

IEC 60068-2-27

IEC 60068-2-21

7.2. Norms and standards for control gears

Safety: IEC 61347-1, IEC 61347-2-13

Performance: IEC 62384

Radio interference: EN 55015 (A1:2007, A2:2009)

Harmonic content: IEC 61000-3-3:2008

Immunity: IEC 61547:2009

®

Core Z2 complies with the following norms:

Temperature range: See corresponding value within the datasheet

Galvanic insulation between

primary and secondary side: 3 kV

No-load proof: Yes

Short circuit proof: Yes

Overload protection: Automatic shutoff, reversible

Overheating protection: Automatic shutoff, reversible

Connection, primary: For OTp 15 HD: screw-terminals

For OTp 35 HD and OTp 45 HD: push-in terminals

Cross section, primary: 0.5 mm

Connection, secondary: 5-pin connector, for use with cable kit

Cross section, secondary: Only for use with special cable kit

Dimensions (L x W x H): 123 x 79 x 33 mm for all OTp 35 and all OTp 45

109 x 50 x 35 mm for OTp 15 HD

Approvals:

For test and certifi cation measurements,

a mains voltage of 230 is recommended.

rms

2

–1.5 mm

2

0 i

]

25

Page 26

NORMS AND STANDARDS

7.3. Photobiological safety

Looking directly at high-performance light sources can

(just approximate classifi cation of safety classes like

looking directly at the sun) be a hazard to the retina of

the human eye. This is why the PrevaLED

have been tested regarding the risk group defi nition within

the framework of EN 62471:2008.

According to EN 62471-1, PrevaLED

have to be classifi ed in risk group 1. In absence of UV and

IR radiation, no labeling is required in RG 1 (TR 62471-2).

®

LED modules

®

Core LED modules

26

Page 27

de

www.osram.com/prevaled-core

www.osram.dewww.osram.

OSRAM GmbH

Head Office

Marcel-Breuer-Strasse 6

80807 Munich

Germany

Phone +49 (0)89-6213-0

Fax +49 (0)89-6213-20 20

www.osram.com

06/13 Subject to change without notice. Errors and omission excepted.

Loading...

Loading...