Page 1

www.osram.com/prevaled-core

Application guide.

PrevaLED® Core light engines.

OCTOBER

2011

Page 2

CONTENTS

Please note:

All information in this guide has been prepared with great care.

OSRAM, however, does not accept liability for possible errors,

changes and/or omissions.

Please check www.osram.com/prevaled-core or contact your sales

partner for an updated copy of this guide.

2

Page 3

CONTENTS

1. Introduction 4

1.1. System overview 4

1.2. System information 7

1.2.1. Nomenclature and marking 7

1.2.2. Technical data 8

1.2.3. System combinations 10

1.2.4. Accessories 12

2. Optical considerations 14

2.1. Refl ector 16

2.1.1. Refl ector design 17

2.1.2. Refl ector mounting HD version 18

2.1.3. Refl ector mounting ECO Z2 version 18

2.2. Light color stability 19

3. Electrical considerations 20

3.1. Safety requirements 20

3.2. Wiring information 20

3.3. Wiring in class I and class II luminaires 22

3.4. Optional cable clamp 22

3.5. ESD protection of light engines 23

3.6. Ingress protection 23

5. Mechanical considerations 34

5.1. Light engine dimensions 34

5.2. ECG dimensions 36

5.3. Light engine mounting 37

6. Fixation in a luminaire (example) 38

6.1. Preparation 39

6.2. Wiring and refl ector/cover 40

®

6.3. Commissioning PrevaLED

41

7. Norms and standards 42

7.1. Standards for PrevaLED

®

42

7.2. Power supply standards and

features applicable to PrevaLED® 43

7.3. Interchangeability of LED light engines 44

7.4. Photobiological safety 44

4. Thermal considerations 24

4.1. Thermal interface material and

other accessories 24

4.2. Heat sink size 25

4.3. T

measurement 30

c

4.4. Thermal simulation 32

4.5. ECG thermal considerations 33

3

Page 4

INTRODUCTION

1. Introduction

1.1. System overview

Brightness levels of today’s LEDs are opening the door for

usage of LEDs in general lighting applications requiring high

lumen output levels. Building an LED-based luminaire poses

a new set of technical challenges, among them new optical

requirements, providing adequate thermal management for

stable operation and lastly dealing with the ever-improving

performance of LEDs.

OSRAM’s PrevaLED

®

family of LED light engines addresses

the challenges of LED-based lighting while at the same time

providing great performance and fl exibility to the user.

The PrevaLED

®

Core series of light engines is ideally suited

for use in refl ector-based, rotational symmetrical applications

such as downlights or spotlights. These light engines provide

several convincing benefi ts in the application:

• PrevaLED

®

Core light engines are available as a system

of matching light engines and ECGs and deliver maximum

performance at very high levels of effi ciency.

• The light engines provide superior optical performance,

both in optical effi ciency as well as high quality of light

(color rendering).

• The wide range of lumen packages (currently available

from 800–3000 lm) allows addressing a wide range of

applications based on a single platform of light engines,

all delivering the same quality of light and performance.

It is, for example, possible to create a range of spotlights,

ranging from halogen-class up to HID levels, all with the

same optical characteristics, delivering a consistent expe-

rience for the end user.

• Thanks to high thermal and optical performance, luminaires

based on PrevaLED

®

Core light engines can be realized

with minimized size of required heat sink and refl ector,

giving a greater design fl exibility to the user.

• PrevaLED

®

Core light engines provide stable interfaces for

the user, in particular by defi ning stable lumen packages

over time. Independent of future increases in LED effi cacy,

the lumen output of a given type of light engine will remain

constant, but at lower power consumption. In this way, a

luminaire designed on the PrevaLED

®

Core platform will

automatically benefi t from effi cacy improvements without

needing a lengthy and costly redesign of the base con-

struction.

4

Page 5

INTRODUCTION

Movable 3D PrevaLED Core ECO Z2 (works with Adobe Acrobat 7 or higher)

PrevaLED® Core light engines are available in different perfor-

mance grades, namely lumen output and color rendering. At

present, the available systems are:

• Lumen packages of 800–3000 lm are available with a high-

quality color rendering (HD light engines – see nomencla-

ture – with CRI > 90/85). Due to internal construction with

a high-dynamic optical control of color point, these light

engines provide exceptional stability of color temperature

and module-to-module consistency.

• For basic applications, the lumen packages of 800–

3000 lm are also available in CRI 80. These light engines

employ a modifi ed housing construction leading to a better

effi cacy of the light engine.

The PrevaLED® system consists of an LED light

engine, dedicated OTp and connecting cable.

Besides providing superior quality of light, the HD-type light

engines also outperform typical modules based on single-

phosphor white LEDs. The effi cacy of the light engines not

only results in minimized energy consumption of the lumi-

naire, but also reduces the thermal load on the luminaire,

allowing for smaller and lighter designs of the heat sink.

All HD types are available in 3000 K and 4000 K CCT. The

CRI 80 (Z2) types are available in fl ux packages of 800 lm,

1500 lm, 2000 lm and 3000 lm in color temperatures of

2700 K, 3000 K, 3500 K and 4000 K.

PrevaLED

OPTOTRONIC

®

Core light engines must be operated with

®

power supplies of the “OTp” type. Available

types and valid system confi gurations are detailed in the next

section.

Additional details on optical, thermal, mechanical and electri-

cal characteristics can be found in the following sections.

Additional and updated information (as well as updates of

this guide) will be posted at

www.osram.com/prevaled-core.

OSRAM also provides an extensive range of energy-saving

light management components, such as sensors and room

controllers. By use of these products, additional energy

savings can be realized. For an overview of these products,

please visit

www.osram.com/lms.

5

Page 6

INTRODUCTION

PrevaLED® Core HD: Four lumen stacks

3000 K

4000 K

PrevaLED

800 m 1500 lm 2100 lm 3000 lm

800 lm 1500 lm 2100 lm 3000 lm

LEP-800-930-HD-C LEP-1500-930-HD-C LEP-2100-930-HD-C LEP-3000-930-HD-C

LEP-800-840-HD-C LEP-1500-840-HD-C LEP-2100-840-HD-C LEP-3000-840-HD-C

®

Core ECO Z2: Four lumen stacks

800 lm 1500 lm 2000 lm 3000 lm

2700 K

3000 K

3500 K

4000 K

6

800 lm 1500 lm 2000 lm 3000 lm

LEP-800-827-C-Z2 LEP-1500-827-C-Z2 LEP-2000-827-C-Z2 LEP-3000-827-C-Z2

LEP-800-830-C-Z2 LEP-1500-830-C-Z2 LEP-2000-830-C-Z2 LEP-3000-830-C-Z2

LEP-800-835-C-Z2 LEP-1500-835-C-Z2 LEP-2000-835-C-Z2 LEP-3000-835-C-Z2

LEP-800-840-C-Z2 LEP-1500-840-C-Z2 LEP-2000-840-C-Z2 LEP-3000-840-C-Z2

Further lm stacks of 4000 lm and 5000 lm will be available in 2012.

Page 7

1.2. System information

1.2.1. Nomenclature and marking

The PrevaLED® family follows a consistent naming conven-

tion for identifying key parameters of the light engine and

the power supply. The nomenclature of light engines and

OPTOTRONIC

®

ECGs is as follows:

INTRODUCTION

Light engine:

LEP-3000-930-HD-C-Z2

Power supply:

LEP = Light engine PrevaLED

®

3000 = 3000 lm

930 = CRI + CCT = CRI > 90 + 3000 K

HD = High Dynamic*

C = Core, round shape

Z2 = Product generation Z2 (if applicable)

OTp: OPTOTRONIC® PrevaLED

®

Control protocol: DALI (if applicable)

Wattage: 45 W

OTp DALI 45/220-240/700 HD FAN

* If HD is not noted, the light engine is an ECO type.

Input voltage range: 220–240 V

Maximum output current: 700 mA

HD = High Dynamic*

FAN = connector/auxiliary output

7

Page 8

INTRODUCTION

1.2.2. Technical data

All values regarding system effi ciency and system power

consumption include the complete system and are based on

T

maximum:

c

Light engine

(at T

max)

c

Power supply

+

(at Tc max)

All values regarding light engine effi ciency and light engine

power are based on T

Technical data product family PrevaLED

Light engine System/

maximum.

c

light engine

®

Core

Luminous

fl ux

System/

light engine

[lm]

Power

[W]

Effi cacy

[lm/W]

PrevaLED® Core HD

LEP-3000-930-HD-C

LEP-3000-840-HD-C

LEP-2100-930-HD-C

LEP-2100-840-HD-C

43/39 3,000 70/77 3,000 > 90 >130 < 3 50,000 60

43/39 3,000 70/77 4,000 > 85 >130 < 3 50,000 65

28/25 2,100 75/84 3,000 > 90 >130 < 3 50,000 65

28/25 2,100 75/84 4,000 > 85 >130 < 3 50,000 65

CCT

[K]

CRI Viewing

angle

[°]

Initial

SDCM

PrevaLED® Core HD

Lifetime

L70/B50

at T

max.

c

[h]

max

T

c

[°C]

LEP-1500-930-HD-C

LEP-1500-840-HD-C

16/19 1,500 75/84 3,000 > 90 >130 < 3 50,000 65

16/19 1,500 75/84 4,000 > 85 >130 < 3 50,000 65

LEP-800-930-HD-C 11/9 800 75/88 3,000 > 90 >130 < 3 50,000 65

LEP-800-840-HD-C 11/9 800 75/88 4,000 > 85 >130 < 3 50,000 65

8

Page 9

INTRODUCTION

PrevaLED® Core ECO Z2

Light engine System/

light engine

Power

[W]

PrevaLED

®

Core ECO Z2

Luminous

fl ux

[lm]

System/

light engine

Effi cacy

[lm/W]

CCT

[K]

CRI Viewing

angle

[°]

Initial

SDCM

Lifetime

L70/B50

at T

max.

c

[h]

max

T

c

[°C]

LEP-3000-827-C-Z2 36/31 3,000 84/97 2,700 80 >120 < 4 50,000 65

LEP-3000-830-C-Z2 33/29 3,000 90/104 3,000 80 >120 < 4 50,000 65

LEP-3000-835-C-Z2 32/29 3,000 93/107 3,500 80 >120 < 4 50,000 65

LEP-3000-840-C-Z2 32/28 3,000 94/108 4,000 80 >120 < 4 50,000 65

LEP-2000-827-C-Z2 32/28 2,000 62/72 2,700 80 >120 < 4 50,000 65

LEP-2000-830-C-Z2 29/25 2,000 68/79 3,000 80 >120 < 4 50,000 65

LEP-2000-835-C-Z2 29/25 2,000 70/81 3,500 80 >120 < 4 50,000 65

LEP-2000-840-C-Z2 28/24 2,000 71/82 4,000 80 >120 < 4 50,000 65

LEP-1500-827-C-Z2 22/19 1,500 67/80 2,700 80 >120 < 4 50,000 65

LEP-1500-830-C-Z2 21/17 1,500 73/87 3,000 80 >120 < 4 50,000 65

LEP-1500-835-C-Z2 20/17 1,500 74/89 3,500 80 >120 < 4 50,000 65

LEP-1500-840-C-Z2 20/17 1,500 75/90 4,000 80 >120 < 4 50,000 65

LEP-800-827-C-Z2 12/10 800 65/79 2,700 80 >120 < 4 50,000 65

LEP-800-830-C-Z2 12/10 800 65/79 3,000 80 >120 < 4 50,000 65

LEP-800-835-C-Z2 12/10 800 65/79 3,500 80 >120 < 4 50,000 65

LEP-800-840-C-Z2 12/10 800 69/84 4,000 80 >120 < 4 50,000 65

9

Page 10

INTRODUCTION

Technical data ECG

ECG Nominal

power

[W]

Con-

trol

Auxiliary

output

[V/W]

Ta

[°C]

Tc

max

[°C]

Lifetime

L70/B50

at T

max.

c

ECG (OTPOTRONIC®)

Dimensions

[mm]

[h]

Length

Width

Height

OTp DALI 45/220-240/700 HD FAN (*) 45 DALI 5/1 -20…50 80 50,000 123 79 33

OTp 45/220-240/700 HD FAN (*) 45 – 5/1 -20…50 75 50,000 123 79 33

OTp 45/220-240/700 HD (*) 45 – – -20…50 80 50,000 123 79 33

OTp DALI 35/220-240/700 HD (*) 35 DALI – -20…50 80 50,000 123 79 33

OTp 35/220-240/700 HD (*) 35 – – -20…50 75 50,000 123 79 33

OTp 35/220-240/700 (*) 35 – – -20…50 80 50,000 123 79 33

OTp 15/220-240/700 HD (*) 15 – – -20…50 75 50,000 109 50 35

Cable clamp kit for strain relief available, see 1.2.4. Accessories (page 13).

(*) Target values

1.2.3. System combinations

Within rated power, light engines and power supplies can be

fl exibly combined, e. g. according to desired control option

The connection between light engine and ECG should be

established by supplied cable kit. Available in lengths 40 cm

and 80 cm, please also refer to: 3.2. Wiring information.

or form factor. Valid and possible combinations of light en-

gines and ECGs are listed below, a general requirement is

that HD light engines require the use of “HD” ECGs and that

each light engine is connected by a single ECG.

All ECGs utilize well-established housing form factors to facili-

tate adoption of existing luminaire housings or accessories to

the PrevaLED

®

technology.

10

Page 11

Compatibility chart PrevaLED

®

light engine – ECG

INTRODUCTION

LEP-3000xxx-HD-C

LEP-2100xxx-HD-C

LEP-1500xxx-HD-C

LEP-800xxx-HD-C

LEP-30008xx-C-Z2

LEP-20008xx-C-Z2

LEP-15008xx-C-Z2

OTp DALI

45 HD Fan

OTp 45 HD

Fan

OTp 45 HD OTp DALI

35 HD

PrevaLED

®

Core HD

xxxx

PrevaLED® Core ECO Z2

xxxx

OTp 35 HD OTp 35 OTp 15 HD

xx

xx

x

x

x

LEP-8008xx-C-Z2

(*) Under development

Recommended

Suitable

x Not possible

ECG and light engines operate 1:1

11

Page 12

INTRODUCTION

1.2.4. Accessories

LEP-PreMix

The PreMix offers an optimized light homogeneity for re-

fl ector-based applications such as downlights and spotlights.

Benefi ts:

• Reduces color fringing and multiple shadows

• Snap mounting in light engine locking ring

• For use with 800–3000 lm light engines

• Additional protection of the light engine against touching

Technical features:

• Diffuse interior and structured outer surface for optimized

light homogeneity

• Durable glass construction

• Min. transmission 85 %

• Compatible with PrevaLED

®

Core HD:

LEP-800, LEP-1500, LEP-2000 and LEP-3000

• No impact on the lifetime of the light engine

Cable kit

The cable is required for contacting and connecting the

individual PrevaLED

®

Core light engine with the power supply.

Two various fl exible and reverse polarity protected cable kits

are available (cable kit for PrevaLED

PrevaLED

®

Core ECO Z2 version with a lower connector).

®

Core HD and the

PrevaLED ® Core HD cable kit

12

PrevaLED ® Core ECO Z2 cable kit

Page 13

Cable clamp for OTp

This cable clamp gives the ECG a strain relief and turns it into

an ECG suitable for independent installation. It is available for

order for all OPTOTRONIC

®

OTp 35 and OTp 45.

INTRODUCTION

13

Page 14

OPTICAL CONSIDERATIONS

2. Optical considerations

Comparison of LED array and chip-on-board (CoB) designs

PrevaLED® Core light engines can be designed in two different ways:

either as LED arrays or as chip-on-board (CoB) technology.

PrevaLED ® Core HD PrevaLED ® Core ECO Z2

When designed as LED arrays, PrevaLED® Core light engines

consist of several high-power LED packages covered with

phosphor and arranged in a certain pattern (cf. the images

above). The key advantage of this design is the large beam

angle: >130° FWHM.

The CoB design is characterized by various single low-power

LED chips, arranged in a certain grid which is covered with

phosphor (cf. the image above). The key advantage of this

design is that it provides a very homogeneous light distribution.

14

Page 15

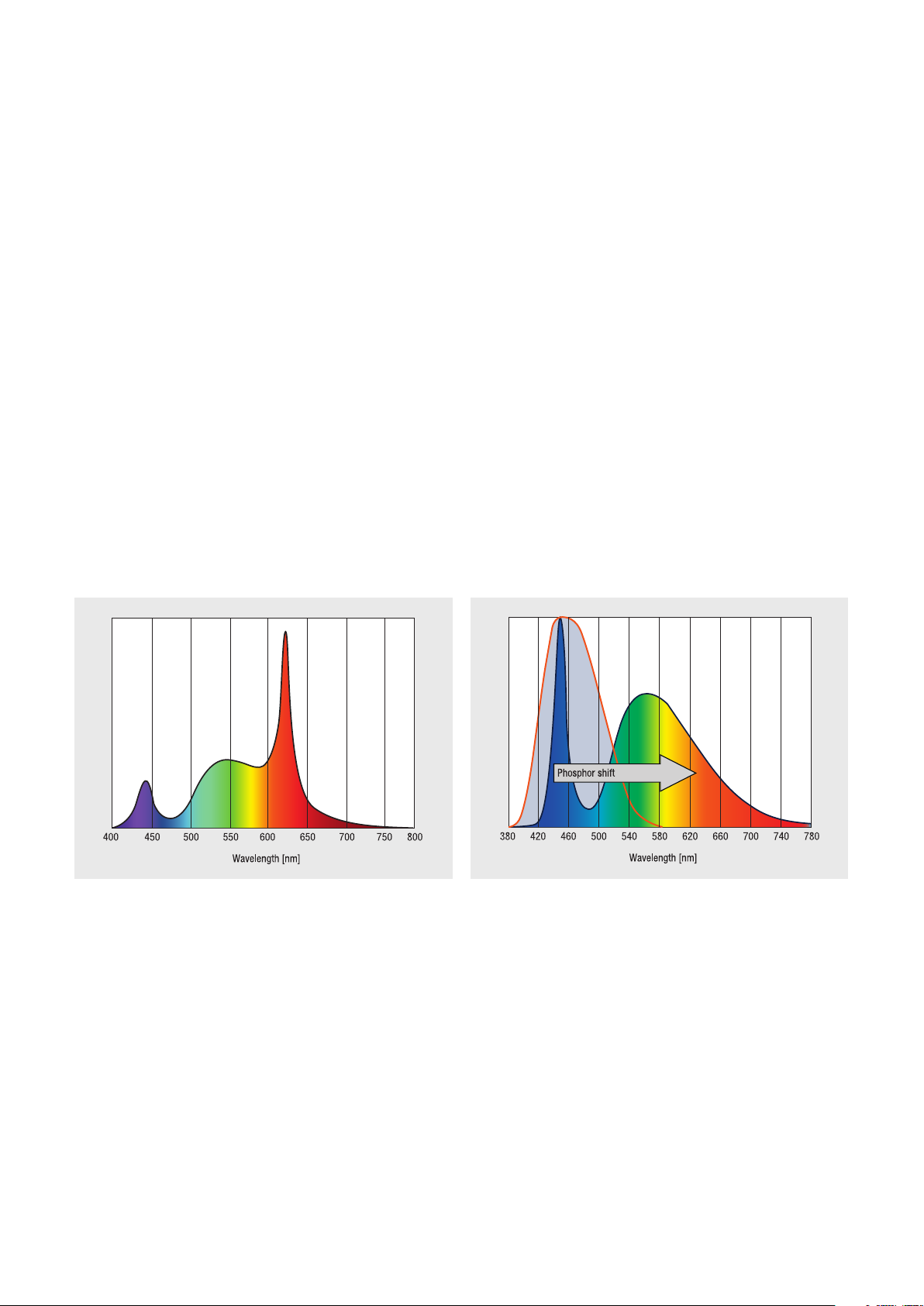

Good red color rendering (R9) and high LED effi ciency are

usually contrary targets because generating red light out of

a blue wavelength generates maximum losses.

OPTICAL CONSIDERATIONS

HD concept

With the HD concept, effi cient red light from direct red-

emitting LEDs is mixed with effi cient, greenish white. In this

way, PrevaLED

®

Core HD light engines provide very high CRI

(>90) with excellent R9 and the highest levels of effi ciency.

Pure phosphor conversion on CoB

Using the pure phosphor conversion with PrevaLED

®

Core

ECO Z2, color rendering quality higher than CRI 80 can be

achieved while providing a very homogeneous light output.

15

Page 16

OPTICAL CONSIDERATIONS

2.1. Refl ector

PrevaLED ® Core ECO Z2PrevaLED ® Core HD

PrevaLED® Core light engines are ideally suited for use with

refl ectors. The HD version of the light engines emit light at

>130° FWHM (full-width, half-maximum) exceeding the

FWHM of Lambertian emitters (120°) which allows shaping

and controlling the emitted light more effectively while at the

same time mini mizing the size of the required refl ector.

Futhermore, this wide emission also maximizes the luminous

intensity that is achieved from a given refl ector design, as

illustrated on the right.

The illustration below shows that an increasing FWHM signif-

icantly reduces the required height of the refl ector needed for

effi cient beam shaping. A reduced refl ector height can either

be used to decrease the overall luminaire height or to im-

prove the thermal performance of the luminaire by increasing

the available height for the heat sink.

An even light emitting surface due to CoB technology of

PrevaLED

®

Core ECO Z2 with great homogeneity eliminates

the need to use diffuser material. A smaller light emitting sur-

face (LES) and a refl ector positioning closer to LES enables a

better optical handling. A beam angle of 10° or even less is

possible with PrevaLED

Luminous intensity curves from a refl ector for different light source FWHMs

®

Core ECO Z2.

16

Page 17

2.1.1. Refl ector design

OSRAM provides mechanical (3D fi les) and optical simulation

data (ray fi les) to support customized refl ector designs.

These data are available upon request through your sales

partner and for public download at:

www.osram.com/prevaled-core.

OPTICAL CONSIDERATIONS

In addition, refl ector design support and off-the-shelf

components are, for example, available through the

following manufacturers:

ACL-Lichttechnik GmbH

+49 2173 9753 0

info@refl ektor.com

www.refl ektor.com

For PrevaLED

®

Core ECO Z2 refl ector 5020 KFAC (ACL,

Alux·Luxar GmbH & Co. KG

+49 2173 279 0

sales@alux-luxar.de

www.alux.de

71.5 mm diameter, 2x8.53° beam angle) and 113309010101

(Jordan, 108 mm diameter, 2x23° beam angle) can be sug-

gested.

Additional diffusing material may be used to optimize homo-

geneity within the application, the best effi ciency is achieved

by placing diffusing material on top of the refl ector. Diffusing

materials may be chosen according to the luminaire‘s design.

Jordan Refl ektoren GmbH & Co. KG

+49 202 60720

info@jordan-refl ektoren.de

www.jordan-refl ektoren.de

In reference designs, the use of Evonik material Plexiglas

®

0D010df with a thickness of 2 mm and with a transmission

of 89.6 % resulted in a good performance. Other materials

can of course also be used, such as Altuglas 145.10000,

for example.

Further support for any Plexiglas

Evonik Roehm GmbH

+49 6151 18 01

info-rohmax@evonik.com

www.evonik.com

www.plexiglas.de

®

material is available at www.ledlightforyou.com or, for example, through the following contacts:

Altuglas International

+33 1 78 66 23 00

www.altuglas.com

Sabic Innovative Plastics

+31 164 29 29 11

www.sabic-ip.com

17

Page 18

OPTICAL CONSIDERATIONS

PrevaLED ® Core HD PrevaLED ® Core ECO Z2

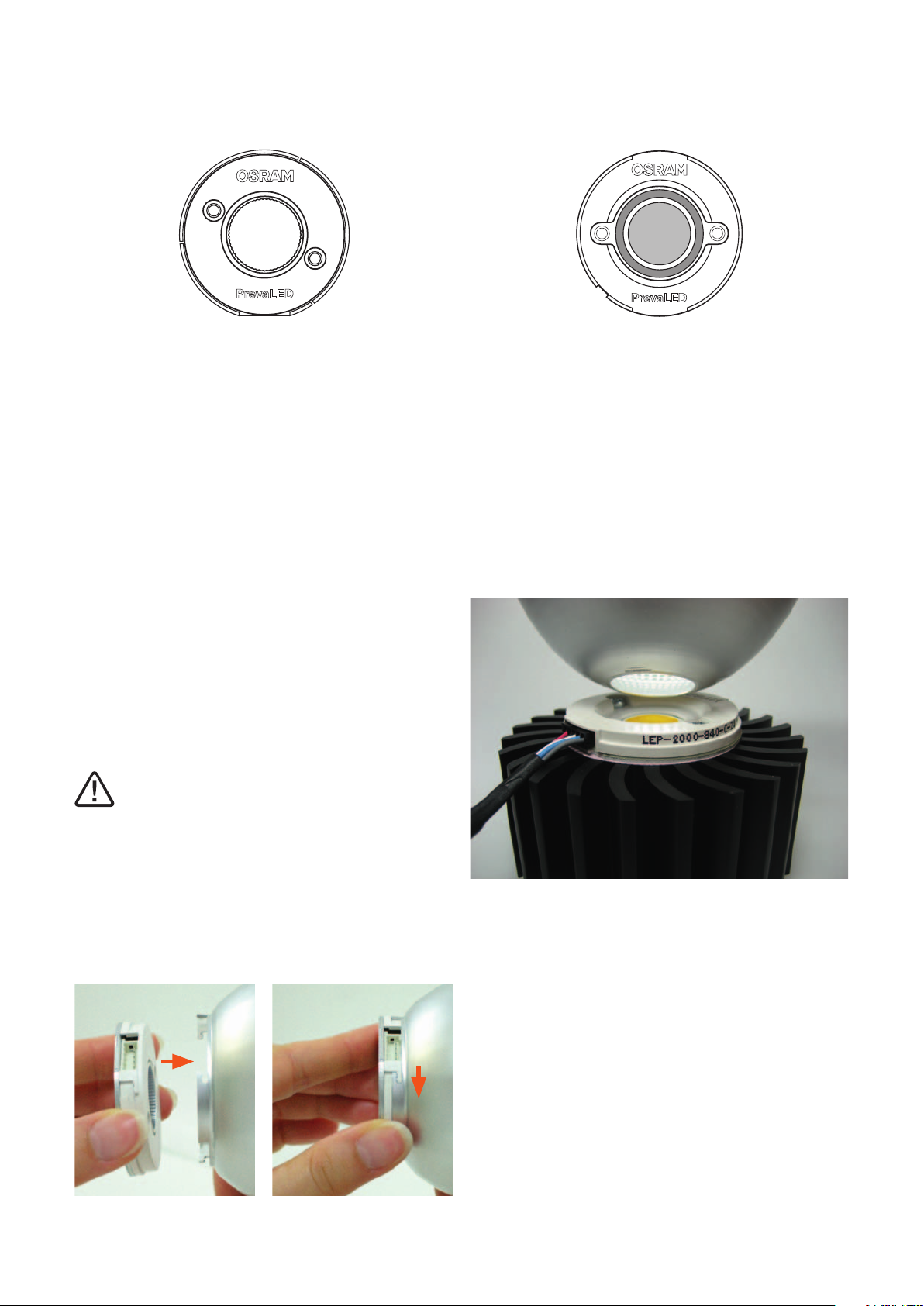

2.1.2. Refl ector mounting HD version

PrevaLED® Core light engines offer multiple mounting points

for a refl ector. For the HD-type light engines, a refl ector can

be centered on a groove along the outer edge of the light

engine as well as in a groove of approximately 23 mm diameter

in the center of the light engine. The 800 lm package provides

an additional groove of approximately 18.10 mm diameter in

the center of the light engine. The inner groove of the light

engines allows mounting the refl ectors as close as possible to

the LED array. Independent of location, all grooves provide a

bayonet-type locking mechanism so that a refl ector can be

fi xed to the light engines. The images below show an example

of a refl ector as it is locked in place, illustrating the location

of the mounting grooves.

By using the provided mounting grooves, the requirements

of IEC 60598 concerning the light engine level are met. For

further details, see the section: 3.1. Safety requirements.

Please note that excessive force on the housing of

the light engine when not mounted to a heat sink can

damage the light engine or housing. Only connect or discon-

nect a refl ector when the light engine is securely mounted to

a heat sink.

2.1.3. Refl ector mounting ECO Z2 version

Z2 ECO light engines employ a different geometry of the

housing. These light engines provide a well-defi ned optical

contact area (OCA) that can be used to center and guide a

refl ector with the light engine. Mounting and mechanical

support of the refl ector in this confi guration must be provided

by the luminaire body or through dedicated refl ector mount-

ing structures. 3D fi les of the light engines and design sup-

port are available upon request.

The locking mechanism is intended for fi xation of the refl ec-

tor only. Do not apply excessive forces or weight as this may

damage the mounting mechanism.

18

Page 19

2.2. Light color stability

The nominal CCT of the light engine is 2,700 K, 3,000 K,

3,500 or 4,000 K, depending on type of light engine. The

light engines provide a module-to-module variation less than

3 (HD) or 4 (ECO Z2) SDCM maximum on Planck around

these color targets, depending on type. The higher light color

stability for HD types is achieved by active electronic control.

OPTICAL CONSIDERATIONS

19

Page 20

ELECTRICAL CONSIDERATIONS

3. Electrical considerations

3.1. Safety requirements 3.2. Wiring information

All OPTOTRONIC® OTp devices intended for operating

PrevaLED® Core light engines are SELV-equivalent devices

with an output voltage of < 120 V

The design of the light engines ensures that the requirements

of IEC 60598 are met for the light engine itself. In particular,

the LEDs on the light engine need not be covered to fulfi ll the

requirements of IEC 60598.

Due to its construction, the light engine can be mounted

directly on an exposed heat sink without further galvanic

insulation.

It remains the responsibility of the luminaire manufacturer to

provide clearance and creepage distances for the luminaire

for an operating voltage of < 120 V

line voltage where applicable.

.

DC

for the light engines and

DC

The recommended wire cross section on the primary side of

the OPTOTRONIC

tion between the OPTOTRONIC

should be established by using the cable kit available for

order in 400 mm and 800 mm length.

The cable material is UL-listed (UL E52653, UL E48762,

UL 10368) and fulfi lls fl ammability requirements UL 94 V-0

and UL VW-1. The inner wires are approved for 105 °C, the

outer cable material for 125 °C.

The maximum diameter of the cable is 5 mm, additional

details on the dimensions of the cable kit are given in the

illustrations on the right page.

For support on customizing cable lengths or construction,

you can use the manual cramping tool from Hirose Electric

or contact your sales partner.

The cable for PrevaLED

connectors and shows a white ring at the light engine side

of the cable (to be confi rmed).

®

OTp ECGs is 0.5–1.5 mm2. The connec-

®

®

ECG and light engine

Core ECO Z2 has two different

20

Page 21

Components of the connection cable between LEP and OTp

*) The picture shows the crimped status of the contact.

**) The crimping socket is produced by Hirose Electric: www.hirose.com

ELECTRICAL CONSIDERATIONS

5-pole plug* (crimping socket**)

DF3-5S-2C

Terminal (straight pin header)

DF3A-5P-2DSA

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

PIN assignment of connector

LED+

LED-

Aux. voltage

Sense comm.

Aux. gnd.

21

Page 22

ELECTRICAL CONSIDERATIONS

3.3. Wiring in class I and class II luminaires 3.4. Optional cable clamp

Depending on the design of the luminaire according to

class I or class II requirements, a protective earth connection

can be established for the OPTOTRONIC

®

ECG.

For class II luminaires standards can be fulfi lled using a cable

clamp. The functional earth may be connected to the ECG to

improve the EMI behavior.

See illustrations below for these requirements.

As the power supplies are SELV-equivalent, no additional

galvanic insulation has to be provided for the light engine.

For OPTOTRONIC

®

OTp 35 and OTp 45 types, an optional

cable clamp is available for order. This cable clamp can be

snapped onto the ECG and thus converts it into an ECG

suitable for independent installation with strain relief.

When using this cable clamp, luminaire design according

to IEC 60598-1 class I and class II is possible. Connection of

protective earth as detailed above must be observed.

Please also note the installation requirements as supplied

with the cable clamp.

Mains

nc

GND

5 V

Light engine

Class I

connection

Earth connection is mandatory in class I luminaires and

improves EMI compliance according EN 55015.

22

Mains

Do not connect

nc

GND

5 V

Light engine

Class II

connection

In class II luminaires do not connect earthing terminal.

Page 23

3.5. ESD protection of light engines 3.6. Ingress protection

ELECTRICAL CONSIDERATIONS

PrevaLED® light engines require special ESD-safe handling

procedures in a production environment. Please refer to the

datasheet for specifi c recommendations.

PrevaLED® Core light engines and matching

OPTOTRONIC® OTp devices are intended for use

in dry locations.

For operation in damp/wet or dusty environments, the

luminaire manufacturer must ensure suitable installation

and protection of light engines and ECG.

You can use up to 15 OTp (35/45) on one 16-A circuit

breaker.

23

Page 24

THERMAL CONSIDERATIONS

4. Thermal considerations

Proper thermal design of an LED luminaire is critical for

achieving best performance and ensuring long lifetime of all

components. While PrevaLED

with minimal thermal losses possible, a substantial amount

of the light engine power as specifi ed (please refer to: 1.2.2.

Technical data) must be dissipated through the backside of

the light engine.

Depending on the application and the light engine chosen,

passive cooling can be achieved. In critical applications

(e. g. small available heat sink size in combination with high-

power light engines), active cooling may be needed. Active

cooling combines a heat sink with a fan or a similar device to

maximize the cooling power out of a given heat sink.

Active cooling systems:

Nuventix www.nuventix.com

Sunon www.sunoneurope.com

Cooler Master www.coolermaster.com

AVC www.avc-cooling.com

Heat sinks:

Fischer Elektronik www.fi scherelektronik.de

Pinbloc www.pinbloc.de

Aavid Thermalloy www.aavidthermalloy.com

Meccal www.meccal.com

Wakefi eld www.wakefi eld.com

R-Theta www.r-theta.com

Cool Innovations www.coolinnovations.com

Radian www.radianheatsinks.com

®

Core light engines operate

Thermal interface materials:

Laird www.lairdtech.com

Kunze Folien www.heatmanagement.com

Aavid Thermalloy www.aavidthermalloy.com

Chomerics www.chomerics.com

Bergquist www.bergquistcompany.com

Wakefi eld www.wakefi eld.com

Arctic Silver www.arcticsilver.com

Dow Corning www.dowcorning.com

Thermagon www.thermagon.com

Kester www.kester.com

Thermafl o www.thermafl o.com

MG Chemicals www.mgchemicals.com

Electrolube www.electrolube.com

Kerafol www.kerafol.de

4.1. Thermal interface material and other accessories

When mounting PrevaLED® Core within a luminaire it is highly

recommended to use thermal interface material between the

light engine’s backside and the luminaire housing. Either

paste or foil can be used. The material has to be as thin as

possible and should meet the desired conduction between

the light engine surface and the luminaire housing surface.

For this purpose, the planarity and roughness of the sur face

should be optimized. Pads made of Kerafol material with a

diameter of 50 mm and with appropriate mounting holes can

be ordered through the Alfatec company: www.alfatec.de.

The lists below show a selection of suppliers of different

cooling solutions and thermal accessories. The light engine

system has been tested, for example, with coolers from

Nuventix (SynJet

Light Cooling system: TA004-10003).

®

Spotlight Cooler 38W) and Sunon (Spot-

Heat pipes:

DAU www.dau-at.com

MB Electronic AG www.mb-electronic.de

Simulation software:

SolidWorks www.solidworks.com

Flotherm www.mentor.com

Comsol www.comsol.de

Thermal probes:

OMEGA www.omega.de

B+B Thermo-

Technik www.bubthermo.de

24

Additional partners for thermal support can also be found at

OSRAM’s LED Light For You network: www.ledlightforyou.com.

Page 25

4.2. Heat sink size

For the selection of a suitable heat sink, several consider-

ations regarding thermal resistance have to be made.

Below, you can fi nd the defi nition of the thermal resistance

concerning the direct conduction through solid material:

THERMAL CONSIDERATIONS

Material

Copper

Aluminium

Brass

Steel

Stainless steel

Glass

Wood

Air (dry at 1,013 mbar,

no convection)

[W/(m · K)]

380–401

200–220

120

42–58

15

1

0.13–0.18

0.0256 at 20 °C

Very good cooling

Bad/no cooling

R

thcond

=

L

A

·

cross

A

L

: Spec. heat conductance value [W/(m · K)]

L: Length through the material in fl ow direction [m]

A: Material cross section/surface of the heat sink [m

2

]

25

Page 26

THERMAL CONSIDERATIONS

For satisfying heat transfer and good cooling, the surface of

the used heat sink material also has to be taken into consid-

eration. Depending on the location of the particular applica-

tion, it could be an advantage to use black anodized heat

sinks to get the best heat transfer to the ambient air.

Within applications with high surrounding heat radiation, it

would on the other hand be an advantage to have a high

refl ective material to avoid collecting additional heat from the

environment.

Within common applications such as normal downlight appli-

cations within recessed ceilings, a black anodized heat sink

would be suffi cient. Below, you fi nd an overview of some

materials with different surfaces:

Material

Gold, polished

Aluminium plate,

rolled, blank

Aluminium,

black anodized

Aluminium, lacquered,

matt black

* Temperature of the material at which the emission ratio was measured

Emission

ratio ⑀

0.018 130

0.040 170

0.022 25

0.600 40

0.970 80

Temperature *

[°C]

Bad/no cooling

Very good cooling

For the optimization of the radiation, special lacquers with a

high emission ratio, which are typically used for radiators, are

available on the market.

26

Page 27

THERMAL CONSIDERATIONS

To give a short guideline for the selection of a suitable heat

sink, the following steps are generally necessary:

Defi ne boundary

conditions

Estimate heat sink thermal resistance

Total power dissipation of the light engine

Max. ambient temperature T

Max. reference temperature Tc according to lifetime requirements

R

thCA

on light engine level

Use the estimated R

Select heat sink

and examine the performance curve in the supplier catalog.

thermal resistance

Check the design with thermal measurements as soon as physical

prototypes are available.

=

T

- T

C

P

Light engine

amb

A

as a target for a possible heat sink profi le

thCA

27

Page 28

THERMAL CONSIDERATIONS

PrevaLED® Core on extruded-profi le heat sink in downlight orientation

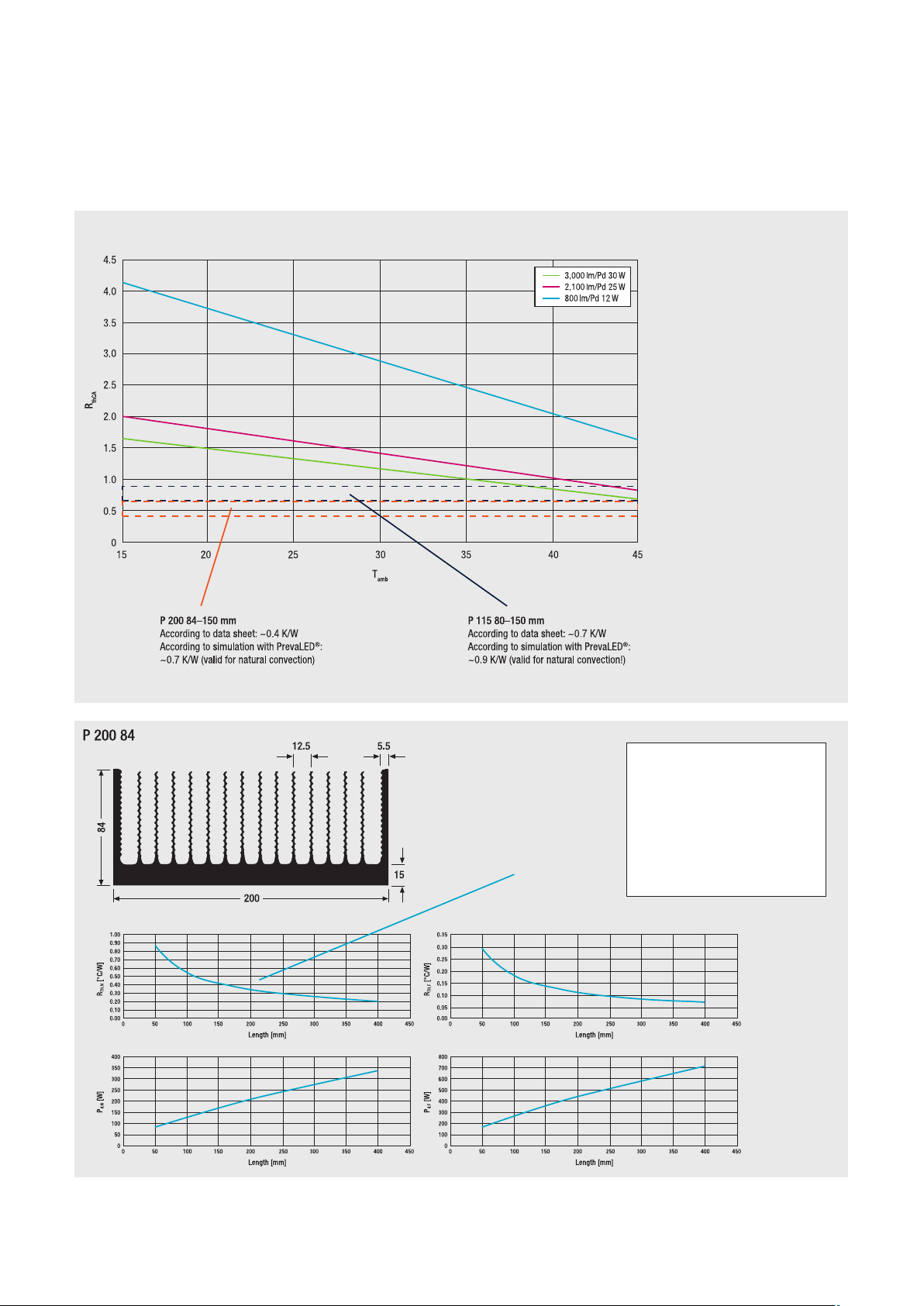

The diagram above can be used to estimate the cooling

performance of a given heat sink size or determine the

approximate size of heat sink required for given ambient

temperatures. Simulations were done without any airfl ow

turbulences, just within free convection.

As an example for heat sinks with 0.25 m² and 0.5 m², the

diagram indicates that a delta of approximately 22 °C or

14 °C respectively can be expected for the LEP-2100

light engines’ T

point as compared to the ambient tempera-

c

ture. The simulations on the next page highlight this result.

In reverse direction, given the maximum Tc temperature of

65 °C of the light engines and an ambient temperature of

45 °C, the resulting temperature difference of 20 degrees

can be used to fi nd the approximate needed heat sink size

for stable operation. For the given temperatures and an

LEP-2100 light engine, this is a heat sink with a surface of

approximately 0.3 m².

Note: The estimations on these two pages are for illustration only. In any case, the realized application has to be tested by a Tc measurement.

28

Page 29

THERMAL CONSIDERATIONS

This diagram shows the correlation between a given ambient temperature and

the resulting R

ferent light engines. The two Meccal extrusion profi les are also marked in the

diagram. From these data, one can estimate the heat sink R

ambient temperatures.

for Tc max. for the dif-

thCA

for different

thCA

P 200 84–150 mm

According to data sheet:

~0.4 K/W (natural convection)

Heat sink P 200 84

Length [mm] 200

Weight [kg/m] 17.70

R

[°C/W] 0.34

TH,N

P

[W] 205

d,N

R

[°C/W] 0.113

TH,F

P

[W] 440

d,F

Note: The estimations on these two pages are for illustration only. In any case, the realized application has to be tested by a Tc measurement.

29

Page 30

THERMAL CONSIDERATIONS

4.3. Tc measurement

After mounting the light engine in the luminaire, the Tc tem-

perature (case temperature) has to be measured within the

planned ambient and operation conditions.

Therefore, a thermal probe has to be fi xed at the T

either by gluing, soldering or welding. Examples of recom-

mended thermal couples are shown below.

With this Tc, you can determine your heat sink solution:

point,

c

(Tc-Ta)

R

heat sink =

th

Thermal power

(PrevaLED® light engine)

K-type thermocouple with miniature connector

Description Temperature [°C] Length

[mm]

Thermal probe -10…+100 2,000

cable

Adhesive foil probe -50…+250 1,000

wire

T90

20

12

All fi gures in mm

30

Page 31

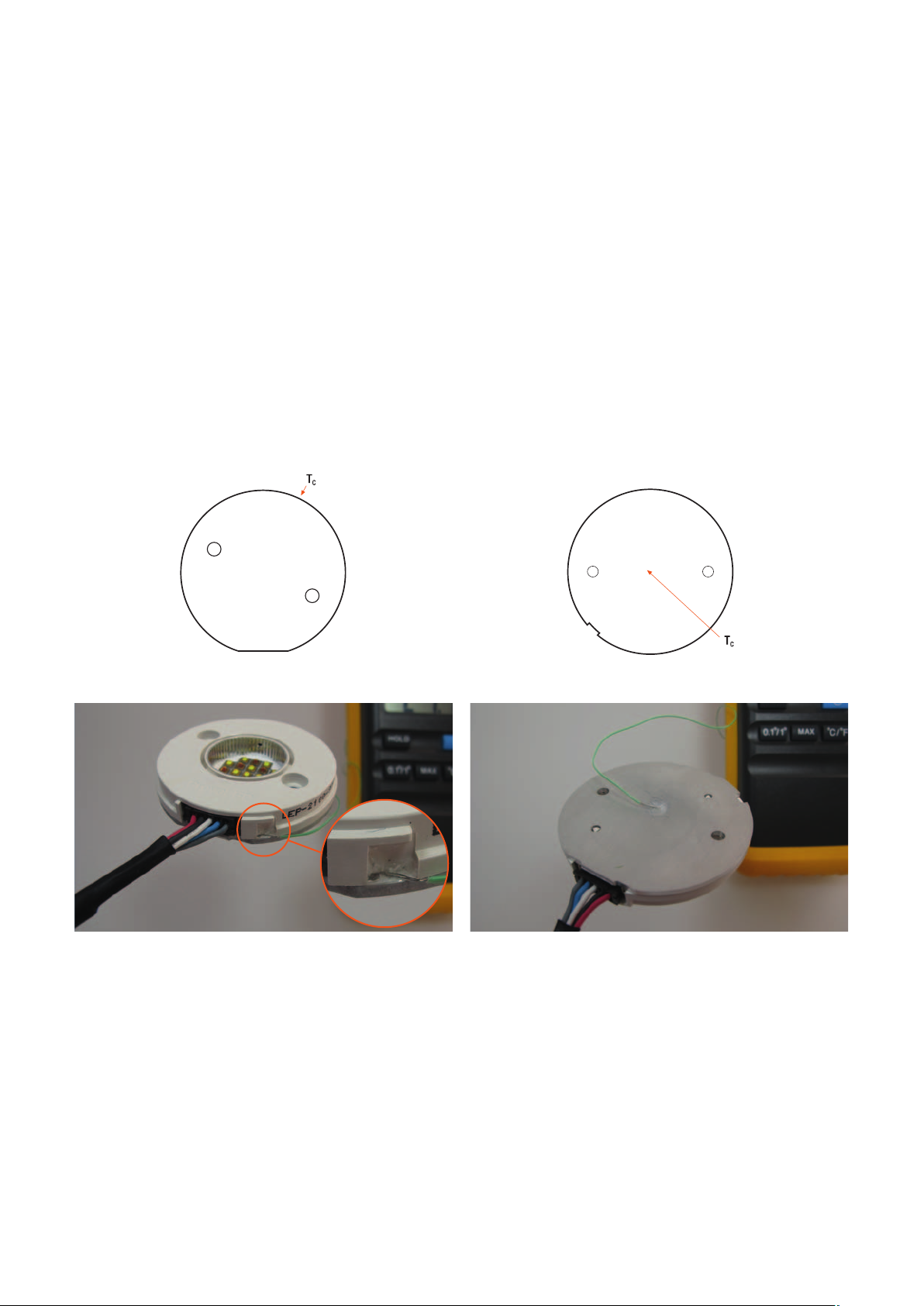

PrevaLED® Core HD PrevaLED® Core ECO Z2

THERMAL CONSIDERATIONS

Tc is measured on the side of the light engine Tc is measured in the center of the back side of the light engine

Please measure the case temperature (Tc) for PrevaLED® Core

HD on the side of the light engine. This can be achieved by

gluing the tip of the thermal couple right from above on the

PCB within the recess as shown on the picture.

Please measure the case temperature (T

Core ECO Z2 in the center of the back side of the light

engine. This can be achieved by a thin, milled channel or a

drilled hole.

) for PrevaLED®

c

Both methods of measurement on the specifi c light engines will assure a precise thermal interface within the thermal path from

the heat source to the ambient air.

31

Page 32

THERMAL CONSIDERATIONS

4.4. Thermal simulation

Two examples of heat sink simulations:

T heat sink:

46…49 °C

Attention: TJ is in any case higher than 60 °C

T ambient: 25 °C

Surface area ~ 0.25 m

TC: 47 °C

T heat sink:

38…41 °C

T ambient: 25 °C

Surface area ~ 0.5 m

2

(P 115 80 Meccal)

2

(P 200 84 Meccal)

Attention: T

®

PrevaLED

LEP-2100 on extruded-profi le heat sink – 150 mm in downlight orientation

32

is in any case higher than 60 °C

J

T

: 39 °C

C

Page 33

THERMAL CONSIDERATIONS

Thermal model description: PrevaLED® Core HD Thermal model description: PrevaLED® Core ECO Z2

Step-fi les for thermal simulation are available on

www.osram.com/prevaled-core.

4.5. ECG thermal considerations

The installation of the ECG must ensure that the maximum

temperature at the T

thermal considerations for OPTOTRONIC

found in the technical guide for OPTOTRONIC

at www.osram.com/optotronic.

is not exceeded. Further details on

c

®

devices can be

®

, available

33

Page 34

MECHANICAL CONSIDERATIONS

5. Mechanical considerations

5.1. Light engine dimensions

The illustrations below provide futher details on the dimensions

of the available PrevaLED® Core light engines. 3D fi les are

available on our website: www.osram.com/prevaled-core.

Please apply no pressure on LED/LES (light-emitting surface).

Handle with care!

kg

34

Page 35

PrevaLED® Core HD PrevaLED® Core ECO Z2

MECHANICAL CONSIDERATIONS

All fi gures in mm (except where noted otherwise)

Lumen

stacks

[lm]

Inner ∅

[mm]

3000

(2100 for Core HD)

2000

21 24

1500

800

16.3 19.15 cat. LES9 8.6 A 13.5

PrevaLED

®

Core HD ECO Z2

Locking

ring ∅

[mm]

Category

LES OCA

∅

[mm]

Category

cat. LES23 22 D 26

cat. LES19 15.75 B 19

Inner ∅

[mm]

Outer ∅

[mm]

28.5 4

Height

[mm]

35

Page 36

MECHANICAL CONSIDERATIONS

5.2. ECG dimensions

ECG dimensions are also given in

the section: 1.2.2. Technical data.

h

OTp DALI 25

l

1

l

OTp 15 OTp DALI 25 All OTp 35 and OTp 45 types

b

Detailed mechanical drawings and 3D fi les are available

on our website.

• Housing material of these devices is PBT and complies

with UL 94 V-0.

• For input wiring, the housing provides push-in terminals.

• It is recommended to use washers when mounting the

ECGs to the luminaire.

All fi gures in mm

36

Page 37

5.3. Light engine mounting

PrevaLED® Core light engines are mounted to a heat sink

with two M3 screws through the mounting holes within the

light engine. The mounting holes are reinforced with metal

bushing, providing additional strength for a reliable and ther-

mally high-performing connection.

MECHANICAL CONSIDERATIONS

Depending on the thermal interface material and contact

surface conditions, the necessary screwing torque can vary.

Good experiences were made with a range of 0.4 to 0.8 Nm,

higher torque levels do not necessarily lead to signifi cantly

better heat transfer to the heat sink, but may lead to damage

of the light engine.

The recommended counter sink diameter of the mounting

holes for good thermal performance is 3.5 mm maximum.

A bigger counter sink can lead to mechanical deformation of

the PCB and a reduction of heat transfer into the heat sink.

When mounting the light engine with self-cutting screws, an

additional torque may be needed to prepare the thread.

In reference designs, good mounting results were achieved

with EJOT ALTracs.

Due to a large number of possible combinations of thermal

interface material, heat sinks and screws above recommen-

dation should be carefully checked for each individual design

to maximize heat transfer between the light engine and the

heat sink. Optimal mounting can lead to a lower operating

temperature of the light engine and to an improved perfor-

mance of the system.

PrevaLED ® Core HD

∅ 35

®

PrevaLED

Core ECO Z2

∅ 3.3

45°

All fi gures in mm (except where noted otherwise)

37

Page 38

FIXATION IN A LUMINAIRE (EXAMPLE)

6. Fixation in a luminaire (example)

To get a better understanding of the light engine concept

and the design of a luminaire, the following pages will lead

through an exemplary mounting into a demonstrator using

the 800 lm light engine PrevaLED

On the fi rst picture, you can see the different components

of the complete system:

®

.

• Housing (acts as heat sink)

• Refl ector

• Cover

• Decorative ring

• Mounting ring

• Main connection wire

• Cable kit

• Thermal interface material

• Light engine

As a fi rst step, the thermal interface material has to be

applied within the light fi xture housing and/or heat sink.

1

2

3

38

4

Page 39

6.1. Preparation

After applying the thermal interface material, the light engine

has to be fi xed to the surface. For mounting instructions and

screw selection, please see the instruction in chapter:

5.3. Light engine mounting.

FIXATION IN A LUMINAIRE (EXAMPLE)

To ease the centering of the light engine, small plastic sticks

or pins can be inserted into the screw holes in the heat sink

to guide the light engine into the right place. After centering,

the guiding pins can be removed and substituted by the

screws.

5

6

7

8

39

Page 40

FIXATION IN A LUMINAIRE (EXAMPLE)

6.2. Wiring and refl ector/cover

To connect the light engine to the power supply, the suitable

cable kit should be used. To get the connector easily into the

housing, a through hole with a minimum diameter of 10 mm

is suggested.

Once the light engine is connected, the refl ector can be

attached to the housing and the diffuse cover can be placed

on top of the luminaire.

Both components have to be properly centered above the

light engine.

9

11

12

13

40

10 14

Page 41

FIXATION IN A LUMINAIRE (EXAMPLE)

6.3. Commissioning PrevaLED

After the fi xation of the mounting ring, the optional decora-

tive ring can be put into place.

As an example for an electrical connection within a class-II

installation, the two wires for the main connection have to be

applied to the OPTOTRONIC

In a class-I installation, the protective earth has to be

connected in addition.

Finally, the complete system can be connected to the mains

and powered up.

®

®

power supply.

17

18

15

16

19

41

Page 42

NORMS AND STANDARDS

7. Norms and standards

7.1. Standards for PrevaLED

PrevaLED® complies with the following standards:

LED modules safety: IEC 62031

DIN EN 62031

Connectors for LED modules: IEC 60838-2-2

Photobiological safety: EN 62471:2008 (CIE S009): Depending on type

Electromagnetic compatibility: DIN EN 55015

DIN EN 61547

DIN EN 61000-3-2

DIN EN 61000-3-3

Ingress protection: IP 20

Vibration, shocks, tensile strength: IEC 60068-2-6

IEC 60068-2-27

IEC 60068-2-21

®

42

Page 43

NORMS AND STANDARDS

7.2. Power supply standards and features applicable to PrevaLED

Safety:

Performance:

Radio interference:

Harmonic content:

Immunity:

Temperature range: See corresponding value within the datasheet

Galvanic insulation between

primary and secondary side:

No-load proof: Yes

Short circuit proof: Yes

Overload protection: Automatic shutoff, reversible

Overheating protection: Automatic shutoff, reversible

Connection, primary: For OTp 15 HD: screw-terminals

IEC 61347-1, IEC 61347-2-13

IEC 62384

EN 55015 (A1: 2007)

IEC 61000-3-2

IEC 61547

3 kV

rms

For OTp 35 HD and OTp 45 HD: push-in terminals

®

2

Cross section, primary: 0.5 mm

Connection, secondary: 5-pin connector, for use with cable kit

Cross section, secondary: For use with cable kit

Dimensions (L x W x H): 123 x 79 x 33 mm for all OTp 35 and all OTp 45

109 x 50 x 35 mm for OTp 15 HD

Approvals:

– 1.5 mm

0 i

2

]

43

Page 44

NORMS AND STANDARDS

7.3. Interchangeability of LED light engines 7.4. Photobiological safety

The Zhaga Consortium (consortium for the standardization of

LED light engines) aims to make the LED light sources (“LED

light engines”) manufactured by different companies inter-

changeable. Zhaga is a global cooperation with participation

by luminaire manufacturers, lamp manufacturers, LED mod-

ule makers, and companies that supply the lighting industry.

Interchangeability of LED light engines is achieved by speci-

fying the interfaces for a variety of application-specifi c light

engines. Zhaga interface specifi cations cover the physical di-

mensions, as well as the photometric, electrical and thermal

behavior of each LED light engine.

The Zhaga consortium was established in February 2010.

More than 100 companies have joined the Zhaga Consor-

tium. The members meet every 6–9 weeks in Asia, the USA,

or Europe. In June 2011, the Zhaga Consortium approved

the second light engine specifi cation. This is the specifi cation

for the interfaces of a spotlight engine.

PrevaLED

®

light engines were tested regarding the risk group

defi nition within EN 62471: 2008. According to this standard,

the following tables show the risk group defi nitions and test

results of the different light engines.

All PrevaLED

®

Core light engines (with and without PreMix)

have to be classifi ed according to EN 62471-1 in risk group 1

(RG 1). In RG 1, in absence of UV and IR radiation, no label-

ing is required (TR 62471-2).

44

Page 45

NORMS AND STANDARDS

LEP-3000 3,000 K

Spectral radiance and local BLH radiance see below.

Maximum permissible BLH dose (EN 62471) 1 MJ/(m

2

sr)

Maximum blue light effective radiance in

a fi eld of view corresponding to 1.7 mrad

BLH (1.7 mrad) 28,169 W/(m2sr)

Maximum exposure time 36 s

The maximum exposure time related to 1.7 mrad is larger than 10 s.

Therefore, the risk group classifi cation may be determined using a

fi eld of view related to 11 mrad.

Maximum blue light effective radiance in

a fi eld of view corresponding to 11 mrad

BLH (11 mrad) 8,502 W/(m2sr)

Maximum exposure time 118 s

Risk group classifi cation RG 1

LEP-2100 3,000 K

Spectral radiance and local BLH radiance see below.

Maximum permissible BLH dose (EN 62471) 1 MJ/(m

2

sr)

LEP-3000 4,000 K

Spectral radiance and local BLH radiance see below.

Maximum permissible BLH dose (EN 62471) 1 MJ/(m

2

sr)

Maximum blue light effective radiance in

a fi eld of view corresponding to 1.7 mrad

BLH (1.7 mrad) 49,583 W/(m

2

sr)

Maximum exposure time 20 s

The maximum exposure time related to 1.7 mrad is larger than 10 s.

Therefore, the risk group classifi cation may be determined using a

fi eld of view related to 11 mrad.

Maximum blue light effective radiance in

a fi eld of view corresponding to 11 mrad

BLH (11 mrad) 12,870 W/(m

2

sr)

Maximum exposure time 78 s

Risk group classifi cation RG 1

Maximum blue light effective radiance in

a fi eld of view corresponding to 1.7 mrad

BLH (1.7 mrad) 14,412 W/(m2sr)

Maximum exposure time 69 s

The maximum exposure time related to 1.7 mrad is larger than 10 s.

Therefore, the risk group classifi cation may be determined using a

fi eld of view related to 11 mrad.

Maximum blue light effective radiance in

a fi eld of view corresponding to 11 mrad

BLH (11 mrad) 3,855 W/(m2sr)

Maximum exposure time 259 s

Risk group classifi cation RG 1

45

Page 46

www.osram.com/prevaled-core

Global presence.

OSRAM supplies customers in 148 countries.

•

85 companies and sales offi ces for 122 countries

•

26 countries served by local agents or OSRAM GmbH, Munich

OSRAM associated companies and support centers:

Albania

Argentina

Australia

Austria

Belarus

Bosnia-Herzegovina

Brazil

Bulgaria

Canada

Chile

China

Colombia

Croatia

Czech Republic

Denmark

Ecuador

Egypt

Estonia

Finland

France

Georgia

Germany

Great Britain

Greece

Hungary

India

Indonesia

Iran

Italy

Japan

Kazakhstan

Kenya

Korea

Latvia

Lithuania

Macedonia

Malaysia

Mexico

Moldavia

Netherlands

Norway

Pakistan

Peru

Philippines

Poland

Portugal

Romania

Russia

Saudi Arabia

Serbia

Singapore

Slovakia

South Africa

Spain

Sweden

Switzerland

Taiwan

Thailand

Tunesia

Turkey

Ukraine

USA

Uzbekistan

United Arab Emirates

Vietnam

OSRAM AG

Head Offi ce

Hellabrunner Strasse 1

81543 Munich

Phone +49 (0) 89-6213-0

Fax +49 (0) 89-6213-20 20

www.osram.com

Loading...

Loading...