Page 1

Driving the Golden Dragon LED

e

Application Note

INTRODUCTION

The Golden Dragon LED is OSRAM Opto

Semiconductors’ high performance LED

requiring special considerations in thermal

management and electrical implementation.

This application note is intended to help the

design engineer with the special electrical

considerations of the Golden Dragon LED.

With a higher current there is higher power,

and therefore more heat to dissipate. The

Golden Dragon LED package is optimized

for removing this heat efficiently. With an

integrated heat slug (also known as a heat

spreader) the thermal performance is far

superior to standard LEDs.

Golden Dragon LEDs are delivered on tape

and reel. It has a flat top to allow pick-andplace machinery installation. All contacts

(including the heat slug) are soldered in

place using standard infrared reflow

processes (Surface-mount component

processing). Up to now the Golden Dragon

is the only high power LED in the market

which is capable to be processed according

to these cost effective standard assembly

techniques. ESD handling guidelines should

be followed when handling the Golden

Dragon LED.

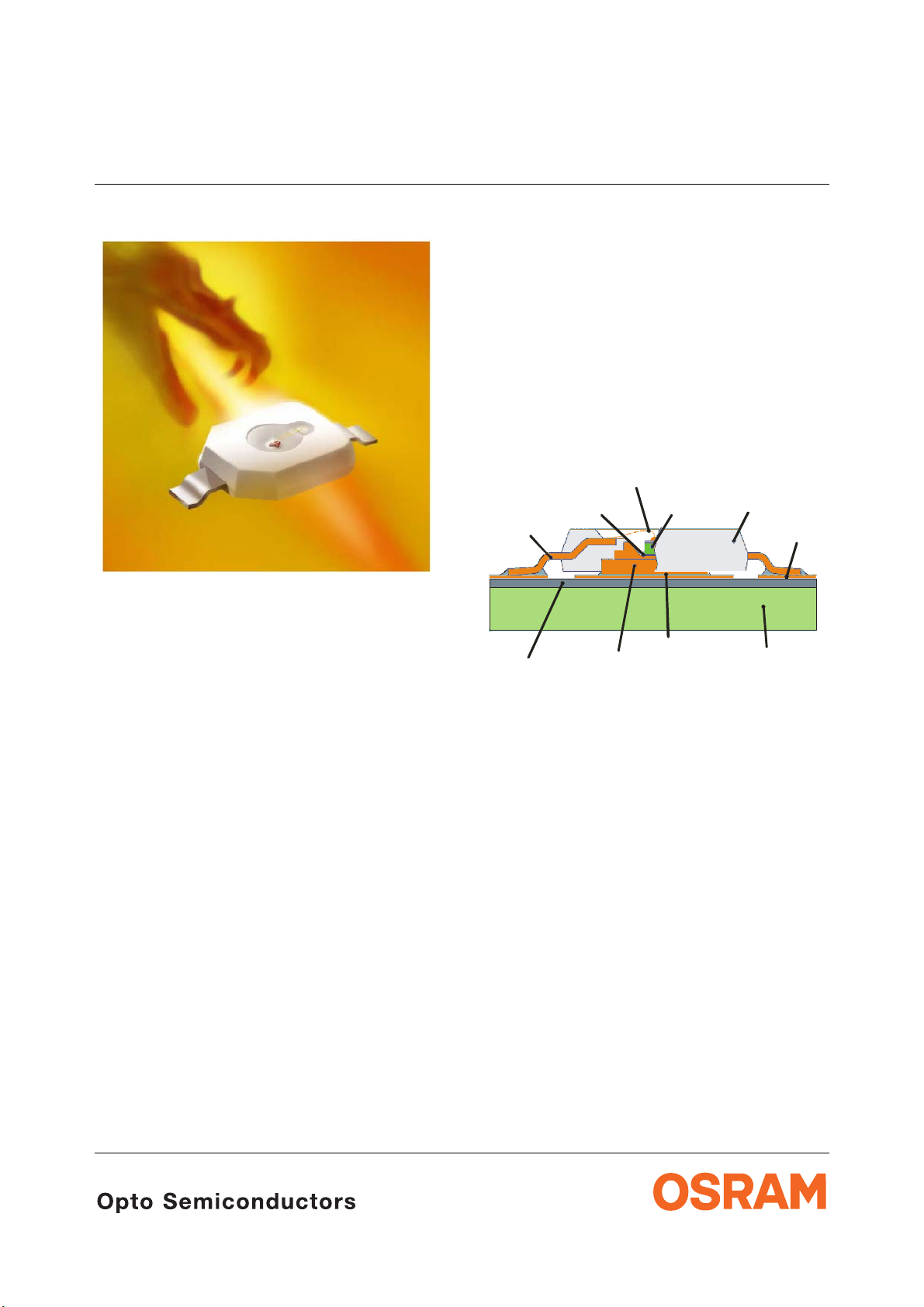

Basic structure

Figure 1 shows the internal structure of the

Golden Dragon LED.

Leads

Dielectric

Figure 1 Structure of the Golden Dragon

LED

There are large leads for a strong mechanical attachment to the printed circuit board

(PCB), and to assist proper orientation of the

part during reflow soldering.

The semiconductor die is directly attached to

the heat slug. This heat slug is cast inside

the molding compound, which forms a

reflector cup around the die. The heat slug is

exposed on the bottom of the part for IR

reflow soldering to the PCB to provide a very

low thermal resistance from the die to the

PCB it is mounted to. The die is covered

with an optically transparent encapsulation

material to protect the die from the ambient

environment.

Bond Wir

Die Attach

Heat Slug

Die

Solder

Molding Compound

Solder Pads

Aluminum Plate

February 2, 2005 page 1 of 14

Page 2

DESIGN CONSIDERATIONS

Thermal design

Because the Golden Dragon LED has a high

power rating, special consideration must be

made to optimize the thermal performance

of the entire system.

OSRAM Opto Semiconductors has released

an application note specifically addressing

thermal design for the Golden Dragon LED.

(The application note is titled “Thermal

Management of the Golden Dragon”). For

more details, please consult that application

note.

Optical design

The scope of this application note does not

include details of optical design. However it

is an important step in the lighting system

design and should not be ignored. Optical

design must target the highest efficiency to

reduce the LED light output requirements

and therefore the driver and heat-sink

requirements.

Electrical design

Semiconductor technology differences

There are two technologies used to produce

LEDs: InGaN and InGaAlP.

Different colors can be achieved with these

two technologies. InGaAlP is used to

produce colors from Green (570nm) to

Super Red (632nm). It has a forward voltage

around 1.8V to 2.3V, depending on the

color. InGaN is used to produce colors from

Blue (460nm) to True Green (528nm) and

phosphor based colors like White (typ.

3250K or typ. 5600K). It has a higher

forward voltage around 3.2V to 3.8V,

depending on the color. Be sure to check

the data sheet for the specific LED you are

using to get the correct information.

High current

The Golden Dragon LED is a high current

LED capable of operation at current levels in

the hundreds of milliamps. InGaAlP products

(Amber-Red and Yellow) can operate from

100mA up to 750mA. InGaN products (Blue,

Verde Green, True Green, and White) can

operate up to 500mA.

This high current develops a great deal of

power to dissipate in the LED. This power

can be up to two Watts in specific products.

OSRAM Opto Semiconductors will continually develop improvements to the Golden

Dragon LED. Please check the data sheets

for the latest performance data.

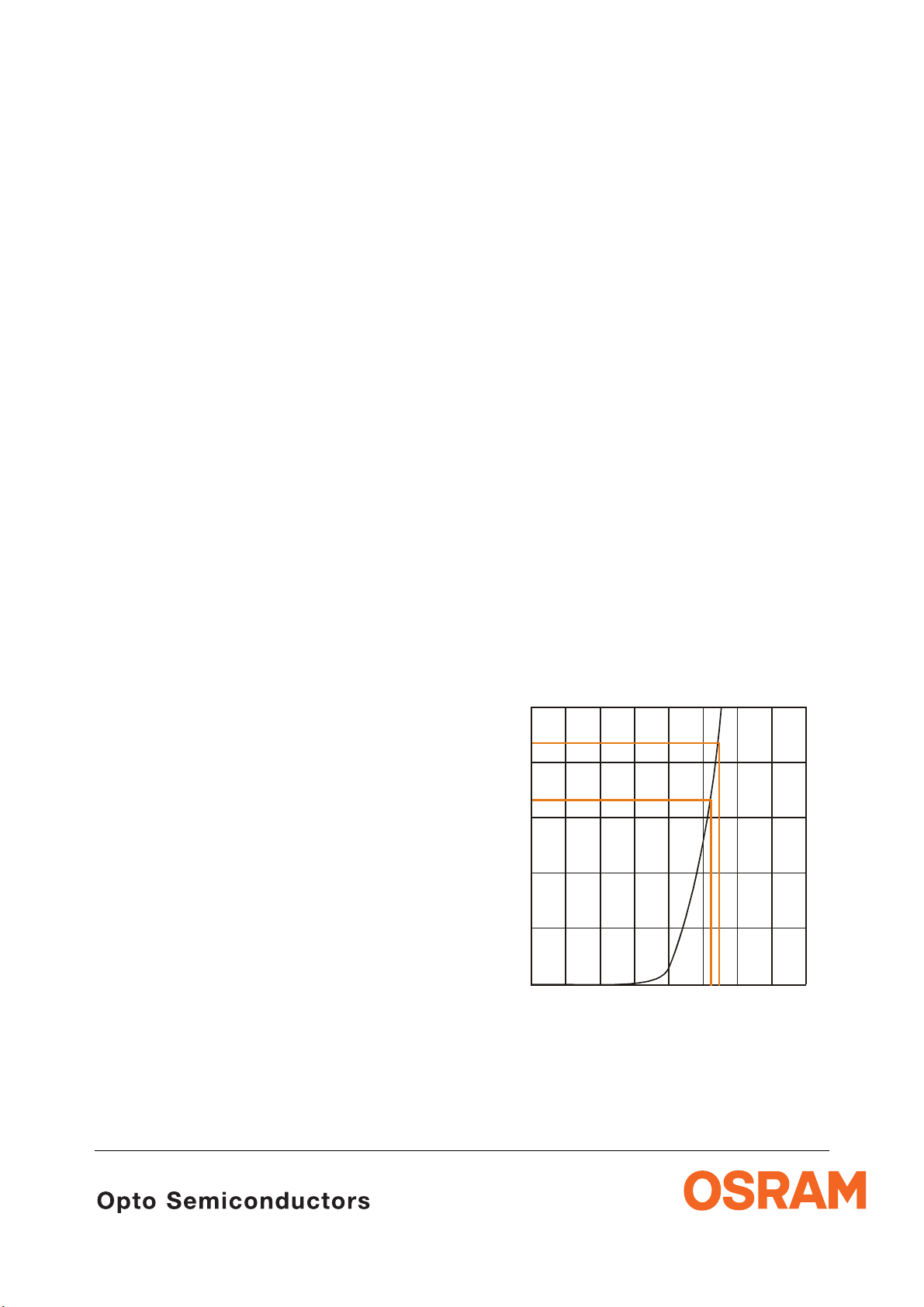

Steep If vs. Vf slope

The Forward Current vs. Forward Voltage

curve of the Golden Dragon LED is very

similar to any other LED. It has a steeper

slope of the I

area. This makes for rapid changes in

forward current with small changes in

forward voltage. The graph in Figure 2

shows this characteristic. Increasing the

current in the diode will not increase the

forward voltage by a significant amount.

0.5

0.4

0.3

0.2

Forward current (Amps)

0.1

0.0

0.0 0.4 0.8 1.2 1.6 2.0 2.4 2.8 3.2

Figure 2: Graph of Forward Voltage versus

Forward Current for a typical yellow Golden

Dragon LED.

vs. Vf curve in the high current

f

Forward Voltage (Volts)

February 2, 2005 page 2 of 14

Page 3

Note that a 0.1 Volt change in forward

voltage is marked, and the indicated forward

current changes approximately 100mA. This

is approximately a 40% change in current

with a 5% change in forward voltage.

The intensity of the Golden Dragon LED is

closely linked to the forward current. With a

40% change in current, the intensity will

change approximately 40%. To properly

control the LED intensity, current control or

current limiting is mandatory.

Temperature coefficient of forward

voltage

All LEDs exhibit a change in forward voltage

as the junction temperature changes. This

temperature coefficient of forward voltage is

published in each data sheet of individual

LEDs. InGaAlP LEDs (Yellow and Amber

Red) have a coefficient of between -3.0mV/K

to -5.2mV/K, and the InGaN LEDs (Blue,

Verde Green, and White) have a coefficient

of between –3.6mV/K and -5.2mV/K. Check

the data sheet for the specific part you are

using to find this coefficient for your designs.

Intensity changes over temperature

variations

All LEDs also exhibit a change in intensity as

the junction temperature changes. This is a

result of changing efficiencies in the

semiconductor, and not a result of the

change in the forward voltage over temperature changes. This temperature change is

non-linear, but is represented in graph form

in all data sheets. Check the data sheet for

the particular LED you are using for this

graph.

Example of critical data sheet

information

The published Forward Voltage of the thin

film amber-red Golden Dragon LED (LA

W5SF) is provided as a minimum (2.05V), a

typical (2.4V) and a maximum (2.65V). This

is the range that the LEDs can be delivered

from production. This voltage is tested at a

specific current. It is best to use any LED as

close to the test current as possible. It is

important to verify operation over this

voltage range to be sure operation is in the

safe range.

The published thermal coefficient of forward

voltage for the thin film amber-red Golden

Dragon LED is -5.2mV/K. The published

maximum junction temperature of the Thin

film amber-red Golden Dragon LED is

125°C. It is important to verify operation over

the specified operating temperature range to

assure that the maximum junction temperature is not exceeded.

The published maximum current of the thin

film amber-red Golden Dragon is 750mA.

All conditions (input supply variations,

temperature variations, and production

variations) must be evaluated to assure the

maximum current is not exceeded.

HOW TO DRIVE A HIGH CURRENT LED

LIKE THE

LED circuit arrangements

Due to the high slope of the Forward Current

vs. Forward Voltage graph (Figure 2) it is

strongly recommended to only connect the

Golden Dragon LED in a series arrangement

with some current control for each series

string in the system. As described in the

application note titled “Comparison of LED

Circuits”, a matrix circuit has uncertainties in

the LED current that result from a mismatch

of the LED forward voltages. The Golden

Dragon LED will have this behavior but more

so.

Series resistor current limiting

Standard LEDs, like the Power TOPLED®,

typically employ a series resistor to limit the

forward current. With 350mA through a

series resistor, and a 12V supply, the

resistor power dissipation can easily exceed

3 Watts when used with a single Golden

Dragon LED.

GOLDEN DRAGON LED

February 2, 2005 page 3 of 14

Page 4

Putting more LEDs in the string, and thus

A

−

=

reducing the resistor value, will reduce the

power dissipation in the series resistor. With

the small resistances resulting, the supply

voltage variations will cause larger current

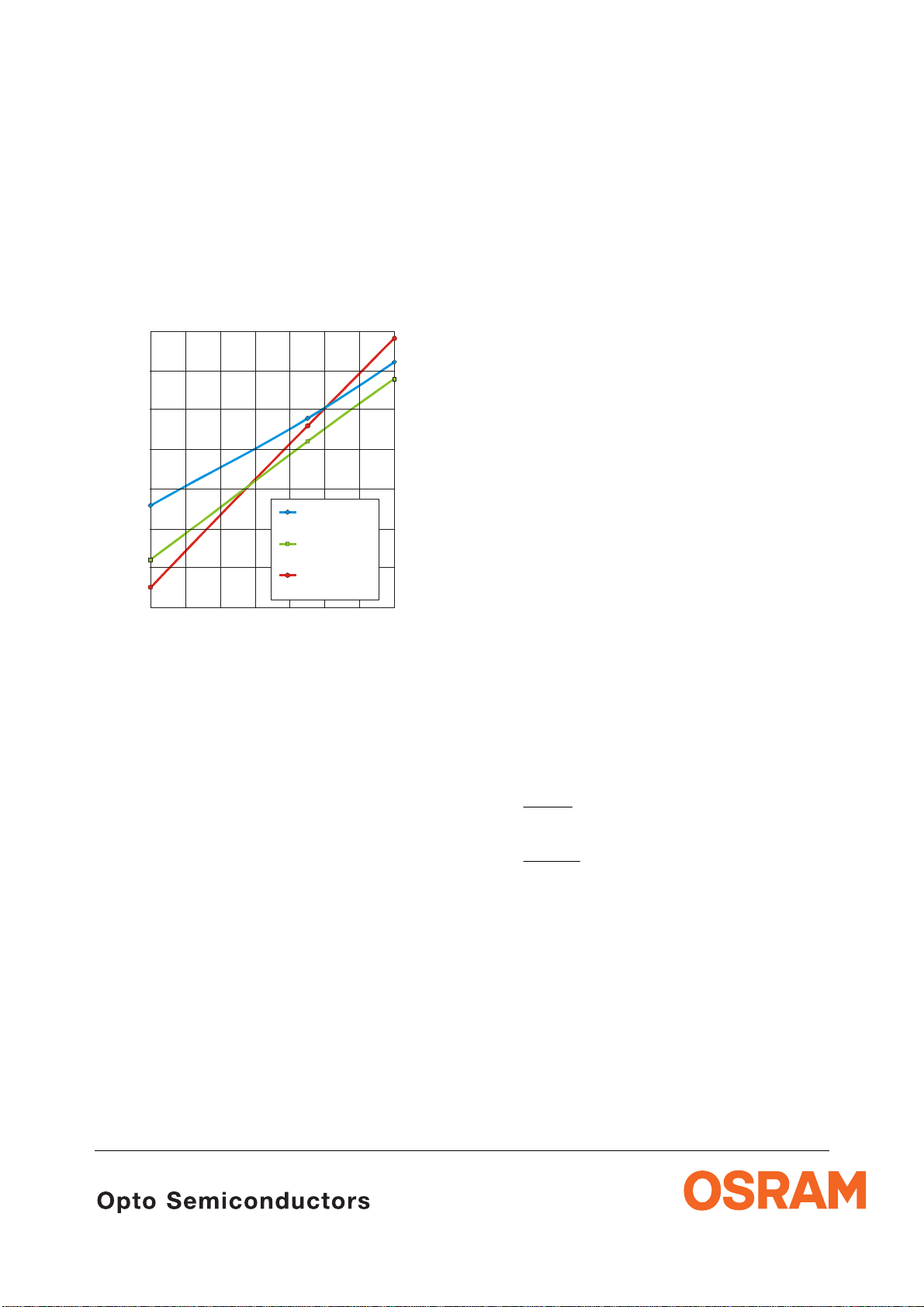

variations in the LEDs. Figure 3 shows the

different effect on the current with supply

voltage variations. (A typical automotive

lighting application will see a variation from

9V to 16V)

400

350

)

300

250

200

LED current (m

150

100

50

9

10

11 12

Supply voltage (V)

1 Dragon

3 Dragons

4 Dragons

13

(37.5

(27.0

(18.0

14

)Ω

)Ω

)Ω

15 16

Figure 3: Comparison of LED current

variations with supply voltage variations

The smaller resistor creates a larger current

variation in the LEDs from the minimum to

the maximum supply voltage. This variation

in current will create a variation in light

output of the LED. There is a possibility that

the maximum forward current (as published

in the data sheet) will be exceeded when the

supply is at its maximum. To minimize this

variation, maximize the resistance by

reducing the number of LEDs in each string.

With high power LEDs, the resistor is kept at

a minimum to minimize power dissipation.

These are mutually exclusive requirements;

therefore a balance must be achieved with a

compromise. High power resistors can be

expensive, and assembly of a high power

resistor can add significant cost. (i.e. hand

soldering, selective soldering, clinching, antivibration mounting.) These factors must also

be considered when determining the

balance.

Example series resistor calculations

There are many factors that affect current in

the LED during operation:

Supply variation

First, the supply voltage has some variation.

(Typically 5% to 10%, automotive experiences a variation from 9V to 16V with

nominal being in the 12.5V to 13.5V range.)

As we discussed previously, the supply

variation can add a significant current

variation in the LEDs.

For example, let’s start with a low cost 5%

regulator supplying 12V (V

reduce the large voltage swings typical in an

automotive lighting application. If we put

three LEDs in a string, each with 2.4V (V

typical for a thin film amber-red golden

dragon LED), the series resistor will have a

4.8V (V

) drop at 0.350A (I

resistor

results in a 13.7Ohm resistor dissipating

1.68W (P

resistor

).

VnVV

*

diodesupplyresistor

resistor

R

R

resistor

V

resistor

=

I

diode

V

8.4

A

350.0

IVP

=

*

=−=

7.13

Ω==

dioderesistorresistor

==

At the limits of the regulator tolerance, the

supply voltage increases only 0.6V (V

12.6V maximum). The voltage dropped

across the resistor increases to 5.4V, and

the current increases by 0.044A. The LED

now passes 394mA.

). This would

supply

diode

VVVV

8.44.2*312

WattsAVP

68.1350.0*8.4

). This

supply

=

f

February 2, 2005 page 4 of 14

Page 5

VnVV

*

resistor

diode

−=

VI

=

resistordiode

diodesupplyresistor

VVVV

4.54.2*36.12

=−=

Resistance/

AVI

394.07.13/4.5

=Ω=

Temperature Variation

The second factor affecting LED current is

the temperature coefficient of the forward

voltage of the LED. The data sheet for every

LED gives a coefficient for the forward

voltage with respect to the junction

temperature. At higher temperatures, the

forward voltage of the LED will decrease.

For the InGaAlP thin film amber-red LED,

the coefficient is –5.2mV/K.

KT

60

=∆

VKKV

3.060/0052.0

−=×−

VLEDsV

9.033.0

−=×−

With a temperature rise of 60K above room

temperature, the forward voltage of each

LED drops 0.3V. With three LEDs in a string,

(in an attempt to reduce power dissipation in

the series resistor) the forward voltage

across the string will drop 0.9V as a result of

the temperature change.

The effects of supply variation and temperature variation add. with a 5% tolerance on a

12V supply, and a 60K temperature

increase, there is a possible total variation of

1.5V across the series resistor. This

increases the current in the LEDs by a total

of 0.11A. The LED now is passing 0.46A.

Production variation

The third factor affecting LED current is

production variation of its forward voltage.

The data sheet of the Thin film amber-red

Golden Dragon LED gives a room

temperature forward voltage variation of

0.6V. With a design targeting the nominal

value, this can be seen as a ±0.3V

tolerance. This voltage change adds with the

first two effects creating a possible total

variation of 1.84V across the series resistor

in this application.

0.3V----Production

0.9V----Temperature

0.6V----Supply

0.3 + 0.9V + 0.6V = 1.8V

So, the voltage across the resistor can

increase by 1.8V. The current in the LED is

now 0.48A. This is not yet at the maximum

current published for the thin film amber-red

Golden Dragon LED, but heat dissipation at

this current level may cause the maximum

junction temperature to be exceeded. This is

still significantly above the design intent of

the LED. The design must account for this

much variation to prevent LED damage. The

power dissipated in the LED and resistor will

increase substantially, and must be taken

into consideration. The current could also

decrease when these tolerances move in the

opposite direction. If all the tolerances were

in the opposite direction, the LED current

would drop to 0.2A. This could create

problems from intensity variation and the

specification may not be satisfied.

Special consideration must be given to these

factors to be sure the LED’s maximum

current rating and the maximum junction

temperature are not exceeded at any time in

the application when using a series resistor.

This means the LED must be used at a

nominal level far below its capacity. Using

the Golden Dragon LED at a reduced

capacity with a series resistor will require

more LEDs. This can significantly increase

system costs. In most applications, the cost

saved by using only the needed Golden

Dragon LEDs and eliminating the special

assembly costs of a high power resistor, will

easily cover the cost of a current control

supply.

February 2, 2005 page 5 of 14

Page 6

CURRENT CONTROL

The current control supply can often be

assembled on the same board as the LEDs

to save on assembly costs. When doing this,

ensure the current control supply does not

excessively heat the LEDs.

In this example, the voltage regulator used

could have been configured as a current

source with no added cost to the system. If

the regulator had been eliminated from the

example, then the wide variations typical for

an automotive application (9V to 16V) would

have overstressed the LED more than what

we saw in the example.

Designing in a current control supply has

several benefits:

• Reduced LED count and thus lower

costs

• The current control supply can be all

SMT components, and a high power

resistor can be eliminated. This

significantly reduces assembly

complexity. Again this will give a cost

savings.

• Reduced power dissipation at the

higher temperature, higher supply

voltage and lower LED forward

voltage conditions (as compared to a

resistor drive).

• Constant intensity output will give a

better, more uniform appearance,

and can better satisfy a tight

tolerance specification.

Current control methods

There are two technologies to consider

when designing a current control driver for

the Golden Dragon LED. The first is a linear

current control driver, and the second is a

switch mode current control driver. This

application note will consider the basics of

using both, but will not detail designs.

Please seek information from the individual

IC manufacturers for designing with their

parts.

Linear current supply

Very similar to a voltage regulator, the linear

current supply uses a linear pass element

with a feedback mechanism that regulates

the current in a path rather than the voltage

at a node (see Figure 4).

Vsupply

Bias Control

Feedback

Figure 4: Principle of a linear current control

Many adjustable voltage regulators can be

configured to operate as a current regulator.

(The IC manufacturer will have suggestions

on maintaining regulator stability in these

configurations) There are specialty parts

designed as a current source or sink for

other applications that can be enlisted to

drive an LED. (battery chargers, solenoid

drivers, etc.)

The linear current supply can only be used

when the input voltage is always higher than

the output voltage. Headroom must also be

added to account for drop voltages in the

driver circuits. Otherwise there is not enough

voltage available to operate the LEDs.

The advantages of a linear current supply

are its simplicity of design, and low

component cost. A linear current supply has

a disadvantage in that in regulating current,

a large amount of power must be dissipated

by the supply. This can occur when there is

a large voltage drop across the supply. (This

dissipation will always be lower than a

resistor drive where the current will increase

as the voltage increases.) This often

requires a heat sink. Since the Golden

Dragon LED requires a heat sink in most

applications, the two can be combined into a

single heat sink.

February 2, 2005 page 6 of 14

Page 7

Linear current control supply design

example

Let’s consider an application example

requiring three Golden Dragon LEDs in a

string. (Three LEDs are needed based on

minimum light requirements) We will use an

input supply voltage of 15V (V

With 3 LEDs (n) each having a 2.2V forward

voltage (V

), the current control supply (or

f

driver) is left to drop the remaining voltage

(V

).

driver

VnVV

*

driver

driver

−=

=

*

diodesupplydriver

VVVV

4.82.2*315

=−=

IVP

diodedriverdriver

94.2350.0*4.8

==

The driver needs to drop 8.4V, so the power

dissipated is 2.94W, which can be very

difficult to dissipate depending on the

maximum ambient temperature.

To reduce this dissipation, add an LED to

the string so the power is used by the

additional LED to generate light, not being

wasted in the supply. The power will still

need to be dissipated by the additional LED,

but more light is generated for use.

This additional light reduces the required

current. This means the Dragons only need

to run at about 280mA, and there is still a

surplus of light. By adding one LED to the

string, the supply now has to drop 6.2V. In

addition, with the LEDs operating at 280mA,

the power to dissipate in the current control

supply is 1.74W. This is manageable with

only PCB copper area around the driver IC,

or a small heat sink depending on the

maximum ambient temperature of the

system.

From this example we can see that adding a

single LED to the string can make the whole

system more thermally manageable. This

improves the overall system thermal management by reducing power loss in the

driver and increasing margin of the design.

This will improve the reliability of the entire

lighting system. In every case, the designer

WattsAVP

Supply

).

must evaluate all three parts of the design:

thermal system performance, electrical

system performance, and system assembly

efficiency, to properly optimize the system.

Examples of Linear current control

supply circuits:

Figure 5: TLE4242G, an example of a linear

current control

Figure 5 is an example of a linear current

control, the TLE 4242G from Infineon

Technologies. This circuit offers simplicity,

and is suitable for use in automotive

applications. There is a PWM input to control

LED brightness, or with a constant low, the

part will shut down and consume less than

1µA. There is also a status feedback for

diagnostics. The part includes overtemperature and short circuit protection.

Figure 6: LM2941, an example of a linear

current control

February 2, 2005 page 7 of 14

Page 8

Figure 6 is an example of a linear current

control, the LM2941 from National

Semiconductor. It offers simplicity in design

and application.

Ω

0.5

10K

LF442

-

+

National LM20

Vout

Vin

GND

NC

91K

169K

2.87K

6.98K

499K

LF442

-

+

10K

Figure 7 LM2941, an example of a linear current control

Figure 7 is another example of a linear

current supply using the LM2941 from

National Semiconductor. It offers a

temperature compensation of the current

level. The current is reduced at higher

temperatures to allow use of a smaller heat

sink while not violating the maximum

junction temperature of the LED at higher

operating temperatures. Both circuits are

suitable for automotive applications and offer

over-temperature protection.

Switching current supply

The switching power supply is well known in

the mobile appliance marketplace. Typically

used to conserve battery power, the

switching power supply is desired for its

efficiency, which is its primary advantage.

This efficiency allows a switching power

supply to control the voltage for a large

current with little power dissipation. This also

applies to controlling the current in a load

with very little power dissipation. A switching

current control supply has a secondary

advantage that it often does not need a heat

when large numbers of LEDs are used in a

single application.

A switching current control supply is a

frequency-based device. This adds to the

complexity of the design. It must be carefully

designed to be frequency stable, and not

radiate electromagnetic noise in undesirable

spectrums. The latter is known as designing

for electromagnetic compatibility (EMC).

Individual manufacturers of switching power

supply integrated circuits can provide

assistance in both of these requirements.

Compared to a linear current control supply,

the switching current control supply can

have a higher cost and more components.

This cost disadvantage can often be offset

by not needing a heat sink and redundant

linear current control drivers, but this must

always be evaluated for each application.

sink to keep cool. This becomes valuable

National L 2941M

Adjust

On/Off

GND

10K

INPU T

10 Fµ

OUTPUT

100 Fµ

9V to 16 V

On/Off

February 2, 2005 page 8 of 14

Page 9

Different topologies of switching power

supply current control

There are three primary topologies of

switching power supplies:

The buck regulator

The boost regulator

The buck-boost regulator

Determining which topology to use in the

design is based on the input and output

voltage levels:

The buck regulator can only function when

the supply voltage is always higher than the

load supply plus some voltage drop from the

buck circuitry.

The boost regulator can only function when

the supply voltage is always lower than the

output voltage minus some voltage drops

from the boost circuitry.

The buck-boost regulator can function when

the supply voltage can vary above or below

the load voltage, or when the load voltage

can vary above and below the supply

voltage. The former can occur when multiple

sources are used, or a source varies widely.

The later can occur with a current control

supply.

The buck topology is used most often when

the power dissipated in a linear current

control supply would be excessive.

The boost topology should be used when

there are too many LEDs to drive using a

linear current control supply. As the number

of LEDs increases, and the cost (and heat)

of the linear current control supplies also

increases, a cross-over point is quickly

found where the switching current control

supply is significantly cheaper than the linear

current control supplies. The LEDs are

arranged all in one string, which makes the

output voltage higher than the input supply

voltage. Putting more LEDs in a string

reduces the number of strings in the system,

and therefore reduces the total number of

current control drivers needed.

The buck-boost topology is often used in

applications where the application is

powered from the AC mains and the rectified

voltage varies from 0V to the peak voltage.

This topology is also used when the

application must operate from many varying

supplies (i.e. 120VAC and 240VAC systems,

or 12V, 24V and 48V DC systems).

Most switching power supply integrated

circuits can be used in multiple topologies.

The manufacturer can provide optional

configuration information of their parts.

Again, in every case, the designer must

evaluate all three portions of the design:

thermal system performance, electrical

system performance, and system assembly

efficiency to properly optimize the system.

Examples of a buck topology switching

current control supply:

Figure 8 shows an example of a buck

topology switcher, the MLX10801 from

Melexis. This circuit features a digital

calibration interface for ‘tuning’ the current

level at production end-of-line, and a remote

temperature sense diode input to shut down

the driver when temperatures reach a

specified maximum. This part is suitable for

automotive applications.

02.02.05 page 9 of 14

Page 10

Figure 8: MLX10801, an example of a buck topology switcher

Examples of a boost topology switching

power supply:

Figure 9 is an example of a boost topology

switching power supply, the EL7512 from

Intersil.

This circuit features an output over-voltage

protection for applications where the load

may be removed from the supply, and an

extended supply operating range up to 16 V.

The Rset (36K) resistor is used to set the

LED current level, which can have a max

range of 200mA to 500mA depending on the

input supply voltage.

Figure 10 is another example of a boost

topology switcher, the LM2733 from National

Semiconductor. This circuit features

simplicity, and a 1.6MHz operating

frequency for small component size.

Figure 9: EL7512, an example of a boost topology switching power supply

10K

Ω

1.0

Figure 10: LM2733, an example of a boost topology switcher

02.02.05 page 10 of 14

Page 11

Figure 11 is another example of a boost

topology switching power supply, the

ZXSC400 from Zetex. This circuit features

driving a white Golden Dragon LED from 2

NiMH or NiCd cells, and an external power

switch to allow a wide range of transistors to

be selected based on the current and

voltage needs of the load.

Ω

17 m

Figure 11: ZXSC400, an example of a boost topology switching power supply

Example of a buck-boost topology

switching power supply:

Figure 12 is a concept example of a buckboost topology switching power supply, the

LM2673-ADJ from National Semiconductor.

This circuit can take a varying supply

voltage, and drive a string of LEDs operating

at a voltage in the middle of the range of the

supply voltage.

Ω

17 m

Figure 12: LM2673-ADJ, an example of a buck-boost topology switching power supply

02.02.05 page 11 of 14

Page 12

Figure 13 is an example of a buck-boost

topology switching power supply, the

HV9906 from Supertex. This circuit is

actually a buck-boost-buck, but it demonstrates the function of a buck-boost. This

circuit offers operation directly from the AC

power mains with power factor correction.

The buck-boost nature allows this circuit to

do the power factor correction. There are no

electrolytic capacitors in the circuit, which

improves long-term reliability. There is a 7V

version of this part allowing it to function in

automotive applications as well.

1N4007

MURS160

65 to 280 V AC

56 µH

MURS160

4.4 uF

15 µH

100 nF

8 M

100 K

Vin

Von

Vdd

AGND

1 µF

Gate

NS

PS

PGND

IRF BC3 0 AF

10 nF

10 nF

MURS160

70

W

Figure 13: HV9906, an example of a buck boost topology switching power supply

02.02.05 page 12 of 14

Page 13

DIMMING THE GOLDEN DRAGON LED

OSRAM Opto Semiconductors has

published an application note on dimming

InGaN LEDs titled “Dimming InGaN LEDs”.

Since the white Golden Dragon LED is

InGaN based, this application note should

be consulted if the application will be

dimming the LED.

Dimming with a switching power supply can

be difficult. Since the supply is frequency

balanced, rapidly switching the supply on

and off can create instabilities in the system.

Some higher frequency switching power

supply integrated circuits have a dimming

input that allows a PWM input. Others have

an analog input pin that allows dimming by

changing the current level of the LEDs.

(This, as mentioned in the dimming

application note, can change the hue of the

white Golden Dragon LED’s emitted light)

Care must be taken when PWM dimming a

switching power supply, as some parts

accept a PWM input, but convert this input to

a change in the applied forward current of

the LED rather than pulsing the LED and

changing the average forward current.

Consult with the individual integrated circuit

manufacturers on how their parts utilize a

PWM input.

SUMMARY

• To minimize lighting system costs,

and maximize performance, all areas

must be evaluated and optimized:

thermal design, electrical design,

optical design and system assembly

efficiency.

• The Golden Dragon LED can be

driven with a series resistor, but at a

greatly reduced capacity. It needs a

current control supply to maintain

reliable and consistent performance

in most applications.

• The lighting system thermal

performance is key: keep the thermal

resistance of the system as low as

economically possible for best

thermal efficiency to keep the LED

and current control parts count low.

Good thermal management will also

improve the reliability of the system.

• Design the system to keep the LED’s

junction temperature as low as

possible, because a cool LED

generates more light than a hot LED.

In all cases design the system to

prevent the LED’s junction temperature from exceeding the rated

maximums given in the data sheet.

• A linear current control supply is best

suited when the load voltage will be

just below the input supply voltage

(to minimize power dissipation in the

current control supply) and when

there are only a few strings.

• A buck topology current control

supply is used in applications where

the input supply voltage will always

be above the load voltage, and the

power dissipated is more than what

can be reasonably handled with a

linear current control supply.

• A boost topology current control

supply is used when the input supply

voltage will always be below the load

voltage, or when there are many

LEDs to drive. In the later case, with

many strings, several supplies would

be needed, or a current divider would

be needed. Putting the LEDs into

one longer string reduces the total

supply need, but the voltage

increases above the input supply.

This then requires a boost topology

current control supply.

• A buck-boost topology current control

supply is used when the supply and

load voltages will not consistently be

higher or lower than one another. In

some cases, adding LEDs to the

strings and using a boost topology

current control supply can offer a

better solution.

02.02.05 page 13 of 14

Page 14

APPENDIX

The following is a list of integrated circuit manufacturers and module manufacturers who have a

product that is designed for driving LEDs or can be configured to drive LEDs. This is only

provided as a reference, and is not exhaustive.

Advanced Analogic Technologies Inc. www.analogictech.com

Advanced Transformer Company www.advancedtransformer.com

Allegro Microsystems Inc. www.allegromicro.com

Intersil Corporation www.intersil.com

Fairchild Semiconductor Corporation www.fairchildsemi.com

Infineon Technologies AG www.infineon.com

IXYS Corporation www.ixys.com

LEDdynamics www.leddynamics.com

Linear Technology Corporation www.linear.com

Lumidrives Ltd. www.lumidrives.com

Maxim Integrated Products www.maxim-ic.com

Melexis Microelectronic Systems www.melexis.com

Microsemi Corporation www.microsemi.com

National Semiconductor Corporation www.national.com

On Semiconductor www.onsemi.com

Power Integrations Incorporated www.powerint.com

ST Microelectronics www.st.com

Supertex Incorporated www.supertex.com

Sipex Corporation www.sipex.com

Texas Instruments Incorporated www.ti.com

Toko Incorporated www.toko.com

Zetex Semiconductors www.zetex.com

Author: Timothy Dunn

About Osram Opto Semiconductors

Osram Opto Semiconductors GmbH, Regensburg, is a wholly owned subsidiary of Osram GmbH, one of

the world’s three largest lamp manufacturers, and offers its customers a range of solutions based on

semiconductor technology for lighting, sensor and visualisation applications. The company operates

facilities in Regensburg (Germany), San José (USA) and Penang (Malaysia). Further information is

available at www.osram-os.com.

All information contained in this document has been checked with the greatest care. OSRAM Opto

Semiconductors GmbH can however, not be made liable for any damage that occurs in connection with

the use of these contents.

02.02.05 page 14 of 14

Loading...

Loading...