OSO TERMO RS E Installation Manual

TERMO ELECTRIC BOILERS

MANUAL

OSO TERMO RS -E

OSO TERMO PLUS - E

OSO TERMO PTV – E

B C

Contents

1. Introduction ....................................................................................................................... 1

1.1. Applicable documents................................................................................................. 1

1.2. Retention of documents .............................................................................................. 1

1.3. Features and benefits ................................................................................................. 1

1.4. Termo concept............................................................................................................ 1

1.5. Outside temperature sensor........................................................................................ 1

1.6. Heating curves............................................................................................................ 1

1.7. Termo E Range........................................................................................................... 2

1.8. Water heater temperature sensor ............................................................................... 2

2. Termo E range .................................................................................................................. 1

2.1. Key to TERMO boilers ................................................................................................ 1

2.1.1. RS - E................................................................................................................... 1

2.1.2. Plus - E .................................................................................................................... 3

2.1.3. PTV - E .................................................................................................................... 5

2.2. Expansion Vessel Characteristics (Plus And PTV Boilers) .......................................... 7

2.3. Supply Characteristics 240V N ~ 50/60 Hz ................................................................. 7

3. Installation ......................................................................................................................... 8

3.1. Content included in delivery ........................................................................................ 8

3.2. Standards & Regulations ............................................................................................ 8

3.3. Physical installation..................................................................................................... 8

3.3.1. Select position for boiler ....................................................................................... 9

3.3.2. Fitting the boiler hanging bracket.......................................................................... 9

3.3.3. Recommendations for handling ............................................................................ 9

3.3.4. Removing/fixing the front and top case................................................................10

3.4. Plumbing & Heating installation & commissioning ......................................................10

3.4.1. Installation ...........................................................................................................10

3.4.2. Ancillary components ..........................................................................................10

3.5. Connection to the electrical mains supply ..................................................................11

3.6. Room thermostat, temperature probes and pumps connection ..................................12

3.6.1. Connect room thermostat/programmer................................................................12

3.6.2. Fit external temperature sensor...........................................................................12

3.6.3. Fitting hot water cylinder temperature sensor (PTV-E only) .................................13

3.6.4. Fitting pump connections and expansion vessel (RS – E only) ...............................13

4. Setting up Boilers .............................................................................................................14

4.1. Control Panel (including fault finding indicators).........................................................14

4.2. Choose type of heating (radiator or under floor heating) ............................................15

4.2.1. Hybrid Systems combining radiator and UFH ......................................................16

4.3. Activating system and programming central heating ..................................................16

4.3.1. Heating curves explained. ...................................................................................16

4.3.2. To set correct curve.............................................................................................17

4.3.3. Setting internal temperature ................................................................................17

4.3.4. Programmable room thermostats & setting variable internal temperatures ..........17

5.4. Domestic hot water priority.........................................................................................18

4.5. Protection from freezing.............................................................................................18

4.5.1. Domestic hot water..............................................................................................18

4.5.2. Central heating........................................................................................................18

5. Recommended annual checks (all boilers) .......................................................................19

6. Central heating controls advanced menu..........................................................................20

The company reserve the right to alter size, shape and specification without prior notice

6.1. Domestic hot water advanced menu (control panel type 2) ........................................22

7. Fault finding guide ............................................................................................................24

8. After Sales service information.........................................................................................30

9. Cascade power limiter......................................................................................................30

10. OSO Hotwater UK Ltd ....................................................................................................30

11. Appendices.....................................................................................................................30

11.1. Appendix 1 - Termo RS with space heating and water heating ................................31

11.1.1. Schematic diagram Termo RS - E .....................................................................31

11.1.2. Wiring diagram Termo RS - E............................................................................31

11.1.3. S-Plan wiring layout Termo RS -E .....................................................................32

11.2. Appendix 2 - Termo RS – Space heating only..........................................................33

11.2.1. Schematic diagram Termo RS - E .....................................................................33

11.2.2. Wiring diagram Termo RS-E..............................................................................33

11.2.3. S-Plan wiring layout Termo RS-E ......................................................................34

11.3. Appendix 3 - Termo PLUS E....................................................................................35

11.3.1. Schematic diagram Termo plus-E......................................................................35

11.3.2. Wiring diagram Termo plus-E ............................................................................35

11.3.3. S-Plan wiring layout...........................................................................................36

11.4. Appendix 4 Termo PTV E ........................................................................................36

11.4.1. Schematic diagram Termo PTV-E .....................................................................36

11.4.2. Wiring diagram Termo PTV-E............................................................................36

11.4.3. S- Plan wiring layout Termo PTV-E ...................................................................37

The company reserve the right to alter size, shape and specification without prior notice

Terminology used in this manual

The central heating boiler water circuit is called primary

The domestic hot water is called secondary (dhw)

1. Introduction

Thank you for purchasing the Oso Termo E electric central heating boiler.

To ensure a correct and safe installation and economical use, please read these instructions thoroughly before

installation.

1.1. Applicable documents

The following additional documents are provided with the appliance:

For the owner of the system:

Instructions for use

Warranty card

1.2. Retention of documents

Please pass on this installation manual to the owner of the system. The owner should retain the manuals so that

they are available when required.

1.3. Features and benefits

The boiler provides wet system central heating by passing the primary water over the immersion heaters. The

immersion heaters are located on the under-side of boiler ensuring the elements are constantly immersed in the

heating medium (water with appropriate inhibitor). The primary temperature in the heating circuit is determined by

the outside temperature sensor and the heating curve selected in the boiler, (see sections 1.2, 1.3 and 3.5.3) The

boiler temperature probe will activate and modulate 1, 2 or 3 elements in the boiler to achieve the desired primary

temperature. The boiler has an automatic pump overrun for both central and water heating that prevents a build

up of heat in the boiler. The boiler reservoir is insulated with 19 mm self-extinguishing Armaflex insulating

material, which is sufficient to direct the whole heat only to the heating system.

The boiler operates by rapidly heating a small water quantity. Energy use is maintained at 100% efficiency.

No flue or fan required - Almost silent in operation - No bulk oil storage tanks required

No annual safety check required

For the qualified technician:

Instructions for installation

Electrical drawing for the appliance

1.4. Termo concept.

The OSO Termo E range of boilers uses technology widely used in Europe but relatively new in the UK, that

modulates the boiler to reduce power consumption.

1.5. Outside temperature sensor

An outside temperature sensor is supplied with the boiler to be fitted to an outside shaded wall. This sensor

informs the boiler of the outside temperature.

1.6. Heating curves

The boiler is pre-programmed with a number of heating curves to select from.

The boiler calculates the heat required in the property based on the outside temperature and the set heating

curve – the colder it is outside, the higher the primary temperature needed in the heating system.

Heating curves are set for a particular property and selection is dependent on the insulation levels of the property.

Modern, well insulated buildings have a different heating curve to a less well insulated building. A poorly insulated

house will require a higher primary heating temperature.

Heating curves also vary according to radiator or under-floor heating. The factory set heating curve is for a

building constructed to 2000 building regulations with radiator heating. Many boilers therefore will not require

adjustment of heating curve.

Changing the heating curves at the time of installation is a simple process for the installer. A table is shown on

page 20 indicating which heating curve is required for the building type. Once the heating curve is correctly set, it

should never require changing.

The heating curve will aim for the property to be heated to 22°C. Not all households wish for the same internal

temperature, if the residents of the property require a higher or lower temperature, the selected curve should be

offset up or down by the appropriate number of degrees. Full instructions are given on page 19.

A room thermostat (not supplied) must be installed to finely regulate internal temperatures.

The company reserve the right to alter size, shape and specification without prior notice

Page 1

1.7. Termo E Range

TERMO RS E is a boiler and software package only. Expansion vessel, pump and motorized valves are not

supplied

TERMO Plus E is a system boiler for central heating only. Expansion vessel & pump is supplied in the boiler.

TERMO PTV E is a system boiler for central heating and will provide heat for a domestic hot water cylinder. For

ease of reference the boilers will be referred to in this installation manual as RS E, Plus E and PTV E.

TERMO boilers are available in (240V single phase): 4.8, 6, 7.2, 10.8, and 14.4 kW. OSO Termo boilers can be

connected together to provide more power, the boilers can also be supplied for use on three phase supplies.

Please contact Oso for details.

1.8. Water heater temperature sensor

The Termo PTV E boiler is supplied with a temperature probe that is inserted between the cylinder wall and

insulation or in a dry pocket. This probe then relays cylinder temperature information back to the boiler. The boiler

will then produce sufficient heat to raise the temperature of the domestic water to the desired level.

The company reserve the right to alter size, shape and specification without prior notice

Page 2

2. Termo E range

2.1. Key to TERMO boilers

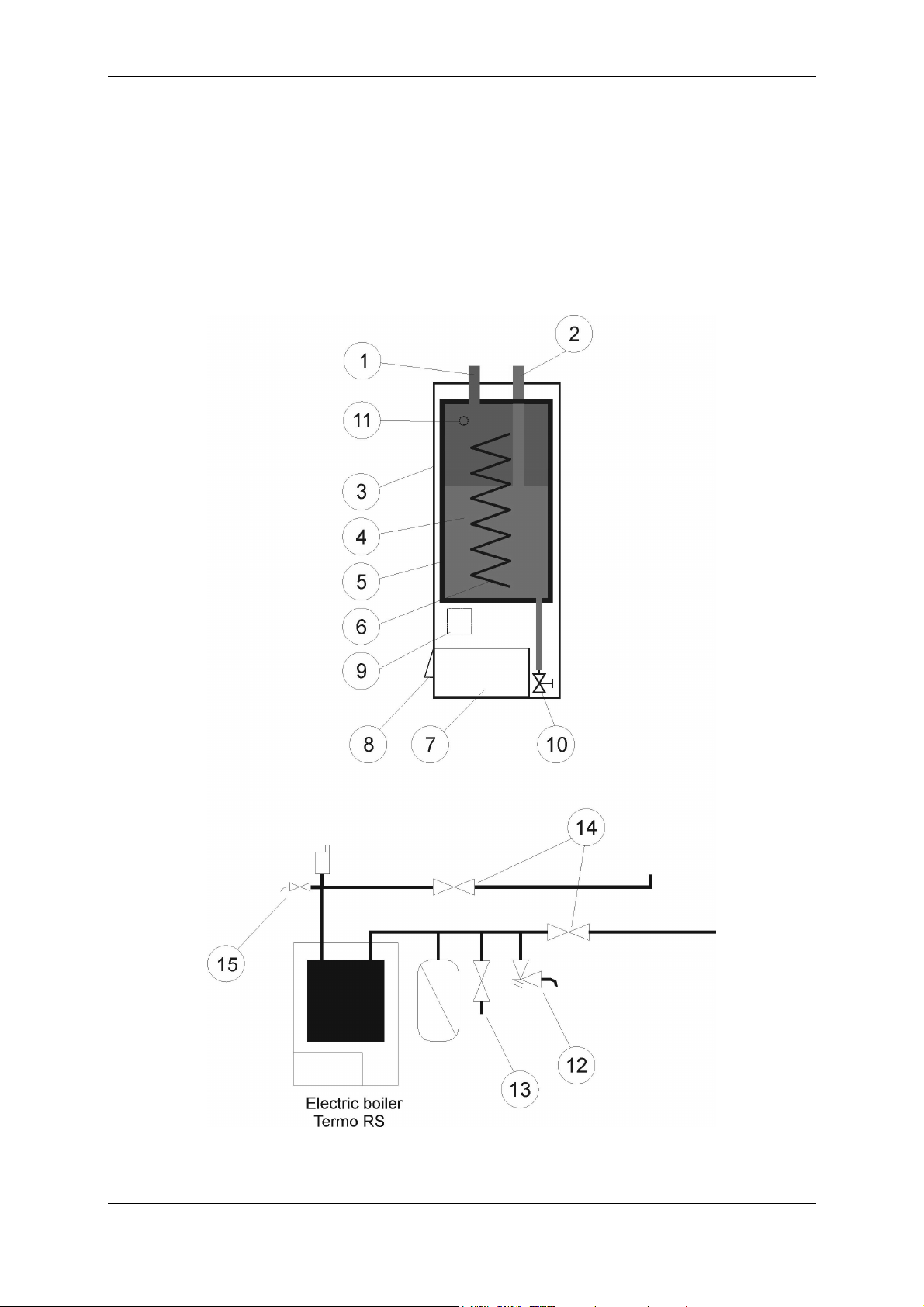

2.1.1. RS - E

1. Primary flow

2. Primary return

3. External boiler jacket

4. Boiler

5. Armaflex Insulation

6. Immersion heaters

7. Control panel

8. Cable entry point

9. Contactors and RCD switch

10. Charge and discharge val ve

11. Pocket with temperature probe

12. Safety valve (supplied loose)

13. Drain valve (not supplied)

14. Isolation valves (not supplied)

15 Manual venting valve (not

supplied)

The company reserve the right to alter size, shape and specification without prior notice

Page 1

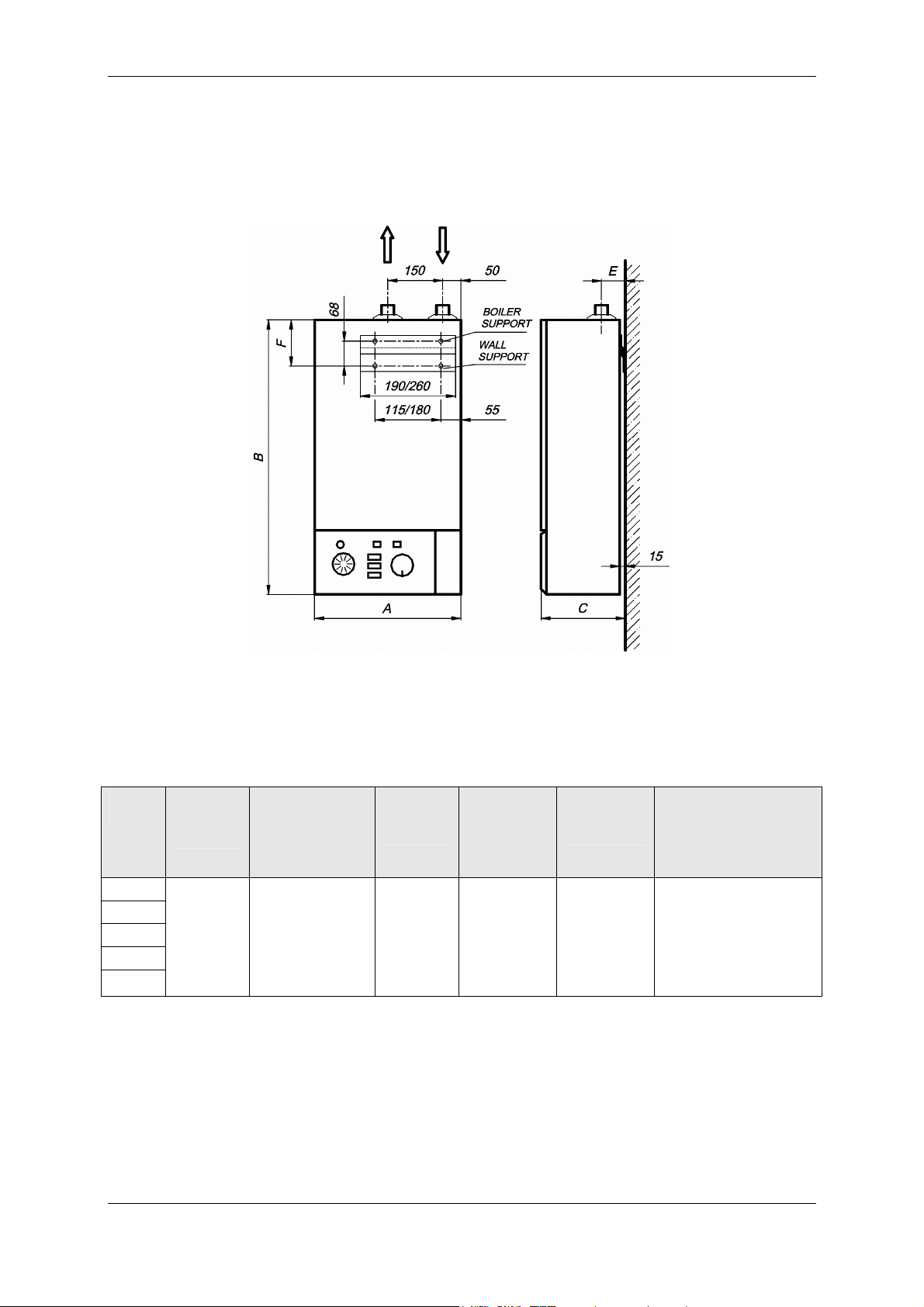

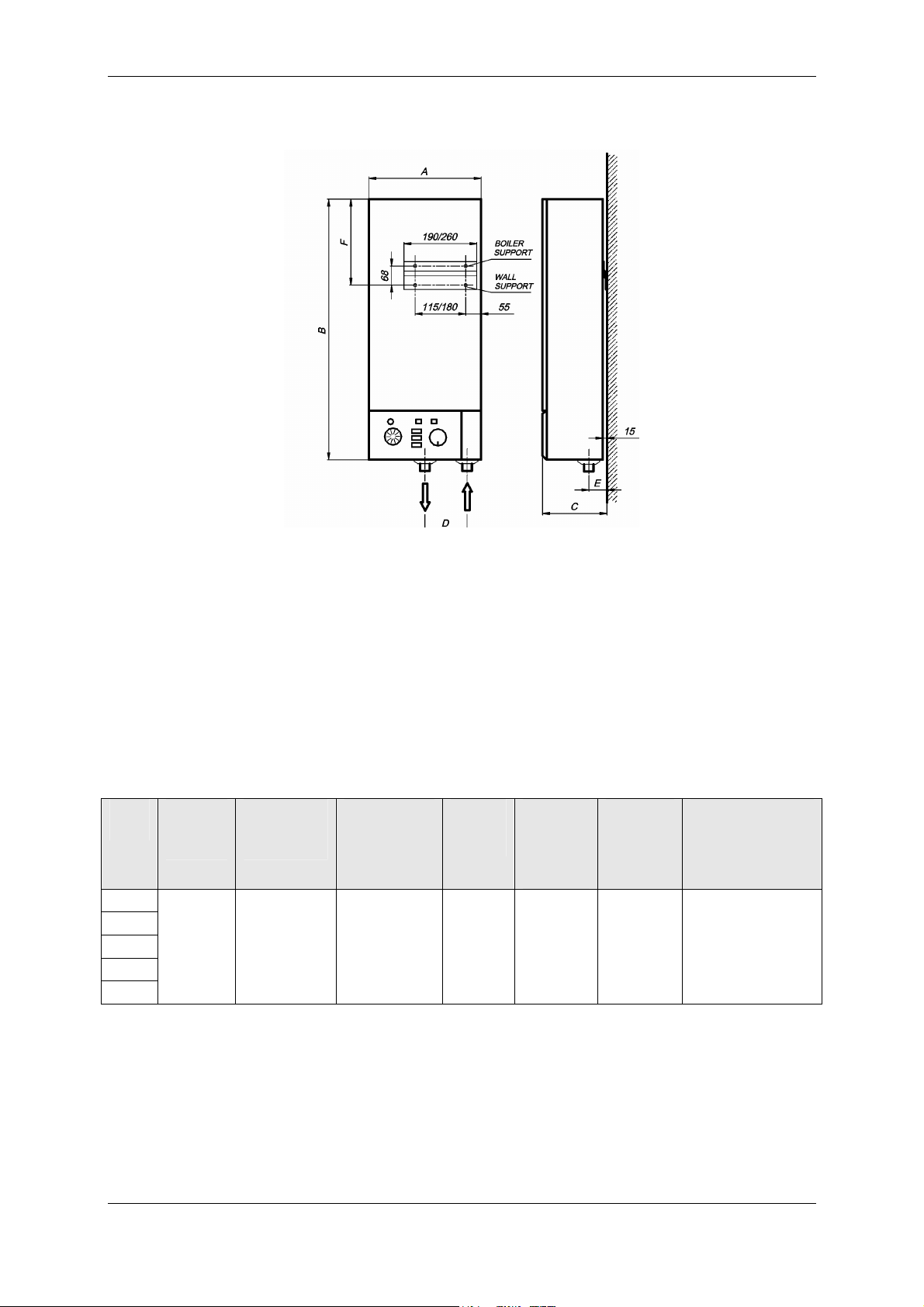

RS – E

Technical Data For RS E

Power

kW

4.8

6

7.2

10.8

14.4

Boiler

Capacity

Litres

6

Dimensions

A 330

B 750

C 230

D 100

E 57

F 126

mm

Dry

Weight

kg

21.4 0,25 (2,5)

Maximum

primary

operating

pressure

MPa (bar)

Connection

BSP male

¾”

Power supply

240V N ~ 50/60 Hz

The company reserve the right to alter size, shape and specification without prior notice

Page 2

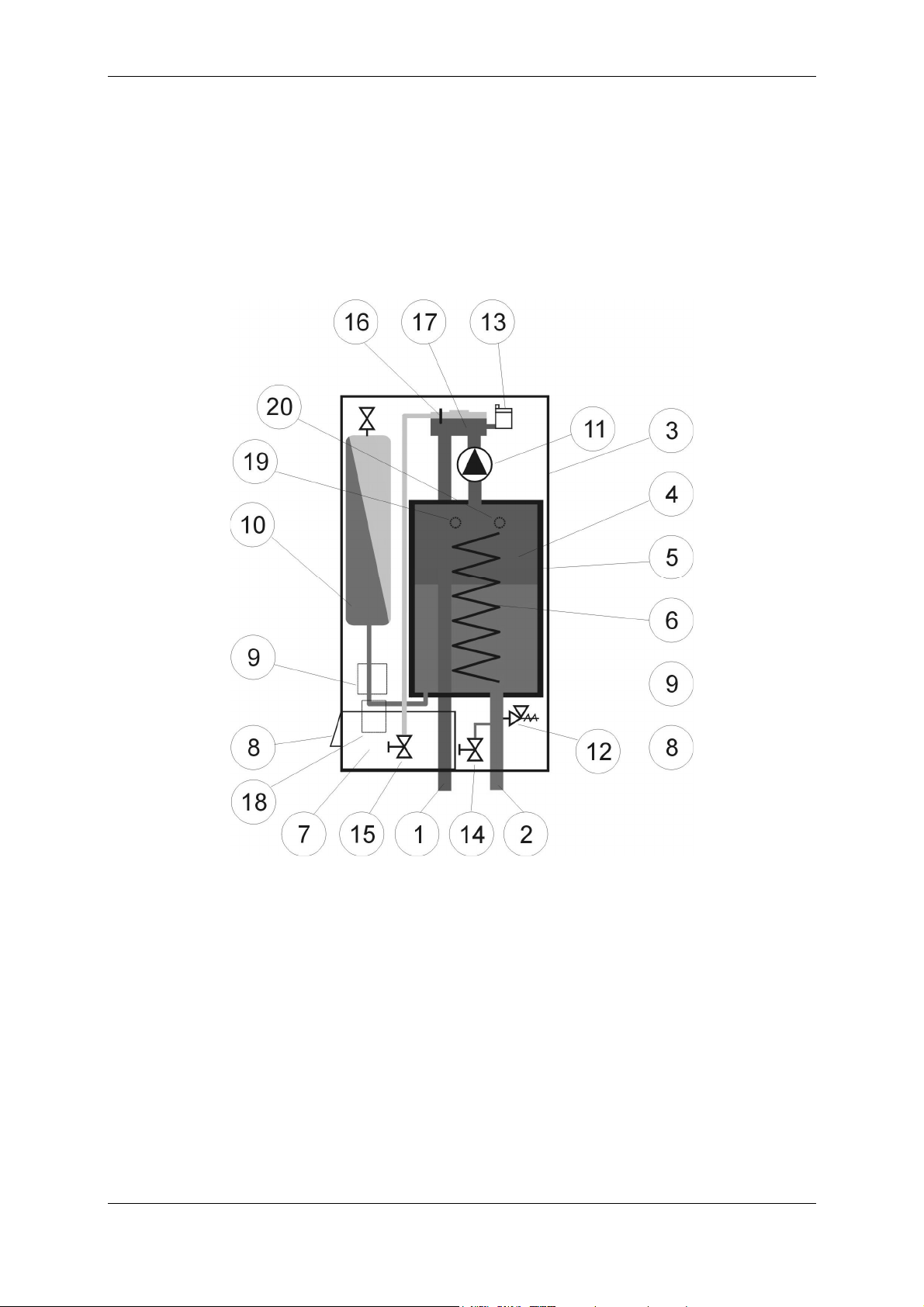

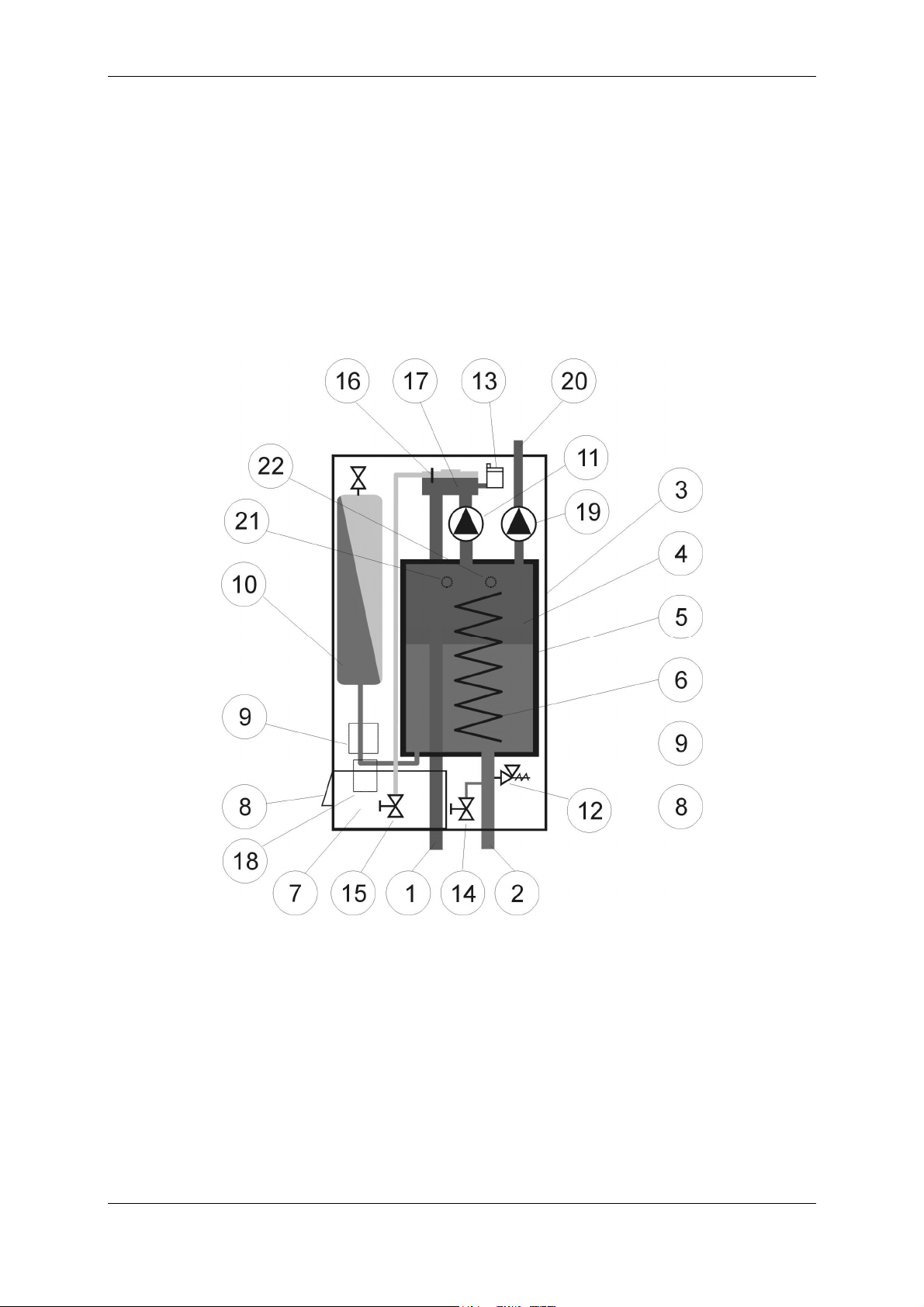

2.1.2. Plus - E

1. Primary flow

2. Primary return

3. External boiler jacket

4. Boiler

5. Armaflex insulation

6. Electrical heaters

7. Control panel

8. Cable entry point

9. Contactors

10. Expansion vessel

11. Circulation pump

12. Safety valve 2.5 bar

13. Automatic air vent (AAV)

14. Charge and drain valve

15. Boiler venting valve

16. Air-indicator

17. Manifold

18. RCD switch

19. Pocket with temperature probe

20. Pressure probe

The company reserve the right to alter size, shape and specification without prior notice

Page 3

Plus – E

Technical Data For Plus E Boilers

Power

kW

4.8

6

7.2

10.8

14.4

Boiler

Capacity

Litres

6 8 / 0,8

Expansion

vessel

L/bar

Dimensions

Mm

A 330

B 930

C 230

D 100

E 65

F 320

Dry

Weight

kg

34.5 0,25 (2,5)

Maximum

primary

operating

pressure

MPa (bar)

Connection

BSP male

¾”

Power supply

240V N ~ 50/60 Hz

The company reserve the right to alter size, shape and specification without prior notice

Page 4

2.1.3. PTV - E

1. Primary flow

2. Primary return

3. External boiler jacket

4. Boiler

5. Armaflex insulation

6. Electrical heaters

7. Control panel

8. Cable entry point

9. Contactors

10. Expansion vessel

11. Circulation pump

12. Safety valve 2.5 bar

13. Automatic air vent (AAV)

14. Charge and drain valve

15. Boiler venting valve

16. Air-indicator

17. Manifold

18. RCD switch

19. Pump for water cylinder

20. Primary flow for water cylinder

21. Pocket for temperature probes

22. Pressure probe

The company reserve the right to alter size, shape and specification without prior notice

Page 5

PTV- E

Technical Data For PTV- E Boilers

Power

kW

4.8

6

7.2

10.8

14.4

Boiler

Capacity

Litres

10 10/0,8

Expansion

Dimensions

vessel

L/bar

Mm

A 400

B 930

C 230

D 150

E 65

F 150

G 50

H 305

Dry

Weight

kg

44.2 0,25 (2,5)

Maximum

primary

operating

pressure

MPa (bar)

Connection

BSP male

¾”

cylinder

1”

(heating)

Power supply

240V N ~ 50/60 Hz

The company reserve the right to alter size, shape and specification without prior notice

Page 6

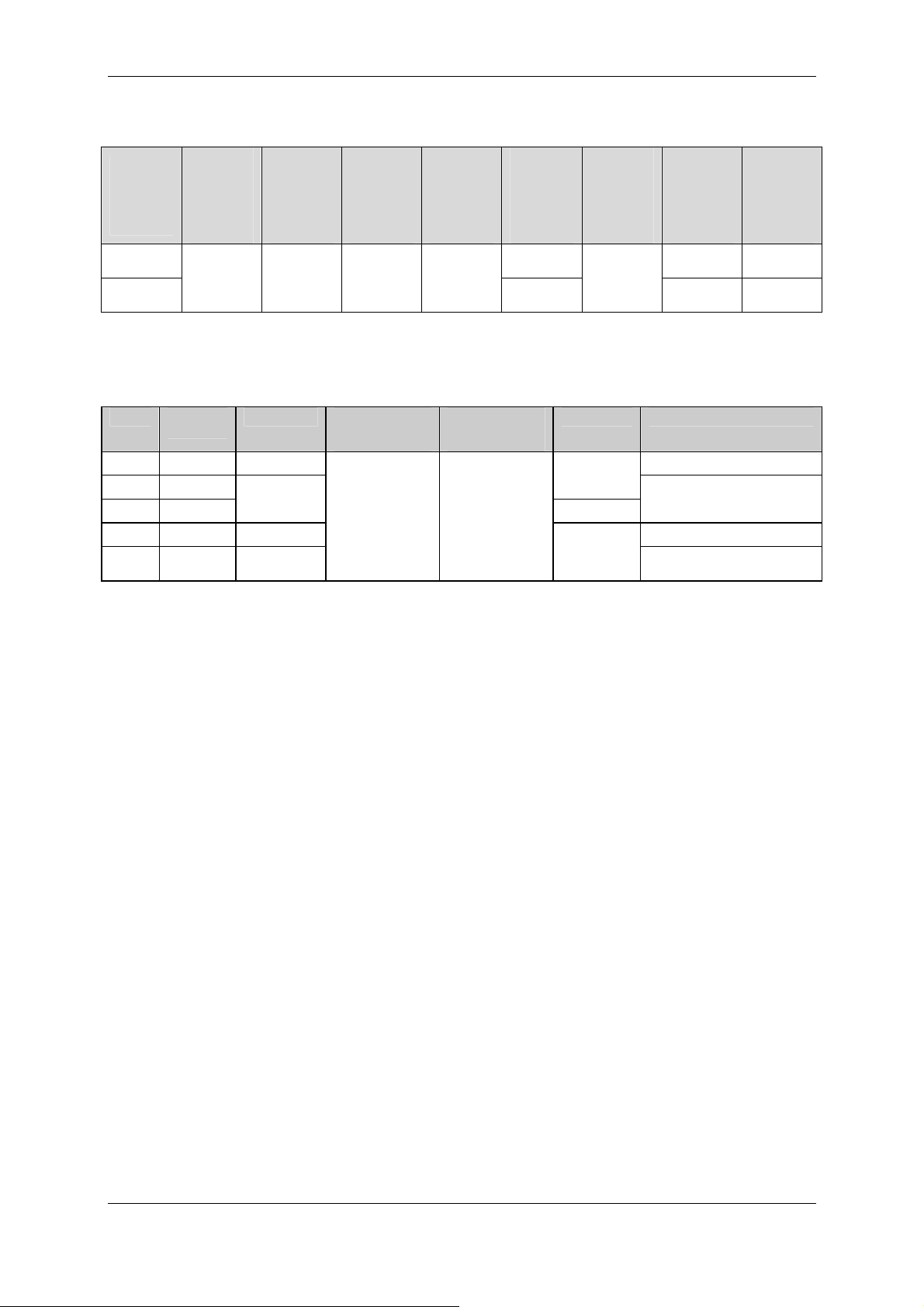

2.2. Expansion Vessel Characteristics (Plus And PTV Boilers)

Volume of

Expansion

Vessel

L

Maximum

Expansion

Vessel

Pressure

MPa (bar)

8 4.0 114 14.4

0.4 (4)

10

2.3. Supply Characteristics 240V N ~ 50/60 Hz

POWER nominal

4.8 kW 20 A B25-1

6 kW 25 A

7.2 kW 30 A

10.8 kW 45 A B50-1

14.4 kW 60 A

current

Filling

Pressure

MPa (bar)

0.08

(0.8)

Maximum

Pressure

In heating

System

MPa (bar)

0.3 (3)

Max Height

Difference

in central

Heating

System

m

10

Effective

capacity of

Expansion

Vessel

L

5.0

Adsorption

Capacity

%

50%

Values are related to working temperature range from 10C to 90C.

MCB Rated short-circuit

B32-1

B63-1

breaking capacity

Icn (EN 60898)

10 kA 15 kA

Rated short-circuit

breaking capacity

Icn (IEC 947-2)

Cable size* RCD switch type

3 x 4 mm2

3 x 6 mm2

3 x 10 mm2

Maximum

amount of

water in

primary

system

L

143 14.4

25-2/0.03 A

40-2/0.03 A

63-2/0,03A or 40-4/0.03 A

80-2/0,03A or 63-4/0.03 A

Maximum

power of

Boiler

kW

*min. conductor's cross-section in mm2 is based on maximum length of 20 m.

The company reserve the right to alter size, shape and specification without prior notice

Page 7

Loading...

Loading...