OSO Dualstream Installation Manual

TECHNICAL AND INSTALLATION MANUAL

HOT WATER

CAPACITY

120 - 380 LITRES

BY

OSO HOTWATER (UK) LIMITED

This manual gives detailed advice for installation and should be read

carefully prior to fitting the OSO Dualstream. Where components are

supplied only for indirect units, this is clearly shown.

The OSO Dualstream must be installed by a competent person and in

accordance with current Building Regulations including Guidance

Document G3.

Drawings on pages 1-18 show

22mm valves on cold water supply.

For 28mm see page 19.

IM/OD/1

1

CONTENTS

INTRODUCTION 1

1-1 Introduction .......................................................... 2

1-1.1 How the OSO Dualstream System Works

. 2

1-1.2 System Contains

.................................................. 2

1-1.3 System Features

.................................................. 2

1-1.4 Central Heating System

.................................... 3

1-1.5 Models Available

.................................................. 3

OPERATOR CONTROLS 2

2-1 Hot Water Temp. ............................................... 4

2-1.1 Hot Water Control - Heating System

.......... 4

2-1.2 Hot Water Control - Immersion Heater

...... 4

2-2 Hot Water Overheating

................................... 6

2-2.1 Water Heated by Heating System

................ 6

2-2.2 Water Heated by Immersion Heater

............ 6

2-3 Shut Off Valves

................................................... 6

2-3.1 Stop Cock

................................................................ 7

2-3.2 Double Check Valve

........................................... 7

2-3.3 Cold Water Shut Off Valve

............................... 7

2-3.4 Supply Water Shut Off Valve

.......................... 7

2-3.5 Hot Water Shut Off Valve

................................. 7

2-4 Pressure Relief

................................................... 7

2-5 Servicing

................................................................ 7

TECHNICAL INFORMATION 3

3-1 System Components....................................... 8

3-2 Specifications

...................................................... 8

3-2.1 Cylinder

.................................................................... 8

3-2.2 Accumulator

.......................................................... 8

3-2.3 Pipes

.......................................................................... 8

3-2.4 Electrics

.................................................................... 8

3-3 Wiring

....................................................................... 9

3-3.1 Immersion Heater

................................................ 9

3-3.2 Wiring Layout S Plan

.........................................10

3-3.3 Wiring Layout Y Plan

..........................................11

INSTALLATION 4

4-1 Building Control ................................................12

4-1.1 Regulations

............................................................12

4-1.2 Electrical Regulations

........................................12

4-2 Installation

............................................................12

4-2.1 Positioning

..............................................................12

4-2.2 Unvented Hot Water Cylinder

........................12

4-2.3 Accumulator

...........................................................13

4-2.4 Tundish

.....................................................................13

4-2.5 Discharge Pipe

.....................................................13

4-2.6 Scale Protection

...................................................14

4-2.7 Pipework

..................................................................14

4-2.8 OSO Dualstream Components

.....................14

4-2.9 Connections to OSO Dualstream

.................14

4-3.0 Direct Cylinders

....................................................14

COMMISSIONING 5

5-1 Commissioning Checks................................15

5-1.1 Commissioning Procedure

..............................15

5-2 Handing Over

......................................................15

SERVICING 6

6-1 Routine Service..................................................16

6-1.1 Service Procedure

...............................................16

SPARE PARTS 7

7-1 Spare Parts...........................................................17

SECONDARY RETURN 8

8-1 Secondary Return.............................................17

OSO DUALSTREAM 9

9-1 OSO Dualstream................................................18

CONNECTIONS 10

10-1 28mm Connections..........................................19

FAULT DIAGNOSIS 11

11-1 Fault Diagnosis ..................................................19

1-1 INTRODUCTION

This Handbook has been compiled to assist in the Installation and Operation of the OSO Dualstream domestic hot and cold

water system. The Installer of the system should give full operating instructions to the householder for the OSO Dualstream

System.

1-1.1 How the OSO Dualstream system works

Fig.1-1 is a schematic illustration of a typical OSO Dualstream system showing how it works.

Option A is used when the accumulator is installed remotely from the unvented cylinder and requires an accessory pack

containing pressure reducing valve, expansion relief valve expansion vessel and bracket, available at additional cost and

should be ordered with the system.

1-1.2 System Contains

1. An unvented hot water cylinder pre-plumbed with all valves and controls with easy access pipe connections for quick,

trouble-free installation.

2. Cylinder Thermostat and High Limit Thermostat.

3. An Accumulator (cold water storage) and associated fittings.

4. One two port motorised valve for connection to heating system flow to cylinder (Indirect only).

5. The OSO Dualstream is supplied with an adjustable pressure reducing valve. This means pressure to all mains water

outlets can be adjusted between 0.5 bar to 5 bar.

1-1.3 System Features

1. All Taps and Showers are at maximum ‘Mains Pressure’.

2. Equal pressure at Hot and Cold Taps.

3. No pressure drop when more than one Tap is in use.

4. More than 25% less pipework than traditional systems.

5. No loft storage tank.

6. Completely sealed system - all Cold Taps are classed as wholesome water.

2

INTRODUCTION 1

Fig. 1-1 Schematic illustration

(Indirect unit)

Rubber expanding

bladder inside vessel.

Pressure is maintained

at maximum

‘Mains Pressure’.

Pressure relief valve

vents excess pressure

from Hot Water System.

Hot Water Cylinder is at

‘Mains Pressure’ due to

incoming cold.

Cylinder with immersion

heater. Water can be heated

by any conventional method.

Existing

Mains Supply

Hot Supply

Option A

Non-return valve. As

water is used system

is equalised to

maximum ‘Mains

Pressure’.

Boiler Return

Secondary Return

Boiler Flow

Air Pressure

Diaphragm

Accumulator

Mains Water

3

INTRODUCTION 1

1-1.4 Central Heating System

The OSO Dualstream system does not affect the Central Heating installation. However consideration has to be

given to the best method of connection and control of the heating system to the indirect cylinder.

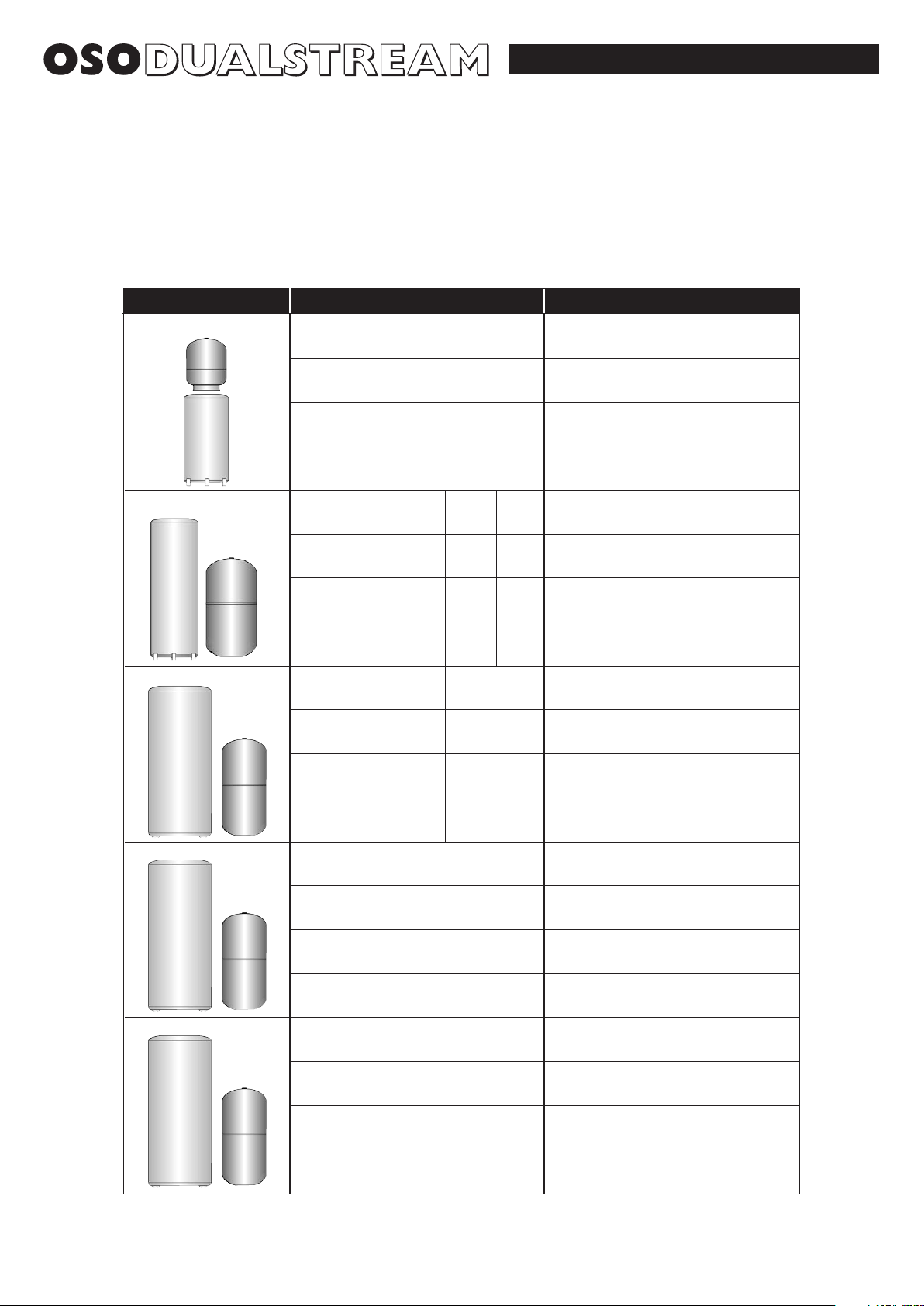

1-1.5 Models Available

Below is a typical selection of the systems available, other combinations can be tailored to suit requirements.

Model Accumulator (Cold Water Storage)

Weight Full (Kg)

Hot Water

Storage Capacity

(L)

Cylinder

Type

Hot Water Cylinder (Direct RD Indirect RI)

20 R

120

120

160

580

720

All sizes are nominal

Very low mains flow rates may require larger or multiple accumulators

Weight Full (Kg)

Diameter

Height

Diameter

Height

Nominal Capacity

(L)

Vessel

Type

19608

100

86

440

890

Weight Full (Kg)

Hot Water

Storage Capacity

(L)

Cylinder

Type

20 R

120

120

160

580

720

20 R

150

150

190

580

900

20 R

200

200

250

580

1150

Weight Full (Kg)

Diameter

Height

Diameter

Height

Nominal Capacity

(L)

Vessel

Type

18891

170

150

535

995

Weight Full (Kg)

Hot Water

Storage Capacity

(L)

Cylinder

Type

20 R

200

200

250

580

1150

20 R F1

200

250

310

580

1400

Weight Full (Kg)

Diameter

Height

Diameter

Height

Nominal Capacity

(L)

Vessel

Type

18892

240

205

540

1220

Weight Full (Kg)

Hot Water

Storage Capacity

(L)

Cylinder

Type

20 R F1

250

250

310

580

1400

20 R F1

300

300

365

580

1600

Weight Full (Kg)

Diameter

Height

Diameter

Height

Nominal Capacity

(L)

Vessel

Type

18893

310

255

540

1500

Weight Full (Kg)

Hot Water

Storage Capacity

(L)

Cylinder

Type

20 R F1

300

300

365

580

1600

20 R F1

380

380

462

580

2100

Weight Full (Kg)

Diameter

Height

Diameter

Height

Nominal Capacity

(L)

Vessel

Type

18894

450

385

665

1550

2-1 HOT WATER TEMPERATURE

2-1.1 Hot Water Control - Heating System (Indirect only)

When the hot water is heated by the heating system the temperature of the hot water at the taps is controlled by the Cylinder Thermostat.

This controls a Motorised Valve that opens and closes the flow from the heating system.

The temperature range is 45°C to 75°C.

Recommended setting is between 50°C minimum and 70°C maximum.

1 Indirect Units

Motorised valve

To comply with regulations governing the installation of indirect unvented

cylinders, a motorised valve must be fitted in the primary flow. Your OSO unit has

been supplied with a two port motorised valve, which will act as a positive energy

cut-out should the safety cut-out operate. The motorised valve will also control the

temperature of the domestic stored water via the cylinder thermostat, which is

located in the electrical box. The unit should be installed on an “S’’ or “Y’’ plan

system. Please follow the instructions carefully. All electrical connections must

conform to current IEE wiring regulations. The working thermostat which controls

the temperature of the domestic hot water (see fig. 2) is adjustable between 45°C

to 75°C. A safety cut out is also incorporated within the thermostat and will

operate at 85°C ± 3°C. Should the safety cut out be brought into operation, the

motorised valve will operate and close down the primary flow to the cylinder. To

reset the safety cut out and the motorised valve the reset button must be pressed

in (see fig. 2). If using a 6-wire 28mm or 1’’ BSP V4043H on either circuit the white

wire is not needed and must be made electrically safe.

2-1.2 Hot Water Control - Immersion Heater

When the hot water is heated by the electric Immersion Heater, the temperature

of the hot water at the taps is controlled by the Immersion Heater Thermostat.

This is located under the electrical box cover, left hand thermostat.

2 Direct units

Wiring instructions for the water heaters are located on the reverse side of the lid.

Follow the wiring instructions connecting the live, neutral and earth as

indicated. All internal wiring is factory mounted. Each immersion heater has

a working thermostat adjustable between 45°C to 75°C. A safety cut-out is

also incorporated within the thermostat and will operate at 85°C ± 3°C.

Should this happen, press the reset button.

Important: Before resetting the safety cut-out or altering the thermostat

setting, isolate electrical supply to the unit prior to removal of the lid.

Ensure the lid to the electrical box is replaced correctly and the

retaining screw is fitted.

The lower immersion heater should be connected to the off peak supply

(if available) whilst the top immersion heater can be connected to the day

tariff. The immersion heater can be connected to the mains supply through a

water heater controller (Contact your local electricity company if in doubt).

WARNING: When the cover is removed electrical live terminals are

exposed.

ALWAYS TURN OFF THE ‘WATER HEATER’ SWITCH BEFORE

REMOVING COVER.

The temperature range is 45°C to 75°C.

Recommended setting is between 50°C minimum and 70°C maximum.

The electrical connection to the immersion heater must conform to

current IEE wiring regulations. The unit must be permanently connected

to the electrical supply through a double-pole linked switch with a

minimum break capacity of 13 amps.

4

OPERATOR CONTROLS 2

Fig. 2-1a Hot Water Control

Fig. 2-1b Immersion Heater Thermostat

Return to Boiler

Motorised valve

Flow from Boiler

Pole Switch

LN

Adjustment

Screw

5

OPERATOR CONTROLS 2

IMPORTANT HEALTH AND SAFETY INFORMATION FOR INSTALLERS AND SERVICE ENGINEERS

HEALTH AND SAFETY AT WORK ACT 1974

CONSUMER PROTECTION ACT 1987

COSHH REGULATIONS 1988

MANUAL HANDLING OPERATIONS REGULATIONS 1992

The regulations set no specific requirements such as weight limits. However common sense still has to be used

based on an ergonomic approach for each individual.

The following information is given as a requirement of the above legislation.

Great care is taken to ensure that OSO Dualstream systems are designed and manufactured to meet general

safety requirements when properly used and installed as recommended in this manual.

It is the responsibility of Users and Engineers to ensure that adequate protective clothing and glasses are worn

when working with the OSO Dualstream system.

SEALS AND INSULATION

Insulation and sealing materials are used in the construction of the OSO Dualstream cylinders. Units are sealed

and when used in the manner for which they are intended the insulating and sealing materials do not present any

known hazard. However always observe the following recommendations:-

1. Avoid inhalation of fibres or dust, wear face mask.

2. Avoid eye contamination by fibres or dust – wear eye protection.

3. As far as possible avoid any skin contact with Fibreglass Insulation, Glass Rope, Mineral Wool, Insulation

Pads and Ceramic Fibre.

OTHER MATERIALS

SEALANTS, ADHESIVES AND PAINTS

Sealants, Adhesives and Paints are used in the construction of the OSO Dualstream components. When used in

the manner for which they are intended they do not present any known hazard.

ELECTRIC

All Cylinders have electrical supply of 240v (enough to endanger life) connected to the Immersion Heater. Always

isolate during adjustment, servicing and repair.

OSO (UK) will not accept responsibility for any damage or personal injury caused by not giving due

consideration to the above safety recommendations.

All replacement parts must be supplied by OSO HOTWATER (UK) LIMITED.

To obtain the address of a local stockist contact:

OSO HOTWATER (UK) LIMITED

E15 Marquis Court, Team Valley Trading Estate, Gateshead, Tyne & Wear, NE11 0RU.

Tel: (0191) 482 0800 Fax: (0191) 491 3655

Email : technical.uk@oso-hotwater.com - spareparts.uk@oso-hotwater.com - sales.uk@oso-hotwater.com

www.oso-hotwater.com

Loading...

Loading...