OSNA GH, GV Original Operating Manual

Ver.17-01

Original Operating Manual

GH/GV High-Pressure

Centrifugal Pump

OSNA-Pumpen GmbH

Brückenstrasse 3

49090 Osnabrück, Germany

Phone: +49 541 1211 - 0

Fax: +49 541 1211 - 220

Internet: http://www.osna.de

E-mail: info@osna.de

GH/GV High-Pressure Centrifugal Pump 1

Contents

1 GENERAL ...................................................................................................................................5

1.1 About this operating manual ................................................................................................5

1.2 Target groups......................................................................................................................5

1.3 Other valid documents.........................................................................................................5

1.4 Warning notices and symbols ..............................................................................................6

1.5 Copyright/changes...............................................................................................................6

2 SAFETY ......................................................................................................................................7

2.1 Correct and proper use ........................................................................................................7

2.2 General safety instructions...................................................................................................8

2.2.1 Product safety..................................................................................................................8

2.2.2 Duties of the system owner ..............................................................................................8

2.2.3 Duties of personnel ..........................................................................................................9

2.3 Dangers of non-observance of the safety instructions ........................................................10

2.4 Unauthorized conversion and production of spare parts .....................................................10

2.5 Unauthorized modes of operation ......................................................................................10

2.6 Special hazards.................................................................................................................10

2.6.1 Explosion area...............................................................................................................10

2.6.2 Hazardous pumping media ............................................................................................10

2.6.3 Noise emissions.............................................................................................................10

3 LAYOUT AND FUNCTION ........................................................................................................ 12

3.1 Labeling.............................................................................................................................12

3.2 Scope of delivery for a type-GH/GV high-pressure centrifugal pump...................................12

3.3 General information ...........................................................................................................12

3.4 Technical data...................................................................................................................13

3.5 Operating point..................................................................................................................13

3.6 Minimum output rates ........................................................................................................13

3.7 Functional and operating elements ....................................................................................14

4 TRANSPORT AND INTERMEDIATE STORAGE ....................................................................... 16

4.1 Transport...........................................................................................................................16

4.1.1 Unpacking and checking the delivery condition ..............................................................16

4.1.2 Lifting.............................................................................................................................16

4.2 Intermediate storage..........................................................................................................17

4.3 Storage..............................................................................................................................17

4.4 Disposal ............................................................................................................................18

5 ASSEMBLY AND INSTALLATION ............................................................................................ 19

5.1.1 Preparing the installation location...................................................................................19

5.1.2 Preparing the base surface and foundations...................................................................19

2 GH/GV High-Pressure Centrifugal Pump

5.2 Installation .........................................................................................................................19

5.2.1 Installing the pump.........................................................................................................19

5.2.2 Assembling the motor ....................................................................................................20

5.2.3 Fine alignment of the coupling........................................................................................21

5.2.4 Electrical connection......................................................................................................22

5.3 Pipelines............................................................................................................................22

6 COMMISSIONING / DECOMMISSIONING ............................................................................... 25

6.1 Commissioning..................................................................................................................25

6.1.1 Determining the pump configuration...............................................................................25

6.1.2 Filling the pump .............................................................................................................25

6.1.3 Checking direction of rotation.........................................................................................25

6.1.4 Starting the pump ..........................................................................................................26

6.2 Decommissioning ..............................................................................................................27

6.2.1 Draining the pump and protecting against frost...............................................................28

6.3 Recommissioning ..............................................................................................................28

6.4 Shaft seal ..........................................................................................................................29

6.4.1 Mechanical seal.............................................................................................................29

6.4.2 Gland packing................................................................................................................29

7 MAINTENANCE AND REPAIR .................................................................................................. 30

7.1 General information ...........................................................................................................30

7.2 Servicing the electric motors ..............................................................................................31

7.3 Operational monitoring.......................................................................................................31

7.4 Gland packing maintenance...............................................................................................32

7.5 Sending the pump to the manufacturer ..............................................................................34

8 FAULTS AND TROUBLESHOOTING........................................................................................ 35

9 APPENDIX ................................................................................................................................ 38

9.1 Spare parts list for constant operation over two years as per DIN 24296 ............................38

9.2 Cross-sections...................................................................................................................39

9.3 Declaration of Conformity as per EC Directive 2006/42/EC, Annex IIA ...............................45

9.4 Clearance Certificate .........................................................................................................46

GH/GV High-Pressure Centrifugal Pump 3

List of Tables

Table 1: Target groups and their tasks ................................................................................................5

Table 2: Other valid documents and their purposes ............................................................................5

Table 3: Warning notices and consequences of non-observance........................................................6

Table 4: Symbols and their meanings..................................................................................................6

Table 5: Sound pressure level...........................................................................................................11

Table 6: Minimum output rates with closed shut-off valve .................................................................13

Table 7: Maximum authorized operating temperature and pressure at the shaft seal .........................14

Table 8: Maximum authorized operating temperature and pressure on the casing .............................15

Table 9: Settings for the time relay when using three-phase motors with star-delta switch .................22

Table 10: Measures in the event of operational interruption..............................................................27

Table 11: Measures depending on the behavior of the pumping medium...........................................27

Table 12: Measures following longer shut down times .......................................................................28

Table 13: Stuffing box in the GH........................................................................................................33

Table 14: Stuffing box in the GV........................................................................................................33

Table 15: Measures for return ...........................................................................................................34

Table 16: Fault/number allocation .....................................................................................................35

Table 17: Troubleshooting table ........................................................................................................37

Table 18: Spare parts for constant operation over two years .............................................................38

Table 19: GH parts list ......................................................................................................................41

Table 20: GV parts list.......................................................................................................................44

4 GH/GV High-Pressure Centrifugal Pump

List of Images

Figure 1: Model code ........................................................................................................................12

Figure 2: Scope of delivery for a GH pump with free shaft ................................................................12

Figure 3: Scope of delivery for a GH pump as a complete unit..........................................................12

Figure 4: Gland packing....................................................................................................................14

Figure 5: Mechanical seal .................................................................................................................14

Figure 6: Lifting a GH centrifugal pump (unit) ....................................................................................16

Figure 7: Lifting a GH centrifugal pump (free shaft end).....................................................................16

Figure 8: Lifting a GV centrifugal pump..............................................................................................17

Figure 9: Mounting material for complete units ..................................................................................20

Figure 10: Mounting material for pump with open shaft end..............................................................20

Figure 11: Positional alignment of the shafts .....................................................................................21

Figure 12: Directional alignment of the shafts ....................................................................................21

Figure 13: Functional and operating elements...................................................................................23

Figure 14: Stuffing box on the GH/GV ...............................................................................................32

Figure 15: Cross-section of GH with mechanical seal ........................................................................39

Figure 16: Cross-section of GH with gland packing............................................................................40

Figure 17: Cross-section of GV with mechanical seal ........................................................................42

Figure 18: Cross-section of GV with gland packing............................................................................43

1 General

GH/GV High-Pressure Centrifugal Pump 5

1 General

1.1 About this operating manual

This operating manual contains important instructions that must be observed during installation, operation and maintenance. For this

reason, ensure that it is read by specialist personnel and the responsible operator/owner

prior to assembly and commissioning. The

manual must be available at all times at the

location where the system is used.

Please observe the safety instructions described in this operating manual, along with the

relevant national accident prevention regulations and any internal work, operational and

safety specifications of the operator. We assume no liability for damages and operational

interruptions resulting from non-observance of

this operating manual.

WARNING

Pay particular attention to section 2 "Safety

instructions" during commissioning and all

maintenance work.

Section 2 also provides an explanation of the

symbols used in this manual. Knowledge of

this operating manual is essential to preventing

errors and ensuring safe and uninterrupted

operation.

The operating specification does not take local

safety regulations into account. The owner

bears full responsibility for compliance with

these, including on the part of the assembly

personnel used.

This operating manual:

• is part of the pump

• is valid for all type series mentioned

• describes safe and proper use in all

phases of operation

1.2 Target groups

Target group

Task

System owner

► Ensure that this manual is available at the location where the system is

used, including for later

reference.

► Ensure that personnel

read and observe this

operating manual and the

other valid documents, in

particular the safety and

warning information.

► Observe additional

system-related regulations and specifications.

Specialist personnel,

assembly staff

► Read, observe and

follow this operating

manual and the other

valid documents, in particular the safety and

warning information.

Table 1: Target groups and their tasks

1.3 Other valid documents

Document

Purpose

Installation diagram Installation dimensions,

connection dimensions, etc.

Spare parts list Ordering spare parts

Clearance certificate Returning the pump

Declaration of

conformity

Conformity with standards,

content of the declaration of

conformity

Table 2: Other valid documents and

their purposes

1 General

6 GH/GV High-Pressure Centrifugal Pump

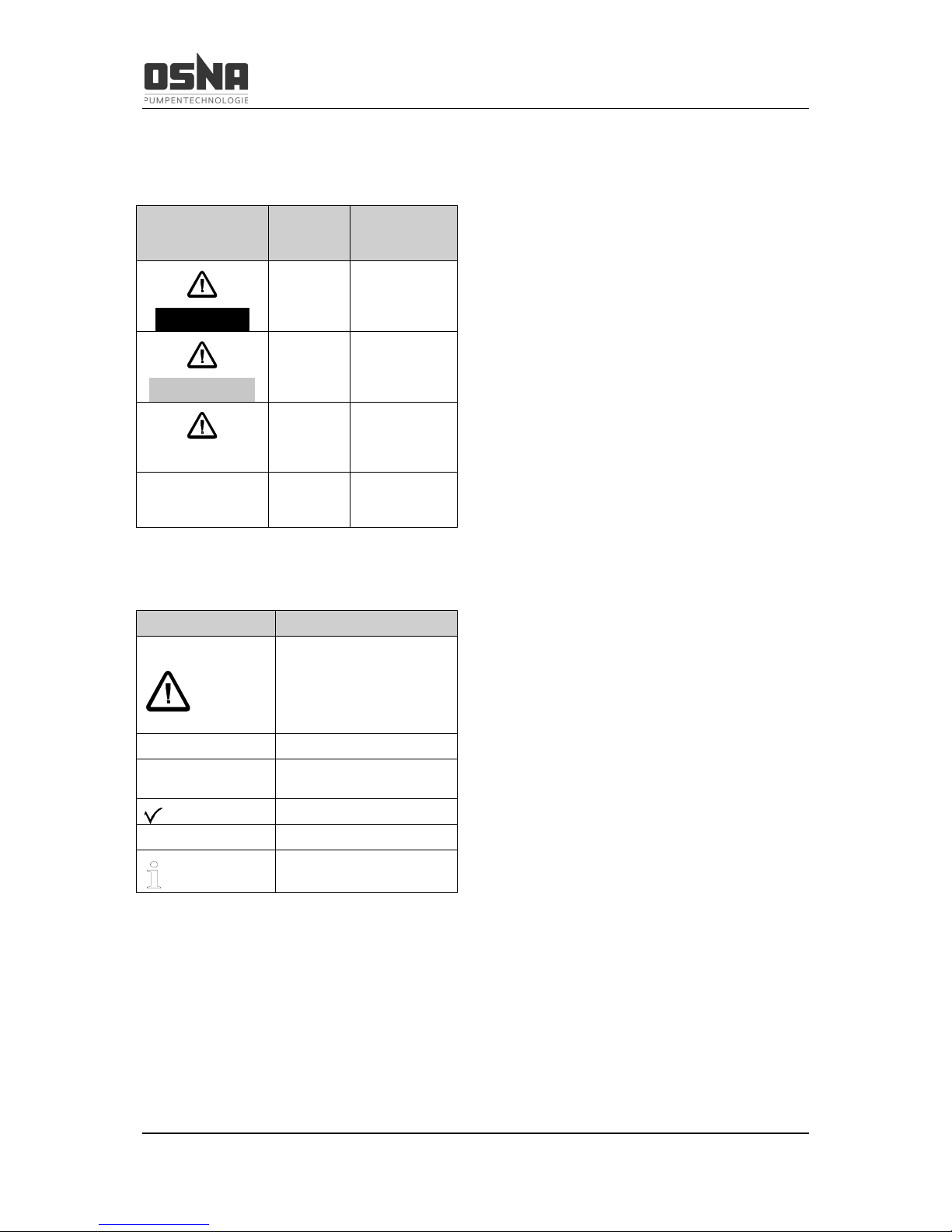

1.4 Warning notices and symbols

Warning notice

Hazard

level

Consequences of nonobservance

DANGER

Immediate

hazard

Death, severe

physical injury

WARNING

Potential

hazard

Death, severe

physical injury

CAUTION

Potentially

dangerous

situation

Minor physical

injury

NOTICE

Potentially

dangerous

situation

Material damage

Table 3: Warning notices and consequences

of non-observance

Symbol

Meaning

Safety sign

► Follow all instructions

identified with safety signs

in order to avoid death or

injuries.

► Instruction

1. , 2. , … Instruction with multiple

steps

Condition

→ Reference

Information, note

Table 4: Symbols and their meanings

1.5 Copyright/changes

The intellectual property and all copyrights

related to this technical documentation remain

exclusively with OSNA-Pumpen GmbH. All

rights reserved, in particular the right to reproduction and distribution of this documentation,

including translations thereof.

No part of this documentation may be reproduced in any form (print, photocopy, microfilm

or any others process), stored, processed,

reproduced or distributed using electronic systems without written permission.

Editorial changes reserved exclusively by OSNA-Pumpen GmbH.

Any violation is punishable and subject to

compensation.

OSNA GmbH reserves the right to change the

contents of this documentation without notice.

2 Safety

GH/GV High-Pressure Centrifugal Pump 7

2 Safety

The manufacturer shall not bear any liability

for damages caused as a result of nonobservance of this documentation.

2.1 Correct and proper use

• Only use this pump for the purposes of

conveying the agreed pumping media.

• Comply with operating limits.

• The water may not contain any abra-

sive or long-fibered components that

may damage the pump materials.

Consult the manufacturer if using other

media.

• Ensure that the pump is only commissioned with pumping medium and is

not operated without it.

• Open the suction-side fitting, and do

not use it to control the flow rate.

• To avoid damaging the motor, observe

the permitted number of times per

hour that the motor can be switched

on (→ Manufacturer information).

• Any other use must be agreed with the

manufacturer.

• The temperature of the pumping medium must not exceed 90 °C.

Avoiding obvious misuse (examples)

• Observe the operating limits of the

pump for temperature, pressure, flow

rate and speed.

The main areas of use are:

• Pressure boosting systems, heating

systems, hot and cold water circulation, water supply systems, power stations, filtering systems, filling and emptying of tanks, water circulation in

pools and sprinkler systems

• Fresh water, drinking water, boiler

feed water, process water, sea and

brackish water, hot water, condensate

and many media without aggressive

components that do not chemically

corrode the materials used in the

pump

Do not operate the pump without water. Dry

running can lead to damage to the pump.

WARNING

Any use that goes beyond the purposes

described above shall be considered improper use. OSNA shall bear no liability for

any resulting damages. The owner bears

full risk for improper use.

2 Safety

8 GH/GV High-Pressure Centrifugal Pump

2.2 General safety instructions

Please observe the following specifications

before performing any activities.

2.2.1 Product safety

This pump is constructed according to the

latest state of the art and accepted safety

rules. Nevertheless, risks to life and limb for

the user or third parties are still possible when

using the pump, as are impairments to the

pump and other material assets.

• Only use the pump in a technically

perfect state and for the intended purpose. Ensure compliance with this operating manual and be aware of the

hazards and safety issues during operation.

• Keep this operating manual and all

other valid documents in a complete

and legible state, and store in a location that is accessible at all times to

personnel.

• Do not permit any activity that endangers personnel or uninvolved third parties.

• In the event of a safety-relevant fault,

stop the pump immediately and have

the fault rectified by responsible personnel.

• In addition to this documentation, ensure compliance with the statutory or

other regulations for safety and accident prevention, as well as the relevant standards and specifications of

the respective country.

• Do not remove any technical stickers.

2.2.2 Duties of the system owner

Safety-conscious work

Observe the safety specifications detailed in

this operating manual, along with the occupational safety regulations and all additional internal safety regulations.

• Only use the pump in a technically

perfect state and for the intended purpose. Ensure compliance with this operating manual and be aware of the

hazards and safety issues during operation.

• Ensure compliance and monitoring:

- correct and proper use

- statutory or other safety and acci-

dent prevention regulations

- safety specifications for handling

hazardous substances

• Provide personal protective equipment.

• Do not remove contact protection during operation.

• Prevent any dangers from electrical

energy (for details, please refer to the

specifications of the VDE and the local

energy supplier).

• Switch off the motor during all assembly and maintenance works, and secure against reactivation.

• Only work on the system when the

pump is at a standstill.

2 Safety

GH/GV High-Pressure Centrifugal Pump 9

Personnel qualification

The owner of the system must ensure that the

personnel tasked with working on the pump

have read and understood this operating manual and all other valid documents before beginning work, in particular information on safety, maintenance and repair.

Work of any kind on the machine may only be

performed when it has been completely decommissioned. Reinstall and reactivate all

safety mechanisms after work.

Before restarting the machine, ensure that all

necessary commissioning steps have been

completed (→ Fehler! Verweisquelle konnte

nicht gefunden werden. Fehler! Verweisquelle konnte nicht gefunden werden., pg

Fehler! Textmarke nicht definiert.).

• Determine responsibilities, tasks and

monitoring for personnel.

• Only allow work of any kind to be performed by specialist technical personnel:

- assembly, maintenance and repair

work

- work on the electrical systems

• Only allow personnel undergoing training to perform work on the pump under

the supervision of specialist technical

personnel.

Safety mechanisms

• Provide the following safety mechanisms and ensure that they function

correctly:

- for moving components: contact

protection for the pump, installed

by the customer

- for potential electrostatic charges:

provide appropriate earthing

Guarantee

• Please consult the manufacturer before carrying out any conversions, repairs or changes during the guarantee

period.

• Only use original parts or parts approved by the manufacturer.

2.2.3 Duties of personnel

• Observe the information on the pump

and ensure it is legible (e.g. direction

of rotation arrow, fluid connection indicators).

• Do not remove the contact protection

for moving parts during operation.

• Use personal protective equipment if

necessary.

• Only work on the system when the

pump is at a standstill.

• Switch off the motor during all assembly and maintenance works, and secure against reactivation.

• Reinstall the safety mechanisms after

working on the pump according to

specifications.

2 Safety

10 GH/GV High-Pressure Centrifugal Pump

2.3 Dangers of non-observance of

the safety instructions

• Non-observance of the safety instructions can lead to hazards to personnel,

the machine and the environment.

• Non-observance of the safety instructions can also lead to the loss of any

damage claims.

• In particular, non-observance can lead

to the following dangers:

- failure of important system func-

tions

- electrical and mechanical hazards

to personnel

2.4 Unauthorized conversion and

production of spare parts

Conversions or changes to the machine are

only permitted following consultation with the

manufacturer. Original spare parts and accessories authorized by the manufacturer help

ensure safety. The manufacturer bears no

liability for the consequences of the use of

other parts.

2.5 Unauthorized modes of operation

The operational safety of the machine is only

guaranteed when it is used for the intended

purpose according to the operating manual (→

2.1 Correct and proper use, pg 7).

Never exceed the limit values indicated in the

technical data (→ Data sheet).

2.6 Special hazards

2.6.1 Explosion area

• Do not use the pump in areas where

there is a risk of explosion.

2.6.2 Hazardous pumping media

• Observe the safety regulations for

handling hazardous substances (e.g.

toxic, hazardous to health).

• Use personal protective equipment

when performing work on the pump.

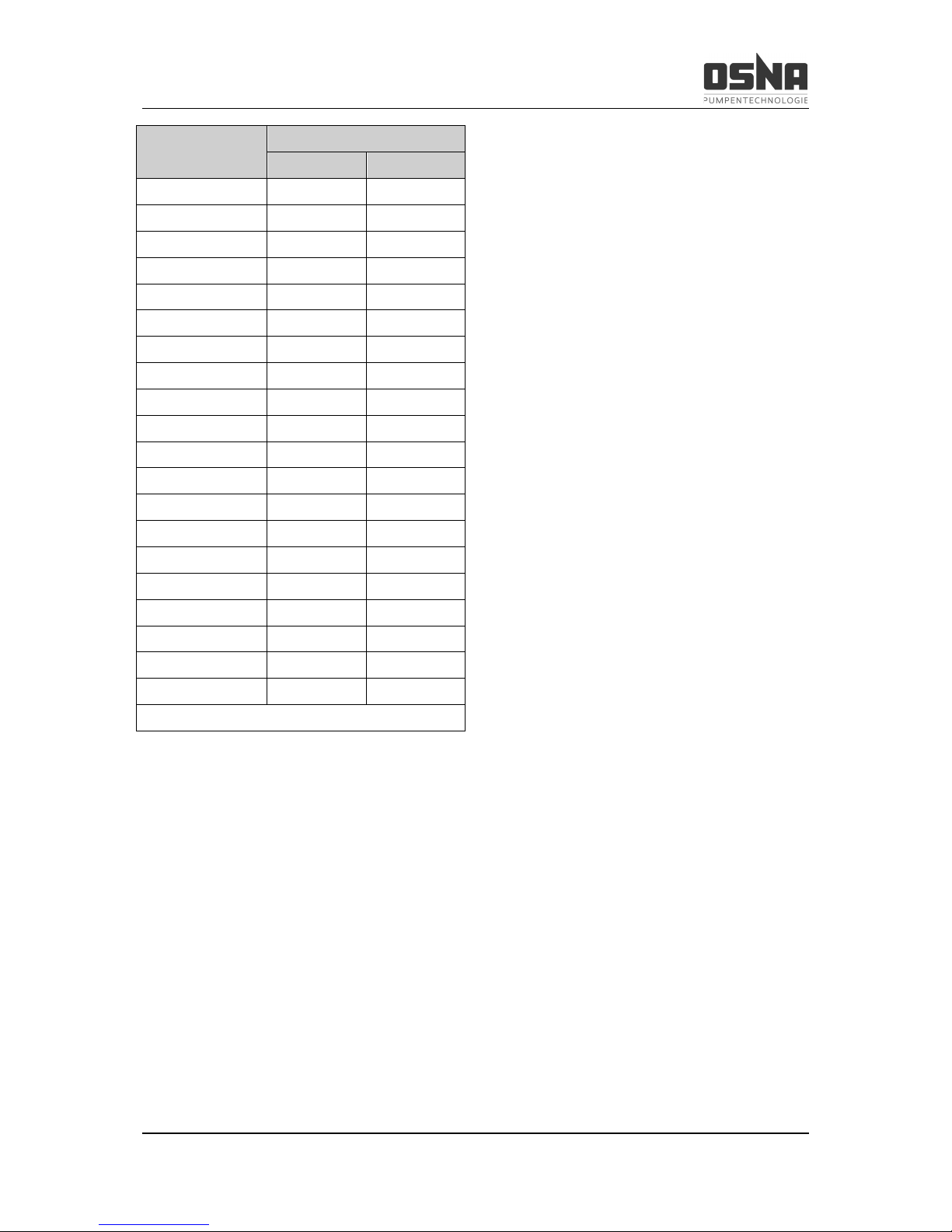

2.6.3 Noise emissions

Conditions for measurement:

• Distance to pumping unit: 1 m

• Operation: Free of cavitation

• Motor: IEC standard motor

• Tolerance: ± 3 dB(A)

2 Safety

GH/GV High-Pressure Centrifugal Pump 11

Drive power in

kW

Noise emissions in dB(A)

1450 min-1 2900 min-1

0.75 50 58

1.1 53 62

1.5 55 62

2.2 56 63

3.0 58 65

4.0 60 66

5.5 64 70

7.5 65 71

11.0 68 73

15.0 69 74

18.5 69 74

22.0 70 75

30.0 71 75

37.0 72 76

45.0 73 77

55.0 73 79

75.0 74 81

90.0 74 82

110.0 75 83

132.0 76 84

Greater power upon request

Table 5: Sound pressure level

Low-noise motors can be provided if the expected noise values exceed the permitted limits.

3 Layout and function

GH/GV High-Pressure Centrifugal Pump 12

3 Layout and function

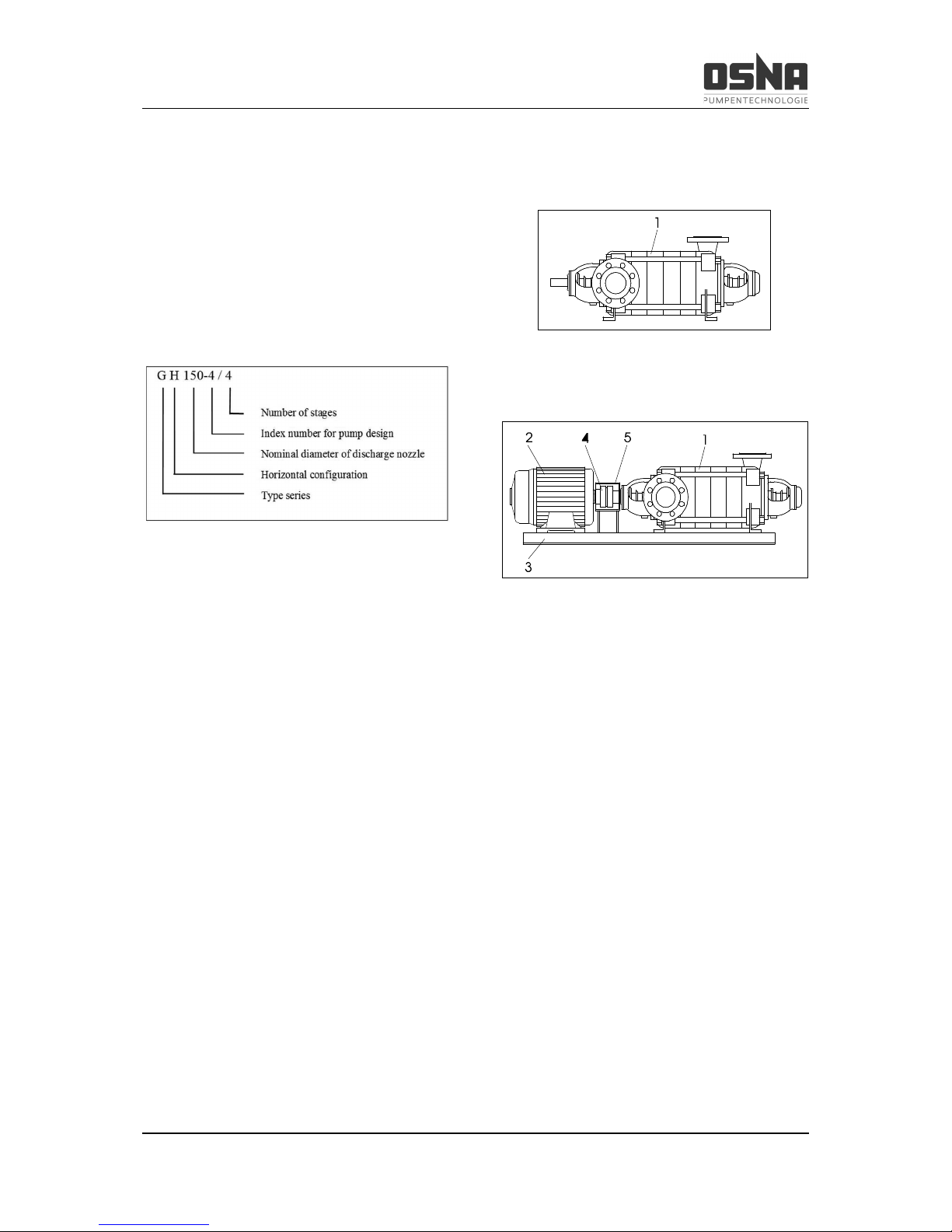

3.1 Labeling

This operating manual applies to the GH/GV

type series.

Model code:

Figure 1: Model code

3.2 Scope of delivery for a typeGH/GV high-pressure centrifugal

pump

The customer can order the pump:

− with a free shaft, i.e. delivery without motor

or foundation (à Figure 2, pg 12)

− as a complete unit, i.e. fully assembled on a

baseplate with drive motor, coupling and

coupling guard (à Figure 3, pg 12)

1 Pump

2 Drive motor

3 Baseplate

4 Coupling

5 Coupling guard

The scope of delivery corresponds to the

scope indicated in the order. Please check that

the delivery is complete upon receipt. Notify

the delivery company of any transport damage

immediately. Please also refer to our conditions of sale and delivery. If using other motor

brands, please ensure that the motors have

the following drive torques as a multiple of the

nominal torque.

Figure 2: Scope of delivery for a GH pump

with free shaft

Figure 3: Scope of delivery for a GH pump

as a complete unit

3.3 General information

The GH/GV is a non self-priming, multistage,

high-pressure centrifugal pump in horizontal

(GH) and vertical (GV) configuration. These

models have proven themselves thanks to

their quiet running and long service lives. The

suction and discharge nozzles can be produced variably at different stages of 90°.

Depending on requirements, the GH/GV

pumps are fitted with either gland packing or

mechanical seals (cooled version also available).

The horizontal configuration uses lubricated

anti-friction bearings, whilst the vertical configuration uses both a lubricated anti-friction

bearing and a liquid-lubricated plain bearing.

Depending on the demands of the pumping

medium or customer requirements, it is also

possible to use materials such as gray cast

iron, spheroidal graphite iron, cast steel,

bronze or stainless steel (also Duplex and

Super Duplex).

3 Layout and function

GH/GV High-Pressure Centrifugal Pump 13

The pumps are driven via standard IEC electronic motors. The horizontal pumps can also

be driven by combustion motors or turbines.

The drive is on the discharge side in the

standard configuration. Drive on the suction

side or on both sides is possible upon request.

The pump can be delivered as a complete unit

(assembled on baseplate with drive motor,

coupling and coupling guard), or with a free

shaft end.

3.4 Technical data

Main parameters:

Output: Up to 550 m³/h

Delivery head: See table

Speed: n= 950, 1450 and 2900 rpm

(at 50 Hz)

n= 1150, 1750 and 3500 rpm

(at 60 Hz)

Diesel and hydraulic motor

with special speed limited to

max. 3500 rpm.

Ambient temperature: Max. 40 °C

Medium temperature: See table

Continuous sound

pressure level: 70 dBA

Flange:

Suction nozzle: From DN 50 to DN 200, PN 40

Discharge

nozzle: From DN 32 to DN 150, PN 40

BS and ANSI flanges possible

Drive unit:

GH: 50 and 60 Hz electric motor, diesel

motor or turbine

GV: Electric motor with IEC flange, V1 con-

figuration or hydraulic motor with special flange

3.5 Operating point

In order to reach the required operating point,

it may be necessary to fit the pump with two

different sizes of impeller blade. For this reason, please provide the impeller blade diameter or position on the shaft when ordering

spare parts (1st, 2nd impeller, etc., beginning

at the suction side of the pump).

Please always indicate the pump type and

order number when ordering spare parts, or in

the event of any queries.

3.6 Minimum output rates

Pump temperature

range

Minimum output rate

at design point

–10 to +100 °C 15% of Qopt

+100 to +140°C 20% of Qopt

Table 6: Minimum output rates with closed

shut-off valve

3 Layout and function

14 GH/GV High-Pressure Centrifugal Pump

3.7 Functional and operating elements

Shaft wearing sleeve:

Shaft wearing sleeve GH GV

Uncooled gland packing Up to 110 °C Up to 100 °C

Cooled gland packing (cooling units) From 110 °C to 160 °C -

Uncooled mechanical seal Up to 120 °C Up to 120 °C

Cooled mechanical seal Up to 160 °C -

Table 7: Maximum authorized operating temperature and pressure at the shaft seal

The pumps can be fitted with gland packing or

mechanical seal as required.

Gland packing consists of a number of compression-molded rings in a stuffing box. Gland

packings can be adjusted by hand with tools.

Figure 4: Gland packing

Mechanical seals are mechanical shaft seals

with internal flushing of the rotating seal rings

(self-adjusting).

Figure 5: Mechanical seal

The technical dry running properties of gland

packing and mechanical seals are extremely

limited. For this reason, avoid dry running.

Ensure that the pump is vented before commissioning.

Casings:

Max. operating temperature and pressure:

Loading...

Loading...