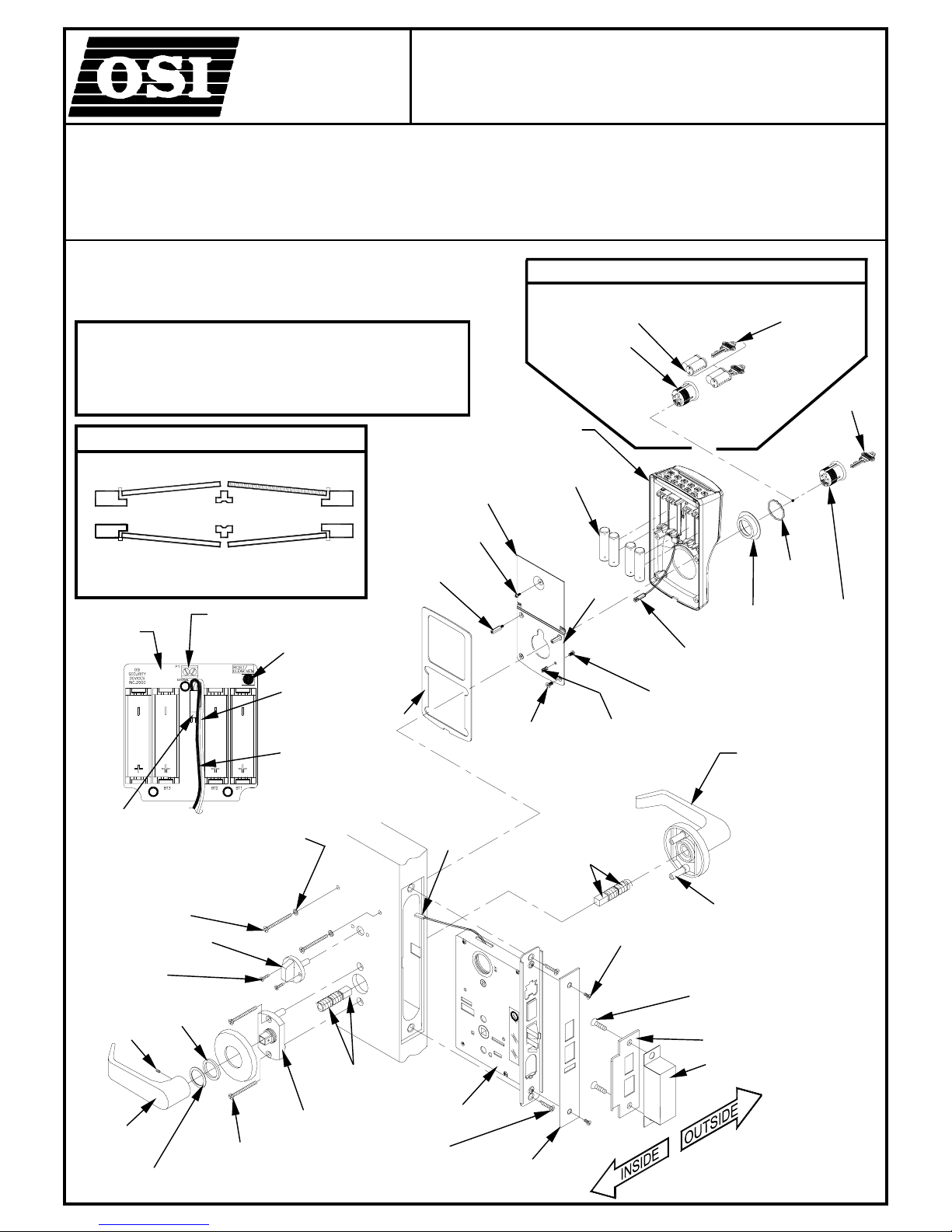

OSI Security Devices OMNILOCK OM100, OMNILOCK OM500, OMNILOCK OM300 Installation Instructions Manual

DEVICES

FOR USE WITH THIS PRODUCT.

BOX

THUMB TURN

WITH CAM

ASSEMBLY

KEY

GROUND

ELECTRONICS MODULE

SPINDLE & SPRING

3/4” THICK

DOOR (2

-

REQD)

INNER INSERT

ASSEMBLY

PG. 1 OF 8

AND OM500 SERIES

SCREW

DOOR HANDLING

RIGHT HAND SHOWN

DOOR HAND DETERMIN

ED FROM OUTSIDE

HAND

RIGHT

RIGHT HAND

LEFT HAND

SECURITY

OMNILOCK

INSTALLATION INSTRUCTIONS FOR OM100, OM300,

ACCESS CONTROL SYSTEMS

LOCKSETS USING FALCON

WARNING: THIS PRODUCT IS NOT WARRANTED FOR

OUTDOORS USE!

NOTE: A DOOR-CLOSER IS HIGHLY RECOMMENDED

THIS PRODUCT IS NORMALLY FACTORY-PACKED

FOR RIGHT-HAND 1-3/4” TO 2” THICK DOORS.

TO CHANGE HAND OF LOCK, SEE

LEFT

REVERSE

BEVEL

CPU PC

BOARD

ASSEMBLY

MOTOR

CONNECTOR

SCREW, PAN HEAD TORX

#8-32X1-1/2” FOR 2” THICK DOOR

#8-32X1-1/4” FOR 1-

SCREW, FLAT

HEAD #6X1/2”

(2-REQD)

SET

INSTRUCTION SECTION 2.

INSIDE

OUTSIDE

INSIDE

OUTSIDE

TERMINAL BLOCK

(FOR REMOTE SWITCH)

WASHER

COLLAR

NYLON

HAND

REVERSE

BEVEL

RESET

BUTTON

RED

WIRE

BLACK

WIRE

SPINDLE & SPRING

SEMS #4-40X1/4”

STANDOFF

#8-32X1”

(2-REQD)

GASKET

™

BATTERY

COVER

PAN HEAD

LOCK

CONNECTOR

(Routes through

the slot in the

Door)

NON-WEATHERIZED, MORTISE

LM SERIES LOCKS (LEVER)

SCREWS,

FLAT HEAD

#8-32X3/8”

LG (2-REQD)

INTERCHANGEABLE CORE (I.C.)

I.C. CORE

(NOT SUPPLIED)

I.C. CYLINDER

WITH CA M

HOUSING

AA ALKALINE

BATTERY, 1.5V

(4-REQD)

U

L

ELECTRONIC AL LY CONT R O LLE D

SINGLE POIN T LOCK OR LATCH

BACK

PLATE

SPRING

ASSEMBLY

SCREW

FLAT HEAD

#8X2-1/4”

(2-REQD)

SCREW

PAN HEAD

#6-32X1/4”

SCREW

FLAT HEAD

#12 X 1”

(2-REQD)

CONTROL KEY

(NOT SUPPLIED)

CYLINDER

COLLAR

CONNECTOR

OUTER TRIM

ASSEMBLY

SCREW

POST

STRIKE

STRIKE

WAVY

WASHER

CYLINDER

INSIDE

LEVER

SCREW, FLAT

WASHER

HEAD #10-32 X 2”

(2 REQD)

ASSEMBLY

LOCK

SCREW

FLAT HEAD

#12 X 1” (2-REQD)

FACE

PLATE

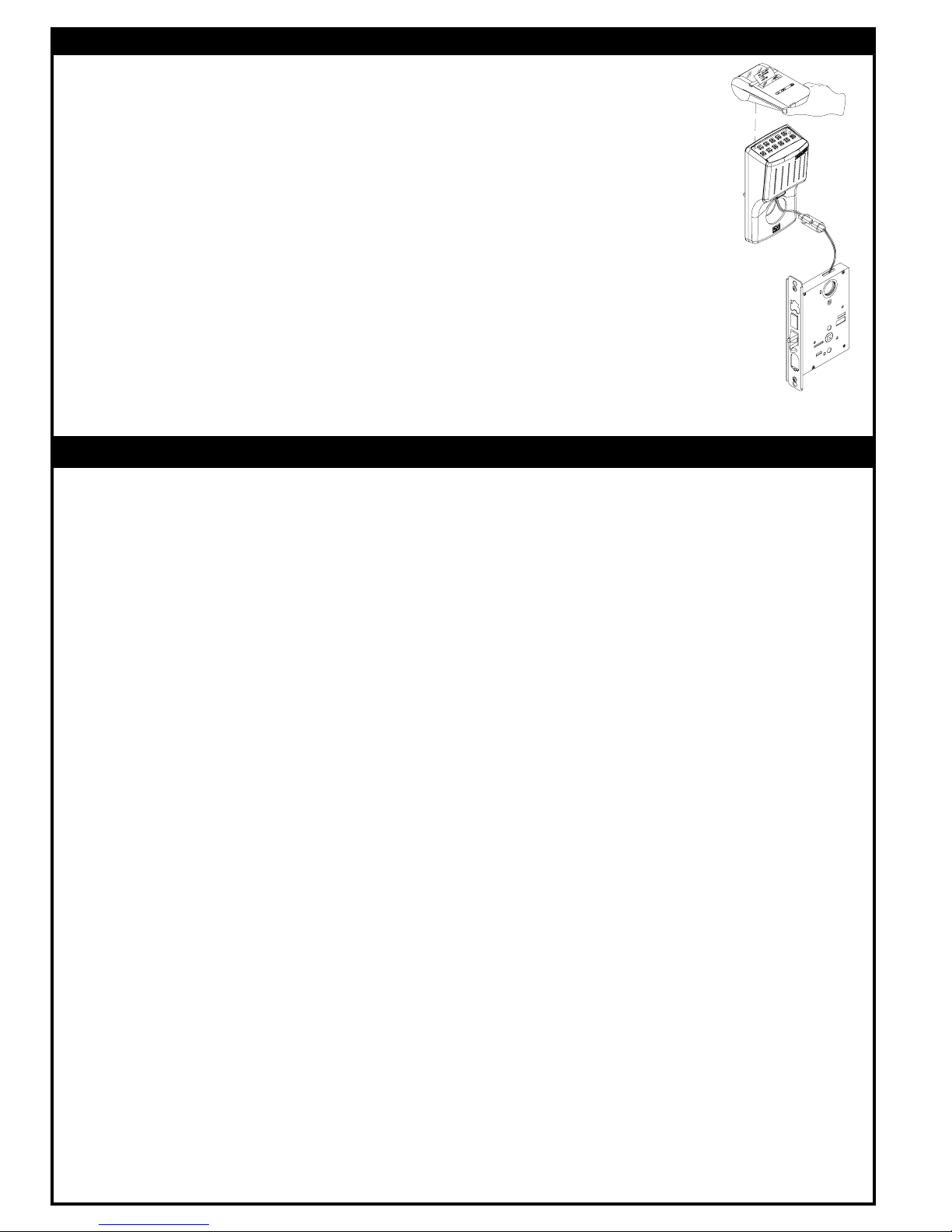

SECTION 1: CHECK OPERATION

PG. 7 OF 8

PG. 2 OF 8

FIG.12

FIG.1

CONNECTOR

MOUNTING SCREW

(2 REQD)

CONNECTOR

WASHER

(2 REQD)

FIG.11

COLLAR

CYLINDER

a. Connect the Lock Connector to the Electronics Module Connector so that the Red Wires ar e aligne d.

b. Verify proper operation of the System by entering the Default Master Code 5011234. The System

c. Verify communication with the WP4000 Printer.

d. Disconnect the Lock Connector.

Refer to Fig.1.

will flash three times to indicate the Battery level and unlock. It will remain unlocked for approximately

5 seconds before flashing red and relocking. While unlocked, check for proper operation of the Lock

using the Outer Trim Assembly and Spindle.

1. Turn on the Printer and Position it over the Keypad so that the Infrared Port of the Printer is aligned

over the Infrared Port of the System.

2. Enter the Default Master Code 5011234 at the Keyboard and then enter 99.

3. The Printer will print some System data and then present a menu of choices.

4. Enter 0 (END) at the Keypad. The System will flash red and re-locked.

5. If the system malfunctions, remove the Battery Cover and check for proper orientation and seating

of the Batteries and Motor Connector. Also ensure that the wires are not pinched. Reset the

electronics by pressing and holding the Reset Button on the circuit board until the light on the

Keypad flashes green, approximately three to five seconds. The System will go through a self-test

and flash green 5 times. Any red flash indicates an electronics or motor problem. If all flashes are

green, repeat Steps b and c.

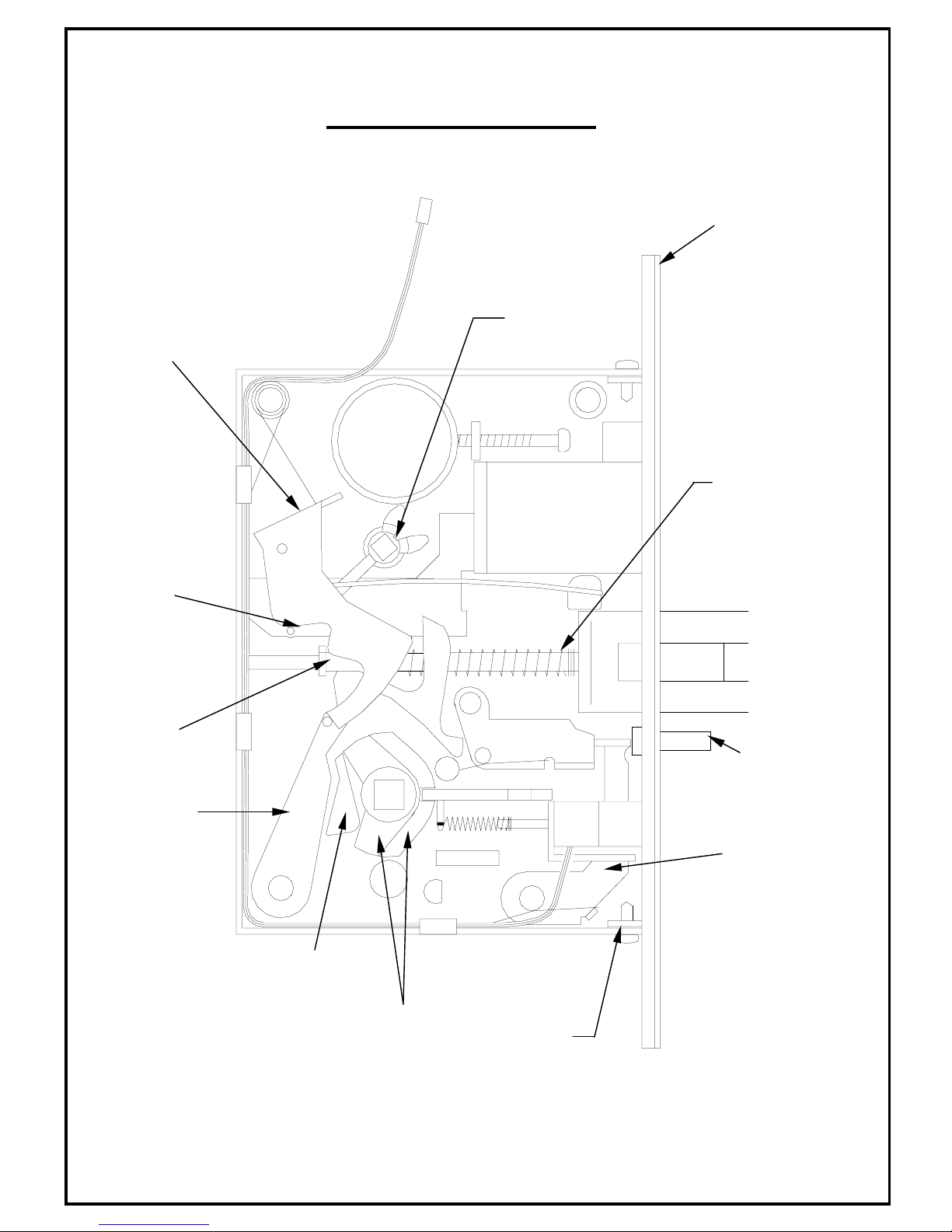

SECTION 2: ADJUST THE LOCK HAND

This section is only required if the lock hand, as received, does not meet your requirements. The Lock is normally

2-1

preset for a right hand door. Verify the hand of the Lock and if required, Change the hand of the Lock as follows, after

checking per Section 1. Refer to Fig.2.

NOTE: If the Lock has a Dead Bolt, it must be in the retracted position when reversing hand.

a. REMOVE COVER

1. Remove the four Cover Retaining Screws and slowly remove the Cover from the Case.

b. REVERSE LATCH BOLT ASSEMBLY

1. Lift out the Cylinder Retract Lever, if included.

2. Lift out the Upper Retract Arm, if included.

3. Compress the Latch Bolt Spring toward the Face Plate to clear the Latch Bolt Guide Seat. Lift out and invert

the Latch Bolt Assembly. Place the Latch Bolt Spring into the Latch Bolt Guide Seat.

NOTE: Lower Retract Arm (below the Upper Retract Arm) must be between the Latch Bolt Foot and the Latch Bolt Guide.

c. REVERSE HUBS

1. To reverse, pull the Coupling toward the rear of the Case.

2. Lift out both Hubs together, invert as an assembly and replace.

3. Ease the Coupling back against the Hubs.

d. REASSEMBLE RETRACT ARM AND LEVER

1. Replace the Upper Retract Arm so that the Arm fits into the space between the Latch Bolt Foot and the

2. Replace the Cylinder Retract Lever so that it straddles the Dead Bolt Pin.

3. Replace the Cover guiding the "T" Turn Hub into the Cover hole. Depress the Latch Bolt to clear the Foot.

NOTE: A Phillips head screwdriver inserted through the Cover into the "T" Turn Hub will retain the Hub and Cylinder Retract

Lever in proper location while replacing the Cover.

e. REPLACE THE COVER RETAINING SCREWS.

f. REVERSE DEADLOCKING BAR

1. Remove the Face Plate. Remove the Deadlocking Bar, reverse it and replace it back into the Assembly.

2. Replace the Face Plate.

NOTE: The Concave Face of the Deadlocking Bar must be on the same side of the Door as the Beveled Face on the Latch

Bolt. If this condition is not met, the Latch Bolt will be blocked from being able to be depressed as it comes into

contact with the Strike.

Coupling.

(Push against Blocker Assembly to allow Deadlocking Bar to be easily inserted)

PG. 3 OF 8

FOOT

RETRACT

ARM

COUPLING

LATCH BOLT

HUB

HUB

LOCK FRONT

SCREW

ASSEMBLY

FACE PLATE

FIG.2

LOCK ASSEMBLY

“T” TURN

CYLINDER

RETRACT

LEVER

SPRING

DEAD BOLT

PIN

DEAD LOCKING

BAR

UPPER

BLOCKER

Loading...

Loading...