O.S. engine MAX-61LX, MAX-61LX-HRING Owner's Manual

It is of vital importance, before attempting to

operate your engine, to read the general

'SAFETY INSTRUCTIONS AND WARNINGS'

section on pages 2-5 of this booklet and to strictly

adhere to the advice contained therein.

●

Also, please study the entire contents of this

instruction manual, so as to familiarize yourself

with the controls and other features of the

engine.

Keep these instructions in a safe place so that

you may readily refer to them whenever

necessary.

It is suggested that any instructions supplied

with the model, radio control equipment, etc.,

are accessible for checking at the same time.

●

●

MAX-61LX-HRING SERIES

SAFETY INSTRUCTIONS AND WARNINGS

ABOUT YOUR O.S. ENGINE

INTRODUCTION

BASIC ENGINE PARTS,

INSTALLATION

BEFORE STARTING

FACTS ABOUT GLOW PLUGS

FUEL

CARBURETTOR CONTROLS

STARTING

RUNNING-IN, SETTING UP,

ST ARTING AND ADJUSTMENT

SUBSEQUENT READJUSTMENTS

CARBURETTOR CLEANLINESS

ADJUSTING CHART

INSTALLATION OF THROTTLE SERVO

CARE AND MAINTENANCE

ENGINE EXPLODED VIEW &

PARTS LIST

CARBURETTOR EXPLODED

VIEW & PARTS LIST

THREE VIEW DRAWING

O.S. GENUINE PARTS & ACCESSORIES

CONTENTS

2~5

6

7

~

8

8

~

10

10

~

11

12

13

~

14

18

18

20

22~23

24

25

15

~

17

19

26

21

1

Remember that your engine is not a "toy", but a highly efficient internalcombustion machine whose power is capable of harming you, or others, if it is

misused.

As owner, you, alone, are responsible for the safe operation of your engine, so act

with discretion and care at all times.

If at some future date, your O.S. engine is acquired by another person, we would

respectfully request that these instructions are also passed on to its new owner.

SAFETY INSTRUCTIONS AND WARNINGS ABOUT YOUR O.S. ENGINE

The advice which follows is grouped under two headings according to the

degree of damage or danger which might arise through misuse or neglect.

WARNINGS

NOTES

These cover events which

might involve serious (in

extreme circumstances, even

fatal) injury.

These cover the many other

possibilities, generally less obvious

sources of danger, but which, under

certain circumstances, may also

cause damage or injury.

2

WARNINGS

•

•

•

•

•

Never touch, or allow any

object to come into contact

with, the rotating parts.

Model engine fuel is poisonous. Do not allow it to come

into contact with the eyes or

mouth. Always store it in a

clearly marked container and

out of the reach of children.

Model engine fuel is also

highly flammable. Keep it

away from open flame,

excessive heat, sources of

sparks, or anything else which

might ignite it. Do not smoke

or allow anyone else to smoke,

near to it.

Model engines generate

considerable heat. Do not

touch any part of your

engine until it has cooled.

Contact with the muffler

(silencer), cylinder head or

exhaust header pipe, in

particular, may result in a

serious burn.

Never operate your engine in an enclosed space. Model engines, like automobile engines, exhaust deadly carbonmonoxide. Run your engine only in an

open area.

3

NOTES

•

•

•

•

•

These engine were designed for model

helicopters. Do not attempt to use it for any

other purpose.

Mount the engine in your model securely, following the manufacturers' recommendations,

using appropriate screws and locknuts.

Install an effective silencer (muffler). Frequent

close exposure to a noisy exhaust (especially

in the case of the more powerful high-speed

engines) may eventually impair your hearing

and such noise is also likely to cause

annoyance to others over a wide area.

Check the linkage to the throttle arm before

each flight.

Avoid sudden high r.p.m. immediately after the

engine is started, as the clutch will engage and

you may be struck by the rotor.

•

•

After starting the engine, carry out any needlevalve readjustments after stopping the rotor by

closing the throttle to the lowest r.p.m..

Stop the engine before attempting to make

other adjustments to the carburetor.

Use an electric starter. The wearing of safety

glasses is also strongly recommended.

Press the rotor head down securely.

Take care that the glow plug clip or battery

leads do not come into contact with rotating

parts.

Adjust the throttle linkage so that the engine

stops when the throttle stick and trim lever on

the transmitter are fully retarded. Alternatively,

the engine may be stopped by cutting off the

fuel supply. Never try to stop the engine

physically.

•

•

4

NOTES

•

•

•

Take care that loose clothing (ties, shirt sleeves,

scarves etc.) do not come into contact with the

rotor. Do not carry loose objects (such as pencils, screwdrivers, etc.) in a shirt pocket from

where they could fall through the rotor disc.

For their safety, keep all onlookers (especially

small children) well back (at least 20 feet or 6

metres) when preparing your model for flight. If

you have to carry the model to the take-off point

with the engine running, be especially cautious.

Hold the rotor securely and keep well clear of

spectators.

Warning! lmmediately after a glowplug-ignition

engine has been run and is still warm,

conditions sometimes exist whereby it is just

possible for the engine to restart when turned

over WITHOUT the glowplug battery being

reconnected. Remember this if you wish to

avoid the risk of accidents.

5

Because of this initial tightness, a

standard electric starter may have

difficulty in rotating the engine when

cold, before it has been adequately

run-in. In this case, use a high-torque

type starter.

DO NOT, however, confuse tightness

with the symptoms of hydraulic lock

caused by an excess of fuel within the

cylinder - often the result of overpriming.

Attempting to force the engine to turn

over in this condition may cause

internal damage. Instead, remove the

glowplug, invert the engine and eject

surplus fuel from the combustionchamber.

Note:

The ringed-piston MAX-61LX-H, MAX61LX-HG(R) and MAX-61LX-HGL are highperformance, high-quality engines that

have been developed specifically for

radio-controlled 60 class helicopters.

They are ideal for scale and sport flyers,

for newcomers to 60 class helicopters and

for contest flyers' first-line or reserve

models.

These motors are produced by the world's

oldest and largest model engine design

and manufacturing company, a company

that has built more helicopter engines

than any other manufacturer worldwide.

INTRODUCTION

6

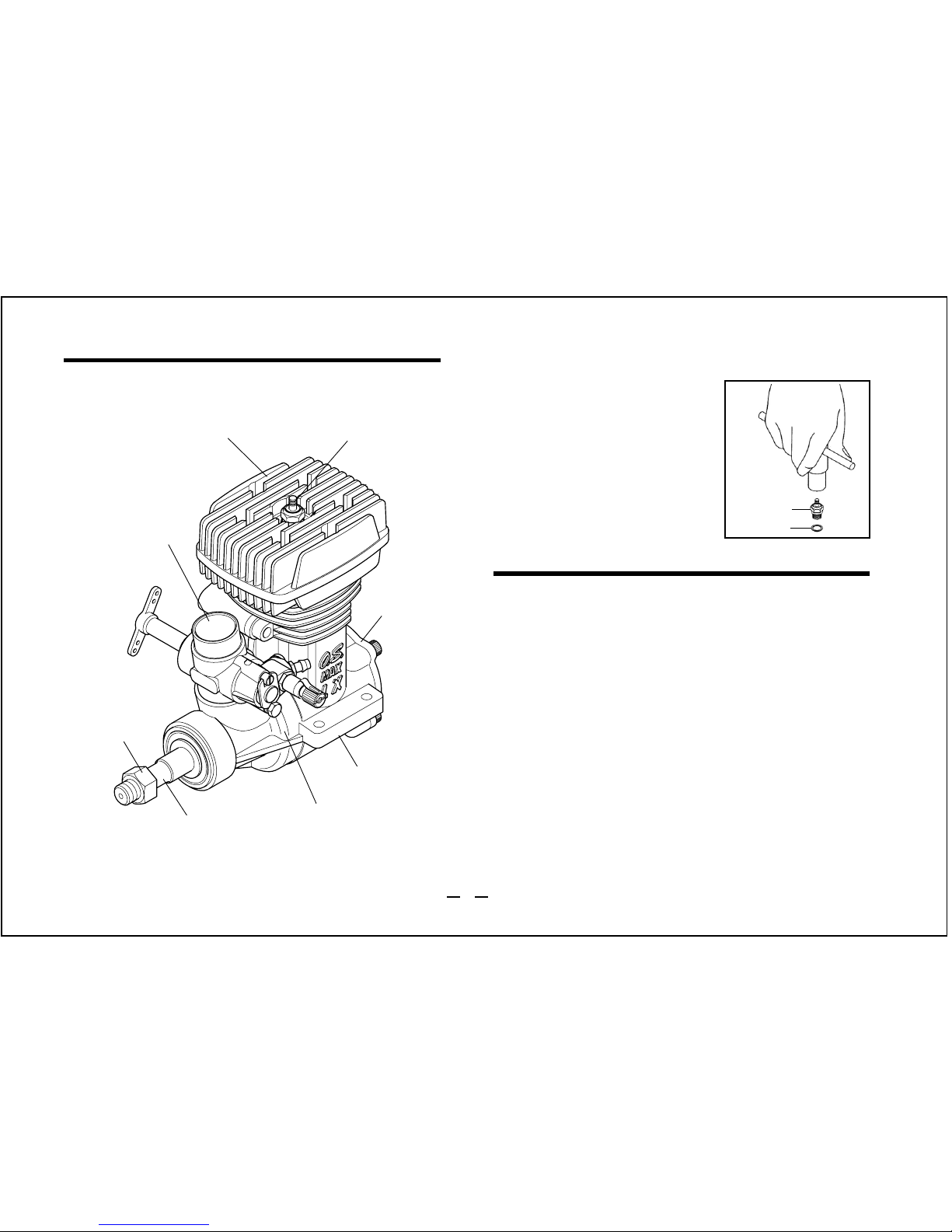

BASIC ENGINE PARTS

Heatsink Head

Carburettor

Crankshaft

Propeller nut

Crankcase

Glowplug

Mounting Lugs

INSTALLING THE GLOWPLUG

Install the washer on the

glowplug and screw

carefully into cylinderhead, making sure that it

is not cross-threaded

before tightening firmly.

Glow plug

Washer

INSTALLATION OF THE ENGINE

The under-surfaces of all O.S. engine beam

mounting lugs are precision machined flat and

exactyly parallel to the engine's horizontal axis. It is

essential that the engine mounts in the model are

also accurately made and aligned. If they are not,

they will cause stress and distortion within the engine

itself, probably resulting in loss of performance and

internal damage.

The recommended screws for securing the engine to

the engine mounts in the model are 4mm or 6-32 NC

steel Allen type. It is also advisable to use lock

washers or LOCTITE to prevent nuts from loosening.

Cover Plate

7

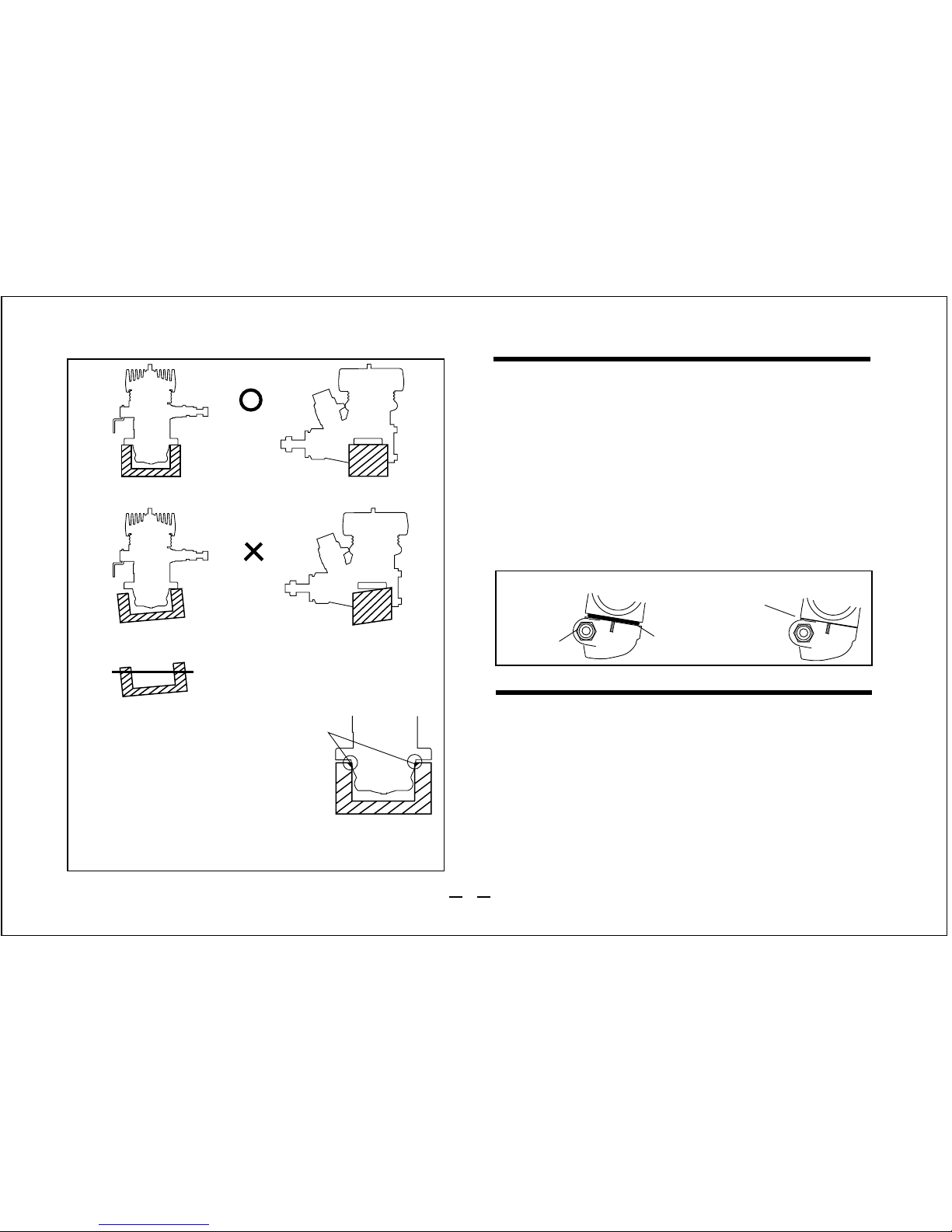

Front view

CORRECT

Side view

Top surfaces are in the same plane.

Re-align the surfaces as necessary

INCORRECT

Top surfaces are not

in the same plane.

Top surfaces are not in the

same plane.

Engine does not rest firmly.

BEFORE STARTING

Tools, accessories, etc.

The following items are necessary for operating the

engine.

1 Fuel

Model glowplug engine fuel of good quality, preferably

containing a small percentage of nitromethane.

Make sure that only the under-surfaces

of the engine’s mounting lugs are in

contact with the engine mount.

If the crankcase body touches the

mount, chamfer the edges of the mount.

As delivered, the engine has its carburetor lightly

fitted into its intake boss. Secure it as follows.

INSTALLATION OF THE CARBURETOR

Retainer

nut

Carburetor Rubber

Gasket

0.2mm gap

Loosen the retainer nut, rotate the carburetor to its

correct position and press it well down into the

intake boss, compressing the rubber gasket as

shown in the sketch, before re-tightening screw.

Rotate the retainer nut gently until it stops, then

tighten a further 90-120 degrees.

1.

2.

8

Loading...

Loading...