O.S. engine MAX-12TG-P, MAX-12TG, MAX-12TG-X, MAX-12TG-PX Instruction Manual

It is of vital importance, before attempting to operate

your eng ine, to read the gene ral 'SA FETY

INSTRUCTIONS AND WARNINGS' section on

pages 2-5 of this booklet and to strictly adhere to the

advice contained therein.

Also, please study the entire contents of this

instruction manual, so as to familiarize yourself

with the controls and other features of the engine.

Keep these instructions in a safe place so that you

may readily refer to them whenever necessary.

It is suggested that any instructions supplied with

the vehicle, radio control equipment, etc., are

accessible for checking at the same time.

JAPAN

1

2-5

6-7

8

9

10-11

12

13-15

16

17

18-19

20-26

27-30

31-34

35-37

38-45

46-49

50-52

53-56

CONTENTS

SAFETY INSTRUCTIONS AND

WARNINGS ABOUT YOUR O.S. ENGINE

ENGINE CONSTRUCTION, NOTES WHEN

APPLYING AN ELECTRIC STARTER

INSTRUCTIONS

BASIC ENGINE PARTS

TOOLS, ACCESSORIES, etc.

STANDARD ACCESSORIES

CARBURETOR CONTROLS,

INSTALLATION OF THE CARBURETOR

NOTES CONCERNING THE RECOIL STARTER

GLOWPLUG

ENGINE INSTALLATION

STARTING THE ENGINE &

RUNNING-IN ('Breaking-in)

FINAL ADJUSTMENT

TROUBLE SHOOTING

CARE AND MAINTENANCE

EXPLODED ENGINES VIEWS &

PARTS LIST

CARBURETOR EXPLODED VIEW &

PARTS LIST

O.S. GENUINE PARTS & ACCESSORIES

THREE VIEW DRAWING

2

!

!

Remember that your engine is not a "toy", but a highly efficient internalcombustion machine whose power is capable of harming you, or others, if it is

misused. As owner, you, alone, are responsible for the safe operation of your

engine, so act with discretion and care at all times.

If at some future date, your O.S. engine is acquired by another person, we would

respectfully request that these instructions are also passed on to its new owner.

SAFETY INSTRUCTIONS AND WARNINGS ABOUT YOUR O.S. ENGINE

The advice which follows applies basically to ALL MODEL ENGINES and is

grouped under two headings according to the degree of damage or danger

which might arise through misuse or neglect.

WARNINGS

NOTES

These cover events which might involve

serious (in extreme circumstances, even

fatal) injury.

These cover the many other possibilities,

generally less obvious sources of danger,

but which, under certain circumstances,

may also cause damage or injury.

3

!

WARNINGS

Model engine fuel is poisonous. Do not allow it to

come into contact with the

eyes or mouth. Always store

it in a clearly marked container and out of the reach

of children.

Model engine fuel is also

highly flammable. Keep it

away from an open flame,

excessive heat, sources of

sparks, or anything else

which might ignite it. Do not

smoke or allow anyone else

to smoke, near to it.

Never operate your engine in an enclosed space. Model engines, like

automobile engines, exhaust deadly

carbon-monoxide. Run your engine

only in an open area.

Model engines generate

considerable heat. Do not

touch any part of your

engine until it has cooled.

Contact with the muffler

(silencer), cylinder head

or exhaust header pipe, in

particular, may result in a

serious burn.

•

•

•

•

4

!

NOTES

Before starting the engine, always check

the tightness of all the screws and nuts

especially those of joint and movable

parts such as throttle arm. Missing

retightening the loose screws and nuts

often causes the parts breakage that is

capable of harming you.

This engine is intended for model cars.

Do not attempt to use it for any other

purpose.

Mount the engine in your model

securely, following the manufacturer's

recommendations, using appropriate

screws and locknuts.

Install an effective silencer (muffler).

Frequent close exposure to a noisy

exhaust (especially in the case of the

more powerful highspeed engines) may

eventually impair your hearing and such

noise is also likely to cause annoyance

to others over a wide area.

The wearing of safety glasses is also

strongly recommended.

Take care that the glowplug clip or

battery leads do not come into contact

with rotating parts. Also check that the

linkage to the throttle arm is secure.

For their safety, keep all onlookers

(especially small children) well back (at

least 20 feet or 6 meters) when

preparing your model for running.

5

!

NOTES

To stop the engine, fully retard the

throttle stick and trim lever on the transmitter, or, in an emergency, cut off the

fuel supply by pinching the fuel delivery

line from the tank.

Warning! Immediately after a glowplugignition engine has been run and is still

warm, conditi ons s ometimes exist

whereby it is just possible for the engine to

abruptly restart if it is rotated over

compression WITHOUT the glowplug

battery being reconnected.

Pull the operating handle straight out

when starting the engine, so that the cord

does not rub against the vehicle body or

engine. This will help prevent the cord

from being damaged by abrasion or

engine heat.

Do not extend the starter cord more than

40cm (16"). Do not abruptly release the

operating handle. Allow the cord to

rewind smoothly while still holding the

handle.

Do not attempt to disassemble the recoil

starter of the 12TG-X and 12TG-PX.

If you do so, the very strong spring inside

will be suddenly ejected. This can be

very dangerous.

6

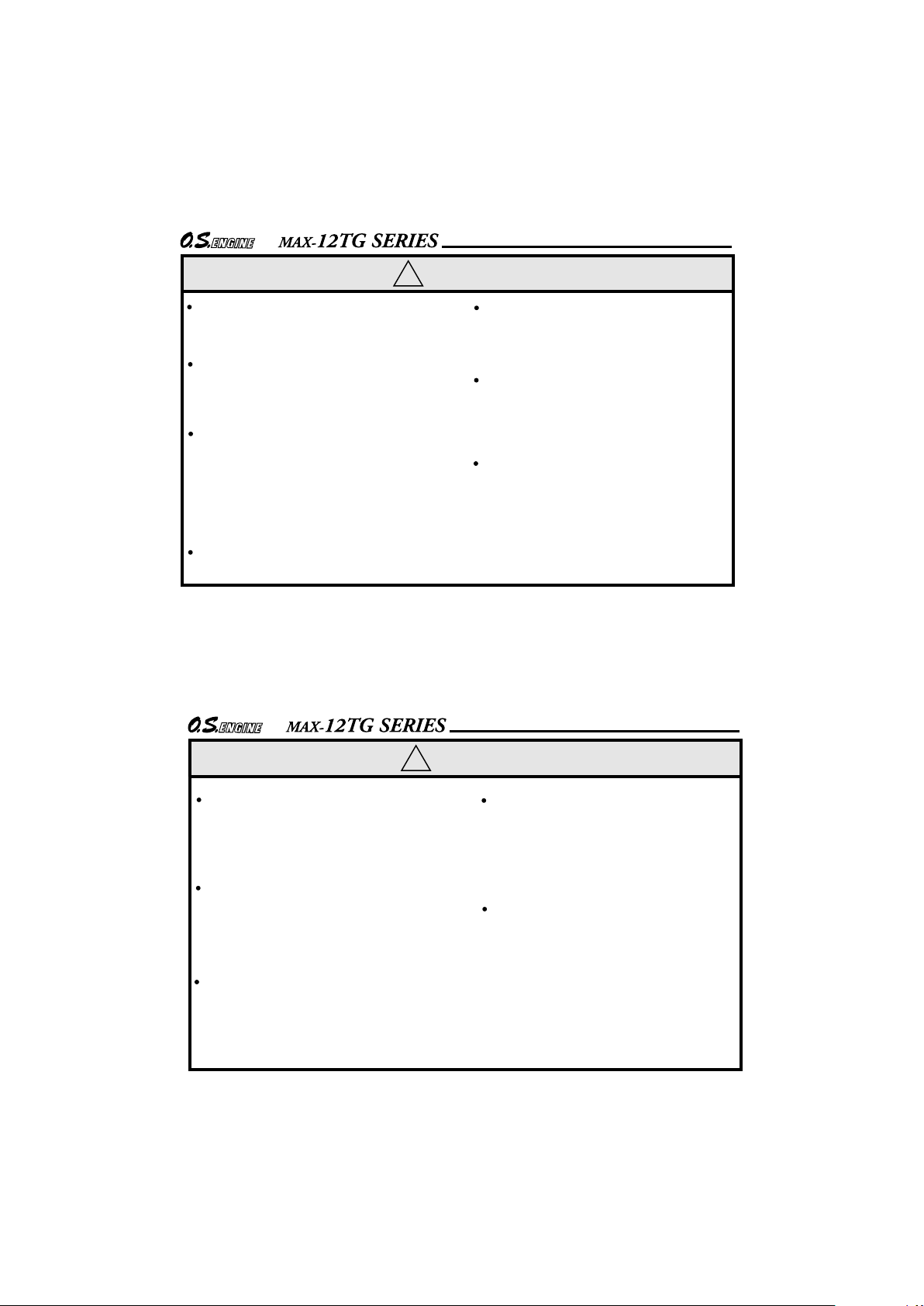

Piston

Cylinder Liner

Crankshaft

ENGINE CONSTRUCTION

With this engine, the piston

will feel tight at the top of its

stroke (TDC) when the engine

is cold. This is normal. The

cylinder bore has a slight

taper. The piston and cylinder

are designed to achieve a

perfect running clearance

when they reach operating

temperature.

Near TDC

Slight taper

When the engine is cold.

When the engine is hot.

7

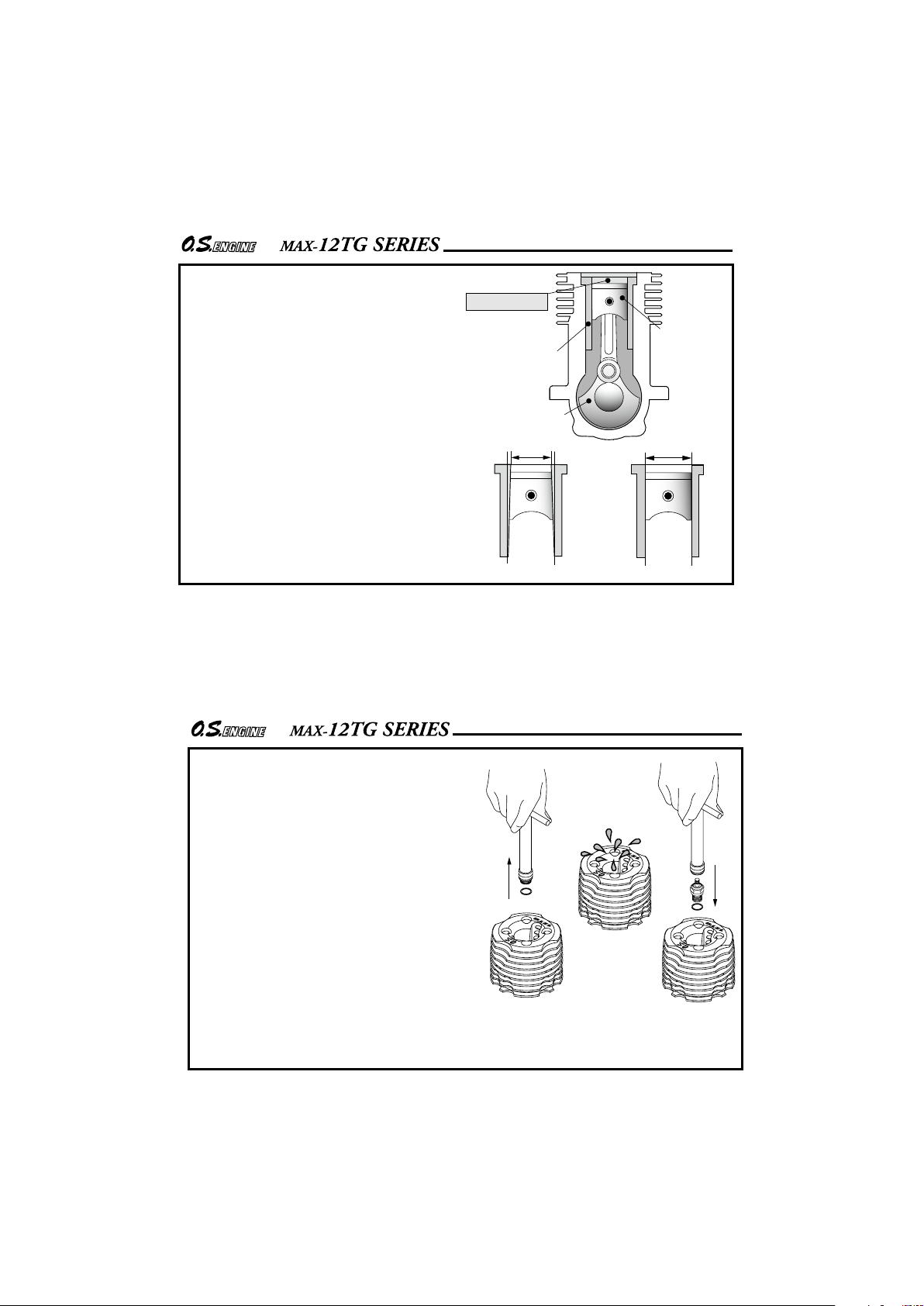

NOTES WHEN APPLYING

AN ELECTRIC STARTER

Do not over-prime. This could

cause a hydraulic lock and damage

the engine on application of the

electric starter.

If over-primed, remove glowplug,

close needle-valve and apply

starter to pump out surplus fuel.

Cover the head with a rag to

prevent any pumped out fuel from

getting into your eyes.

Remove the glowplug.

Pump out surplus fuel.

Install the glowplug.

8

This manual handles the following five

versions.

MAX-12TG SERIES INSTRUCTIONS

NOTE

As delivered, the engine has its

carburetor lightly fit into its intake.

Secure it according to the INSTALLATION

OF THE CARBURETOR section.

MAX-12TG

with 12E carburetor

MAX-12TG-X

with 12E carburetor

MAX-

12TG-P

with 12D carburetor

MAX-

12TG-PX

with 12D carburetor

The 12TG Series engines are developed for

1/10 scale R/C cars. They are rear exhaust

engines designed for sport use.

For easier handling, the engines are

equipped with a newly designed 12E or 12D

carburetor. An O.S. No.8 glowplug is also

supplied with the engines. The 12E and 12D

engines have mild and smooth accelerating

characteristics most suitable for sport

running. Recoil starter incorporated

versions which eliminate the need for a

separate electric starter and starter battery

are also available.

MAX-12TG-P

with 12E carburetor

9

MAX-12TG-PX

MAX-12TG

Heatsink Head

Crankcase

Mounting Lugs

Exhaust

Cover Plate

Carburetor

Type 12E

Crankshaft

BASIC ENGINE PARTS

Heatsink Head

Drive Hub

Carburetor

Type 12D

Crankshaft

Crankcase

Mounting Lugs

Exhaust

Starter Handle

Recoil Starter

Assembly No.N1

Rear Adaptor

10

Items necessary for starting

TOOLS, ACCESSORIES, etc.

The following items are necessary for operating the

engine.

FUEL

Generally, it is suggested that the user selects a fuel

that is commercially available for model two-stroke

engines and contains 10-30% nitromethane.

As a starting point, we recommend a fuel containing

20% nitromethane, changing to a fuel containing more

nitro if necessary. When the brand of fuel is changed,

or the nitro content increased, it is advisable to repeat

the running-in procedure referred to in the RUNNINGIN paragraphs.

Please note that with high-nitro fuels,

although power may be increased for

com pe tition purposes , glow pl ug

elements do not last as long and

engine life will be shorter.

!

REMINDER!

Model engine fuel is poisonous. Do not

allow it to come into contact with the eyes

or mouth. Always store it in a clearly

marked container and out of the reach of

children.

!

Model engine fuel is also highly flammable.

Keep it away from open flame, excessive

heat, sources of sparks, or anything else

which might ignite it. Do not smoke or allow

anyone else to smoke, near to it.

GLOWPLUG IGNITER

Commercialy available handy

glowplug heater in which the

glowplug battery and battery leads

are integrated.

11

FUEL PUMP

For filling the fuel tank, a simple, polyethylene "squeeze" bottle, with a suitable spout, is required.

FUEL FILTER

To be installed in the fuel line between

fuel tank and carburetor to prevent

foreign matter from entering the

carburetor.

STARTER BOX

For starting the engine.

It is not necessary for 12TG-X

and 12TG-PX.

SILICONE FUEL LINE

Heatproof silicone tubing of approx.

5mm o.d. and 2mm i.d. is required for

the connection between the fuel tank

and engine.

TOOLS

HEX SCREWDRIVER

SCREWDRIVER

Necessary for engine installation.

1.5mm, 2mm, 2.5mm, 3mm

Necessary for carburetor adjustments.

No.1, No.2, etc

LONG SOCKET WRENCH WITH PLUG GRIP

Recommended for easy removal and replacement of

the angled and recessed glowplug, the O.S.Long

Socket Wrench incorporates a special grip.

12

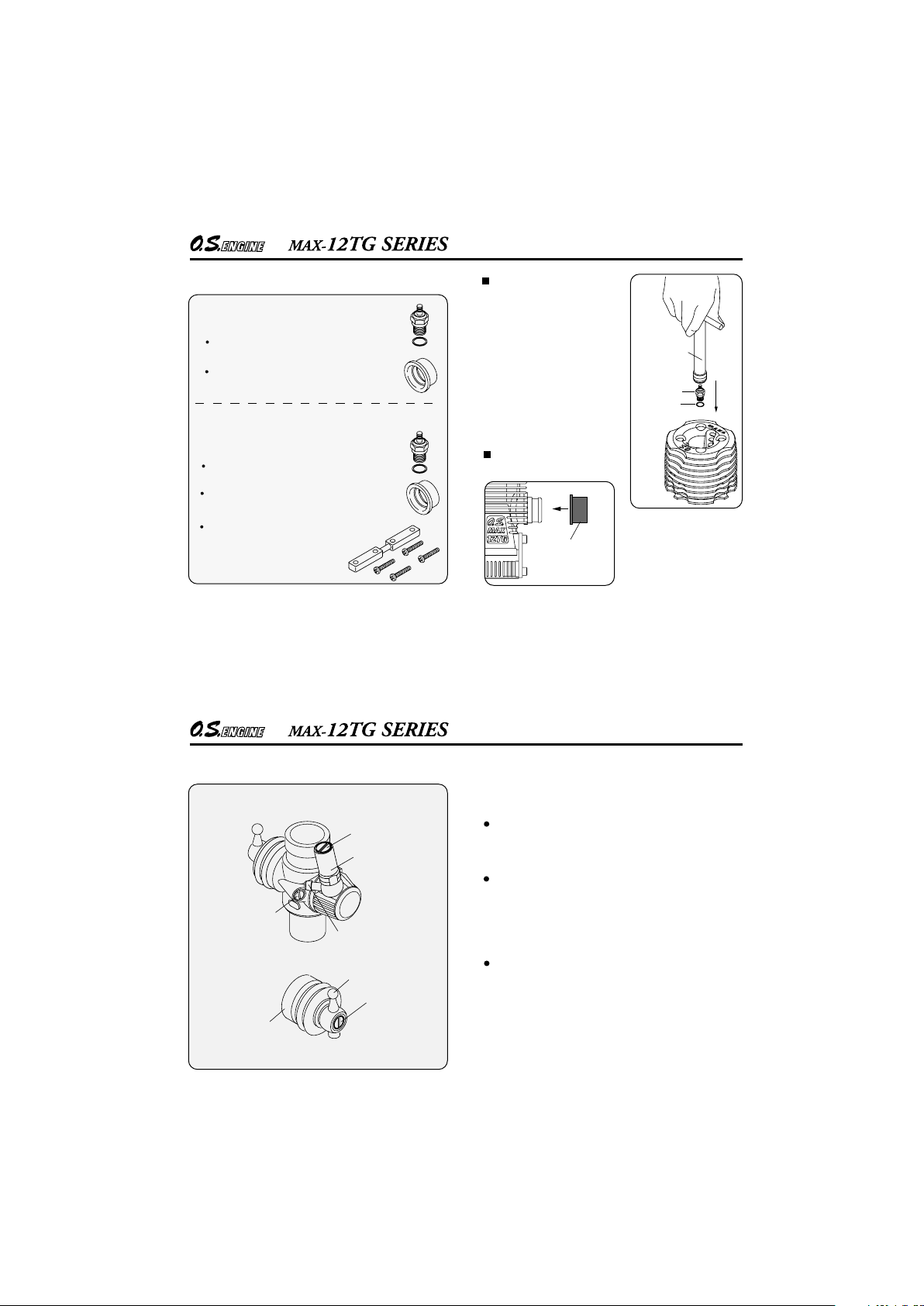

MAX-

12TG,

MAX-

12TG-P

Standard accessories

Engine Mount Spacer 1piece

Glow Plug No.8 1piece

Exhaust Seal Ring 1piece

MAX-12TG-X, MAX-12TG-PX

Glow Plug No.8 1piece

Exhaust Seal Ring 1piece

INSTALLING THE

GLOWPLUG

Fit washer to glowplug and

insert carefully into cylinderhead, making sure that it is

not cross-threaded before

tightening firmly.

Install the exhaust seal

ring supplied.

Exhaust

Seal Ring

Glowplug

Socket

Wrench

Washer

Use it when the engine interferes

with the car chassis.

13

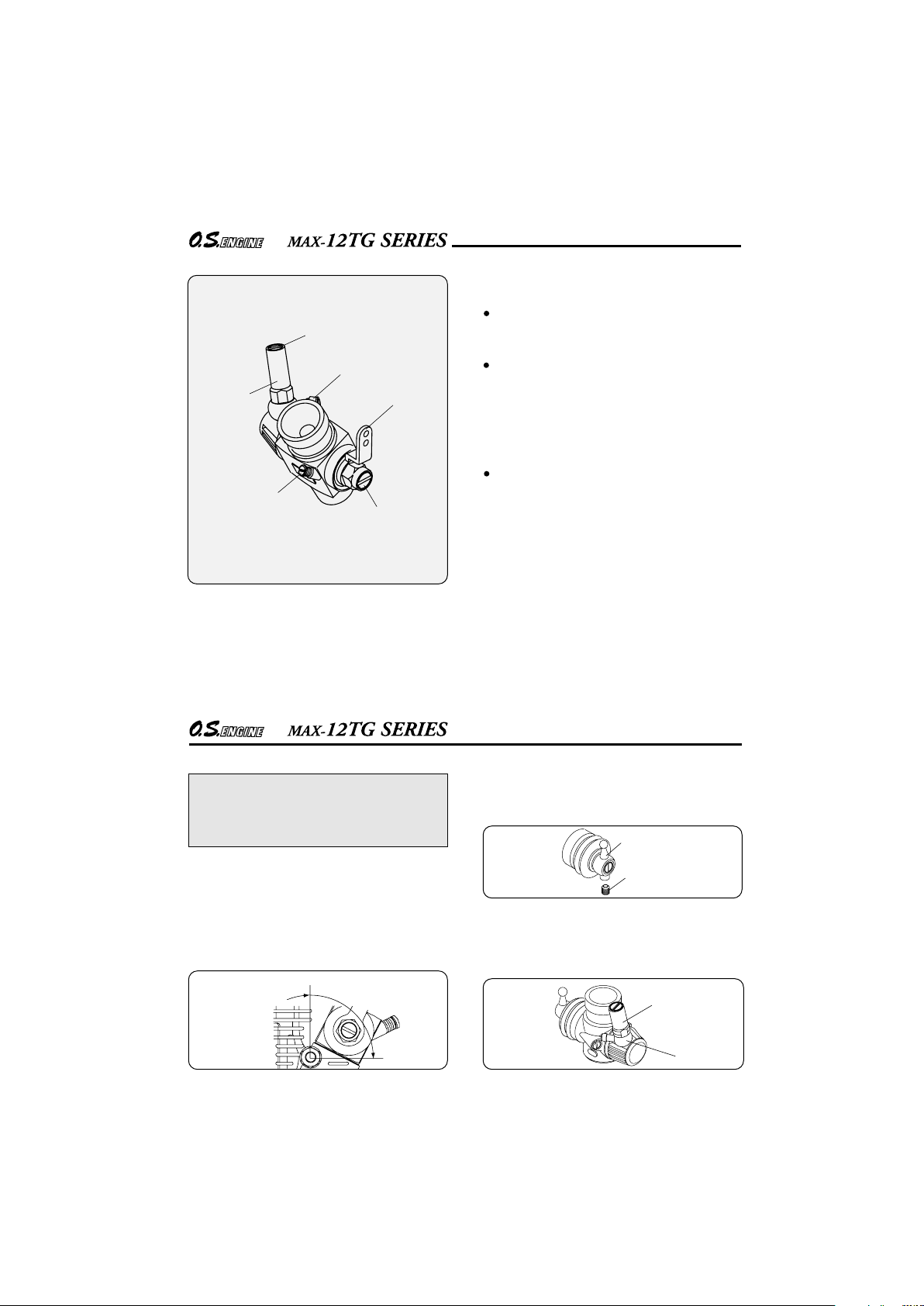

CARBURETOR CONTROLS

The Needle-Valve(Adjusted at the factory):

Three adjustable controls are provided on this

carburetor.

For adjusting the mixture strength when the throttle

is fully open.

The Throttle Stop Screw

(Adjusted at the factory):

For setting the minimum idle speed:

For adjusting the mixture strength at part-throttle

and idle speed, to obtain steady idling and smooth

acceleration to mid speed.

The Metering Needle

(Adjusted at the factory):

NOTE : Readjustment may b e n ecessary,

occasionally to allow for changes in fuel formula,

gear ratio or clutch engagement point.

Metering Needle

Throttle Stop

Screw

Needle Valve

Ball Link No.5

Dust Cover

Carburetor Type 12D

Fuel Inlet

Needle Holder

14

Carburetor Type 12E

Mixture Control Screw

Throttle

Stop Screw

Needle Valve

Needle Holder

Fuel Inlet

Throttle Lever

The Needle-Valve(Adjusted at the factory):

Three adjustable controls are provided on this

carburetor.

For adjusting the mixture strength when the throttle

is fully open.

The Throttle Stop Screw

(Adjusted at the factory):

For setting the minimum idle speed:

For adjusting the mixture strength at part-throttle

and idle speed, to obtain steady idling and smooth

acceleration to mid speed.

The Mixture Control Screw

(Adjusted at the factory):

NOTE : Readjustment may b e n ecessary,

occasionally to allow for changes in fuel formula,

gear ratio or clutch engagement point.

(It should be screwed in or out less tan one turn.)

15

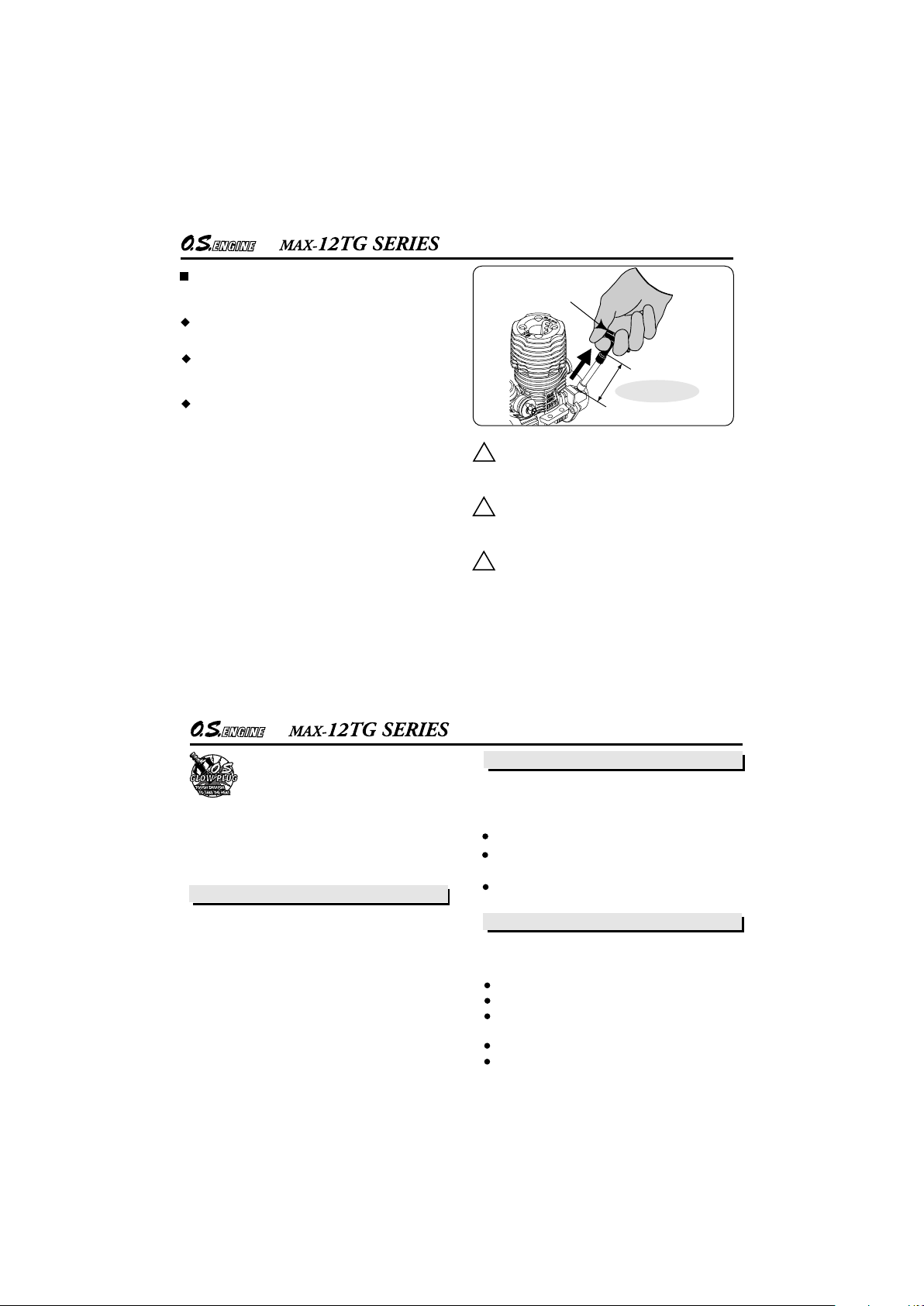

INSTALLATION OF THE CARBURETOR

As delivered, the engine has its carburetor lightly fit into

the intake boss. Secure it as follows.

Rotate the retainer screw gently until it stops, then

tighten a further 60-90˚. Do not overtighten the

screw as this will damage the carburetor body.

1.

Rotate the retainer nut

gently until it stops.

Tighten a further 60-90˚

Fuel Inlet

Needle

Holder

Ball Link

Retaining Screw

Loosen the retainer screw, rotate the carburetor to

its correct position and make sure that it is

pressed well down into the intake boss,

compressin g the rubb er ga sket, before

retightening the screw.

NOTE

As delivered, the engine has its carburetor

lightly fit into its intake. Secure it changing its

angle according to the car chassis.

2.

When changing the ball link direction, loosen the

retaining screw with a 1.5mm Hex wrench.

After changed the fuel inlet direction, tighten the

needle holder slowly and gently until it stops. Then,

tighten 45~60 degrees further. Do not tighten further

or the fuel inlet will be distorted, which may result in

fuel leaking.

16

!

!

!

◆

NOTES CONCERNING THE RECOIL STARTER

REMINDER!

Do not attempt to disassemble the recoil

starter. If you do so, the very strong spring

inside will be suddenly ejected. This can be

very dangerous.

Do not extend the starter cord more than

40cm (1 6"). Do not abruptl y rele ase the

operating handle. Allow the cord to rewind

smoothly while still holding the handle.

Pull the operating handle straight out when

starting the engine, so that the cord does not

rub against the vehicle body or engine.

This will help prevent the cord from being damaged

by abrasion or engine heat.

Try to avoid spilling fuel over the starter unit and its

cord. Some fuels have a detrimental effect on these

parts.

The starter prevents the engine from being rotated

in the wrong direction.The unit will be damaged if you

attempt to force the flywheel in the opposite direction (i.e. clockwise when viewed from the crankshaft

end).

Starter Handle

16" 40cm MAX!

It is suspected that the engine is over-primed when

the pulling load is too heavy to pull the starter. In this

case, refer to page 7 and TROUBLE SHOOTING

about over priming.

17

GLOWPLUG

The role of the glowplug

Glowplug life

Particularly in the case of very high performance

engines,

glowplugs must be regarded as expendable

items. However, plug life can be extended and engine

performance maintained by careful use, i.e.:

Install a plug suitable for the engine.

Use fuel containing a moderate percentage of

nitromethane unless more is essential for racing events.

Do not run the engine too lean and do not leave the

battery connected while adjusting the needle.

With a glowplug engine, ignition is initiated by the

application of a 1.5-volt power source. When the

battery is disconnected, the heat retained within the

combustion chamber remains sufficient to keep the

plug filament glowing, thereby continuing to keep the

engine running. Ignition timing is 'automatic' : under

reduced load, allowing higher rpm, the plug becomes

hotter and, appropriately, fires the fuel/air charge

earlier; conversely, at reduced rpm, the plug become

cooler and ignition is retarded.

Apart from when actually burned out, a plug may

need to be replaced because it no longer delivers its

best performance, such as when:

When to replace the glowplug

Filament surface has roughened and turned white.

Filament coil has become distorted.

Foreign matter has adhered to filament or plug

body has corroded.

Engine tends to cut out when idling.

Starting qualities deteriorate.

Since the glowplug and fuel combination

used may have a marked effect on per-

formance and reliability, it would be

worthwhile to experiment with different plug types. An

O.S. No.8 glowplug is supplied with the engine. Recommended O.S. plugs are the No.8 and A5. Carefully

install plug finger-tight, before final tightening with the

correct size plug wrench.

Loading...

Loading...