Oseco VAPRO, VRDI Installation Instructions Manual

Installation Instructions for VAPRO Rupture Disks in VRDI

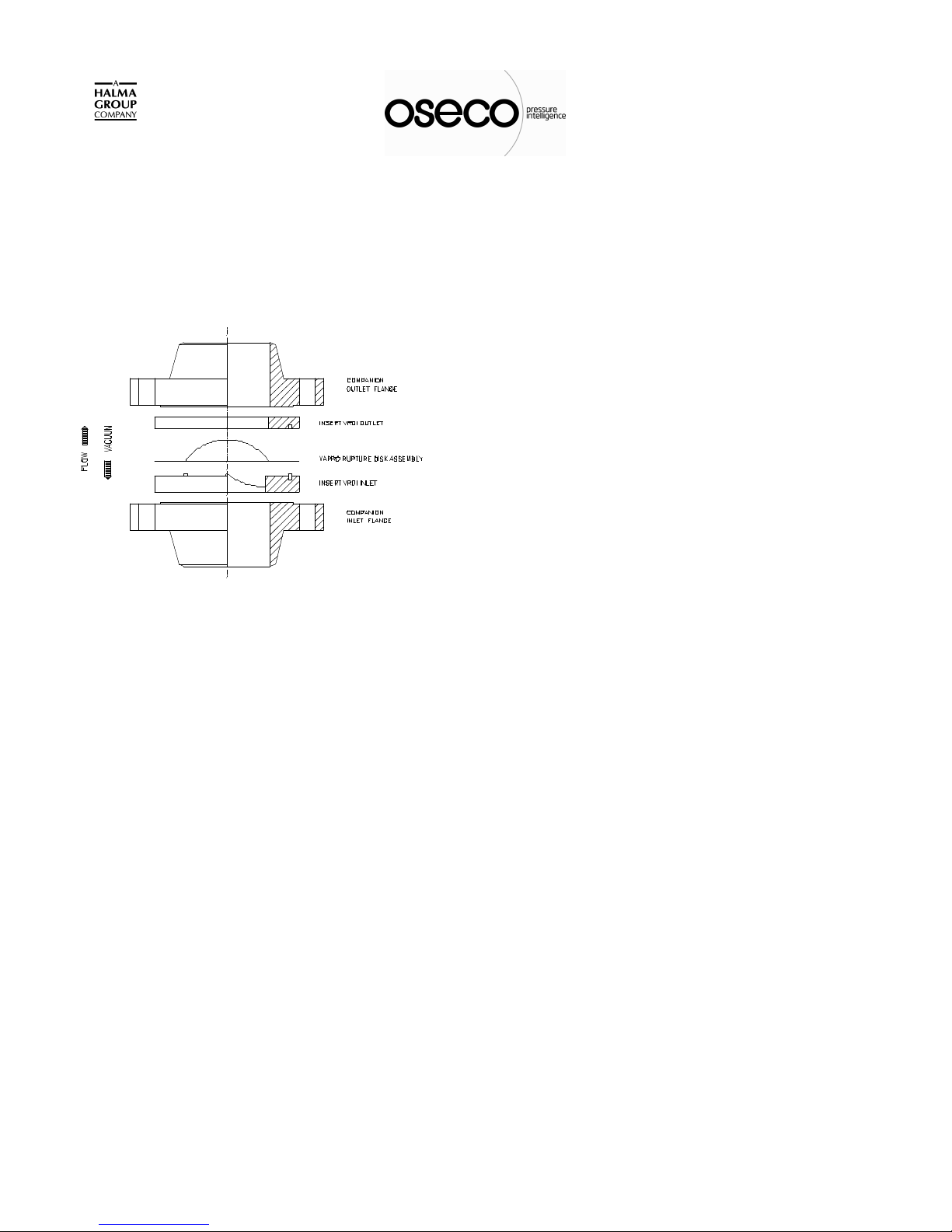

TYPICAL VRDI INSTALLATION

CAUTION

All rupture disk installations should be located to

allow full unrestricted discharge of a burst disk when

over pressure of the system occurs. Never locate a

rupture disk assembly where the discharge from a

burst disk can directly impact personnel or equipment.

Venting of a burst disk discharge must always be

routed to a safe disposal area. Handle burst rupture

disks carefully! Avoid their sharp, jagged edges when

removing same from holder. The knife blades in the

VRDI holder are extremely sharp. Handle holders

very carefully to avoid injury.

IMPORTANT

The VAPRO rupture disk assembly is a dual acting

precision piece of equipment. Handle it with

extreme care. Avoid scratching, bending, denting

or damaging the dome and/or flat seat areas of the

metal disk membrane. Handle the disk by the flat

outer annular seating surfaces and avoid the dome

area as much as possible. Never carry a VAPRO

disk/holder assembly by the name tag alone as

damage to the disk could occur. Do not place tools

or foreign objects on top of the knife blades or

P.O. Box 1327 / 1701 W. Tacoma/ Broken Arrow, OK 74012

“Quality Products to meet Industry Needs”

Holder

holder. The knife blades must be kept very sharp

and free of nicks and defects in order for the disk

assembly to function properly.

RUPTURE DISK HOLDER PREPARATION

1) Loosen and remove flange bolting only after

verifying that the system is de-pressurized. Always

purge toxic and/or dangerous materials area from

any system that is to be opened to a safe disposal.

.

2) Slip the holder insert from between the

companion piping flanges and place on a flat work

surface. Verify that all holder restraints have been

removed. Separate the holder inlet from the outlet

and remove the existing rupture disk assembly.

Telephone: (918) 258-5626 Fax: (918) 251-2809

3) Thoroughly inspect and clean all seating

surfaces of the disk holder. Do not scrape or

scratch any seating surface including the raised

nubbin area! If wiping these surfaces with a clean

cloth and a suitable solvent does not remove

surface residues, fine emery cloth or steel wool may

be utilized. Care should be exercised not to exert

sufficient pressure on the emery cloth or steel wool

to "cut or groove" these surfaces. When in doubt

about the proper condition of these sealing

surfaces, contact OSECO for further instructions.

4) Inspect knife blade points and edges. Knife blade

edges must be razor sharp and free of nicks or

defects. Points must be sharp and undamaged for

the disk assembly to function properly. Contact

OSECO for repair or replacement of dull or

damaged knife blades.

Do not install the Assembly if the blades are

dull, nicked or Damaged.

PS 11.12

Installation Instructions for VAPRO Rupture Disks in VRDI

Holder

RUPTURE DISK INSTALLATION

1) Carefully unpack the rupture disk from its box. If

your disk assembly was packaged with a dome-shaped

shipping protector marked "SHIPPING PROTECTOR -

DO NOT USE", remove it now.

2) Place the Insert VRDI Inlet on flat work surface

with the knife blades pointing up. Place the rupture disk

assembly on the holder, carefully aligning the holes in

the flange portion of the rupture disk assembly with the

alignment pins in the VRDI inlet.

3) Position the Insert VRDI Outlet over the dome of

the rupture disk assembly, carefully aligning the VRDI

Inlet alignment pins with the holes in the VRDI Outlet.

Lower the VRDI Outlet until it engages the VRDI Inlet

alignment pins and rests on the flat outer annular seating

surface of the rupture disk assembly. No binding should

occur during this procedure. If interference occurs,

discontinue installation until the source of the

interference is determined and corrected.

4) Install side bars; however, cap screws should

only be snug, not wrench tight.

5) Check companion flanges and verify that sealing

surfaces are clean, free of corrosion and debris, and are

not bent or warped.

6) Position the Vapro/VRDI assembly within the bolt

circle of companion piping flanges. The concave side of

the rupture disk assembly should face the process or

possible vacuum source. Reinstall studs, nuts and

suitable gaskets. Studs and nuts should be lightly oiled

and free running.

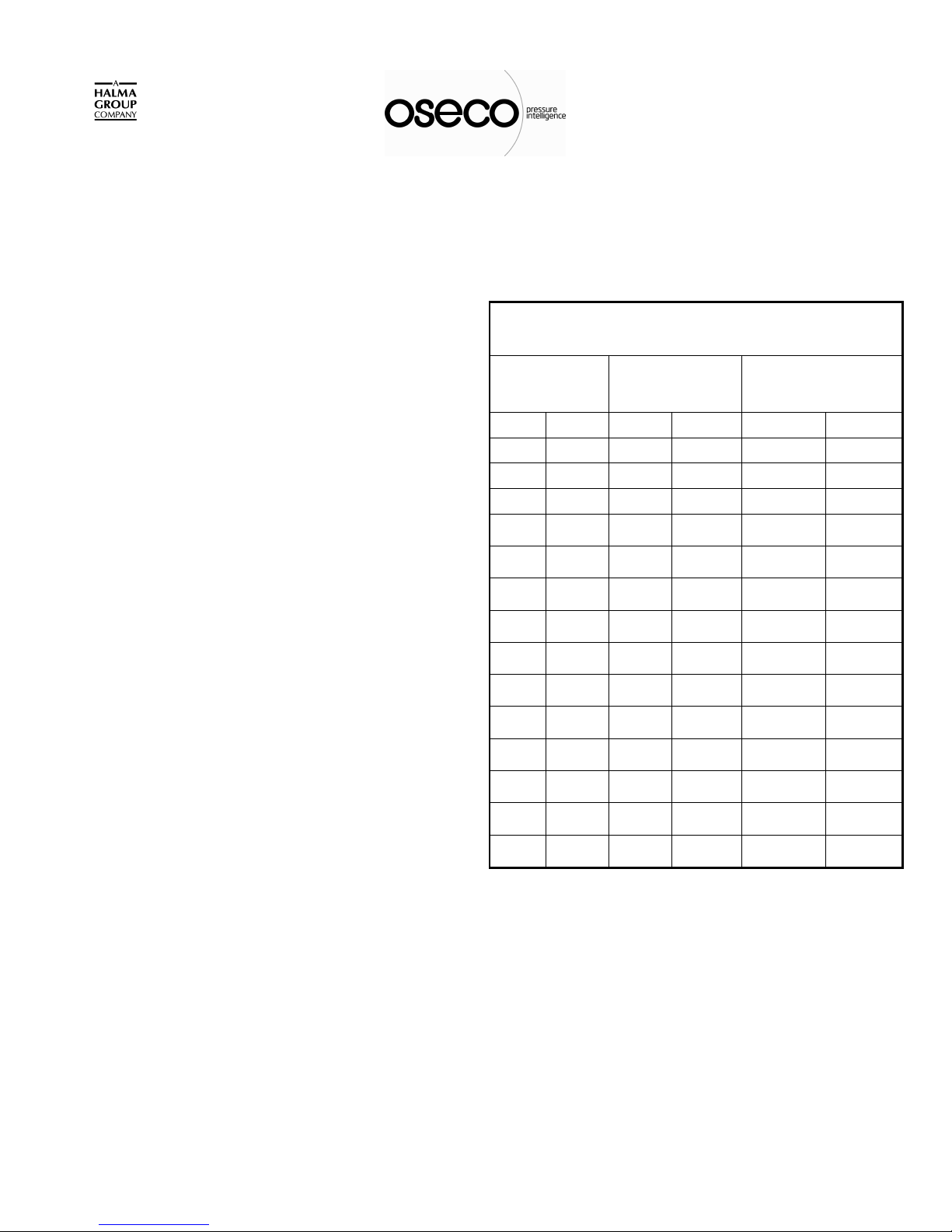

7) Tighten each nut finger tight, then using a

calibrated torque wrench, tighten each nut in a cross

pattern. Use increments of 20% of the recommended

torque value listed in the table below. Do not use torque

values in excess of those shown in the Torque Table as

this may damage the disk or the bite seal on the holder.

VAPRO / VRDI TORQUE TABLE

SIZE

FLANGE

RATING

IN. mm ANSI DIN

RECOMMENDED

TORQUE VALUE

Ft-Lb

3 80 150 - 40 54

- - - 10/16 20 27

4 100 150 10/16 30 41

6

-

8

-

-

10

-

-

12

-

-

150 150 - 40 54

- - 10/16 42 57

200 150 - 50 68

- - 10 52 70

- - 16 35 47

250 150 - 70 95

- - 10 63 85

- - 16 76 103

300 150 - 80 108

- - 10 72 98

- - 16 86 117

N-M

P.O. Box 1327 / 1701 W. Tacoma/ Broken Arrow, OK 74012

“Quality Products to meet Industry Needs”

Telephone: (918) 258-5626 Fax: (918) 251-2809

PS 11.12

Loading...

Loading...