Page 1

INSTRUCTIONS FOR O.S. PA-104 PUMP SYSTEM

The O.S. PA-104 Pump System consists of the unique O.S. Type PD-04 diaphragm fuel pump and matching large-throat

carburettor (O.S. Type 46), and has been developed specifically for O.S. MAX-40SF, 46SF, 40VF and 46VF engines.

The O.S. Pump System provides more power and ensures that fuel is delivered to the carburettor at the pressure reguired to

maintain the optimum mixture strength, irrespective of fuel tank location or aircraft attitude.

Note: This pump system cannot be fitted to the O.S. MAX-40FSR or 45FSR since the Type 46 carburettor cannot be installed in these engines.

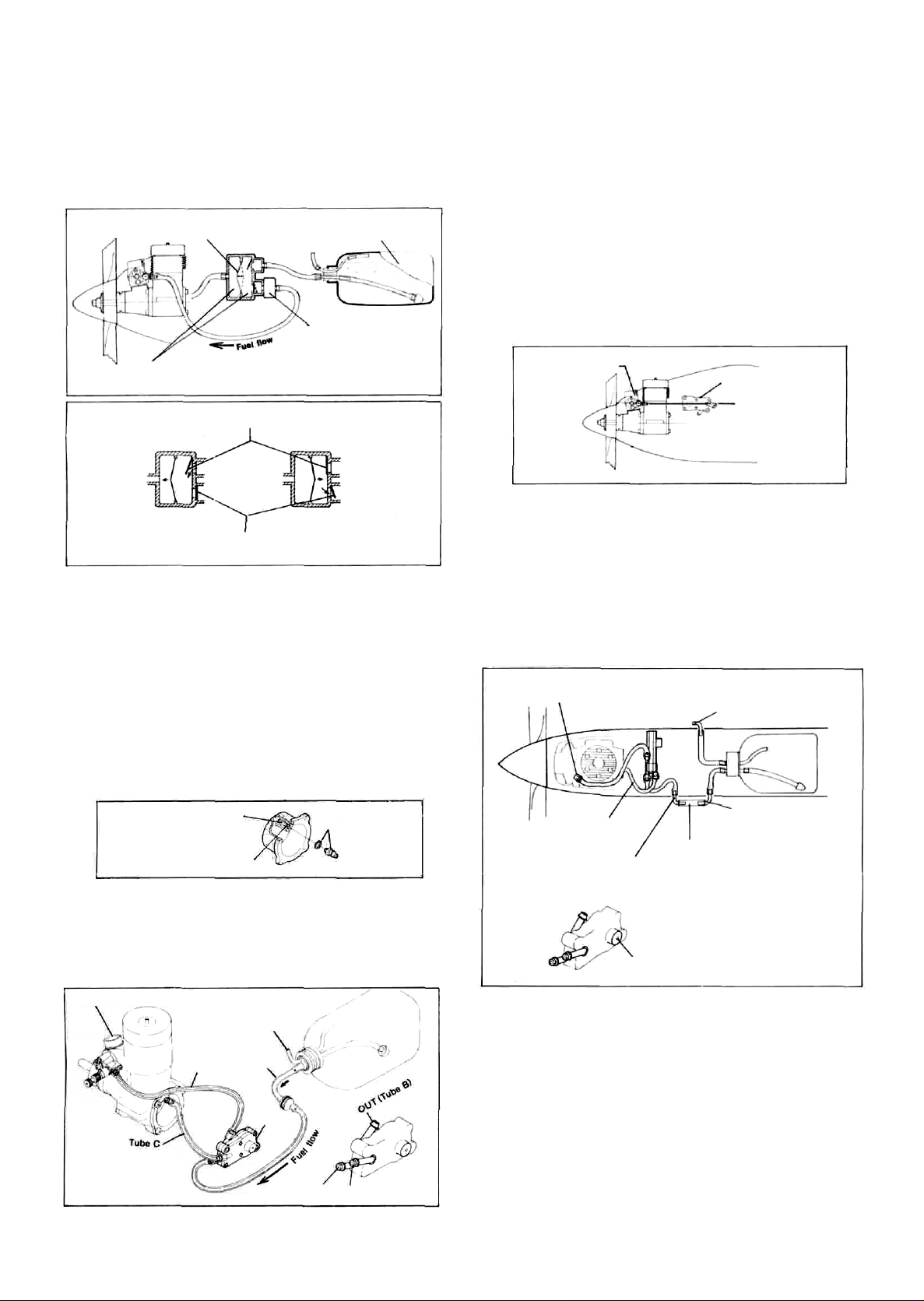

PRINCIPLE OF THE DIAPHRAGM PUMP

Diaphragm

(oscillates as the pressure in the crankcase varies.)

Pump incorporates a regulator here

to maintain fuel outlet pressure at a

constant level.

Negative and positive pressures occur in these

chambers in accordance with upward and downward strokes of engine's piston.

Check Valve No.1. Negative pressure causes Check Valve 1to open and admit fuel from

tank to pump. Valve automatically closes under positive pressure to prevent reverse

flow.

Under negative pressure

Check Valve No 2 Positive pressure opens Check Valve 2 and delivers fuel to carburettor.

Valve automatically closes under negative pressure to prevent reverse flow

Figs 1 & 2 are merely diagrammatic to explain the principle of the

diaphragm pump. Actual construction is more complicated.

Under positive pressure

Fuel tank

Fig.1

Fig.

2

INSTALLATION OF PRESSURE NIPPLE AND CARBURETTOR

* Remove the crankcase cover-plate (backplate) from the engine.

Drill and tap cover-plate boss with M3.5x0.6 Metric thread and

fit nipple supplied.

Important! After tapping, be sure to wash out screw hole

thoroughly with kerosine.

Note:

For this modification, an M3.5 tap set, including a 2.9mm

drill for the pilot hole, is available as an optional extra

(Code No. 27901002). Alternatively, for owners who do

not care to do this work, a replacement cover-plate, complete

with nipple installed, is also obtainable (Code No.25407001).

* Refit cover-plate and install the O.S. Type 46 carburettor.

Make a pilot hole with

2.9mm drill.

Cut thread at least 5mm (3/16") deep

Nipple supplied

Fig.

3

PIPING

* For piping, use heavy duty silicone fuel tubing of approximately

2.5mm bore and 5mm outer diameter.

* A feature of the O.S. Pump System is that the fuel tank does

not have to be placed close behind the engine, but tube lengths

should be kept as short as possible. Take care not to cause any

kinks in the "plumbing".

Type 46 carburettor

Make sure that the length

of Tube C is less than

10cm

(4

in.).

Fig.

4

Tube A: To draw fuel from the fuel tank to the pump.

Tube B : To deliver fuel from the pump to the carburettor.

Tube C: To deliver the crankcase pressure pulse to the pump.

TubeB

Overflow

(Do not seal off)

TubeA

PD-04

IN (Tube A)

P (Tube C)

Fig.

INSTALLATION

Here are examples of typical installations. (Figs 6 & 7)

* The ideal location for the pump is one in which the center

of the pump is on the same level as the axis of the carburettor

barrel as shown in Fig. 6. In many cases, this cannot be achieved, precisely, within the existing structure of the airframe.

However, try to fit the pump as closely as possible to this

optimum location. If the pump is installed more than 5cm

(2 in) above or below the ideal position, there may be a slight

variation in fuel/air mixture strength between level and inverted

flight.

Type 46 carburettor

PD-04 pump

Carburettor center line

Fig.

6

Fix the pump on the firewall, front bulkhead, or side of the

engine compartment with 3mm self-tapping screws. It is advisable to insert a piece of sheet rubber between the pump and

mounting surface. DO NOT attach the pump directly to any

part of the engine.

If it is not possible to mount the pump as described, it may

be possible to wrap it in foam rubber and insert it into a convenient space in the engine compartment, but make sure that

it does not touch the engine itself.

Caution:

When installing the pump, take care that the vent hole in

the pump body is not obstructed.

Do not ill the tank from here,

or the pump may be damaged.

Overflow

L-shaped nipple or aluminum

tubing.

Silicone tubing

It may be convenient to lead the pipes

outside the fuselage and connect with

approx. 40~50mm(l-1/2~2") length

of silicone tubing.

Fig.

7

Fig.

8

Connect to the nipple

of the cover plate.

Disconnect here when

filling the tank.

Do not block or seal.

WARNINGS

* Do not dissassemble the pump

Never take the pump unit apart. Once the pump has been

dismantled, its original performance may not be restored when

it is reassembled.

* Do not insert anything into the nipples

Inserting a pin, etc., into the nipples and/or air vent hole is

likely to damage the pump and render it inoperative.

* Use fuel filters

Any foreign matter entering the Pump System may interfere

with its correct functioning and may even damage the pump

5

diaphragm. Be sure to filter, all fuel before filling the tank and,

most important, use a good quality fine filter in the delivery

tube between the tank and pump.

Page 2

FUEL TANK

If the fitting of the "klunk" type fuel pick-up weight in the fuel

tank is incorrect, the weight may stick to the tank wall, resulting

in an irregular fuel flow to the carburettor, or, alternatively, in

the fuel flow being cut off during the course of sharp acrobatic

manoeuvres. Therefore, it is advisable to make slots in the end of

the weight, with a file or hacksaw blade, as shown in Fig. 10.

Thoroughly wash out the weight to remove any minute particles

of metal before reinstalling it in the tank.

Use thick silicone tubing.

10-15mm

not

(3/8-5/8")

"froth"

in

Fig.

the

tank when

10

Fig.

9

STARTING THE ENGINE

1. Fill the fuel tank.

2. From its fully closed position, open the needle-valve approximately 1 to 1-1/4 turns (when the standard O.S. 873 silencer

is used), or 1-1/2 to 2 turns (when a tuned silencer is used).

3. Open the throttle fully.

4. Placing your finger over the carburettor to choke the intake,

turn the propeller by hand until fuel is pumped as far as the

carburettor.

5. When fuel is seen to reach the carburettor, remove your finger

from the intake immediately.

6. Close the throttle to the idling position and turn the propeller

through two extra revolutions to prime the engine. DO NOT

turn the prop more than this, or the engine will be over-primed.

7. Connect the battery to the glowplug and start the engine.

Note:

If the engine is over-primed (i.e. flooded), pinch the fuel

delivery tube (Tube B) with a suitable clip or clamp before

attempting to start the engine. If the engine remains overprimed and unwilling to start, close the needle-valve completely, remove the glowplug and flip the propeller briskly

to eject excess fuel from the cylinder via the glowplug hole.

8. Check that sufficient fuel can reach the engine to cause it to

run rich (for running-in purposes, etc.) when the needle-valve

is more than 3 turns open. If the engine cannot be made to run

rich, check as follows:

* Make sure that the fuel filter or carburettor is not partially

obstructed with foreign matter.

* Make sure that there are no holes in the piping or air bubbles

in the fuel flow.

*

Make sure

the engine is running. This can occur if the tank is not

properly insulated from vibration.

that

the

fuel does

* Make sure that the fuel pick-up weight is not being partially

obstructed by contact with the tank wall. (Refer to previous

instructions under "FUEL TANK".)

In the unlikely event that the engine cannot be persuaded

to run rich, after checking the above, it is possible that a

fault has developed in the pump. In this case, consult the

O.S. engine distributor in your country.

Coution:

In the throttle is 'blipped' rapidly and repeatedly between

the idling and medium speed positions during (for example)

taxying, an excess of fuel will be pumped into the engine.

The engine may then refuse to pick up speed, even when

the throttle is opened fully, and may stop. The throttle

lever should be opened gradually to match the engine's

natural acceleration under load. The recommended pre

take-off check is to fully open the throttle, once, with the

aircraft under restraint. The throttle is then returned to the

idling position, before being smoothly advanced for the

take-off run.

Time

Fi».11

ADJUSTMENTS

Adjustment of the PA-104 System is confined to the Type 46

carburettor. No adjustments to the pump are called for. Carburettor adjustment broadly follows the procedure for setting up

a conventional suction-feed system. See separate instruction leaflet

for O.S. Type 46 carburettor.

MAINTENANCE

If, after use, the fuel system is left unattended for a lengthy period,

there will be a tendency for the methanol content of the fuel to

evaporate sufficiently for the oil content to "gum" the internal

parts of the pump. Therefore, it is advisable, at the end of the

day's flying, to empty the fuel tank, invert the engine, and pump

out the remaining fuel in the system by rotating the propeller

until no more fuel is ejected from the carburettor.

If the pump is not in use for a while (more than one month),

remove the pump and wash out its interior by injecting methanol

or kerosene through the "IN" nipple. Fit the sealing caps (provided) to the nipples, after draining out the methanol or kerosene.

Note:

If you use kerosene, take care not to allow this to come into

contact with the fuel tubing, otherwise the tubing will swell

and deteriorate.

Time

© Copyright 1990 by O.S. Engines Mfg. Co., Ltd. All rights reserved. Printed in Japan

O.S.PUMP SYSTEM

Distributed in the United

States by permission of

Perry Aeromotive. Inc. under

U.S. Patent No. 3,96 7,606.

6-15 3-chome Imagawa Higashisumiyoshi-ku

Osaka 546, Japan. TEL. (06) 702-0225

FAX.

(06)

704-2722

Loading...

Loading...