Ortopedia Impuls-System, Impuls 1, Impuls 1 Euro, Impuls 1 Vario, Impuls 2 Operating Manual

...

Operating Manual

FOLDING WHEELCHAIR

Impuls-System

S T A Y M O B I L E

1

Table of Contents

1. Introduction .................................................................................................................. 6

2. Handling the wheelchair .............................................................................................. 7

2.1 Appli cation ........................................................................................................................... 7

2.2 Performance .......................................................................................................................... 8

2.3 Safety information ................................................................................................................. 8

2.4 Additional user/safety information ..................................................................................... 9

2.4.1 User information .................................................................................................. 10

2.5 Folding/unfolding ............................................................................................................... 15

2.5.1 Folding the wheelchair ........................................................................................ 15

2.5.2 Unfolding the wheelchair .................................................................................... 15

2.6 Transportation ..................................................................................................................... 16

3. Overview...................................................................................................................... 16

3.1 IMPULS 1............................................................................................................................. 17

3.2 IMPULS 2-4 ......................................................................................................................... 18

3.2a IMPULS XX ........................................................................................................................ 19

3.3 Components ....................................................................................................................... 20

3.3.1 Seat band ............................................................................................................ 20

3.3.1.1 Seat band XX ...................................................................................... 20

3.3.1.2 Seat cushion ........................................................................................ 20

3.3.1.3 Fixed seat on the Impuls XX ............................................................... 20

3.3.2 Backrest ................................................................................................................ 21

3.3.2.1 Backrest with angle adjustment ......................................................... 21

3.3.2.2 Back band, standard ........................................................................... 22

3.3.2.3 Back, ORTOFLEX .................................................................................. 22

3.3.2.4 Backrest with 30° angle adjustment ................................................... 23

3.3.2.5 Height-adjustable sliding handles ..................................................... 24

3.3.2.6 Back stiffening bar .............................................................................. 24

3.3.3 Armrest ................................................................................................................ 25

3.3.3.1 Clothes guard ..................................................................................... 25

3.3.3.2 Non-locking armrest ........................................................................... 25

3.3.3.3 Armrest with double locking .............................................................. 26

3.3.3.4 Hei ght-ad justab le armr est ................................................................. 26

3.3.4 Leg supports ........................................................................................................ 27

3.3.4.1 Calf support ........................................................................................ 27

3.3.4.2 Folding up the foot plates .................................................................. 27

3.3.4.3 Swivelling leg supports aside ............................................................. 28

3.3.4.4 Removal of leg supports ..................................................................... 29

3.3.4.5 Attachment of leg supports ................................................................ 29

3.3.4.6 Positioning of foot plates .................................................................... 30

3.3.4.7 Adjustment of foot plate angle .......................................................... 30

3.3.4.8 Adjustment of foot plate height ......................................................... 31

3.3.4.9 Foot board .......................................................................................... 31

3.3.4.10 Leg support with angle adjustment (774-1) ...................................... 32

3.3.4.11 Leg support with angle adjustment and

length compensation (774-2 AL) ........................................................ 33

32

3.3.5 Driving wheels ..................................................................................................... 34

3.3.5.1 Full float ing axle ................................................................................. 34

3.3.5.2 Hand wheels ....................................................................................... 35

3.3.6 Brakes................................................................................................................... 35

3.3.6.1 Safety information .............................................................................. 35

3.3.6.2 Toggle joint brake .............................................................................. 36

3.3.6.3 Drum brake ........................................................................................ 36

3.3.6.4 Service brake function ........................................................................ 36

3.3.6.5 Locking the brake ............................................................................... 37

3.3.6.6 Releasing the brake ............................................................................ 37

3.3.6.7 Changing or replacing driving wheels ............................................... 37

3.3.6.8 Drum brake for carers ......................................................................... 38

3.3.6.9 Adjustment of toggle joint brake ....................................................... 38

3.3.7 Swivel wheels ...................................................................................................... 39

3.3.8 Tyres ..................................................................................................................... 39

4. Individual customisation ........................................................................................... 40

4.1 Seat height/seat inclination ............................................................................................. 40

4.1.1 Driving wheel position ......................................................................................... 41

4.1.2 Swivel wheel position .......................................................................................... 42

4.2 Wheel camber .................................................................................................................. 42

5. Optional accessories ................................................................................................... 43

5.1 Lap belt ............................................................................................................................ 43

5.1.1 Fastening lap belt ................................................................................................ 43

5.1.2 Setting belt length .............................................................................................. 43

5.2 Stabilisers ......................................................................................................................... 44

5.2.1 Swivelling the stabilisers ..................................................................................... 44

5.2.2 Setting the height ................................................................................................ 45

5.2.3 Correct stabiliser length: ..................................................................................... 45

5.3 Tread cap ............................................................................................................................ 45

5.3.1 Setting the height ................................................................................................ 45

5.4 Transit wheels...................................................................................................................... 46

5.4.1 Setting the height ................................................................................................ 46

5.4.2 Removing driving wheels ..................................................................................... 46

5.4.3 Locking brake ....................................................................................................... 46

5.5 Spoke guard ..................................................................................................................... 47

5.5.1 Removal ............................................................................................................... 47

5.5.2 Installation ...........................................................................................................47

5.6 Brake lever extension ....................................................................................................... 47

5.7 Tray................................................................................................................................... 48

5.7.1 Standard tray ....................................................................................................... 48

5.7.2 8001 tray .............................................................................................................. 48

6. Care and maintenance ................................................................................................ 4 9

6.1 Care ................................................................................................................................. 49

6.2 Maintenance .................................................................................................................... 50

6.2.1 Tools ..................................................................................................................... 50

6.2.2 Maintenance instructions ..................................................................................... 51

6.2.3 Punctures.............................................................................................................. 52

6.3 Repairs.............................................................................................................................. 53

6.4 Customer service .............................................................................................................. 53

6.5 Spare parts .......................................................................................................................53

7. Technical data ............................................................................................................. 54

7.1 Impuls 1 model ................................................................................................................ 54

7.2 Impuls 1 Euro model ........................................................................................................ 55

7.3 Impuls 1 Vario model ....................................................................................................... 56

7.4 Impuls 2 model ................................................................................................................ 57

7.5 Impuls 3 model ................................................................................................................ 58

7.6 Impuls 4 model ................................................................................................................ 59

7.7 Impuls XX model ..............................................................................................................60

9. Guarantee .................................................................................................................... 61

Notes: ....................................................................................................................................... 62

54

1. Introduction

2. Handling the wheelchair

Thank you choosing a wheelchair from the

IMPULS model range.

With its many design versions and accessories, the IMPULS wheelchair system can

be adapted to suit your varying clinical

needs.

Like any other vehicle, a wheelchair is a

technical aid. It requires explanations for

use and a degree of maintenance. It also

has hidden dangers that may appear if it

is used incorrectly. It is therefore important to learn how to handle it correctly .

These instructions are intended for use in

conjunction with the booklet "Safety Information for Mechanical Wheelchairs",

to help you to familiarise yourself with the

operation of the wheelchair and to prevent accidents.

Children should read these instructions

and the booklet "Safety Information for

Mechanical Wheelchairs" with their parents, guardian or carer before venturing

out for the first time.

☞ Note:

Please note that the equipment versions illustrated may differ from your

model.

2.1 Application

The IMPULS 1 wheelchair is a standard

lightweight wheelchair with a fixed driving wheel position.

IMPULS 2-4 models are activity wheelchairs, which can be adapted to suit the

corresponding requirements of respective users.

The Impuls XX wide wheelchair is for

heavier users weighing up to max. 160

kg.

The Impuls Postura wheelchair offers a

padded backrest with angle adjustment

and a padded seat, which can also be

adjusted in depth.

IMPULS System wheelchairs are designed for daily use, both indoors and

outdoors, for work or for leisure. For the

experienced user, the IMPULS System

wheelchair offers possible settings for

active performance with high manoeuvrability.

Before being used for the first time, the

wheelchair should be adjusted by your

ORTOPEDIA dealer . The adaptation will

take into account the driving experience, the physical limits of the user and

the main place of use of the wheelchair.

Warning:

Setting or adjustment should only be

carried out by an authorised ORTO-

!

PEDIA dealer.

76

2.2 Performance

Optimisation of the performance characteristics of the IMPULS System wheelchair to fit your personal circumstances

should be discussed with your

ORTOPEDIA dealer or physician.

The adaptability of the wheelchair offers you a high degree of comfort and

safety in all areas of life, e.g. family , work

or leisure.

2.3 Safety information

▲ Please follow the safety information

for mechanical wheelchairs contained in the relevant booklet.

▲ A direct change of movement to the

opposite direction, e.g. from reverse

to forward movement without involving a steering action, causes full braking if the swivel wheels are moving

inwards at the same time.

▲ The use of a safety belt prevents the

user from falling out of the wheelchair.

2.4 Additional user/

safety information

▲ When travelling in public thorough-

fares, clean passive lighting must be

used!

▲ Do not throw or drop parts belong-

ing to the wheelchair!– Removable

parts such as armrests and leg supports should be handled correctly to

ensure lasting performance. To guarantee their function.

▲ Before moving off, check that remov-

able parts such as armrests and leg

supports, are locked correctly in position. Drive wheels with defective

linchpin (quick-fit) axles can detach

from the wheelchair during the drive.

▲ The addition or removal of accesso-

ries/components will cause the dimensions and weight of the wheelchair to change. This can also result

in a change in performance.

▲ Never leave children/young persons

unsupervised in wheelchairs.

▲ For smaller obstacles, e.g. small

ledges/slopes, always move slowly

and at a right angle (90°) to the obstacle, until the swivel wheels are almost touching the obstacle. Briefly

stop the wheelchair and then drive

over the obstacle.

▲ Give a wide berth to grooves, rails,

manhole covers or similar sources of

danger. If not possible, cross such

obstacles at a right-angle (90°).

▲ Maintain a safe distance from steep

inclines, staircases and obstacles to

allow sufficient space to react, brake

and turn.

▲ Always reduce speed before a bend.

A sharper curve requires a lower

speed. Never lean outwards in a

curve.

98

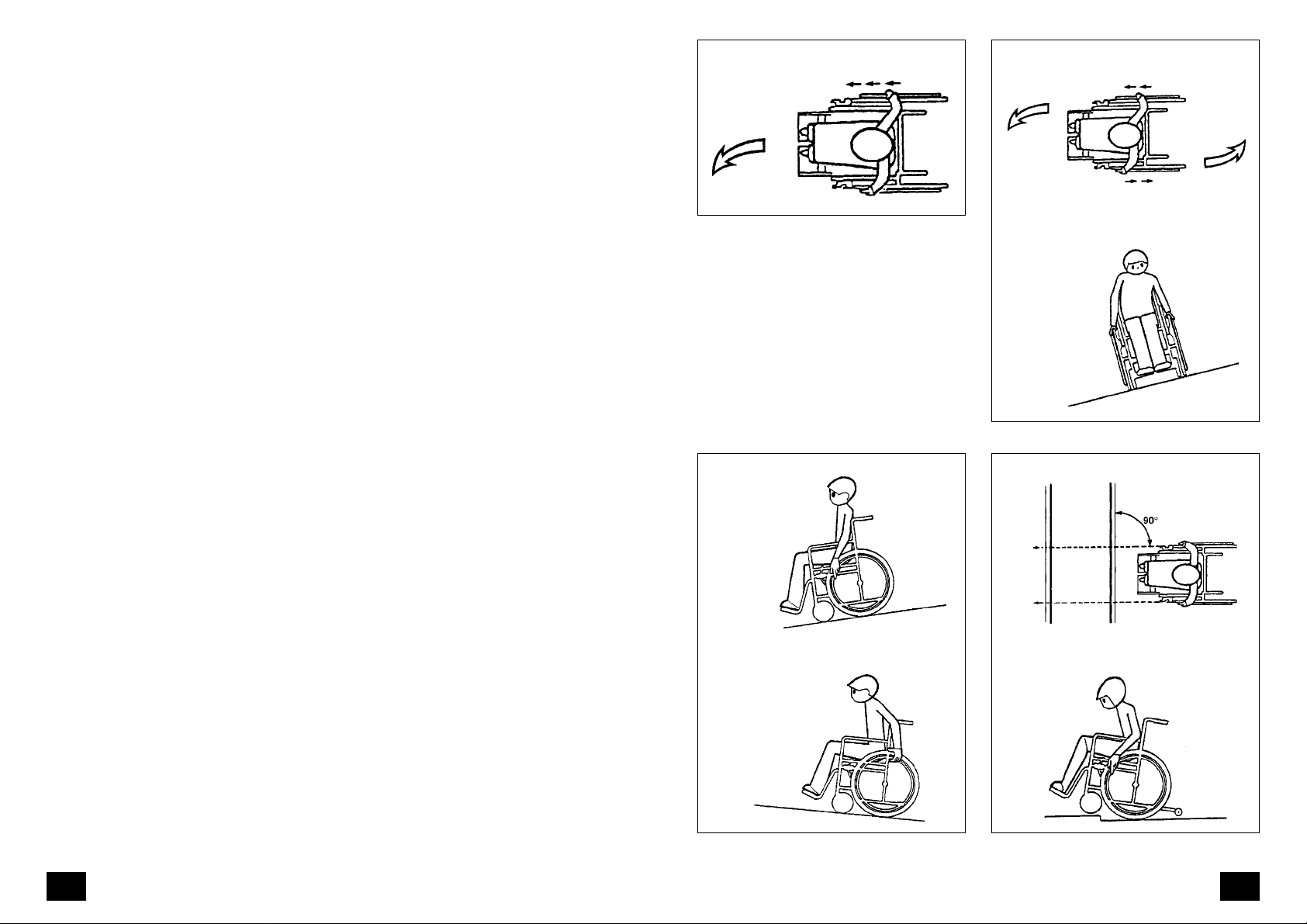

Negotiating a bend

Turning

▲ Tyres are made of a rubber com-

pound and may leave marks on some

surfaces (e.g. plastic, wooden or parquet flooring, rugs, carpets) that are

hard to remove or even permanent.

▲ To prevent damage from corrosion,

do not use the wheelchair in damp

conditions, do not travel through

puddles or water and do not expose

it to continuous rain.

Recommendations for travelling

at dusk or at night

▲ During periods of darkness, avoid

roads and cycle paths as far as possible. Wear light-coloured clothing that

can be seen at a distance.

2.4.1 User information

The following pages give general information and suggestions for handling

and use of the wheelchair in everyday

situations. Make yourself thoroughly and

carefully familiar with the wheelchair.

New driving situations must be practised

with the support of a helper.

▲ Before changing from one seating

option to another, or before leaving

or entering the wheelchair, always

lock the brakes to prevent the wheelchair from rolling away.

▲ T o lean the upper body well forward,

manoeuvre the wheelchair backwards until the swivel wheels face

forwards for increased stability.

Turning on a slope

Driving downhill Approaching an obstacle

Driving uphill

Obstacle crossing

1110

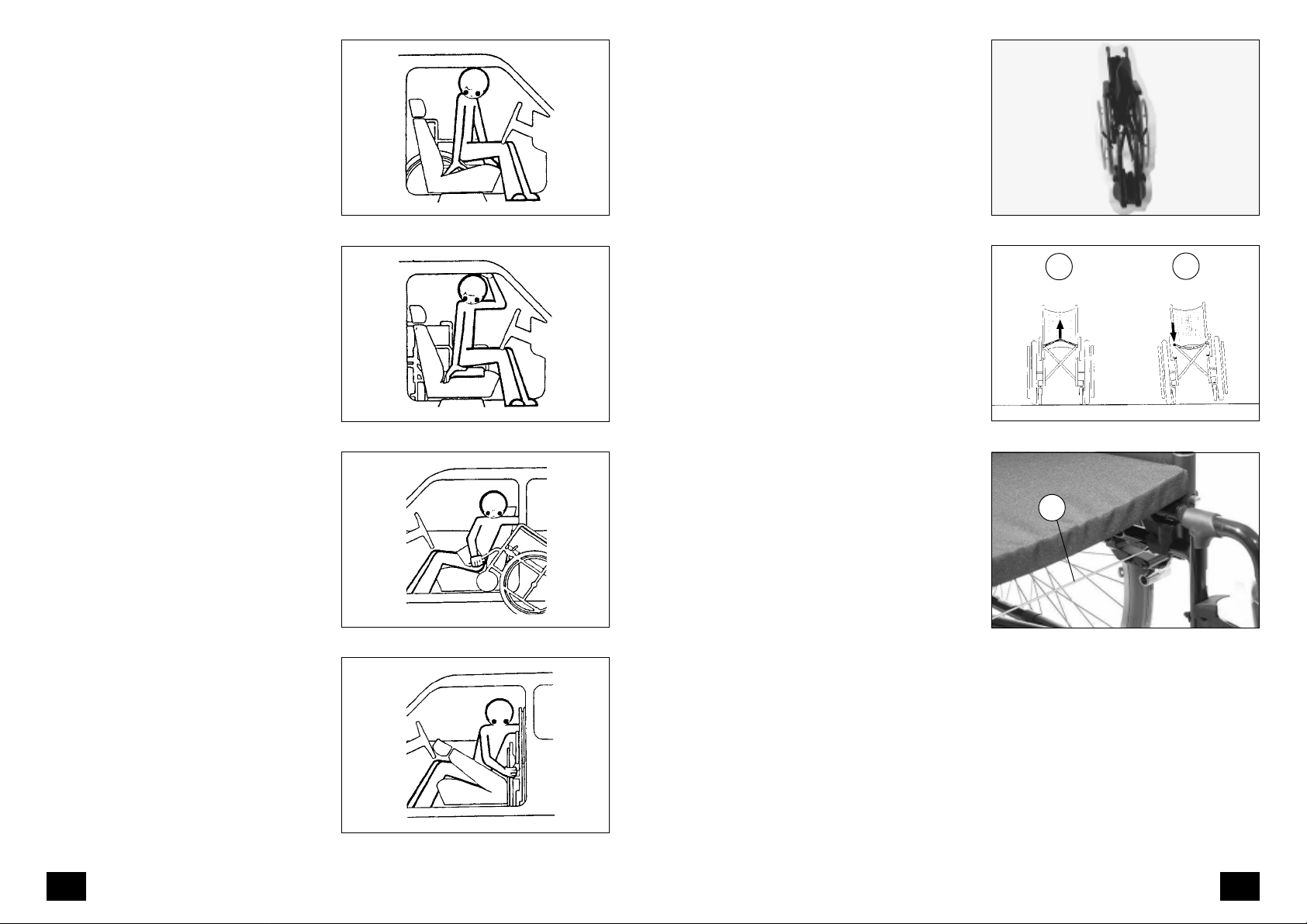

Climbing in

Crossing drops/steps

Steering wheels forwards = safe stability Transfer

Bringing the wheelchair upright

Toilet use Climbing into the bath

Transfer with sliding board

Lowering the legs

1312

Wheelchair and the car

2.5 Folding/unfolding

Move the wheelchair parallel and adjacent to the driver or passenger seat.

Detach the legrests and the armrests in

order to reduce the wheelchair weight

and make the lifting into the car easier.

Lock the brakes to prevent the wheelchair from moving. The door frame can

be used for holding or the seat for support during the transfer into the car.

A sliding board can be used to bridge

the gap between the wheelchair and

the car seat. The possibilities here depend on the type of vehicle, the height

of the car seat and the height of the

wheelchair seat.

Unlock the brakes of the wheelchair

before its loading. The personal possibilities and the spaciousness of the vehicle determine whether the wheelchair

is now pulled into the car from the driver's seat or the front passenger seat.

Transferring to the car

Transfer into the car

2.5.1 Folding the wheelchair

To fold the wheelchair (Fig. 1), fold up

the foot plates of the leg supports or

remove the leg supports. Press the centre of the chest belt backwards. Lift the

back and the front of the seat cover upwards from the centre (Fig. 2/

➀).

2.5.2 Unfolding the wheelchair

To unfold the wheelchair, tilt it slightly

to one side. On the side which is standing firm on the ground, push the seat

tube downwards until it reaches its limit

(Fig. 2/

➁).

☞ Note:

To do this, it may be necessary to

force both seat tubes into their final

position by hand.

The Bowden wire (Fig. 2.1/

vents the side frames being pushed

too far apart.

➀) pre-

1

1

2

1

2

Two-door cars usually cause fewer problems because the doors are usually

wider. In the case of a four-door car it

may be necessary for a helper to lift the

wheelchair into the passenger space or

the boot.

Loading the wheelchair

Loading the wheelchair

2.1

1514

2.6 Transportation

For storage or transportation purposes,

the wheelchair can be dismantled into

portable elements without the need for

tools.

Firstly the dimensions of the wheelchair

can be reduced by removing all removable parts. These include the leg supports and the armrests (arm pads are

not removable). Stabilisers (if present)

can be folded forwards.

The wheelchair can now be folded in

the normal way. In addition, driving

wheels equipped with full floating axles

can now also be removed.

During reassembly, ensure that each

part is correctly installed and securely

fastened. Check that components are

correctly positioned. Check the correct

seating of the components.

3. Overview

The overview shows the most important

components and operating elements of

the IMPULS System wheelchair .

The components shown in the following illustrations may not be identical to

those on your wheelchair. The location

and handling of the parts are nevertheless applicable to your IMPULS System

wheelchair model. Each time the wheelchair is assembled, or each time a setting is made, checks should be carried

out to ensure that the component in

question is fitted correctly and functioning properly.

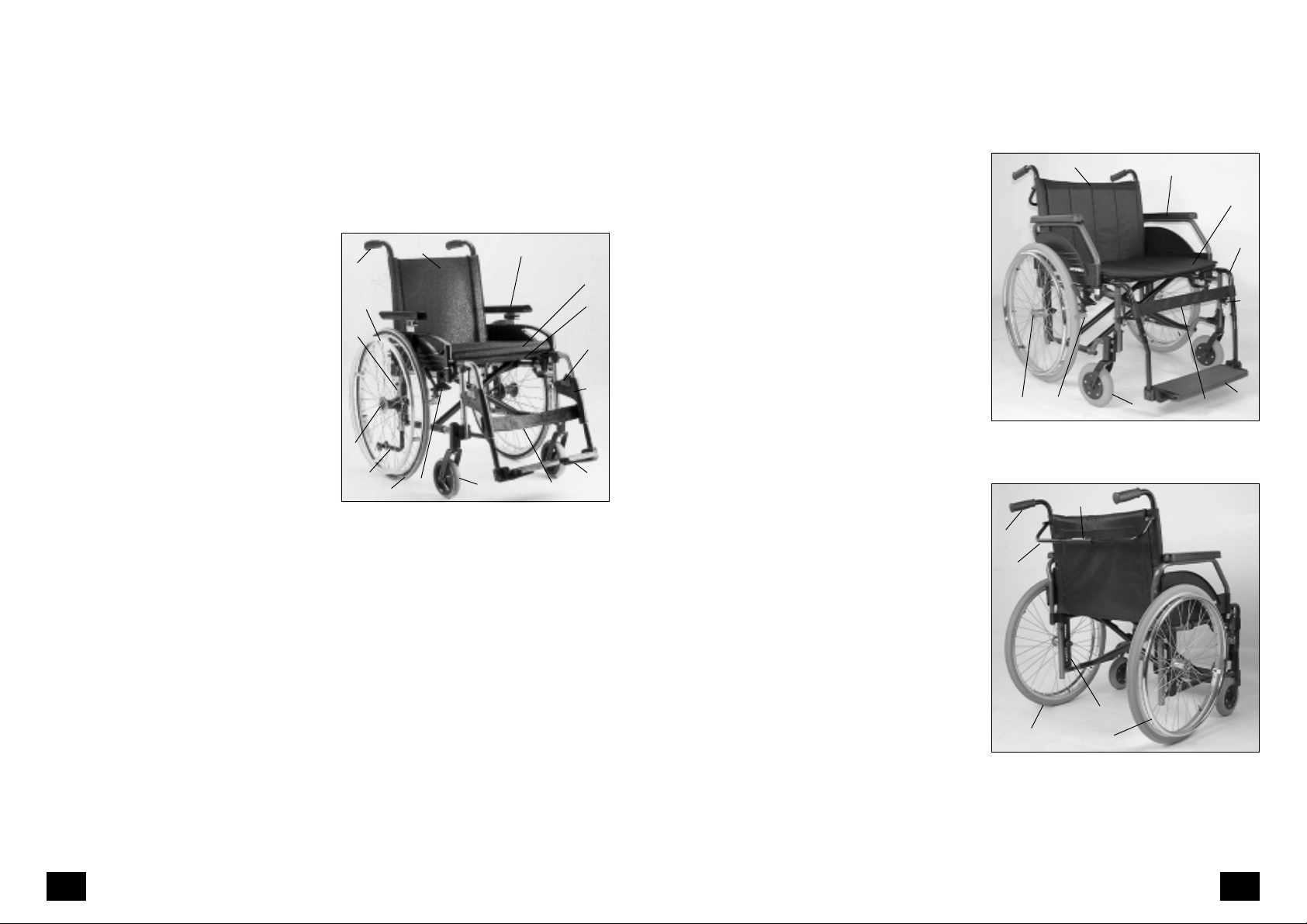

3.1 IMPULS 1

The model shown in Fig. 3 is representative of all IMPULS standard lightweight

wheelchairs.

– IMPULS 1

– IMPULS 1 Euro

– IMPULS 1 V ario

1 Sliding handle

2 Backrest

3 Armrest

4 Seat band

5 Leg support lock

6 Legrest

7 Footrest

8 Calf support

9 Swivel wheel

10 Brake and locking mechanism

11 Drive wheel

12 Hand wheel

1 3 Full floating axle

1

13

12

3

23

11

10 9

4

5

6

7

8

1716

3.2 IMPULS 2-4

3.2a IMPULS XX

The model shown in Fig. 3 is representative of all IMPULS adaptable/activity

wheelchairs.

– IMPULS 2

– IMPULS 3 Hemi

– IMPULS 4

1 Sliding handle

2 Backrest

3 Armrest

4 Seat belt

4. 1 Seat cushion

5 Leg support lock

6 Legrest

7 Footrest

8 Calf support

9 Swivel wheel

10 Brake and locking mechanism

11 Drive wheel

12 Hand wheel

1 3 Full floating axle

1 4 Support wheel

15 Plate with punched holes for set-

ting variable seat height and wheel

position

1

15

13

14

3.1

12

2

10

The model shown in Fig. 3.2 and 3.3 is

representative of all IMPULS XX wheelchairs.

1 Sliding handle

2 Backrest

3 Armrest

3

4.1

4

5

6

7

911

8

4 Seat belt

5 Legrest

6 Leg support lock

7 Foot board

8 Calf support

9 Swivel wheel

10 Brake and locking mechanism

11 Drive wheel

12 Hand wheel

1 3 Full floating axle

14 Back stiffening bar

15 Plate with punched holes for set-

ting variable seat height and wheel

position

1 6 Sliding sleeve for dismantling back

stiffening bar

3.2

1

14

2

1013

16

3

4

5

6

7

9

8

3.3

11

15

12

1918

3.3 Components

3.3.2 Backrest

3.3.1 Seat band

The standard seat band can be adjusted

to two depths. After removing the end

caps (Fig. 4), the seat band and the seat

depth adapter can be pulled out from

the seat tube and replaced in any order, depending on the seat depth selected.

The ORTOFLEX seat cover can be adjusted on the underside using Velcro

strips.

3.3.1.1 Seat band XX

The seat band of the Impuls XX is fastened by four screws on each side, which

can be moved to two further positions,

each time by 3 cm, to adjust the seat

depth.

3.3 .1.2 Seat cushion

The seat cushion (accessory) is placed

with the rubberised side against the seat

band (Fig. 4.1).

4

4.1

The standard backrest has a rigid rear

tube with lumbar tilt (Fig. 6).

Warning:

Hanging bags or other objects behind the backrest increases the risk

!

of the wheelchair tipping over!

3.3.2.1 Backrest with angle adjustment

To adjust the angle from -12° to +12°

loosen the locking screw (Fig. 7/ ➀) on

each side and pull it out as far as required to engage the new setting.

Warning:

Adjust both sides equally .

!

After setting the angle (Fig. 8) re-tighten

the locking screws.

☞ Note:

If the seat back is angled too far forward, this can cause problems when

folding the wheelchair.

6

1

7

3.3 .1. 3 Fixed seat on the Impuls

XX

The Impuls XX with seat width 57 cm

and 60 cm is supplied with a fixed seat

(Fig. 5).

5

8

2120

3.3.2.2 Back band, standard

The standard back cover (Fig. 6) is

stretched into position by the rear tubes

when the wheelchair is unfolded.

The extended back section (Fig. 9/

➂)

is fastened below the seat area.

3.3 .2. 3 Back, ORTOFLEX

The tension of the back band can be

adjusted by means of Velcro strips (Fig.

9/

➁).

The ORTOFLEX pad

adjustable back band section using

➀ is fastened to the

➁

Velcro strips.

The extended back section (Fig. 9/

➂)

is fastened below the seat area.

ORTOFLEX

back band section

9

ORTOFLEX

pad

Standard

seat cover

Standard

back cover

3.3.2.4 Backrest with 30° angle

adjustment

For variable adjustment up to 30°, pull

the release levers (Fig. 9.1/

➀).

☞ Note:

Set both rear tubes to the same position when the seat is occupied.

Pistons should be kept clean and

lightly greased with Vaseline (Fig.

9.2) for lasting performance.

Warning:

Adjusting the angle increases the

danger of tipping over and should

!

only be undertaken if stabilisers are

fitted!

1

1

9.1

9.2

2322

3.3 .2. 5 Height-adjustable sliding

handles

The height of the sliding handles (Fig.

9.3) can be variably adjusted. The han-

dles can also be secured against twisting and pulling out of position

3.3.3 Armrest

Warning:

Do not use wheelchair without armrests/clothes guards fitted.

!

Do not lift wheelchair by armrests/

clothes guards.

1

2

2

For variable height adjustment, loosen

the locking screw (Fig. 9.4/

tighten when adjustment is complete.

3.3 . 2 . 6 Back stiffening bar

The Impuls XX for heavier users has a

back stiffening bar fitted as standard

(Fig. 9.5/

Before folding the wheelchair, the sliding sleeve for locking the back stiffening bar should be pushed outwards to

the right (Fig. 9.6/

➀).

➀).

➀). And re-

9.3

9.4

9.5

3.3.3.1 Clothes guard

The clothes guard (Fig. 10/

forwards or backwards over the centre

of the wheel.

The position of the clothes guard can

be adjusted by loosening the fixing

screws (Fig. 10/

1

1

Re-tighten the fixing screws when adjustment is complete.

Warning:

Do not push the clothes guards outwards when supporting yourself.

!

3.3.3.2 Non-locking armrest

The standard armrest (Fig. 11) can be

removed by pulling upwards. The armrest is installed by pushing the guide

tubes downwards as far as possible into

the corresponding openings.

➁).

➀) can swivel

10

11

9.6

1

2524

3.3 .3.3 Armrest with double

locking

To install the armrest, push the diagonally positioned rear pin (Fig. 12/

into the corresponding opening, then

swivel it forwards into the corresponding opening until you hear the locking

button click into place.

➀)

☞ Note:

When the armrest is swivelled forward, the rear lock (Fig. 12/

automatically engaged.

To remove the armrest, press the locking button (Fig. 13/

of the armrest free and pull upwards.

Warning:

When supporting yourself on plastic

armrests, place your hands over the

!

central column (Fig. 13).

3.3 .3. 4 Height-adjustable armrest

To adjust the height, push in the ratchet

button (Fig. 14/

rest pad in stages to the desired height.

To adjust the armrest height on the

Impuls XX, push the ratchet button (Fig.

14.1/

➀).

➁) swivel the front

➀) and bring the arm-

➀) is

12

13

14

3.3.4 Leg supports

Warning:

Do not use the leg supports to lift or

carry the wheelchair.

!

• For the Impuls XX model with sepa-

1

2

1

rate leg supports, the maximum permissible user weight is reduced to 130

kg!

3.3.4.1 Calf support

The calf support (Fig. 15/

on to the retaining pin on the leg support. The calf support can be adjusted

to the required length using the Velcro

fastening on the rear side of the support.

3.3.4.2 Folding up the foot

plates

Locking the brakes prevents the wheelchair from unintentional movement.

Remove the calf support and lift both

feet from the foot plates.

T o keep the foot area free, e.g. for "propelling" (moving the wheelchair forwards using the feet), the foot plates

should be folded to the side (Fig. 16).

➀) is pushed

15

16

17

1

14.1

1

2726

3.3. 4.3 Swivelling leg supports

aside

For transferring easily into or out of the

wheelchair or for moving close to a cupboard, bed, or bath, the leg supports

can be swivelled inwards or outwards

after the foot plates have been folded

up (Fig. 17).

Depending on the model and version:

a) Push the lever for locking the leg sup-

port (Fig. 18/

b)Lift the leg support from the locking

device (Fig. 19/

wards (Fig. 17).

For the Impuls XX model, the locking

pin must first be activated (Fig. 19.1).

Warning:

Leg supports which have been moved

aside are automatically unlocked and

!

can easily fall off. Note this when

handling (e.g. transport).

When putting the leg supports back

in position, remember to check the

levers (Fig. 18/

(Fig. 19/

➀) to the side or

➁) and swivel it out-

➀) or locking devices

➁).

18

19

19.1

3.3.4.4 Removal of leg supports

Before removing the leg supports, remove the calf support and fold up the

foot plates. Depending on the model

and version, the leg supports can now

be removed as follows:

1

2

a) Push the lever for locking the leg sup-

port (Fig. 20/

the leg supports slightly and remove

by pulling upwards.

b)Leg supports without locking levers

can be removed by pulling upwards.

3.3.4.5 Attachment of leg sup-

Depending on the model and version,

the leg supports are attached as follows:

a) Insert leg supports from above at an

angle into the leg support holders

(Fig. 21), and swivel supports forwards

until you hear them click into place.

b)Leg supports without a locking lever

are inserted from above into the leg

support holders. The locking device

(Fig. 22/

ess.

For the Impuls XX model, the locking pin

must first be activated (Fig. 19.1).

➀) to the side. Swivel

ports

➀) is activated in the proc-

20

21

22

1

1

2928

3.3 .4. 6 Positioning of foot plates

To set the foot plate position, the locking screws (Fig. 23/

➀)must first be re-

moved. Re-tighten screws.

When the screwed connections have

been loosened (Fig. 23/

➀) the position

of the foot plate can be adjusted by 1.5

cm either forwards or backwards. Retighten screwed connections.

3.3 .4. 7 Adjustment of foot plate

angle

After removing the locking screw (Fig.

24/

➁) pull out the teeth and set the

angle of the foot plate. Re-tighten screw.

The regulating screw (Fig. 24/3) is used

to correct the angle of the foot plate in

a crosswise direction.

23

24

3.3.4.8 Adjustment of foot plate

height

1

Depending on the model and version,

the height of the foot plate is adjusted

1

as follows:

a) After removing the locking screw (Fig.

➀) adjust the foot plate telescop-

24/

ically to the desired height. Observe

markings indicating maximum exten-

25

sion. Re-tighten locking screw.

b)After loosening the screwed connec-

tion (Fig. 25/

➀) adjust the foot plate

telescopically to the desired height.

Re-tighten screwed connection.

3.3.4.9 Foot board

The foot board can be folded up (Fig.

26).

When folding it down, ensure that the

lateral guide (Fig. 26.1/

on the locking pin (Fig. 26.1/

➀) is supported

➁).

26

1

If folding up to the other side is required,

the foot board can be pulled out after

2

loosening the screwed connections (Fig.

24/

➁), turned round and re-installed.

Re-tighten screwed connections.

Loosening the locking screws (Fig. 27/

➂) allows variable adjustment of depth

positioning. To adjust the angle, loosen

the locking screw (Fig. 27/

➁) and pull

out the teeth and set the angle of the

foot board. Re-tighten screw .

26.1

27

3

2

2

3130

3.3.4.10 Leg support with angle

adjustment (774-1)

When seated in the wheelchair, ask a

carer to raise the leg support to the desired level.

To lower the leg support, remove the

load momentarily from the support by

raising the lower thigh (ask a carer if

necessary), and push the clamping lever (Fig. 28/

The leg support can now be moved

slowly downwards.

Warning:

When setting the height-adjustable

leg support, never touch the adjust-

!

ment mechanism with your free

hand.

The position of the calf support can be

adjusted by installing it on the second

set of drilled holes (Fig. 29/

Loosening the locking screw (Fig. 29/

allows the calf pad to be moved upwards.

The length of the leg support can be

adjusted in stages after the screw (Fig.

29/

➃) has been loosened.

Re-tighten all screws when adjustment

is complete.

➀) forwards.

➁).

➂)

28

29

3.3.4.11 Leg support with angle

adjustment and length

compensation (774-2 AL)

When seated in the wheelchair, ask a

carer to raise the leg support to the desired level. The length of the leg sup-

1

3

2

4

port is automatically adjusted by spring

force.

To lower the leg support, remove the

load momentarily from the support by

raising the lower thigh (ask a carer if

necessary), and push the clamping lever (Fig. 29.1/

The leg support can now be moved

slowly downwards.

Warning:

When setting the height-adjustable

leg support, never touch the adjust-

!

ment mechanism with your free

hand.

The height and depth positioning of the

calf plate can be adjusted by installing

it in the corresponding holes (Fig. 29.1/

➀) forwards.

29.1

29.2

1

2

3

➁).

The length of the leg support can be

adjusted in stages after the screw (Fig.

29.1/

➂) has been loosened.

To adjust the angle of the foot plate,

loosen the locking screw (Fig. 29.2) located on the side, pull out the teeth and

set the new angle.

Re-tighten all screws when adjustment

is complete.

3332

3.3.5 Driving wheels

The driving wheels are mounted on a

fixed axle or a full floating axle, depending on the wheelchair model.

☞ Note:

The tyre pressure is shown on both

sides of the tyre surface and can also

be found in the Technical data.

3.3 .5 .1 Full floating axle

The driving wheels can be installed or

removed without the need for tools (Fig.

30). Free the axle by pressing on the

rubber cap and pull outwards.

To install the driving wheels, free the

axle by pressing on the rubber cap (Fig.

30) and push the wheel into the axle

opening until it locks.

Warning:

Each time the wheels are installed,

test the locking mechanism by pull-

!

ing/pushing the driving wheel from

the side (Fig. 31).

30

31

– The full floating axle must be kept

clean. A functional fault may occur

in the case of contamination due to

sand or earth or in the event of freezing of moist cold air.

– If the drive wheel has too much lat-

eral play or the full floating axle does

not lock, it should be repaired immediately by an authorised ORTOPEDIA dealer.

3.3.5.2 Hand wheels

The distance between the hand wheels

and the driving wheels is adjustable. To

change this distance, loosen the four fixing screws (Fig. 32/

one turn. Move the hand wheel to the

required position parallel to the driving

wheel. Tighten the fixing screws crosswise.

3.3.6 Brakes

The wheelchair can be halted via the

hand wheels, the toggle joint brakes

(Fig. 33) or the drum brakes (carers

only).

3.3.6.1 Safety information

▲ The wheelchair must not be pushed

when the brakes are locked on.

▲ If the braking effect reduces, the

wheelchair should be repaired immediately at an authorised repair centre.

▲ In order to prevent unwanted swerving when stopping the wheelchair or

when locking the brakes on a sloping

surface, both brake levers should be activated simultaneously .

➀) by approximately

1

32

33

3534

▲ Do not lean on the lateral brake lever

(Fig. 34/

!

3.3 .6.2 T oggle joint brake

➀).

Warning:

The braking effect is dependent on:

– the condition of the tyres,

– the condition and fixing of the

brakes,

– the brake lever setting,

– the quality of the road surface.

34

3.3.6.5 Locking the brake

1

To secure the wheelchair against unintentional movement, both lateral brake

levers should be pushed forward until

they reach their limit stops (Fig. 36).

3.3.6.6 Releasing the brake

To release the brake, both brake levers

should be pulled backwards until they

reach their limit stops (Fig. 37).

36

Activation of the toggle joint brake causes

a brake bolt to press on the tyre (Fig.

35).

3.3 .6.3 Drum brake

Activation of the drum brake causes

brake pads to press against the wheel

hub from the inside.

3.3. 6.4 Service brake function

For measured braking, the lateral brake

levers of the toggle joint brakes (Fig. 34/

➀) should be pushed forward slightly

and equally.

35

3.3.6.7 Changing or replacing

driving wheels

After a change of driving wheels, checks

should be made to ensure that the

brakes are functioning correctly. The

brakes should then be reset if necessary

Driving wheels with PU tyres require a

special toggle joint brake.

When changing to a wheel with PU tyres,

or from PU tyres to another type of tyre,

the toggle joint brakes must be changed

at the same time.

37

3736

3.3 .6. 8 Drum brake for carers

3.3.7 Swivel wheels

(Fig. 37.1)

T o lock the brake lever once it has been

applied (

the rocker lever upwards (

the brake, pull up the brake lever (

➀), press the forward part of

➂). T o release

➀)

and press on the rear part of the rocker

➁).

arm (

3.3 .6. 9 Adjustment of toggle

joint brake

☞ Note:

After modifications/adjustments to

the chassis, the brakes must be reset.

Please observe the safety information given in Section 3.3.6.1!

Before resetting the brakes, the tyre

pressure must be checked and, if

necessary , adjusted. The correct tyre

pressure is given in the Technical

data.

Loosen the screws of the clamping device (Fig. 38/

brake. Dimension X = 21 mm. When

adjustment is complete, re-tighten the

clamping device screws. Check that the

braking effect of the toggle joint brakes

is equal and that the brakes are functioning correctly .

➀). Move the toggle joint

37.1

38

The swivel wheels can be easily replaced

(Fig. 39).

T o remove the wheels, unscrew and remove the axles.

The correct tyre pressure can be found

1

2

3

in the Technical data or on the outer

surface of the tyre.

39

3.3.8 T yres

Pneumatic tyres:

The appropriate tyre pressures are given

in the >T echnical data <. The maximum

1

pressure is shown on the outer surface

of the tyre.

Solid tyres:

><

X

These can be distinguished by the absence of a compressed air valve.

3938

4. Individual

customisation

This setting option offers:

– customised adjustment of the seat

height to suit your lower thigh length,

– customised adjustment of seat incli-

nation for user,

– increased stability against tipping up.

Warning:

– Customised adjustment or modifi-

cation should only be carried out

!

by an authorised dealer.

– Any new adjustment may have an

effect on performance.

4.1 Seat height/seat

inclination

Customised setting of seat height and

inclination involves:

– changing the driving wheel size,

– moving the adapter (Fig. 43.1/

or axle holder (Fig. 40+41/

adaptable/activity model range) vertically within the perforated plate

(

➁).

– Changing the swivel wheel size.

– setting the angle on the castor con-

trol socket (Fig. 42/

➂).

➁)

➀, in the

40

41

42

4.1.1 Driving wheel position

The driving wheel position depends on:

– the desired seat height,

2

2

3

1

1

– the wheel size,

– the seat inclination,

– the swivel wheel.

Warning:

If the perforated plate (Fig. 43/

positioned horizontally, the wheel

!

position changes, which also results

in a change in performance.

– Each forward movement of the per-

forated plate increases the risk of tipping up!

– Positioning a wheel adapter (Fig.

43.1/

➁) on the inside increases the

risk of tipping up!

➁) is

2

43

2

43.1

4140

4.1.2 Swivel wheel position

The required swivel wheel position (Fig.

44) is determined according to the po-

sition specified for the driving wheel.

☞ Note:

Each time the position of the driving

wheel is changed, the castor control

socket (Fig. 45/

➂) must be reset.

4.2 Wheel camber

Changing the wheel camber is only

possible with the perforated plate of the

IMPULS 3

Various wheel cambers (Fig. 46) can be

set by inserting camber discs of 0°– 4°.

.

44

5. Optional accessories

Optional accessories are not included in

the standard scope of supply .

5.1 Lap belt

The lap belt is used for securing a person sitting in the wheelchair .

– Additional stabilisation of the sitting

position.

– Prevents the wheelchair user from

tipping out of the wheelchair (depends on degree of disability).

– Continuous adjustment to suit the

3

user’s needs.

5.1.1 Fastening lap belt

Pull both belt bands forwards and push

the two parts of the fastening together.

Then carry out a pull test.

Warning:

Please ensure that nothing is stuck

under the belt in order to avoid pain-

!

ful bruising! – Thus you avoid painful

pressure points

Warning:

Customised adaptation or modification should only be carried out by an

!

authorised dealer.

45

46

☞ Note:

A lap belt should only be retrofitted

by an authorised dealer!

Warning:

The lap belt is not part of the retaining system for the wheelchair and/

!

or occupant during transportation in

a vehicle for transporting disabled

persons.

5.1.2 Setting belt length

☞ Note:

The lap belt should be pulled tightly

but should not pinch.

4342

5.2 Stabilisers

5.2.2 Setting the height

The stabilisers (Fig. 48) provide increased

stability from tipping and can be swivelled inwards under the seat (Fig. 49).

Warning:

In certain situations, stabilisers do not

provide sufficient protection against

!

overturning.

Therefore never:

▲ Lean the upper body too far back.

▲ Start off too quickly , particularly when

travelling uphill.

☞ Note:

Please observe the advice given in

the booklet "Safety Information for

Mechanical Wheelchairs"!

5.2.1 Swivelling the stabilisers

Push the stabilisers downwards from the

locking device, then swivel them inwards under the seat (Fig. 49) until the

locking element engages automatically

at the top.

48

49

The stabiliser tube is height-adjustable.

Loosen the locking screws (Fig. 50/

position the stabiliser tube (Fig. 50/

according to the driving wheel. Retighten locking screws.

Warning:

T o provide sufficient stability from tipping, both stabilisers must be set to

!

the same height.

5.2.3 Correct stabiliser length:

In order to ensure sufficient support, the

stabilisers must extend beyond the driving wheel.

➀),

➁)

5.3 Tread cap

The tread cap (Fig. 51/ ➀) is used by

the carer to tilt the wheelchair when

negotiating obstacles and can be

mounted on the right or left.

5.3.1 Setting the height

To set the height, loosen the locking

screws (Fig. 51/

screws when adjustment is complete.

➁). Re-tighten locking

1

2

50

1

2

51

4544

5.4 Transit wheels

5.5 Spoke guard

For narrow openings or passages (e.g.

in trains) the transit wheels (Fig. 53/

allow the wheelchair to be pushed by a

carer without using the driving wheels.

5.4.1 Setting the height

Loosen the locking screws (Fig. 52/

and position the tube as required. Retighten locking screws.

5.4.2 Removing driving wheels

Before removing the driving wheels,

push in the spring-loaded button (Fig.

52/

➀). Push the transit wheel down-

wards to the floor. Tilt the wheelchair

on one driving wheel and push the transit wheel downwards until the button

engages (Fig. 53/

ing wheel.

5.4.3 Locking brake

Lock and release the transit wheel by

operating the kick bar (Fig. 53/

➀). Remove the driv-

➀)

➁)

➂).

52

53

1

2

1

3

The spoke guard prevents injury to

hands from touching the turning spokes.

It also protects the spokes against damage.

5.5.1 Removal

To remove the spoke guard, unscrew the

screwed connection (Fig. 54) and carefully push the guard through the hand

wheel.

5.5.2 Installation

To fit the spoke guard, position the indentations on the circumference of the

guard over the hand wheel support bars.

5.6 Brake lever exten-

54

1

55

sion

Remove the handle (Fig. 55/ ➀), to enable insertion of the brake lever extension (Fig. 56/

➁).

2

56

4746

5.7 Tray

Warning:

Always ensure that brakes are secured

before the installation, setting, adjust-

!

ment or removal of the tray.

• Sharp objects (e.g. watches, rings,

knives or belt buckles) or coarse

grains of dirt can leave unsightly

scratches and grooves on the tray

surface.

• Do not use aggressive or abrasive

substances to clean the tray!

• Do not place hot objects on the tray!

• Do not travel with the tray in place if

it holds loose objects or containers

filled with liquid!

5.7.1 Standard tray

The tray is pushed over the armrest pads

from the front (Fig. 57).

Warning:

For guaranteed stability of the tray,

only armrests with long armrest pads

!

should be used (Fig. 57).

5.7.2 8001 tray

On the XX model, the guide bar of the

8001 tray is pushed into the holder on

the armrest (Fig. 57.1) and secured using the locking screw (Fig. 57.1/

Loosening the locking screw (Fig. 57.1/

➀) allows the tray to be swung to the

side (Fig. 57.2).

➀).

57

57.1

57.2

6. Care and maintenance

6.1 Care

Seat and back cover:

Clean the covers with warm water .

In the case of stubborn soiling, the

fabric can be washed with a standard washing powder for delicate

fabrics. Spots can be removed with

a sponge or a soft brush. Do not

soak! Do not use a washing machine!

Do not use aggressive cleaning

agents e.g. solvents, or hard brushes etc.

1

Rinse with clear water and let get

dry.

Rinse with clean water and leave to

dry naturally. To disinfect, use commercial brands and observe the instructions for use given on the product.

Plastic parts:

The side panel on the side section

and some other elements are of

high quality plastic. Take care of

these by means of standard plastics cleaning agents. Always observe

the specific product information.

Finish:

The high quality surface finish guarantees

optimal protection against corrosion. If the

surface finish is damaged by scratches or

similar, touch it up with a varnish pen available from us. Occasional application of a light

cover of oil to all moving parts (see also Maintenance Instructions) will ensure that your

wheelchair will give you many years of service.

Tyres:

Check tyre pressure regularly. Ensure pres-

sure on both tyres is correct and equal.

Tyre pressure: See Technical data.

Check condition of tyres regularly (wear,

deterioration).

4948

Chassis:

The chassis and wheels can be cleaned

with a damp cloth using a mild detergent. Dry thoroughly after cleaning.

Check the chassis for corrosion and other

damage. Clean the plastic parts using a

mild commercial detergent suitable for

plastics.

Brakes:

Check that brakes are working properly

and are easy to use.

Removable parts

Check that removable parts, e.g. leg

supports, armrests and driving wheels

are firmly and securely fixed in position.

Moving parts:

Check all moving parts are functional

and unobstructed.

6.2 Maintenance

To ensure safety and to prevent accidents as a result of wear on components

going undetected, the wheelchair

should be checked and serviced annually by an ORTOPEDIA dealer. The

ORTOPEDIA dealer will check and maintain all safety-relevant parts of the wheelchair and check the operability and the

operational safety. He will be able to

recognise the onset of wear and will use

only original ORTOPEDIA spare parts or

parts tested and approved by

ORTOPEDIA.

6.2.1 T ools

The following tools are required for setting and adjustment carried out by the

user:

Hexagon socket head wrench DIN 911

1x WA* 4 mm

1x WA* 5 mm

1x WA* 6 mm

Open (face) or box spanner

1x WA* 8 mm

1x WA* 10 mm

* WA = width across

6.2.2 Maintenance instructions

Before setting out:

▲ Check brake unit for correct function.

Operate brake lever until it reaches its

limit. The locked wheels should not be

able to turn under operating conditions.

If they can still turn, the brakes must be

repaired by an authorized specialist

workshop.

▲ Check toggle joint brake for wear

Move brake lever sideways. There should

not be excessive play .

▲ Check tyre pressure

Standard values

Standard tyre: 2.5 bar

Easy tyre: 7,5 bar

☞ Note:

Always observe the pressure stated

on the tyre.

▲ Check tyre profile

If the tyre profile is worn down or if the

tyre is damaged, consult an authorized

specialist workshop for repairs.

▲ Check rear tubes for stability

In the event of deformation or cracking

around the soldered seams, contact an

authorised repair centre immediately for

repair. – Danger of accidents!

Every 8 weeks

(depending on frequency of use)

▲ Lubricate the following components

with a few drops of oil:

– cross brace bearings.

– Moving parts of the locking mecha-

nism.

– Brake lever bearings.

Components must be free from used oil

residues before lubrication.

Please ensure that excess oil does not

contaminate the environment (e.g. your

clothing)

▲ Check that all screwed connections

are tight.

▲ Check that the sliding handles are

tight by forceful twisting.

Every 6 months

(depending on frequency of use)

▲ Check:

– Cleanliness, see Care section.

– General condition, see Care and maintenance section.

5150

6.2.3 Punctures

6.3 Repairs

6.5 Spare parts

If pneumatic tyres are punctured by

sharp objects such as nails, screws, glass

slivers etc., the puncture should be repaired (by mending the inner tube) or

the tube replaced.

Warning:

Before repairing a tyre, the air valve

must be opened in order to let out

!

the air remaining in the tube.

The outer part of the tyre must be

removed and replaced using appropriate tyre levers (bicycle accessories).

Do not use a screwdriver or other

pointed or sharp-sided object as a

lever!

Swivel wheels:

Before replacement or repair, the swivel

wheel axle must be removed (Fig. 58).

☞ Note:

Observe the position of any sleeves

or washers for reassembly.

Consult your repair centre for repairs

and servicing. Centres are experienced

in this work and usually employ specially

trained personnel.

6.4 Customer service

Should you have any questions or require

assistance, please consult your

ORTOPEDIA dealer, who has been

trained at our factory in accordance with

our guidelines and can give advice as

well as carry out servicing and repairs.

Parts can only be obtained through your

dealer. In the event of repairs, use only

original ORTOPEDIA spare parts.

To enable the correct supply of spare

parts, always quote the appropriate serial number, which is shown on the

nameplate!

For all modifications carried out on the

wheelchair, the dealer must add the

date of modification and the appropriate assembly instructions to the wheelchair Operating Instructions.

This ensures that no incorrect details will

be given for future orders of spare parts.

58

5352

7. T echnical data

7.1 Impuls 1 model

Dimensions

Length across leg supports........................104 cm

Height....................................................... 90 cm

Width of seat: 40 / 43 / 46 / 48 cm ...........Seat depth: 40 / 42 / 44 cm

Seat width, folded.....................................31 cm

Seat height ...............................................48 / 50,5 cm

Back height ...............................................40 cm

Armrest height..........................................23 cm

Seat height and seat angle with 24" driving wheels

Swivel wheel: ............................................ 200 x 50 (8“)

Seat height: 50,5 cm.................................Seat angle: 2,5°

Seat height and seat angle with 22" driving wheels

Swivel wheel: ............................................6“

Seat height: 48 cm....................................Seat angle: 2,5°

Tyres/T yre pressures........................... Standard values

Swivel wheel 6“ ........................................solid

Swivel wheel 200 x 50 mm........................ 2,5 bar

Driving wheel 22“ x 1“ .............................7,5 bar

Driving wheel 22“ x 1

Driving wheel 24“ x 1“ .............................7,5 bar

Driving wheel 24“ x 1

☞ Note:

Always observe the pressure stated on the tyre.

3

/8“ ......................... 4,5 bar

3

/8“ ......................... 4,5 bar

7.2 Impuls 1 Euro model

Dimensions

Length across leg supports........................113 cm

Height....................................................... 90 – 95 cm

Width of seat: 40 / 43 / 46 cm................... Seat depth: 40 / 42 / 44 cm

Seat width, folded.....................................31 cm

Seat height ...............................................45,5 – 50 cm

Back height ...............................................40 cm

Armrest height..........................................23 cm

Seat height and seat angle with 24" driving wheels

See order form

Tyres/T yre pressures........................... Standard values

Swivel wheel 6“ ........................................solid

Swivel wheel 200 x 50 ............................... 2,5 bar

Driving wheel 24“ x 1“ .............................7,5 bar

Driving wheel 24“ x 1

☞ Note:

Always observe the pressure stated on the tyre.

Distance from hand wheel ........................ two positions can be set

Weights

Weight when empty..................................from 12,6* kg

Max. passenger weight

Seat width up to 46 cm .............................130 kg

3

/8“ ......................... 4,5 bar

(depending on model and version)

Distance from hand wheel ........................ two positions can be set

Weights

Weight when empty..................................from 12,6* kg

(depending on model and version)

Max. passenger weight

Seat width up to 46 cm .............................130 kg

Seat width 48 cm ......................................130 kg (with double cross brace)

* = Seat width 43 cm, without armrests and leg supports

* = Seat width 43 cm, without armrests and leg supports

5554

7.3 Impuls 1 Vario model

7.4 Impuls 2 model

Dimensions

Length across leg supports........................110 cm

Height....................................................... 90 – 101 cm

Width of seat: 38 / 40 / 43 / 46 / 48 cm ....Seat depth: 40 / 42 / 44 cm

Seat width, folded.....................................31 cm

Seat height ...............................................41,5 – 52 cm

Back height ...............................................40 cm

Armrest height..........................................23 cm

Seat height and seat angle with 22" or 24" driving wheels

See order form

Tyres/T yre pressures........................... Standard values

Swivel wheel 4“x 1¼.................................solid

Swivel wheel 5“x 1¼.................................solid

Swivel wheel 7“x 1¼.................................solid

Swivel wheel 7“x 1¾................................. 2,5 bar

Driving wheel 22“ x 1“ .............................7,5 bar

Driving wheel 22“ x 1

3

/8“ ......................... 4,5 bar

Driving wheel 24“ x 1“ .............................solid rubber

Driving wheel 24“ x 1“ .............................7,5 bar

Driving wheel 24“ x 1

3

/8“ ......................... 4,5 bar

☞ Note:

Always observe the pressure stated on the tyre.

Distance from hand wheel ........................ two positions can be set

Weights

Weight when empty..................................from 13,0* kg

(depending on model and version)

Max. passenger weight

Seat width up to 46 cm .............................130 kg

Seat width 48 cm ......................................130 kg (with double cross brace)

* = Seat width 43 cm, without armrests and leg supports

Dimensions

Length across leg supports........................102 cm

Height....................................................... 91 – 105 cm

Width of seat: 38 / 40 / 43 / 46 / 48 cm ....Seat depth: 40 / 42 / 44 cm

Seat depth (2nd frame): ........................... Seat depth: 44 / 46 / 48 cm

Seat width, folded.....................................31 cm

Seat height ...............................................40 – 51 cm

Back height ...............................................30 – 50 cm

Armrest height..........................................19 – 28,5 cm

Seat height and seat angle with 22" or 24" driving wheels

See order form

Tyres/T yre pressures........................... Standard values

Swivel wheel 4“, 5“, 6“, 7“.......................solid

Swivel wheel 7“x 1¾................................. 2,5 bar

Swivel wheel 200 x 50 mm........................ 2,5 bar

Driving wheel 22“ x 1“ .............................7,5 bar

Driving wheel 22“ x 1

3

/8“ ......................... 4,5 bar

Driving wheel 24“ x 1“ .............................7,5 bar

Driving wheel 24“ x 1

3

/8“ ......................... 4,5 bar

☞ Note:

Always observe the pressure stated on the tyre.

Distance from hand wheel ........................ two positions can be set

Weights

Weight when empty..................................from 13,9* kg

(depending on model and version)

Max. passenger weight

Seat width up to 46 cm .............................130 kg

Seat width 48 cm ......................................130 kg (with double cross brace)

* = Seat width 43 cm, without armrests and leg supports

5756

7.5 Impuls 3 model

7.6 Impuls 4 model

Dimensions

Length across leg supports........................93,5 – 96 cm

Height....................................................... 82 – 94 cm

Width of seat: 38 / 40 / 43 / 46 / 48 cm ....Seat depth: 40 / 42 / 44 cm

Seat width, folded.....................................31 cm

Seat height ...............................................36 – 42 cm

Back height ...............................................30 – 50 cm

Armrest height..........................................19–28,5 cm

Seat height and seat angle with 22" or 24" driving wheels

See order form

Tyres/T yre pressures........................... Standard values

Swivel wheel 4“, 5“, 6“.............................solid

Driving wheel 22“ x 1“ .............................7,5 bar

Driving wheel 22“ x 1

3

/8“ ......................... 4,5 bar

Driving wheel 24“ x 1“ .............................7,5 bar

☞ Note:

Always observe the pressure stated on the tyre.

Distance from hand wheel ........................ two positions can be set

Weights

Weight when empty..................................from 12,3* kg

(depending on model and version)

Max. passenger weight

Seat width up to 46 cm .............................130 kg

Seat width 48 cm ......................................130 kg (with double cross brace)

* = Seat width 43 cm, without armrests and leg supports

Dimensions

Length across leg supports........................98 cm

Height....................................................... 91 – 105 cm

Width of seat: 38 / 40 / 43 / 46 / 48 cm ....Seat depth: 40 / 42 / 44 cm

Seat depth (2nd frame): ........................... Seat depth: 44 / 46 / 48 cm

Seat width, folded.....................................31 cm

Seat height ...............................................44 – 51 cm

Back height ...............................................30 – 50 cm

Armrest height..........................................19 – 28,5 cm

Seat height and seat angle with 22" or 24" driving wheels

See order form

Tyres/T yre pressures........................... Standard values

Swivel wheel 4“, 5“, 6“, 7“.......................solid

Swivel wheel 7“x 1¾................................. 2,5 bar

Driving wheel 22“ x 1“ .............................7,5 bar

Driving wheel 22“ x 1

3

/8“ ......................... 4,5 bar

Driving wheel 24“ x 1“ .............................7,5 bar

Driving wheel 24“ x 1

3

/8“ ......................... 4,5 bar

☞ Note:

Always observe the pressure stated on the tyre.

Distance from hand wheel ........................ two positions can be set

Weights

Weight when empty..................................from 12,6* kg

(depending on model and version)

Max. passenger weight

Seat width up to 46 cm .............................130 kg (with double cross brace)

Seat width 48 cm ......................................130 kg (with double cross brace)

* = Seat width 43 cm, without armrests and leg supports

5958

7.7 Impuls XX model

Dimensions

Length across leg supports........................100 cm

Height....................................................... 95 cm

Width of seat: 48 / 51 / 54 / 57 / 60 cm ....Seat depth: 42 / 45 / 48 cm

Seat width, folded.....................................29 cm

Seat height ...............................................44 – 51,5 cm

Back height ...............................................40, 45 cm

Armrest height..........................................19 – 28,5 cm

Seat height and seat angle with 22" or 24" driving wheels

See order form

Tyres/T yre pressures........................... Standard values

Swivel wheel ø 142 mm ............................solid

Swivel wheel ø 200 x 50 mm ....................solid

Swivel wheel ø 200 x 50 mm ....................2,5 bar

Swivel wheel 7“x 1¼.................................solid

Swivel wheel 7“x 1¾................................. 2,5 bar

Driving wheel 22“ x 1

Driving wheel 22“ x 1

Driving wheel 24“ x 1

Driving wheel 24“ x 1

3

/8“ ......................... solid

3

/8“ ......................... 4,5 bar

3

/8“ ......................... solid

3

/8“ ......................... 4,5 bar

9. Guarantee

The guarantee period for each of these products is 24 months and covers material

and manufacturing defects. Excluded are wearing parts and parts/assemblies that

are subject to normal wear and damage resulting from over-stressing, improper

handling, damage through use of force or improper/unauthorised modification/

repair.

Please contact your dealer where you purchased the product in the event of a

guarantee claim.

For product liability reasons, repair and maintenance work may only be carried out

by an authorised dealer and only original–ORTOPEDIA–spare parts may be used for

such repair/maintenance.

The products are subject to technical improvement and design modification.

This publication is valid as of December 2000.

ORTOPEDIA GmbH, Kiel

This product complies with EU – Directive 93/42/EEC for

medical products.

☞ Note:

Always observe the pressure stated on the tyre.

Distance from hand wheel ........................ two positions can be set

Weights

Weight when empty..................................from 17,8* kg

(depending on model and version)

Max. user weight: ................................................................................160 kg

Max. permissible user weight when using separate leg supports: ........ 130 kg

* = Seat width 48 cm, without armrests and leg supports

6160

Notes:

Please send me your current catalogue and product information, free of

charge and without obligation, on the following:

WheelchairsWheelchairs

Wheelchairs

WheelchairsWheelchairs

Universal and activity wheelchairs, wheelchairs for toilet and shower,

electric wheelchairs, scooters,

accessories

Aids for domestic care, everAids for domestic care, ever

Aids for domestic care, ever

Aids for domestic care, everAids for domestic care, ever

Bath and toilet equipment, mobility aids and equipment, home care

yday life and rehabilitationyday life and rehabilitation

yday life and rehabilitation

yday life and rehabilitationyday life and rehabilitation

6362

Sender:

Name

Street

Please prepay

if stamp

available

Postcode Town

Tel.

Fax.

Active and universal wheelchairs

Toilet and shower wheelc hairs

Electric wheelchairs

Scooter

Equipment for home care, everyday life and the rehabilitation

Response

ORTOPEDIA GmbH

– Öffentlichkeitsarbeit –

Postf ach 64 09

D-24125 Kiel

ORTOPEDIA GmbH

Postfach 64 09

Salzredder 30

T elephone +49 (0)431 2003 -0

Fax +49 (0)431 2003 - 378

Ident – Nr. 8 460 199 – 5101

•

http://www.ortopedia.de

0301 – 1 – 1. ST

• D-24125 Kiel

• D-24149 Kiel

QM system

certification according

to DIN EN ISO 9001

and DIN EN 46001

64

Technical consultancy

We reserve the right to make technical modifications to our products

and accept no responsibility for printers' errors and colour variations

in our publications!

• Sales • Service

Loading...

Loading...