Assembly instructions

and operating manual

ORTNER Wood-fired oven (HBO)

To avoid any errors, please first carefully read our assembly instructions!

CAUTION: The door must be provided as a covering door; the oven opening is smaller

than the door (see chapter “Plaster support surface”)

The assembly manual provided below should merely serve as a guide. The details can

be designed individually.

The respective national or local regulations and general provisions, stipulations and

codes of practice must be complied with.

ORTNER GmbH

Hürmer Straße 36 Tel.: +43 (0) 2754 / 27 07 office@ortner-cc.at

A-3382 Loosdorf/Melk Fax: +43 (0) 2754 / 27 08 www.ortner-cc.at Page 1 of 25

ORTNER GmbH

Hürmer Straße 36 Tel.: +43 (0) 2754 / 27 07 office@ortner-cc.at

A-3382 Loosdorf/Melk Fax: +43 (0) 2754 / 27 08 www.ortner-cc.at Page 2 of 25

Contents

General information ................................................................................................................................................................. 3

Additional information in the event of the use of the wood-fired oven in the interior area ............................................... 4

Technical specifications ............................................................................................................................................................ 5

It is prohibited to use the following substances for combustion ........................................................................................... 5

Design examples ....................................................................................................................................................................... 6

Foundation preparation ........................................................................................................................................................... 7

Base frame, base, substructure of the wood-fired oven ...................................................................................................... 10

Assembly of the interior parts ................................................................................................................................................ 12

Model 0 ............................................................................................................................................................................... 12

Model 1 & 2 ........................................................................................................................................................................ 13

Model 3 & 4 ........................................................................................................................................................................ 14

Further assembly (all models) ........................................................................................................................................... 16

Insulation of the jacket segments .......................................................................................................................................... 17

Plaster base surface ................................................................................................................................................................ 18

Information on the heating procedure .................................................................................................................................. 19

Tips for your customers .......................................................................................................................................................... 19

Dimensioned drawings ........................................................................................................................................................... 20

Model 0 (art. no. 1500000) ............................................................................................................................................... 20

Model 1 (art. no. 1500001) ............................................................................................................................................... 21

Model 2 (art. no. 1500002) ............................................................................................................................................... 22

Model 3 (art. no. 1500003) ............................................................................................................................................... 23

Model 4 (art. no. 1500004) ............................................................................................................................................... 24

Accessories for ORTNER wood-fired oven ............................................................................................................................. 25

ORTNER GmbH

Hürmer Straße 36 Tel.: +43 (0) 2754 / 27 07 office@ortner-cc.at

A-3382 Loosdorf/Melk Fax: +43 (0) 2754 / 27 08 www.ortner-cc.at Page 3 of 25

General information

Before the commissioning of the firing installation, read this operating manual and assembly instructions and

observe the warnings and cautions. As soon as the commissioning of the oven has been performed, the

operating manual and assembly instructions including all usage regulations are considered as accepted without

exception, this also applies in the event that the operating manual and assembly instructions have not been

read.

Heat energy is released with the combustion of wood, which leads to a strong heating up of the surrounding

parts. Coming into contact with these components without the use of corresponding protection or aids (heatprotection glove) must be prevented.

Ensure sufficient distance to combustible objects.

Instruct your children of this particular hazard and keep them out of reach of the oven during heating

operation.

It is prohibited to place objects that are not heat-resistant on the firing installation or to bring them into its

vicinity.

The handling of highly combustible or explosive substances is prohibited during the operation of the oven.

Operating errors can lead to deflagration and as a result to the damaging of the oven or cause severe injuries.

Only spare parts approved by the manufacturer may be installed.

The most important precondition for the proper and reliable function of your wood-fired oven is dry, untreated

hardwood (permissible types of wood: beech, birch, hornbeam) with a maximum residual moisture content of

20%. Wood will only achieve an optimal heating value when it has been stored dry and ventilated under a roof

for at least two years.

In addition to a greatly reduced heating value, wet wood generates an excess of shining soot deposits (pitch-

like deposit) on the ceramic components as well as the chimney (risk of a chimney fire in the event of indoor

installation).

In regard to the use of the processing materials, pay attention that these are suitable for the exterior area or

the respective area of application.

Additionally, it is recommended to protect the Ortner wood-fired oven against weather influences (e.g. driving

rain). This can for example be performed with a roof, a pergola or a protective tarpaulin (please note that the

wood-fired oven poses a possible source of flying sparks).

Please remember that all national laws/regulations (e.g. building regulations, safety distances, etc.) must be

complied with for the installation of the oven.

ORTNER GmbH

Hürmer Straße 36 Tel.: +43 (0) 2754 / 27 07 office@ortner-cc.at

A-3382 Loosdorf/Melk Fax: +43 (0) 2754 / 27 08 www.ortner-cc.at Page 4 of 25

Additional information in the event of the use of the wood-fired oven in the interior area

Please note that neither combustible nor explosive substances may be located in the installation space of the

oven.

The wood-fired oven may not be installed in spaces with insufficient combustion air supply. (CAUTION: Please

note that newly constructed or renovated buildings can be very airtight and as a result, a sufficient combustion

air supply may not be possible without additional equipment.)

The wood-fired oven may not be operated in installation spaces that are ventilated by means of fans in

ventilation or heating air systems with the exception that the safe operation of the oven can be ensured. This

means:

A simultaneous operation of an air extraction system and the firing installation must be prevented.

The negative pressure in the installation space must be prevented automatically and reliably by means of

corresponding safety equipment.

Overall, the negative pressure generated as a result of the combustion air flow of the oven and the volume

flows of the ventilation systems in the installation space and the rooms connected via the ventilation

system may not exceed a value of 2 Pa. This must also be ensured in the event of the adjustment or

removal of easily accessible control devices of the ventilation system.

The system may only circulate the air within a room.

The oven may not be installed in freely accessible spaces or on freely accessible areas (this also includes

stairwells in the event of multiple tenants). Installation/exhibition spaces are exempted from this; however,

the firing installation must be operated under expert supervision.

No combustible objects may be located at a distance of 80 cm to the adjustment door.

Attention must be paid that the installation of the wood-fired oven is only permitted on those locations in

which a sufficient load-bearing capacity of the installation area is ensured. Should this not be the case, then

additional measures must be taken to achieve this (e.g. incombustible board for the distribution of the load).

The regular cleaning of the chimney may only be performed by a licensed specialist.

This firing installation is NOT suitable for multiple connections of the chimney.

The firing installation must be connected in a gas-tight manner in the event of a vertical connection of the

chimney.

Consult your local chimney sweep on the suitable chimney connection.

ORTNER GmbH

Hürmer Straße 36 Tel.: +43 (0) 2754 / 27 07 office@ortner-cc.at

A-3382 Loosdorf/Melk Fax: +43 (0) 2754 / 27 08 www.ortner-cc.at Page 5 of 25

Technical specifications

Ortner wood-fired oven

Variant

Model 0

Model 1

Model 2

Model 3

Model 4

Max. fuel amount (per firing instance) [kg]

8 9 12

14

20

Total weight [kg]

235

370

370

435

510

Material thickness (combustion chamber parts)

[kg/m3]

1,900

1,900

1,900

1,900

1,900

Temperature resistance [°C]

1,200

1,200

1,200

1,200

1,200

Average CO2 content [%]

6.2

6.9

6.9

7.1

7.2

Average exhaust temperature [°C]

160

205

213

210

227

Required discharge pressure [Pa]

4 4 4 4 4

Stack gas mass flow [g/s]

28.3

31.1

36.1

42.4

51.4

It is prohibited to use the following substances for combustion

Moist wood

Soft or resinous wood

Bark and chipboard waste

Painted and coated wood

Woodchips, wood pellets

Plastics, cardboard

Kitchen and household waste

Coal of any type

Combustible liquids

ORTNER GmbH

Hürmer Straße 36 Tel.: +43 (0) 2754 / 27 07 office@ortner-cc.at

A-3382 Loosdorf/Melk Fax: +43 (0) 2754 / 27 08 www.ortner-cc.at Page 6 of 25

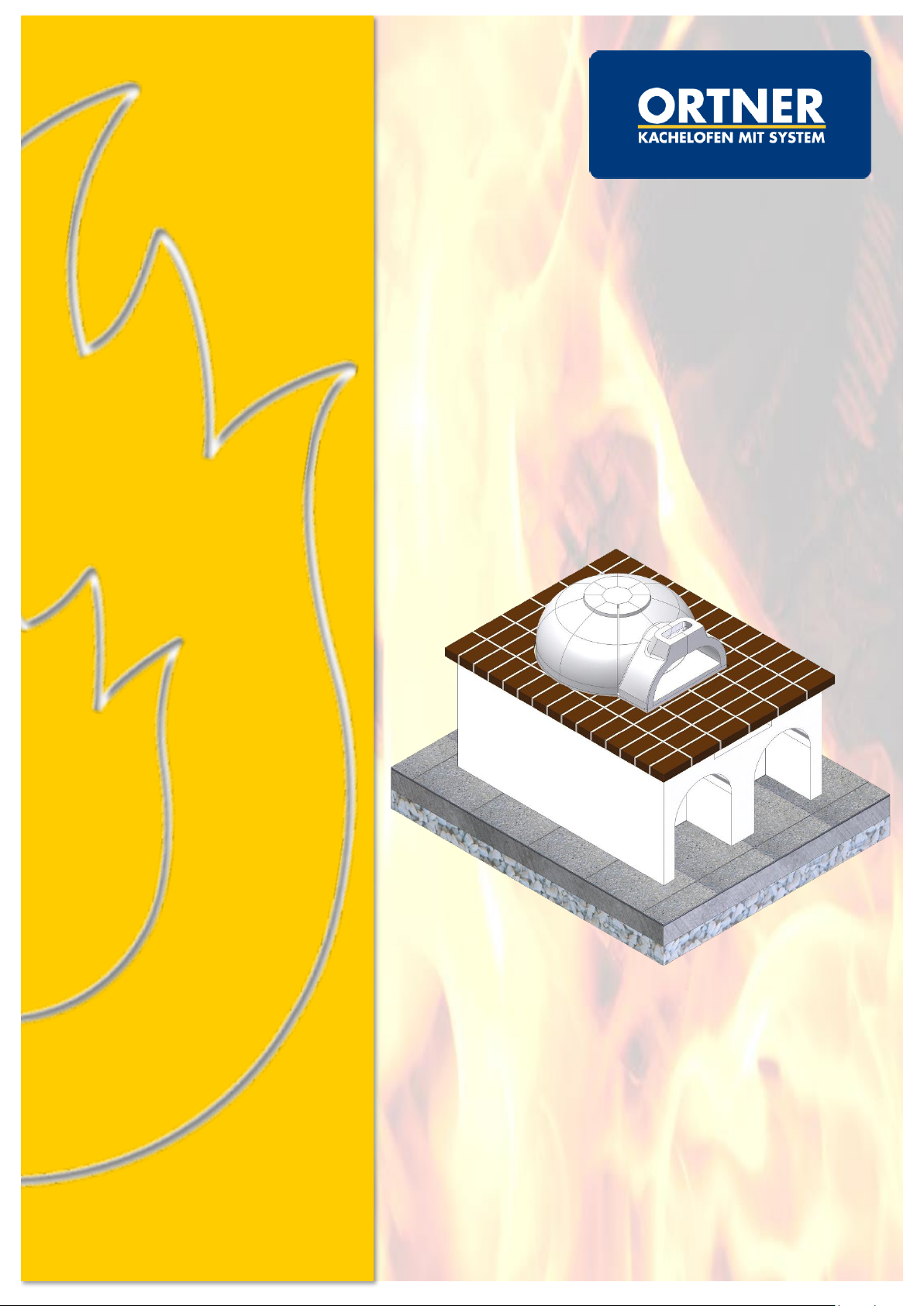

Design examples

ORTNER GmbH

Hürmer Straße 36 Tel.: +43 (0) 2754 / 27 07 office@ortner-cc.at

A-3382 Loosdorf/Melk Fax: +43 (0) 2754 / 27 08 www.ortner-cc.at Page 7 of 25

Foundation preparation

2.

Perform the excavation. Depending on the

building regulation, excavate your area down

to the frost line in order to achieve a stable

and frost-resistant foundation.

1.

Choose the desired size of your foundation

length x width

Minimum requirement:

Model 1: 1.25 m x 1.25 m

Model 2: 1.4 m x 1.4 m;

Model 3: 1.5 m x 1.5 m;

Model 4: 1.65 m x 1.65 m

Depending on the model size or the floor

covering, you can design the measurements

yourself; however, the minimum dimensions

must be adhered to.

Model 1 (1.25 m x 1.25 m)

Size of the desired floor space

ORTNER GmbH

Hürmer Straße 36 Tel.: +43 (0) 2754 / 27 07 office@ortner-cc.at

A-3382 Loosdorf/Melk Fax: +43 (0) 2754 / 27 08 www.ortner-cc.at Page 8 of 25

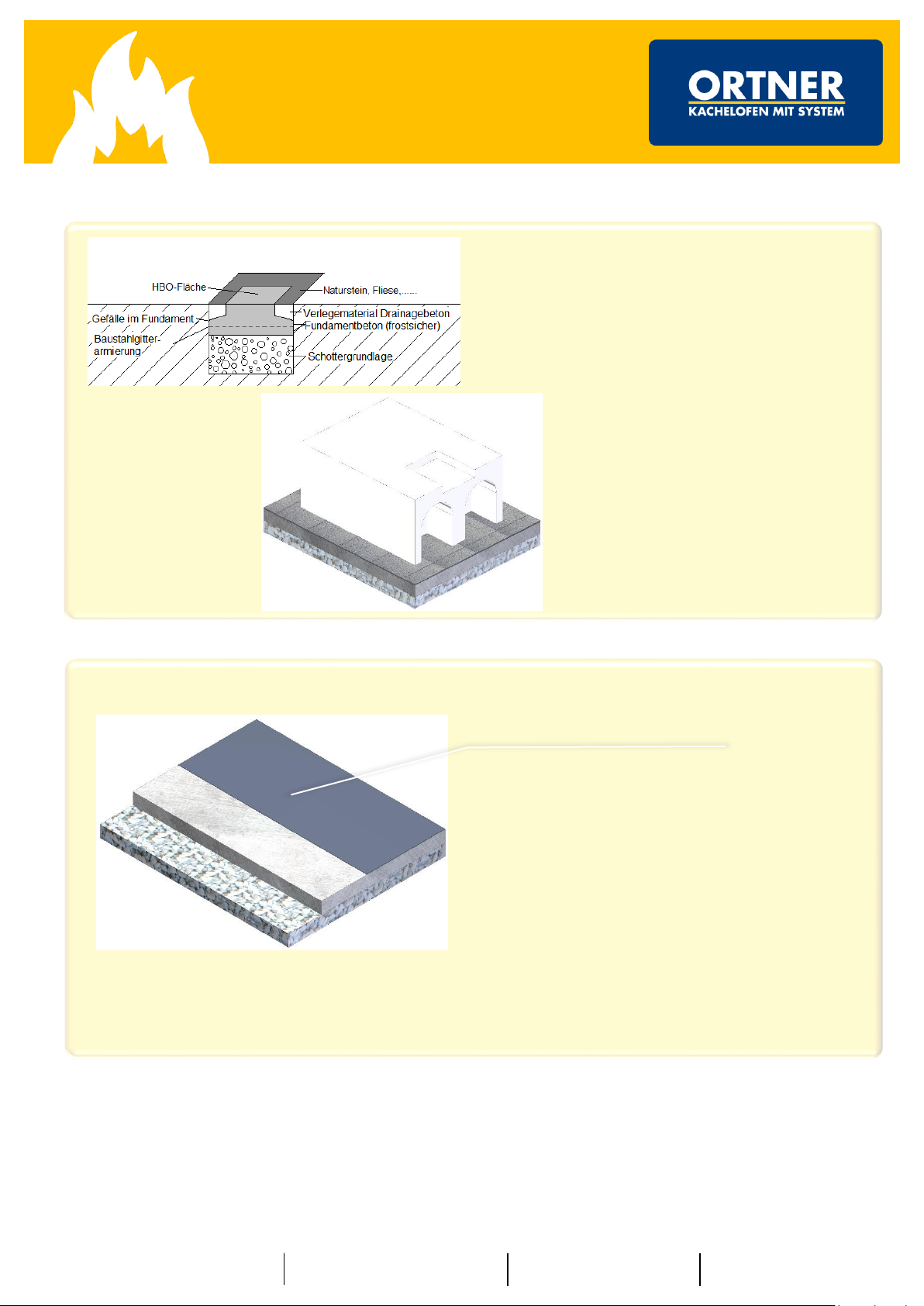

4.

Compact the gravel base (by means of

pounding, plate vibrator, etc.).

Cast the concrete slab with a minimum

thickness of 10 cm (observe local building

regulations). Provide the base plate with a

reinforcement.

3.

Fill the pit with corresponding subsoil or

gravel material; at least 10 cm should remain

free for a concrete slab.

ORTNER GmbH

Hürmer Straße 36 Tel.: +43 (0) 2754 / 27 07 office@ortner-cc.at

A-3382 Loosdorf/Melk Fax: +43 (0) 2754 / 27 08 www.ortner-cc.at Page 9 of 25

6.

It is recommended to provide the floor area

of the HBO with building sealing to protect

the oven against rising moisture.

5.

Note: If you want to install a footpath made

of natural stone tile or a paving stone surface

fixed cast in concrete, then please pay

attention to the required height of the

structure for the respectively selected

installation material. If required, create

inclined concrete.

Seal against rising moisture

ORTNER GmbH

Hürmer Straße 36 Tel.: +43 (0) 2754 / 27 07 office@ortner-cc.at

A-3382 Loosdorf/Melk Fax: +43 (0) 2754 / 27 08 www.ortner-cc.at Page 10 of 25

Base frame, base, substructure of the wood-fired oven

8.

Cover your base frame and create a structural

weight-bearing foundation for the inner parts

(Ortner HBO) using suitable building

materials. (Lintel, bricks, cellular concrete,

concrete, metal board, etc. Caution:

Temperature load of up to 250 °C possible.)

Note 1: Pay attention to recesses such as for

the desired ash pan.

Note 2: Pay attention to the height of the

construction. The oven must be insulated

against the loss of heat below the interior

parts.

(2 x Isoboard sheet 6 cm)

7.

Now design the desired base frame shape of

your Ortner HBO using suitable building

materials (e.g. open-end blocks, bricks,

cellular concrete blocks, concrete, etc.).

Because the base frame is not subjected to a

thermal load, these building materials do not

have to be heat-resistant. However, attention

must be paid that sufficient structural loading

capacity is ensured. Frost-resistant materials

must be used in the exterior area.

Example 1

Example 2

Insulation made of Isoboard

Recess for the ash pan

Example

ORTNER GmbH

Hürmer Straße 36 Tel.: +43 (0) 2754 / 27 07 office@ortner-cc.at

A-3382 Loosdorf/Melk Fax: +43 (0) 2754 / 27 08 www.ortner-cc.at Page 11 of 25

10.

When the foundation has been completed,

you can begin with the construction of the

inner parts of the Ortner HBO.

9.

Adjust the difference of level of the

insulation. Cast your cover to the desired

shape in concrete.

Note: Ensure that possible surface water can

drain off.

Natural stone, bricks, tiles

Desired cover shape

Drip edge

ORTNER GmbH

Hürmer Straße 36 Tel.: +43 (0) 2754 / 27 07 office@ortner-cc.at

A-3382 Loosdorf/Melk Fax: +43 (0) 2754 / 27 08 www.ortner-cc.at Page 12 of 25

Assembly of the interior parts

Model 0

Important: The base plates are only

assembled dry and should not be bonded.

Slide the base plates together and secure

with clamps made of stove fitter’s wire in

order to safeguard additional stability.

For this, cuts and holes have already been

provided for the position of the clamps.

Scope of material for the construction of the

floor:

2 base plates

Stove fitter’s wire (clamps)

ORTNER GmbH

Hürmer Straße 36 Tel.: +43 (0) 2754 / 27 07 office@ortner-cc.at

A-3382 Loosdorf/Melk Fax: +43 (0) 2754 / 27 08 www.ortner-cc.at Page 13 of 25

Model 1 & 2

Slide the base plates together and secure

with clamps made of stove fitter’s wire in

order to safeguard additional stability.

For this, cuts and holes have already been

provided for the position of the clamps.

Caution:

On model 1 & 2, the base plates are

assembled flush (without metallic assembly

aids).

Scope of material for the construction of the

floor:

Stove fitter’s wire (clamps)

Important: The base plates are only assembled

dry and should not be bonded.

ORTNER GmbH

Hürmer Straße 36 Tel.: +43 (0) 2754 / 27 07 office@ortner-cc.at

A-3382 Loosdorf/Melk Fax: +43 (0) 2754 / 27 08 www.ortner-cc.at Page 14 of 25

Model 3 & 4

Then the same applies to the opposite side.

First slide the base plates flush together on

one side (left or right) and then secure with

the metal clamps.

Scope of material for the construction of the

floor:

2 or 4 base plates (depending on the

model)

Stove fitter’s wire (clamps)

Packing strip, Ø 10 mm

Metallic assembly aids (thickness =

6 mm)

Important: The base plates are only assembled

dry and should not be bonded.

ORTNER GmbH

Hürmer Straße 36 Tel.: +43 (0) 2754 / 27 07 office@ortner-cc.at

A-3382 Loosdorf/Melk Fax: +43 (0) 2754 / 27 08 www.ortner-cc.at Page 15 of 25

Now close the 6 mm gap that has been

created with the provided packing strip.

Finally, also clamp the parts of the right and

left-hand side. In the course of this, pay

attention that the base plates press against

the packing strip.

Now insert the assembly aids and slide the

parts of the left and right-hand side together

in a secured manner, creating a gap with a

width of 6 mm.

Subsequently, remove the assembly aids.

ORTNER GmbH

Hürmer Straße 36 Tel.: +43 (0) 2754 / 27 07 office@ortner-cc.at

A-3382 Loosdorf/Melk Fax: +43 (0) 2754 / 27 08 www.ortner-cc.at Page 16 of 25

Further assembly (all models)

Place the base plates on the insulation

→ Creation of the base plate.

Do not bond!

Position the connection adapter with shut-off

damper (CAUTION: Tension is generated as a

result of the thermal load of the combustion

chamber shell bricks).

Assemble the jacket segments (tongue and

groove system) dry. Install the jacket segment

with the two grooves as the end stone.

Do not bond!

Changeable floor

Jacket segments

Base plate

ORTNER GmbH

Hürmer Straße 36 Tel.: +43 (0) 2754 / 27 07 office@ortner-cc.at

A-3382 Loosdorf/Melk Fax: +43 (0) 2754 / 27 08 www.ortner-cc.at Page 17 of 25

Insulation of the jacket segments

Cover the jacket segments with rock wool for

insulation (at least 10 cm) and Stauss fabric as

a plaster base.

CAUTION: The installation of the wood-fired

oven on a combustible wall is not permissible.

Ensure that the chimney is also insulated.

Keep in mind that a high chimney will cause a

high draught and as a result may limit the

heat storage capacity (the ideal chimney

height lies in the range of 0.75 to 1.25 m,

proof of functionality of the chimney is

required in accordance with EN 13384-1). In

the event of higher chimneys, a

corresponding reduction of the draught must

be ensured.

Plaster

Stauss fabric

Rock wool

ORTNER GmbH

Hürmer Straße 36 Tel.: +43 (0) 2754 / 27 07 office@ortner-cc.at

A-3382 Loosdorf/Melk Fax: +43 (0) 2754 / 27 08 www.ortner-cc.at Page 18 of 25

Plaster base surface

Create a plaster base surface on the mineral wool using suitable building materials (Stauss brick fabric, bricks, etc.).

Plaster or cover the oven individually for your customer using suitable materials. These should

be suitable for the exterior area, frost-resistant and matching the foundation (e.g. tiles, natural

stone, quarry stone, or similar).

During processing, pay attention to the various building regulations and the respective processing

regulations of the manufacturers or the selected building materials.

Door connection:

The Ortner adjustment door for the woodfired oven has not been designed as a slide-in

door, but as a covering door. The door is

larger than the oven opening.

Create an arch roof based on the door size

using bricks, chamotte or other suitable

building materials as a connection to the

combustion chamber and for insulation.

Fabrication of the cleaning opening to the ash

pan in the arch roof or the adjustment door

area.

Stop for the adjustment

ORTNER GmbH

Hürmer Straße 36 Tel.: +43 (0) 2754 / 27 07 office@ortner-cc.at

A-3382 Loosdorf/Melk Fax: +43 (0) 2754 / 27 08 www.ortner-cc.at Page 19 of 25

Information on the heating procedure

The ORTNER wood-fired oven can be used both as a cooking or bread baking oven as well as dehydration and pizza oven.

First a cross stack is created in the oven cavity with approx. 2/3 of the maximum wood stacking amount (approx. 33 cm

logs) and is ignited to a roaring fire using suitable fire-lighters. Set the adjustment door in the intended opening. Ensure

that the chimney damper is open and that the ventilation slots of the adjustment door are open. After approximately

half an hour the first goods to be baked can be inserted in the oven. Pay attention that it is covered with tinfoil.

Depending on the size of the logs, the remaining 1/3 of the logs can be piled on after approximately half an hour. In the

course of this, the walls of the baking oven and the floor absorb a large amount of heat energy and store this for several

hours. The heating material (hardwood) should be absolutely dry.

Tips for your customers

Tip 1:

In the event of baked goods (desserts, breads, etc.) the embers must be distributed along the entire area of the oven

cavity. Here, the ventilation dampers and the ventilation slots of the adjustment door should be closed. To ensure that

the heat distributes evenly throughout the oven cavity, the oven should now “rest” (approx. 1/2 hour). Following this,

clean the ash out of the baking oven. Due to the generation of dust, the chimney damper should remain open during

cleaning, but should be closed immediately after sweeping out. Now the oven is ready for baked goods.

The burnt wood and the hot stones provide the distinctive flavour for the baked and cooked goods.

Tip 2:

The ash should be removed completely from the oven cavity after each baking instance.

Otherwise, the wood-fired oven requires little or no servicing or maintenance.

Do not use cleaning tools in the event of soiling (brushes, chemical cleaning agents, etc.), this soiling will be burnt out

completely in the course of the next heating up.

ORTNER GmbH

Hürmer Straße 36 Tel.: +43 (0) 2754 / 27 07 office@ortner-cc.at

A-3382 Loosdorf/Melk Fax: +43 (0) 2754 / 27 08 www.ortner-cc.at Page 20 of 25

Dimensioned drawings

Model 0 (art. no. 1500000)

Dimensions in mm

ORTNER GmbH

Hürmer Straße 36 Tel.: +43 (0) 2754 / 27 07 office@ortner-cc.at

A-3382 Loosdorf/Melk Fax: +43 (0) 2754 / 27 08 www.ortner-cc.at Page 21 of 25

Model 1 (art. no. 1500001)

Dimensions in mm

ORTNER GmbH

Hürmer Straße 36 Tel.: +43 (0) 2754 / 27 07 office@ortner-cc.at

A-3382 Loosdorf/Melk Fax: +43 (0) 2754 / 27 08 www.ortner-cc.at Page 22 of 25

Model 2 (art. no. 1500002)

Dimensions in mm

ORTNER GmbH

Hürmer Straße 36 Tel.: +43 (0) 2754 / 27 07 office@ortner-cc.at

A-3382 Loosdorf/Melk Fax: +43 (0) 2754 / 27 08 www.ortner-cc.at Page 23 of 25

Model 3 (art. no. 1500003)

Dimensions in mm

ORTNER GmbH

Hürmer Straße 36 Tel.: +43 (0) 2754 / 27 07 office@ortner-cc.at

A-3382 Loosdorf/Melk Fax: +43 (0) 2754 / 27 08 www.ortner-cc.at Page 24 of 25

Model 4 (art. no. 1500004)

Dimensions in mm

ORTNER GmbH

Hürmer Straße 36 Tel.: +43 (0) 2754 / 27 07 office@ortner-cc.at

A-3382 Loosdorf/Melk Fax: +43 (0) 2754 / 27 08 www.ortner-cc.at Page 25 of 25

Accessories for ORTNER wood-fired oven

Art. no.

Article designation

Article description

1500000

Wood-fired oven model 0

Surface oven area 50.4 dm²

1500001

Wood-fired oven model 1

Surface oven area 63.2 dm²

1500002

Wood-fired oven model 2

Surface oven area 80.1 dm²

1500003

Wood-fired oven model 3

Surface oven area 98.7 dm²

1500004

Wood-fired oven model 4

Surface oven area 118.8 dm²

1500010

Connection pipe with damper

for HBO 0

Connection pipe Ø 180 mm with damper to HBO 0,

damper operation 4-sided 12 x 12 mm

1500011

Connection adapter

Wood-fired oven connection adapter, flue Ø

180 mm for HBO models 1-4

1603007

Control handle with flexible

jointed shaft

Stainless steel, Ø 70 mm, jointed shaft l = 350 mm

1500020

Adjustment door HBO model 0

Wood-fired oven covering door black plate with an

adjustable ventilation damper for HBO model 0

1500021

Adjustment door, stainless steel

Wood-fired oven covering door, stainless steel with

2 adjustable ventilation dampers for HBO models 14

1500030

Ash drawer, stainless steel

Wood-fired oven, ash pan, stainless steel

1500040

Chimney roof

Wood-fired oven, chimney roof

1901001

Square wooden shovel

Beach wood, certified for foodstuffs; dimensions 320

x 320 mm, overall length 1,820 mm

1901002

Round pizza shovel

Aluminium, Ø 330 mm, overall length 1,520 mm

1901003

Round, perforated pizza shovel,

small

Aluminium perforated, Ø 330 mm, overall length

1,520 mm

1901004

Angular, perforated pizza shovel

Aluminium perforated, dimensions 330 x 330 mm,

overall length 1,520 mm

1901005

Rotating brush with natural

bristles

Rotating brush with natural bristles, dimensions 200

x 66 mm, overall length 1,300 mm

1901006

Ember puller

Made of stainless steel and galvanised iron,

dimensions 55 x 40 mm, overall length 1,530 mm

1901007

Adjustment thermometer

Oven thermometer made of stainless steel for

temperatures up to 400 °C

Loading...

Loading...