Orthman TERRA FIRM'R Owner's Manual

www.orthman.com

TERRA

FIRM’R

OPERATOR’S MANUAL

ORTHMAN

MANUFACTURING

INCORPORATED

STILL THE STRONGEST

ORTHMAN MFG. INC.

75765 RD. 435

LEXINGTON, NE 68850

OM06-04-01

Farm Safety

Danger

Potential Eff e ct or Inju ry

Prevention

Chemicals/Pesticides

Skin and respiratory injury or death

MSDS and proper Personal Pr o tective Equipment. Rev iew Manufacturers dat a sheets

Cold

Illness, Frostbite or death

Dress properly for the day.

Dust

Respiratory injury or explosive combinat ions

Be aware of your surroundings and activity

Electricity

Shock, burns, fire, death

Use a qualified profess ional for wiring dangerou s electrical devices. Never overload a

Grain bins, Silos

Entrapmen t, Suffocat ion, Explosion from

formation of dangerous gases and poisoning.

Make sure the bin is properly ventilated and maintained. Never walk the grain.

Hand tools

Injury including cuts abrasions, electrocution,

strains, sprains and death

Make sure you hand tools are in good condition. Never leave a damaged tooling

accessib l e f o r someone els e to use.

Highway traffic

Collisions r es ulting in injur y or death

Follow regulations, stay alert. Avoid alcohol and use of communication devices while

driving

Lifting and lifting

Back injury, sprains, strains. Falling material

material

Use proper lifting technique. Get help when the load is too heavy. Inspect chains, straps

Livestock handling

Serious injury or death resulting from being

pinned struck or trampled.

Always mak e sure you have adequate room a nd an escape r o ute

Machinery/Equipment

Cuts, abrasions, amp u tat io ns , de at h.

Thoroughly read and understand your Owners Equipment M an ual. Never oper ate the

otherwise put into operation while you are working on it.

Manure pits

Explosion from formation of dangerous gases.

Suffocation. Poisoning

Proper main tenance.

Mud

Sprains, strains, entrapment and suffocation.

Eye injury and skin irritation.

Proper Personal Protective Equip ment. In some con ditions a “Spotter” may be needed.

Noise

Hearing damage

Personal Protective E quipment.

Ponds

Drowning

Wear a life p reserver and make sure help i s readily ava ilable.

Slips/Trips/Falls

Sprains, strains, back and neck injury, bone

breaks or dea t h

Keep work area free from clutter and organized. If working on anything elevated make

sure you have appropriate guarding and/or fall protection such as a harness and lanyard.

Sun/Heat

Sun burn, Heat Stroke, shock, death

Use common sense on excess ively hot days, use sun screen, wear a hat and stay hydrated.

Toxic gases

Skin and respiratory injury or death.

MSDS and proper Personal Pr o tective Equipment. Rev iew Manufacturers dat a sheets

Tractors

Cuts, abrasions, amp u tat io ns , de at h.

Thoroughly read and understand your Owners Equipment Manual. Never operate the

Wells

Electrocution, am pu ta tion, death

Avoid contact with water while working o n an electrical device. Always be sure the

equipment can/will not be energized during repair or maintenance. Make sure all guarding

is in place.

Severe Weath er

Electrocu t ion, “struck by” injurie s , death

Move to a safe place. Lightening, hail and tornadoes are unpredictable.

Contrary to the popular image of fr esh air and peaceful surroundings, a farm is

not a hazard-free work setting. Every yea r, th o u sands of farm workers are injured

and hundreds more die in farming accidents. According to the National Safety

Council, agriculture is the most hazardous industry in the nation.

How You Can Improve Farm Safety

You can start by increasing your awareness of farming hazards and making a conscious effort to prepare for emergency

situations including fires, vehicle accidents, electrical shocks from equipment and wires, and chemical exposures. Be

especially alert to hazards that may affect children and the elderly. Minimize hazards by carefully selecting the products

you buy to ensure that you provide go od tools and equ ipment. Always use seat belts when operating tractors, and

establish and maintain good housekeeping practices. Here are some other steps you can take to reduce illnesses and

injuries on the farm:

• Read and follow instructions in equipment operator’s manuals and on product labels.

• Inspect equipment routinely for problems that may cause accidents.

• Discuss safety hazards and emergency procedures with your workers.

• Install approved rollover protective structures, protective enclosures, or protective frames on tractors.

• Make sure that guards on farm equipment are replaced after maintenance.

• Review and follow instructions in material safety data sheets (MSDSs) and on labels that come with chemical products

and communicate information on these hazards to your workers.

Health and Safety Hazards on Farms

Farm workers including farm families and migrant workers are exposed to hazards such as the following:

devices

resulting in being struck or crushed by heavy

Explosion.

circuit. Replace damaged el ectrical devices or cords. Electrical tape will not insulate you

from injury.

or cables routinely to make sure they are in good condition.

equipment without guards in place. Make sure the equipment can not be energized or

equipment without guards in place. Anti-roll over devices.

Orthman Manufacturing, Inc. does not limit the potential effects or injurie s nor preventio n measures to those listed above. They are prov id ed solely as a

guideline to ma king your farm life safer. Always consult your Owner/Operators Manual for specific tool and equipment safety requirements.

High Risk Factors on Farms

The following factors may increase risk of injury or illness for farm workers:

• Age – Injury rates are highest among children age 15 and under and adults over 65.

• Equipment and Machinery – Most farm accidents and fatalities involve machinery. Proper machine guarding and doing

equipment maintenance according to manufacturers’ recommendations can help prevent accidents.

• Protective Equipment – Using protective equipment, such as seat belts on tractors, and personal protective equipment

(such as safety glo ves, co v eralls, bo ots, hats, apro ns , gogg les, face shields) could significantly reduce farming injuries.

• Take precautions to prevent entrapment and suffocation caused by unstable surfaces of grain storage bins, silos, or

hoppers. Never “walk the grain.”

• Be aware that methane gas, carbon dioxide, ammonia, and hydrogen sulfide can form in unventilated grain silos and

manure pits and can suffocate or poison workers or explode.

• Take advantage of safety equipment, such as bypass starter covers, power take-off master shields, and slow-moving

vehicle emblems.

• Medical Care – Hospitals and emergency medical care are typically not readily accessible in rural areas near farms.

The Benefits of Improved Safety and Health Practices

Orthman Manufacturing Provides this document in the hope that everyone that has a job to do, does it SAF E L Y. Our goal

and yours should be to end each day in the best possible health. Better safety and health practices reduce fatalities,

injuries, and illnesses as well as associated costs such as workers’ compensation insurance premiums, lost production,

and medical expenses. A safer and more healthful workplace improves morale and productivity.

WARRANTY

Orthman Mfg., Inc. warrants the whole goods products it manufactures to be free from defects in material or workmanship for a period of

one (1) year from the date of sale of the product(s) to the original user. Products not manufactured, but supplied by Orthman Mfg., Inc. on

Orthman products, are subject to, conform with, and are limited to the warranty of our suppliers.

Orthman Mfg., Inc. warrants the parts it manufactures to be free from defects in material or workmanship for a period of ninety (90) days

from the date of delivery of the product(s) to the original user. Products not manufactured, but supplied by Orthman Mfg., Inc. on Orthman

products, are subject to, conform with, and are limited to the warranty of our suppliers.

Warranty of Orthman whole goods and/or parts applies only to material and workmanship. Misuse, misapplication, neglect, alteration,

accident, normal wear, or acts of God affecting Orthman products are not eligible for warranty.

Warranty of serial numbered goods will only be considered if the product has a completed Warranty Registration on file at Orthman. This

Warranty Registration must be completed and returned to Orthman within thirty (30) days of the sale of the product(s) to the original user.

No serial numbered goods or related parts and/or labor will be warranted without a Warranty Registration on file.

issues falling within the first thirty days of a product’s use will be handled at the discretion of Orthman. Warranty of parts will not require a

Warranty Registration, but proof of date of delivery of the product to the original customer must be provided.

Warranty

WARRANTY CLAIMS:

Department by the selling dealer describing the defect in material or workmanship of an Orthman product(s) within ten (10) days of its

discovery. This claim may be made via phone, e-mail, fax, or written request. Claims for warranty of serial numbered goods must include the

Orthman product serial number and model number. Claims for warranty of parts will not require a product serial number or model number,

but must be identified by an Orthman part number. Claims for warranty of whole goods or parts must also include proof of date of sale of the

product to the original customer by an Orthman dealer.

The Orthman Service Department will proceed in making a preliminary decision as to the eligibility of the claim for warranty consideration.

After the Orthman Service Department deems it necessary to proceed with warranty consideration, a Return Goods Authorization (RGA)

will be completed by the Orthman Service Department in conjunction with the selling dealer. Upon completion of the RGA, the defective

product(s) must be returned to Orthman to ensure warranty consideration. Defective product(s) must be returned to Orthman by either the

selling dealer or the customer. Customer delivery of defective product(s) must be approved by Orthman and the selling dealer prior to delivery.

The defective product(s) in question must be sent, freight prepaid, within sixty (60) days of the discovery of the product(s) failure and initial

warranty claim. Replacement product(s) may be sent to the selling dealer, directly to the customer, or picked up at the Orthman facility.

Replacement product(s), sent directly to the customer or picked up must be approved by Orthman and the selling dealer. At the discretion

of the Orthman Service Department, replacement product(s) may be sent prior to, or after, the Orthman Service Department receives the

defective product(s).

A warranty claim and request to return defective product(s) must be presented to the Orthman Service

Any variation in the above procedure is at the sole discretion of the Orthman Service Department.

No products will be accepted at Orthman without all proper paperwork completed including Warranty Registration and RGA(s).

ts returned to Orthman without proper authorization will be returned to the sender at the sender’s expense.

Par

Orthman agrees to handle all warranty claims in a timely manner and will inform dealers of any revisions or modifications to the Orthman

Warranty Policy. Eligible warranty claims will be processed by Orthman within sixty (60) days of receiving failed product(s) or a valid service

or repair labor claim. Eligible warranty claims regarding returned product(s) or service and/or repair labor will be paid through a credit memo

issued to the appropriate dealer’s account as determined by the Orthman Service Department.

If a warranty claim is found to be ineligible for warranty coverage, the Orthman Service Department will be responsible to inform the dealer in

order to determine the course of action to be taken. Orthman reserves the right to make changes in specification and design without notice

and without incurring any obligations to owners of products previously sold.

© Copyright 2005

Orthman Manufacturing Inc.

Lexington, Nebraska

All rights reserved.

Orthman provides this manual without warranty of any kind, expressed or implied. This manual reflects the product at the time of publication. All information

within is based upon current information on the publication date. Orthman assumes no responsibility for damages incurred due to the use of the illustrations,

information, and specifications within this publication.

3

These bearings have been greased at the factory. They do

not need to be greased until sufficient usage. Overgreasing will cause triple

-

v

lip seal failure.

Quinstar Equipment Company L.P.

P.O.

Box 424

-

2550 County Road 76

-

Quinter,

KS

67752

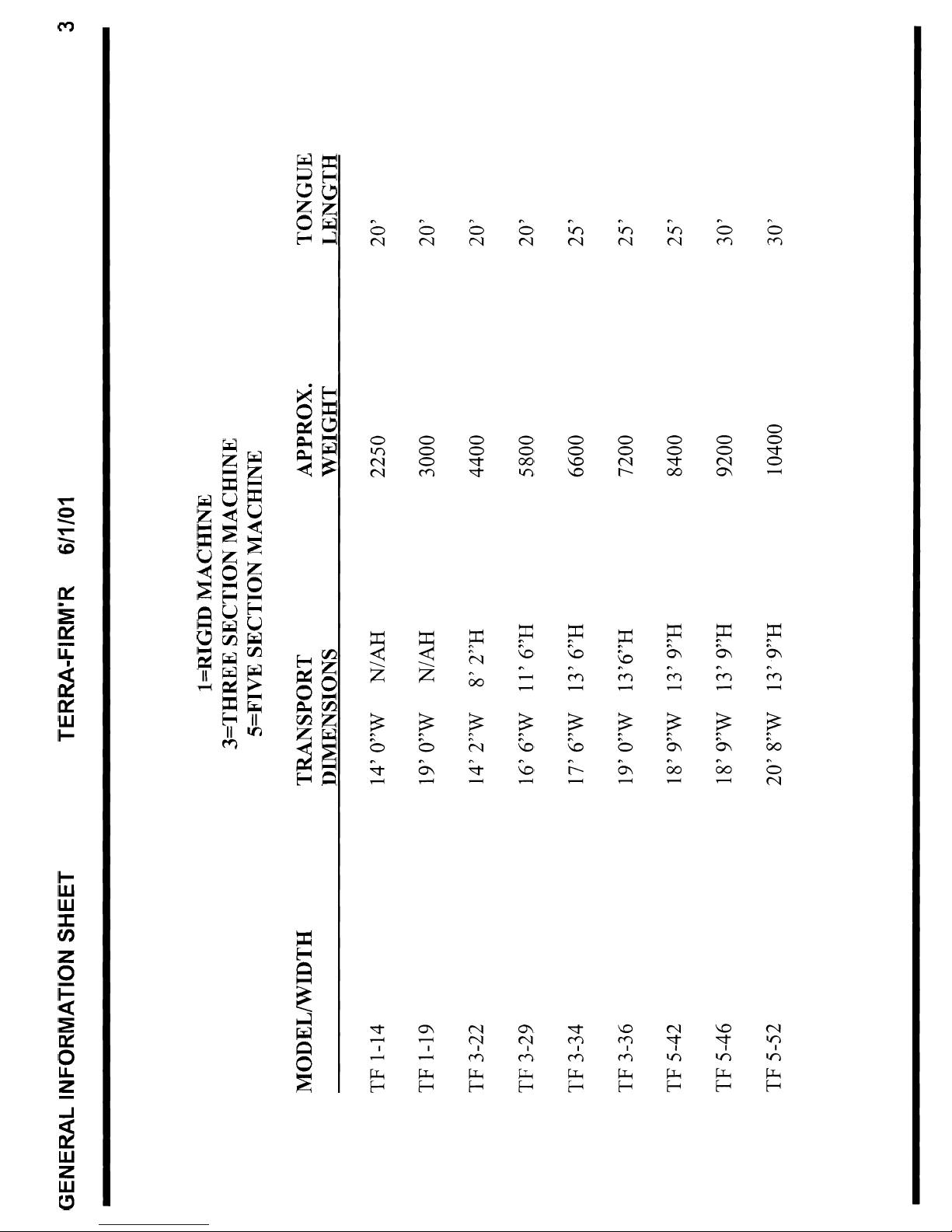

TERRA-FIRM'R

TABLE

CONTENTS

General Information

3

................................................................................................................

General

information

Sheet

...............................................................................................

3

Operation and Maintenance Instructions

.................................................................

4

1-11 4 Terra-Firm'r

,

5

........................................................................................................................

14' Rigid Section

....................................................................................................................

6

Tongue Assembly

..................................................................................................................

7

Wheel Assembly and phcement

...................................................................................

8

Hydraulic Schen-latics

..........................................................................................................

9

1-1 9 Terra-Firm'r

,

I0

......................................................................................................................

19' Rigid Section

..................................................................................................................

11

Tongue Assembly

................................................................................................................

12

wheel Assembly and Placement

.................................................................................

13

Hydraulic schematics

........................................................................................................

14

3-22

Terra-Firm'r

,

15

......................................................................................................................

13' Center Section

...............................................................................................................

16

4-1 12' Right wing

...............................................................................................................

17

4-1 12' Left wing

....................................................................................................................

18

Basket and Truss Assembly

..........................................................................................

19

3-29 Terra-Firm'r Continued

Wing Rest Assembly

.....................................................................................................

30

Wheel Assembly and pkl~ement

...............................................................................

31

Hydraulic s~klematics

......................................................................................................

32

5-42 Terra-Firm'r

51

......................................................................................................................

13' Center Section

...............................................................................................................

52

10' Right 1t-lser-t

......................................................................................................................

53

10' Left Insert

.........................................................................................................................

54

4-1

12'

Right wing

.................................................................................................................

55

4-1 12' Left wing

....................................................................................................................

56

5-42 Terra-Firm'r (Continued)

......................................................................................

57

Basket and Truss Assembly

..........................................................................................

57

5-46 Terra-Firm'r

62

......................................................................................................................

13' Center Section

...............................................................................................................

63

......................................................................................................................

10'

Right Insert 64

1 0'

Left I~sert

.........................................................................................................................

65

5-46 Terra-Firm'r Continued

Tongue Assembly

................................................................................................................

69

Wing Rest Assembly

..........................................................................................................

70

Wheel Assembly and phx?ment

.................................................................................

71

........................................................................................................

Hydraulic schematics 72

5-52 Terra-Firm'r

73

.......................................................................................................................

15'

Center Section

...............................................................................................................

74

Tower Assembly with Walking Dual Option

..................................................

85

Tower Assembly with Walking Dual Option

...........................................................

85

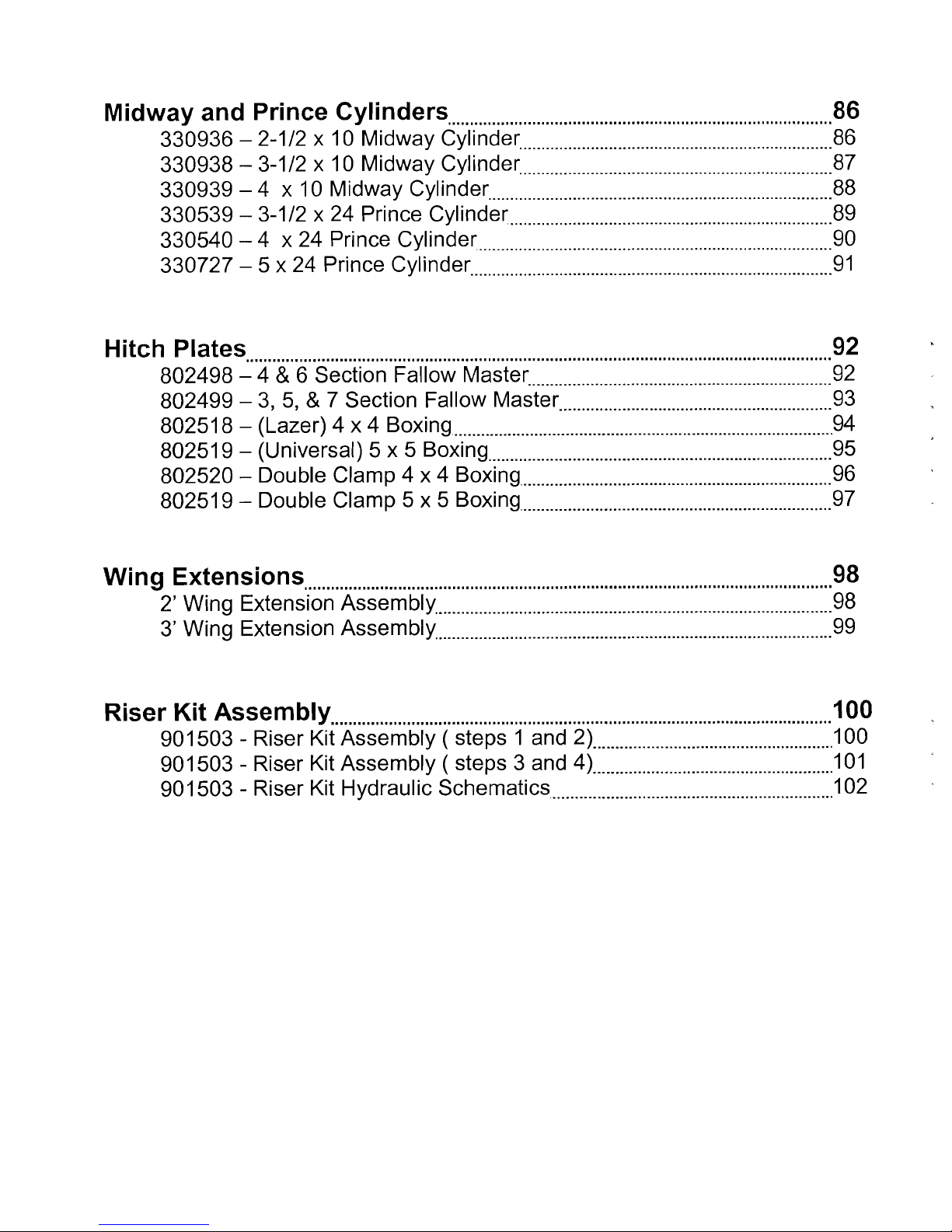

SAFETY DECALS TERRA-FIRM'R

1

0/25/01

SERIOUS INJURY

OR

DEATH

CAN

OCCUR

-

CRUSH

POINT

-

STAND CLEAR OF

\.

DO NOT WALK OR RIDE

CRUSH POINTS

(300097)

ON IMPLEMENTS (300098)

I

!

'

STAY CLEAR OFOVERHEAD

1

I

A

I

FRAMES (300095)

L

SERIOUS INJURY CAN OCCUR

31011

KEEP FEET CLEAR OF

GROUND ENGAGING

TOOLS (3001 02)

POWERLINES.

ELECTROCUTION CAN OCCUR.

/

ON

IMPLEMENTS

STAY CLEAR OF OVERHEAD POWERLINES (300158)

STAY CLEAR OF WING

WATCH FOR SHARP OBJECTS

(3001 00)

STAY

CLEAR OF SHARP

OVERHEAD OBJECTS

SERIOUS INJURY

STAY CLEAR OF OVERHEAD

OBJECTS (300099)

HYDRAULIC FLUID UNDER PRESSURE

-

WEAR EYE PROTECTION WHEN

WORKING ON HYDRAULIC LINES

-

fl

-

DO NOT STOP FLUID LEAK

WITH PARTS OF BODY

-

SERIOUS

INJURY

OR LOSS

OF

LIMB

CAN OCCUL

HYDRAULIC FLUID UNDER

PRESSURE (300096)

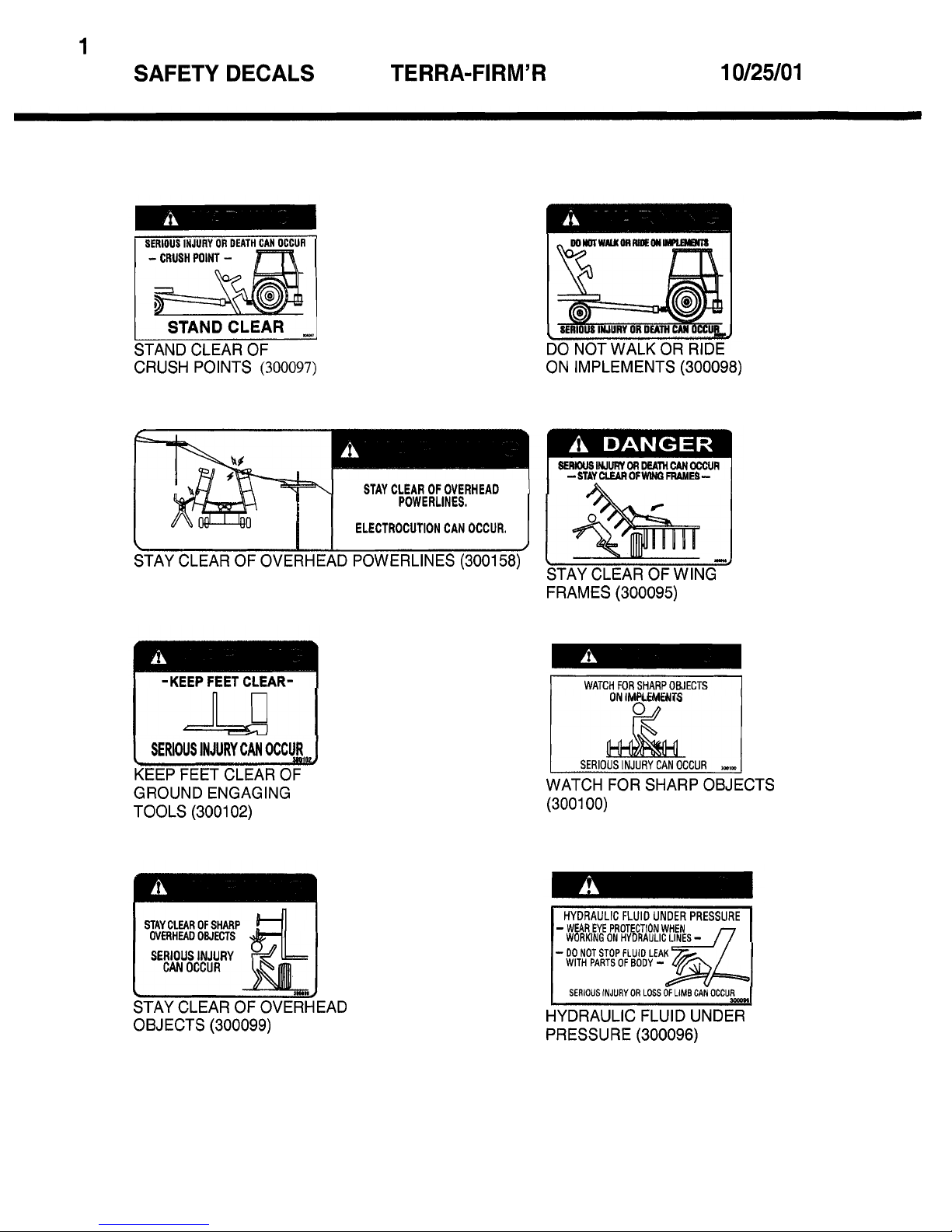

TERRA-FI RM'R

MOST ACCIDENTS CAN

BE

AVOIDED WHEN SAFETY RULES ARE FOLLOWED

THE FOLLOWING RULES WILL KEEP MACHINE-RELATED ACCIDENTS TO A MINIMUM:

READ THE INSTRUCTION AND PARTS MANUAL CAREFULLY BEFORE USING THE

MACHINE.

NEVER WALK UNDER AN UNPINNED WING.

ALWAYS REQUIRE BYSTANDERS TO STAND CLEAR OF THE MACHINE WHILE FOLDING

AND UNFOLDING WINGS OR WHILE RAISING OR LOWERING THE MACHINE.

NEVER ALLOW FEET TO BE UNDER THE BASKETS.

DO NOT WALK ON THE FRAMES.

DO NOT ADJUST, LUBRICATE OR CLEAN THE MACHINE WlTH THE TRACTOR RUNNING.

ALWAYS USE LOCK-UP PlNS WHEN WINGS ARE IN THE FOLDED POSITION, ON THE

5-

SECTION MACHINES

ALWAYS USE ROAD LOCKOUT BRACKETS WHEN ROADING.

COMPLY WlTH ALL STATE AND LOCAL TRANSPORTATION LAWS.

CHECK WHEEL BOLTS EVERY

100

HOURS.

DO NOT TRANSPORT THE MACHINE OVER

15 MILES PER HOUR.

NEVER ALLOW RIDERS ON THE IMPLEMENT.

DO NOT STAND OVER THE TONGUE WHEN HITCHING OR UNHITCHING.

NEVER REMOVE ANY LOCK PlNS UNLESS HYDRAULIC CYLINDERS AND LINES ARE FREE

OF AIR AND FULL OF HYDRAULIC OIL.

CHECK THE

TIRE PRESSURE AND INSPECT THE TIRES FOR CUTS OR WEAR DAILY. (USE

RECOMMENDED PRESSURES ON THE TIRES.)

DO NOT REMOVE OR TAMPER WlTH SAFETY DEVICES, SUCH AS: HYDRAULIC

RESTRICTORS, LOCKOUT ARMS, OR LOCKOUT BRACKETS.

WATCH OUT AND AVOID PROTRUDING OBJECTS, SUCH AS: BASKET RODS, SCRAPERS

ETC.

STAY CLEAR OF CRUSH POINTS, SUCH AS: HITCH POINT, PIVOT POINTS ETC.

FOLD AND UNFOLD THE WINGS ON LEVEL GROUND.

INSPECT PlNS FOR WEAR, REPLACE WORN PARTS.

INSPECT THE HYDRAULIC SYSTEM FOR FRAYED HOSES AND LEAKY FITTINGS

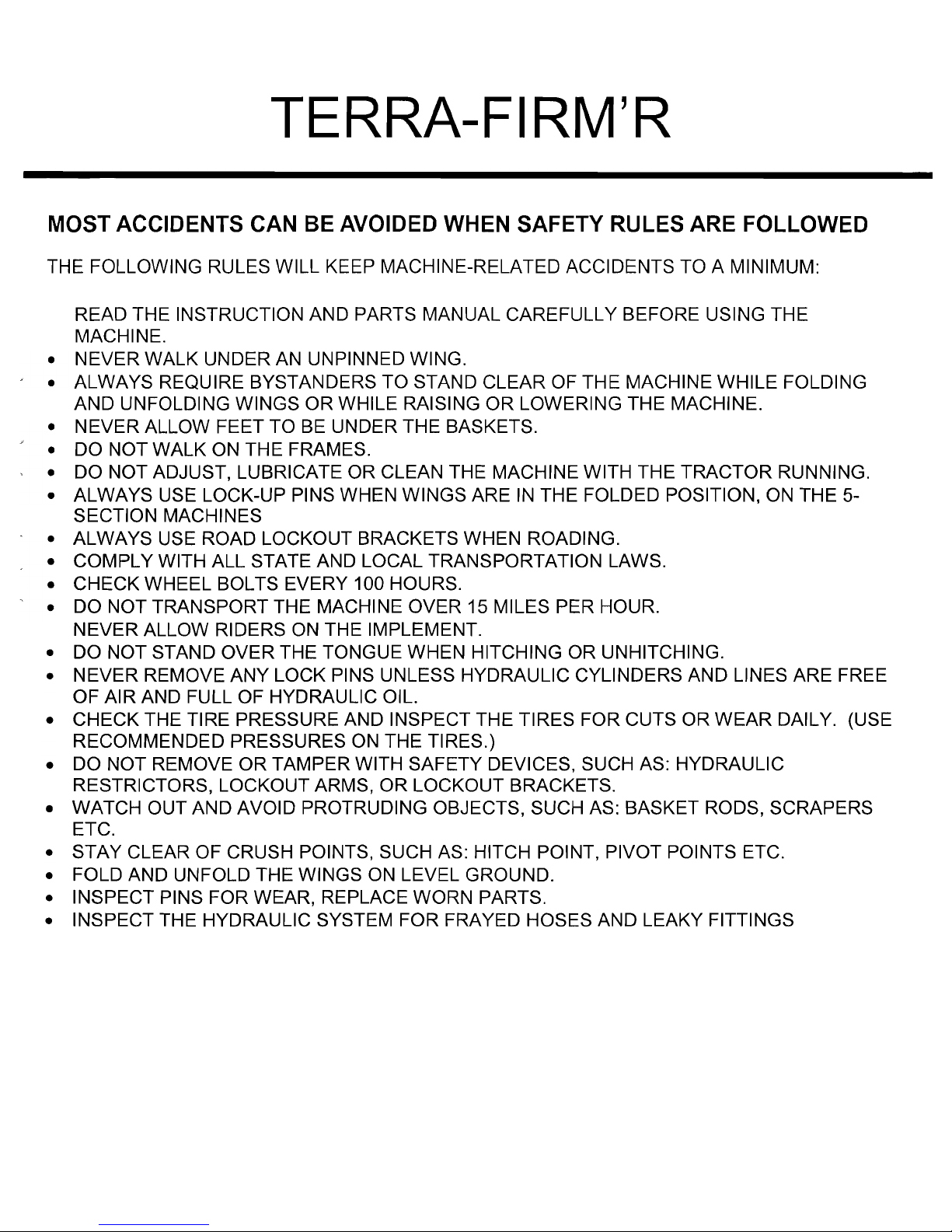

GENERAL

INFORMATION SHEET TERRA-FIRM'R

6/1/01

3

l=RIGID MACHINE

3=THREE SECTION MACHINE

5=FIVE SECTION MACHINE

MODELJWIDTH TRANSPORT APPROX. TONGUE

DIMENSIONS WEIGHT LENGTH

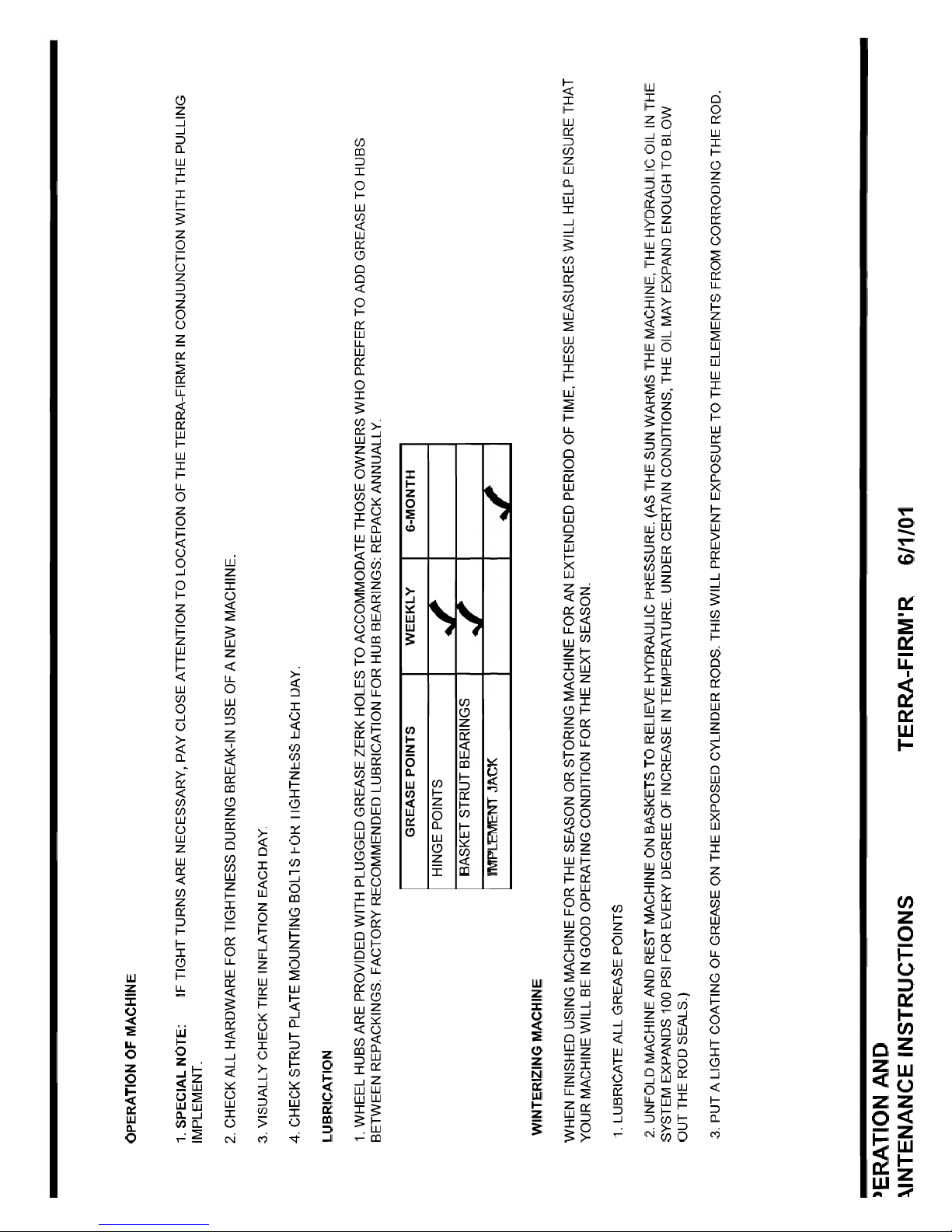

OPERATION OF MACHINE

1.

SPECIAL NOTE:

IF TIGHT TURNS ARE NECESSARY, PAY CLOSE ATTENTION TO LOCATION OF THE TERRA-FIRM'R IN CONJUNCTION WlTH THE PULLING

IMPLEMENT.

2.

CHECK ALL HARDWARE FOR TIGHTNESS DURING BREAK-IN USE OF A NEW MACHINE.

3.

VISUALLY CHECK TIRE INFLATION EACH DAY.

4.

CHECK STRUT PLATE MOUNTING BOLTS FOR TIGHTNESS EACH DAY.

LUBRICATION

1.

WHEEL HUBS ARE PROVIDED WlTH PLUGGED GREASE ZERK HOLES TO ACCOMMODATE THOSE OWNERS WHO PREFER TO ADD GREASE TO HUBS

BETWEEN REPACKINGS. FACTORY RECOMMENDED LUBRICATION FOR HUB BEARINGS: REPACK ANNUALLY.

BASKET STRUT BEARINGS

IMPLEMENT JACK

WINTERIZING MACHINE

WHEN FINISHED USING MACHINE FOR THE SEASON OR STORING MACHINE FOR AN EXTENDED PERIOD OF TIME, THESE MEASURES WlLL HELP ENSURE THAT

YOUR MACHINE WlLL BE IN GOOD OPERATING CONDITION FOR THE NEXT SEASON.

1.

LUBRICATE ALL GREASE POINTS

2.

UNFOLD MACHINE AND REST MACHINE ON BASKETS TO RELIEVE HYDRAULIC PRESSURE. (AS THE SUN WARMS THE MACHINE, THE HYDRAULIC OIL IN THE

SYSTEM EXPANDS

100

PSI FOR EVERY DEGREE OF INCREASE IN TEMPERATURE. UNDER CERTAIN CONDITIONS, THE OIL MAY EXPAND ENOUGH TO BLOW

OUT THE ROD SEALS.)

3.

PUT A LIGHT COATING OF GREASE ON THE EXPOSED CYLINDER RODS. THIS WlLL PREVENT EXPOSURE TO THE ELEMENTS FROM CORRODING THE ROD.

'ERATION AND

IINTENANCE INSTRUCTIONS TERRA-FIRM'R

611

I01

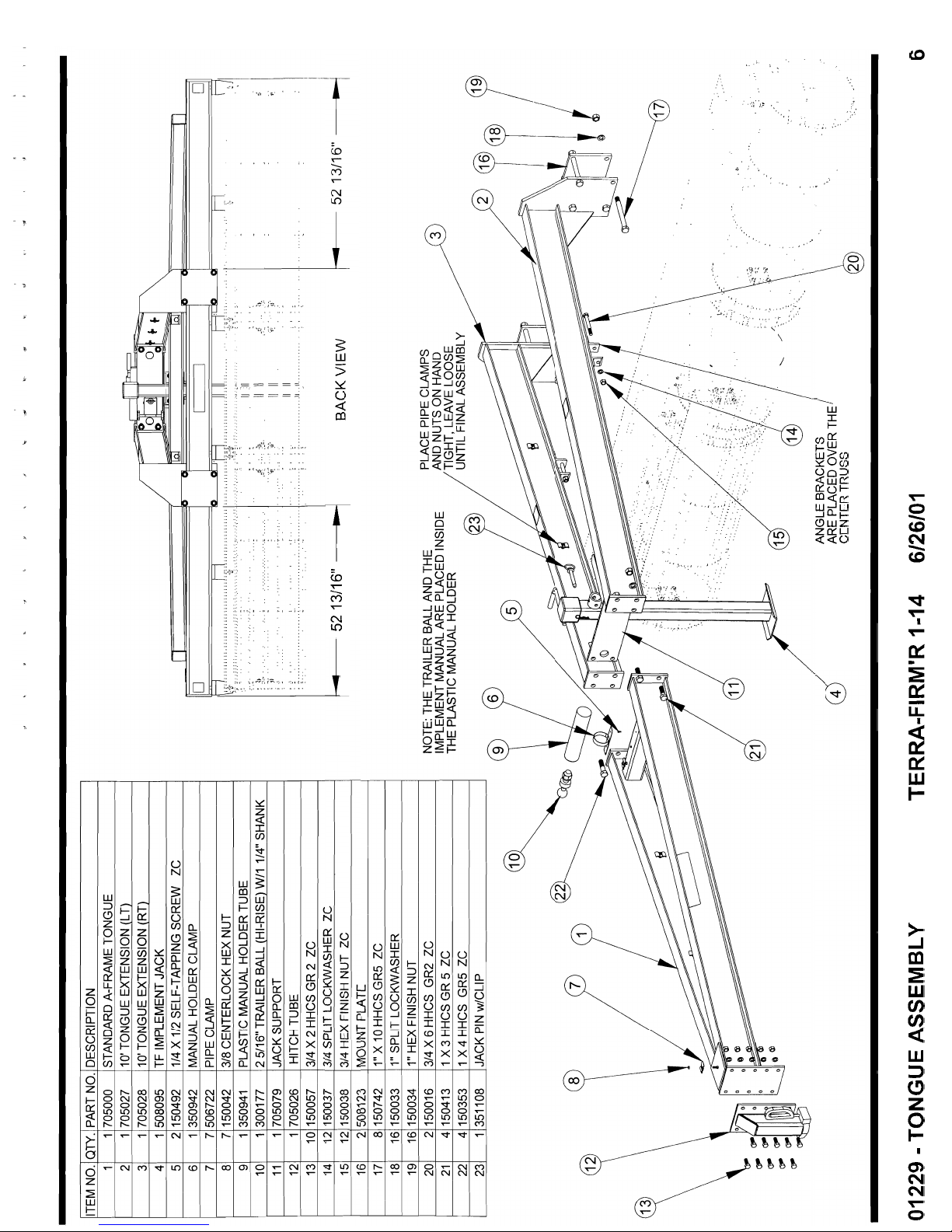

52

13116"

-

BACK

VIEW

ANGLE BRACKETS

/

AREPLACEDOVERTHE

CENTER TRUSS

01229

-

TONGUE ASSEMBLY TERRA-FIRM'R 1-1

4

6/26/01

301531

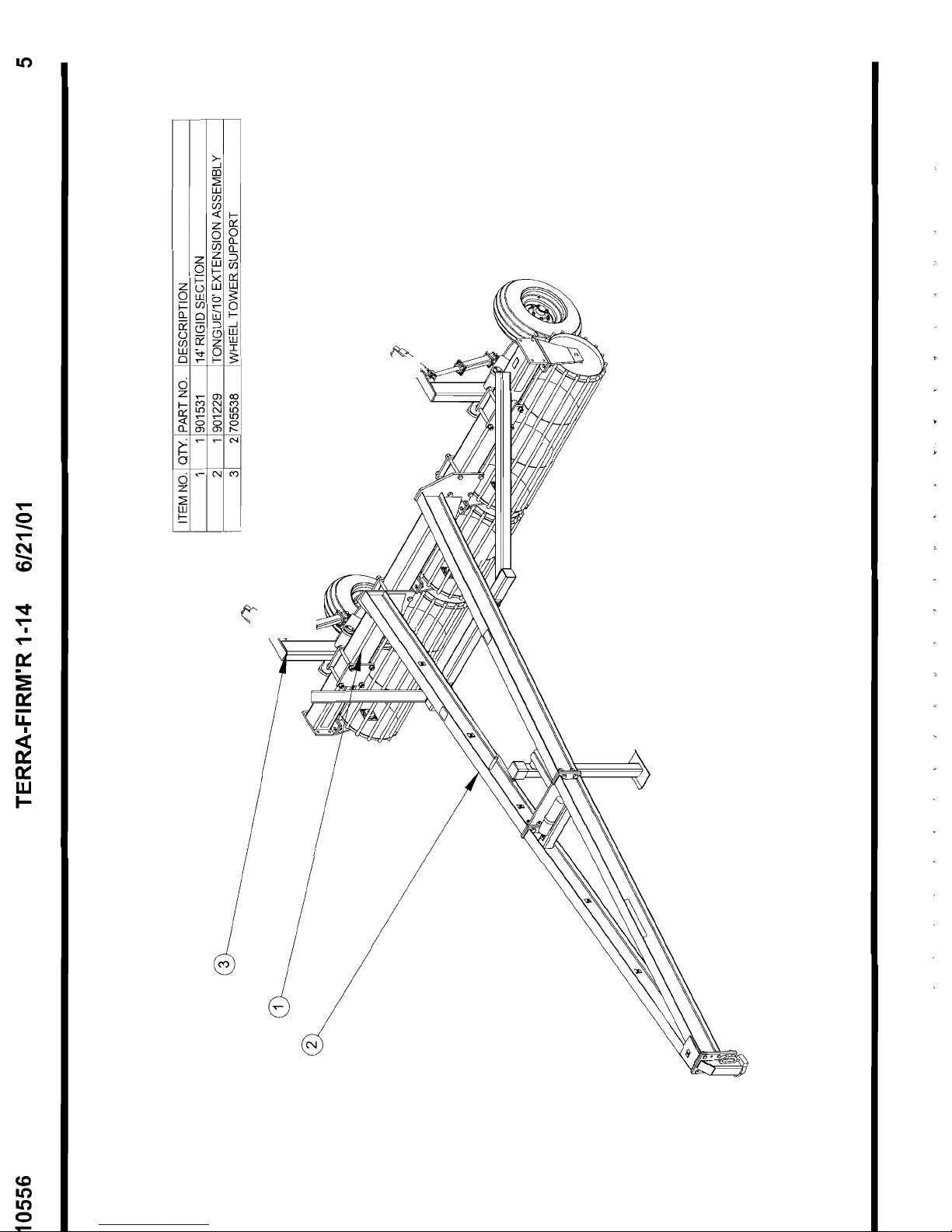

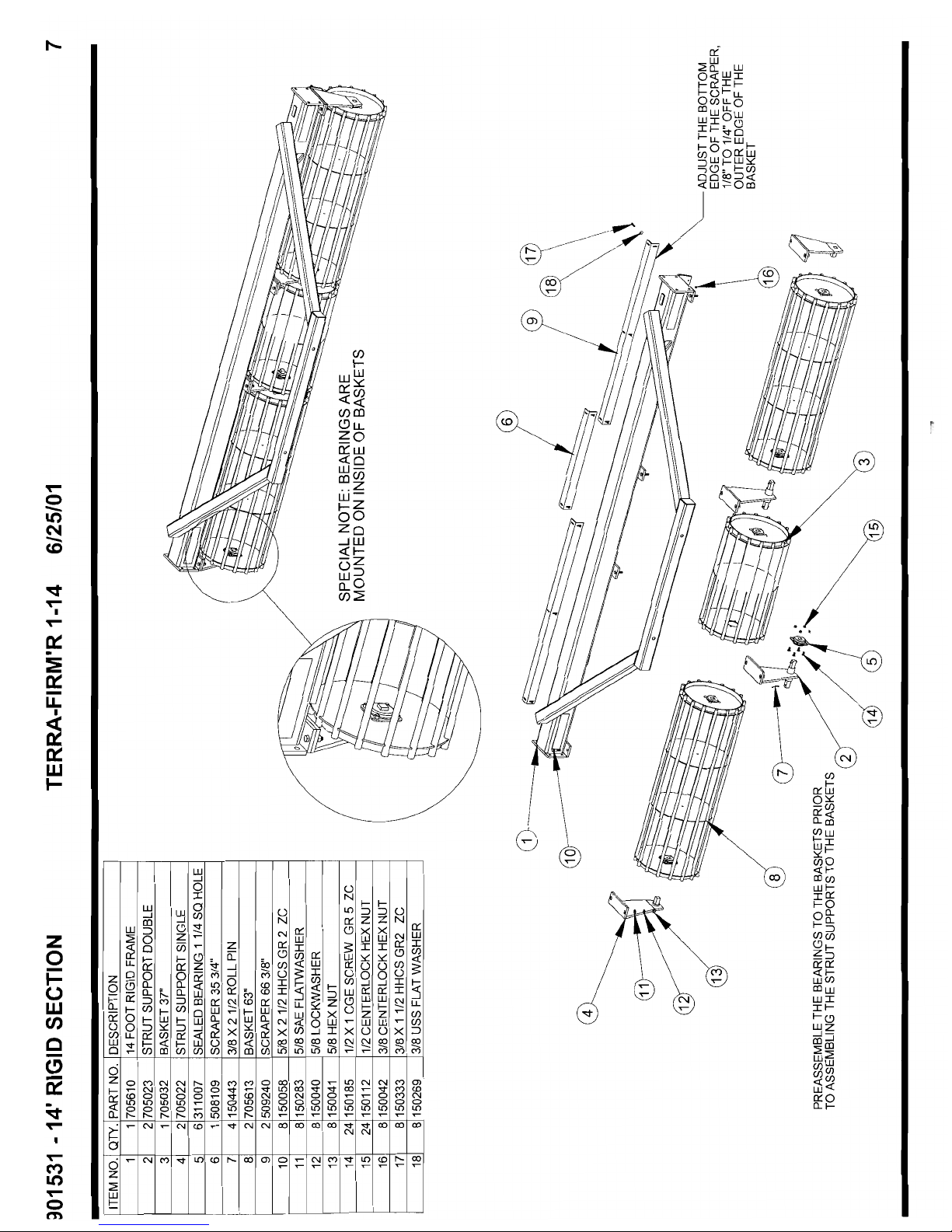

-

14' RIGID

SECTION

TERRA-FIRM'R 1 -1

4

6/25/01

7

141 241150185 1112~ 1

CGE SCREW GR

5

ZC

151 241 1501 12 1112

CENTERLOCK HEX NUT

2

13

PREASSEMBLE THE BEARINGS TO THE BASKETS PRIOR

TO ASSEMBLING THE STRUT SUPPORTS TO THE BASKETS

16

17

18

.ADJUST THE BOTTOM

EDGE OF THE SCRAPER.

118"

TO

114"

OFF THE

OUTER EDGE OF THE

8 8 8

BASKET

150042

150333

150269

318

CENTERLOCK HEX NUT

318 X 1 112

HHCS GR2 ZC

318

USS FLAT WASHER

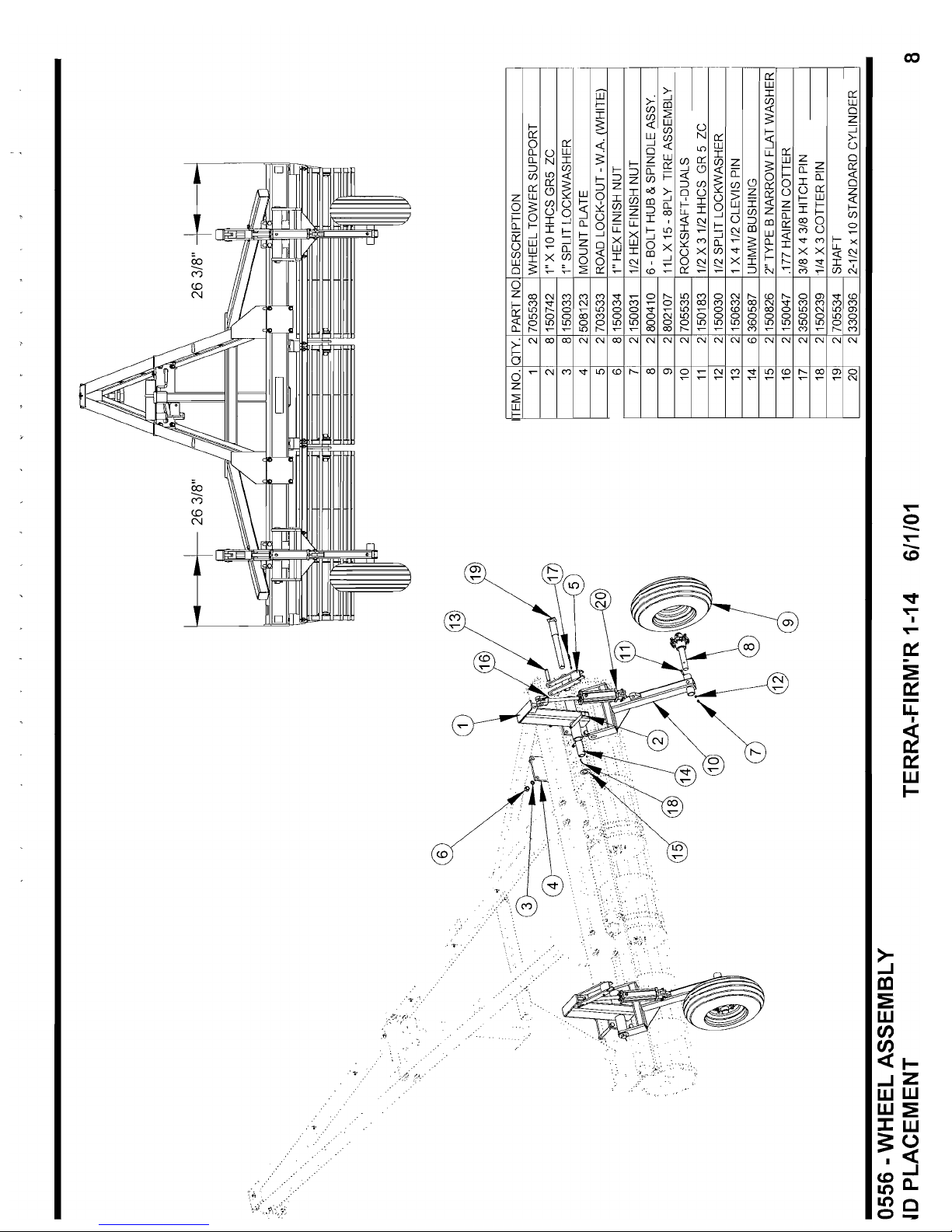

0556 -WHEEL ASSEMBLY

4D

PLACEMENT TERRA-FI RM'R 1 -1

4

611 101

8

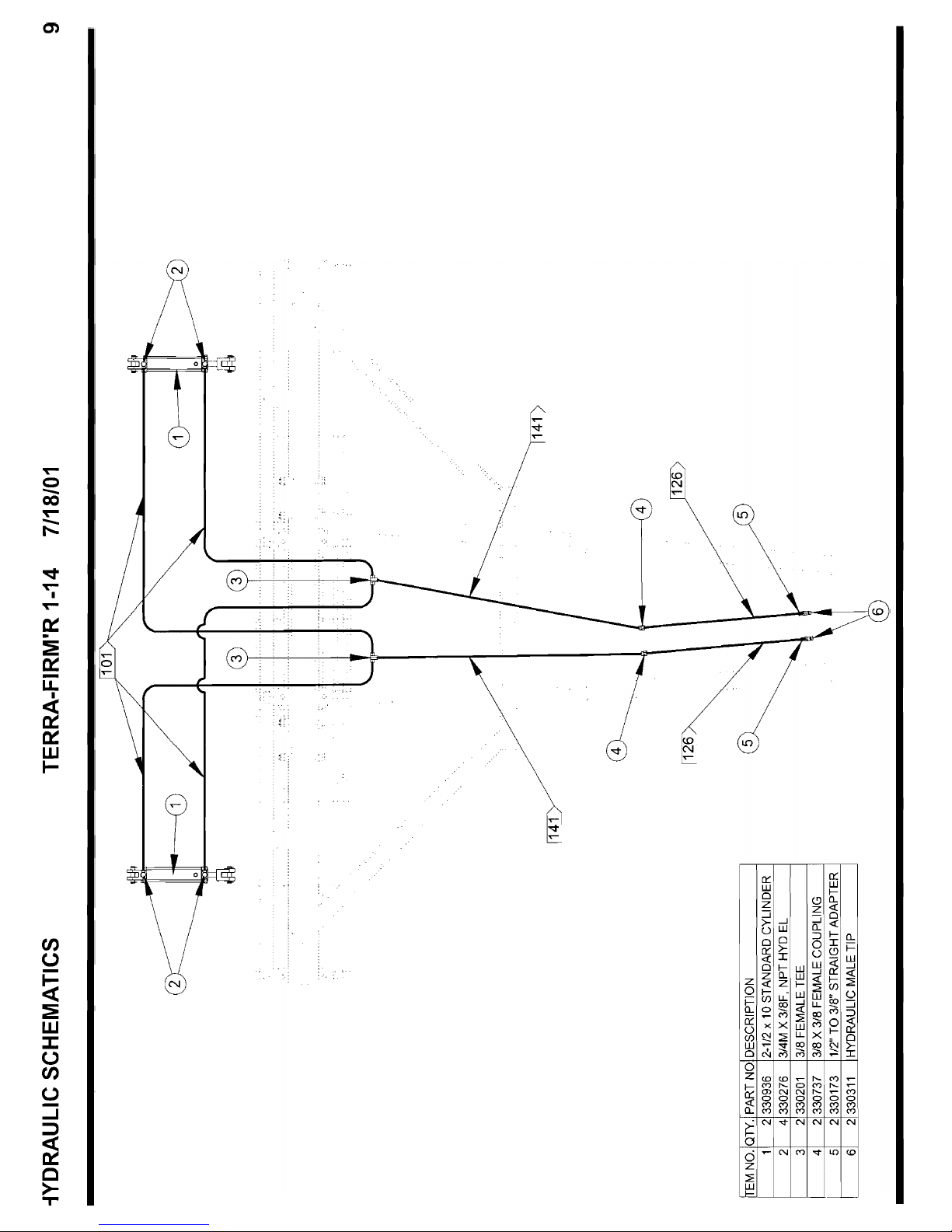

4YDRAULIC SCHEMATICS TERRA-FIRM'R

1 -1

4

711 8101

9

I

ITEM NO. QTY. PART NO. DESCRIPTION

!

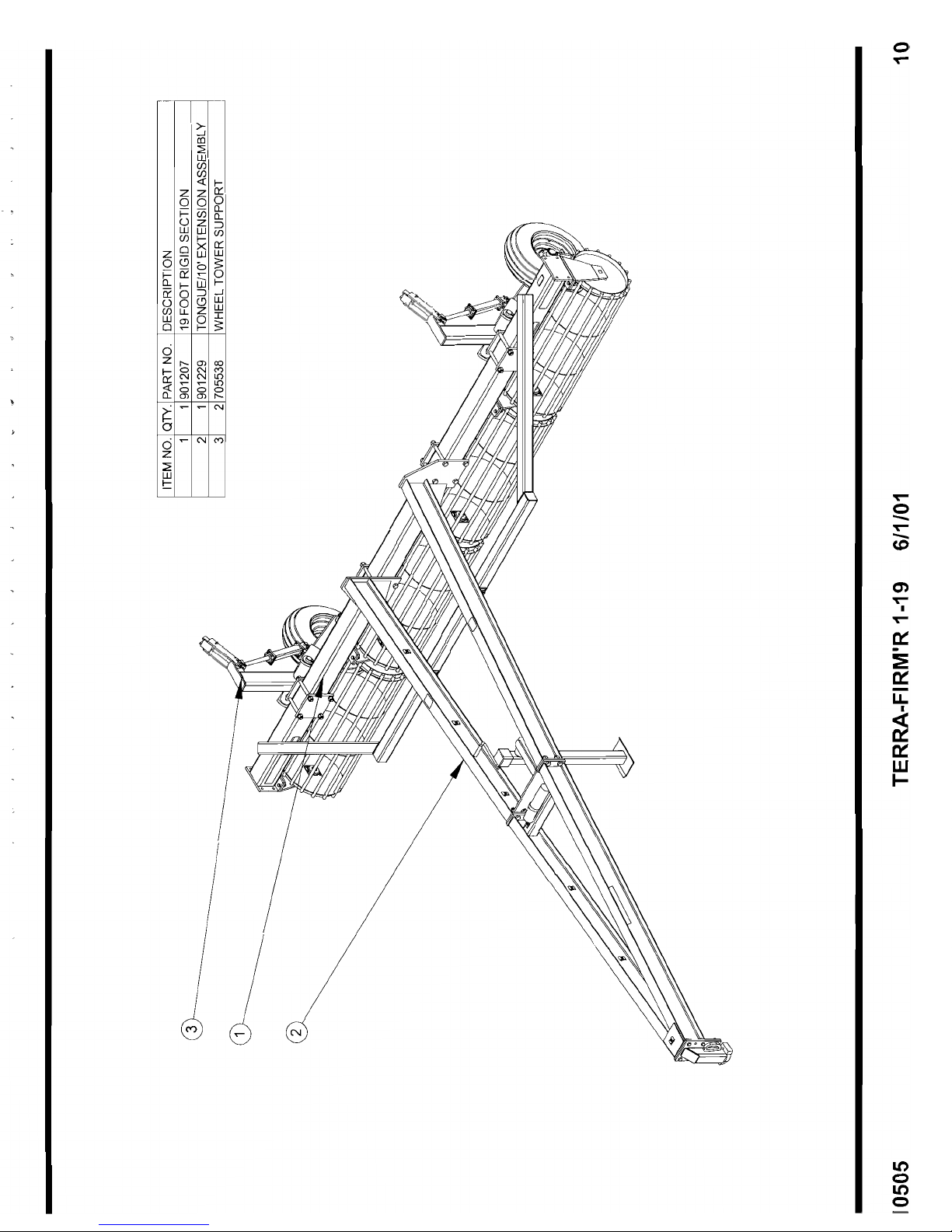

1 1 901207 19 FOOT RIGID SECTION

2 1 901229 TONGUVI

0'

EXTENSION ASSEMBLY

3 2 705538 WHEEL TOWER SUPPORT

10505

TERRA-FIRM'R

I

-1

9

611 101

I0

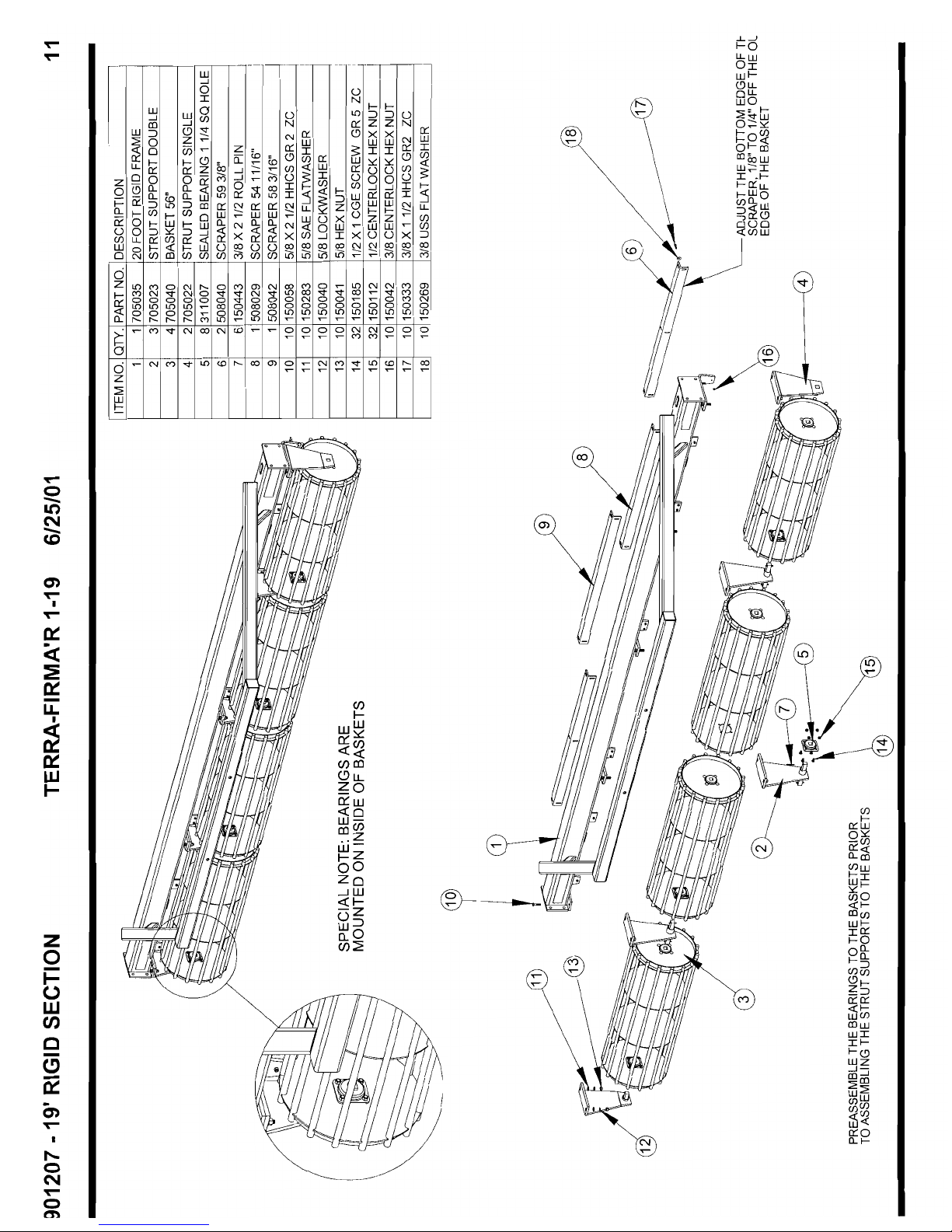

901207

-

19'

RIGID SECTION TERRA-FIRMA'R

1-1

9

6125101 11

ADJUST THE BOTTOM EDGE OF

SCRAPER,

118"

TO

114"

OFF THE

EDGE OF THE BASKET

PREASSEMBLE THE BEARINGS TO THE BASKETS PRIOR

TO ASSEMBLING THE STRUT SUPPORTS TO THE BASKETS

BACK

VIEW

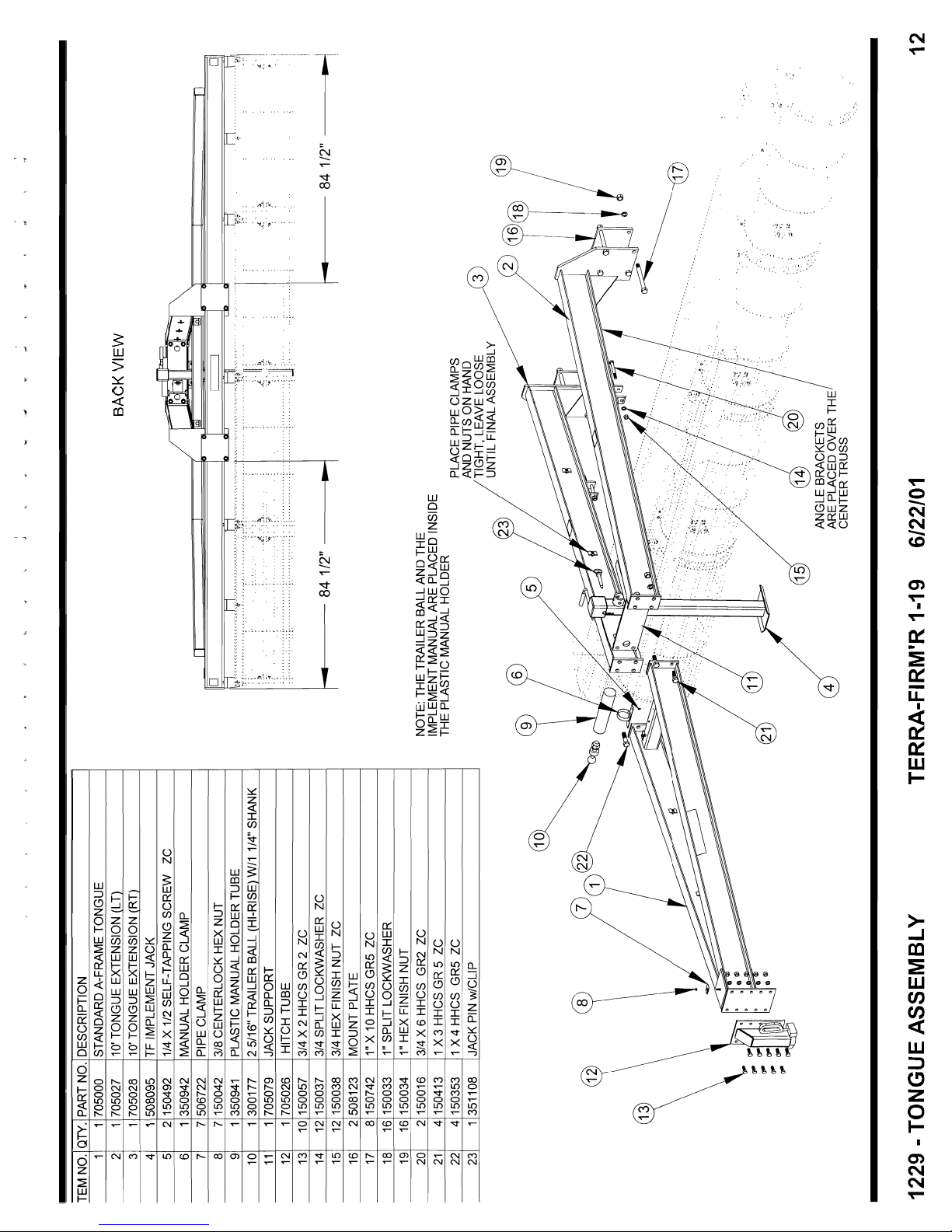

1229

-

TONGUE

ASSEMBLY

TERRA-FIRM'R

1-1 9 6/22/01

12

110505

-

WHEEL ASSEMBLY TERRA-FIRM'R

1-1

9

6/1/01 13

4ND PLACEMENT

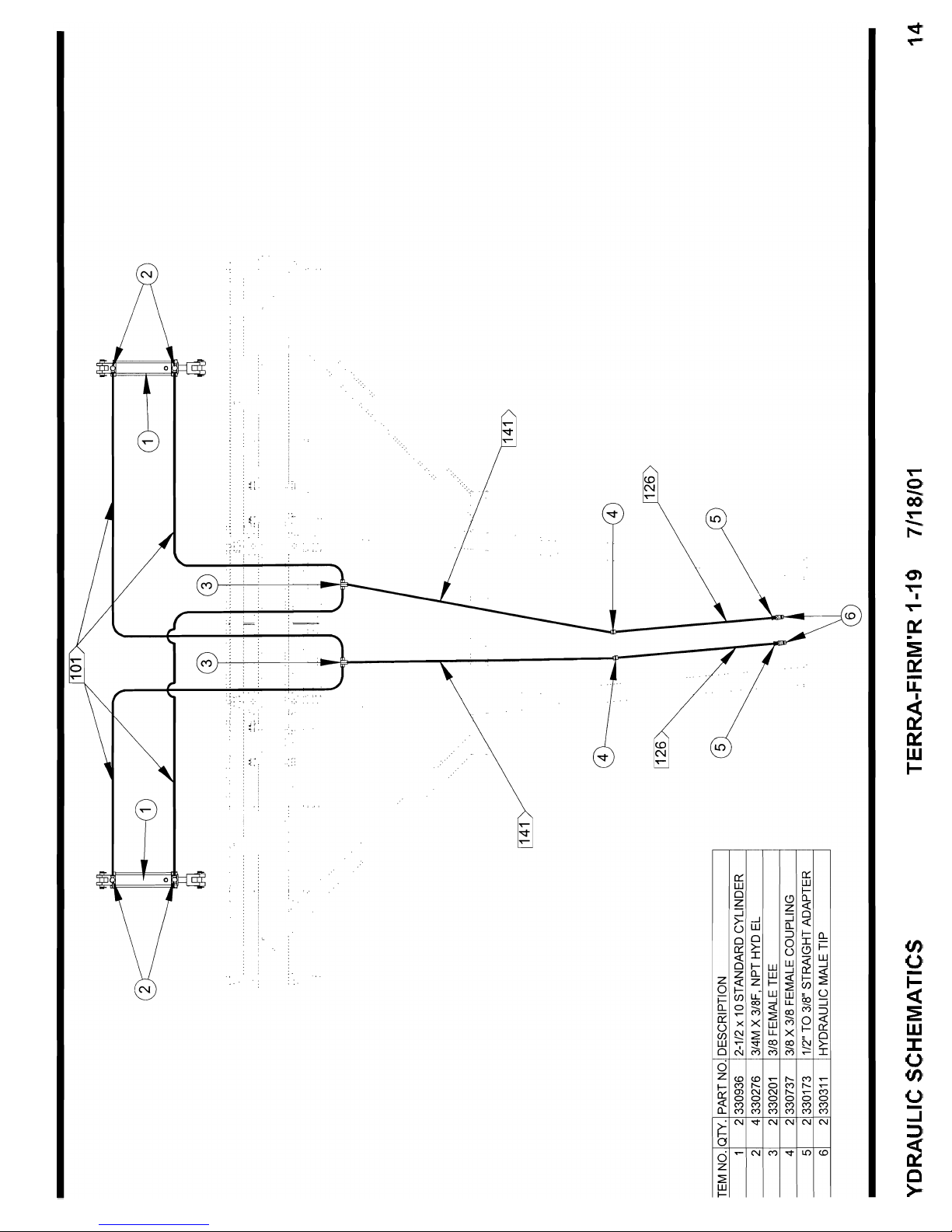

YDRAULIC SCHEMATICS TERRA-FIRM'R 1-1 9 711

8/01

14

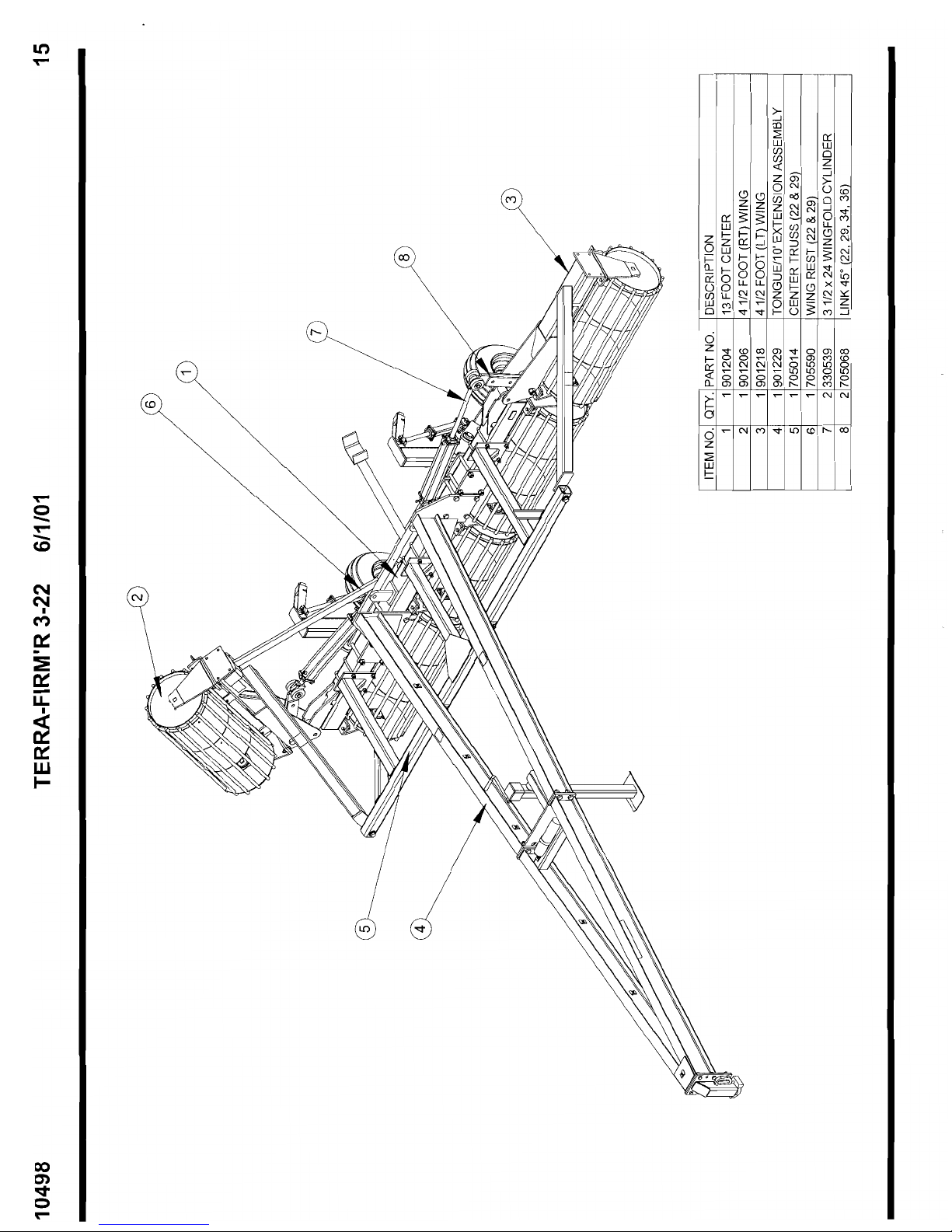

10498

TERRA-FIRM'R 3-22

6/1/01

15

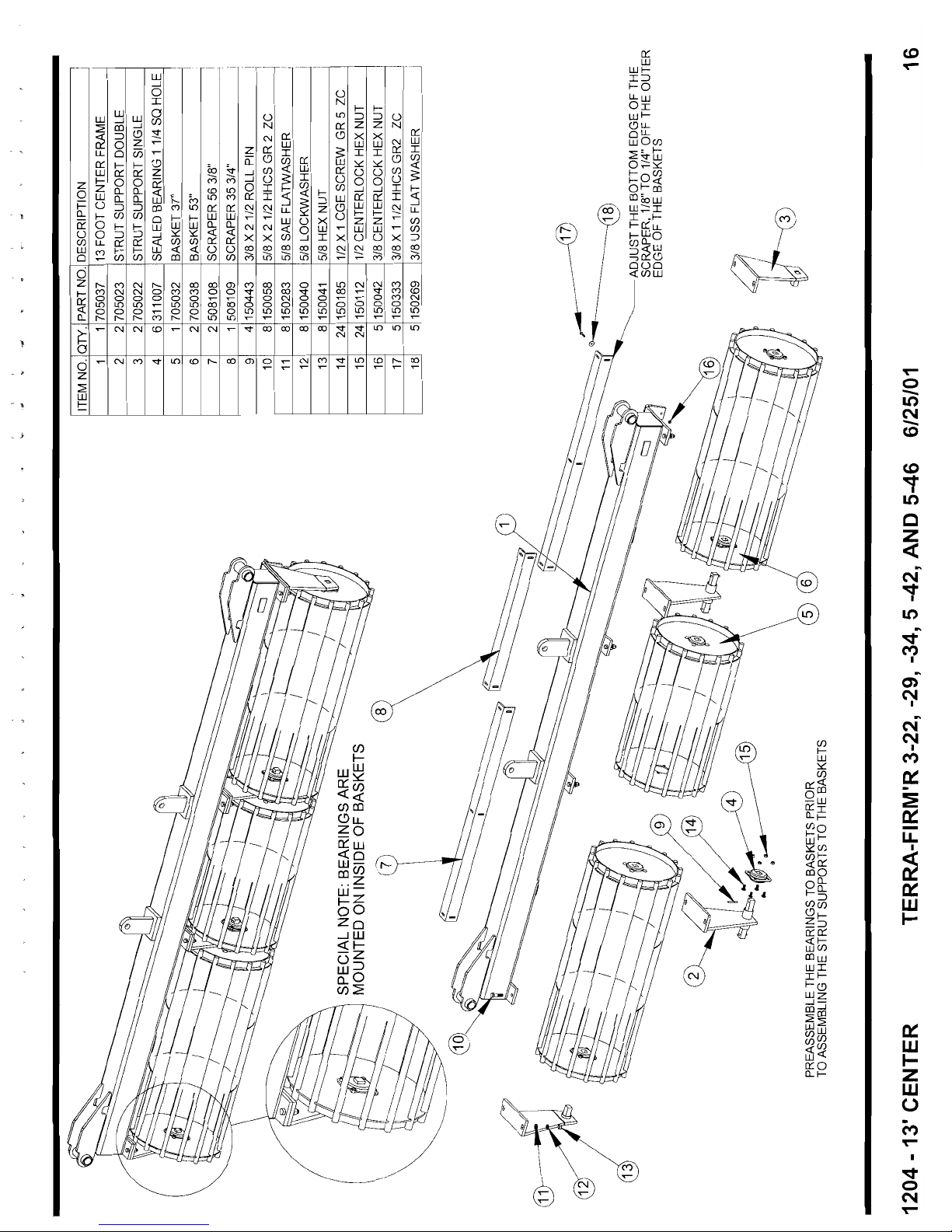

1204

-

13' CENTER TERRA-FIRM'R 3-22, -29, -34, 5

-42,

AND

5-46 6/25/01

16

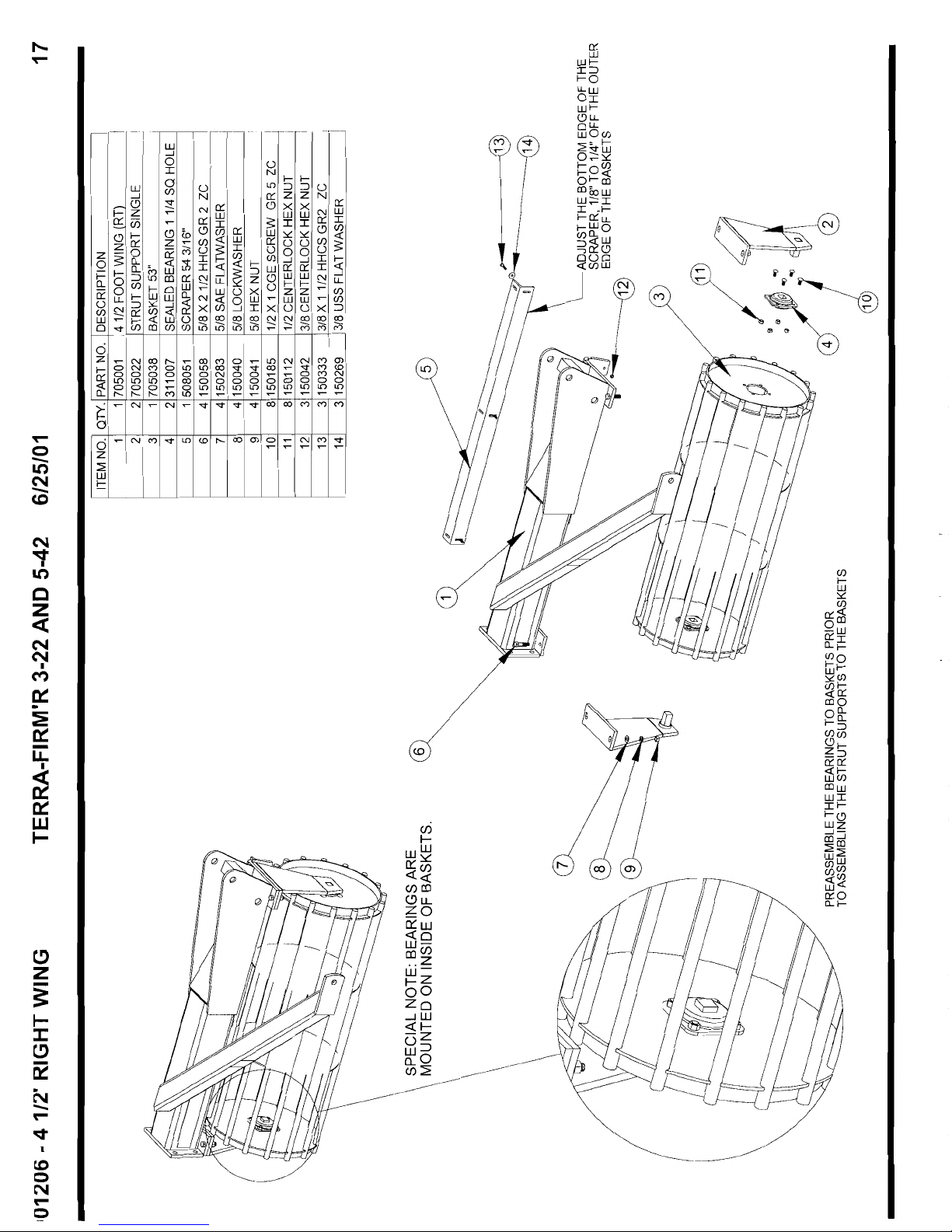

101206

-

4

112'

RIGHT

WING

TERRA-FIRM'R

3-22

AND

5-42 6/25/01

17

21

21705022

ISTRUT

SUPPORT SINGLE

31

11705038

I

BASKET 53"

1

SPECIAL NOTE: BEARINGS ARE

91 41150041 I518

HEX

NUT

101 81150185 1112~1 CGESCREW GR5

ZC

I

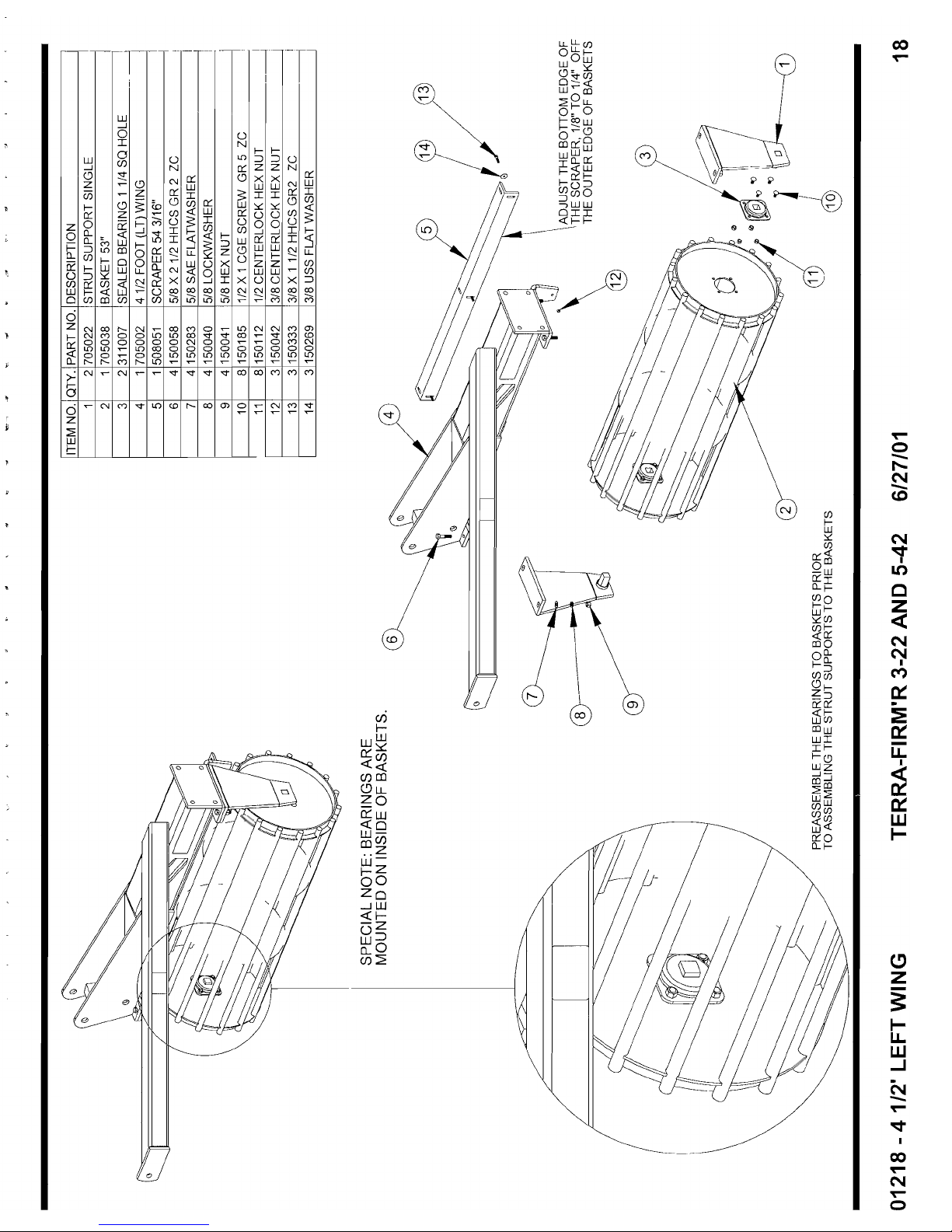

01218

-

4

112' LEFT

WING

TERRA-FIRM'R

3-22

AND

5-42

6/27/01

18

11

12

13

14

112 CENTERLOCK HEX NUT

I

318 CENTERLOCK HEX NUT

318 X 1 112 HHCS GR2

ZC

1

318 USS FLAT WASHER

8 3 3

3

1501 12

150042

150333

150269

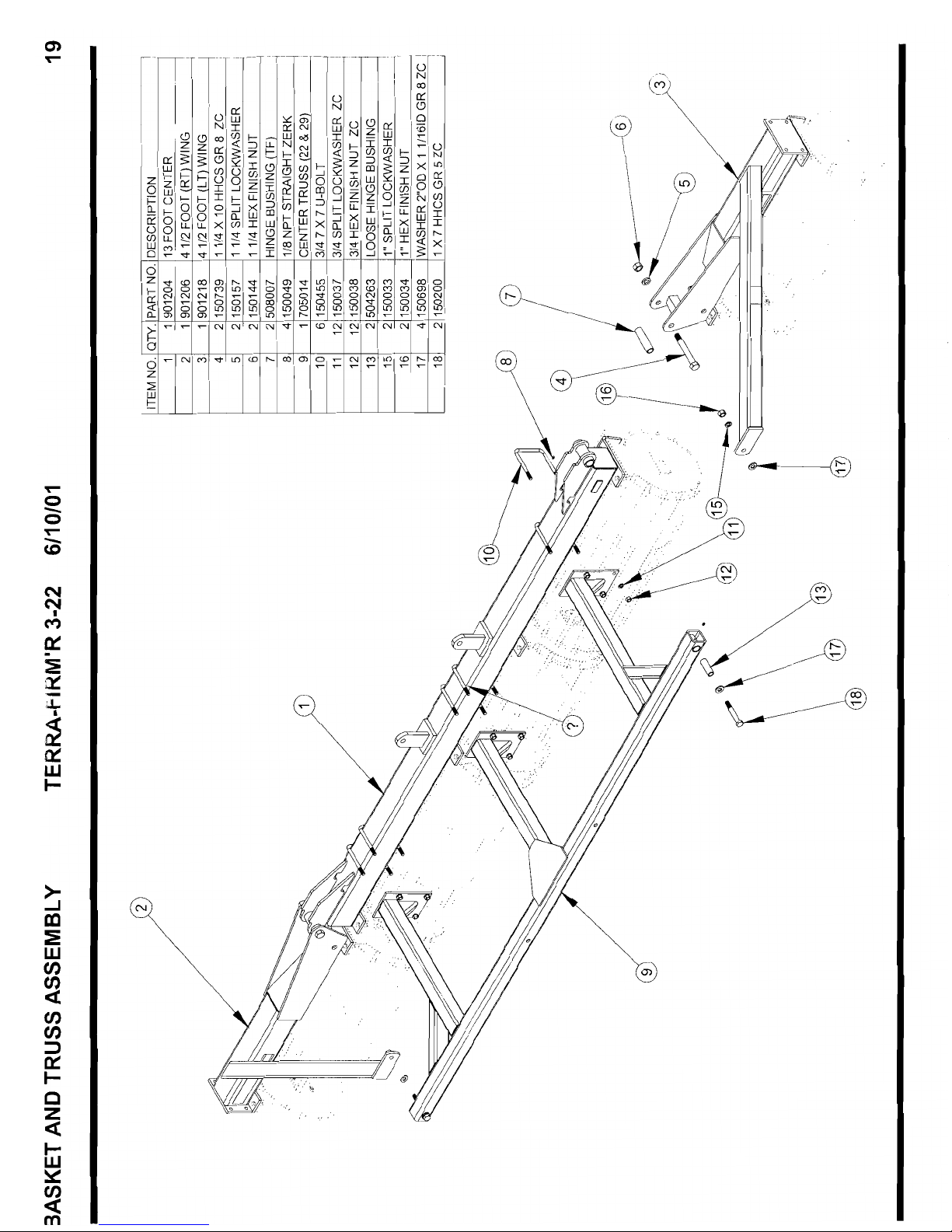

3ASKET AND TRUSS ASSEMBLY TERRA-FlHM'R 3-22

611 0101

19

BACK

VIEW

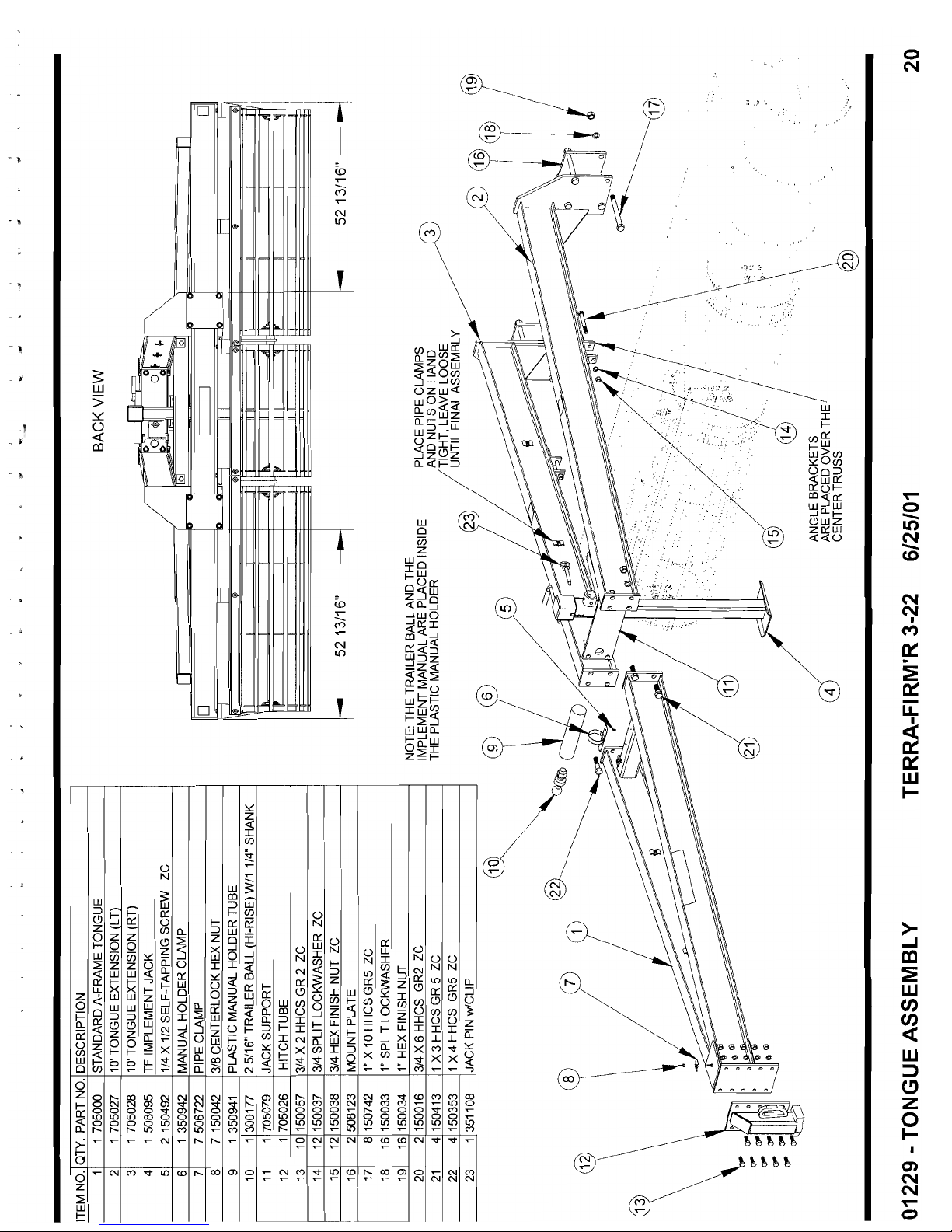

01229

-

TONGUE ASSEMBLY TERRA-FIRM'R 3-22 6/25/01 20

VlNG

REST ASSEMBLY TERRA-FI RM'R 3-22 611

010

1

21

Loading...

Loading...