Orthman 1tRIPr Owner's Manual

1tRIPr

125-000-01

Operator’s Manual

INTRODUCTION

PREPLANT TILLAGE AND

PRECISION NUTRIENT PLACEMENT

Made in the U.S.A.

INTRODUCTION

(6 row - 30 inch configuration)

(standard row units with baskets)

The Orthman

precision nutrient placement, and seedbed preparation in a single field pass to provide

unprecedented field efficiency. The

operations to meet preplant objectives while conserving moisture, soil, time, and money,

in

1tRIP.

The

1tRIPr®

foundation. The strong foundation, teamed with Orthman’s rigid, folding, or stacking

toolbars, provides supreme implement strength. Four down pressure springs per row unit

supply down pressure to assist with soil penetration. Parallel linkages allow the row unit to

operate independent of the toolbar to provide uniform tillage depth despite terrain varia-

tions.

1tRIPr®

preplant tillage tool combines proven strip-till soil management,

1tRIPr®

name is derived from combining multiple

row unit wraparound mount and parallel linkage provide a durable row unit

The depth band coulter assembly initiates the strip-till application. The depth

band provides consistent row unit tooling depth while the coulter cuts all surface

and subsurface residue to reduce rearward tooling interference and aid in residue

decomposition. The coulter also reduces side draft by providing lateral implement stability.

The trash opener assembly reduces field residue directly behind the depth band coulter

assembly prior to the arrival of rearward tooling.

The tillage shank assembly shatters the root zone compacted layer to increase soil

porosity, reduce run off, and allow root systems to utilize deeper soil moisture and

nutrients. Tillage shank assembly fertilizer tube(s) allow precision fertilizer placement

at two depths, if desired, to provide crop plants with timely fertilizer access to maximize

development from germination through maturity.

Made in the U.S.A.

1 - 21 - 2

INTRODUCTION

The wavy coulter assemblies “lift and pinch” action incorporates field residue, decreases

soil variability, and firms the seedbed. Optional rearward mounted rolling baskets

are available to reduce clod size, retain existing soil moisture, firm, and complete the

seedbed.

The

1tRIPr®

utilized with a Combo Caddy or attachment package attaches the planter

and

1tRIPr®

to maximize each field pass. Contact your Orthman dealer for Combo

Caddy or attachment package information to meet your needs. The

utilized as a stand-alone preplant tillage and precision nutrient placement tool.

NOTE: If combining strip-tillage and planting operations with a Combo Caddy or

attachment package, lateral offset of the 1tRIPr® row unit relative to seed placement is

recommended to allow fertilizer placement without detriment to seed germination.

1tRIPr®

can also be

(6 row - 30 inch configuration)

(automatic reset row units with baskets)

This manual is considered to be an integral component of the

to educate the owner and/or operator(s) regarding safety, operation, maintenance,

1tRIPr®

and is designed

Made in the U.S.A.

troubleshooting, and component identification. All personnel involved in the operation of

this implement are responsible for reading and understanding entire manual content.

This manual is designed to keep the operator safe and knowledgeable as well as prolong

the life of the implement and maximize field efficiency. This manual should accompany

the implement if it were ever to be sold.

We would like to thank you for placing your confidence in Orthman Mfg., Inc. Your

is manufactured to meet the highest standards and is built with precision and strength to

increase your agricultural operation’s dependability and profitability.

Thank you for choosing Orthman.

1tRIPr®

STILL THE STRONGEST.

1 - 21 - 3

INTRODUCTION

WARRANTY

Orthman Mfg., Inc. warrants the whole goods products it manufactures to be free from defects in material or workmanship for a period of one (1) year

from the date of sale of the product(s) to the original user. Products not manufactured, but supplied by Orthman Mfg., Inc. on Orthman products, are

subject to, conform with, and are limited to the warranty of our suppliers.

Orthman Mfg., Inc. warrants the parts it manufactures to be free from defects in material or workmanship for a period of ninety (90) days from the date

of delivery of the product(s) to the original user. Products not manufactured, but supplied by Orthman Mfg., Inc. on Orthman products, are subject to,

conform with, and are limited to the warranty of our suppliers.

Warranty of Orthman whole goods and/or parts applies only to material and workmanship. Misuse, misapplication, neglect, alteration, accident,

normal wear, or acts of God affecting Orthman products are not eligible for warranty.

Warranty of serial numbered goods will only be considered if the product has a completed Warranty Registration on file at Orthman. This Warranty

Registration must be completed and returned to Orthman within thirty (30) days of the sale of the product(s) to the original user.

goods or related parts and/or labor will be warranted without a Warranty Registration on file.

product’s use will be handled at the discretion of Orthman. Warranty of parts will not require a Warranty Registration, but proof of date of delivery of

the product to the original customer must be provided.

Warranty issues falling within the first thirty days of a

No serial numbered

WARRANTY CLAIMS:

selling dealer describing the defect in material or workmanship of an Orthman product(s) within ten (10) days of its discovery. This claim may be

made via phone, e-mail, fax, or written request. Claims for warranty of serial numbered goods must include the Orthman product serial number and

model number. Claims for warranty of partswill not require a product serial number or model number, but must be identified by an Orthman part

number. Claims for warranty of whole goods or parts must also include proof of date of sale of the product to the original customer by an Orthman

dealer.

The Orthman Service Department will proceed in making a preliminary decision as to the eligibility of the claim for warranty consideration. After the

Orthman Service Department deems it necessary to proceed with warranty consideration, a Return Goods Authorization (RGA) will be completed by

the Orthman Service Department in conjunction with the selling dealer. Upon completion of the RGA, the defective product(s) must be returned to

Orthman to ensure warranty consideration. Defective product(s) must be returned to Orthman by either the selling dealer or the customer. Customer

delivery of defective product(s) must be approved by Orthman and the selling dealer prior to delivery. The defective product(s) in question must be

sent, freight prepaid, within sixty (60) days of the discovery of the product(s) failure and initial warranty claim. Replacement product(s) may be sent

to the selling dealer, directly to the customer, or picked up at the Orthman facility. Replacement product(s), sent directly to the customer or picked

up must be approved by Orthman and the selling dealer. At the discretion of the Orthman Service Department, replacement product(s) may be sent

prior to, or after, the Orthman Service Department receives the defective product(s).

No products will be accepted at Orthman without all proper paperwork completed including Warranty Registration and RGA(s).

Orthman agrees to handle all warranty claims in a timely manner and will inform dealers of any revisions or modifications to the Orthman Warranty

Policy. Eligible warranty claims will be processed by Orthman within sixty (60) days of receiving failed product(s) or a valid service or repair

labor claim. Eligible warranty claims regarding returned product(s) or service and/or repair labor will be paid through a credit memo issued to the

appropriate dealer’s account as determined by the Orthman Service Department.

A warranty claim and request to return defective product(s) must be presented to the Orthman Service Department by the

Any variation in the above procedure is at the sole discretion of the Orthman Service Department.

Parts returned to Orthman without proper authorization will be returned to the sender at the sender’s expense.

If a warranty claim is found to be ineligible for warranty coverage, the Orthman Service Department will be responsible to inform the dealer in order

to determine the course of action to be taken. Orthman reserves the right to make changes in specification and design without notice and without

incurring any obligations to owners of products previously sold.

© Copyright 2010

Orthman Manufacturing Inc.

Lexington, Nebraska

All rights reserved.

Made in the U.S.A.

Orthman provides this manual without warranty of any kind, expressed or implied.

This manual reflects the product at the time of publication. All information within

is based upon current information on the publication date. Orthman assumes no

responsibility for damages incurred due to the use of the illustrations, information,

and specifications within this publication.

1 - 4

TABLE OF CONTENTS

INTRODUCTION

INTRODUCTION

General Information -

Warranty Information ...................................................................................................................................1 - 4

Table of Contents ........................................................................................................................................1 - 5

1tRIPr®

. .....................................................................................................................1 - 2

IMPORTANT SAFETY INFORMATION

Your Protection - Equipment Safety - Safety Alert Symbol ..........................................................................2 - 1

Signal Words - Shutdown and Storage ........................................................................................................2 - 2

Safe Transport - Warning and Safety Lights ................................................................................................2 - 3

Safe Operation - No Riders .........................................................................................................................2 - 4

Practice Safe Maintenance ..........................................................................................................................2 - 5

Practice Safe Maintenance - Prepare for Emergencies ................................................................................2 - 6

Anhydrous Ammonia - Liquid Fertilizer Precautions - Safety Never Hurts ...................................................2 - 7

Safety Decals ..............................................................................................................................................2 - 8

Orthman Decals ..........................................................................................................................................2 - 9

Orthman Serial Tab ...................................................................................................................................2 - 10

PREPARATION AND SETUP

Made in the U.S.A.

Shipping Configuration ................................................................................................................................3 - 1

Preparing the

Standard Row UnitComponent Identification ..............................................................................................3 - 3

1tRIPr® - Implement-to-Tractor Connection

...........................................................................3 - 2

TOOLING OPTIONS AND INSTALLATION

Rolling Basket Assembly - Installation ........................................................................................................4 - 1

Mole Shank Assembly.................................................................................................................................4 - 2

Mole Knife Assembly ...................................................................................................................................4 - 3

Tillage Shank Assembly (mole shank and mole knife) - Installation ............................................................4 - 4

Mole Shank Assembly Fertilizer Tube - Installation .....................................................................................4 - 5

Mole Shank Assembly Adjustable Dry Fertilizer Boot - Installation .............................................................4 - 6

Air Diffuser and Air Diffuser Mount - Installation .........................................................................................4 - 7

Mole Knife Assembly Fertilizer Tube - Installation ........................................................................................4 - 8

Auto Reset Trip Linkage - Installation...........................................................................................................4 - 9

1 - 5

INTRODUCTION

TABLE OF CONTENTS

FIELD SETTINGS

Toolbar Height and Orientation ....................................................................................................................5 - 1

Row Unit Depth ...........................................................................................................................................5 - 2

Row Unit Down Pressure .............................................................................................................................5 - 3

Trash Opener Assembly Depth ....................................................................................................................5 - 4

Trash Opener Assembly Width ....................................................................................................................5 - 5

Tillage Shank (mole shank and mole knife) Assembly Depth .....................................................................5 - 6

Wavy Coulter Assembly Depth and Width ...................................................................................................5 - 8

Wavy Coulter Assembly Fore and Aft ..........................................................................................................5 - 9

Rolling Basket Down Pressure ...................................................................................................................5 - 10

Standard Shear Bolt Protected Tail ...............................................................................................................5-11

Adjustable Liquid Tubes ...............................................................................................................................5-13

Adjustable Dry Fertilizer Boot ......................................................................................................................5-15

Automatic Reset Linkage .............................................................................................................................5-17

Spring / Set Screw Setting Chart .................................................................................................................5-20

TROUBLESHOOTING

Row unit tooling does not penetrate soil. Wing row units float upward ........................................................6 - 1

Row unit plugs with field residue between the depth band coulter assembly and trash opener assembly ..6 - 2

Row unit plugs with field residue between the trash opener assembly and tillage shank ............................6 - 3

Row unit plugs with field residue between the tillage shank and wavy coulters...........................................6 - 4

Field residue plugs between row units .........................................................................................................6 - 5

Row unit tripping or shear bolt problems......................................................................................................6 - 6

PARTS IDENTIFICATION

Row Unit Assembly ........................................................................................................................... 7 - 1, 7 - 2

Mount and Parallel Linkage Assembly .........................................................................................................7 - 3

Depth Band Coulter Assembly .....................................................................................................................7 - 4

Row Cleaner Assembly ...............................................................................................................................7 - 5

Mole Shank Assembly .................................................................................................................................7 - 6

Mole Knife Assembly ...................................................................................................................................7 - 7

Wavy Coulter Assembly ...............................................................................................................................7 - 8

Trip Linkage Assembly .................................................................................................................................7 - 9

Rolling Basket Assembly ...........................................................................................................................7 - 10

MAINTENANCE

Practice Safe Maintenance ..........................................................................................................................8 - 1

Lubrication - Implement Inspection .............................................................................................................8 - 2

Torque Specifications...................................................................................................................................8 - 3

Implement Storage ......................................................................................................................................8 - 4

Notes ...........................................................................................................................................................8 - 5

Made in the U.S.A.

1 - 6

SAFETY INFORMATION

C A U T I O N

OPERATOR’S

MANUAL

FOR YOUR PROTECTION

READ AND UNDERSTAND THE ENTIRE CONTENT OF THIS MANUAL BEFORE

OPERATING OR SERVICING IMPLEMENT. Read and understand all operator manuals

for the machinery used in conjunction with your Orthman equipment.

• Carefully READ ALL SAFETY DECALS in this manual as well as on the implement.

Keep implement clean so decals are easily visible. Keep all safety decals in good, clean,

and legible condition. Immediately replace damaged and/or missing decals. Replace-

ment decals are available from your Orthman dealer.

• Learn to operate the implement and all components properly. Do not let others operate

implement without proper instruction. Unauthorized implement modifications may impair

function and safety. If you do not understand any content in this manual or need assis-

tance, contact your Orthman dealer.

(Orthman Manufacturing Inc. - 75765 Rd. 435 - Lexington, NE 68850 - (308) 324-4654)

EQUIPMENT SAFETY GUIDELINES

Operator safety is the primary concern when designing an Orthman implement. Orthman

integrates as many safety features into the implement as possible. You can avoid many

hazards and possible accidents by observing precautions in this safety section.

• Insist that yourself and personnel working with and around you follow all safety precau-

tions. Be cautious when working with or around implement to avoid injury.

SAFETY ALERT SYMBOL

The SAFETY ALERT SYMBOL warns of potential hazards to personal safety and

that extra precautions must be taken. When you see this symbol, carefully read the

message(s) that follow. Follow all recommended precautions and safe operating practices

in this manual.

NOTE: Hazard control and accident prevention are dependent upon the safety awareness

and proper training of personnel involved in the operation of this implement.

Made in the U.S.A.

2 - 1

SAFETY INFORMATION

BE AWARE OF SIGNAL WORDS

SIGNAL WORDS designate a degree or level of HAZARD seriousness.

These signal words include:

DANGER indicates a hazardous situation that, if not avoided, will result in death or

D A N G E R

RED

W A R N I N G

ORANGE

C A U T I O N

YELLOW

serious injury. Danger is limited to extreme situations, typically for machine components

which for functional purposes, cannot be guarded.

WARNING indicates a potentially hazardous situation that, if not avoided, could result in

death or serious injury. Warning includes hazards that are exposed when safety guards

are removed. Warning may also be used to alert against unsafe practices.

CAUTION indicates a potentially hazardous situation that, if not avoided, may result in

minor or moderate injury. Caution may also be used to alert against unsafe practices.

W A R N I N G

off

D A N G E R

SHUTDOWN AND STORAGE

AVOID CRUSHING. Make sure all personnel are clear of the implement. Lower implement

to the ground, place tractor in park, turn off engine, and remove key.

USE BAR STANDS AND CYLINDER STOPS TO SUPPORT THE IMPLEMENT.

Store implement on a clean, dry, and level surface. An uneven surface could cause

implement to shift or fall, resulting in injury or death, as well as implement damage.

Securely support all implement components that must be raised. Store implement away

from human activity.

Made in the U.S.A.

2 - 2

SAFETY INFORMATION

SAFE TRANSPORT

• Engage transport locking devices prior to transport.

• Plan your route to avoid traffic. Yield to traffic in all situations.

• Maximum transport speed is 20 mph (32 kph). Various conditions will require reduced

speed. Travel at speeds that allow for adequate control of stopping and steering.

D A N G E R

SMV

STOP

AVOID ELECTROCUTION. Be aware of overhead power lines. Contact or close proximity

to power lines can result in injury or death. Use extreme care when operating implement

near power lines.

• Know implement transport height and gross weight. Avoid overhead obstructions not

allowing your transport height. Do not use bridges rated below combined implement and

tractor weight.

• Make sure a slow moving vehicle (SMV) placard is mounted to the implement and is

easily visible to other motorists.

• Make allowances for implement size when transporting. Sudden braking can cause a

towed load to swerve and/or rollover. Never use independent braking with implement in

tow as loss of control and/or rollover can result. Reduce speed if towed implement is not

equipped with brakes.

• Do not coast. Always keep tractor or towing device in gear to provide engine braking when

traveling downhill.

• Comply with state and local laws governing implement transport.

Made in the U.S.A.

C A U T I O N

WARNING AND SAFETY LIGHTS

• Oversized implements and slow moving vehicles create a hazard when transported on

public roads.

• Make sure all warning, safety lights, and turning signals are working and clean. Use safety

lighting when using public roads day and night. Replace missing or damaged lights

immediately. Comply with state and local laws governing implement safety lighting.

• A safety lighting package, conforming to implement lighting standard ANSI/ASAE S279.12,

if not supplied with, is available for addition to your equipment. Contact your Orthman

dealer for safety lighting package information. Refer to toolbar operator’s manual for safety

lighting package installation and adjustment.

2 - 3

SAFETY INFORMATION

SAFE OPERATION

C A U T I O N

OPERATOR’S

MANUAL

D A N G E R

D A N G E R

READ AND UNDERSTAND THE ENTIRE CONTENT OF THIS MANUAL BEFORE

OPERATING OR SERVICING IMPLEMENT. Implement is to be operated by qualified per-

sonnel only. Never let children operate implement. A complete understanding of safety

precautions, operation, and maintenance is mandatory before implement use.

AVOID ELECTROCUTION. Be aware of overhead power lines. Contact or close proximity

to power lines can result in injury or death. Use extreme care when operating implement

near power lines.

• Know implement transport height and gross weight. Avoid overhead obstructions not

allowing your transport height. Do not use bridges rated below combined implement and

tractor weight.

AVOID ROLLOVER. Do not fold or unfold implement and avoid sharp turns when on a

hillside, as shift of weight could cause rollover. Operate implement at a safe distance from

terrain irregularities and other obstructions that could cause rollover.

W A R N I N G

W A R N I N G

AVOID CRUSHING. Make sure all personnel are clear of implement at all times imple-

ment is in motion. Be aware of obstructions above, below, and around implement when in

operation or transport. Injury or death can result from being struck by the implement.

NO RIDERS

NEVER ALLOW RIDERS ON TRACTOR OR IMPLEMENT. Riders hinder operator

visibility and can be thrown from the implement and/or be struck by foreign objects

resulting in injury or death.

Made in the U.S.A.

2 - 4

SAFETY INFORMATION

PRACTICE SAFE MAINTENANCE

W A R N I N G

off

D A N G E R

D A N G E R

Proper maintenance is your responsibility. Maintenance neglect and/or poor maintenance

practices can result in injury or death. Always use the proper tools to maintain implement.

AVOID CRUSHING. Make sure all personnel are clear of the implement. Lower implement

to the ground, place tractor in park, turn off engine, and remove key.

USE BAR STANDS AND CYLINDER STOPS TO SUPPORT THE IMPLEMENT. Store

implement on a clean, dry, and level surface. An uneven surface could cause implement

to shift or fall, resulting in injury or death, as well as implement damage. Securely support

all implement components that must be raised. Store implement away from human

activity.

AVOID ENTANGLEMENT. Never lubricate or service implement in motion. Keep away from

power driven parts when in motion. Disengage power sources prior to maintaining imple-

ment. Injury or death can result from contact with power driven parts when in motion.

D A N G E R

D A N G E R

AVOID CRUSHING. Do not stand between the tractor and implement when connecting

or disconnecting implement. Injury or death can result from being trapped between the

tractor and implement.

Escaping pressurized hydraulic fluid can penetrate skin, resulting in injury or death. Re-

lieve hydraulic system pressure before connecting or disconnecting tractor. Use cardboard

or wood, NOT BODY PARTS, to check for suspected hydraulic leaks. Wear protective

gloves and safety glasses or goggles when working with hydraulic systems. If an accident

occurs, see a doctor immediately for proper treatment.

Made in the U.S.A.

2 - 5

SAFETY INFORMATION

PRACTICE SAFE MAINTENANCE

D A N G E R

D A N G E R

C A U T I O N

• Never operate a combustion engine in an enclosed area. Make sure there is adequate

ventilation. Exhaust fumes can cause asphyxiation.

• Service tires safely. Tire and rim separation can result in serious injury or death. Do not

over inflate tires. Only mount or dismount tires if you possess the proper equipment,

otherwise contact a trained professional. Always maintain correct tire pressure. Inspect

tires and wheels daily. Do not operate tires with inadequate pressure, cuts, visible dam-

age, or missing hardware.

• Be extremely careful working around unshielded sharp edges. Injury may result from

contact with sharp edges.

• Keep all parts in good condition and properly installed. Replace damaged or missing

parts immediately.

• Remove tools and unused parts prior to implement operation.

C A U T I O N

91 1

PREPARE FOR EMERGENCIES

• Be prepared for a fire. Keep a readily accessible fire extinguisher at all times.

• Keep a readily accessible stocked first aid kit and emergency phone numbers for your

doctor, hospital, ambulance, and fire department.

• Wear protective clothing and equipment. Wear clothing appropriate for the situation.

Protect your eyes, ears, hands, and feet with the use of protective goggles, ear plugs,

gloves, boots, etc.

Made in the U.S.A.

2 - 6

SAFETY INFORMATION

D A N G E R

ANHYDROUS AMMONIA - NH

LIQUID FERTILIZER

ANHYDROUS AMMONIA (NH3) AND LIQUID FERTILIZER APPEARS HARMLESS.

DIRECT EXPOSURE TO NH3 OR LIQUID FERTILIZER IS EXTREMELY DANGEROUS

AND CAN RESULT IN INJURY AND/OR DEATH.

• Keep a clean supply of water readily accessible in case of exposure to NH3 or liquid

fertlizer.

• Wear protective goggles and gloves when working with NH

all persons involved in the operation are properly trained concerning the dangers and

precautions involved in the application of NH

• If you choose to apply NH

information regarding safe handling and application of NH

is available from the following recognized sources:

1. American National Standards Institute -

2. Material Safety Data Sheets - MSDS -

3. National Safety Council -

4. The Fertilizer Institute -

5. United States Department of Transportation - D.O.T. -

6. Compressed Gas Association -

or liquid fertilizer, it is advisable to consult documented

3

www.nsc.org/necas

www.tfi.org

or liquid fertilizer.

3

www.ansi.org - (212) 642-4900

www.msdsonline.com

www.cganet.com

or liquid fertilizer. Be sure

3

or liquid fertilizer. Information

3

www.dot.gov

3

Made in the U.S.A.

C A U T I O N

OPERATOR’S

MANUAL

SAFETY NEVER HURTS

READ AND UNDERSTAND THE ENTIRE CONTENT OF THIS MANUAL BEFORE

OPERATING

OR SERVICING IMPLEMENT.

• Understand all implement functions.

• Never stand between tractor and implement when connecting or disconnecting imple-

ment.

• Be aware of all surroundings before moving implement.

• Operate implement from operator’s seat only.

• Never mount or dismount a moving tractor.

• Never leave engine running when implement is unattended.

• Keep away from power driven parts when in motion.

• Make sure all personnel are clear before lowering implement to the ground.

2 - 7

SAFETY INFORMATION

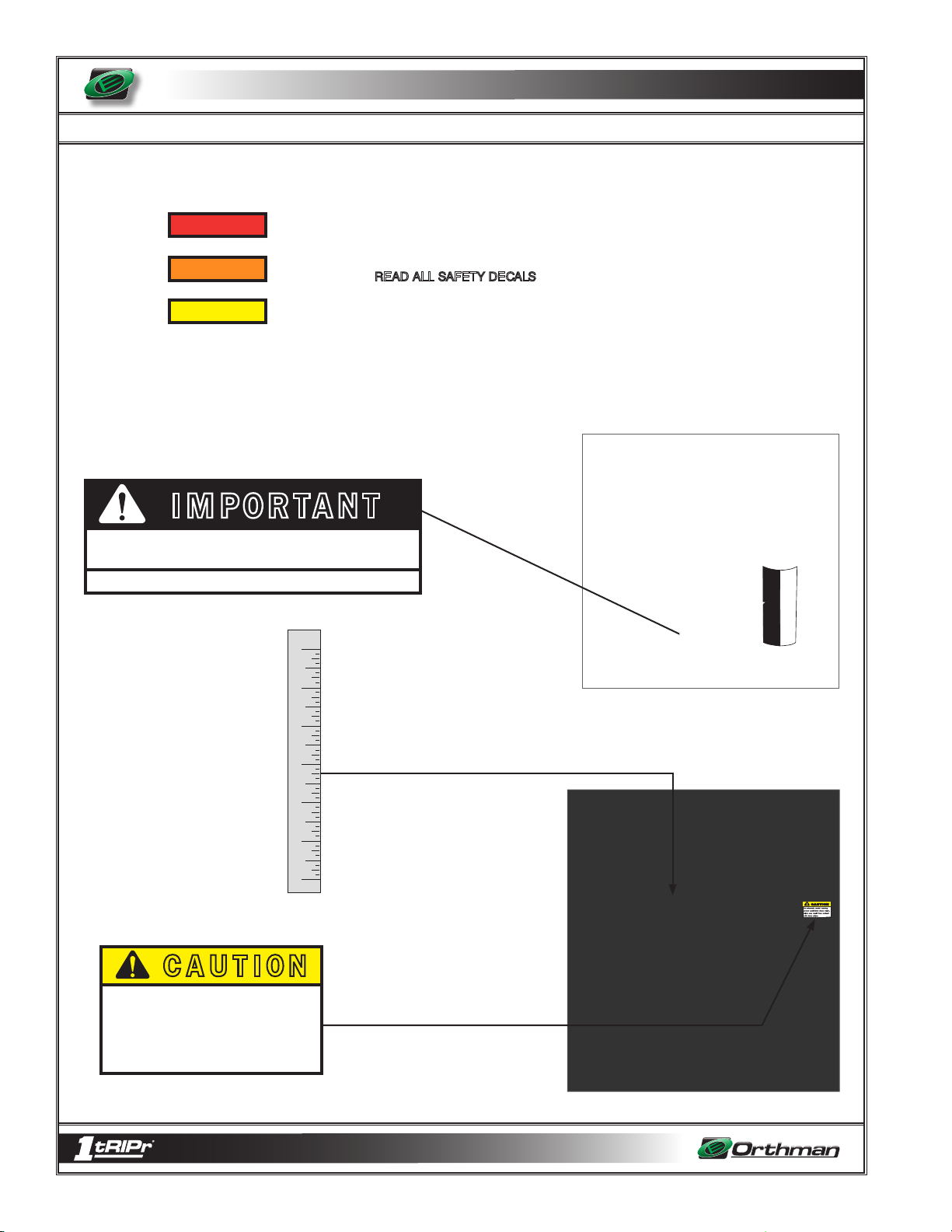

SAFETY DECALS

D A N G E R

W A R N I N G

C A U T I O N

Safety decals promote awareness and knowledge concerning safe operation and

maintenance of the implement.

Carefully READ ALL SAFETY DECALS in this manual as well as on the implement.

Keep implement clean so decals are easily visible. Keep all decals in good and legible

condition. Immediately replace damaged and/or missing decals. Replacement decals are

available from your Orthman dealer.

To install decals: Thoroughly clean area where decal is to be placed and attach decal void

of bubbles. Refer to this safety information section for proper decal placement.

I M PO R TA N T

Equipment operators should understand the enclosed manual before

operating this equipment. Replacement manual, call 308-324-4654

Orthman Mfg., Inc. - 75765 Rd. 435 - Lexington, NE 68850

(manual enclosure)

6

153-101

IMPORTANT

READ MANUAL

5

4

3

2

1

0

153-152

(side of tillage shanks and trash openers)

C A U T I O N

Be extremely careful working

around unshielded sharp edges.

Injury may result from contact

with sharp edges.

(outer side of outer row units)

153 - 045

Made in the U.S.A.

2 - 8

(front right and rear left of toolbar)

SAFETY INFORMATION

ORTHMAN DECALS

153-000

153-194

(front left and rear right of toolbar)

153-193

(outer side of outer row units)

Made in the U.S.A.

2 - 9

SAFETY INFORMATION

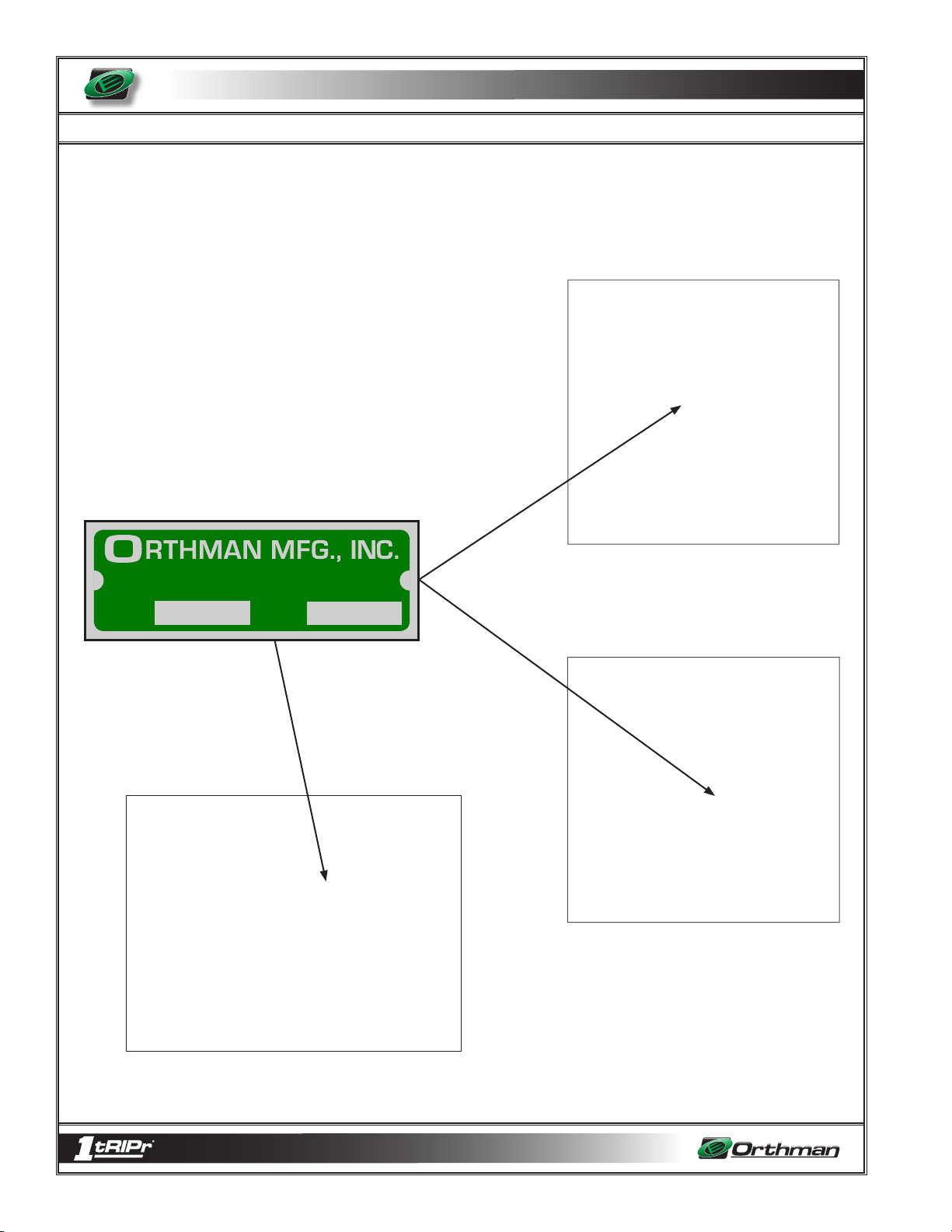

ORTHMAN SERIAL TAG

The Orthman serial tag contains valuable information. The model and serial numbers pro-

vide Orthman dealers and the Orthman Service Department with the exact specifications

of your implement if any warranty or service issues need to be addressed.

MODEL

LE X INGT O N, N E BRAS K A

30 8 -324 - 4654

#

SERIAL

(serial tag location on rigid toolbar)

#

153-011

(serial tag location on 1500 folding

(serial tag location on 1550 folding toolbar)

Made in the U.S.A.

2 - 10

PREPARATION AND SETUP

SHIPPING CONFIGURATION

The majority of the 1tRIPr® is assembled at Orthman Mfg., Inc. The 1tRIPr® is as-

sembled in an appropriate shipping configuration to ensure transport safety and efficiency

from the manufacturer. Installation of optional tooling (if applicable) and adjustment of

installed tooling is necessary prior to an initial field trial.

Trash

Opener

Shipping/Storage Surface

Tillage Shank Assembly

Made in the U.S.A.

C A U T I O N

Be extremely careful working

around unshielded sharp edges.

Injury may result from contact

with sharp edges.

C A U T I O N

153 - 045

The shipping configuration provides even implement weight distribution between the

depth band coulter assembly and the wavy coulter assemblies. The trash opener

assembly and the tillage shank assembly do not bear implement weight, as illustrated

above.

Prior to off-season storage, it is recommended to restore the 1tRIPr® row units to the ship-

ping configuration illustrated above to avoid placing weight on the trash opener or tillage

shank assembly. When storing in-season, lower implement very slowly to avoid sharp

impact between the storage surface and the tillage shank assembly foot piece.

NOTE: The tillage shank assembly foot piece consists of a hard material to decrease

wear and improve field performance. Due to material hardness, sharp impact, excessive

weight, etc. can damage the tillage shank assembly foot piece.

3 - 1

PREPARATION AND SETUP

PREPARING THE 1TRIPR

C A U T I O N

OPERATOR’S

MANUAL

D A N G E R

Tooling options available for added 1tRIPr® versatility are illustrated and explained in the

tooling options section of this manual. Field adjustments are illustrated and explained in

the field settings section of this manual.

If an Orthman toolbar is used in conjunction with 1tRIPr® row units, be sure to consult the

toolbar operator’s manual before attempting to operate the implement. Read and under-

stand operator manuals for machinery used in conjunction with the 1tRIPr®.

Before each use, check hardware for wear and proper torque. Replace damaged or

missing hardware with hardware of an identical grade to restore implement to original

specifications.

IMPLEMENT TO TRACTOR

CONNECTION

AVOID CRUSHING. Do not stand between tractor and implement when connecting or

disconnecting implement. Injury or death can result from being trapped between the trac-

tor and implement.

AVOID CRUSHING. Make sure all personnel are clear of the implement. Lower implement

to the ground, place tractor in park, turn off engine, and remove key.

D A N G E R

Made in the U.S.A.

3 - 2

USE BAR STANDS TO SUPPORT THE IMPLEMENT. Park implement on a clean, dry,

and level surface. An uneven surface could cause implement to shift or fall, resulting in

injury or death, as well as implement damage. Securely support all implement compo-

nents that must be raised.

PREPARATION AND SETUP

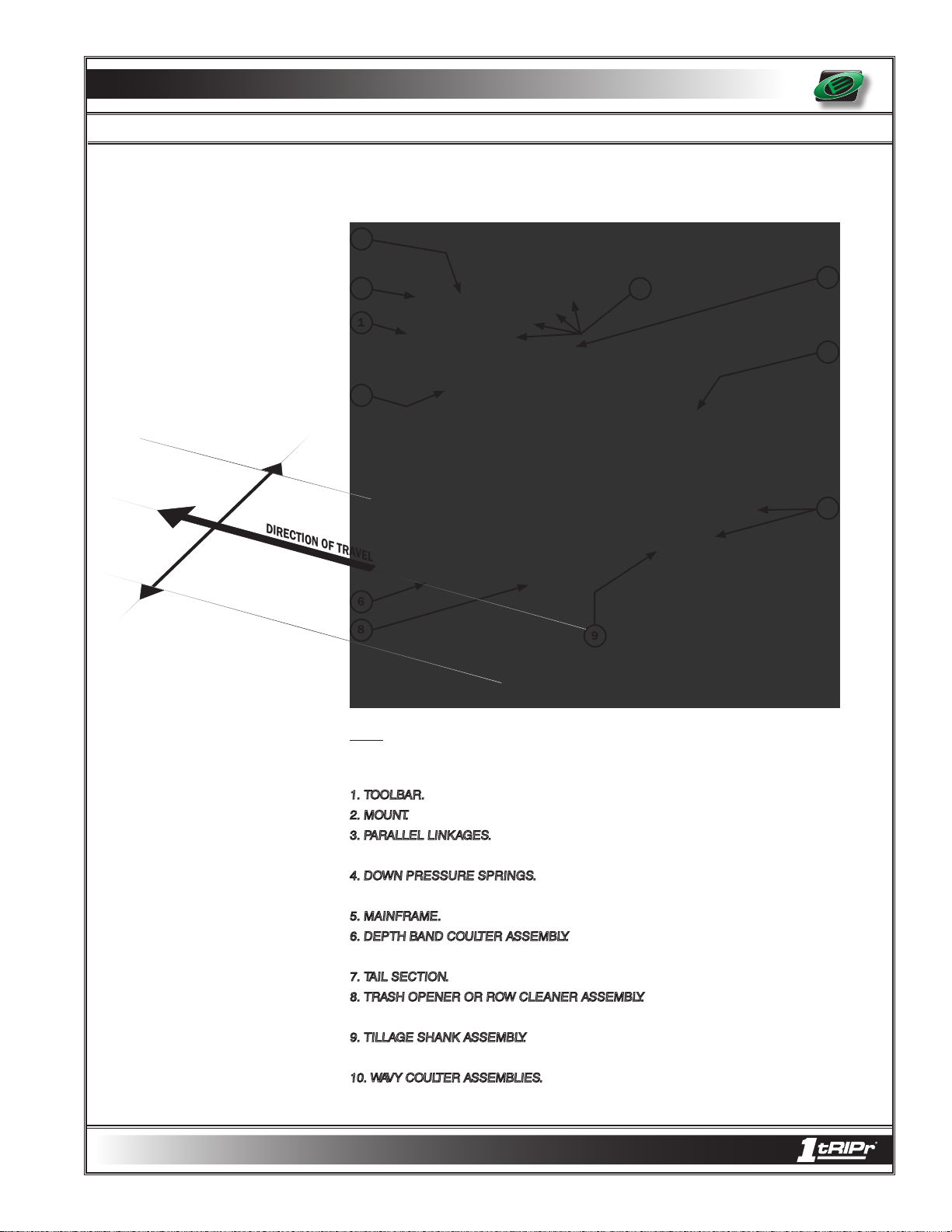

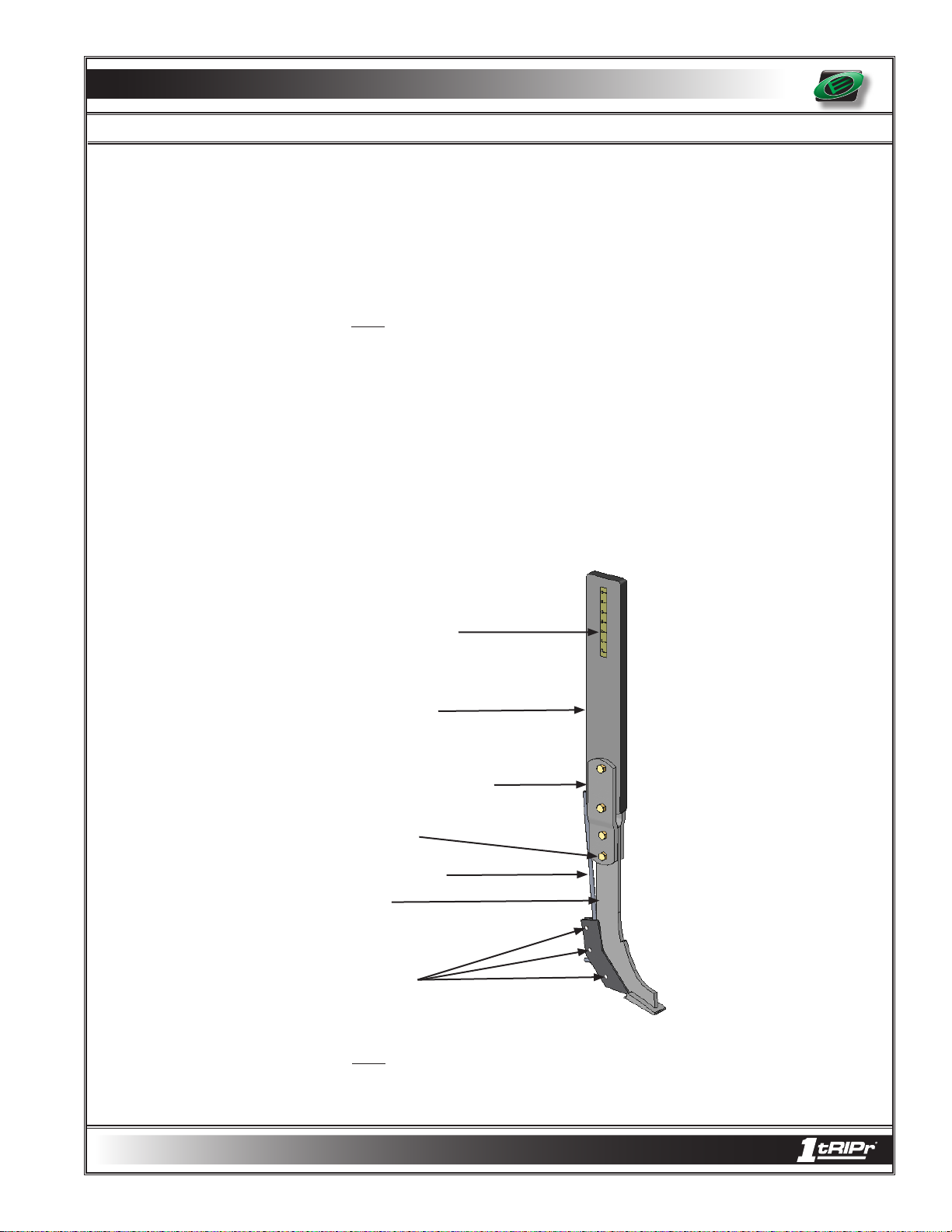

STANDARD ROW UNIT

COMPONENT IDENTIFICATION

3

LEFT

RIGHT

DIRECTION OF TRAVEL

2

1

3

6

8

4

9

5

7

10

NOTE: Right and left as illustrated above and referenced from this point on, is determined

by facing the same direction the implement will travel while in use.

1. TOOLBAR.

2. MOUNT.

3. PARALLEL LINKAGES.

to operate independent of the toolbar to allow uniform tillage depth despite terrain variations.

4. DOWN PRESSURE SPRINGS.

supply down pressure to assist with row unit tooling soil penetration.

5. MAINFRAME.

6. DEPTH BAND COULTER ASSEMBLY.

ing depth while the coulter cuts surface and subsurface residue.

7. TAIL SECTION.

8. TRASH OPENER OR ROW CLEANER ASSEMBLY.

residue directly behind the depth band coulter prior to the arrival of rearward tooling.

9. TILLAGE SHANK ASSEMBLY.

the root zone compacted layer, while allowing precision fertilizer placement at two depths, if desired.

10. WAVY COULTER ASSEMBLIES.

to incorporate field residue, till, and firm the seedbed.

Proven Orthman toolbar design provides unmatched strength.

A wrap- around mount provides a long lasting row unit foundation.

Parallel linkages, with the ability to travel vertically, allow the row units

Four adjustable down pressure springs per row unit

The row unit mainframe serves as the primary mount for row unit tooling.

The depth band provides consistent row unit tool-

The tail section houses adjustable tooling.

The trash opener reduces field

The tillage shank assembly

Wavy coulter assemblies provide “lift and pinch” action

(mole shank or mole knife)

shatters

Made in the U.S.A.

3 - 3

TOOLING OPTIONS AND INSTALLATION

ROLLING BASKET ASSEMBLY

D A N G E R

An optional rolling basket assembly is available to complement the

ing baskets reduce clod size, retain existing soil moisture, firm, and complete the optimum

seedbed. The rolling basket is mounted to the rear of the row unit tail section.

1tRIPr®

row unit. Roll-

INSTALLATION OF ROLLING

BASKET ASSEMBLY

AVOID CRUSHING. Make sure all personnel are clear of the implement. Lower implement

to the ground, place tractor in park, turn off engine, and remove key.

USE BAR STANDS TO SUPPORT THE IMPLEMENT. Park implement on a clean, dry,

and level surface. An uneven surface could cause implement to shift or fall, resulting in

personal injury or death, as well as implement damage. Securely support all implement

components that must be raised. Remove buildup of grease, oil, or debris prior to

installing the rolling basket.

Tail Section Bolt Holes (4)

Tail Section

Carriage Mounting

Bolt (4)

Lock Washer (4)

Rolling Basket

Rolling Basket

Nut (4)

Bolt Hole (4)

Assembly

Made in the U.S.A.

C A U T I O N

Be extremely careful working

around unshielded sharp edges.

Injury may result from contact

with sharp edges.

C A U T I O N

153 - 045

DIRECTION OF TRAVEL

1. Align tail section and rolling basket bolt holes.

2. Mount rolling basket assembly to tail section with carriage mounting bolts, lock

washers, and nuts.

3. Tighten all hardware to proper torque specifications.

NOTE: Recommended tools: 3/4” socket or end wrench.

NOTE: Due to clearance issues, rolling baskets cannot be used in conjunction with

certain planter attachment packages. A lift assist wheel extension package is available to

utilize rolling baskets and lift assist wheels simultaneously. Contact your Orthman dealer

for lift assist wheel extension package information to alleviate clearance issues. For

basket down pressure adjustment, see page 5-10.

(pg. 8 - 4)

4 - 1

TOOLING OPTIONS AND INSTALLATION

MOLE SHANK ASSEMBLY

The mole shank assembly provides benefits to maximize strip-till soil management. The

foot piece shatters the root zone compacted layer to increase soil porosity, reduce run

off, and allow root systems to utilize deeper soil moisture and nutrients.

NOTE: A depth indicator allows for uniform mole shank assembly depth between row

units. Depth indicator decal does not reflect actual tillage depth. Use depth indicator

decal as a tool to achieve uniform depth across the implement.

Fertilizer tube(s) allow precision fertilizer placement at two depths,

if desired. Precision fertilizer placement provides crop plants with

timely fertilizer access to maximize development from germination

through maturity.

If combining strip-tillage and planting operations with a Combo Caddy or attachment

package, lateral offset of the

to allow fertilizer placement without detriment to seed germination.

1tRIPr®

row unit relative to seed placement is recommended

Depth Indicator

Shank

Fertilizer Tubes

Shin Cap

(see note)

Pin Holes

(used to support

fertilizer tube(s)

Foot Piece

NOTE: Refer to (pg. 4 - 4) for mole shank assembly installation instructions. Refer to (pg.

4 - 5) for fertilizer tube installation instructions.

Shin cap may not be included or fit on later model machines due to footpiece design.

Made in the U.S.A.

4 - 2

TOOLING OPTIONS AND INSTALLATION

MOLE KNIFE ASSEMBLY

The mole knife assembly provides benefits to maximize strip-till soil management. The

knife shatters the root zone compacted layer to increase soil porosity, reduce run off, and

allow root systems to utilize deeper soil moisture and nutrients. The fertilizer knife clamp

shear bolt provides mole knife shear protection.

NOTE: A depth indicator allows for uniform mole knife assembly depth between row

units. Depth indicator decal does not reflect actual tillage depth. Use depth indicator

decal as a tool to achieve uniform depth across the implment.

Fertilizer tube(s) allow precision fertilizer placement at two depths,

if desired. Precision fertilizer placement provides crop plants with

timely fertilizer access to maximize development from germination

through maturity.

If combining strip-tillage and planting operations with a Combo Caddy or attachment

package, lateral offset of the

to allow fertilizer placement without detriment to seed germination.

1tRIPr®

row unit relative to seed placement is recommended

Depth Indicator

1” x 4” Shank

Fertilizer Knife Clamp

Shear Bolt

Fertilizer Tube

Knife

Pin Holes

(used to support

fertilizer tube)

NOTE: Refer to (pg. 4 - 4) for mole knife assembly installation instructions. Refer to (pg. 4 - 5)

for fertilizer tube installation instructions. Contact your Orthman dealer for additional fertilizer

tubes to place fertilizer at two depths.

Made in the U.S.A.

4 - 3

Loading...

Loading...