For Model ODS-8003HS-14 ODS-9003HS-14 ODS-1109HS ODS-12012HS ODS-15011HS

WARNING

READ AND SAVE THESE INSTRUCTIONS

Installer: Leave this manual with the homeowner.

CAUTION

CLEANING & MAINTENANCE

OPERATION

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you have questions, contact the manufacturer at the

address or telephone number listed in the warranty.

2. Before servicing or cleaning unit, switch power off at service panel and lock the service disconnecting means to prevent

power from being switched on accidentally. When the service disconnecting means cannot be locked, securely fasten

a prominent warning device, such as a tag, to the service panel.

3. Installation work and electrical wiring must be done by a qualified person(s) in accordance with all applicable codes and

standards, including fire-rated construction codes and standards.

4. Sufficient air is needed for proper combustion and exhausting of gases through the flue (chimney) of fuel burning equip ment to prevent backdrafting. Follow the heating equipment manufacturer’s guideline and safety standards such as those

published by the National Fire Protection Association (NFPA), and the American Society for Heating, Refrigeration and

Air Conditioning Engineers (ASHRAE), and the local code authorities.

5. When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. Acceptable for use over a tub or shower when connected to a GFCI (Ground Fault Circuit Interrupter) - protected branch

circuit (ceiling installation only).

8. This unit must be grounded.

1. For general ventilating use only. Do not use to exhaust hazardous or explosive materials and vapors.

2. This product is designed for installation in ceilings up to a 12/12 pitch (45 degree angle). Duct connector must point up.

DO NOT MOUNT THIS PRODUCT IN A WALL.

3. To avoid motor bearing damage and noisy and/or unbalanced impellers, keep drywall spray, construction dust, etc. off

power unit.

4. Please read specification label on product for further information and requirements.

For quiet and efficient operation, long life, and attractive appearance - lower or remove grille and vacuum interior of unit

with the dusting brush attachment.

The motor is permanently lubricated and never needs oiling. If the motor bearings are making excessive or unusual noises, replace the motor with the exact service motor. The impeller should also be replaced.

Use an on/off switch to operate this fan. See “Connect Wiring” for details.

The humidity control and fan can be operated separately. Use a 1 or 2 function wall control. Do not use a dimmer switch

to operate the humidity control or light. See “Connect Wiring” for details.

SENSOR OPERATION

The humidity-sensing fan uses a sophisticated humidity sensor that responds to: (a) rapid to moderate (user-adjustable)

increases in humidity or (b) humidity above a user-adjustable set-point (50%-100% relative humidity). The humidity sensor may occasionally turn the fan ON when environmental conditions change. If the fan continuously responds to changing environmental conditions, “H” (means “humidity”) adjustment may be required. This figure is factory-set for about 75%

(Ambient temperature of 25℃).

SENSITIVITY ADJUSTMENT

The “H” has been factory set for most shower applications. However, if the fan is in a tub area or is being used for dampness control, the “H” may need to be increased toward maximum “+”. If the control is responding too often to changing

environmental conditions, movement toward less “-” “H” may be required.

To adjust the “H”:

1. Disconnect power at service entrance.

2. Through the grille, locate the slot marked “H”.

3. Carefully rotate the “H” adjustment toward “+” or “-”.

1

MODEL: ODS-8003-14 ODS-9003-14 ODS-1109 ODS-12012 ODS-15011

ODS-8003HS-14 ODS-9003HS-14 ODS-1109HS ODS-12012HS ODS-15011HS

VENTILATION FAN

2. Mount with mountion holes and hanger bar

Slide one hanger bar into the channel on the housing and adjust as

needed to fit between framing. Hold housing in place so that the housing

contact the bottom of the joist, Screw housing to joist through the hole A

and hole B. Screw the hanger bar onto the other side of joist through the

hole (refer to the right diagram).

Screw hanger bar to housing with screw A.

OPERATION

PLAN THE INSTALLATION

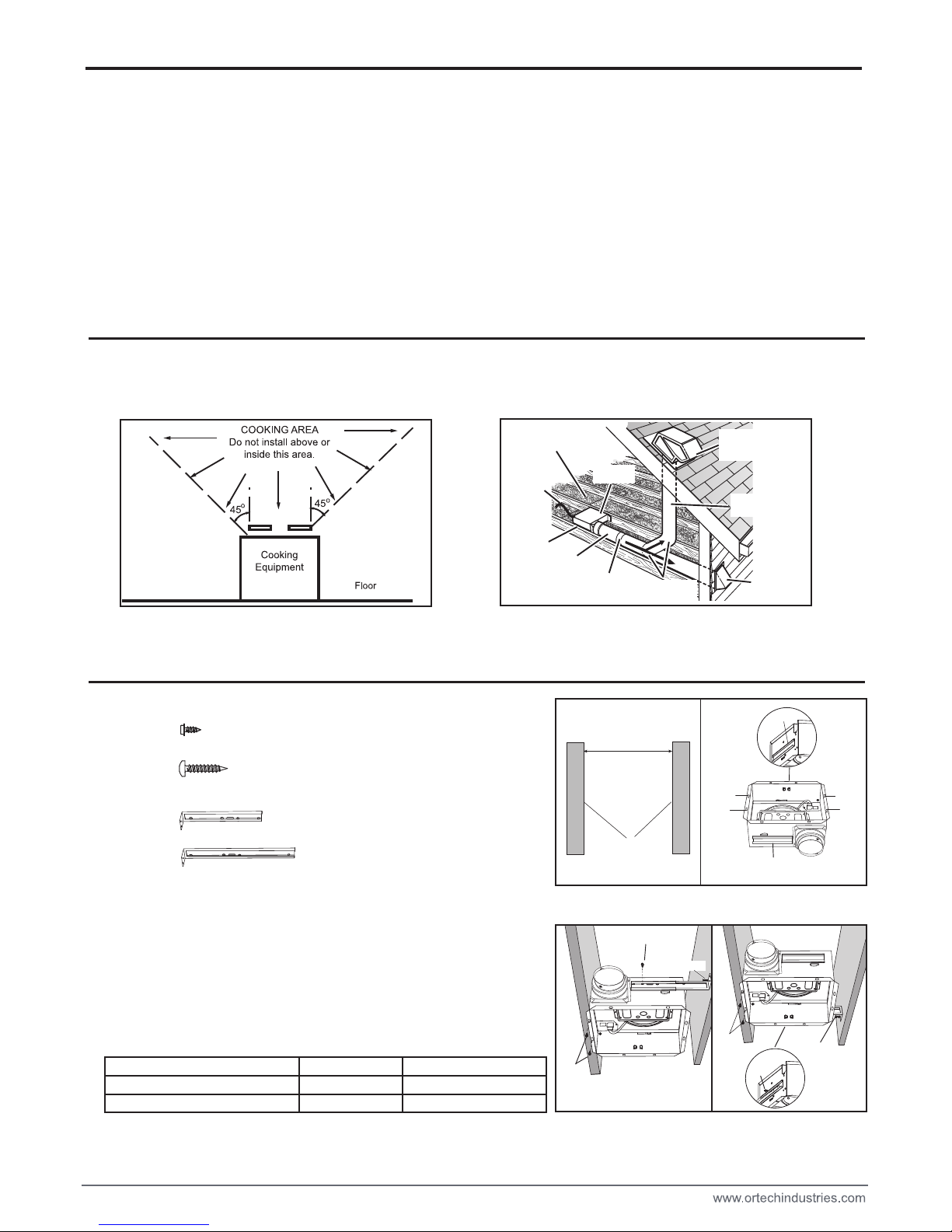

1. Do not use in a cooking area.

2. Two ways to connect ductwork to a factory-shipped unit.

ASSEMBLY INSTRUCTIONS

2

4. Turn on power and check operation by turning on the shower or other humidity source until the fan turns on.

5. Repeat above steps if necessary.

When the temperature changes, humidity sensor values will have deviation.

TIMER ADJUSTMENT

The humidity sensing fan has a “T” (means timer) that can be adjusted from 5 to 60 minutes (factory-set at about 20 minutes). This “T” controls the length of time that the fan remains ON after the sensor has stopped sensing a rise in humidity

and the humidity level is below the user-adjustable set-point. To adjust the “T”:

1. Disconnect power at service entrance;

2. Through the grille, locate the slot marked “T”;

3. Carefully rotate the “T” adjustment to desired setting (from 5 to 60 minutes).

4. Check operation by turning on a humidity source until the fan turns on.

5. Turn humidity source off and time the unit.

6. Repeat above steps if necessary.

Distance A

JOIST

1. Before installation, you need to know:

Fig. 1 Fig. 2

Hole A

Hole B

Hole A

Hole B

Distance A

13 1/4 in to 15 1/2 in (336mm-394mm)

16 1/2 in to 18 7/8 in (419mm-480mm)

Hanger Bar

Channel

Channel A (Fig. 1)

Channel B (Fig. 2)

Hanger bar (short)

Hanger bar (long)

The choice of Hanger Bar

Channel A

Channel B

ST4.2*13mm

Screw A

Screw B

Hanger bar

(short)

Hanger bar

(long)

ST4.2*25mm

7 1/2 in (190mm)

13 3/8 in (340mm)

Screw A

Screw B

Note: Hanger bar (short) only can slide into channle A.

Screw A

Screw A

Screw A

Screw B

ROOF CAP*

(with built-in

damper)

ROUND

DUCT*

WALL CAP*

(with built-in

damper)

* Purchase

separately

POWER

CABLE*

INSULATION*

(Place around and

over Fan Housing.)

Seal gaps

around

Housing.

FAN

HOUSING

ROUND

ELBOW(S) *

Seal duct

joints with

tape.

Keep duct

runs short

3. Mount with hanger bars only

Slide hanger bars onto housing and adjust as needed to fit between

framing. Extend the hanger bars to the width of the framing. Position the

ventilator with the hanger bar tabs wrapped around the bottom edge of

the framing, holding the ventilator in place.

Secure hanger bars to framing using one screw on each end of hanger

bar. (refer to the right diagram)

Screw hanger bar to housing with screw A.

4. Mount to I-joist

Slide one hanger bar (long) into channel B on the housing and adjust as

needed to fit between framing. Hold housing in place so that the housing

contacts the bottom of the joist. Screw housing to joist through the hole D

and hole C. Screw the hanger bar onto the other side of joist through the

hole (refer to the right diagram).

Screw hanger bar to housing with screw A.

5. INSTALL ROUND DUCTWORK

Connect the round ductwork (not included) to the damper/duct connector,

and run the ductwork to a roof or wall cap (not included). Using tape (not

included), secure all the ductwork connections so that they are air tight.

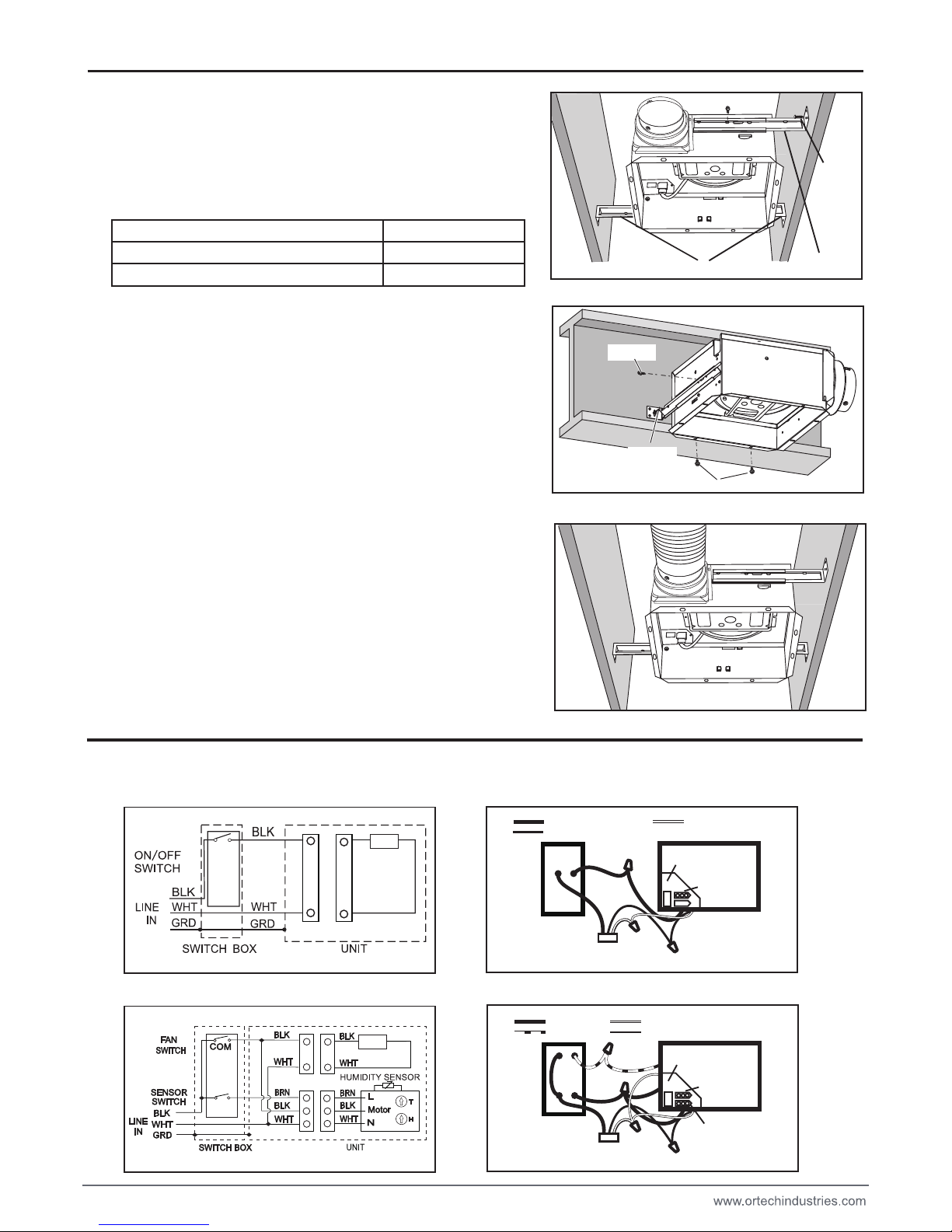

Run 120 V AC house wiring to the location of the fan. Use only UL-approved connectors (not included) to attach the house wiring to the

wiring plate. Refer to the wiring diagram, and connect the wires as shown.

ASSEMBLY INSTRUCTIONS

CONNECT ELECTRICAL WIRING

UNIT

BLACK (BLK)

SENSOR

SWITCH

SWITCH BOX

POWER SUPPLY

120V AC

GROUND (GRD)

BROWN (BRN)

WHITE (WHT)

WIRING

PLATE

FAN

RECEPTACLE

SENSOR

RECEPTACLE

UNIT

BLACK (BLK)

SWITCH BOX

FAN

SWITCH

FAN

SWITCH

POWER SUPPLY

120V AC

GROUND (GRD)

WHITE (WHT)

WIRING

PLATE

FAN

RECEPTACLE

3

FAN

FAN

For: ODS-8003-14 ODS-9003-14 ODS-1109 ODS-12012 ODS-15011

For: ODS-8003HS-14 ODS-9003HS-14 ODS-1109HS ODS-12012HS ODS-15011HS

Distance A

14 in to 23 1/2 in (356mm-597mm)

21 1/4 in to 23 1/2 in (540mm-597mm)

Hanger Bar A

Hanger bar (short)

Hanger bar (long)

The choice of Hanger Bar A

Hanger bar (long)

Hanger bar A

Screw A

Screw B

Screw A

Screw A

Screw B

Install ceiling material to complete the ceiling construction. Then, cut around

the fan housing.

To attach the grille assembly to the fan housing, pinch the grille springs on

the sides of the grille assembly, and position the grille into the housing with

the grille springs in the appropriate slots. Push the grille assembly towards

the ceiling to secure.

WARRANTY

INSTALL GRILLE

SERVICE PARTS

5

6

d

e

a

1

2

3

4

b

c

7

10

9

8

11

8

12

PART PART NAME Qty.

1

2

3

4

5

6

7

8

9

10

11

12

a

b

c

d

e

Housing

Damper / Duct Connector

Wiring plate

Screw

Blower Wheel

Wire Panel / Harness Assembly

Motor

1

2

1

1

1

1

1

1

1

1

3

1

4

4

1

4

1

Isolator

Motor Plate

Washer

Nut, Hex Lock

Grille Assembly (includes part 2)

Grille Spring

Hanger Bar Kit (short)

Hanger Bar Kit (long)

Screw

Humidity Sensor System (for sensor model)

* Blower Assembly includes part 6, 5, d, 4, c, b, a.

Replacement installation:

Remove the screw (part c), then take out the motor plate (part 4) from

the housing (part 10) by pushing down the rib in the plate while pulling

out on the side of the housing. Replace the broken parts.

4

WARNING: Before replacing, be sure to turn off power at power source.

ONE YEAR LIMITED WARRANTY from the original date of purchase against defects in material and workmanship.

This warranty is limited up to the amount of the original purchase price of the product, excluding any labor cost. For

inquiries please visit www.ortechindustries.com or call 1-888-543-6473.

Four Model ODS-8003HS-14 ODS-9003HS-14 ODS-1109HS ODS-12012HS ODS-15011HS

VENTILATEUR

AVERTISSEMENT

PRÉCAUTION

L ENTRETIEN

FONCTIONNEMENT

5

MODEL: ODS-8003-14 ODS-9003-14 ODS-1109 ODS-12012 ODS-15011

ODS-8003HS-14 ODS-9003HS-14 ODS-1109HS ODS-12012HS ODS-15011HS

fabricant.Pour toute question, veuillez contacter le fabricant

pas

qualifiée, qui doit suivre les

Veuillez suivre les les

tels

qu’expliqués par les fabricants d’équipement de chauffage, tels que publiés

Lorsque vous découpezv

électriques ou autres

générale seulement. N’utilisez pas cet

jusqu’à 12 ½ (45 degrés au maximum). Le raccordement pour le conduit d’aération

doit être dirigé vers

aux paliers du moteur ou augmenter le bruit ou déséquilibrer les roues à aubes,

d’huile. Si les paliers du moteur deviennent plus bruyants que d’habitude, remplacez le moteur

avec un moteur de rechange identique. La roue à aubes devra être remplacée aussi.

CONSERVER

Donnez ce manuel au propriétaire

FONCTIONNEMENT

PLANIFIE VOTRE INSTALLATION

6

INSTRUCTIONS POUR L’ASSEMBLAGE

2. Installation utilisant les trous de fixation et le support de montage.

Glissez un des supports de montage dans la rainure du boîtier et ajustez au

besoin afin de placer entre les solives. Tenez le boîtier en place afin de le

fixer vis-à-vis le bas de la solive. Vissez le boîtier à la solive en passant par

le trou A ainsi que le trou B. Vissez le support de montage de l’autre côté de

la solive à travers le trou (veuillez consulter l’illustration à droite). Vissez le

support de montage au boîtier en utilisant la vis A.

Distance A

Solive

1. Avant l’installation, veuillez prendre en note les détails suivants:

Fig. 1 Fig. 2

Trou A

Trou B

Trou A

Trou B

Distance A

13 1/4 po à 15 1/2 po (336mm-394mm)

16 1/2 po à 18 7/8 po (419mm-480mm)

Support de montage

Rainure

Rainure A (figure 1)

Rainure B (figure 2)

Support de montage (court)

Support de montage (long)

Le choix de support de montage

Rainure A

Rainure B

Filetage 4.2 * 13mm

Vis A

Vis B

Support de montage

(court)

Support de montage

(long)

Filetage 4.2 * 25mm

7 1/2 po (190mm)

13 3/8 po (340mm)

Vis A

Vis B

Nota: Seul le court support de montage peut glisser dans la rainure A.

Vis A

Vis A

Vis A

Vis B

POUR: ODS-8003-14 ODS-9003-14 ODS-1109 ODS-12012 ODS-15011

POUR: ODS-8003HS-14 ODS-9003HS-14 ODS-1109HS ODS-12012HS ODS-15011HS

BRUN

NOIR

TERRE

BLANC

NOIR

TERRE

BLANC

7

INSTRUCTIONS POUR L’ASSEMBLAGE

BRANCHEMENT DES FILS ÉLECTRIQUES

FAN

FAN

3. Installation utilisant seulement les supports de montage

Glissez les supports de montage dans la rainure du boîtier et ajustez au

besoin afin de le placer entre les solives. Ajustez les supports de montage

afin qu’ils touchent les solives. En tenant le ventilateur en place, arrangez-le

afin que les languettes situées sur les supports de montage enveloppent le

bord des solives. Fixez les supports de montage aux solives en utilisant une

vis à chacun des bouts de ceux-ci. (voir la figure à droite). Vissez le support

de montage au boîtier avec la vis A.

4. Installation aux solives en I

Glissez un des supports de montage (long) dans la rainure B du boîtier et

ajustez au besoin afin de le placer entre les solives. En tenant le boîtier en

place, assurez-vous que celui-ci touche le bas de la solive. Vissez le boîtier

à la solive en passant par les trous D et C. Vissez le support de montage

de l’autre côté de la solive en passant par le trou (veuillez voir la figure à

droite). Vissez le support de montage au boîtier avec la vis A.

5. L’installation du conduit rond

Raccordez le conduit rond (non compris) à l’amortisseur/le raccordement de

conduit, et joignez-le à un évent mural ou de toiture (non compris). En

utilisant du ruban adhésif pour conduit (non compris), assurez-vous qu’il n’y

ait aucune fuite d’air.

Distance A

14 po à 23 1/2 po (356mm-597mm)

21 1/4 po à 23 1/2 po (540mm-597mm)

Support de montage A

Support de montage (court)

Support de montage (long)

Support de montage (long)

Support de

montage A

Le choix de support de montage A .

Vis A

Vis B

Vis A

Vis A

Vis B

Relier le circuit électrique de votre maison de 120 V c.a. à l’emplacement du ventilateur. Utilisez seulement des raccords

homologués par UL pour relier le circuit électrique de votre maison à la plaque de câblage. Branchez les fils comme

illustré ci-dessous.

8

5

6

d

e

a

1

2

3

4

b

c

7

10

9

11

8

12

LIST DE PIECES DE RECHANGE

1

2

3

4

5

6

7

8

9

10

11

12

a

b

c

d

e

1

2

1

1

1

1

1

3

1

1

1

1

4

4

1

4

1

* 6, 5, d, 4, c, b, a.)

Remplacement de pièces: Enlevez la vis (piéce c), puis retirez la plaque du moteur (piéce 4)

du boîtier en poussant la nervure vers le bas, tout en tirant sur le côté du boîtier (piéce 10).

Remplacez les pièces défectueuses.

8

L’INSTALLATION DE LA GRILLE

Pincez ensemble les ressorts de la grille et insérez-les dans la plaque

du moteur dans le boîtier. Poussez la grille fermement vers le plafond.

Pour fixer la grille au boîtier du ventilateur, pincez les ressorts se

trouvant sur les côtés de la grille, puis installez la grille dans le boîtier

en insérant les ressorts dans leurs fentes respectives.

Poussez la grille vers le plafond pour la fixer fermement.

2

PIÈCE NOM DE LA PIÈCE Qté

GARANTIE LIMITÉE

(Pour capteur model)

AVERTISSEMENT: Avant de remplacer une pièce, assurez-vous de couper

l’alimentation électrique à la source.

(court)

(long)

grille

c

grille

d

d

d

b

b

f

f

GARANTIE limitée d'un an de la date d'achat contre tout vice de matériau et de fabrication. Cette garantie est limitée

à concurrence du montant du prix d'achat initial du produit, à l'exclusion de tout coût de main de œuvre. Si vous avez

des questions s'il vous plaît visitez notre site www.ortechindustries.com 1 888 543 6473 .

Loading...

Loading...