WARNING

READ AND SAVE THESE INSTRUCTIONS

Installer: Leave this manual with the homeowner.

CAUTION

CLEANING & MAINTENANCE

OPERATION

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you have questions, contact the manufacturer at the

address or telephone number listed in the warranty.

2. Before servicing or cleaning unit, switch power off at service panel and lock the service disconnecting means to prevent

power from being switched on accidentally. When the service disconnecting means cannot be locked, securely fasten

a prominent warning device, such as a tag, to the service panel.

3. Installation work and electrical wiring must be done by a qualified person(s) in accordance with all applicable codes and

standards, including fire-rated construction codes and standards.

4. Sufficient air is needed for proper combustion and exhausting of gases through the flue (chimney) of fuel burning equip ment to prevent backdrafting. Follow the heating equipment manufacturer’s guideline and safety standards such as those

published by the National Fire Protection Association (NFPA), and the American Society for Heating, Refrigeration and

Air Conditioning Engineers (ASHRAE), and the local code authorities.

5. When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. Acceptable for use over a tub or shower when connected to a GFCI (Ground Fault Circuit Interrupter) - protected branch

circuit (ceiling installation only).

8. This unit must be grounded.

1. For general ventilating use only. Do not use to exhaust hazardous or explosive materials and vapors.

2. This product is designed for installation in ceilings up to a 12/12 pitch (45 degree angle). Duct connector must point up.

DO NOT MOUNT THIS PRODUCT IN A WALL.

3. To avoid motor bearing damage and noisy and/or unbalanced impellers, keep drywall spray, construction dust, etc. off

power unit.

4. Please read specification label on product for further information and requirements.

For quiet and efficient operation, long life, and attractive appearance - lower or remove grille and vacuum interior of unit

with the dusting brush attachment.

The motor is permanently lubricated and never needs oiling. If the motor bearings are making excessive or unusual noises, replace the motor with the exact service motor. The impeller should also be replaced.

1

MODEL: ODS45-9003 ODS45-1106

VENTILATION FAN

The fan continues to run at the preset lower speed of 45 CFM. When the switch is turned on, the fan will run at high speed.

WARRANTY

ONE YEAR LIMITED WARRANTY from the original date of purchase against defects in material and

workmanship. This warranty is limited up to the amount of original purchase price of the product,

excluding any installation, nor repair labor cost. For inquiries call 1 888 543 6473 or

info@ortechindustries.com

LED MODULES: THREE YEAR LIMITED WARRANTY from the original date of purchase against

defects in material and workmanship. This warranty is limited up to the amount of original purchase

price of the product, excluding any installation, nor repair labor cost. For inquiries call 1 888 543 6473

or info@ortechindustries.com

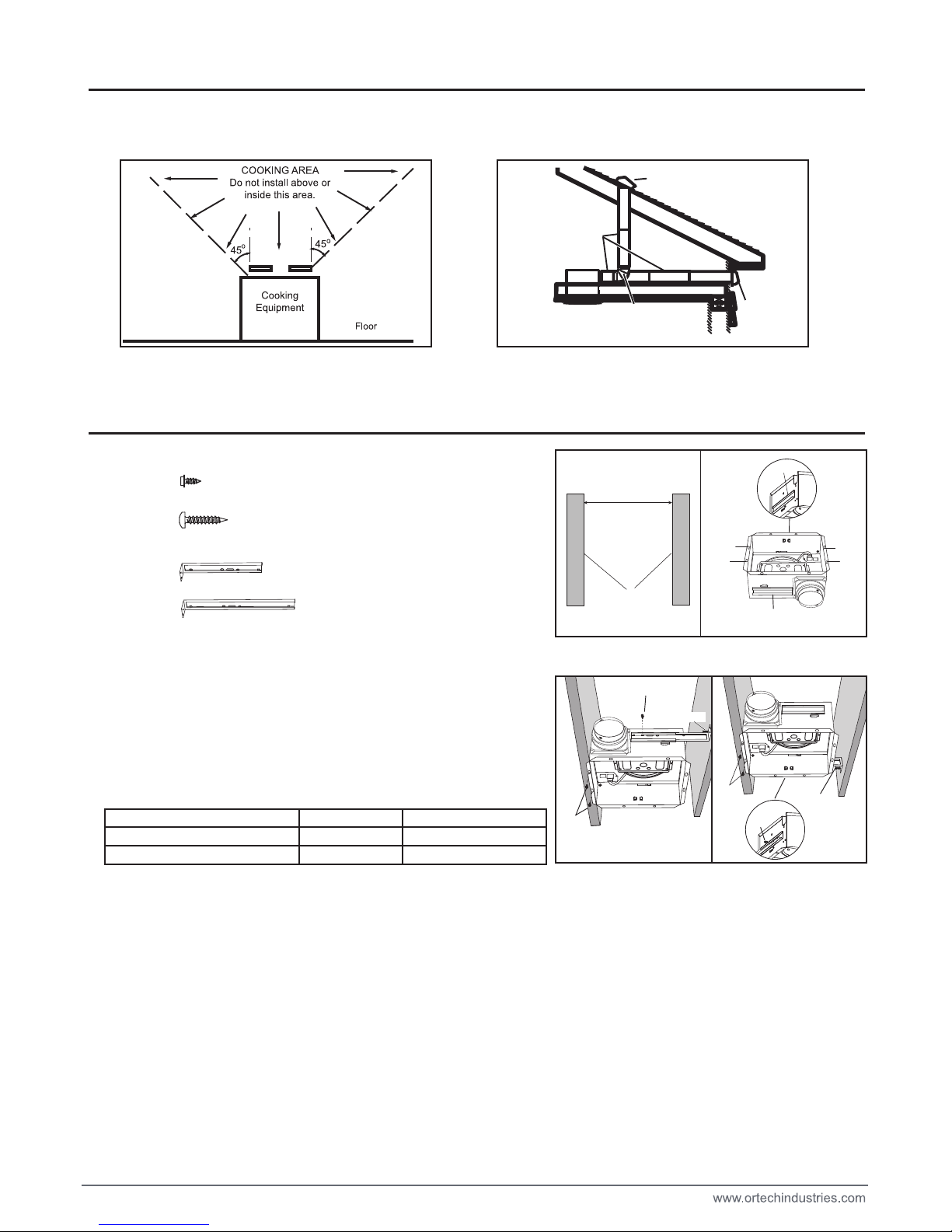

2. Mount with mountion holes and hanger bar

Slide one hanger bar into the channel on the housing and adjust as

needed to fit between framing. Hold housing in place so that the housing

contact the bottom of the joist, Screw housing to joist through the hole A

and hole B. Screw the hanger bar onto the other side of joist through the

hole (refer to the right diagram).

Screw hanger bar to housing with screw A.

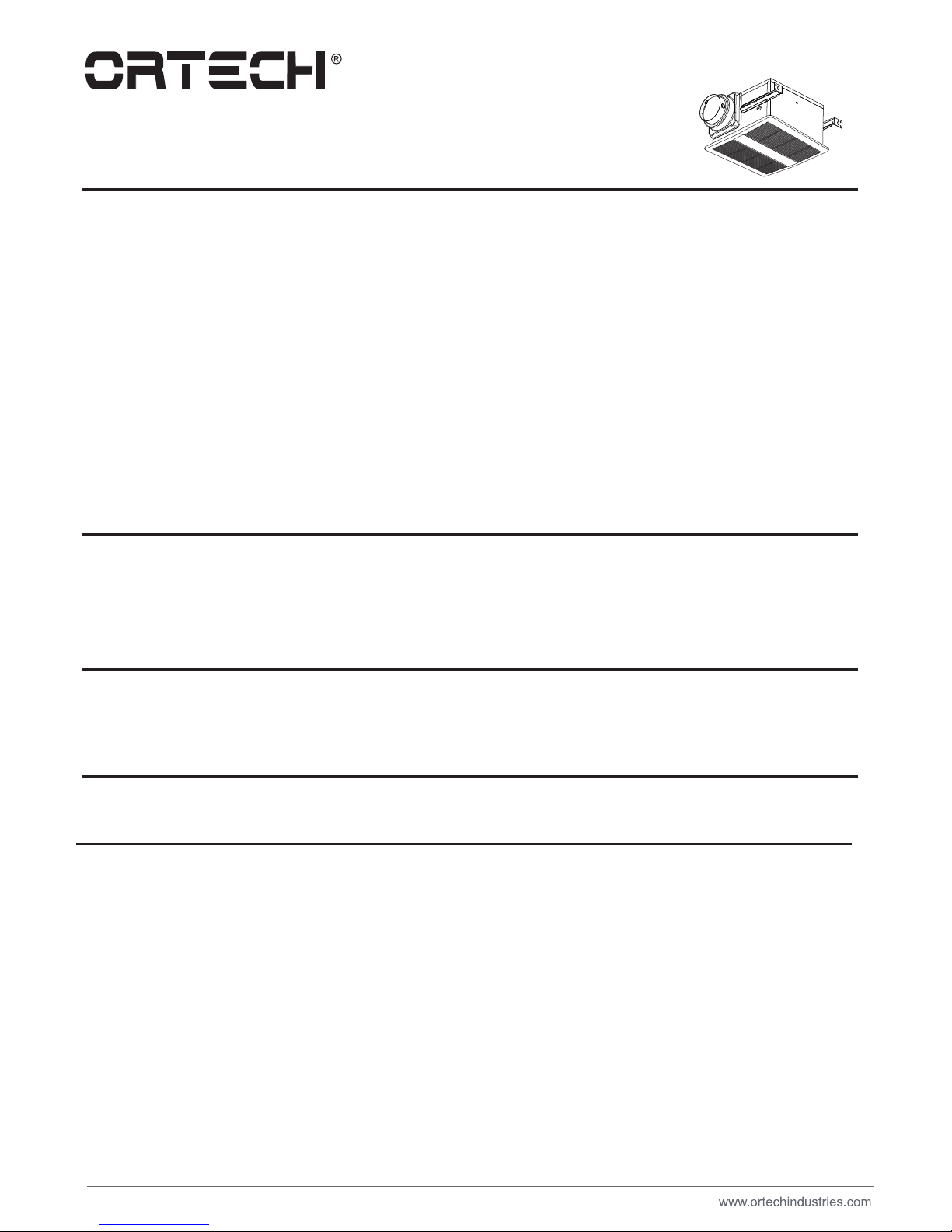

PLAN THE INSTALLATION

1. Do not use in a cooking area.

2. Two ways to connect ductwork to a factory-shipped unit.

ASSEMBLY INSTRUCTIONS

2

*Purchase

separately

ROUND

ELBOW *

ROUND

DUCT *

ROOF CAP *

WALL

CAP *

Distance A

JOIST

1. Befor installation, you need to know:

Fig. 1 Fig. 2

Hole A

Hole B

Hole A

Hole B

Distance A

13 1/4 in to 15 1/2 in (336mm-394mm)

16 1/2 in to 18 7/8 in (419mm-480mm)

Hanger Bar

Channel

Channel A (Fig. 1)

Channel B (Fig. 2)

Hanger bar (short)

Hanger bar (long)

The choice of Hanger Bar

Channel A

Channel B

ST4.2*13mm

Screw A

Screw B

Hanger bar

(short)

Hanger bar

(long)

ST4.2*25mm

7 1/2 in (190mm)

13 3/8 in (340mm)

Screw A

Screw B

Note: Hanger bar (short) only can slide into channle A.

Screw A

Screw A

Screw A

Screw B

3. Mount with hanger bars only

Slide hanger bars onto housing and adjust as needed to fit between

framing. Extend the hanger bars to the width of the framing. Position the

ventilator with the hanger bar tabs wrapped around the bottom edge of

the framing, holding the ventilator in place.

Secure hanger bars to framing using one screw on each end of hanger

bar. (refer to the right diagram)

Screw hanger bar to housing with screw A.

4. Mount to I-joist

Slide one hanger bar (long) into channel B on the housing and adjust as

needed to fit between framing. Hold housing in place so that the housing

contacts the bottom of the joist. Screw housing to joist through the hole D

and hole C. Screw the hanger bar onto the other side of joist through the

hole (refer to the right diagram).

Screw hanger bar to housing with screw A.

5. INSTALL ROUND DUCTWORK

Connect the round ductwork (not included) to the damper/duct connector,

and run the ductwork to a roof or wall cap (not included). Using tape (not

included), secure all the ductwork connections so that they are air tight.

Run 120 V AC house wiring to the location of the fan. Use only UL-approved connectors (not included) to attach the house wiring to the

wiring plate. Refer to the wiring diagram, and connect the wires as shown.

ASSEMBLY INSTRUCTIONS

CONNECT ELECTRICAL WIRING

3

Distance A

14 in to 23 1/2 in (356mm-597mm)

21 1/4 in to 23 1/2 in (540mm-597mm)

Hanger Bar A

Hanger bar (short)

Hanger bar (long)

The choice of Hanger Bar A

Hanger bar (long)

Hanger bar A

Screw A

Screw B

Screw A

Screw A

Screw B

UNIT

BLACK (BLK)

SWITCH BOX

POWER SUPPLY

120V AC

GROUND (GRD)

WHITE (WHT)

FAN

RECEPTACLE

FAN

WIRE

PANEL

BLK

BLU

BLK

SWITCH

SWITCH

BLUE (BLU)

Install ceiling material to complete the ceiling construction. Then, cut around

the fan housing.

To attach the grille assembly to the fan housing, pinch the grille springs on

the sides of the grille assembly, and position the grille into the housing with

the grille springs in the appropriate slots. Push the grille assembly towards

the ceiling to secure.

WARRANTY

INSTALL GRILLE

SERVICE PARTS

4

5

d

e

a

1

2

3

b

c

6

9

8

7

10

7

11

PART PART NAME Qty.

1

2

3

4

5

6

7

8

9

10

11

a

b

c

d

e

Housing

Damper / Duct Connector

Wiring plate

Screw

Blower Wheel

Wire Panel / Harness Assembly

Motor

1

2

1

1

1

1

1

1

1

3

1

4

4

1

4

1

Isolator

Motor Plate

Washer

Nut, Hex Lock

Grille Assembly (includes part 2)

Grille Spring

Hanger Bar Kit (short)

Hanger Bar Kit (long)

Screw

* Blower Assembly includes part 5,4, d, 3, c, b, a.

Replacement installation:

Remove the screw (part c), then take out the motor plate (part 3) from

the housing (part 9) by pushing down the rib in the plate while pulling

out on the side of the housing. Replace the broken parts.

4

WARNING: Before replacing, be sure to turn off power at power source.

This warranty covers all defects in workmanship or materials for:

The mechanical and electrical parts contained in this product, for a period of 12 months, from the date of purchase. You

must keep and be able to provide your original sales receipt as proof of the date of purchase. This warranty covers

the original retail purchaser of this product. the manufacturer will be responsible to replace all defetive parts for the period

of 12 months

THIS WARRANTY DOES NOT COVER:

• Damages from improper installation.

• Damages from shipping.

• Damages from misuse, abuse, accident, alteration, lack of proper care and maintenance.

• Damages from service by persons other than an authorized dealer or service center.

• Labour, service, transportation and shipping charges for the removal of defective parts and for installation of a replacement

part, beyond the initial 12-month period.

This warranty does not extend to fluorescent lamp starters and tubes.

THIS LIMITED WARRANTY IS GIVEN IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING

THE WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

The remedy provided in this warranty is exclusive and is granted in lieu of all other remedies. This warranty does not cover

incidental or consequential damages. Some states do not allow the exclusion of incidental or consequential damages, so

this limitation may not apply to you. Some states do not allow limitations on how long an implied warranty lasts, so this

limitation may not apply to you. This warranty gives you specific legal rights, and you may also have other rights, which

vary from state to state.

VENTILATEUR

AVERTISSEMENT

PRÉCAUTION

L ENTRETIEN

FONCTIONNEMENT

5

MODEL: ODS45-9003 ODS45-1106

fabricant.Pour toute question, veuillez contacter le fabricant

pas

qualifiée, qui doit suivre les

Veuillez suivre les les

tels

qu’expliqués par les fabricants d’équipement de chauffage, tels que publiés

Lorsque vous découpezv

électriques ou autres

générale seulement. N’utilisez pas cet

jusqu’à 12 ½ (45 degrés au maximum). Le raccordement pour le conduit d’aération

doit être dirigé vers

aux paliers du moteur ou augmenter le bruit ou déséquilibrer les roues à aubes,

d’huile. Si les paliers du moteur deviennent plus bruyants que d’habitude, remplacez le moteur

avec un moteur de rechange identique. La roue à aubes devra être remplacée aussi.

CONSERVER

Donnez ce manuel au propriétaire

Le ventilateur continue à tourner à la vitesse inférieure prédéfinie de 45 CFM. Lorsque l'interrupteur est allumé, le ventilateur tourne à grande vitesse

PLANIFIE VOTRE INSTALLATION

6

INSTRUCTIONS POUR L’ASSEMBLAGE

2. Installation utilisant les trous de fixation et le support de montage.

Glissez un des supports de montage dans la rainure du boîtier et ajustez au

besoin afin de placer entre les solives. Tenez le boîtier en place afin de le

fixer vis-à-vis le bas de la solive. Vissez le boîtier à la solive en passant par

le trou A ainsi que le trou B. Vissez le support de montage de l’autre côté de

la solive à travers le trou (veuillez consulter l’illustration à droite). Vissez le

support de montage au boîtier en utilisant la vis A.

Distance A

Solive

1. Avant l’installation, veuillez prendre en note les détails suivants:

Fig. 1 Fig. 2

Trou A

Trou B

Trou A

Trou B

Distance A

13 1/4 po à 15 1/2 po (336mm-394mm)

16 1/2 po à 18 7/8 po (419mm-480mm)

Support de montage

Rainure

Rainure A (figure 1)

Rainure B (figure 2)

Support de montage (court)

Support de montage (long)

Le choix de support de montage

Rainure A

Rainure B

Filetage 4.2 * 13mm

Vis A

Vis B

Support de montage

(court)

Support de montage

(long)

Filetage 4.2 * 25mm

7 1/2 po (190mm)

13 3/8 po (340mm)

Vis A

Vis B

Nota: Seul le court support de montage peut glisser dans la rainure A.

Vis A

Vis A

Vis A

Vis B

NOIR

TERRE

BLANC

7

INSTRUCTIONS POUR L’ASSEMBLAGE

BRANCHEMENT DES FILS ÉLECTRIQUES

3. Installation utilisant seulement les supports de montage

Glissez les supports de montage dans la rainure du boîtier et ajustez au

besoin afin de le placer entre les solives. Ajustez les supports de montage

afin qu’ils touchent les solives. En tenant le ventilateur en place, arrangez-le

afin que les languettes situées sur les supports de montage enveloppent le

bord des solives. Fixez les supports de montage aux solives en utilisant une

vis à chacun des bouts de ceux-ci. (voir la figure à droite). Vissez le support

de montage au boîtier avec la vis A.

4. Installation aux solives en I

Glissez un des supports de montage (long) dans la rainure B du boîtier et

ajustez au besoin afin de le placer entre les solives. En tenant le boîtier en

place, assurez-vous que celui-ci touche le bas de la solive. Vissez le boîtier

à la solive en passant par les trous D et C. Vissez le support de montage

de l’autre côté de la solive en passant par le trou (veuillez voir la figure à

droite). Vissez le support de montage au boîtier avec la vis A.

5. L’installation du conduit rond

Raccordez le conduit rond (non compris) à l’amortisseur/le raccordement de

conduit, et joignez-le à un évent mural ou de toiture (non compris). En

utilisant du ruban adhésif pour conduit (non compris), assurez-vous qu’il n’y

ait aucune fuite d’air.

Distance A

14 po à 23 1/2 po (356mm-597mm)

21 1/4 po à 23 1/2 po (540mm-597mm)

Support de montage A

Support de montage (court)

Support de montage (long)

Support de montage (long)

Support de

montage A

Le choix de support de montage A .

Vis A

Vis B

Vis A

Vis A

Vis B

Relier le circuit électrique de votre maison de 120 V c.a. à l’emplacement du ventilateur. Utilisez seulement des raccords

homologués par UL pour relier le circuit électrique de votre maison à la plaque de câblage. Branchez les fils comme

illustré ci-dessous.

FAN

BLEU

BLEU

7

4

5

d

e

a

1

2

3

b

c

6

9

8

10

7

11

LIST DE PIECES DE RECHANGE

1

2

3

4

5

6

7

8

9

10

11

a

b

c

d

e

1

2

1

1

1

1

3

1

1

1

1

4

4

1

4

1

* 5, 4,d, 3, c, b, a.)

Remplacement de pièces: Enlevez la vis (piéce c), puis retirez la plaque du moteur (piéce 3)

du boîtier en poussant la nervure vers le bas, tout en tirant sur le côté du boîtier (piéce 9).

Remplacez les pièces défectueuses.

8

L’INSTALLATION DE LA GRILLE

Pincez ensemble les ressorts de la grille et insérez-les dans la plaque

du moteur dans le boîtier. Poussez la grille fermement vers le plafond.

Pour fixer la grille au boîtier du ventilateur, pincez les ressorts se

trouvant sur les côtés de la grille, puis installez la grille dans le boîtier

en insérant les ressorts dans leurs fentes respectives.

Poussez la grille vers le plafond pour la fixer fermement.

2

PIÈCE NOM DE LA PIÈCE Qté

GARANTIE LIMITÉE

La présente garantie couvre tous les défauts de fabrication et de matériaux des éléments suivants : les pièces mécaniques

et électriques contenues dans ce produit, pour une période de 12 mois à compter de la date d’achat. Vous devez conserver

le reçu original afin d’être en mesure de le fournir à titre de preuve de la date d’achat. La présente garantie n’est offerte qu’à

l’acheteur original. Pendant une période de douze (12) mois, le fabricant réparera ou remplacera toute pièce

mécanique ou électrique s’avérant défectueuse, à condition que l’appareil ait seulement fait l’objet d’un usage domestique

normal.

LA PRÉSENTE GARANTIE NE COUVRE PAS LES ÉLÉMENTS SUIVANTS :

• les dommages causés par une installation inadéquate;

• les dommages subis pendant le transport;

• les dommages causés par un usage inapproprié, un usage abusif, un accident, une modification ou un entretien inadéquat;

• les dommages causés par une réparation ou un entretien effectués par toute personne ou toute entité autres qu’un détaillant

ou un centre de service autorisés;

• les frais de main-d’œuvre, de réparation, d’entretien, de transport et d’expédition liés au retrait de pièces défectueuses et à

l’installation de pièces de rechange, après la période initiale de douze (12) mois.

La garantie ne couvre pas les tubes ni les démarreurs de lampe fluorescente.

LA PRÉSENTE GARANTIE LIMITÉE REMPLACE TOUTE AUTRE GARANTIE EXPRESSE OU IMPLICITE, Y COMPRIS

TOUTE GARANTIE DE QUALITÉ MARCHANDE OU DE CONFORMITÉ À UN USAGE PARTICULIER.

La présente garantie constitue l’unique recours de l’acheteur et remplace tout autre recours. La présente garantie ne couvre

pas les dommages accessoires ou consécutifs. Certains États ou certaines provinces ne permettent pas l’exclusion des

dommages accessoires ou consécutifs, de sorte que les limitations mentionnées ci-dessus peuvent ne pas s’appliquer à

vous. Certains États ou certaines provinces ne permettent pas de limitations quant à la durée des garanties implicites, de

sorte que ces limitations peuvent ne pas s’appliquer à vous. La présente garantie vous confère des droits précis. Il est

possible que vous disposiez également d’autres droits, qui varient d’un État ou d’une province à l’autre.

AVERTISSEMENT: Avant de remplacer une pièce, assurez-vous de couper

l’alimentation électrique à la source.

(court)

(long)

grille

grille

d

d

d

b

b

f

f

Loading...

Loading...