WARNING

READ AND SAVE THESE INSTRUCTIONS

Installer: Leave this manual with the homeowner.

CAUTION

CLEANING & MAINTENANCE

OPERATION

1. For general ventilating use only. Do not use to exhaust hazardous or explosive materials and vapors.

2. This product is designed for installation in ceilings up to a 12/12 pitch (45 degree angle). Duct connector must point up.

DO NOT MOUNT THIS PRODUCT IN A WALL.

3. To avoid motor bearing damage and noisy and/or unbalanced impellers, keep drywall spray, construction dust, etc. off power unit.

4. Please read specification label on product for further information and requirements.

*The manual in electronic format can be download in our company website, or obtained from our dealer.

For quiet and efficient operation, long life, and attractive appearance - lower or remove grille and vacuum interior of unit with the dusting

brush attachment on a regular basis.

The motor has been permanently lubricated at the factory and never needs oiling. If the motor bearings are making excessive or unusual

noises, replace the motor with the exact service motor. The impeller should also be replaced.

1

MODEL: ODD-110

VENTILATION FAN

1. Use this unit only in the manner intended by the manufacturer. If you have questions, contact the manufacturer.

2. Before servicing or cleaning unit, switch power off at service panel and lock the service disconnecting means to prevent power from being switching

on accidentally. When the service disconnecting means cannot be locked, securely fasten a prominent warning device, such as a tag, to the service panel.

3. Installation work and electrical wiring must be done by a qualified person in accordance with all applicable codes and standards, including fire-rated

construction codes and standards.

4. Sufficient air is needed for proper combustion and exhausting of gases through the flue (chimney) of fuel burning equipment to prevent backdrafting.

Follow the heating equipment manufacturer’s guideline and safety standards such as those published by the National Fire Protection Association (NFPA),

and the American Society for Heating, Refrigeration and Air Conditioning Engineers (ASHRAE), and the local code authorities.

5. When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. Acceptable for use over a tub or shower when connected to a GFCI (Ground Fault Circuit Interrupter) - protected branch circuit (ceiling installation only).

8. This unit must be grounded.

9. Not for Use in Kitchens.

10. Install Fan At Least 2.5 m (8.2 feet) Above The Floor.

11. To reduce risk of fire and to properly exhaust air, be sure to duct air outside – Do not vent exhaust air into spaces within walls or ceilings or into attics,

crawl spaces, or garages.

12. WARNING: To Reduce The Risk Of Fire Or Electric Shock, Do Not Use This Fan With Any Solid-State Speed Control Device.

13. The fan must not be installed in a ceiling thermally insulated to a value greater R40.

WARNING -TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

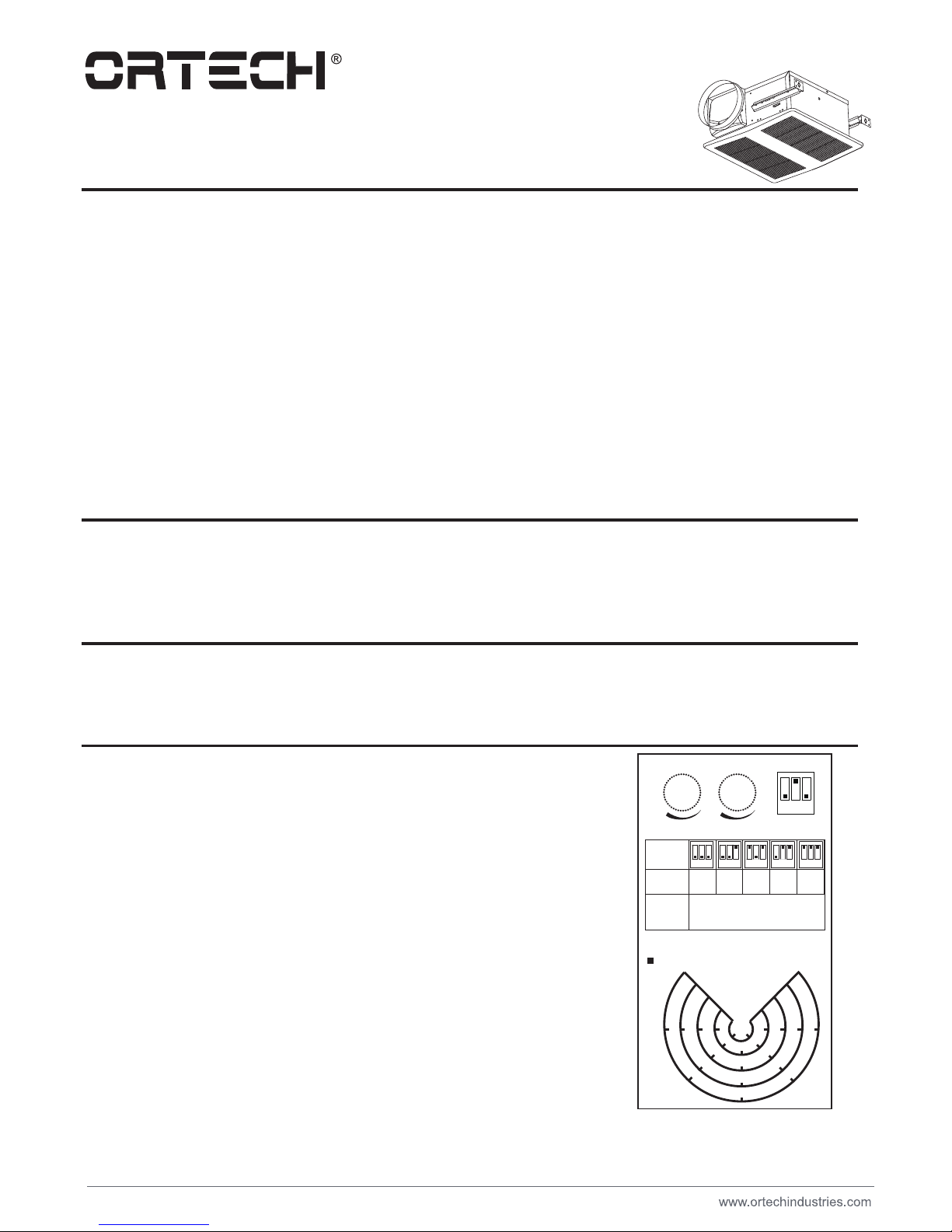

For Dual Speed Setting.

See “Connect Wiring” for details (Fig.1).

To Turn Fan ON

Turn the switch I (according to the following “

CONNECT ELECTRICAL WIRING”

) ON.

• Fan will run at the certified airflow rate if the switch II is ON.

• Fan will run at the user-adjustable airflow rate if the switch II is OFF.

To Use Fan Time Delay Airflow Rate Change

1. Turn the switch I ON.

2. Turn the switch II ON - fan will run at the certified airflow rate.

3. When the switch II is turned OFF, fan will continue to run at

the certified airflow rate until the user-adjustable time delay has elapsed,

and then will automatically change to the user-adjustable airflow rate.

To Turn Fan OFF

Turn the switch I OFF

User setting

The control box, located inside the fan housing, has three separate adjustments:

(1) The low airflow knob adjusts the lower airflow from 30CFM up to the air

flow rate of the high fan speed determined by the toggle switch setting.

(2) The time delay knob is adjustable from 3 to 30 minutes and will switch the

fan to the low speed setting after motion is no longer detected in the room for

the set period of time.

(3) The toggle switch will adjust the upper fan speed setting from 90 to 140.

Switch

position

Duct

diameter

(inches)

Air deliver

(CFM)

To change the pre-selected airflow,adjust

the control switches as per the table above.

is the position of the switch

S T

6"

30min

10min

20min

3min

-

+

-

+

1 2 3

For Single Speed Setting

Use switch to operate this fan. See “Connect Wiring” for details (Fig.2).

90 110 120 140

1 2 31 2 31 2 31 2 3

80

1 2 3

S

30

30

5070

80

30

30

30

40

50

60

60

90

50 50 60

130

110 100 80

60

80

80

100

90

110

120

140

70

90

100

120

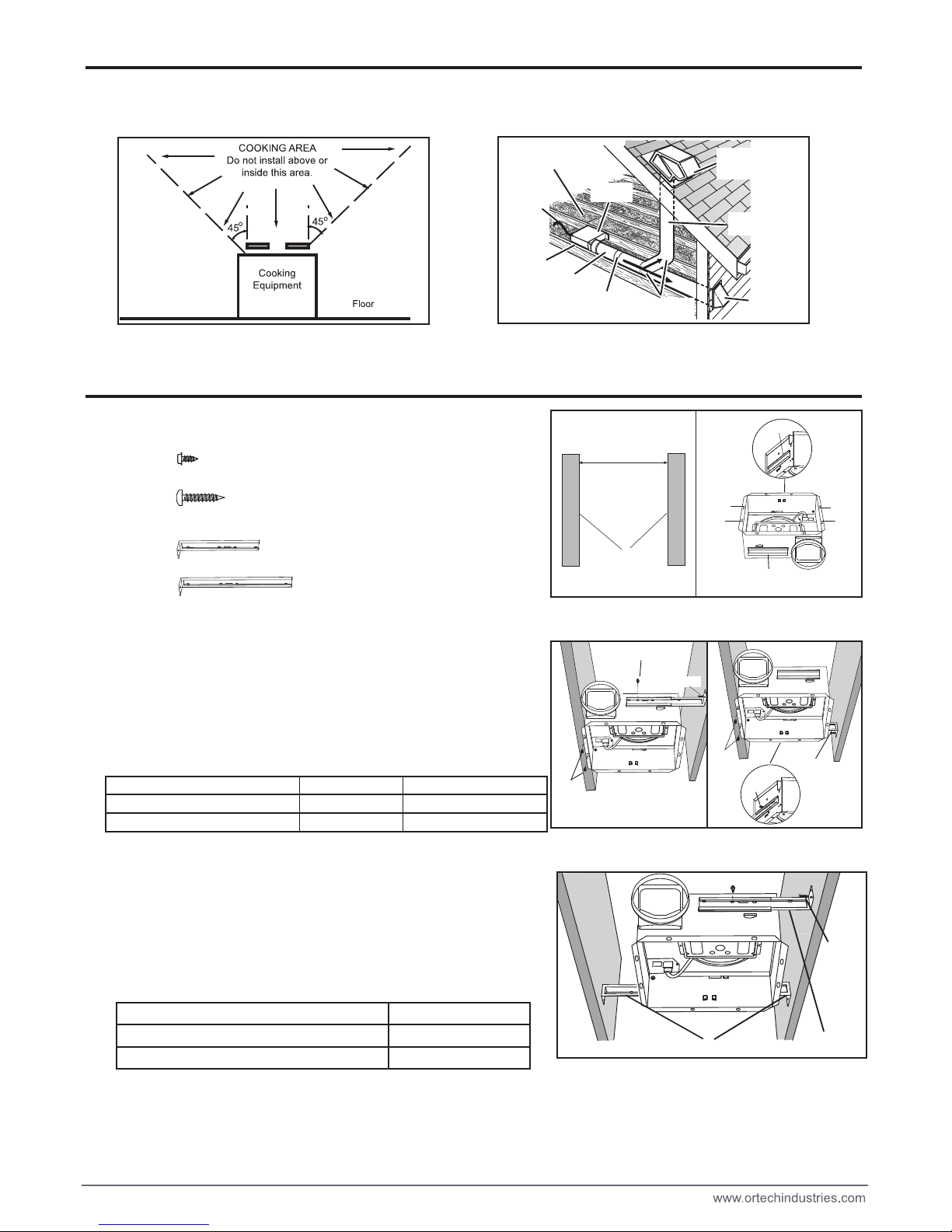

2. Mount with mountion holes and hanger bar

Slide one hanger bar into the channel on the housing and adjust as

needed to fit between framing. Hold housing in place so that the housing

contact the bottom of the joist, Screw housing to joist through the hole A

and hole B. Screw the hanger bar onto the other side of joist through the

hole (refer to the right diagram).

Screw hanger bar to housing with screw A.

3. Mount with hanger bars only

Slide hanger bars onto housing and adjust as needed to fit between

framing. Extend the hanger bars to the width of the framing. Position the

fan with the hanger bar tabs wrapped around the bottom edge of

the framing, holding the fan in place.

Secure hanger bars to framing using one screw on each end of hanger

bar. (refer to the right diagram)

Screw hanger bar to housing with screw A.

PLAN THE INSTALLATION

1. Do not use in a cooking area.

2. Two ways to connect ductwork to a factory-shipped unit.

ASSEMBLY INSTRUCTIONS

2

1. Before installation, you need to know:

Distance A

13 1/4 in to 15 1/2 in (336mm-394mm)

16 1/2 in to 18 7/8 in (419mm-480mm)

Hanger Bar

Channel

Channel A (Fig. 1)

Channel B (Fig. 2)

Hanger bar (short)

Hanger bar (long)

The choice of Hanger Bar

Distance A

14 in to 23 1/2 in (356mm-597mm)

21 1/4 in to 23 1/2 in (540mm-597mm)

Hanger Bar A

Hanger bar (short)

Hanger bar (long)

The choice of Hanger Bar A

ST4.2*13mm

Screw A

Screw B

Hanger bar

(short)

Hanger bar

(long)

ST4.2*25mm

7 1/2 in (190mm)

13 3/8 in (340mm)

Note: Hanger bar (short) only can slide into channle A.

ROOF CAP*

(with built-in

damper)

ROUND

DUCT*

WALL CAP*

(with built-in

damper)

* Purchase

separately

POWER

CABLE*

INSULATION*

(Place around and

over Fan Housing.)

Seal gaps

around

Housing.

FAN

HOUSING

ROUND

ELBOW(S) *

Seal duct

joints with

tape.

Keep duct

runs short

Hanger bar (long)

Hanger bar A

Screw A

Screw B

Distance A

JOIST

Hole A

Hole B

Hole A

Hole B

Channel A

Channel B

Fig. 1 Fig. 2

Screw A

Screw B

Screw A

Screw A

Screw A

Screw B

4. Mount to I-joist

Slide one hanger bar (long) into channel B on the housing and adjust as

needed to fit between framing. Hold housing in place so that the housing

contacts the bottom of the joist. Screw housing to joist through the hole A

and hole B. Screw the hanger bar onto the other side of joist through the

hole (refer to the right diagram).

Screw hanger bar to housing with screw A.

5. INSTALL ROUND DUCTWORK

Connect the round ductwork (not included) to the damper/duct connector,

and run the ductwork to a roof or wall cap (not included). Using tape (not

included), secure all the ductwork connections so that they are air tight.

Run 120 V AC house wiring to the location of the fan. Use only UL-approved connectors (not included) to attach the house wiring to the

wiring plate. Refer to the wiring diagram, and connect the wires as shown.

ASSEMBLY INSTRUCTIONS

CONNECT ELECTRICAL WIRING

UNIT

BLACK (BLK)

SWITCH BOX

SWITCH I

POWER SUPPLY

120V AC

GROUND (GRD)

WHITE (WHT)

FAN

RECEPTACLE

3

FAN

WIRE

PANEL

Insulated flexible duct is recommended for the quietest possible installation.

If rigid duct is used, a short (1-3 feet) section of insulated flexible duct will

ensure quiet operation

BRN

BLK

SWITCH I

SWITCH II

SWITCH II

BROWN (BRN)

UNIT

BLACK (BLK)

SWITCH BOX

FAN

SWITCH

POWER SUPPLY

120V AC

GROUND (GRD)

WHITE (WHT)

FAN

RECEPTACLE

FAN

WIRE

PANEL

BRN

BLK

FAN

SWITCH

BROWN (BRN)

The ducting from this fan to the outside of building has a strong effect on the

air flow,noise and energy use of the fan. Use the shortest, straightest duct

routing possible for best performance, and avoid installing the fan with

smaller ducts than recommended. Insulation around the ducts can reduce

energy loss and inhibit mold growth. Fans installed with existing ducts may

not achieve their rated air flow.

Screw A

Screw A

Screw B

(Fig.2)For Single Speed Setting

(Fig.1)For Dual Speed Setting

(Fig.3)Fan with ADD on Motion Sensor Grille

UNIT

LIGHT

NIGHT

LIGHT

SWITCH BOX

FAN

120V AC LINE IN

GROUND (GRD)

BROWN (BRN)

FAN

RECEPTACLE

SENSOR

RECEPTACLE

LIGHT

RECEPTACLE

RED

BLACK (BLK)

WHITE (WHT)

BLUE (BLU)

WIRE

PANEL

LIGHT

SWITCH

NIGHT LIGHT

SWITCH

LIGHT

NIGHT

LIGHT

FAN

FAN

SWITCH BOX

WHT

D

Low CFM

switch

S

elay time

Preset switch

FAN

N

Sensor

GRD

GRD

UNIT

SWITCH

BLK

WHT

LINE

IN

CONTROL

CIRCUIT

BLK

WHT

WHT

BLU

RED

Install ceiling material to complete the ceiling construction. Then, cut around

the fan housing.

To attach the grille assembly to the fan housing, pinch the grille springs on

the sides of the grille assembly, and position the grille into the housing with

the grille springs in the appropriate slots. Push the grille assembly towards

the ceiling to secure.

WARRANTY

INSTALL GRILLE

SERVICE PARTS

5

6

d

e

a

1

2

3

4

b

c

7

10

9

8

11

8

12

PART PART NAME Qty.

1

2

3

4

5

6

7

8

9

10

11

12

a

b

c

d

e

Housing

Damper / Duct Connector

Wiring plate

Screw

Blower Wheel

Wire Panel / Harness Assembly

Motor

1

2

1

1

1

1

1

1

1

1

3

1

4

4

1

4

1

Isolator

Motor Plate

Washer

Nut, Hex Lock

Grille Assembly (includes part 2)

Grille Spring

Hanger Bar Kit (short)

Hanger Bar Kit (long)

Screw

Power box

* Blower Assembly includes part 6, 5, d, 4, c, b, a.

Replacement installation:

Remove the screw (part c), then take out the motor plate (part 4) from

the housing (part 10) by pushing down the rib in the plate while pulling

out on the side of the housing. Replace the broken parts.

4

WARNING: Before replacing, be sure to turn off power at power source.

ONE YEAR LIMITED WARRANTY from the original date of purchase against defects in material and workmanship.

This warranty is limited up to the amount of the original purchase price of the product, excluding any labor cost. For

inquiries please visit www.ortechindustries.com or call 1-888-543-6473.

Loading...

Loading...