ORTEC 660 User Manual

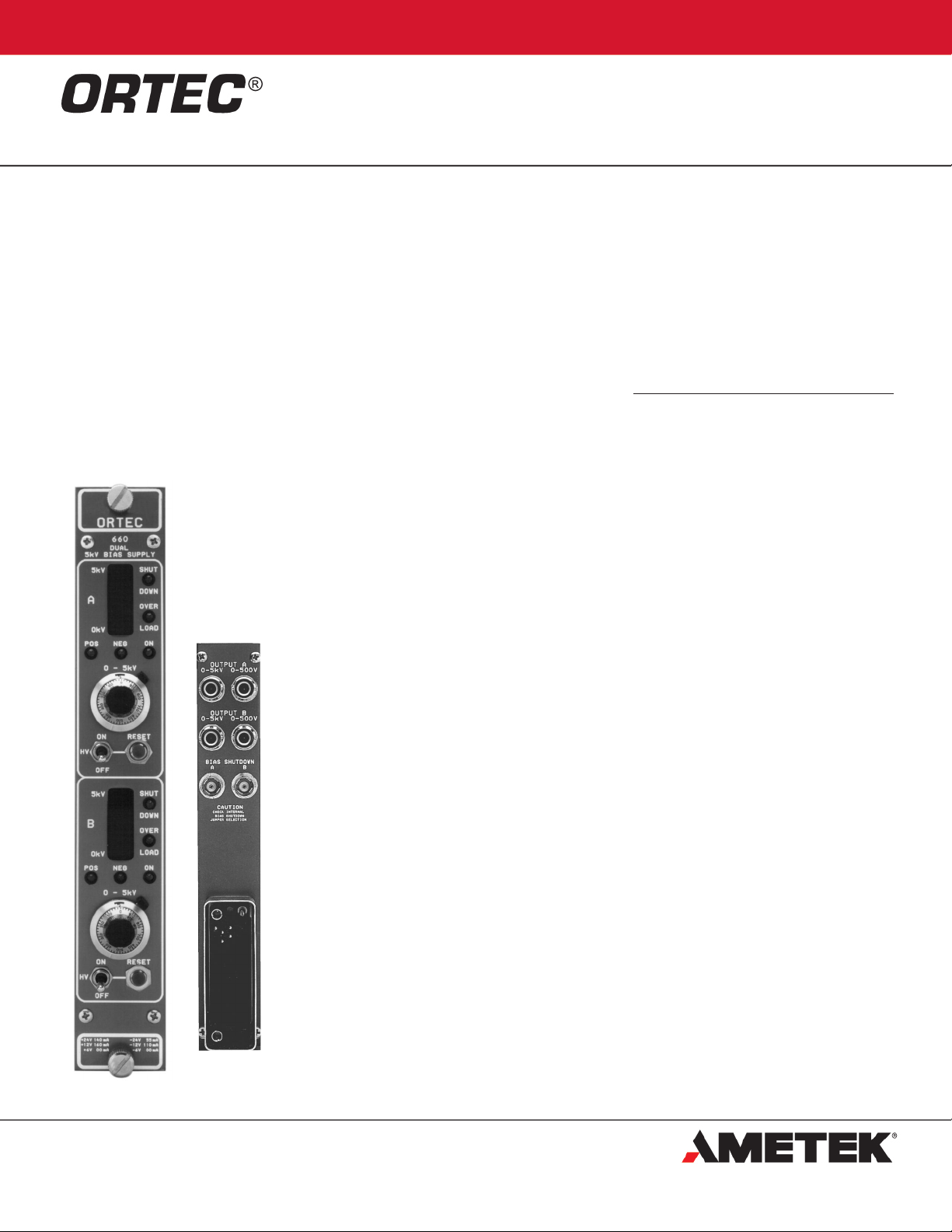

660

Dual 5-kV Detector Bias Supply

•Two independent bias supplies in a single

module for germanium and silicon detectors

•0

–5 kV or 0–500 V at 0–100 µA

•Remote shutdown feature compatible with

ORTEC and TTL outputs from warmup

sensors on germanium detectors

•Reset safety feature on remote shutdown

minimizes risk of preamplifier FET damage

•Selected output polarity indicated before bias

voltage is turned on

•Automatic overload protection and overload

indicator

The ORTEC Model 660 Dual 5-kV Detector Bias

upply contains two independently adjustable

S

power supplies for furnishing the bias voltage to

germanium detectors, silicon detectors, or

ionization chambers. It can be used with any

etector that draws less than 100 µA of current,

d

and whose gain is insensitive to the applied

voltage. The output voltages are continuously

adjustable from zero to full scale with calibrated

and locking 5-turn dials. Each supply provides two

outputs controlled by the same dial: a 0 to 5 kV

output, and a 0 to 500 V output. Two 10-segment

bar-graph indicators verify that the selected

voltages are being supplied at the outputs.

Security against accidentally changing the output

polarity to the wrong state is ensured by two

features. The selected output polarity for each

supply is indicated by front-panel LEDs whenever

the NIM bin power is turned on. Thus, the correct

polarity can be verified before the HV ON/OFF

switch is used to turn on the bias voltage to the

detector. In addition, the side panel must be

removed in order to alter the output polarity. This

discourages unintentional changes.

The Model 660 includes a remote shutdown

feature to protect the preamplifier FET against

damage when a cooled germanium or Si(Li)

detector warms up. Each supply includes a BIAS

SHUTDOWN input that is compatible with the

standard warmup sensor output on ORTEC

preamplifiers. When the preamplifier signals a

warmup condition, the Model 660 shuts off the

bias voltage to that detector, and turns on a

SHUTDOWN indicator light. The bias voltage

remains off, independent of the signal from the

preamplifier warmup sensor, until the shutdown

mode is manually cancelled by pressing the

RESET push button. This protects the preamplifier

FET if the detector is cooling down with the HV

ON/OFF switch accidentally left on. For further

protection against operator error in the ORTEC

shutdown mode, the bias shut-down input

interprets a disconnected cable or a shorted cable

as a warm detector, and responds by turning off

the bias voltage. Some detector manufacturers

provide a TTL logic level output from their detector

warmup sensor. A board-mounted jumper in the

Model 660 can be moved to the TTL position to

make the bias shutdown input com-patible with

detectors supplying a TTL output. It is also

possible to disable the bias shutdown feature by

moving the board jumper to the BYPASS position.

The Model 660 is shipped from the factory with

oth supplies set to the ORTEC mode.

b

The high voltage outputs are protected against

overload. When the bias supply senses an

xcessive output current demand, it turns on the

e

overload light and reduces the output voltage until

the output current is within tolerable limits.

Recovery from overload is automatic when the

excessive current demand is eliminated.

Specifications

Channels A and B are independent supplies. The specifications

listed below apply to either channel.

PERFORMANCE

BIAS VOLTAGE RANGES 0–5 kV, or 0–500 V, on

separate outputs, with each output controlled by a

common, 5-turn, direct-reading, precision potentiometer

located on the front panel.

BIAS VOLTAGE POLARITY Positive or negative.

Internally selectable. Polarity indicated by front-panel

LEDs whenever bin power is on.

RATED OUTPUT CURRENT 0–100 µA.

OUTPUT LINEARITY Within ±3% of dial setting from

10% to 100% of full range.

TEMPERATURE SENSITIVITY OF OUTPUT VOLTAGE

<±0.08%/°C through the 10 to 50°C operating range.

VOLTAGE STABILITY <±0.1%/h variation in output

voltage with constant temperature, constant load, and

constant input voltages from the bin supply.

NOISE AND RIPPLE <10 mV peak-to-peak from 5 Hz

to 50 MHz.

OUTPUT VOLTAGE RISE TIME Nominally 500 ms.

INDICATORS

0 kV–5 kV Front-panel, 10-segment, bar-graph display

indicates actual output voltage at the 0–5 kV output.

Each segment corresponds to a 0.5-kV increment in

output voltage, starting with 0.5 kV to turn on the first

segment, and ending with 5 kV to turn on the tenth

segment.

POS Front-panel LED is lit when the bin power is on, if

the positive output polarity has been selected.

NEG Front-panel LED is lit when the bin power is on, if

the negative output polarity has been selected.

ON Front-panel LED indicates when the output bias

voltage is turned on. This LED turns off when the HV

ON/OFF switch is turned off, the bin power is off, or the

shutdown mode has been activated.

OVERLOAD Front-panel LED turns on when the bias

supply senses an excessive output current demanded by

the external load. Under overload, the output voltage is

reduced automatically until the output current is within

660

Dual 5-kV Detector Bias Supply

tolerable limits. Recovery from overload is automatic

when the overload is eliminated.

SHUTDOWN Front-panel LED turns on when the

shutdown mode has been activated to turn off the output

voltage. The shutdown mode is activated by the

appropriate signal level on the rear-panel, BIAS

SHUTDOWN input, or whenever the bin power is turned

off and on.

CONTROLS

0–5 kV Front-panel, 5-turn, direct-reading, locking

potentiometer with 500 dial divisions adjusts the output

voltages simultaneously for the 0–500 V and the 0–5 kV

outputs.

HV ON/OFF Front-panel toggle switch turns the

0–500 V and the 0–5 kV outputs on or off. For added

safety, the RESET push button must be pressed after

turning the HV ON/OFF switch to the ON position, in

order to turn on the output voltage. The output voltage

will not turn on if a shutdown condition is present at the

BIAS SHUTDOWN input.

RESET Pressing this front-panel push-button switch

enables the high voltage to turn on after the bin power

has been turned on, the HV ON/OFF switch has been

turned on, or the supply has been disabled by the BIAS

SHUTDOWN input. If a shutdown condition is still

present at the BIAS SHUTDOWN input, the RESET

button will be ineffective.

ORTEC/TTL/BYPASS Internal printed wiring board

jumper selects the operating mode of the BIAS

SHUTDOWN input for compatibility with the warmup

sensor in the associated Ge detector. The ORTEC

position is used for ORTEC detectors. The TTL position

is for detectors employing TTL levels. The BYPASS

position disables the BIAS SHUTDOWN input, but does

not alter the function of the RESET button. The Model

660 is shipped with this jumper in the ORTEC mode.

OUTPUT VOLTAGE POLARITY The output polarity is

changed between positive and negative by changing the

position of a daughter board in the module.

INPUTS

BIAS SHUTDOWN INPUT Rear-panel BNC connector

accepts signals from warmup sensors in cooled

germanium detectors. When a warmup is signalled, this

input turns off the detector bias voltage in order to

protect the preamplifier FET input. The

ORTEC/TTL/BYPASS jumper selects the operating mode

of the BIAS SHUTDOWN input for compatibility with the

warmup sensor in the associated Ge detector.

ORTEC Mode The input is compatible with the

warmup sensor output on ORTEC germanium

detectors. For added safety, an open or shorted

coaxial cable on the BIAS SHUTDOWN input will

also cause the supply to shut down.

TTL Mode A source supplying >+2 V or an open

circuit will allow the Model 660 to produce the full

output voltage. A source supplying <+0.8 V and

capable of sinking 700 µA will shut down the high

voltage output.

BYPASS MODE The BIAS SHUTDOWN input is

rendered inactive, and cannot trigger a bias

shutdown.

OUTPUTS

0–5 kV Rear-panel SHV connector furnishes the

adjusted output voltage in the 0 to 5-kV range through

an output impedance of approximately 2 M W. A voltage

foldback circuit protects the output against demands for

excessive output current. Recovery from overload is

automatic when the overload is eliminated.

0–500 V Rear-panel SHV connector furnishes the

adjusted output voltage in the 0 to 500-V range through

an output impedance of approximately 700 kW. A voltage

foldback circuit protects the output against demands for

excessive output current. Recovery from overload is

automatic when the overload is eliminated.

ELECTRICAL AND MECHANICAL

POWER REQUIREMENTS The Model 660 derives its

power from a NIM bin power supply. Required DC

voltages and currents are: +24 V at 135 mA, +12 V at

150 mA, –12 V at 100 mA, –24 V at 75 mA.

WEIGHT

Net 0.90 kg (2.0 lb).

Shipping 1.4 kg (3.0 lb).

DIMENSIONS Standard single-width NIM module, 3.43

X 22.13 cm (1.35 X 8.714 in.) front panel per DOE/ER0457T.

Ordering Information

To order, specify:

Model Description

660 5-kV Detector Bias Supply

OPTIONAL CABLE ACCESSORIES

Model Description

C-24-12 RG-62A/U 93-W Cable with two BNC male

plugs; 12-ft length

C-36-12 RG-59A/U 75-W Cable with two SHV female

plugs; 12-ft length

Specifications subject to change

102120

Loading...

Loading...