ORTAL Clear 40 H TS, Clear 40 LS, Clear 40 H Tunnel, Clear 40 TS, Clear 40H 70 LS Technical Manual

...

ORTAL TECHNICAL GUIDE

December 2015

2

Ortal Technical Guide December 2015

Ortal have now obtained certification for all the

CE marked fires to use flexible flue liners - with

certain conditions.

The conditions are;

1. For use only with renovation or adaptation

of an existing chimney

2. The Metaloterm Renovation Kit for joining

the liner to their approved flue terminal

must be used.

3. The flexible liner itself can be locally

sourced but must be approved to EN

1856-2. (This European Standard

supersedes the withdrawn BS715 )

4. During installation the flue restrictor plate

size is selected using the same tables as

used with rigid flues. (Restrictors are

supplied with the fires)

Flue Renovation

Balanced Flue Horizontal. ( Up and out ) Balanced Flue Vertical

3

Ortal Technical Guide December 2015

IMPORTANT - THE COMBUSTION CHAMBER OF THIS

APPLIANCE SHOULD ONLY BE OPENED AND SERVICED

BY A REGISTERED GAS INSTALLER, and should not be

used if the glass is broken and must never be used with the

front open.

Please read these instructions carefully before installation or use, and leave with

the customer for storage in a safe place for future reference.

4

Ortal Technical Guide December 2015

This manual covers the following appliances:

Clear 40 RS/LS/TS/Tunnel, Stand Alone 40 TS, Clear 40 H RS/LS/TS/Tunnel,

Clear 40H 70 LS/TS/Tunnel, Clear 75 RS/LS/TS, Stand Alone 75 ITS, Minimal

75, Space Creator 75, Clear 75x65 /Tunnel, Stand Alone 75x65 Curve /Tunnel,

Clear 60x80 I Tunnel, 60x80 OVAL, Classic F, Circle 70, Clear 110 RS/LS/TS/

Tunnel, Minimal 110 /Tunnel, Stand Alone 110, Clear 110 H, Clear 110 HH Clear

130 RS/LS/TS/ Tunnel, Minimal 130 /Tunnel, Space Creator 120, Clear 150 RS/

LS/TS/Tunnel, Space Creator 150, Stand Alone 150, Clear 170 RS/LS/TS/

Tunnel, Clear 200 RS/LS/TS/Tunnel, Space Creator 200

CONTENTS

GENERAL INFORMATION

Important Safety Notice 5

General Fitting Information 6

Battery Type (Remote Versions Only) 6

INSTALLER INFORMATION

Ventilation 7

General Balanced Flue Notes and Position 7

Commissioning the Appliance 10

Servicing Instructions 11

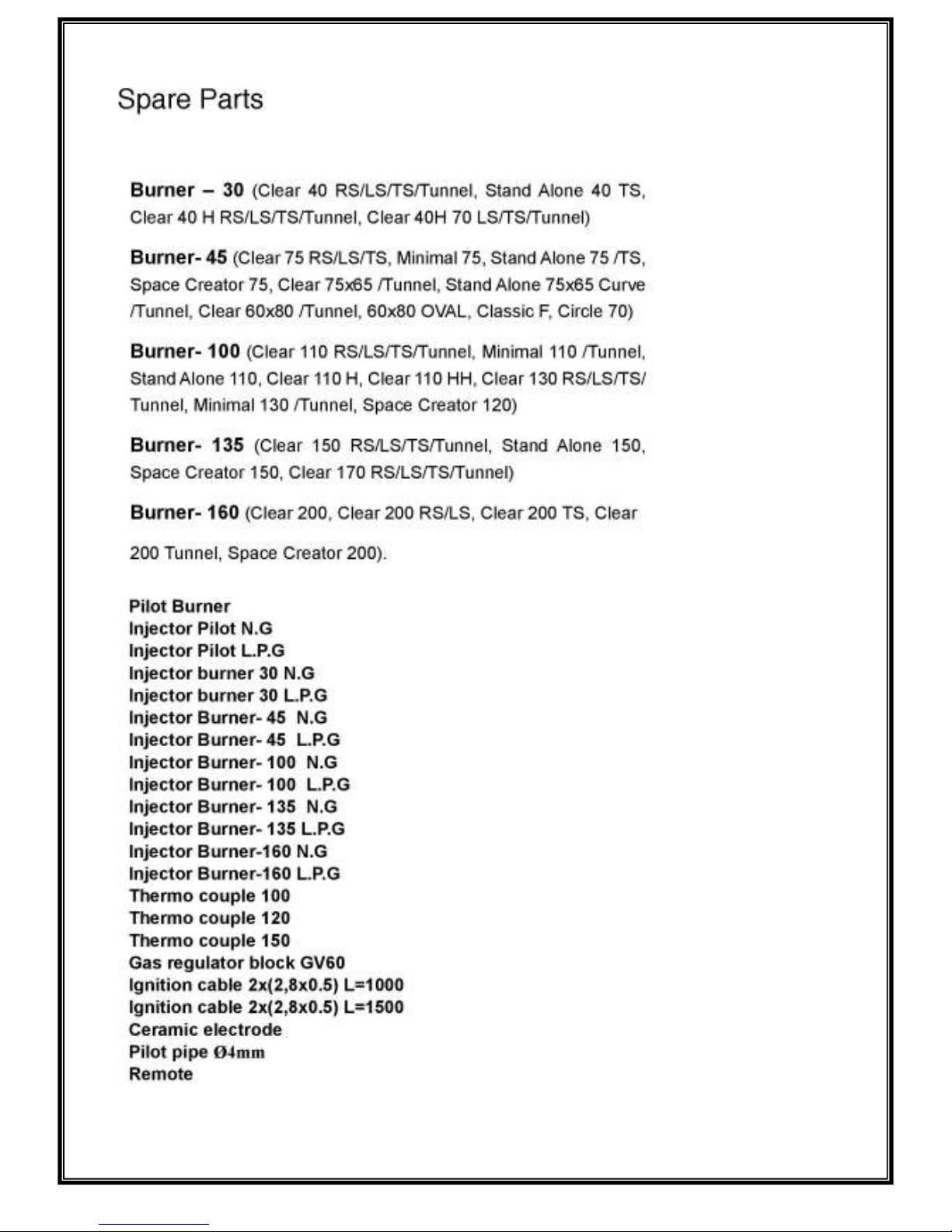

Spare Parts 12

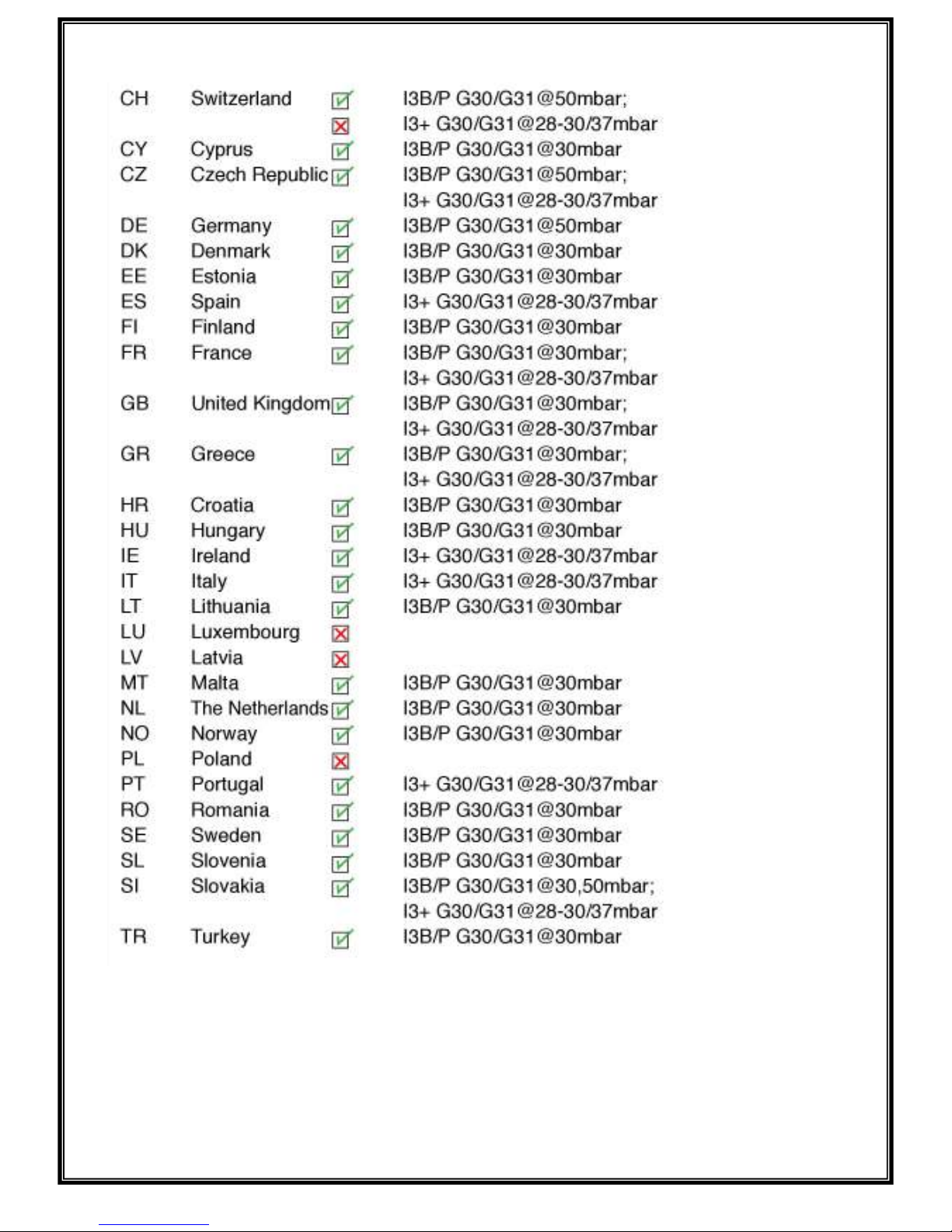

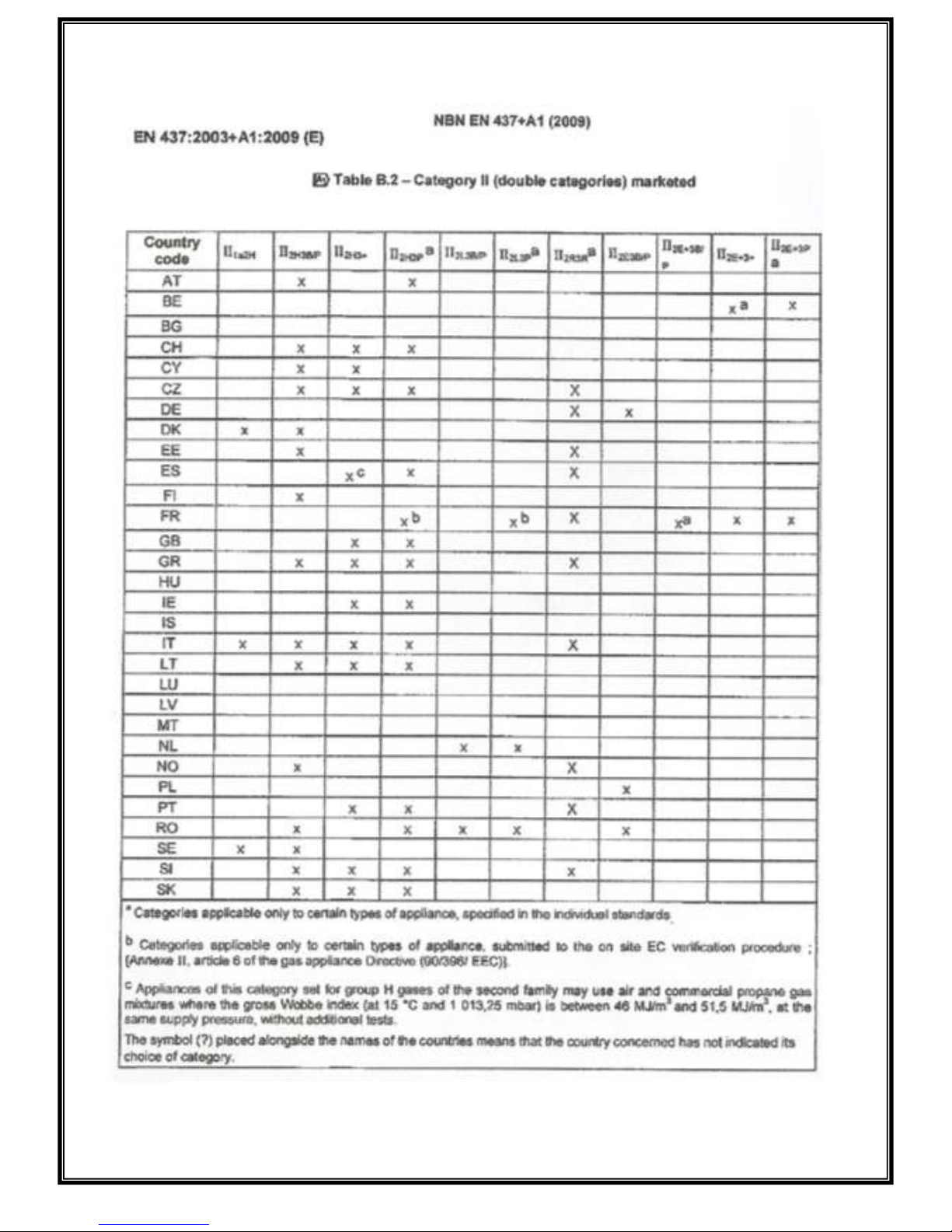

Countries of Destination / Gas Categories 13

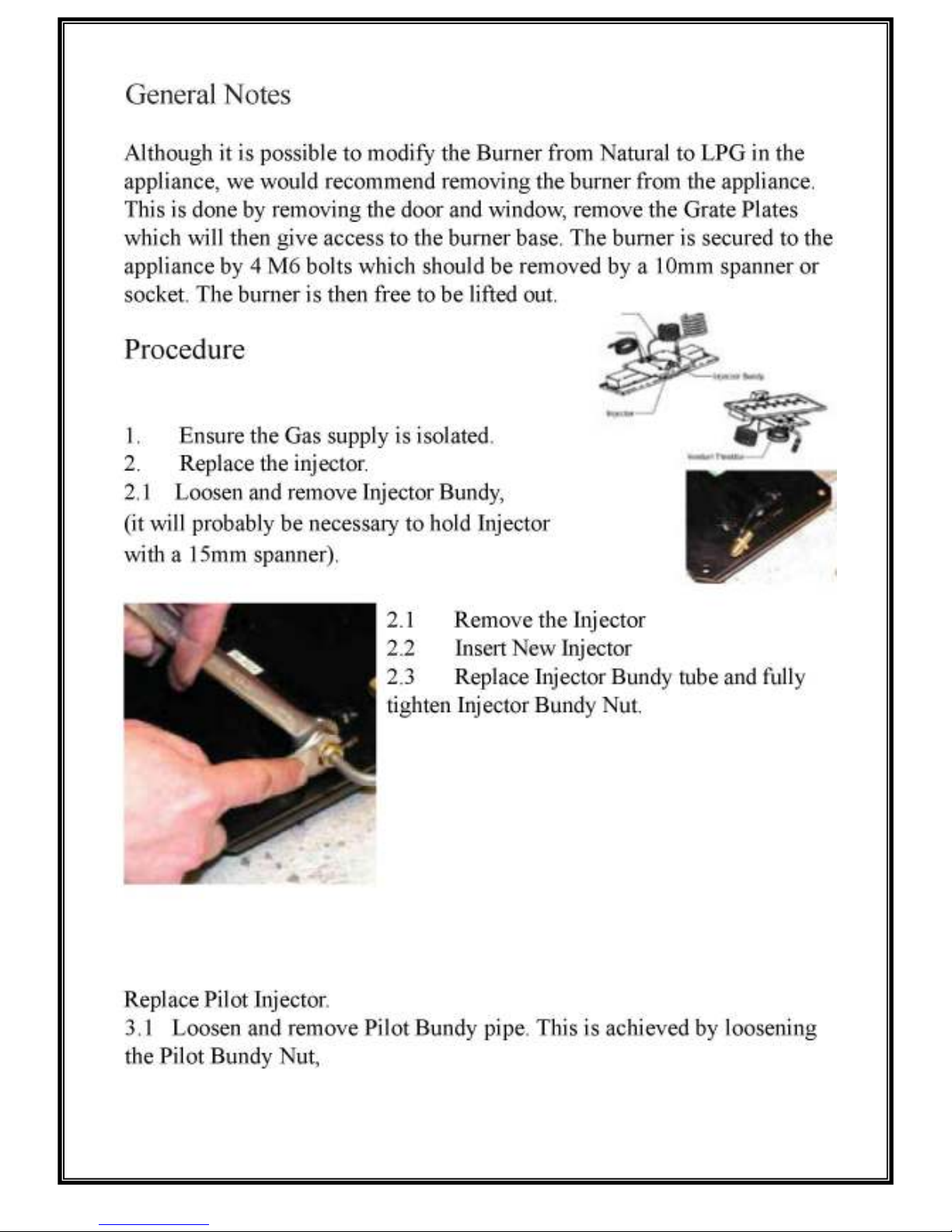

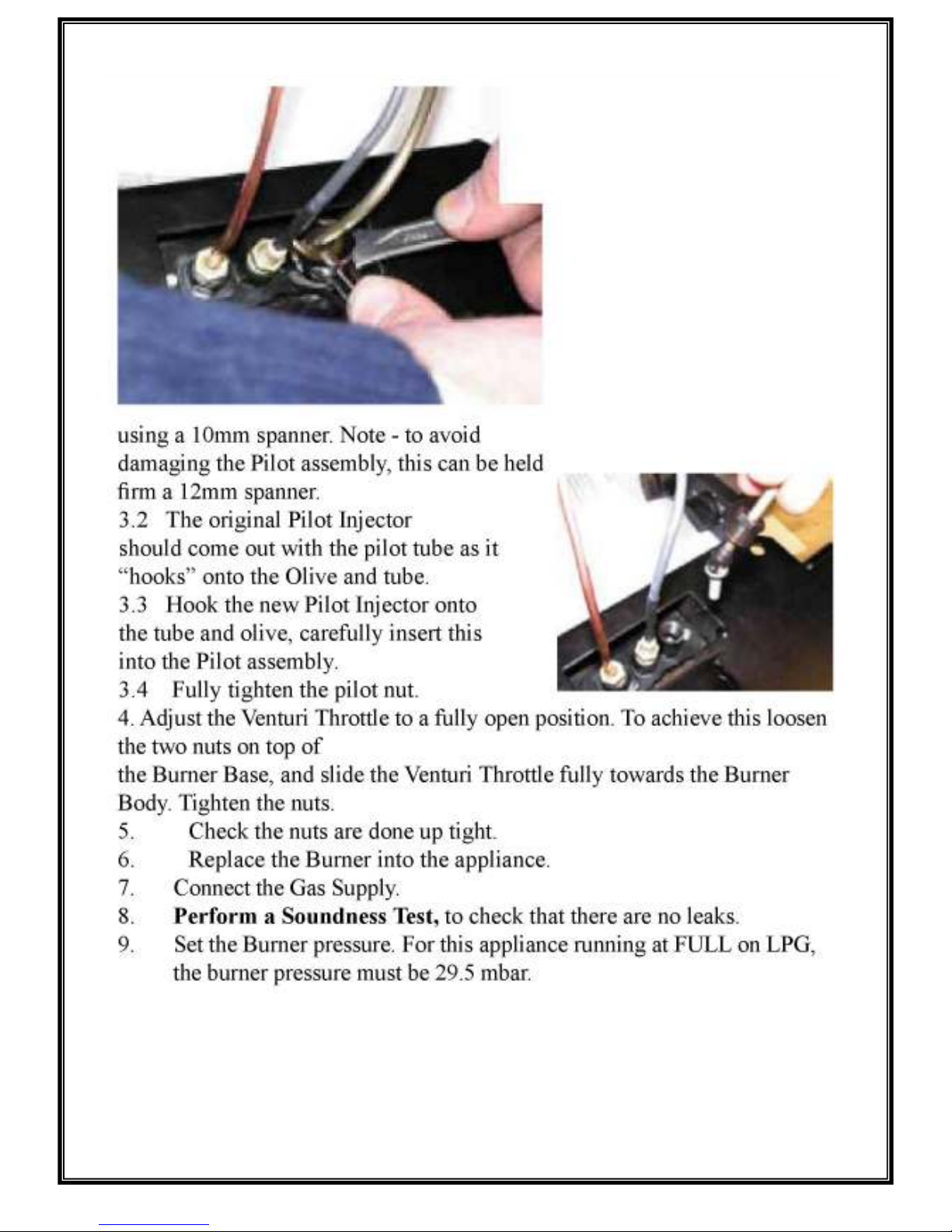

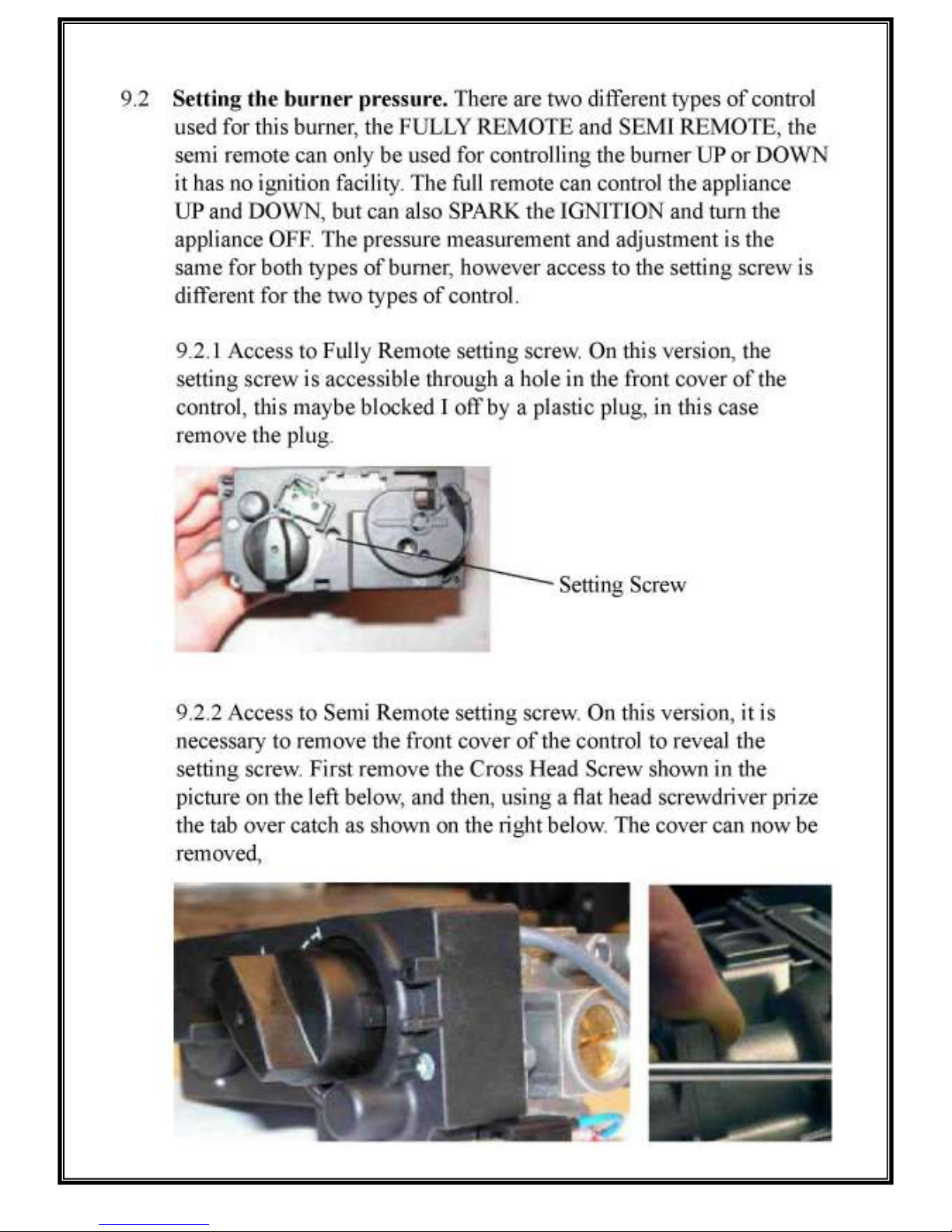

Instructions for Changing the Burner From Natural Gas to LPG 16

TECHNICAL INFORMATION

Technigas CE Approval Test Results 21

Contents - Single Step Burner (N) 21

Contents - Double Step Burner (D) 22

Minimum Clearances to Combustible Materials 23

DECORATION ARRANGEMENT

English Branches 37

Small Pebbles 42

Large Pebbles 46

Refractory Clay Logs (6 piece set) 50

FLUE

Flue Design Options 55

Troubleshooting 61

Operating Instructions 62

OPERATING INSTRUCTIONS

5

Ortal Technical Guide December 2015

This appliance has a ceramic Fire-bed arrangement; this contains

Refractory

Ceramic Fibres, which are man-made vitreous silicate fibres.

Excessive

exposure

to

these materials can cause irritation to eyes, skin and

respiratory organs.

Hence

we recommend that when handling these

materials the release of dust should

be

kept to a minimum. During

installation and servicing we recommend that a HEPA filtered vacuum be

used to remove any dust and soot in and around the fire. If

any

of the

ceramic fire-bed components need to be replaced we recommend that

the

removed parts be sealed in a heavy-duty polythene bag, and be labelled as

RCF

waste. RCF is not "Hazardous waste" and can be disposed of at a

licensed

tipping

site for the disposal of industrial

waste.

The appliance incorporates a permanent pilot. This is located on the front

of

the

burner, and must not be adjusted by the installer. This system must not

be put

out

of operation, and if any parts require changing, only original

manufacturer

parts

shall be

used.

This appliance is designed to be used either Natural or LPG gas however,

each

individual appliance is only capable of running off the type of gas

specified at

the

time of purchase. It is important to note that once a type of

gas has been

specified

the stove cannot run off any other type. The type of

gas that your stove is

capable

of burning is stated on the data information

panel.

This appliance has been designed, tested and approved to meet standards in

place

for product use, performance and safety. Installation of your appliance

must

comply

with current building regulations. It is therefore recommend

that a registered

gas

installer be employed for this task. The engineer will

provide you with

information

about the safety limits of the installation and

should fix a notice plate in a

place

where it can be readily

seen.

This appliance is designed as an efficient heating device and consequently all

body

parts become very hot in use. Except for the control knob and control

access door, which are designed to stay cool, all other parts are working

surfaces and

should

not be

touched.

The glass and frame on this appliance acts as a fireguard conforming to BS:

1945

—1971 and satisfies the Heating Appliance (Fireguards) regulations

1991.

No

part of the window or frame should be permanently removed. It

does not give

full

protection for young children or the infirm, extra protection

should be considered

for

these conditions conforming to BS 6539 or BS

6778.

Bearing in mind that the heat given off by this appliance may affect articles

placed

close to it, curtains should not be placed within

30cm.

The appliance is not designed as a

dryer. It is not therefore recommended

that

the

appliance be used in such a manner. Do not place any articles within

30cm of

this

appliance as this may result in damage to the

articles.

The installation must be carried out in accordance with the following

regulations:

IMPORTANT SAFETY NOTICE

6

Ortal Technical Guide December 2015

The Building Regulations issued by the Department of the Environment, the

Building Standards (Scotland) (Consolidation) Regulations issued by the Scottish

Development Department.

BS 1251, BS 5440 part 1, BS 5871 part 2, BS 6461 part1, BS 6891 and BS 8303

In the Republic of Ireland the installation must also conform to the relevant standards,

particularly in regard to flue sizing and ventilation. Refer to documents IS813, ICP3,

IS327 and any other rules in force.

This appliance must be installed in accordance with the rules in force and used only

in a sufficiently ventilated space, and is intended for use on a gas installation with

a governed meter.

Before installation, ensure that the local distribution conditions (identification of the

type of gas and pressure) and the adjustment of the appliance are compatible. The

technical specification of this appliance is given on the rear page of this manual.

This appliance should not be used if the Glass is broken, and should never

be used with the Door open.

General Fitting Information

Inlet Pipe Connection 15mm Compression fitting supplied to fit gas valve

Chimney requirement Balanced Flue

Flame monitor Permanent Pilot

User control: Variable rotary control inc. integrated Piezo ignition, Permanent pilot

facility, Flame failure device and Oxygen Depletion Cut-out.

Before installation of these appliances, the area into which the fire is to be fitted

must be cleared of all debris (including dust), in particular combustible material.

The appliance must sit on a hearth (or base surface) sufficient to support the weight

of the fire. The firebox must then also be secured. Adjustable brackets are supplied

on the firebox for this purpose.

For model size 150 and over it is recommended that the glass is handled by 2 people.

See ‘Commissioning The Stove’

Battery type (Remote Versions only)

Receiver: 4 x AA.

Transmitter: 3 x AAA

If the Flame Supervision Device is extinguished either

intentionally or unintentionally, no attempt should be made to

re-light the gas until at least 3 minutes have elapsed.

7

Ortal Technical Guide December 2015

Ventilation

This appliance can be installed in a completely sealed or mechanically

ventilated

house without extra ventilation and/or fume

extraction.

General Balanced Flue

Notes

There are many possibilities for installing this Concentric Balanced Flue

system

into a building, both Roof and Wall terminations are possible, and the flue

can

either be built into an existing chimney or a completely new flue system may

be

constructed.

The system is based upon a Concentric Flue system which utilises an inner flue

which passes through an outer flue, for flue size see ‘Flue Design Options’ . The

flue

gasses that are the products of combustion of the fire, pass through the inner flue

and are safely vented to the outside environment. The gap between the inner

and

outer flues is the channel by which the stove is supplied with air for

combustion.

These concentric flues terminate outside of the property in a terminal, this

terminal

will keep the expelled gasses and the fresh air for combustion separate. It

is

important that the terminal is not blocked, a suitable guard maybe required if

the

terminal is located at a "Low" level (usually when the terminal is within 2m of

floor

level).

The Balanced Flue gas appliance can be installed as an insertion into an

existing

or new fireplace. If an existing Flue or Chimney is to be utilised, then the

installation

engineer must be consulted. If the chimney has been previously used it must

be

professionally cleaned and certified as being sound and fit for

use.

The European CE approval on this appliance is restricted to the Flue systems as

specified by the supplier, thus the appliance must only be installed with the

original

flue system, no others may be

used

The gas fire, in combination with the concentric flue system, has been approved

in

accordance with the European CE-norm for gas appliances and may

therefore

be used only with this system. The guarantee is invalidated if the appliance

is

(completely or partially) installed using a different

system.

The concentric flue systems can be used with either a newly-built or

existing

chimney.

These appliances are designed with the "Firebox" raised up off the ground level

by

the built in "Base unit".

Thus these appliances require no special Hearth arrangements, as the floor will not

get hot and is protected by the steel construction of the "Base unit".

The appliance must not be fitted against a rear wall constructed from a

combustible

material; a gap of 300mm should be given all round the stove before

combustible

materials may be used in the wall construction.

If the appliance has to be located in an opening, a minimum clearance of

50mm

should be allowed to non-combustible

materials.

8

Ortal Technical Guide December 2015

If the appliance is located in a recess, then the recess must have adequate

ventilation, we recommend a minimum total vent area of 200 cm 2.

The stove must be located at least 280mm from any combustible materials.

Timber Frame

Construction

Whilst it is possible to install room-sealed appliances in timber frame

properties

,

great care needs to be taken to ensure that the flue assembly does not interfere

with the weather proofing qualities of any outer wall which it may penetrate.

Before

attempting this work, further details need to be referenced, (e.g. "Gas Installations

in

Timber Frame Buildings" from the CORGI installer series in the UK).

Carport or Building

Extension

Where a flue terminal is sited within a carport or building extension,

it should

have

at least two completely open and unobstructed sides. The distance between

the

lowest part of the roof and the top of the terminal should be at least 600mm.

Note: A covered passageway should not be treated as a carport. Flues should not

be sited in a covered passageway between

properties.

Basements, Lightwells and Retaining

walls

Flue terminals should not be sited within the confines of a basement area, light well

or external space formed by a retaining wall, unless steps are taken to ensure

the

products of combustion can disperse safely at all times. It may be possible to

install

this Balanced Flue system in such a location provided that it is not sited lower

than

1m from the top level of that area to allow combustion products to disperse safely.

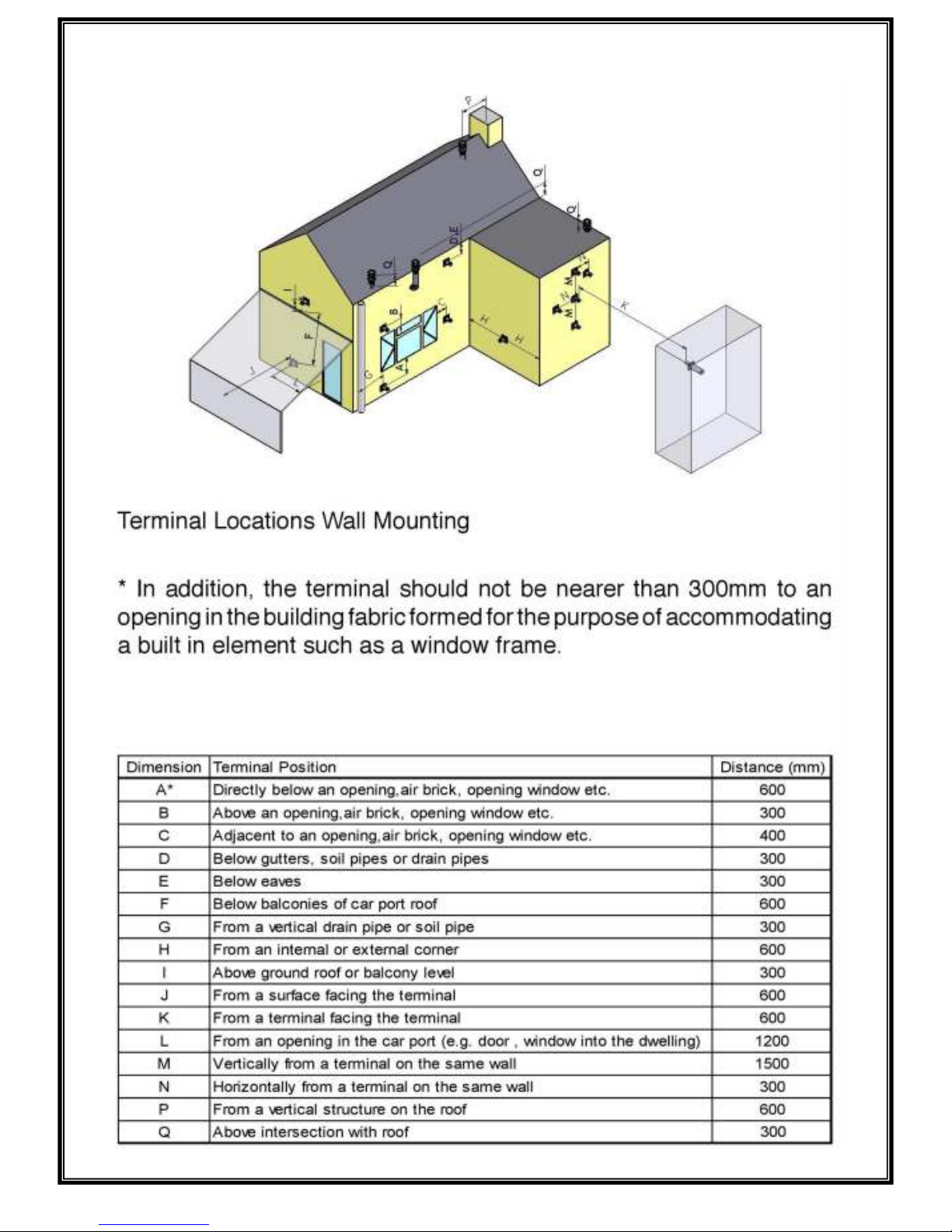

Flue terminals should be sited to ensure total clearance of the combustion

products

in accordance with the enclosed information.

When the products of combustion are discharged, they should not cause a

nuisance

to adjoining or adjacent properties and they should be positioned so that

damage

cannot occur to other parts of the building. If the outer wall surface is constructed of

combustible material, a non-combustible plate should be fitted behind the

terminal

projecting 25mm beyond the external edges of the

terminal.

9

Ortal Technical Guide December 2015

10

Ortal Technical Guide December 2015

Terminal Locations Roof

Termination

"Distance" = minimum distance required for positioning of the outlet to avoid

adverse

effects with respect

to:

A. A ventilation opening serving an occupied room, a toilet or a

bathroom

B. A heating air supply, when the supply flows through an occupied

room.

C.

A window that can be opened and that is near an occupied

room, a

toilet or

a

bathroom.

(*)

If the required distance cannot be

achieved, the outlet position rules

take

precedence.

(**)

If the outlet is positioned at least 1 m higher than the intake supply opening, or a

window that can be

opened.

(***)

If the required distance cannot be achieved, the position of the outlet must

be

at least 1 m above the highest

facade/roof.

Important note for Roof Terminations,

(C31).

When installing the appliance with a roof termination (classification C31), it

is

important to fit a 30mm flue restriction strip across the flue outlet inside the stove.

COMMISSIONING THE

STOVE

A soundness test MUST be made before the installed stove is left with

the

customer.

Ensure that the fire is burning at full rate for a minimum of 5 minutes to warm

the

flue.

If there are

problems,

the flue may require

attention.

The stove will produce an odour and/or smoke for the first few hours of use.

Please

ventilate the room. Also please note that during this initial burning

period, a grey

dust deposit will be formed on the inside of the glass, please clean this

before

leaving the appliance with the

customer.

Distance: Outlet

A,B or C

At the same roof level > 6m (*)

At different roof level >3m (*) (**)

At a lower positioned wall > 2m (**)

At a higher sloping surface > 6m (***)

To avoid adverse effects

11

Ortal Technical Guide December 2015

For model size 150 and over it is recommended that the glass is handled by 2 people.

Use appropriate glass suction cup lifters where necessary, support with gloved hands

as much as possible. Place the glass on a sheet or soft surface to protect the edges.

When replacing glass the retaining screws should be ‘finger tight plus a quarter turn’.

Do not over tighten or the glass may crack.

For TS, LS, RS and Island models

When the glass is finally assembled ensure the glass to glass joints are pushed

together before tightening the retaining screws and cold. It is recommended that a thin

smear of high temperature silicone sealant is used on the glass to glass joints:

Place masking tape down the edges of the adjoining glass to protect the faces, smear

a small amount of silicone to seal the joint, wiping away excess so only a small film fills

the corner of the joint and remove tape before operating the fire. At service this film

can be carefully cut with a sharp thin blade, taking care not to damage the glass

edges. On reassembly the sealing procedure is repeated.

SERVICING INSTRUCTIONS

The following outlines only the minimum work that should be performed on an

annual basis. This service work, like any other work on the appliance, must only be

done by a qualified and competent engineer who is Gas Safe registered.

Open the door and remove all ceramics.

Remove any debris from the top of the burner using a vacuum cleaner and brush.

Inspect the burner unit.

Perform an ignition check.

Perform a flame failure check

There should be no need to service the burner. If however this is required, then the

engineer should check the setting pressure at the gas valve.

Brush off and replace ceramic arrangement as shown in this manual, replacing any

broken or damaged pieces.

Check all seal on door (including glass) and refit the door. See ‘Commissioning the

Stove’

Check the installation for gas leaks.

Check the flue joints are secure, including those in voids, and that the flue is working

satisfactorily.

Check that there are no flue products leaking from the appliance.

If

any parts need to be replaced use only genuine manufacturer parts, non-standard

parts will invalidate the guarantee and may be dangerous.

Natural Gas Burner

Pressures

Burner Size

Double Step Burner

Both Rows Burning

45 10 mbar 16.3 mbar

100 10.7 mbar 6.5 mbar

135 5.7 mbar 11.4 mbar

160 8.8 mbar 16.1 mbar

Single Step Burner

12

Ortal Technical Guide December 2015

13

Ortal Technical Guide December 2015

14

Ortal Technical Guide December 2015

15

Ortal Technical Guide December 2015

16

Ortal Technical Guide December 2015

17

Ortal Technical Guide December 2015

18

Ortal Technical Guide December 2015

19

Ortal Technical Guide December 2015

20

Ortal Technical Guide December 2015

21

Ortal Technical Guide December 2015

22

Ortal Technical Guide December 2015

23

Ortal Technical Guide December 2015

Loading...

Loading...