Page 1

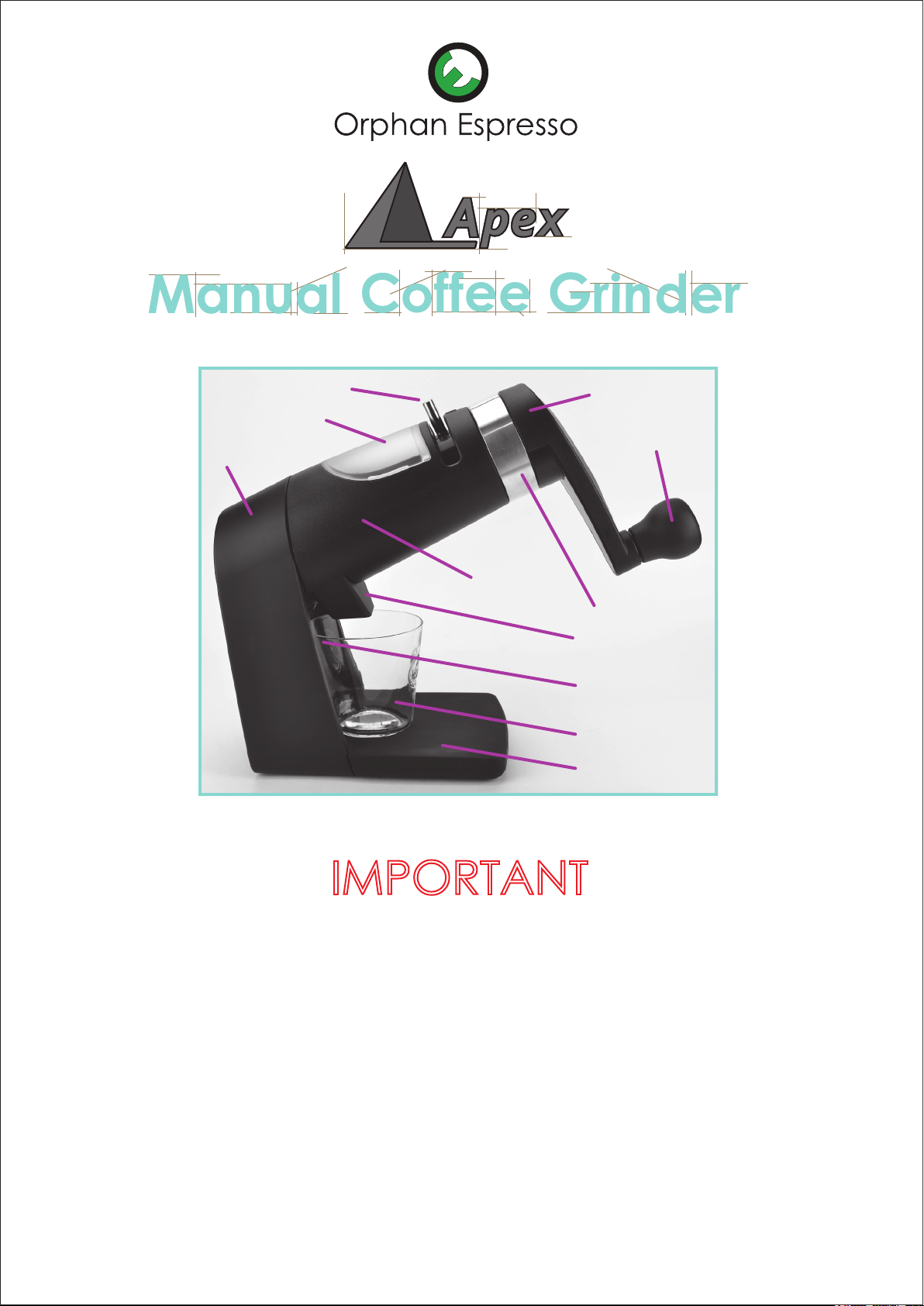

Adjustment Lever

Hopper Cover

Back Cover

Bean

Hopper/

Body Cover

Handle

Knob

Planetary

Gear Box

Grounds Chute

Inner Frame

Catch Glass

Silicone

Base Cover

IMPORTANT

Read Before Grinding:

The OE Apex is unlike other hand coffee grinders.

It uses a Planetary Gear System to provide the needed speed for efficient grinding.

One turn of the handle turns the burr 4 times.

Burr speed is essential to provide the power to grind the beans.

We recommend a handle turn speed of about 120 turns per minute.

As you turn the handle, you are turning the Planetary Gear - NOT the burr.

Unlike direct drive systems found in most hand grinders where 1 handle turn equals 1 burr turn

BRUTE FORCE does not work with the OE Apex Grinder.

If the grinding action stops DO NOT PUSH HARDER ON THE HANDLE.

Just reverse direction of the handle to reposition the beans, and start again, spinning up to your target RPM.

The burrs are bi-directional, and reversing does not affect the burrs or the grind consistency.

Page 2

In the box:

-- OE Apex Manual Coffee Grinder

-- Hand Made Glass Catch Jar

-- Silicone Base Cover

-- Handle with knob

-- Parts Bag containing:

-- Handle Screw

-- 6 Silicone Reusable Sticky Gel Pads

-- 3 L-Key Hex Wrenches: 2.5mm, 3mm, 4mm

-- Anti Static Brush

Set up for use:

Attach the handle using the provided screw, and the large (4mm) hex tool. The handle to shaft

fitting is quite tight - make sure you have the handle aligned to the shaft before pushing it down all

the way. Insert & tighten the handle screw.

From experience with manual coffee grinding, we have found that the ‘holding hand’ does much more

work than the ‘turning hand’. The OE Apex is no different than any other hand grinder in this regard holding the grinder in place is the larger challenge. Depending on the beans you use (roast level, age,

fineness level of the grinding) and your worktop, various approaches can be used:

1. As-is: 4 Silicone feet already in place will stabilize the grinder under many circumstances, in particular

grinding darker roasts (soft beans) and in mid range grind settings. This method requires the most work

with the holding hand, pushing straight down on the grinder to hold it in place while you grind.

2 If using on a smooth worktop or counter, install the 6 reuseable non-marking sticky gel pads on the

bottom of the grinder. This method requires moderate holding hand pressure to hold the grinder in place.

3. Affix the OE Apex to a worktop, or HEAVY cutting board, using bolts or screws through the 4 provided

holes in the metal base. This method provides total stability, and in general, one hand operation.

No holding hand required.

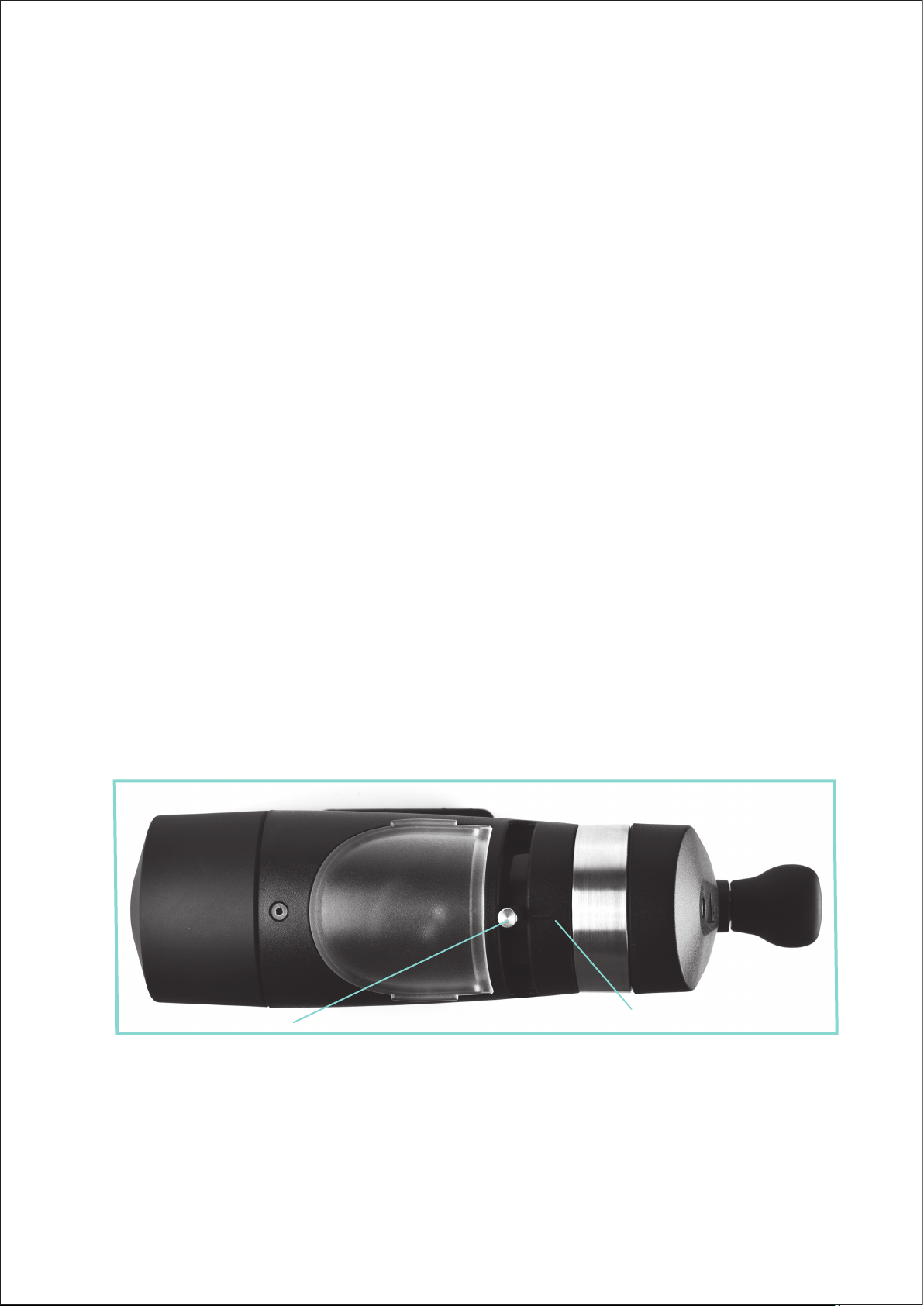

RIGHT hand view

Coarse

-

Adjustment Lever

Fine

Center mark of range

Setting the Grind Size:

Your OE Apex arrives set up for right hand operation... When facing the grinder the handle is on your right

- in this position the finest grind setting is at the front, the coarsest is at the back. There are 20 steps

available for the grind range. From the finest setting to the coarsest setting the burrs will open a total

of 1.5mm. The range is set at the factory and can not be changed by the user. The raised mark on

the outer housing is halfway in the range. Once the burr is loaded with beans it is difficult to move the

grind setting in a finer direction, so set before grinding the beans!

For Left hand operation please see the appropriate section of the manual, and the video

available to show you how to re-wrap the auger spring.

Page 3

Using the OE Apex:

As mentioned in the cover page “Important Read This” section, maintaining an adequate & consistent

handle speed is important for the efficient & satisfying use of the grinder. Depending on your worktop

application, using the grinder is as simple as setting the grind, and grinding the beans.

Here’s a few tips & observations:

When you first begin to grind the beans there will be a short lag of a few turns while the burrs load with

beans and grounds - this is normal.

Our target burr speed is about 500 RPM. Turning the handle about 120 RPM will provide that speed.

There are Metronome videos on Youtube which are VERY helpful to get a feel for this - or you can use a

real life Metronome!

As a rule of thumb, if your grinder is continually stopping you aren’t turning the handle fast enough.

If and when your burrs stop while grinding just reverse the handle direction - 1/4, or 1/2 turn is enough to

reposition the beans, and get a fresh start on your speed. You will get a feel for this fairly quickly!

If the burrs stop, and feel ‘stuck’, rock the handle back & forth to dislodge the beans. The burrs are

bi-directional, and will cut through.

Once again - BRUTE FORCE IS NOT HELPFUL for grinding coffee beans with the OE Apex.

The handle motion can best be described as ‘spinning’ the handle. You’ll find it to be generally effortless

with little feeling of resistence except for the finest, and coarsest settings. This is because on the finest

settings the burrs are fully loaded as you grind, and much of the work of the burrs is expelling the grounds.

On the coarsest settings the number of beans broken per revolution is very high resulting in an increased

feeling of resistence while grinding.

If your worktop installation & beans require the use of your ‘holding hand’ it is best to place your hand in

the center of the grinder body - not on the heel of the grinder. Your hand should cover approximately

the lower half of the hopper cover.

OE Apex Mechanicals

Parts first! The construction of the OE Apex is such that all of the mechanical components are

contained in one main part of the grinder - the Chassis. The Chassis is a die cast aluminum frame

with roller bearings on each end. A precision stainless steel axle is mounted in the roller bearings.

Chassis

Roller

Bearings

The Keyed Sun Gear

of the Planetary Gear Box

is press-fit on the end of the axle.

OE Apex Triangular Prism Tooth Burr Set

Page 4

All of the functional components are either mounted ON the axle, or centered in relation to

the axle. Once assembled, the Chassis and grinding system consists of 4 chambers:

End Plate

Tensioning

Spring

Axle

Needle Bearing

Set

Tensioning

Chamber

Roller

Bearing

(not visible)

Grind

Chamber

78mm Rotating

Burr

Carrier

Burr

Hopper

Chamber

Auger Spring Mount

& Axle Cover Tube

75mm Stationary

Burr

Auger Spring

Needle Bearing

(not visible)

Adjustment

Chamber

Roller

Bearings

(not visible)

Set

Adjustment

Wheel

Adjustment

Ramp

Sun Gear

Mounted on

Axle

Final assembly of the Chassis mounted drive system includes the Grind Chamber Cover, and

Adjustment Chamber Cover / Support.

Grind Chamber

Cover

Integral Chassis

Grounds Chute

Adjustment Chamber

Cover

Please NOTE: We are presenting a lot of information about the mechanics, and internals of the

OE Apex - this is for your information, and NOT an open invitation to disassemble the grinder

beyond

the Deep Cleaning Instructions. If you pull the axle in order to hold the burr set in your hand you

have entered into an area that is purely recreational. You do so at your own risk, and expense, if

you are unable to reassemble it yourself. Pulling the axle is NOT recommended. or endorsed, and

will void your warranty. Don’t do it....

Page 5

The operative speed for the OE Apex is achieved by the use of a Planetary Gear system

mounted on the handle side of the grinder.

Sun Gear

Mounted on

Axle End

Aluminum Gear

Box Outer Housing

Planetary Gears

& Ring Gear

Planetary Gear Assembly

Alignment Pin

Ring Gear Anchor Screw Hole

The Planetary Gear Box on the OE Apex functions to INCREASE the rotational speed of the burr.

The Ring Gear is held stationary to the Housing. The Handle turns the Planet Gears, which then

turn the Sun Gear, resulting in a 1:4 Speed Increase - one turn of the handle turns the burr 4 times.

Cleaning and Maintenance

-- The Adjustment Chamber requires no cleaning or maintenance.

-- The Hopper Chamber can be swept clean with a brush, puffed clean with compressed air,

or vacuumed out.

-- The Tensioning Chamber is isolated from the Grounds Chamber by the Grounds Chamber

Cover and accumulates few, if any, coffee bits.

-- This brings us to the Grind Chamber. You can generally clean any accumulated coffee bits

from the Grind Chamber without disassembly by using compressed air. A rubber bulb hand

puffer with the nozzle directed up through the Grinds Chute works well.

-- The Triangular Prism Tooth burr is made of hardened stainless steel, therefore free of rust, or

other problems. Any retained coffee in the burrs is generally expelled through grinding or

turning the handle while opening/closing the burrs using the Grind Setting Adjuster.

You may desire to manually deep clean the Grind Chamber of the OE Apex grinder. We find

this isn’t generally necessesary, but if you’re motivated to do this task, this is how you do it:

A narrative description of this procedure is that you disassemble the grinder from the handle end.

You remove the Planetary Gear Box (PGB), remove the Outer Cover, detach the Chassis and Inner

Frame from the outer parts of the body, do the cleaning, and put it all back together. What

follows is a step by step guide to this process.

1. Do NOT remove Handle - Leave Handle attached to the Planetary Gear Box (PGB).

2. Remove the Ring Gear Anchor screw - 3mm Hex. Slide the internal PGB Assembly with Handle

attached straight out of the aluminum housing. This has a VERY tight tolerance - slide the PGB STRAIGHT

out of the housing to avoid jamming.

Page 6

3. Remove the 3 screws which hold the PGB Housing to the body. (Note - these are longer than the

Ring Gear Anchor screw. Lift away the Housing and set aside.

4. Remove the Adjustment Lever Pin (unscrew CCW) and remove the small screw on the top of the

plastic Body Cover - 2.5mm Hex.

6. Slide off the plastic Body Cover and remove the Adjustment Chamber Cover.

7. Remove the 3 screws holding the Inner Frame to the Back Cover. WHILE supporting the Chassis with

one hand, remove the single Back Cover external screw (4mm Hex). The Chassis and Inner Frame will

pull out as one unit.

Page 7

8. You now have complete access to the Grind Chamber. Lift off the Grind Chamber Cover, brush,

clean, etc.

9. Assembly is the reverse - Remember to replace the Grind Chamber Cover. Finger tighten the 3

screws of the Inner Frame, fully tighten the Outer Back Cover screw, then finish tightening the inner 3

screws. Place the Adjustment Chamber Cover in position. Install the Body Cover. Install small top

screw in the Body Cover Do NOT overtighten the screw.

10. Install the PGB Outer Housing using the 3 longest screws. Our factory orientation of this part has the

screw hole on the bottom for cosmetic reasons - you can install it with the screw hole on either side

instead for easier future access.

Here is the tricky part to this step - Align the Ring Gear Anchor hole perfectly to the outer Housing hole.

The PGB MUST be inserted precisely and squarely so it will slide in smoothly without binding. Once it is in

the proper position the Planetary Gears must be meshed with the Sun Gear - while holding the Handle/

PGB in place wiggle the Auger back & forth a little bit to mate the gears. The PGB will drop into place

when they mesh. Install the Ring Gear Anchor screw. Install the Adjustment Wheel Lever. You are done!

Setting up for Left Hand operation:

Your grinder will arrive set up for Right hand operation - holding with the left hand, turning the handle with

the right hand. The Auger Spring is wrapped in the Right hand use direction. The burr is bi-directional so

for TRUE Left Hand operation you will need to re-wrap the spring in the opposite direction so that beans

will properly feed into the burrs.

If you are Left handed we assume you have a high level of motivation to undertake this somewhat

difficult task. We also assume you have a reasonable mastery of tools and will proceed safely. This

procedure is easier to do with the help of an assistant acting as a third hand!

Page 8

Referring to the previous section - deep cleaning - proceed through Steps 1-6. This opens up the top

of the grinder so you have access to the Auger Spring screws.

A. Set the grind to the finest setting (this will allow better access to the lower Auger Spring screw).

Loosen and remove the upper Auger Spring screw WHILE holding the end of the spring to prevent it

from snapping back. (2.5mm Hex)

B. Slightly loosen the lower Auger Spring screw just enough so that the spring loop can move under the

screw head. Re-wrap the spring in the opposite direction by turning the Sun Gear/Axle - easiest to turn

this by protecting your fingers - wear glove, a leather pad - the Sun Gear is sharp! This is where an

assistant comes in handy! From the point of origin of the lower Auger Spring screw wrap the spring 2 1/2

times (the upper & lower Auger Spring screws are opposite each other when the spring is wrapped 2 1/2

times). You will need to stretch the spring, which gets especially difficult in the last 1/2 wrap. Insert the

upper Auger Spring screw in the loop of the Auger Spring, and into the Auger Shaft (be sure it is straight

in). Tighten the screw. Check the orientation of the spring, making sure it is evenly wrapped, then

tighten the lower Auger Spring screw.

This is how the Left Hand Auger Spring looks when done:

To reassemble proceed with Deep Cleaning Steps 9 - 10 .

Maintenance

The OE Apex requires very little maintenance:

-- Outer body parts can be wiped with a clean, soft cloth

-- Silicone Base Cover can be washed in mild soap & water

-- Reuseable Silicone Base Gel Pads can be washed in mild soap & water, and air dried

(Make sure both the counter, and base of the grinder are clean before applying gel pads)

We hope you enjoy your grinder, and the coffee you make with it!

Doug & Barb Garrott

Orphan Espresso

11/14/2018

Loading...

Loading...