ORO W401A User Manual

ORO TPMS Manual

To ensure correct operation and service please read these instructions before installing and

operating the TPMS

TABLE of CONTENTS

1. Notice………………………………………………………...…………………1

2. W401A Tire Pressure Monitoring System………………………………….2

3. W401A Tire Pressure Monitoring System Specification………………2

4. W401A Tire Pressure Monitoring system Accessories…………………3

5. W401A System Installation ……………………………………3

Display Unit Installation………………………………………………...3

Wireless Transmitter Sensor Installation………………………………...4

6. W401 A System Operation….………………………………………………6

Description for Display……………………………………………………...6

Description for Change Mode Method……………………………………...7

Change Factory Default Set Up……………………………………………...7

1. Front Tire-Low Tire Pressure Setting Mode………………………...7

2. Rear Tire-Low Tire Pressure Setting Mode………………………...8

3. Tire Pressure Temperature-High Tire Pressure Setting Mode……9

4. Initial Display Mode Set Up……………………………….............10

7. W401A Waring Sy stem Description………………………………………..11

8. W401A Reset for Tire Change and Rotation……………………………..13

Mode1:Front and Rear Tire Parallel Exchange……………………..……..13

Mode 2:Tire Diagonal Exchange………………………………………..…..13

Mode 3:Front T ire exchange,Rear T ire Parallel change to front………..14

Mode 4:Random Reposition…………………………………………..……..14

Mode 5:Single Tire Sensor Replace…………………………..……………..16

9. Warranty Policy…………………………………………...………………….18

10. APPENDIX…………………………………………………………………….18

NOTICE

FCC & E-Mark Notice

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference.

(2) This device must accept any interference received, including interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the

factoring measures.

z Reorient or relocate the receiving antenna.

z Increase the separation between the equipment and receiver.

z Connect the equipment into an outlet on a circuit different from that to which the receiver is connected

Caution: Any changes or modifications in construction of this device which are not expressly approved by the

party responsible for compliance could void the user’s authority to operate the equipment.

To comply with the FCC RF exposure compliance requirements, this device and its antenna must not be

co-located or operating to conjunction with any other antenna or transmitter.

System Scope of Use and Warnings

Tire Pressure Monitoring System, TPMS

This system is a sensing device designed to measure and display tire operation and / or activate an alert to the

driver when pressure and temperature irregularities are detected. It is the responsibility of the driver to react

promptly and with discretion to alerts. Abnormal tire inflation pressure should be corrected at the earliest

opportunity.

System Installation and Usage

Use of the TPMS requires that qualified personnel according to the instructions here have properly installed it. This

system is suitable for use on a passenger car, SUV and 4

76 Psi (Guage) or 90psi (Absoulte), below instruction is Guage value mentioned.

Reacting to Alerts

When an alert or warning is received, reduce vehicle’s speed and proceed to a safe location to stop where the tire

can be inspected and /or serviced.

X4 tires, with up to maximum cold inflation pressure of

The low-pressure alert indicates that the air pressure has dropped to a selected minimum and a high-temperature

alert indicates that the temperature of the tire content has surpassed the threshold value set.

Use of Chemicals

Temporary resealing or re-inflation products containing internal sealants or propellants in any tire assembly may

adversely affect the operation of the sensor/transmitter.

Caution: the system is wireless RF product; therefore, it may not receive a signal due to the poor environment or

incorrect operating either on incorrect installation. When the system continually cannot receive any signal from any

tire sensor more than 10 minutes since the system has been switch on for monitoring, the system will shown “ E2 ”

and turn on the RED abnormal LED light with alert sound. In this case, it may cause by a RF interference

environment, a driver need to drive the vehicle and leave the place where are running. If the display still cannot

receive any correct signal from tire sensor, then, a driver need to find a close qualified tire maintain service for

checking or maintain. It may cause by a tire sensor damages or battery power consumption. (Battery in normal

condition can be used more than 7 year, but in abnormal condition, the tire sensor will continually send warning

signal to the driver, thus it wills consumption the battery quickly than normal prediction.)

W401A Tire Pressure Monitoring System

ORO-W401A Tire Pressure Monitoring Systems (TPMS), can monitor and provide tire pressure, tire temperature

and car battery information by real time to help the driver to control and keep the normal tire pressure in order to

reduce the fuel consumption and extend the tire life, and also through the battery information, the driver can

change the battery before happens any bug and reduce the % of vehicle breakdown on the road.

ORO-W401A Tire Pressure Monitoring System, includes 4 tire sensors and 1 receiver display, the

TPMS can monitoring the pressure/temperature by snap-in installation into the tire, and transmit the

tire information to the receiver by wireless. The TPMS display will alarm when any abnormal happens

to the tire in order to prevent any possible accidents which may happen to the driver/vehicle.

W401A TPMS Specification

1. Tire Sensor’s Specification

Battery life 3~5 years normally use.

Battery Voltage 3.6 V

Storage Temperature -40 ℃ to 125 ℃

Operation T emperat ure -30 ℃ to 120 ℃

Operation Frequency

Transmission Frequency Transmit 1 signal each 30 sec.

Pressure Monitoring Range 0 ~ 800 kPa

Pressure Reading Accuracy

Temperature Monitoring Range -30 ℃ to 100 ℃

433.92MHz ±4.25MHz

±10kPa

Temperature Reading Accuracy

2. Receiver Specification

Operation Voltage 9V ~ 15V

Normal Operation Voltage

±4℃

≦200mA

Storage Temperature Range -40 ℃ to 90 ℃

Operation T emperat ure Range -30 ℃ to 85 ℃

Tire Pressure Reading Range 0 ~ 800 kPa

Temperature Reading Range -30 ℃ to 100 ℃

Cold-Tire Std. Tire pressure setting range

Tire Temperature Warning Range

1.9 ~ 2.8 bar (27 ~ 40 psi; 190 ~ 280 kPa),the factory

default is.3bar (32psi; 230kPa)

60℃~99℃(140℉~212℉),the factory default is 80 ℃

(176℉)

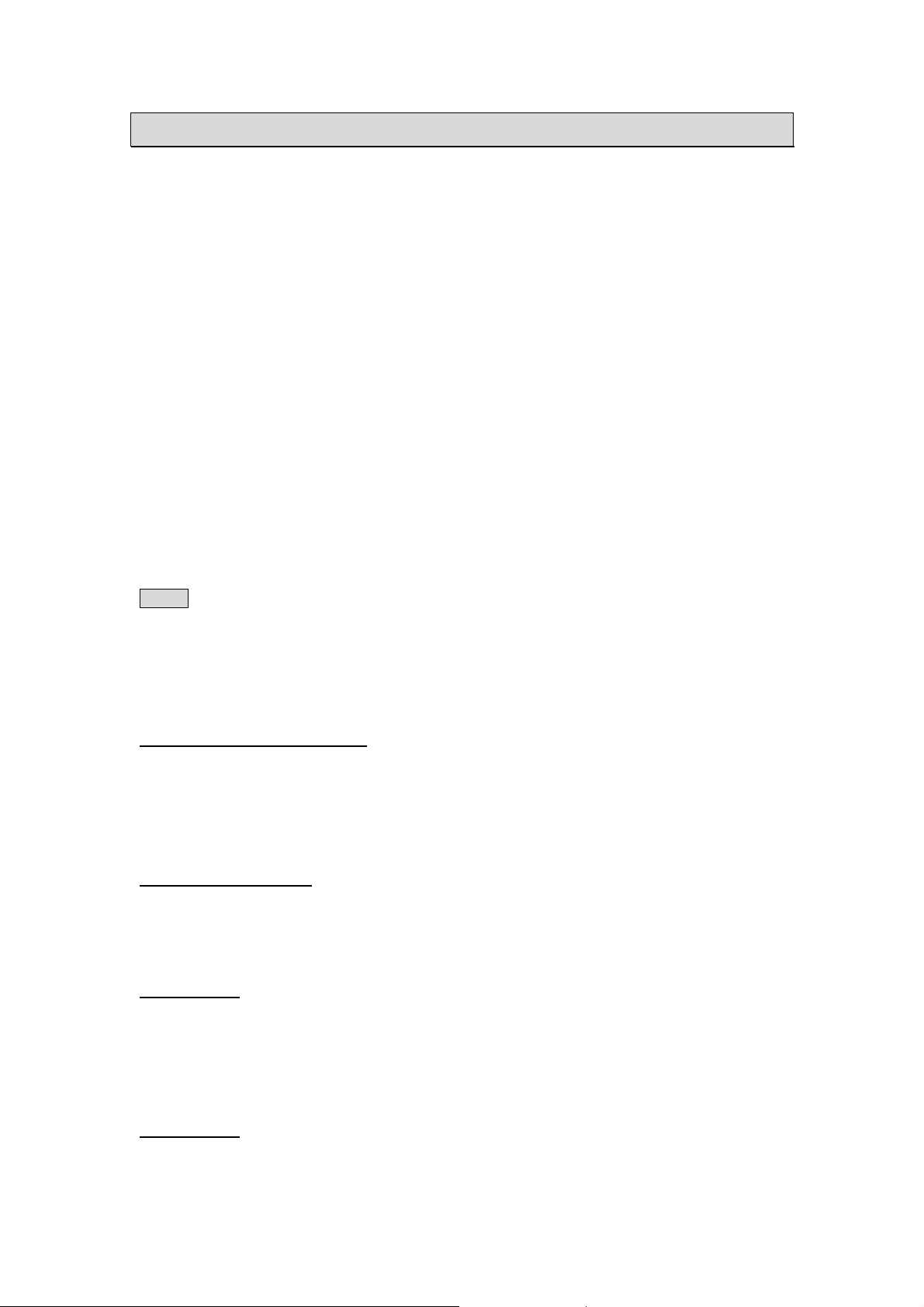

W401A TPMS Accessories

Accessories Pictures QTY Accessories Picture QTY

Display

Tire Sensor 4 Magnetic Holder

1 Nylok Screw

5

1

Cigarette Power

Cable

Aluminum Valve 4

T-20

1

Screw Driver

Manual

1

W401A TPMS INSTALLATION

1. Display Installation:

a. Firm the magnetic holder in the suitable place. (Suggest place , as shows in the picture)

b. Plug in the USB cigarette power cable on the back of display.

c. Put the display on the magnetic holder.

d. Plug in the power cable to the cigarette lighter power connection.

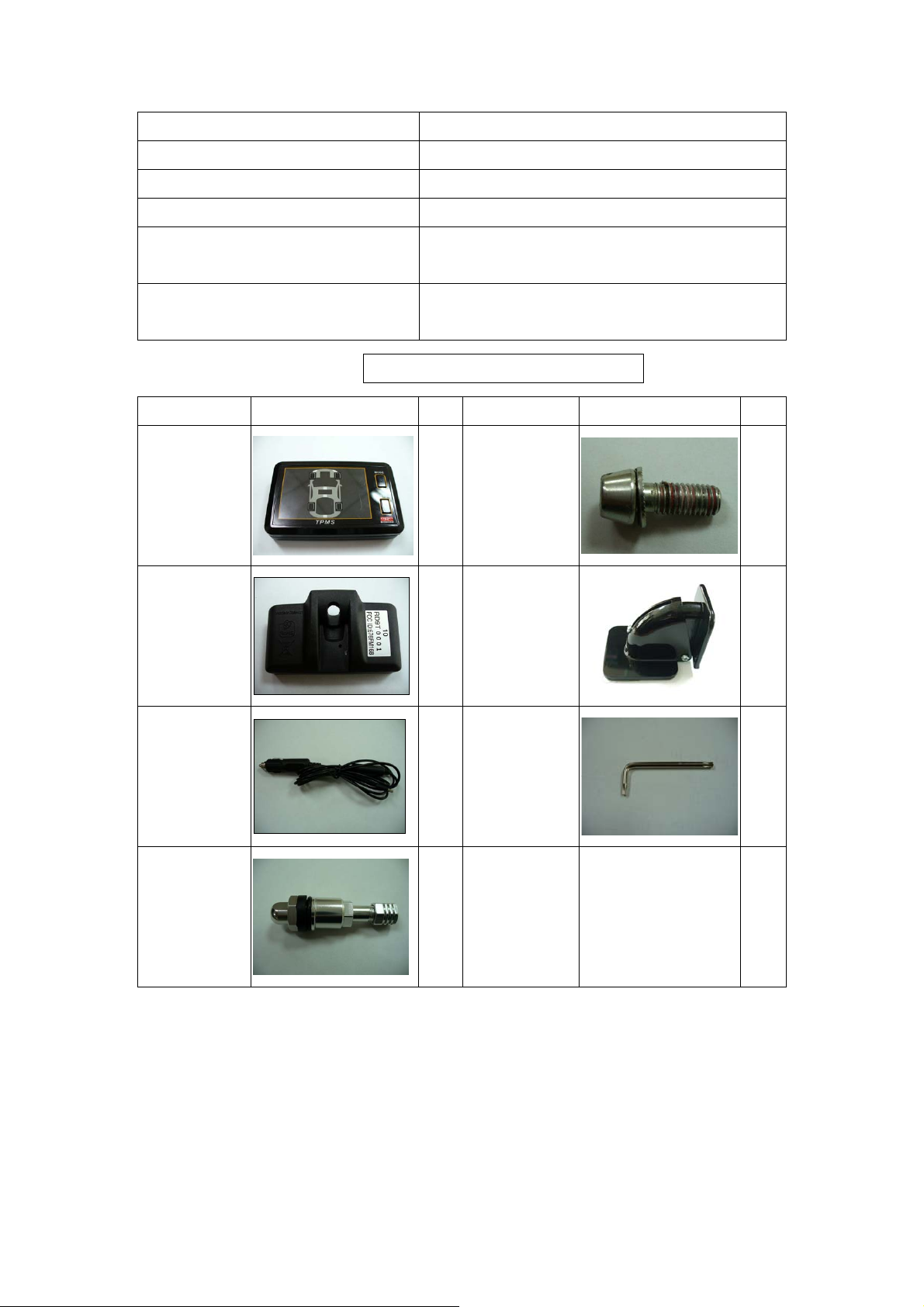

2. Tire Sensor Installation:

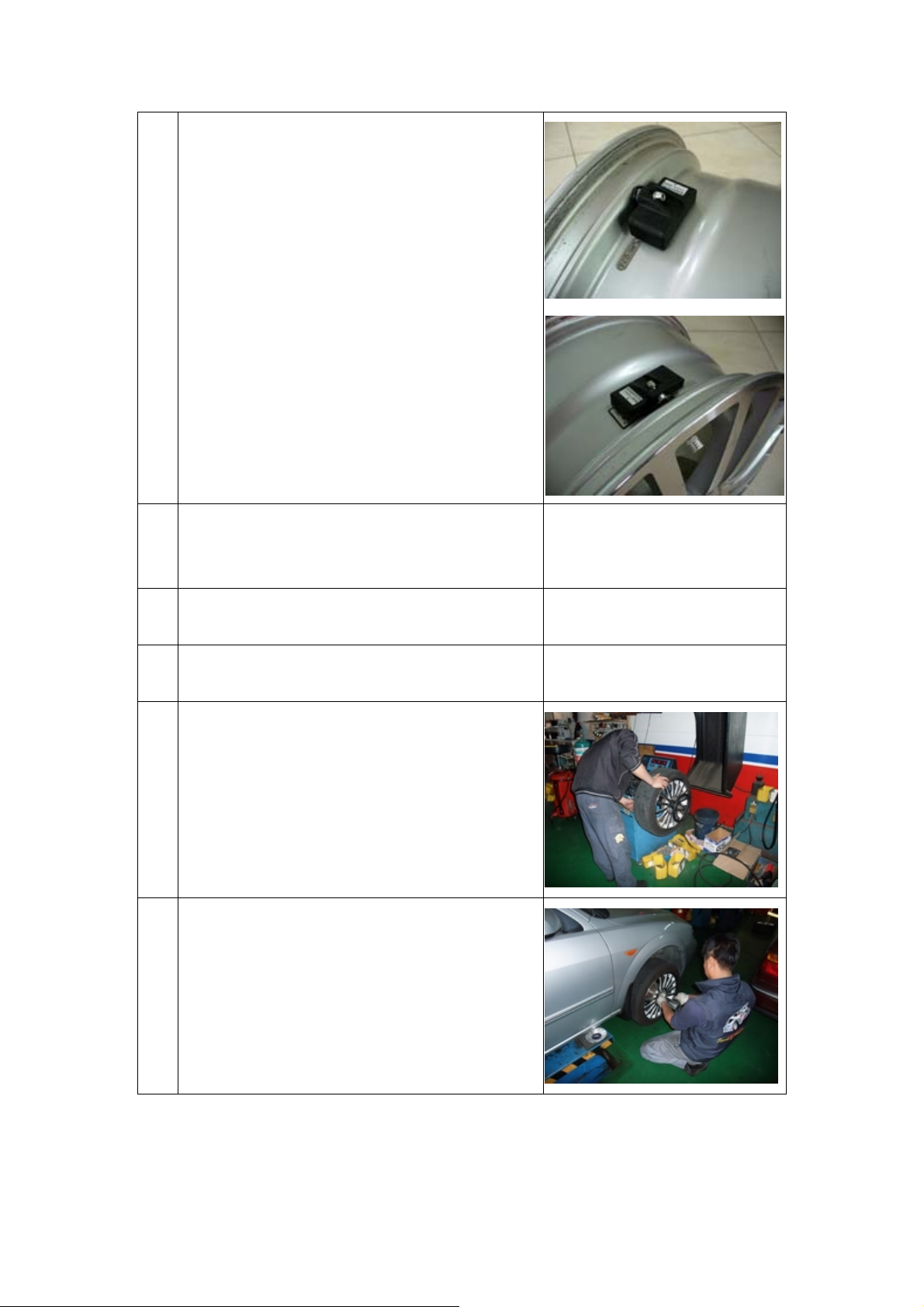

Step Operation Process Photograph

a Take off the 4 tires and mark 1~4 for each tire position.

No.4 = Left Front Tire ; No.1 = Right Front Tire。

No.3 = Left Rear Tire ; No.2 = Right Rear Tire。

b Take off the tire and bleed the air, then should change to

the ORO-TEK TPMS valve, and follow the steps:

1. Snap in the valve from the internal edge side of the

wheel.

2. Adjust the valve’s angle, and make the valve be

vertical by the edge of the wheel.

3. Put on the circle screw from the outside of the wheel.

4. Tight up the valve with the nylok screw from the

outside of the wheel.

5. Use the 6 angle screwdriver to tight up.

b

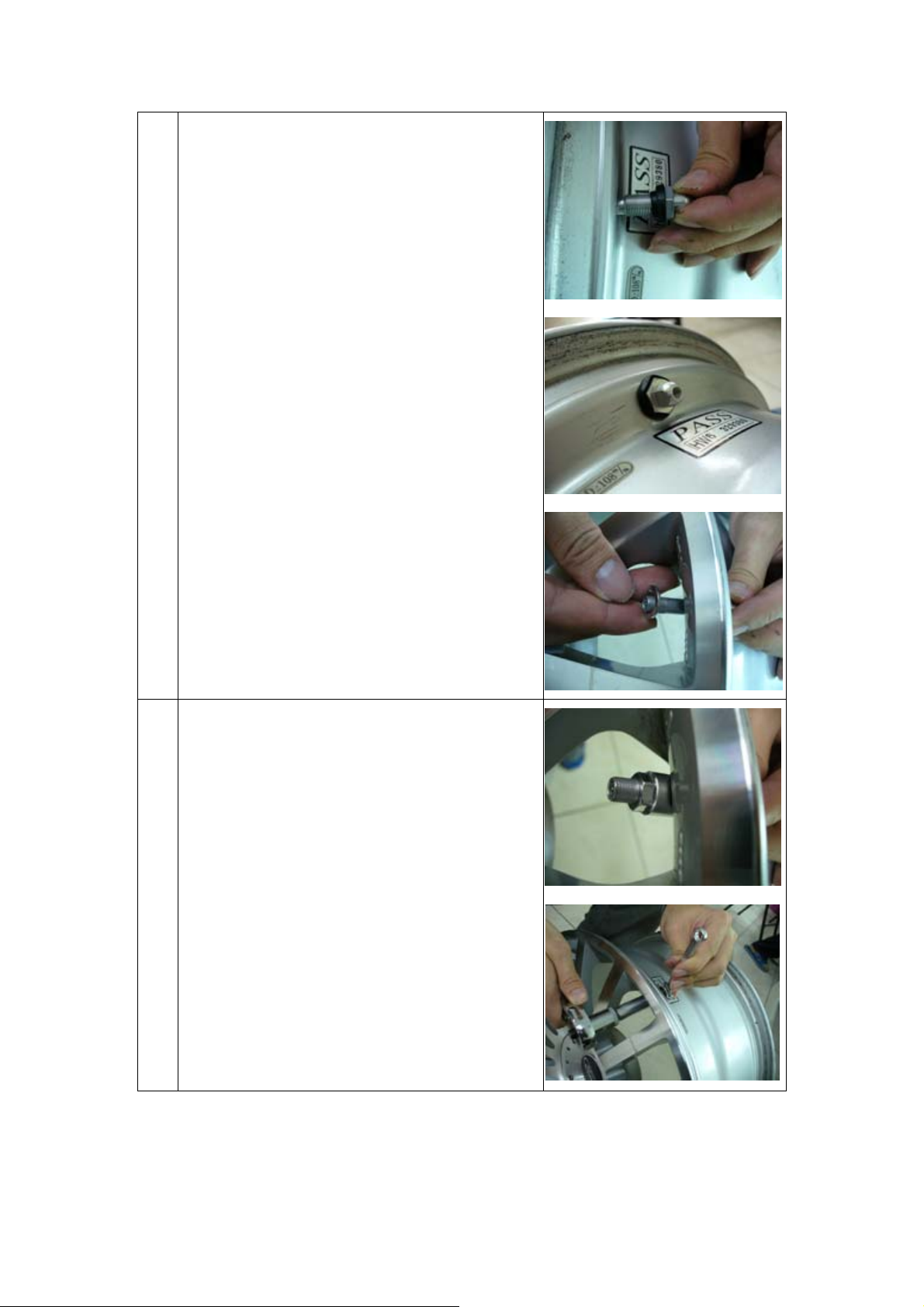

c Put the marked No. 1 tire sensor to the tire which market

No. 1. as step a. photo and follow steps:

1. Install the tire sensor to the valve.

2. Use the nylok screw and tight up with the tire sensor.

(Pls. use the screwdriver which is included to the

accessories bag)

3. Adjust the tire sensor’s angle (paste on the surface of

the wheel), then tight up the with the nylok screw.

4. Put on the valve’s cap, and finish the installation.

When there is necessary to re-install the tire sensor, pls.

use the new nylok screw in order to prevent to re-use the

old ones.

d Put on the No. 2 tire sensor to the tire which marked

No.2, and set up the other 2 sensor in the same manner as

shows in the step c.

e Make sure there is no other liquid or dust beside of the

tire sensor.

f Follow the tire specification and inflate appropriate air to

the tire after finished the installation.

Balance the tires with the balance machine。

g

h Put back the tires to it’s corresponding position as shows

in the photograph on step a.

Turn on the ignition after the TPMS installation and start to monitoring the tire pressure/temperature

and car battery.

Loading...

Loading...