IG-021-GB

version 07

General Instructions

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

PF

LIB

29.08.2008

Transformer

Substations

Secondary Distribution

Switchgear

Primary Distribution

Switchgear

Protection and

Automation

Low Voltage

Boards

Distribution

Transformers

Legal Deposit: BI-2359/08

ATTENTION!

When MV equipment is operating, certain components are live, other parts may be in movement, and some may reach high

temperatures. Therefore, the use of this equipment poses electrical, mechanical and thermal risks.

In order to ensure an acceptable level of protection for people and property, and in compliance with applicable environmental

recommendations, Ormazabal designs and manufactures its products according to the principle of integrated safety, based on

the following criteria:

• Elimination of hazards wherever possible.

• Where elimination of hazards is not technically or economically feasible, appropriate protection functions are

incorporated in the equipment.

• Provision of information on residual risks to facilitate the design of operating procedures which prevent such

risks, training for the personnel in charge of the equipment, and the use of suitable measures for personal

protection.

• Use of recyclable materials and establishment of procedures for the disposal of equipment and components so

that once the end of their useful lives is reached, they are duly processed in accordance, as far as possible, with

the environmental restrictions established by the competent authorities.

Consequently, the equipment to which the present manual refers complies with the requirements of section 11.2 of the

forthcoming IEC standard 62271-1. It must only be operated by qualified and supervised personnel, in accordance with the

requirements of standard EN 50110-1 on the safety of electrical installations and standard EN 50110-2 on activities in or near

electrical installations. Personnel must be fully familiar with the instructions and warnings contained in this manual and in other

recommendations of a more general nature which are applicable to the situation according to current legislation.

The above must be carefully observed, as the correct and safe operation of this equipment depends not only on its design but

also on general circumstances which are in general beyond the control and responsibility of the manufacturer. More specifically:

• The equipment must be handled and transported appropriately from the factory to the place of installation.

• All intermediate storage should occur in conditions which do not alter or damage the characteristics of the

equipment or its essential components.

• Service conditions must be compatible with the equipment rating.

• The equipment must be operated strictly in accordance with the instructions given in the manual, and the

applicable operating and safety principles must be clearly understood.

• Maintenance should be performed properly, taking into account the actual service and environmental conditions

in the place of installation.

The manufacturer declines all liability for any significant indirect damages resulting from violation of the guarantee, under any

jurisdiction, including loss of income, stoppages and costs resulting from repair or replacement of parts.

Guarantee

The manufacturer guarantees this product against any defect in materials and operation during the contractual period. In the

event that defects are detected, the manufacturer may opt either to repair or replace the equipment. Improper handling of this

equipment and its repair by the user shall constitute a violation of the guarantee.

Registered Trademarks and Copyrights

All registered trademarks cited in this document are the property of their respective owners. The intellectual property of this

manual belongs to the manufacturer.

In view of the constant evolution in standards and design, the characteristics of the elements contained in this manual are

subject to change without prior notification.

These characteristics, as well as the availability of components, are subject to confirmation by Ormazabal’s Technical - Commercial

Department.

IG-021-GB

version 07

29.08.2008

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

CONTENTS

1. DESCRIPTION AND MAIN CHARACTERISTICS ........................................................ 4

2. TRANSPORT................................................................................................................. 5

2.1. ACCESS ...................................................................................................................... 5

2.2. TRANSPORT............................................................................................................... 5

3. INSTALLATION............................................................................................................. 8

3.1. LOCATION .................................................................................................................. 8

3.2. PLANNING .................................................................................................................. 8

3.3. PREPARING THE GROUND....................................................................................... 9

3.3.1. Excavation Dimensions........................................................................................ 9

3.3.2. Types of Ground .................................................................................................. 9

3.4. LEVELLING PROCESS ............................................................................................ 10

3.4.1. Levelling Tools ................................................................................................... 10

3.5. HANDLING PANELS AND CONCRETE COMPONENTS........................................ 13

3.5.1. PF-200 / 300 & PF-2015 / 3015 SERIES CONCRETE COMPONENTS ........... 14

3.6. ASSEMBLING TOOLS.............................................................................................. 15

3.7. PF ENCLOSURE ASSEMBLY PROCESS ............................................................... 15

3.7.1. Assembling Bottom Plates ................................................................................. 17

3.7.2. Assembling the Vertical Panels.......................................................................... 20

3.7.3. Remaining Vertical Panels................................................................................. 26

3.7.4. Floor Plates, Slabs and Transformer Platform ................................................... 30

3.7.5. Cubicles and Transformer.................................................................................. 34

3.7.6. Low Voltage Board............................................................................................. 34

3.7.7. Transformer Protection Fences.......................................................................... 35

3.7.8. Covers................................................................................................................ 35

3.7.9. Ventilation grilles................................................................................................ 37

3.7.10. Doors.................................................................................................................. 38

3.7.11. Low Voltage Auxiliary Feeder ............................................................................ 39

3.8. CONNECTING THE EARTH CIRCUIT...................................................................... 40

3.8.1. Panel Reinforcing Mesh..................................................................................... 40

3.8.2. Earthing Circuit................................................................................................... 42

3.8.3. Earthing Ring ..................................................................................................... 43

4. MAINTENANCE .......................................................................................................... 44

4.1. REMOVING THE SIDE COVERS.............................................................................. 44

4.2. REMOVING THE CENTRAL COVERS ..................................................................... 44

4848

Page 3 of 48

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

1. DESCRIPTION AND MAIN CHARACTERISTICS

Ormazabal’s PF Modular Enclosures for walk-in type outdoor Transformer Substations are

designed according to standard EN 61330 for use in electrical power distribution networks up

to 36 kV.

PF consists of prefabricated concrete panels that can be combined in various configurations.

Depending on their configuration, these enclosures comprise some of the following elements:

Front, back and side concrete modular panels.

Covers (roof panels).

Transformer platforms.

Bottom plates.

IG-021-GB

version 07

29.08.2008

Supplementary floor plates.

Hinged personnel access door, folding 180º over the outside wall, with a two-fixing-

point lock and a fastening rod to hold it open.

Hinged transformer door, folding 180º over the outside wall, and with a ventilation

grille in its lower section. An interlocking lock may be fitted.

Ventilation grilles: for transformer powers under or equal to 630 kVA, an air exhaust

grille is fitted in the rear upper part of the enclosure and an air intake grille is fitted in

the lower part of the transformer door. For transformer powers of 1000 kVA, 4 extra

grilles are incorporated in the sides.

Moulded holes for LV and MV cable input/output. Some of these holes can be used

for the output of the earthing circuit cables.

Oil collection pit with a fire-extinguisher device.

Document holder for documentation relating to the Transformer Substation.

Page 4 of 48

IG-021-GB

version 07

29.08.2008

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

2. TRANSPORT

2.1. ACCESS

The site must be visited in advance to check if vehicles (tow-truck or separate truck and

crane) can have access and if there is sufficient space for the PF unloading and assembly

operations, taking into account the distances to overhead lines, slopes, etc.

2.2. TRANSPORT

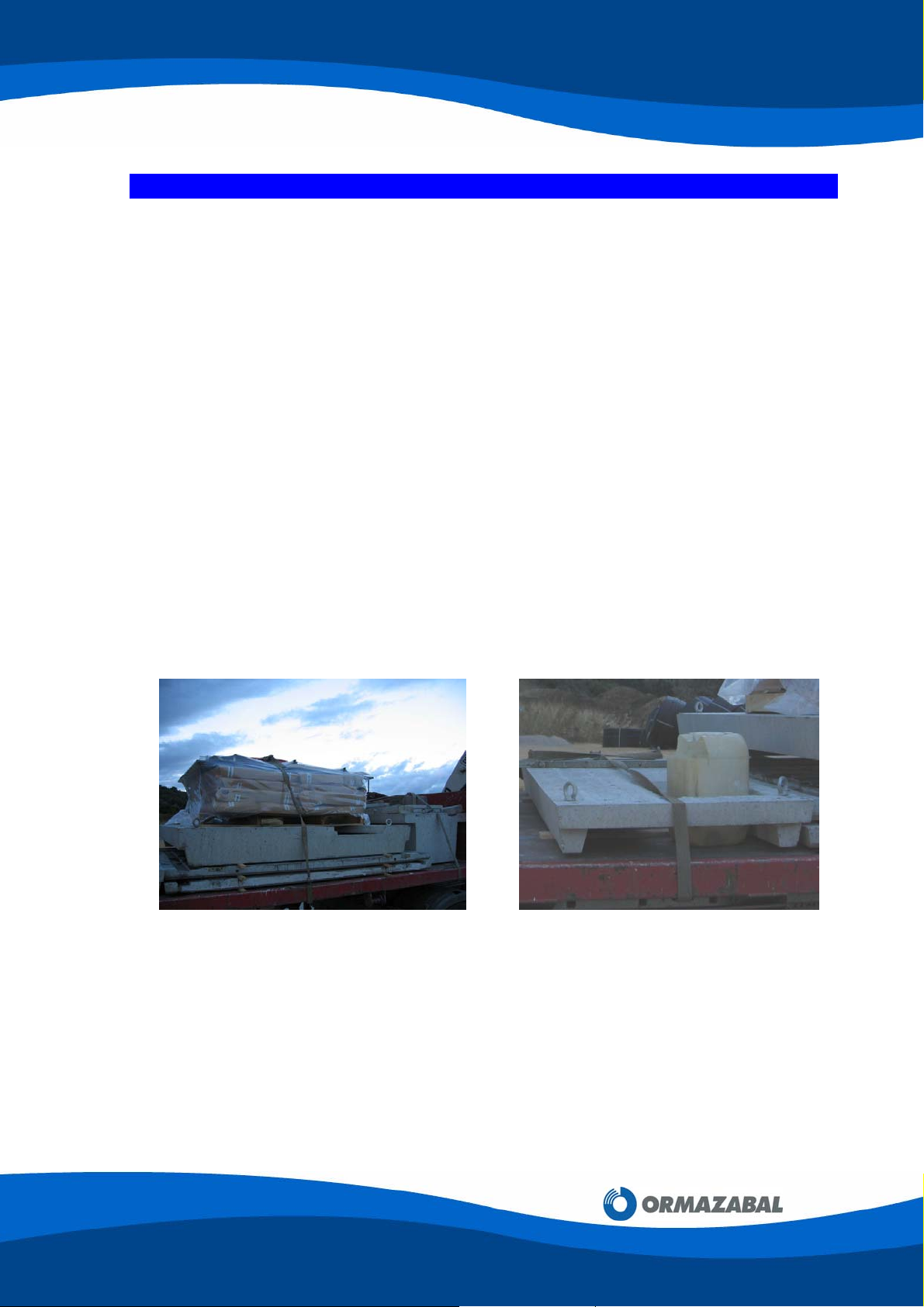

The panels are transported in trucks, taking the appropriate precautions to avoid breakage

caused by differential settlements.

The elements required to assemble the PF Transformer Substation are grouped into two

classes, according to how they are transported:

a) Horizontally-transported components

Transformer platforms, PF-200/300 series bottom plates and supplementary floor plates

are transported lying flat on the truck bed, separating them with wooden battens to avoid

damage to the edges.

Apart from these components, other miscellaneous material such as floor slabs, grilles,

doors, etc., are transported on wooden pallets on the truck bed.

They are tied down using slings suitable for the load.

Figure 2.1: Fixing slings

Figure 2.2: Fixing slings

4848

Page 5 of 48

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

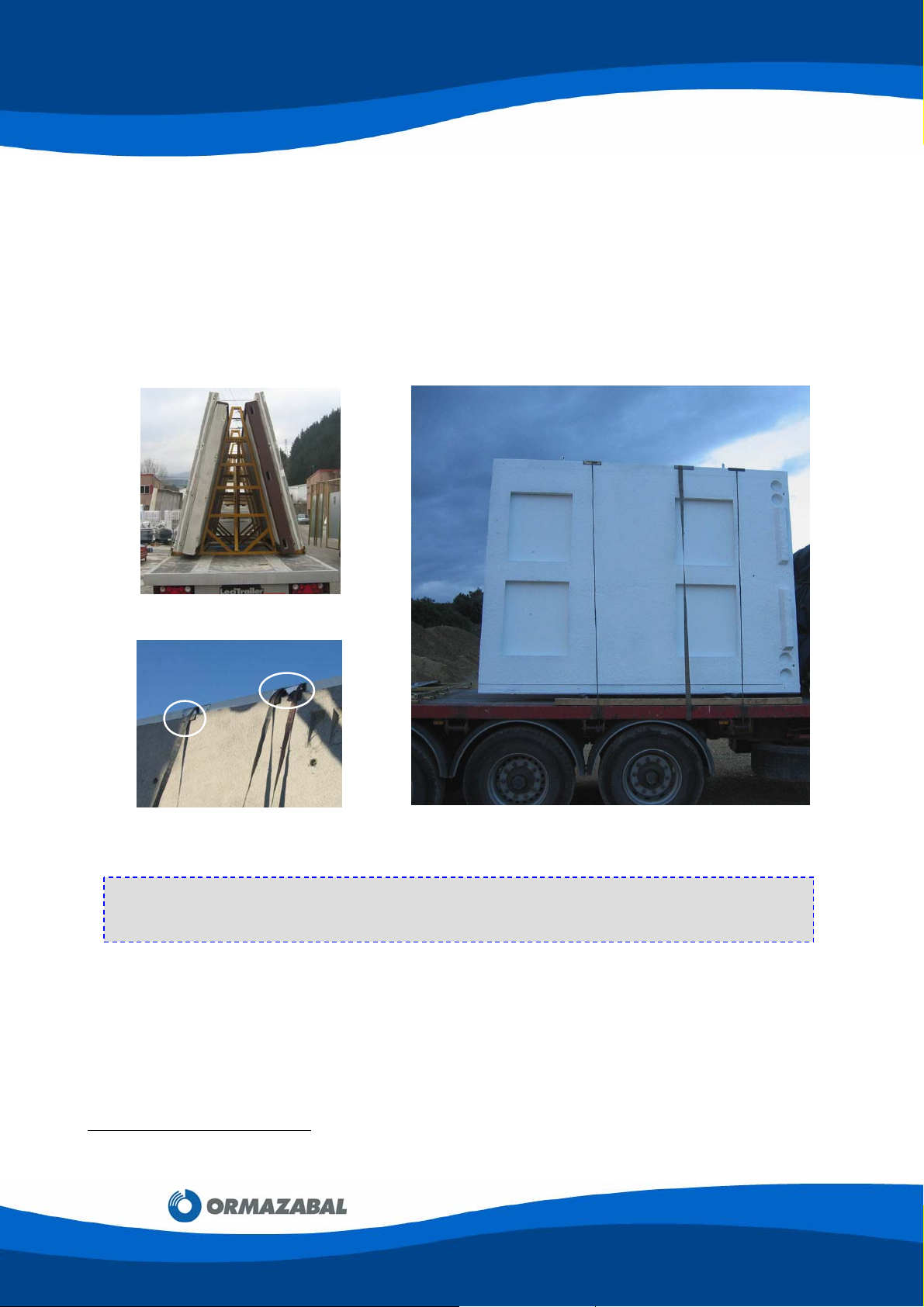

b) Vertically-transported components

Front and side panels

[1]

, PF-2015 / 3015 series bottom plates and the remaining floor

plates are transported on trestle (reference 160026), as shown in figure 2.3. On

occasions, floor plates can be transported horizontally.

The load is tied down on the truck using slings or cables that are tensed using the truck’s

reels. In turn, the concrete components have rubber and/or metal protection parts, as

shown in figure 2.4, to avoid any damage as the straps are tightened.

Figure 2.3: Trestle160026

Figure 2.4: Protection parts Figure 2.5: Vertically-transported components

IMPORTANT:

Before unloading, check the orientation of the loaded components. This will make unloading

and assembly easier.

IG-021-GB

version 07

29.08.2008

[1]

If the front and rear panels are transported vertically, instead of horizontally, they can be moved directly from

the truck to their final positions.

Page 6 of 48

IG-021-GB

version 07

29.08.2008

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

Figure 2.6: 2360 mm wide panel placed vertically

Figure 2.7: 3540 mm wide panel placed vertically

Figure 2.8: Panels supported by a trestle

Side panels must be rested on the ground in order to insert the rubber strip required for

sealing the enclosures

[2]

.

[2]

See section 3.7. PF Enclosure Assembly Process.

4848

Page 7 of 48

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

Preferably, the truck used to transport the components should have a bed height no more

than 900 mm; there are two possible cases:

200/2015 Series panels

The maximum height of these panels when transported vertically is 3000 mm, enabling

them to be transported on low loaders up to 900 mm high without requiring a special

permit.

When this is not possible, a special transport permit should be obtained. In this case, the

truck bed height should be no more than 1400 mm, in order not to exceed the maximum

permitted height of 4500 mm.

300/3015 Series panels

[3]

The maximum height of these panels when transported vertically is 3,400 mm, as a result

of which they exceed 4000 mm in height both when carried on 900 mm high low loaders

and in other types of truck. Therefore, a special permit is required to transport them, and

the maximum permitted height of 4500 mm must never be exceeded.

3. INSTALLATION

IG-021-GB

version 07

29.08.2008

Assembly and installation of PF TS must only be carried out by qualified personnel with

sufficient experience and training. All safety rules for unloading and handling elevated loads

must be observed. Operators must use the obligatory personal protection equipment,

helmets and protective footwear.

3.1. LOCATION

The site location should be defined exactly, indicating the levels of alignment and height to

reference points, such as: roads, kerbs, milestones, pavilions, fences, electricity pylons, etc.

It is recommended, although it is not essential, to get a drawing or sketch with the customer’s

letter head and stamp and/or signature, indicating these distances.

3.2. PLANNING

On the location sketch or drawing (or on another one), mark out the spaces available for the

crane and the transport truck.

In addition, indicate the existence of any circumstance or object that could impede or

obstruct the smooth operation of the installation (posts, cables, ditches, walls, pipelines,

etc.), marking their positions on the drawing with the corresponding measurements.

[3]

The maximum height limit for vehicles, including the load, is specified in the Spanish Royal Decree 2822/1998

dated the 23rd December, which approved the General Vehicle Regulations (Article 14, Annex IX).

Page 8 of 48

IG-021-GB

version 07

29.08.2008

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

Confirm that the crane is sufficiently powerful to unload the components comprising the

transformer substation (the maximum weight of any individual part is about 2500 kg) and that

it can move them the distances required to install the transformer substation.

3.3. PREPARING THE GROUND

3.3.1. Excavation Dimensions

The excavation dimensions depend on the enclosure model:

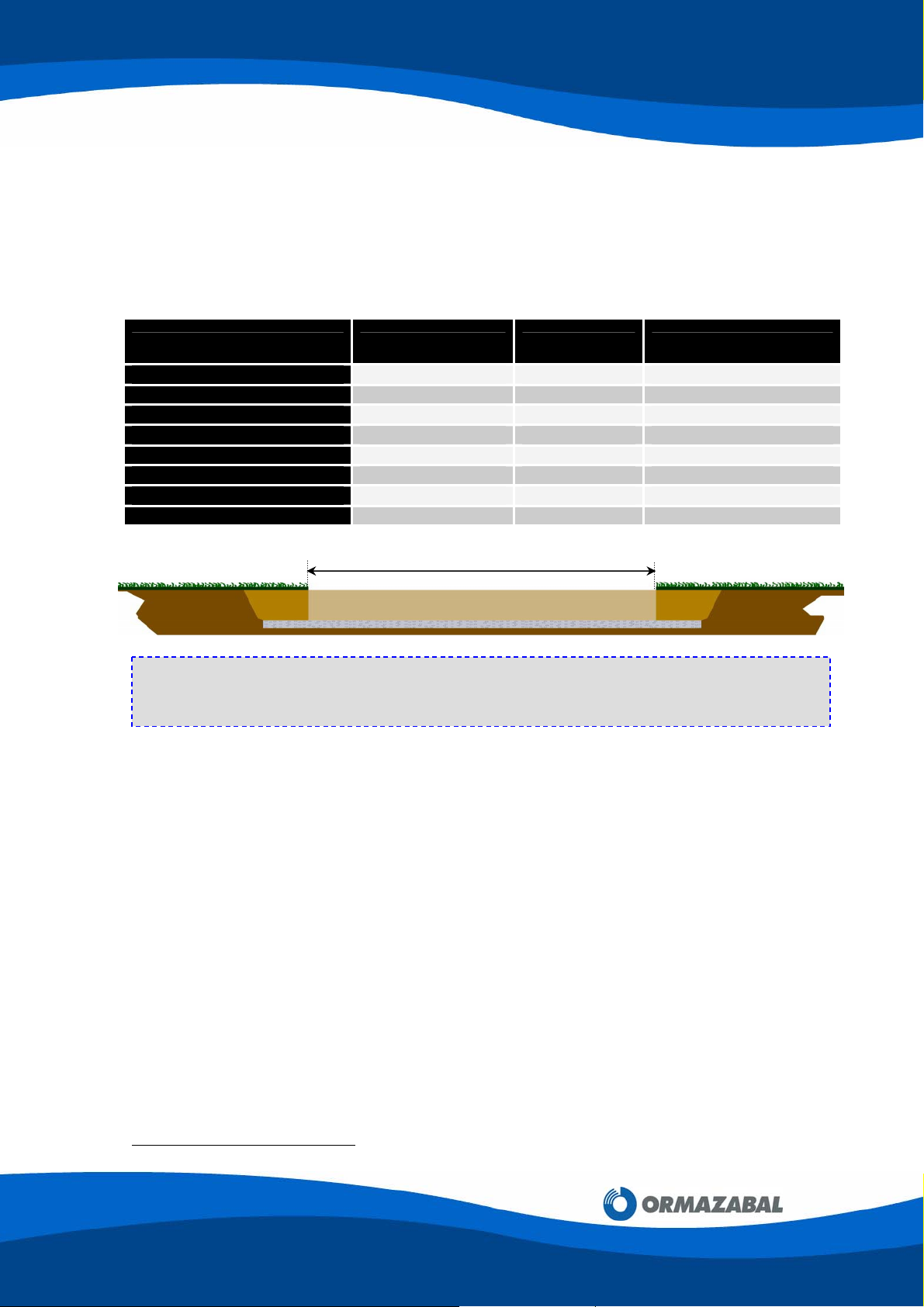

MODEL LENGTH (L) [mm] WIDTH [mm] DEPTH [mm]

PF201 / PF301

PF202 / PF302

PF203 / PF303

PF204 / PF304

PF205 / PF305

PF2015 / PF3015

PF2030 / PF3030

PF3035

3420 3420 650

5680 3420 650

8040 3420 650

10400 3420 650

12760 3420 650

4500 3420 650

8040 3420 650

9220 3420 650

L

NOTE: For other configurations, the distance L must be increased by 2360 mm for each

additional 200/300 series panel, and by 3540 mm for each additional 2015/3015 series

panel. Consult Ormazabal’s Technical - Commercial Department.

3.3.2. Types of Ground

The type of ground on which the PF Modular Transformer Substation will rest is an essential

factor, given the weight of the equipment. The ground could subside or become uneven, or

could provide differential settlements, causing cracks in the enclosure.

There are two types of ground:

A) Hard Grounds: Grounds where the soil is settled and properly compacted by natural

causes, with a strength of at least 1 kg/cm

2

.

When the excavation is finished, a sand layer of approximately 100 mm should be laid

down and compacted until a person can walk on it without leaving footprints (only a

surface mark).

Once the levelling boards

[4]

have been removed, the gaps they leave should be filled with

sand. Take the measures appropriate to each case to prevent the filling sand from

eroding.

[4]

See section 3.4. Levelling process

4848

Page 9 of 48

IG-021-GB

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

29.08.2008

B) Soft Grounds: These are sandy areas, landfills, etc., with a strength of less than

0.9 – 1 kg/cm

2

.

In these cases, foundations suitable for the ground conditions must be prepared, and this

may imply the construction of a reinforced concrete bed to distribute the load over a wider

surface

[5]

.

Thereafter, it should be levelled using sand, as in the previous case.

3.4. LEVELLING PROCESS

This is a fundamental operation which has a decisive influence in both the assembly and the

stability of the PF Modular Transformer Substation.

3.4.1. Levelling Tools

1 Spirit Level

1 Pickaxe

1 Round-end spade

1 Square-end spade

1 Wooden or Plastic lump hammer

1 Levelling board set (reference 3947251-10)

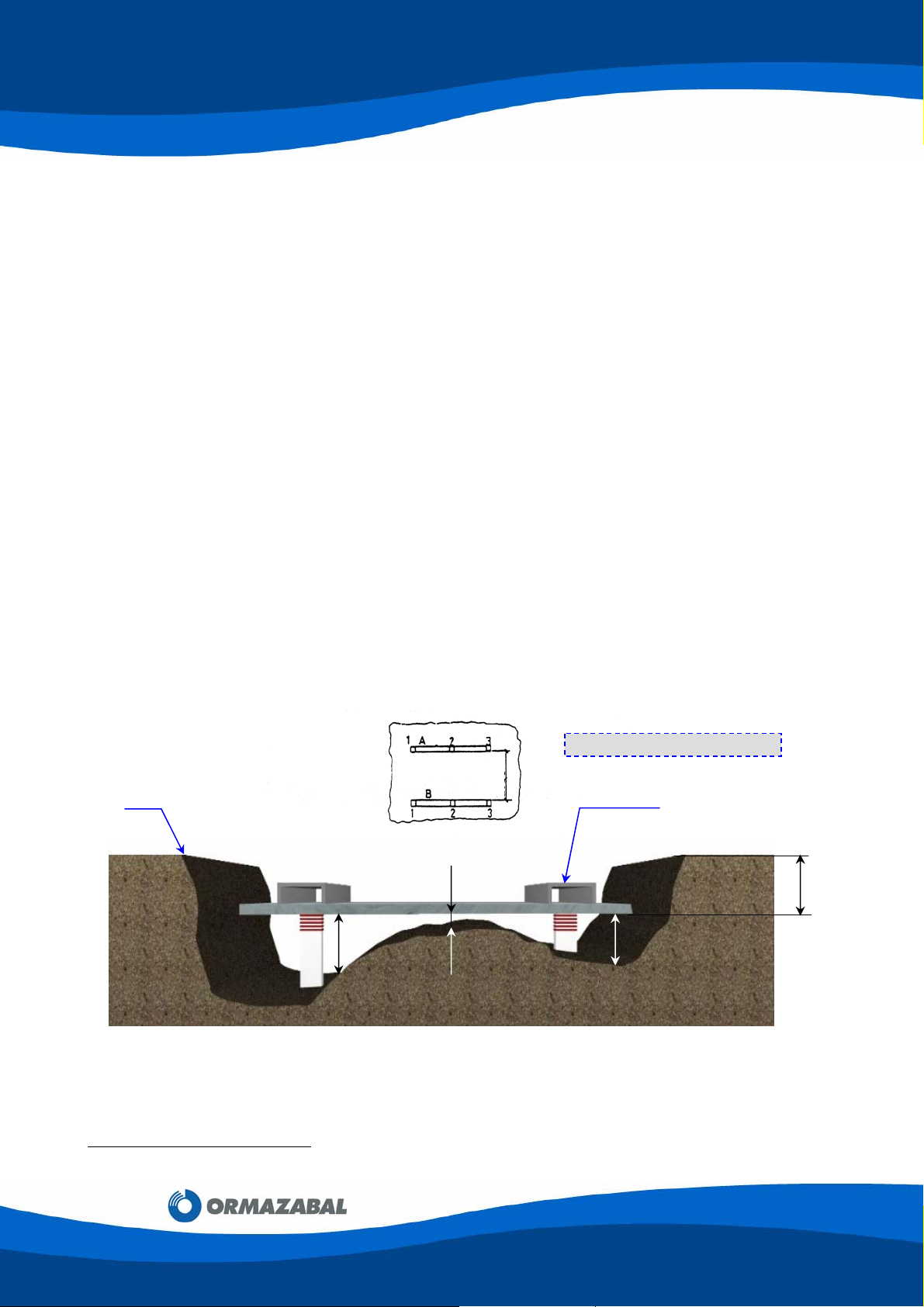

A) Normal Conditions

The levelling boards are placed according to the measurements on the drawing below

(the level of 3100 mm is a minimum value).

0 Level

A B

150

Figure 3.1: Levelling Specifications

Once the levelling rods have been positioned, the levelling boards should be used to check

that the ground is in perfect condition.

3100

20

Dimensions in millimeters

Levelling board

550

80

version 07

[5]

Consult Ormazabal’s Technical-Commercial Department.

Page 10 of 48

IG-021-GB

version 07

29.08.2008

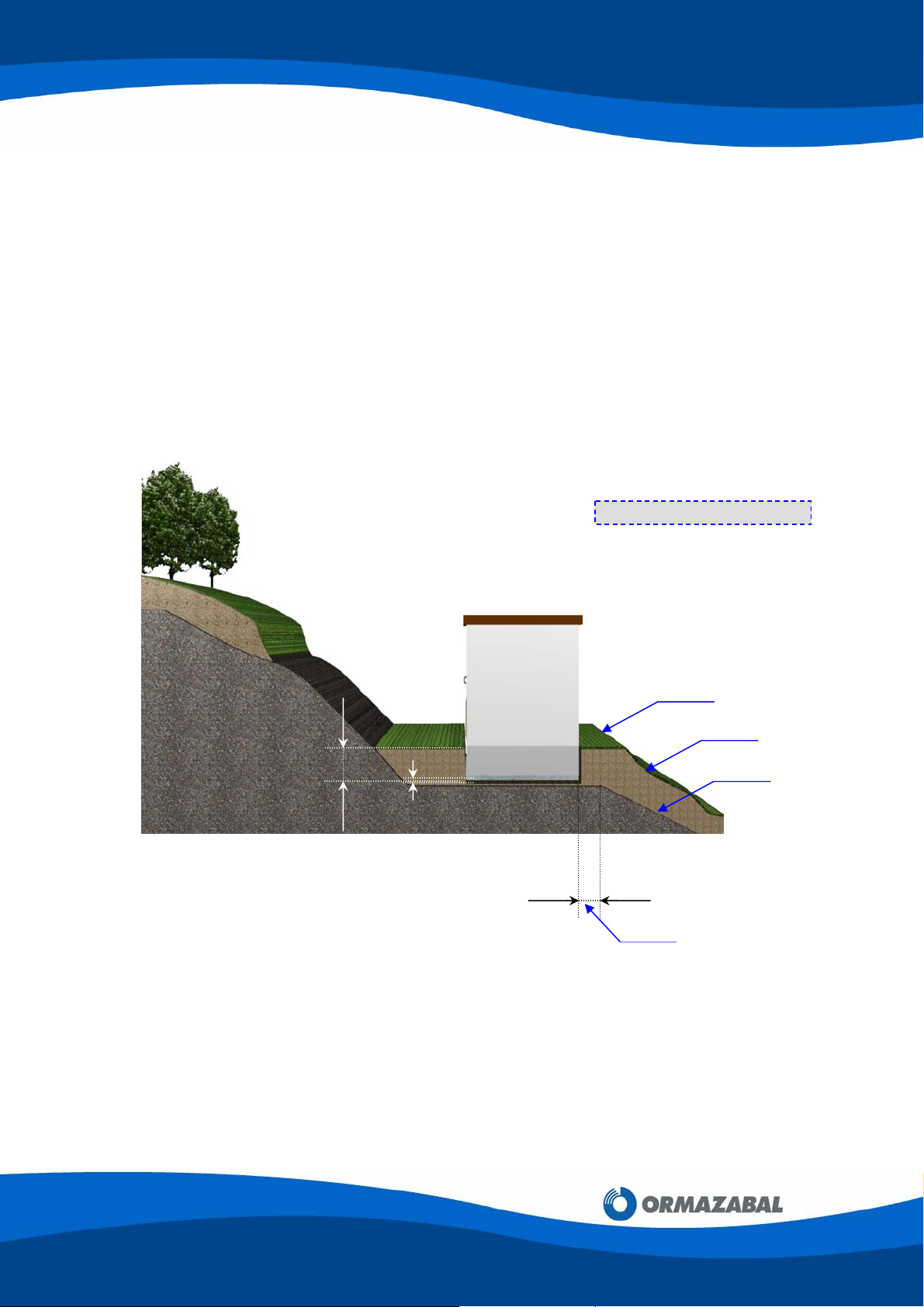

B) Sloping Grounds

The excavation should be prepared in such a way that the base platform is on a hard

area.

In these cases, it is essential that rainwater from the higher ground be channelled, to

avoid it washing the ground away from under the enclosure.

If there are any doubts concerning this subsequent channelling, it is best to use a

mixture of sand and cement when levelling the ground.

Example:

650

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

Dimensions in millimeters

0 Level

Landfill or vegetal matter

Hard ground

100

100

Minimum level

4848

Figure 3.2: Sloping Grounds

Page 11 of 48

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

C) Ground with a High Water Table

When there is a high water table, proceed as follows:

1) Establish the water table level.

2) Excavate no deeper than necessary, then level the ground as in sections A) and

B), above.

Example:

Water table

Figure 3.3: Ground with a High Water Table

IG-021-GB

version 07

29.08.2008

Dimensions in millimeters

0 Level

350

550

100

Page 12 of 48

IG-021-GB

version 07

29.08.2008

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

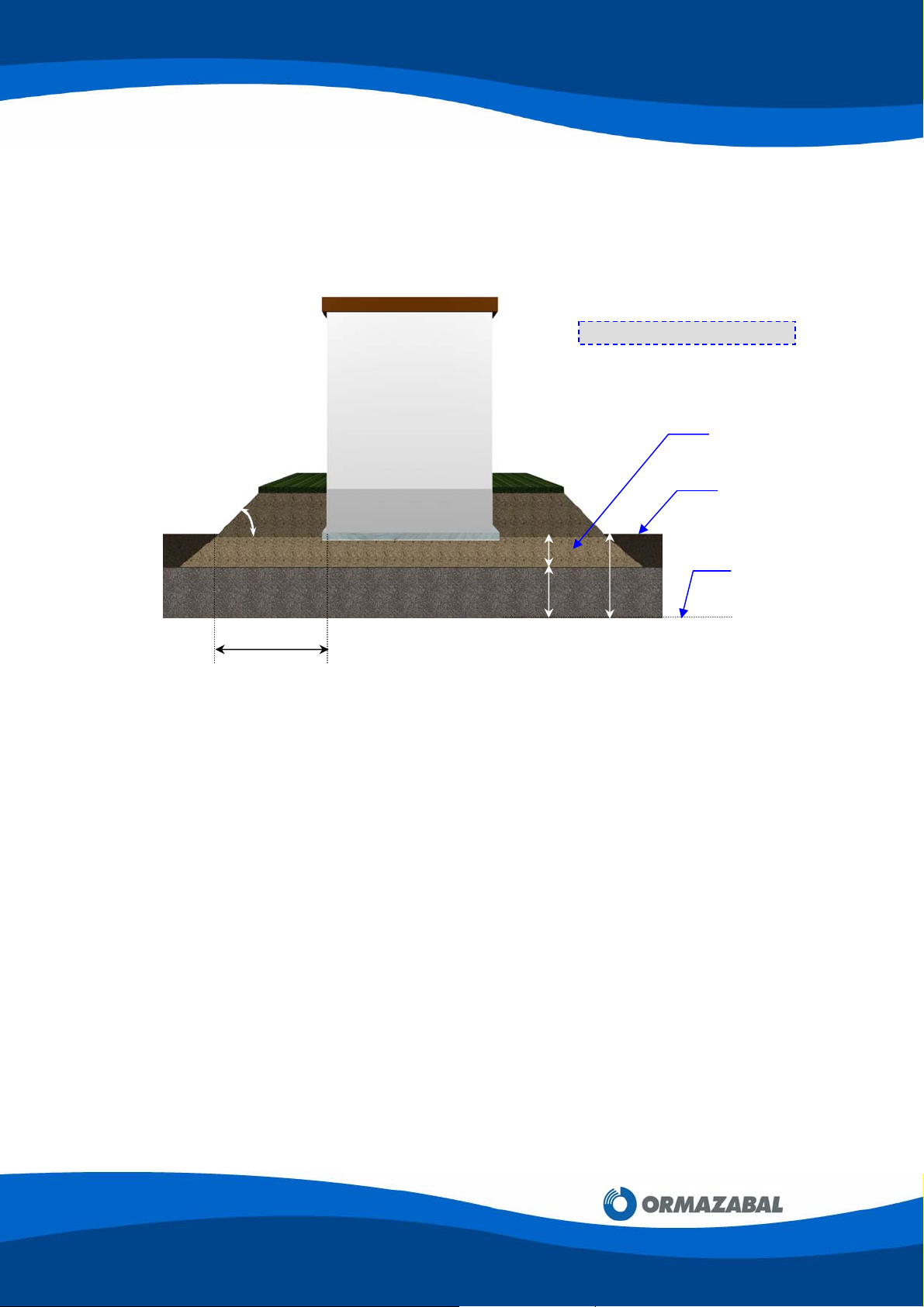

D) Grounds at Risk of Flooding

In these cases, the enclosure bottom plate should be raised to 100 mm above the

predicted flood level, and then level the foundations as in section A).

Example:

Dimensions in millimeters

45º

100 200

300

X

Figure 3.4: Grounds at Risk of Flooding

The landfill should be such that the distance X is at least 400 mm and the slope angle

is 45°.

A one-meter wide pavement around the enclosure is recommended.

Since these cases are found near rivers, the landfill must be firmly retained (with

concrete, rockfill, etc) to provide stability to the prefabricated enclosure.

3.5. HANDLING PANELS AND CONCRETE COMPONENTS

Predicted Flood Level

Landfill height

0 Level

Handling the concrete components correctly requires the following tools:

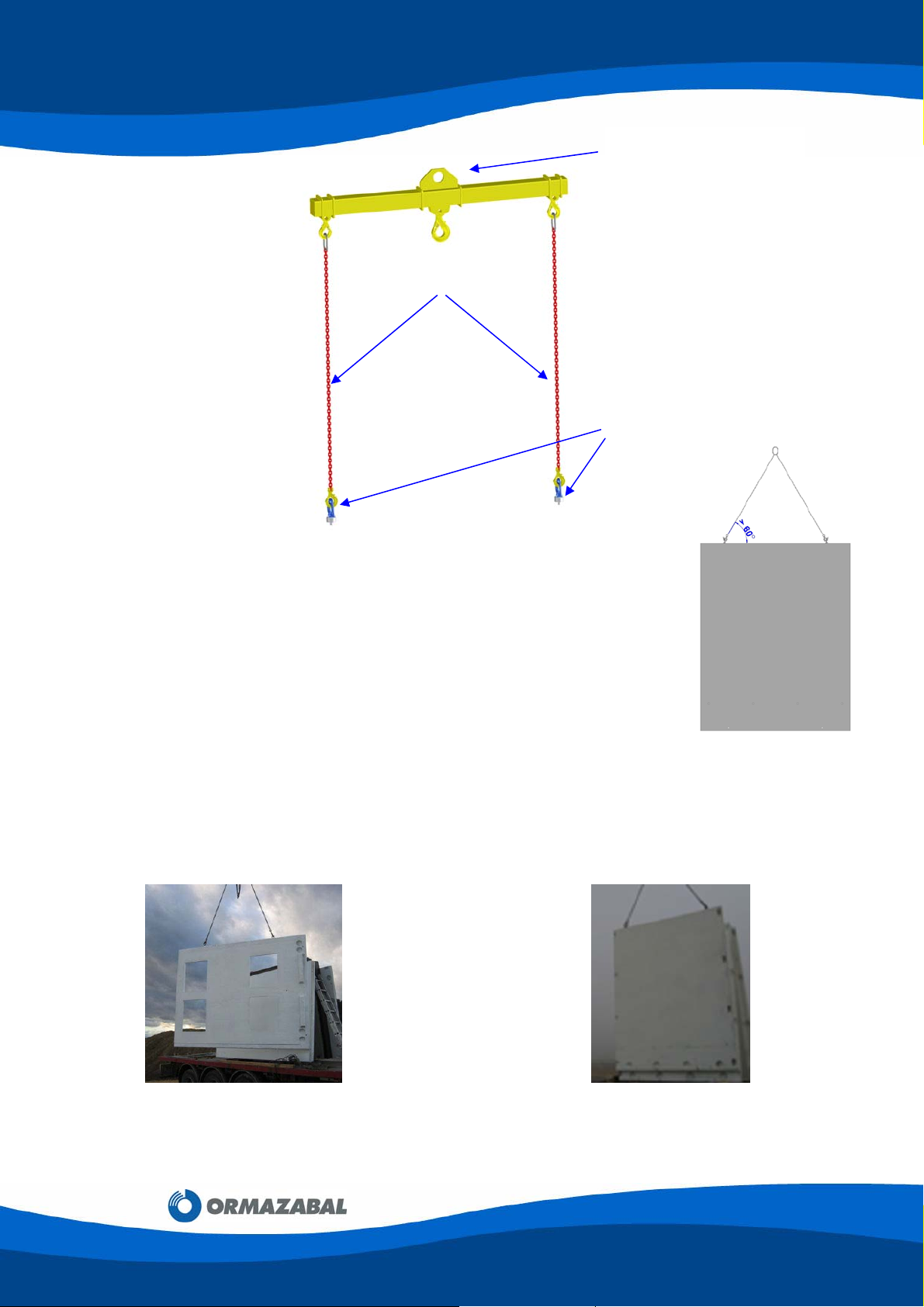

• Lifting beam (reference 160023, “PF 4 T Unloading Beam”)

• Sling set (reference 160024, “PF Unloading Slings”)

• Turning Eyebolts RD20 (reference160027)

4848

Page 13 of 48

GENERAL INSTRUCTIONS FOR PF

d

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

PF 4 T Unloading Beam

PF Unloading Slings

ref 160024

Turning Eyebolts RD20

Figure 3.5: Panel handling tools

To lift the components as evenly as possible, the lifting beam should be used

to handle all the concrete components.

The chains' angle of pull should be as vertical as possible (at least 60º from

horizontal).

Figure 3.6: Angle from the horizontal > 60º

3.5.1. PF-200 / 300 & PF-2015 / 3015 SERIES CONCRETE COMPONENTS

ref. 160023

ref 160027

IG-021-GB

version 07

29.08.2008

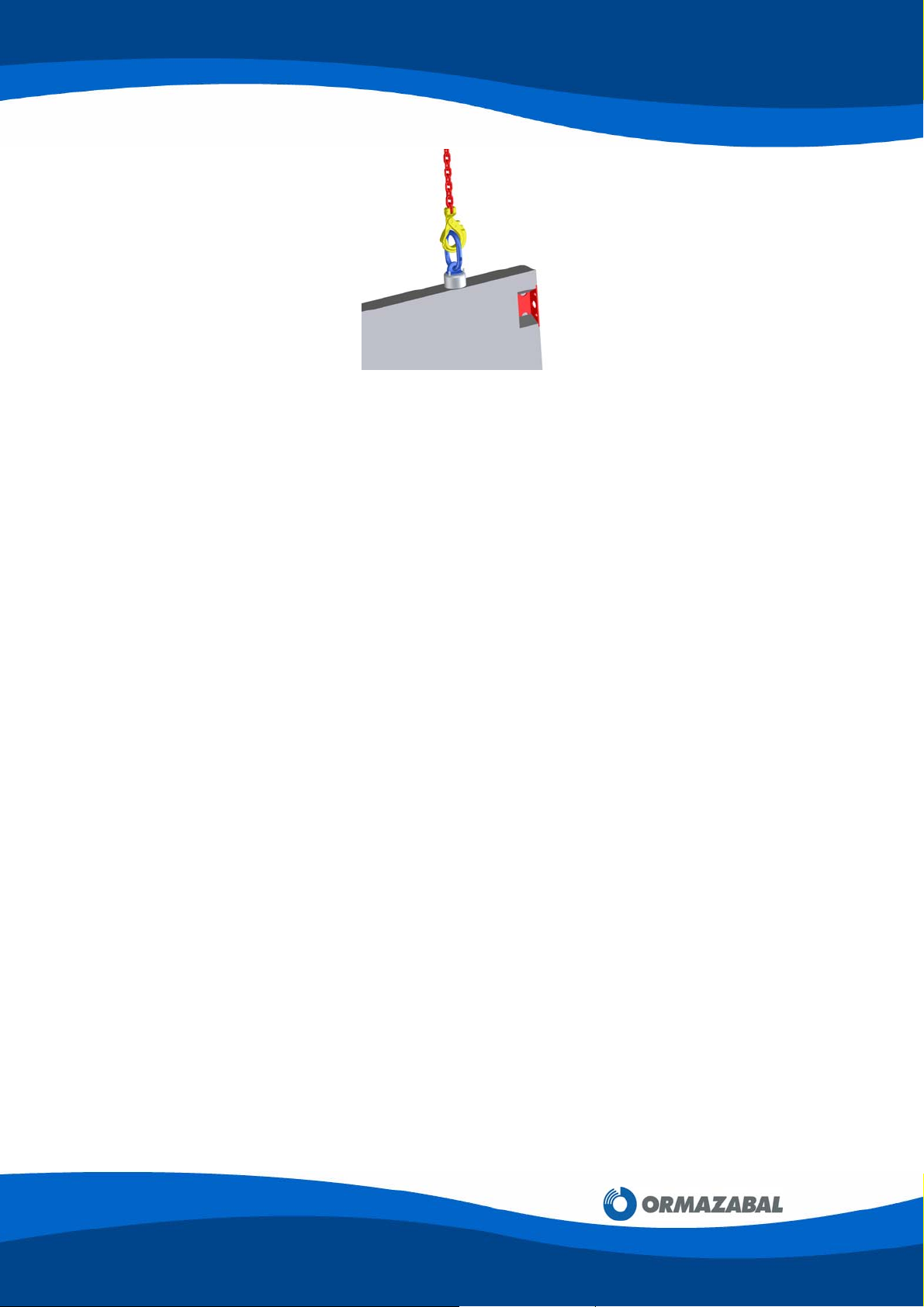

PF enclosure concrete components have RD20 threaded inserts embedded in the concrete;

therefore, the components can be lifted and handled with a crane by anchoring RD20

threaded turning eyebolts.

Figure 3.7: 200 series side panel transported horizontally an

handled with threaded eyebolts

Figure 3.8: 200 series front panel transported vertically

and handled with threaded eyebolts

Page 14 of 48

IG-021-GB

version 07

29.08.2008

Figure 3.9: Anchoring with threaded turning eyebolts

3.6. ASSEMBLING TOOLS

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

Proper assembly of the PF Modular Transformer Substations requires the following elements

to be available:

PF Assembling Prop (reference 160028)

The number of required props depends on the number of modules forming the

enclosure. PF-203 requires 3 props; PF-304 requires 4 props; PF-305 requires 5

props, etc.; therefore, the number of required props equals the number of modules

making up the enclosure.

1 ratchet wrench set

1 low-profile ratchet wrench (reference 394253-31, ‘PF Assembling Ratchet’)

2 ladders

1 brush

1 set of spanners and screwdrivers

Painting utensils, for painting the transformer substation or for retouching painted

panels.

For correct assembly of the panels, the enclosure foundations must be levelled with the

greatest care according to the instructions in section 3.4.

3.7. PF ENCLOSURE ASSEMBLY PROCESS

By way of example, the assembly process for a PF-205 enclosure with 2 transformers and

1 personnel access door is explained below.

The panels used to assemble the PF Modular Transformer Substations are grouped into two

classes, according to how they are assembled:

a) Horizontally-assembled panels: These are the bottom plates, floor plates and

covers.

b) Vertically-assembled panels: These are the front, back and side panels.

4848

Page 15 of 48

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

Before handling the panels, their assembling position, as well as the way they are

transported in the truck, must be considered. Taking this into account, the following cases

can be found:

a) Horizontally-assembled panels

These panels are transported on a trestle (although in exceptional cases bottom and floor

plates may also be transported lying flat on the truck bed), and they have two inserts in the

long edge where a crane can be attached to lift them off the truck and lay them flat on the

ground.

Once on the ground, or on the truck bed itself if they are transported flat, they should be lifted

using the 4 inserts in the panel and placed in their final positions.

Figure 3.10 Figure 3.11 Figure 3.12

b) Vertically-assembled panels

These panels are transported on a trestle, and they have 2 inserts in the long edge and 2 in

the short edge for their handling.

If they are transported horizontally (figure 3.13), they must be lifted by the long

edge and laid onto the ground (figure 3.14) in order to transfer the hooks to the short

edge and lift the panel to the vertical position as required for its final position

(figure 3.15).

Figure 3.13 Figure 3.14 Figure 3.15

IG-021-GB

version 07

29.08.2008

Page 16 of 48

IG-021-GB

version 07

29.08.2008

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

If they are transported vertically (figure 3.16), they should be lifted by the short side

and placed directly in their final position (figure 3.17).

Figure 3.16 Figure 3.17

3.7.1. Assembling Bottom Plates

After checking that the ground is correctly levelled, the enclosure assembly starts by placing

the first bottom plate in its final position. Check that the plate is properly levelled by means of

a hose level.

If the enclosure consists of more than one module, insert a 20 x 10 mm adhesive rubber strip

(reference 090006-33) in the joint between the different bottom plates.

Figure 3.18 Figure 3.19

Great care should be taken when installing this strip, since the sealing of the Transformer

Substation depends on it.

4848

Page 17 of 48

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

The strip should be inserted so that it projects up 3 - 4 mm in the slot area where the front

and rear panels will rest.

Figure 3.20: Area where the rubber strip

should project 3 - 4 mm

After the second or subsequent bottom plates are put into place, the plates should be firmly

bolted together using M16 x 40 nuts and bolts. After this, a flexible earthing cable must be

bolted in the angle bar of one of the slots in order to make up the earthing ring.

Figure 3.21 Figure 3.22: M16 x 40 nuts and bolts to join bottom plates

Figure 3.23

IG-021-GB

version 07

29.08.2008

Page 18 of 48

IG-021-GB

version 07

29.08.2008

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

For example, PF-205 uses 5 bottom plates and they are fitted as shown in the figure below:

Once the bottom plates are bolted together, brush clean the slots where the vertical panels

will rest.

Figure 3.24: Cleaning the slots

Next, insert the sealing strip between the bottom plates and the vertical panels, placing it in

the centre of the slots.

Double 20 x 10 mm rubber strips should be laid, and when two or more bottom plates are

used, the strips should run the entire length in one piece, leaving 3 - 4 mm projecting at each

end.

Figure 3.25

Figure 3.26: Area where the rubber strip Figure 3.27

should project 3-4 mm

4848

Page 19 of 48

IG-021-GB

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

version 07

29.08.2008

3.7.2. Assembling the Vertical Panels

Assembly of the vertical panels starts with a front panel on one of the end bottom plates.

Figure 3.28 Figure 3.29

In order to assemble the vertical panels, the assembling props must be employed (reference

160028, 'PF Assembling Prop').

The 2-piece telescopic PF panel assembling prop uses the available slots in both the

vertical panels and the bottom plates, so that the enclosures can be safely assembled.

These props must always be used in enclosures with 2 or more modules (PF-203/303,

PF-204/304, etc.)

Page 20 of 48

IG-021-GB

version 07

29.08.2008

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

Place the first back panel corresponding to one of the enclosure ends (in this example, the

left end) in its position in the bottom plate.

Fix the panel using the PF panel assembling prop, without releasing it from the chains that

keep it fastened to the crane.

In the bottom plates, the prop is fixed bolting 2 M10 screws in the end holes available in the

slot bars.

4848

Page 21 of 48

GENERAL INSTRUCTIONS FOR PF

r

r

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

In the vertical panel, the prop is fixed using an auxiliary assembling bar so that the panels

can be properly fastened.

When the next panel is joined, this bar will be removed.

Auxiliary assembling ba

IG-021-GB

version 07

29.08.2008

Once the prop is laid and fixed to the first panel, the panel can be released from the crane.

Fit the panel joining angle bars (reference 394256-64) to fix the panel to the bottom plate.

For this purpose, use M16 x 120 nuts and bolts with a plastic DUBO washer at the back.

Panel joining angle ba

ref. 394256-64

Page 22 of 48

IG-021-GB

version 07

29.08.2008

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

Figure 3.30 Figure 3.31: M16 x 120 nuts and Figure 3.32: Plastic DUBO washer

bolts to join front/rear panels

After attaching the first front panel, a side panel must be added to close off the corner.

All side panels have a 20 x 10 mm rubber strip placed as follows:

A continuous strip is placed around both sides and the bottom edge of the panel

(see figure 3.33.)

A second strip is placed around the inner bottom, reaching up the sides to a

height of 600 mm (see figures 3.34 and 3.35).

Figure 3.33

600

Figure 3.34 Figure 3.35

4848

Page 23 of 48

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

A 20 x 10 mm rubber strip is also placed along the edge of the bottom plate where

the side panel supports will rest (see figure 3.36).

Figure 3.36

This side panel is attached to the bottom plate using M16 x 120 screws, with an M16 plastic

DUBO washer on the outside.

Figure 3.37: M16x120 nuts and bolts to

attach side panels

Figure 3.38

IG-021-GB

version 07

29.08.2008

Page 24 of 48

IG-021-GB

version 07

29.08.2008

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

Next, the side panels and the front panels are attached using M16 x 30 screws.

Figure 3.39

Figure 3.40 Figure 3.41

View after laying and fixing the first side panel

4848

Page 25 of 48

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

3.7.3. Remaining Vertical Panels

Next, the remaining vertical panels are assembled, leaving the second side panel till last.

When assembling the panels, always bolt the end screws first, followed by the central

screws, since in panels with doorways, the doorframe concrete is very thin.

The front panels are joined together using M16 x 40 nuts and bolts (see figures 3.42 and

3.43); and the front panels are joined to the bottom plate using the 394256-64 flatbar:

'PANEL JOINING ANGLE BAR’ and M16 x 120 nuts and bolts, with the plastic DUBO washer

(see figures 3.36, 3.37 and 3.38.)

The rubber strips are installed in the front panels as follows (see figure 3.44):

A continuous strip is fitted along the full length of the panel side.

IG-021-GB

version 07

29.08.2008

A second strip is fitted at the inner lower part, reaching up a height of 600 mm.

Figure 3.42

600 mm

Figure 3.43 Figure 3.44

Page 26 of 48

IG-021-GB

version 07

29.08.2008

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

In PF-205 enclosures, after fitting the side panel, 2 front panels are fitted following the above

stated premises (section 3.7.3) to join panels to each other and to bottom plates.

Put a new prop in the second front panel in the opposite direction to the first one. As in the first

panel, use the auxiliary assembling bar to fasten a prop end to the panel and the other end straight

to the opposite bottom plate slot.

To assemble the second back panel, release the prop to remove the auxiliary assembling bar.

4848

Page 27 of 48

GENERAL INSTRUCTIONS FOR PF

A

r

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

Lay the second back panel and fit the prop again using the screws and fixing the 2 panels.

Afterwards, lay the next back panel (in this case, it is the third one) and follow the same

procedure as in the first panel to fit the assembling prop.

Fit the third assembling prop, in the same direction as the first one, using the auxiliary

assembling bar.

uxiliary assembling ba

IG-021-GB

version 07

29.08.2008

Page 28 of 48

IG-021-GB

version 07

29.08.2008

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

From here on, follow the same assembling sequence until all front and back vertical panels have

been fitted.

The props must be fitted in alternate directions.

4848

Page 29 of 48

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

Before laying the closing panel, remove the last prop fitted to finish so that the enclosure

closing can be finished.

3.7.4. Floor Plates, Slabs and Transformer Platform

IG-021-GB

version 07

29.08.2008

The floor plates are installed according to the assembling drawing, if any, as required by the

transformer substation configuration.

The procedure is as follows:

The floor plate supports are bolted to the front and rear panels using M12 x 180 screws

with a plastic DUBO washer on the outside.

Note: Remember that there are floor plates of different thicknesses that require supports of

different heights. Great care should be taken to use the correct supports for each floor plate.

Figure 3.45 Figure 3.46

Figure 3.47: M12x180 nuts and bolts

to join floor plate supports

Page 30 of 48

IG-021-GB

t

version 07

29.08.2008

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

Put two 20 x 10 mm rubber strips on these supports, in the areas where the floor plates

will rest.

In order to insert the floor plates, start releasing the first prop.

s

1

Prop

Afterwards, introduce the first floor plate through the enclosure upper part.

Figure 3.48 Figure 3.49

Fit the floor plate and then fasten the prop to the panels. Now the prop must be fixed to

the front panel slot located just above the floor plate, instead of the bottom plate. Keep

the same fixing slot in the back panel.

4848

Page 31 of 48

IG-021-GB

t

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

version 07

29.08.2008

Fixing the first prop after laying the floor plate.

1

s

Prop

Follow the same procedure to lay the next floor plates and transformer platforms,

according to the specific configuration of each transformer substation.

See the prop position after fitting the floor plates and transformer platforms.

Page 32 of 48

IG-021-GB

version 07

29.08.2008

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

Put a 4 x 15 mm rubber strip around the slots where the slabs will rest (reference

090005-22), so that the slabs can be better settled.

Figure 3.50

The transformer platform locations depend on the TS configuration. Before installing them,

a 20 x 10 mm sealing rubber strip should be placed around the bottom edge.

Figure 3.51 Figure 3.52

When the transformer is to be introduced through the transformer door rather than through

the roof, the transformer platform should be located as close as possible to the door, in order

to facilitate this operation.

Next, the fire barrier tray for the platform must be put into place and adjusted with its 6

supports.

A layer of pebbles is added to the tray, to act as fire barrier.

Figure 3.53: Fire barrier tray

4848

Page 33 of 48

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

3.7.5. Cubicles and Transformer

Depending on the Transformer Substation configuration, including the interior equipment, the

various props may have to be released to lay this equipment.

If possible, the cubicles and transformer should be installed in the positions corresponding to

the configuration before the covers are put on.

Figure 3.54

3.7.6. Low Voltage Board

IG-021-GB

version 07

29.08.2008

To install the LV boards, the 20 mm thick layer of the floor plates should be broken and the

LV boards should be attached to the floor plate using M12 x 120 screws.

Figure 3.55

Page 34 of 48

IG-021-GB

version 07

29.08.2008

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

3.7.7. Transformer Protection Fences

The transformer protection fences are inserted through the roof using the crane and are

attached to the floor plate and to the front and rear panels.

Figure 3.56 Figure 3.57

3.7.8. Covers

The covers are lowered onto the vertical panels using the crane.

Figure 3.58 Figure 3.59

Figure 3.60: M16 x 40 nuts and bolts to join the covers

Figure 3.61

Once the first roof panel is in place, and if two or more modules are being used, two

20 x 10 mm rubber strips must be inserted into the joint between the different covers, and

these must be tightly bolted together using M16 x 40 nuts and bolts.

4848

Page 35 of 48

GENERAL INSTRUCTIONS FOR PF

t

t

r

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

After laying the cover, this module's prop can be removed, if it has not already been done.

s

1

Prop 1

s

Cove

Finish the process by assembling all the covers and releasing the corresponding props.

IG-021-GB

version 07

29.08.2008

Page 36 of 48

IG-021-GB

version 07

29.08.2008

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

3.7.9. Ventilation Grilles

Before mounting the ventilation grilles, a 4 x 15 mm rubber strip should be placed on the top

edge of the concrete in order to prevent water from getting in.

Figure 3.62 Figure 3.63

Figure 3.64 Figure 3.65

The grilles are inserted from outside to inside, engaging the bottom edge first and then

bolting the angle bars at the top of the grilles firmly to the concrete wall.

4848

Page 37 of 48

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

3.7.10. Doors

The doors are hung on the hinges, which first have to be mounted in the holes that exist in

the panels for this purpose.

Figure 3.66

Figure 3.67 Figure 3.68

Figure 3.69: Installed door

IG-021-GB

version 07

29.08.2008

Page 38 of 48

IG-021-GB

version 07

29.08.2008

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

3.7.11. Low Voltage Auxiliary Feeder

A 140 mm diameter hole, located in the front panel and close to the doors, allows the LVB to

be fed by an external temporary feeder.

This auxiliary input is located 2000 mm above level 0 and can be closed using a cover that

assures an IP 23D rating.

This cover can only be removed by manually loosening the wing nut and unscrewing it from

inside the enclosure.

The following figure shows an example of LV feeder hole location in relation to a transformer

door.

TRANSF.

DOOR

Location of LV auxiliary input in PF enclosures

STAFF

DOOR

Dimensions in millimeters

For PF Transformer Substations with 2 transformers, a LV auxiliary input is available for each

of the transformers.

4848

Page 39 of 48

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

3.8. CONNECTING THE EARTH CIRCUIT

3.8.1. Panel Reinforcing Mesh

The panel reinforcing mesh is connected to earth via some of their slots or via inserted nuts.

Each type is described below:

Bottom plates

The reinforcing mesh in the bottom plates is connected to earth via all of their slots.

Front Panels

These have earth connections in the 2

Side Panels

These have earth connections in the 2

Floor plates

These have an M12 threaded insert for the earth connection.

Covers

The covers have earth connections in their end slots, except for single-module

covers, that have an M12 nut for the earth connection.

To allow correct earthing, PF Modular Transformer Substations have an interior protective

earthing circuit that allows the entire concrete enclosure to form an equipotential surface.

The reinforcing meshes in the different concrete components are connected together as

follows:

1. The vertical panels are joined mechanically.

nd

and 4th slots, counted from the bottom.

nd

and 4th nuts, counted from the bottom.

IG-021-GB

version 07

29.08.2008

2. The joints between covers, and between these and the vertical panels, are made

Page 40 of 48

using a 50 mm

2

cross-section bare cooper wire between the suitable slots, except in

the case of a single-module covers where the connection is made between the M12

nut and the slot in the front or rear panels.

Figure 3.70

IG-021-GB

version 07

29.08.2008

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

3. The connection between the system formed by the panels mentioned above and the

various floor panels is achieved using a 50 mm

2

cross-section bare copper wire,

between the M12 threaded inserts in each floor plate and the nearest earthing slot to

the front or rear panels.

Figure 3.71

4. The bottom plates are joined mechanically. These are connected to the vertical

panels using a 50 mm

which in the vertical panels are those above the floor (2

2

cross-section bare copper wire between the suitable slots,

nd

and 4th).

Figure 3.72

4848

Page 41 of 48

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

3.8.2. Earthing Circuit

The doors and ventilation grilles are not connected to earth unless specified and accepted by

the customer.

Once the different metallic elements in the concrete reinforcement mesh have been

connected, the reinforcement mesh must be connected to the prepared internal earthing

circuit.

This connection is made to one of the slots in the bottom plates, which is connected to the

external earth electrodes through a hole previously moulded that is then sealed.

The Transformer Substation installation project must include a section corresponding to the

execution of the earthing installation (check the Utility’s standard project), as well as

justification of its sizing The requirements for this type of installation are established in the

Regulations on Power Plants, Substations and Transformer Substations.

The copper connector cross-section, the terminal contact surface and tightening torques

must be suitable for a default current delimited by network protections. A protection earth

network of 50 mm

2

minimum cross-section copper wire is recommended.

Where maintaining the values of the step and touch voltages within the limits laid down in the

applicable Regulations is not viable, the owner of the installation must apply at least one of

the additional safety measures laid down in the said regulation in order to reduce personal

and material hazards.

The tightening torque recommended for electrical connections in the earthing network is

shown in the following table:

METRICS

M8 21

M10 38

M12 60

TIGHTENING TORQUE [Nm]

8.8 Steel A2 Stainless

IG-021-GB

version 07

29.08.2008

Page 42 of 48

IG-021-GB

version 07

29.08.2008

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

3.8.3. Earthing Ring

The use of an earthing ring around PF Modular Transformer Substations is recommended.

The following configuration is offered as an example. The earthing network should be

calculated in accordance with the standard project for Transformer Substation installation,

which is available from the Utility.

EARTHING RING

The construction of an earthing ring

600 mm underground is

recommended. This ring should

consist of a continuous bare copper

wire with a 50 mm

The wire should continue into the

inside of the TS where it is connected

to the enclosure earthing bar.

2

cross-section.

ENCLOSURE

PF-201/PF-301 2620

PF-202/PF-302 4880

PF-203/PF-303 7240

PF-204/PF-304 9600

PF-205/PF-305 11960

PF-2015/PF-3015 3700

PF-2030/PF-3030 7240

PF-3035 8420

[6]

L [mm]

[6]

For other configurations of PF TS, consult Ormazabal’s Technical - Commercial Department.

4848

Page 43 of 48

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

4. MAINTENANCE

4.1. REMOVING THE SIDE COVERS

Undo and remove the joint screws.

Using a crane, lift the cover, pulling it outwards and taking care not to pull off the

sealing rubber strip.

Rest this lifted cover on another of the covers.

Change the equipment as required.

Replace the cover, checking the sealing of the rubber strip, and reset the joint.

4.2. REMOVING THE CENTRAL COVERS

Undo and remove the joint screws.

IG-021-GB

version 07

29.08.2008

Move the side covers 100 mm outwards, taking care not to pull off the rubber strip.

Using a crane, lift up the panel that is to be removed.

Rest this lifted cover on another of the covers.

Change the equipment as required.

Replace every cover, checking the sealing of the rubber strip, and reset the joint.

Page 44 of 48

IG-021-GB

version 07

29.08.2008

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

NOTES

4848

Page 45 of 48

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

IG-021-GB

version 07

29.08.2008

Page 46 of 48

IG-021-GB

version 07

29.08.2008

GENERAL INSTRUCTIONS FOR PF

MODULAR ENCLOSURES FOR

TRANSFORMER SUBSTATIONS

4848

Page 47 of 48

TECHNICAL - COMMERCIAL DEPARTMENT:

www.ormazabal.com

Page 48 of 48

Loading...

Loading...