Ormazabal ekor.rpa, ekor.rpa-110, ekor.rpa-110-v, ekor.rpa-120, ekor.rpa-110-p General Instructions Manual

...

ekor.rpa

Protection, metering and control

multifunction unit

General Instructions

IG-267-EN, version 01, 07/04/2017

LIB

CAUTION!

When medium-voltage equipment is operating, certain components are live, other parts may be in movement and some may

reach high temperatures. Therefore, the use of this equipment poses electrical, mechanical and thermal risks.

In order to ensure an acceptable level of protection for people and property, and in compliance with applicable environmental

recommendations, Ormazabal designs and manufactures its products according to the principle of integrated safety, based on

the following criteria:

• Elimination of hazards wherever possible.

• Where elimination of hazards is neither technically nor economically feasible, appropriate protection functions are

incorporated in the equipment.

• Communication about remaining risks to facilitate the design of operating procedures which prevent such risks,

training for the personnel in charge of the equipment, and the use of suitable personal protective equipment.

• Use of recyclable materials and establishment of procedures for the disposal of equipment and components so

that once the end of their service lives is reached, they are duly processed in accordance, as far as possible, with the

environmental restrictions established by the competent authorities.

Consequently, the equipment to which the present manual refers complies with the requirements of section 11.2 of Standard

IEC 62271-1. It must therefore only be operated by appropriately qualified and supervised personnel, in accordance with the

requirements of standard EN 50110-1 on the safety of electrical installations and standard EN 50110-2 on activities in or near

electrical installations. Personnel must be fully familiar with the instructions and warnings contained in this manual and in other

recommendations of a more general nature which are applicable to the situation according to current legislation

The above must be carefully observed, as the correct and safe operation of this equipment depends not only on its design but also

on general circumstances which are in general beyond the control and responsibility of the manufacturer. More specifically:

• The equipment must be handled and transported appropriately from the factory to the place of installation.

• All intermediate storage should occur in conditions which do not alter or damage the characteristics of the equipment

or its essential components.

• Service conditions must be compatible with the equipment rating.

• The equipment must be operated strictly in accordance with the instructions given in the manual, and the applicable

operating and safety principles must be clearly understood.

• Maintenance should be performed properly, taking into account the actual service and environmental conditions in

the place of installation.

The manufacturer declines all liability for any significant indirect damages resulting from violation of the guarantee, under any

jurisdiction, including loss of income, stoppages and costs resulting from repair or replacement of parts.

[1]

.

Warranty

The manufacturer guarantees this product against any defect in materials and operation during the contractual period. In the

event that defects are detected, the manufacturer may opt either to repair or replace the equipment. Improper handling of this

equipment and its repair by the user shall constitute a violation of the guarantee.

Registered Trademarks and Copyrights

All registered trademarks cited in this document are the property of their respective owners. The intellectual property of this manual

belongs to Ormazabal.

[1]

For example, in Spain the “Regulation on technical conditions and guarantees for safety in high-voltage electrical installations” – Royal Decree

337/2014 is obligatory.

In view of the constant evolution in standards and design, the characteristics of the elements contained in this manual are subject

to change without prior notice. These characteristics, as well as the availability of components, are subject to confirmation by

Ormazabal.

General Instructions

ekor.rpa

Contents

Contents

1. General description ..................................................5

1.1. General operating features ...................6

1.2. Components.................................7

1.2.1. Electronic relay ..............................8

1.2.2. Current sensors ..............................9

1.2.3. Voltage sensors ..............................9

1.2.4. “Binox” bistable tripping device and

tripping coil ................................10

1.3. Functionality of the unit.....................10

1.4. Communications............................11

2. Applications .............................................................12

2.1. Remote control of transformer and

distribution substations .....................12

2.2. Automatic reclosing of lines .................12

2.3. Line protection with circuit-breaker..........13

2.4. Transformer protection......................14

2.5. Automatic transfer . . . . . . . . . . . . . . . . . . . . . . . . . .16

2.6. Detection of phase with earthing............16

2.7. Protection and control of

MV interconnection stations.................17

2.8. Energy balances ............................17

3. Metering functions ..................................................18

3.1. Current and voltage metering ...............18

3.2. Power meterings............................19

3.3. Energy meter ...............................19

4. Protection functions ................................................20

4.1. Overcurrent units ...........................20

4.1.1. Timed overcurrent units.....................20

4.1.2. Instantaneous overcurrent units.............21

4.1.3. Block diagram ..............................21

4.2. Ultra-sensitive earth.........................22

4.3. Directional units ............................23

4.3.1. Phase directional units ......................23

4.3.2. Neutral and sensitive neutral

directional units ............................24

4.4. Thermal image unit .........................25

4.4.1. Estimated thermal capacity..................26

4.4.2. Functionality................................27

4.4.3. Block diagram ..............................28

4.5. Broken conductor unit ......................29

4.5.1. Calculation of sequence currents ............29

4.5.2. Functionality................................32

4.5.3. Block diagram ..............................32

4.6. Voltage units ...............................33

4.6.1. Timed overvoltage units ....................34

4.6.2. Instantaneous overvoltage units.............34

4.6.3. Timed undervoltage units...................35

4.6.4. Instantaneous undervoltage units ...........35

4.6.5. Block diagram ..............................36

4.7. Second harmonic blocking unit .............37

4.7.1. Functionality................................37

4.7.2. Block diagram ..............................39

4.8. Block by I

5. Detection, automation and control functions .......42

5.1. Recloser automation ........................42

5.1.1. Functionality................................42

5.1.2. VREF........................................42

5.1.3. Settings ....................................43

5.1.4. Recloser statuses............................43

5.2. Voltage presence/absence automation ......45

5.2.1. Functionality................................45

5.2.2. Settings ....................................45

5.2.3. Voltage presence/absence

automation statuses ........................45

5.3. Switch control ..............................46

5.3.1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

5.3.2. Settings ....................................46

5.3.3. Switch control statuses......................47

5.4. Remote control .............................47

6. Sensors ......................................................................48

6.1. Current sensors .............................48

6.1.1. Functional characteristics

of current sensors...........................49

6.1.2. Vector sum/zero-sequence wiring ...........50

6.2. Voltage sensors .............................51

6.2.1. Bushing ....................................51

6.2.2. ekor.evt-c ..................................52

7. Technical characteristics of the equipment ...........53

7.1. Rated values ................................53

7.2. Mechanical design ..........................53

7.3. Insulation tests..............................54

7.4. Electromagnetic compatibility...............54

7.5. Climatic tests ...............................55

7.6. Mechanical tests ............................55

7.7. Power tests .................................55

7.8. CE Conformity ..............................55

.................................41

max

IG-267-EN versión 01; 07/04/2017

3

Contents General Instructions

ekor.rpa

8. Protection, metering and control models .............56

8.1. Description of models vs functions ..........56

8.1.1. ekor.rpa-110................................58

8.1.2. ekor.rpa-120................................58

8.1.3. ekor.rpa-100-v/ekor.rpa-100-p..............59

8.1.4. Relay configurator ..........................60

8.2. “v” ekor.rpa-110-v and ekor.rpa-120-v

type units...................................61

8.2.1. Functional description ......................61

8.2.2. Definition of digital inputs/outputs .........62

8.2.3. Installation in a cubicle......................63

8.2.4. Checking and maintenance .................64

8.3. “p” ekor.rpa-110-p and ekor.rpa-120-p

type units ..................................66

8.3.1. Functional description ......................66

8.3.2. Definition of digital inputs/outputs ..........67

8.3.3. Fuse protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

8.3.4. Installation in a cubicle......................71

8.3.5. Checking and maintenance .................72

9. User configuration settings .....................................73

9.1. Local protection and automation settings ...73

9.2. Date and time settings ......................79

9.3. Remote communication settings ............79

11. User interface ...........................................................85

11.1. Web server. Checking and

configuring parameters .....................85

11.1.1. Characteristics of the Web server ............85

11.1.2. Access to the Web server: Local and

remote access ..............................86

11.2. Keyboard/Display ..........................90

11.2.1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

11.2.2. Display screen ..............................91

11.2.3. Error codes .................................96

11.3. Fileserver in USB memory ...................97

11.3.1. Connection to the system ...................97

11.3.2. Use of the interface .........................98

11.3.3. ekor.soft-xml ............................. 100

12. Communications ................................................... 102

12.1. Physical medium: RS-485.................. 102

12.1.1. MODBUS protocol ........................102

12.1.2. PROCOME protocol .......................107

12.2. Physical medium: Ethernet ................110

12.3. Physical medium: Mini-USB................111

13. Annex ..................................................................... 112

10. Log record .................................................................80

10.1. Fault report ................................80

10.1.1. Data capture logic ..........................80

10.1.2. Structure of the report ......................81

10.1.3. List of available signals .....................82

10.2. Event record ................................84

4

IG-267-EN versión 01; 07/04/2017

General Instructions

ekor.rpa

1. General description

General description

Within the ekor.sys family, the ekor.rpa range of protection,

metering and control units groups together a series of

multifunctional devices. Depending on the model, the

equipment can incorporate voltage and current functions,

along with automation functions, local/remote control,

etc. All these functions are related to current and future

automation, control and protection requirements in

switching and transformer substations.

As a result of new demands in supply quality, there is an

increasing need for automation in distribution networks

and for equipment to carry out metering and control

supervision functions for the switch in distribution cubicles.

The ekor.rpa-100 protection, metering and control units

have been designed to meet these needs, in accordance

with national and international standard requirements and

recommendations that are applied to each part that makes

up the unit:

• EN 60255, EN 61000, EN 62271-200, EN 60068, EN 60044.

• IEC 60255, IEC 61000, IEC 62271-200, IEC 60068, IEC 60044,

IEC 61958.

Integrating the ekor.rpa units in the Ormazabal cubicle

system allows specific products for requirements in different

facilities.

2. Delivering the complete integrated solution (cubicle +

relay + sensors) reduces handling of interconnections

when installing the cubicle in the network connection.

The only connection necessary is the medium-voltage

cables (MV). The possibility of wiring and installation

errors is removed, thus minimising commissioning time.

3. Voltage and current sensors are installed in the cubicle

cable bushing. Metering of V, I, P, Q and energies are

obtained without the need for voltage transformers.

4. All the units are factory installed, adjusted and checked;

each piece of equipment (relay + control + sensors)

also undergoes a comprehensive check before being

installed. The final unit tests are carried out once the

unit is incorporated in the cubicle before delivery.

5. Current metering is carried out by current sensors

with a high transformation ratio, making it possible for

the same equipment to detect a wide range of power

levels. This is possible thanks to the high sensitivity and

low noise of the relay's analogue channels.

The ekor.rpa-100 units in the ekor.rpa range have outputs

to, either locally or remotely, open and close the switch

in the cubicle where it is installed. Furthermore, the

equipment series has inputs which receive the status of the

cubicle switch.

The ekor.rpa-100 units also have the following benefits

compared to conventional systems:

1. The remote control unit (RTU or Remote Terminal Unit)

and protection are integrated in the cubicle in a compact

manner, simplifying the solution and minimising the

need to install control boxes on the cubicles.

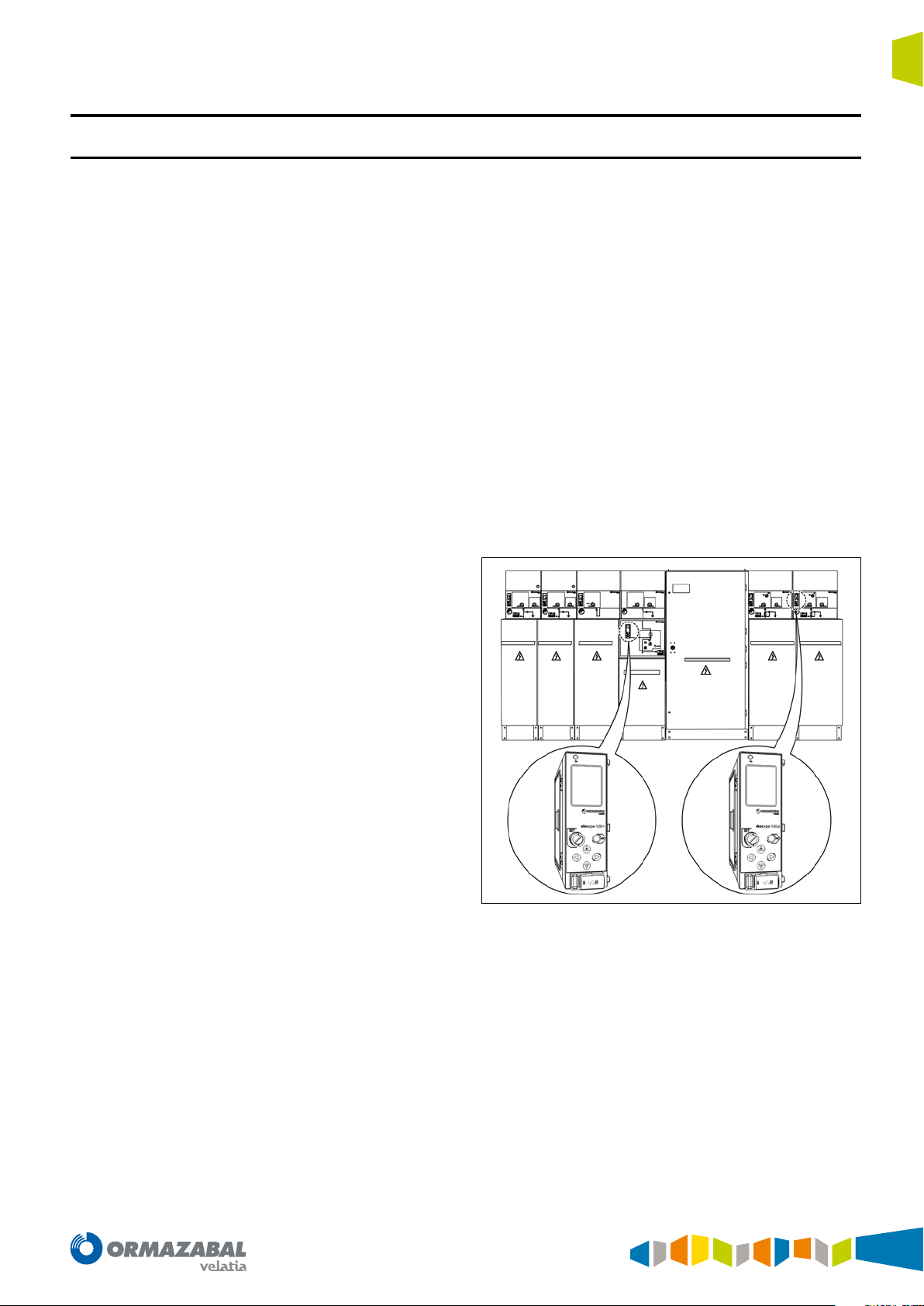

Figure 1.1. Protection, metering and control units: ekor.sys family

IG-267-EN versión 01; 07/04/2017

5

General description General Instructions

ekor.rpa

1.1. General operating features

All the relays of the ekor.rpa-100 series include a

microprocessor for processing the metering sensor signals.

They process voltage and current meterings and eliminate

the influence of transient states, calculate the magnitudes

required to ensure current and voltage protection functions,

automation, etc. At the same time they calculate the

efficient values of the electrical meterings that report the

instantaneous value of these parameters of the installation.

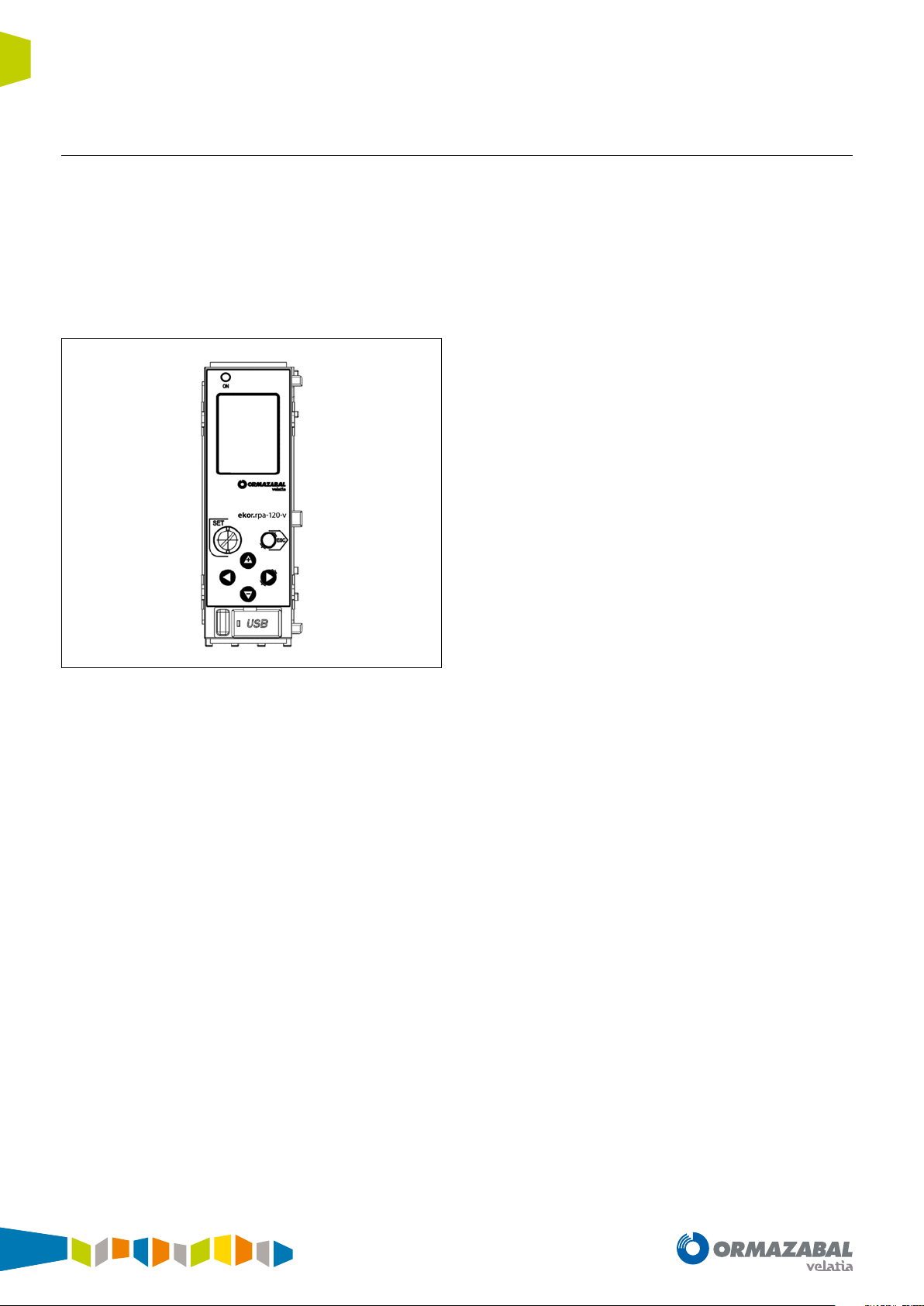

Figure 1.2. ekor.rpa-100 series relay

The ekor.rpa-100 relays are equipped with a keypad for

local display, set-up and operation of the unit, as well as

communication ports to handle these functions from a PC,

either locally or remotely. The ergonomic keyboard menus

have been designed to make use as intuitive as possible.

Current metering is carried out via high transformation

ratio current sensors. These transformers or current sensors

maintain the accuracy class in all of their rated range.

Voltage metering is normally by capturing the voltage

signal using a capacitor divider built into the cubicle's

bushing. There is an option of installing ekor.evt-c external

capacitive voltage sensors for applications which require

high-voltage metering precision, such as applications with

MV network energy meters.

The different interfaces, local (display) or remote (Web), also

provide settings parameters, logs, events, etc., in addition

to instantaneous values for metering of currents, voltages,

powers and energies.

From a maintenance perspective, the ekor.rpa-100 units

have a series of features that reduce the time and the

possibility of errors in the test and service restoration tasks.

Among the main characteristics, the most prominent are

the large diameter toroidal-core current transformers

installed in the cubicle bushing, their built-in test bars

(for easier checking), and accessible terminal blocks for

current or voltage injection tests as well as for checking

the relay inputs and outputs. This configuration enables a

comprehensive testing of the unit.

6

IG-267-EN versión 01; 07/04/2017

General Instructions

ekor.rpa

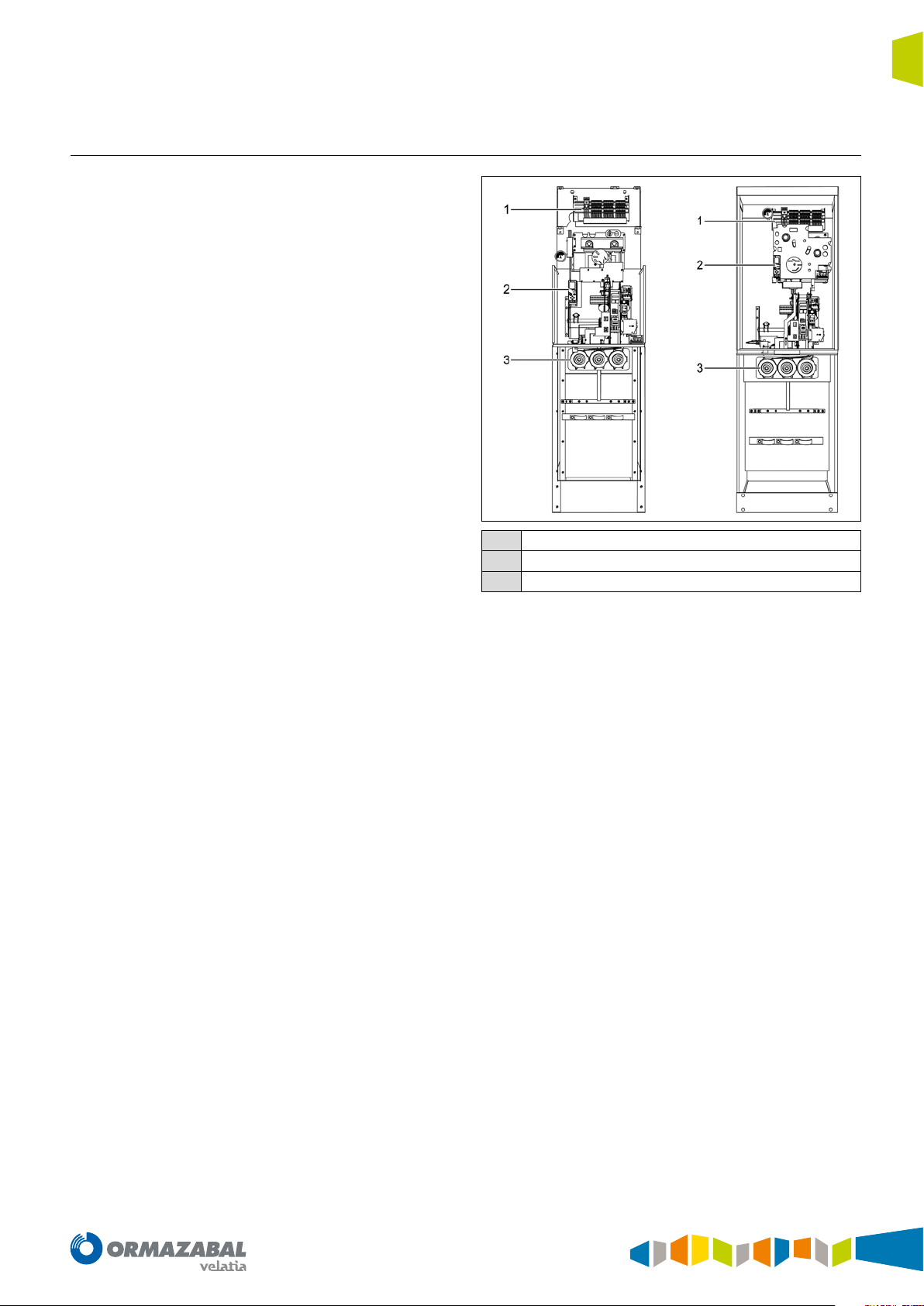

1.2. Components

The parts which make up the ekor.rpa-100 protection,

metering and control series are the electronic relay, voltage

and current sensors, auxiliary circuits (terminal block and

wiring), the bistable release and the tripping coil.

General description

Terminal block

1

ekor.rpa electronic relay

2

Voltage and current sensors

3

Figure 1.3. Parts of the assembly of ekor.rpa-100 in cubicle

IG-267-EN versión 01; 07/04/2017

7

General description General Instructions

ekor.rpa

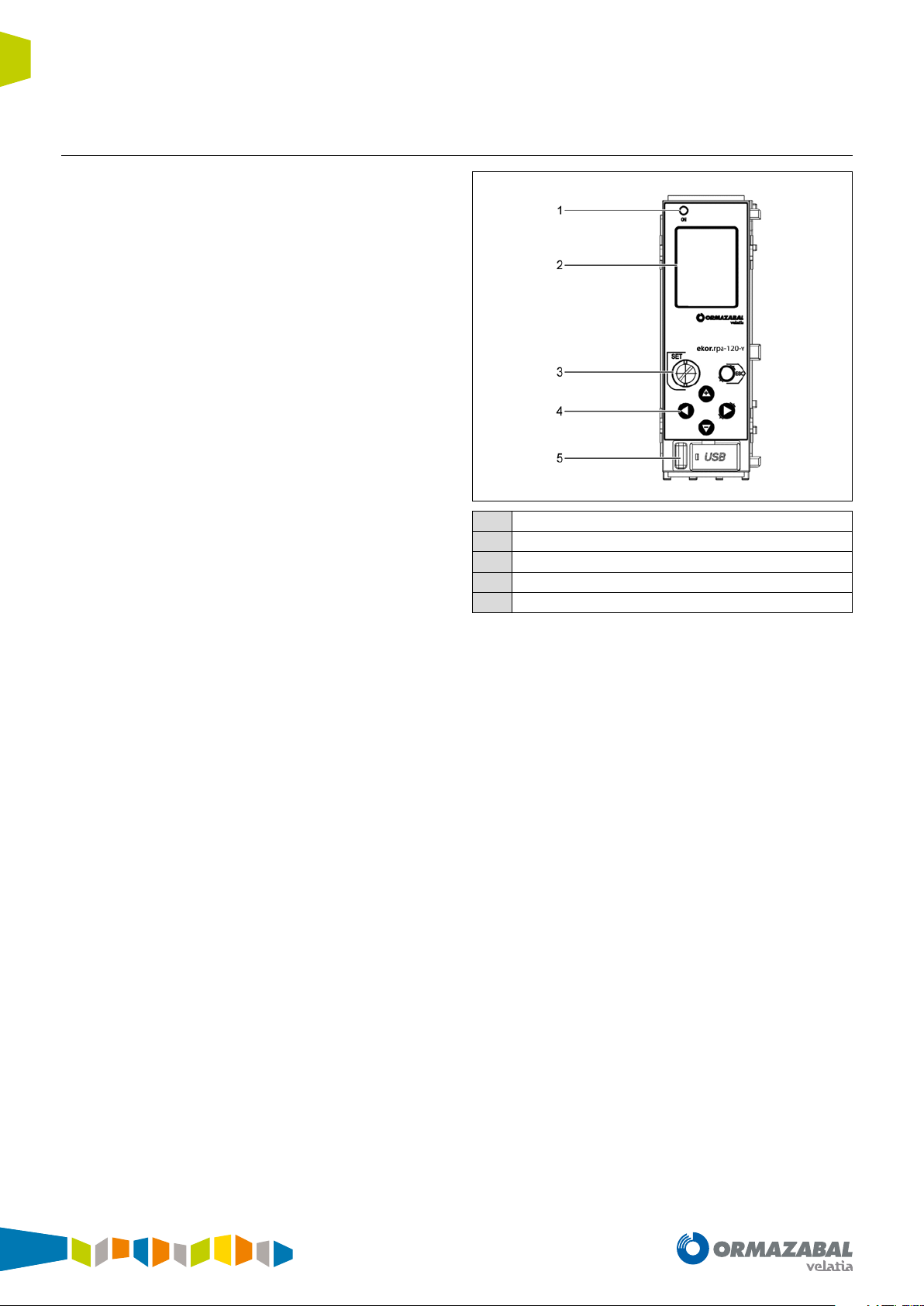

1.2.1. Electronic relay

The electronic relay has a keyboard and display to set and

view the protection and control parameters. Moreover, the

display provides information of the system's meterings,

alarms and control signals in real time. The keyboard

includes a seal on the <<SET>> key to ensure that once the

settings have been made they cannot be changed unless

the seal is broken.

The protection trips are registered on the display with the

following parameters:

• Trip unit

• The phasor at the moment of tripping (currents and

voltages).

• Tripping time. The time passing from start-up to tripping

of the unit.

• The time and date the event occurred.

Unit errors are also permanently displayed. Furthermore, it

is possible to check the fault reports using the front USB port

by connecting a PC to this port and using the implemented

folder system.

The “ON” LED is activated when the equipment receives

power from an external source and flashes quickly when

the relay starts up. This LED will flash less frequently

once the microprocessor has checked that the status of

the equipment is correct and all the protection units are

active. In this situation, the unit is operational to carry out

protection functions.

The voltage and current analogue signals are conditioned

internally by small and very accurate transformers that

isolate the electronic circuits from the rest of the installation.

The system has, in all its variants, 9 inputs and 4 outputs.

Both the inputs and the outputs are protected from

unwanted enabling/disabling.

The unit has 2 rear Ethernet ports for configuration, a

front mini-USB port for maintenance, and two rear RS-485

communications ports for remote control. The standard

communication protocols for all models are MODBUS and

PROCOME.

"ON" signalling LED

1

Metering and parameter setting display

2

SET key

3

Keyboard for scrolling through screens

4

Front mini-USB communication port

5

Figure 1.4. Description of the elements available on the front of the

ekor.rpa-120 relay

8

IG-267-EN versión 01; 07/04/2017

General Instructions

ekor.rpa

1.2.2. Current sensors

The current sensors are toroidal-core current transformers

with a 300/1 A or 1000/1 A or 2500/1 ratio, depending on

the models. These transformers cover the entire operation

range of Ormazabal cubicles, from rated currents 5A up to

2500 A.

The phase toroidal transformers are factory-installed in

the cubicle bushings, which significantly simplifies on-site

assembly and connection. This way, once the mediumvoltage cables are connected to the cubicle, the installation

protection is operational. Installation errors of the sensors,

due to earth grids, polarities, etc., are removed upon

installation and checked directly at the factory.

All the current sensors have an integrated protection

against the opening of secondary circuits, which prevents

overvoltages.

General description

1.2.3. Voltage sensors

Cubicle voltage metering is carried out using a capacitor

divider incorporated in the cubicle’s bushing, which ensures

a precision of ± 5 % in the worst case scenario.

Ormazabal ekor.evt-c capacitive sensors can be used

for greater precision. These are capacitor divider voltage

sensors for gas-insulated cubicles. They are designed to

allow assembly in both separable T-connectors and busbars.

Their operation is autonomous and passive (without

external auxiliary supply), with low-voltage analogue

output and low power applicable directly to the metering

systems without prior conditioning, for installation in

medium-voltage automation and supervision systems in

networks up to 36 kV. It can also measure partial discharges

and establish communication via PLC.

Bushing

1

Current sensors

2

Figure 1.5. Location of the current sensors

Figure 1.6. ekor.evt-c voltage sensors

IG-267-EN versión 01; 07/04/2017

9

General description General Instructions

ekor.rpa

1.2.4. “Binox” bistable tripping device and tripping coil

The "Binox" bistable trigger is a precision electromechanical

actuator which is sealed with its own reinforcement and

integrated in the switch driving mechanism. This release

acts upon the switch when there is a protection trip. It is

characterised by the low actuation power (high energy

efficiency) it requires for tripping. This energy is delivered in

the form of a pulse from the relay in a controlled manner to

ensure the proper operation of the release and the opening

of the switch.

The trials and tests passed by the ekor.rpa-100 unit set and

cubicle, along with quality assurance in manufacture, mean

this is a highly reliable element in the tripping chain. The

solutions presented by Ormazabal with ekor.rpa-100 units

have this tripping device installed as standard.

Figure 1.7. “Binox” Tripping coil

The operations ordered by the ekor.rpa-100 unit digital

outputs are performed by means of conventional tripping

coils. This way, a redundant and therefore more reliable

operational system is achieved.

1.3. Functionality of the unit

The functionality of the assembly as a unit (MV cubicles for

protection, metering and control, sensors, and protection

and metering transformers) is validated in a test plan carried

out in an in-house controlled environment.

To achieve this, Ormazabal counts on the CIT, its Research

and Technology Centre, which represents an essential

instrument in R&D, in order to capture and improve existing

technologies and carry out research into new ones.

The CIT facilities offer services to the science and technology

sector in order to carry out research, development and type

tests both for Ormazabal's business unit products and also

for the rest of the electricity sector.

The CIT is made up mainly of:

1. HPL: Electrotechnical power laboratory, with the goal

of identifying, acquiring and disseminating process

technologies and strategic products within Ormazabal.

2. UDEX: Demonstration and experimentation unit

consisting of a fully configurable, independent

medium-voltage singular experimentation network to

allow tests for new technologies, products and services

to be developed and carried out in a safe, controlled

environment.

10

IG-267-EN versión 01; 07/04/2017

General Instructions

ekor.rpa

1.4. Communications

All the relays of the ekor.rpa-100 units have two TCP/IP

connection Ethernet ports and a Web server for

configuration. They also have a front mini-USB port for

maintenance and two rear ports with serial communication

RS-485 twisted pair (COM0 and COM1) for remote control.

The standard communication protocols implemented in all

equipment are MODBUS in RTU transmission mode (binary)

and PROCOME, through the rear RS-485 COM0 port fitted in

these units.

Optionally, the ekor.rpa-120 model also has a bus for

temperature sensor connection.

The ekor.rpa-100 relays can be interconnected to other

units in the ekor.sys family, as shown in the image below.

General description

ekor.ccp

1

ekor.bus

2

ekor.rci

3

ekor.rpa

4

ekor.rpt

5

ekor.rpg

6

Figure 1.8. Intercommunicated units of the ekor.sys family

IG-267-EN versión 01; 07/04/2017

11

Applications General Instructions

ekor.rpa

2. Applications

2.1. Remote control of transformer and distribution substations

The ekor.rpa-100 protection, metering and control units

make it possible to handle remote control applications of the

transformer and switching substations, by implementing

the control and monitoring of each switch through the

units associated with each functional unit.

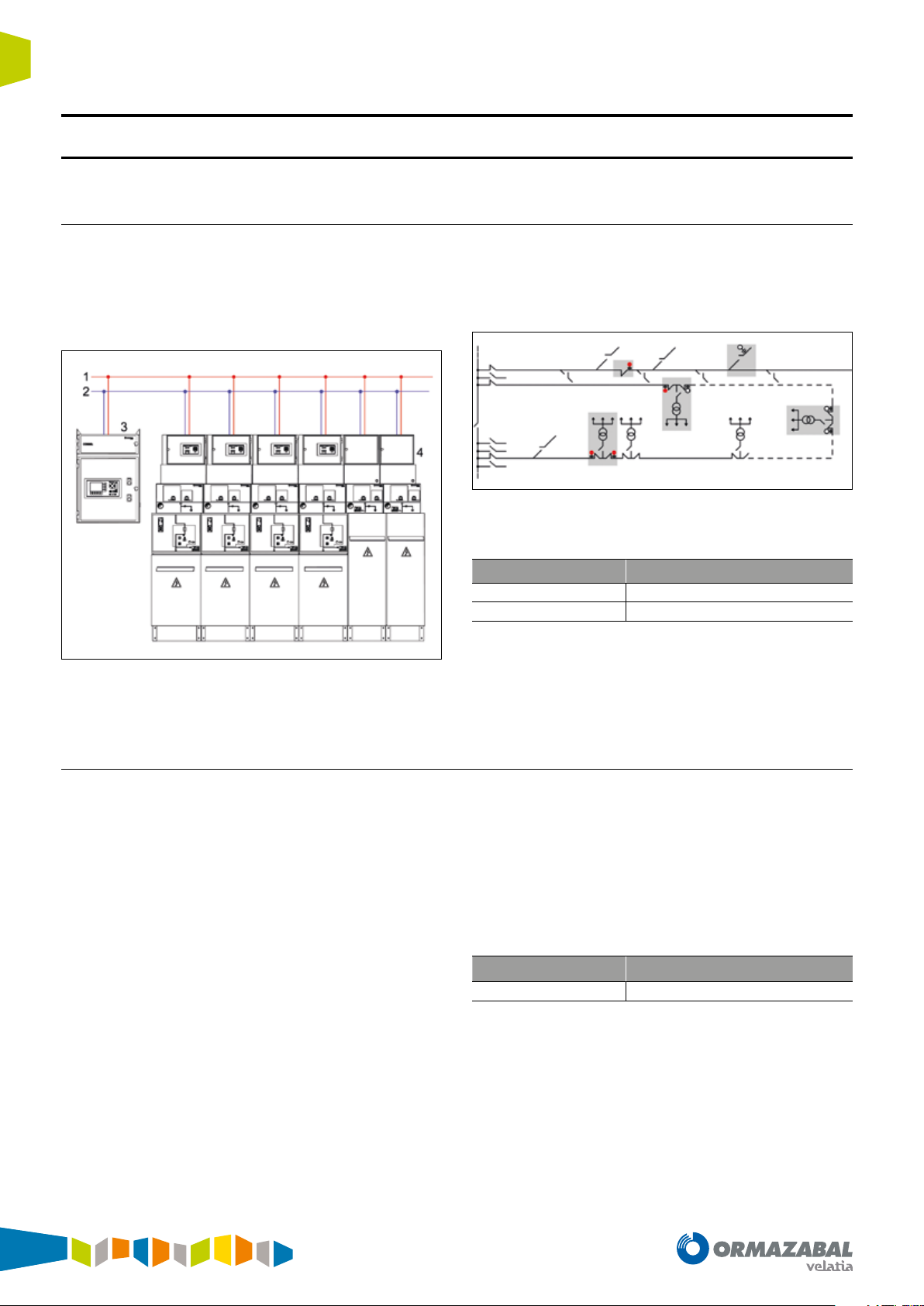

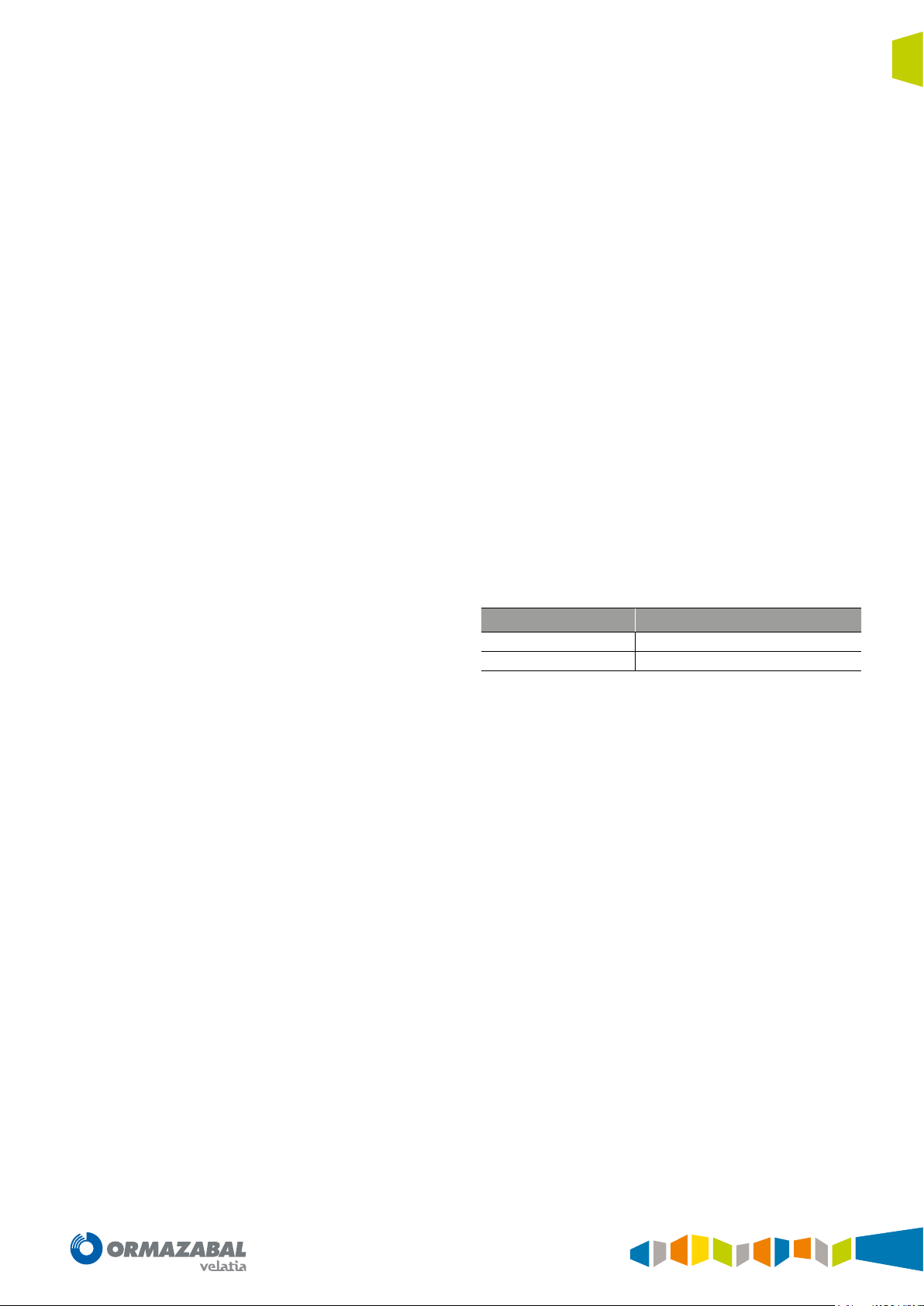

Figure 2.1. Remote-controlled switching substation

The use of a remote control terminal and ekor.rpa-100 units

enable the user to visualise and operate each functional

unit remotely thanks to the inputs and outputs fitted for

this purpose.

Figure 2.2. Layout of dierent stations in the network

Units that include this remote control function:

Unit Type of cubicle

ekor.rpa-100 type = p

ekor.rpa-100 type = v

Table 2.1. Remote control function units

Fuse-combination switch

Circuit-breaker

The remote controlling applications complement the

ekor.rci integrated control unit associated to feeder

functions (see Ormazabal document IG-158).

2.2. Automatic reclosing of lines

The reclosing function performs the automatic reclosing of

lines once the protection unit has commanded the trip and

the switch has opened.

This function is always associated with Ormazabal circuitbreaker cubicles.

The protection units with automatic reclosing have a series

of advantages over protections without reclosing:

• They reduce the time in which electrical power is

interrupted.

• They avoid the need to locally re-establish the service in

substations without remote control for transient faults.

• They reduce the fault time using a combination of fast

switch trips and automatic reclosings, which results in

lesser damage caused by the fault and generates a lower

number of permanent faults derived from transient faults.

The unit which includes this function is:

Unit Type of cubicle

ekor.rpa-100 type = v

Table 2.2. Recloser function unit

Circuit-breaker

12

IG-267-EN versión 01; 07/04/2017

General Instructions

ekor.rpa

2.3. Line protection with circuit-breaker

Applications

The purpose of the line protection is to isolate this part

of the network in case of fault, without it affecting the

rest of the lines. In a general way, it covers any faults that

originate between the substation, transformer substation

or switching substation and the consumption points.

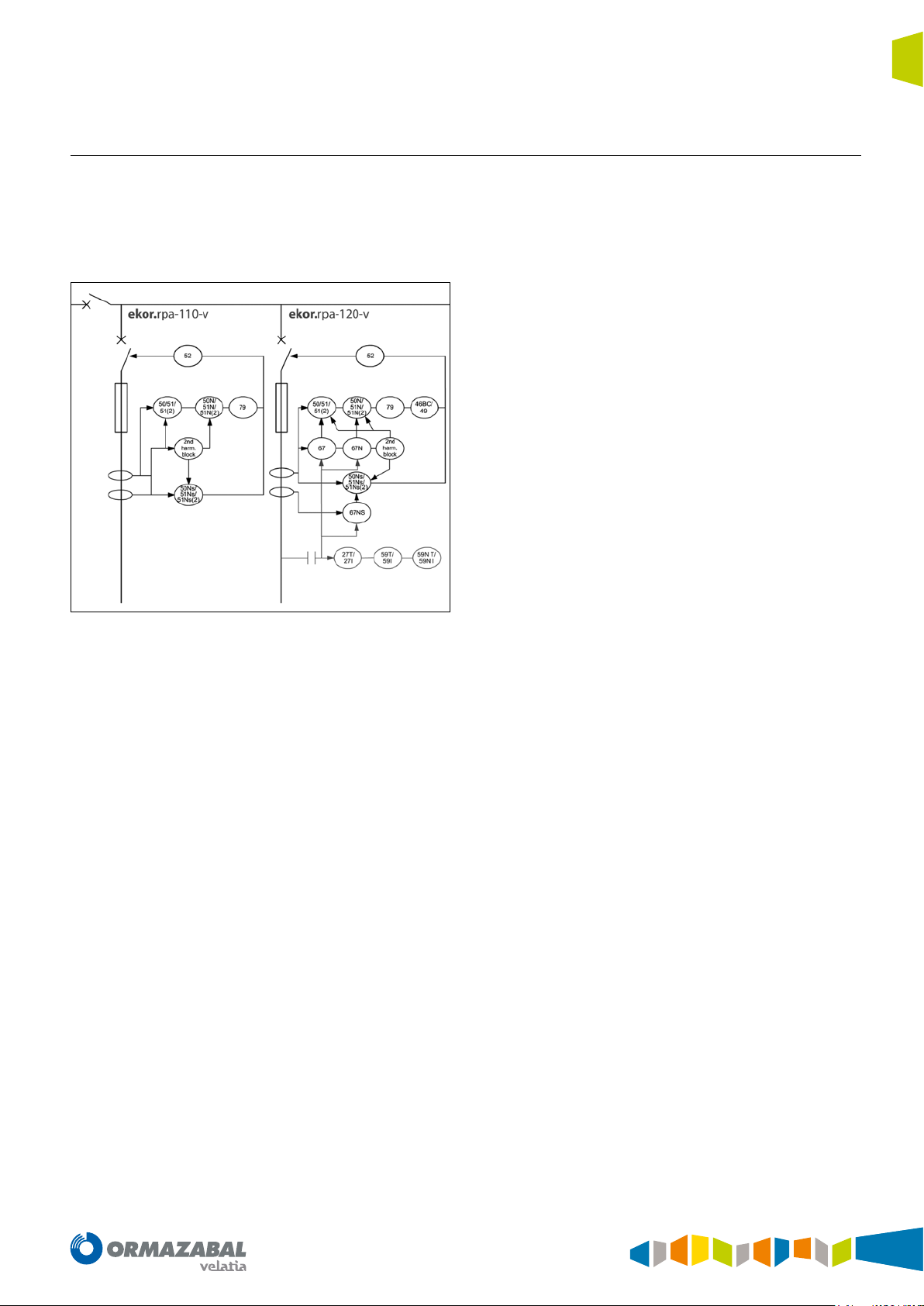

Figure 2.3. Feeder protection functions in ekor.rpa-100 relays

The types of fault that occur in these areas of the network

depend primarily on the nature of the line, overhead line or

cable and the neutral used.

In networks with overhead lines, the majority of faults are

transient, which makes many line reclosings effective; in

these cases, the reclosing function associated with circuitbreakers is used.

This is not the case for underground cables where faults are

usually permanent.

On the other hand, in case of phase-to-earth faults in

overhead lines, when the ground resistance is very high,

the zero-sequence fault currents have a very low value In

these cases, an ‘ultrasensitive’ neutral current detection is

required.

The underground cables have earth coupling capacities,

which causes the single phase faults to include capacitive

currents. This phenomenon makes detection difficult in

isolated or resonant earthed neutral networks and thus

requires the use of the directional function.

In ekor.rpa-100 units, model ekor.rpa-110, line protection

is carried out mainly by the following functions:

• 50 ≡ Instantaneous overcurrent relay. Protects against

short-circuits between phases.

• 51 ≡ Inverse time overcurrent relay. Protects against

excessive overloads, which can deteriorate the

installation.

• 51_2 ≡ Inverse time overcurrent relay II. Additional

step to protect against excessive overloads, which can

deteriorate the installation.

• 50N ≡ Instantaneous earth overcurrent relay. Protects

against phase-to-earth short-circuits.

• 51N ≡ Inverse time earth overcurrent relay. Protects

against highly resistive faults between phase and earth.

• 51_2_N ≡ Inverse time earth overcurrent relay II.

Additional step to protect against highly resistive faults

between phase and earth.

• 50NS ≡ Instantaneous sensitive earth overcurrent

relay. Protects against phase to earth short-circuits of

very low value.

• 51NS ≡ Inverse time sensitive earth overcurrent

relay. Protects against highly resistive faults between

phase and earth of very low value.

• 51_2_NS ≡ Inverse time sensitive earth overcurrent

relay II. Additional step to protect against highly

resistive faults between phase and earth of very low

value.

nd

• 2

Harm. Block ≡ Second harmonic blocking. Blocks

overcurrent units during transformer magnetisation

• 79 ≡ Reclosing relay. Enables the automatic reclosing

of lines.

IG-267-EN versión 01; 07/04/2017

13

Applications General Instructions

ekor.rpa

In addition, the ekor.rpa-100 equipment, ekor.rpa-120

model, also have the following functions:

• 67/67N and 67NS ≡ Directional overcurrent relay,

directional earth fault relay and directional sensitive

earth fault relay. Phase, neutral and sensitive neutral

directional functions which are associated to their

corresponding overcurrent units, together allowing

directional overcurrent units.

• 49 ≡ Machine or transformer thermal relay. Protects

against thermal overloads in lines which cannot be

detected by the overcurrent units.

• 46BC ≡ Broken conductor detection. Detects open

lines, which are generally quite difficult to detect using

overcurrent units.

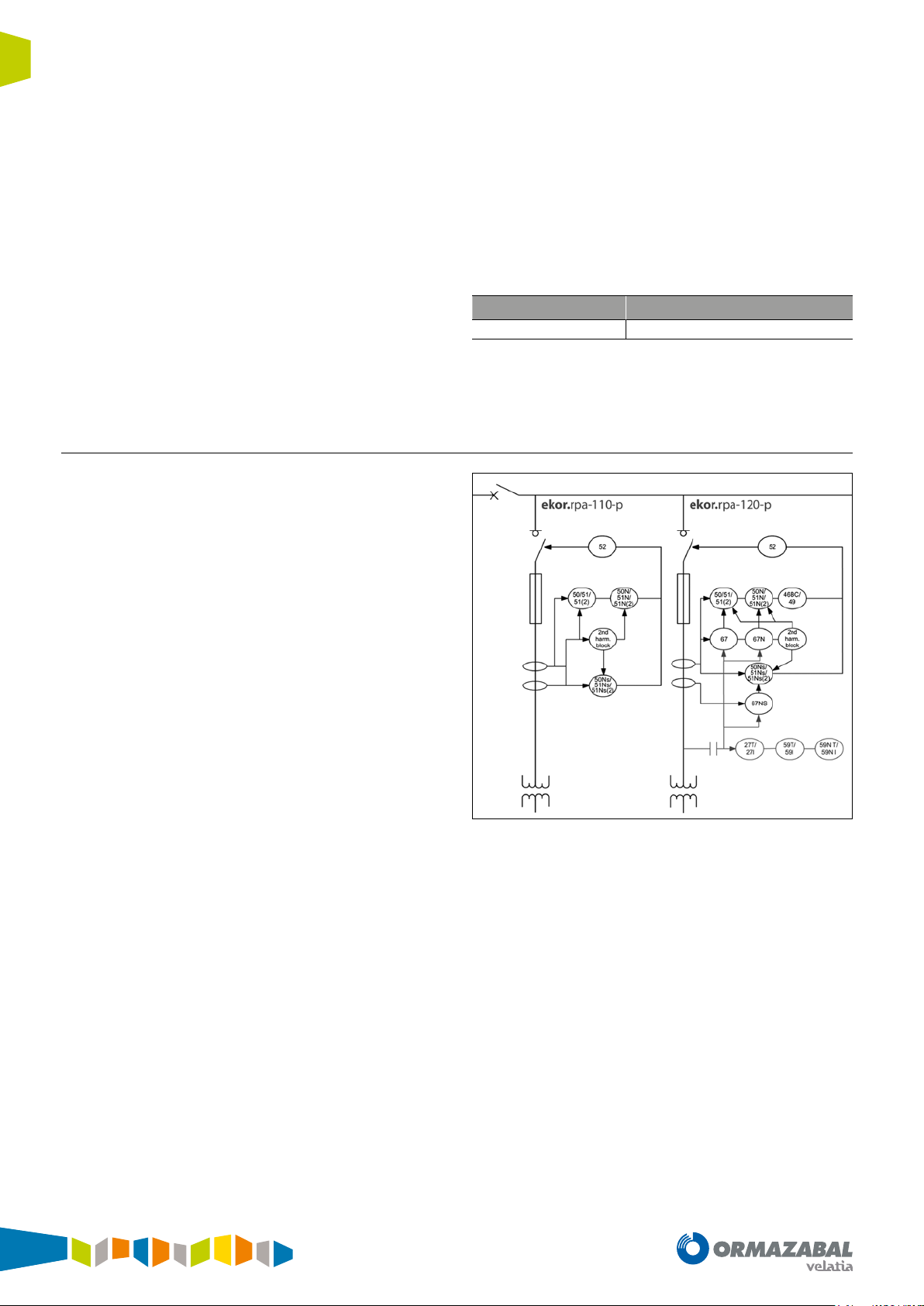

2.4. Transformer protection

The distribution transformers require various protection

functions. Their selection depends primarily on the power

and level of responsibility they have in the installation.

• 59/59N ≡ Overvoltage and residual overvoltage

relay. Protects against phase and neutral overvoltages

in the lines with 2 units for each phase and neutral, one

timed and the other instantaneous.

• 27 ≡ Undervoltage relay. Protects against phase

undervoltages in the lines with 2 units for each phase,

one timed and the other instantaneous.

The units which provide the aforementioned functions are:

Unit Type of cubicle

ekor.rpa-100 type = v

Table 2.3. ekor.rpa-100-v

Circuit-breaker

14

Figure 2.4. Transformer protection functions in ekor.rpa-100 relays

IG-267-EN versión 01; 07/04/2017

General Instructions

ekor.rpa

Applications

The protection functions, available in models

ekor.rpa-110, which must be implemented to protect

distribution transformers with power ratings between 160

kVA and 2 MVA are the following:

• 50 ≡ Instantaneous overcurrent relay. Protects against

short-circuits between phases in the primary circuit, or

high value short-circuit currents between phases on the

secondary side. This function is performed by the fuses

when the protection cubicle does not include a circuitbreaker.

• 51 ≡ Inverse time overcurrent relay. Protects

against excessive overloads, which can deteriorate the

transformer, or against short-circuits in several turns of

the primary winding.

• 51_2 ≡ Inverse time overcurrent relay II. Additional

step to protect against excessive overloads, which can

deteriorate the transformer, or against short-circuits in

several turns of the primary winding.

• 50N ≡ Instantaneous earth overcurrent relay. Protects

against phase to earth short-circuits or secondary

winding short-circuits, from the interconnections and

windings in the primary.

• 51N ≡ Inverse time earth overcurrent relay. Protects

against highly resistive faults from the primary circuit to

earth or to the secondary circuit.

• 51_2_N ≡ Inverse time earth overcurrent relay II.

Additional step to protect against highly resistive faults

from the primary circuit to earth or to the secondary.

• 50NS ≡ Instantaneous sensitive earth overcurrent

relay. Protects against phase to earth short-circuits of

very low value.

• 51NS ≡ Inverse time sensitive earth overcurrent

relay. Protects against highly resistive faults between

phase and earth of very low value.

• 51_2_NS ≡ Inverse time sensitive earth overcurrent

relay II. Additional step to protect against highly resistive

faults between phase and earth of very low value. 2

nd

Harm. Block ≡ Second harmonic blocking. Blocks

overcurrent units during transformer magnetisation.

In addition, the ekor.rpa-100 equipment, ekor.rpa-120

models, also have the following functions:

• 67/67N and 67NS ≡ Directional overcurrent relay,

directional earth fault relay and directional sensitive

earth fault relay. Phase, neutral and sensitive neutral

directional functions which are associated to their

corresponding overcurrent units, together allowing

directional overcurrent units.

• 49 ≡ Machine or transformer thermal relay. Protects

against thermal overloads of transformers which cannot

be detected by the overcurrent units.

• 46BC ≡ Broken conductor detection. Detects open

lines. Broken conductors are quite difficult to detect

using overcurrent units.

• 59/59N ≡ Overvoltage relay and residual overvoltage

relay. Protects against phase and neutral overvoltages

in the lines with 2 units for each phase and neutral, one

timed and the other instantaneous.

• 27 ≡ Undervoltage relay. Protects against phase

undervoltages in the lines with 2 units for each phase,

one timed and the other instantaneous.

The protection units that include the above mentioned

functions are:

Unit Type of cubicle

ekor.rpa-100 type = p

ekor.rpa-100 type = v

Table 2.4. ekor.rpa-100-p/ekor.rpa-100-v

Fuse-combination switch

Circuit-breaker

IG-267-EN versión 01; 07/04/2017

15

Applications General Instructions

ekor.rpa

2.5. Automatic transfer

The automatic transfer of lines with circuit-breakers

minimises power outages in loads fed by transformer or

switching substations with more than one incoming line,

thereby improving continuity of service.

Under normal conditions with voltage present on two

possible incoming lines, the switch selected as preferred

remains closed and the reserve one is opened. A voltage

drop in the preferred line will cause the switch of this line

to open and the reserve switch to close afterwards. Once

normality has been re-established in the preferred line, the

inverse cycle is performed, and the system returns to its

initial status.

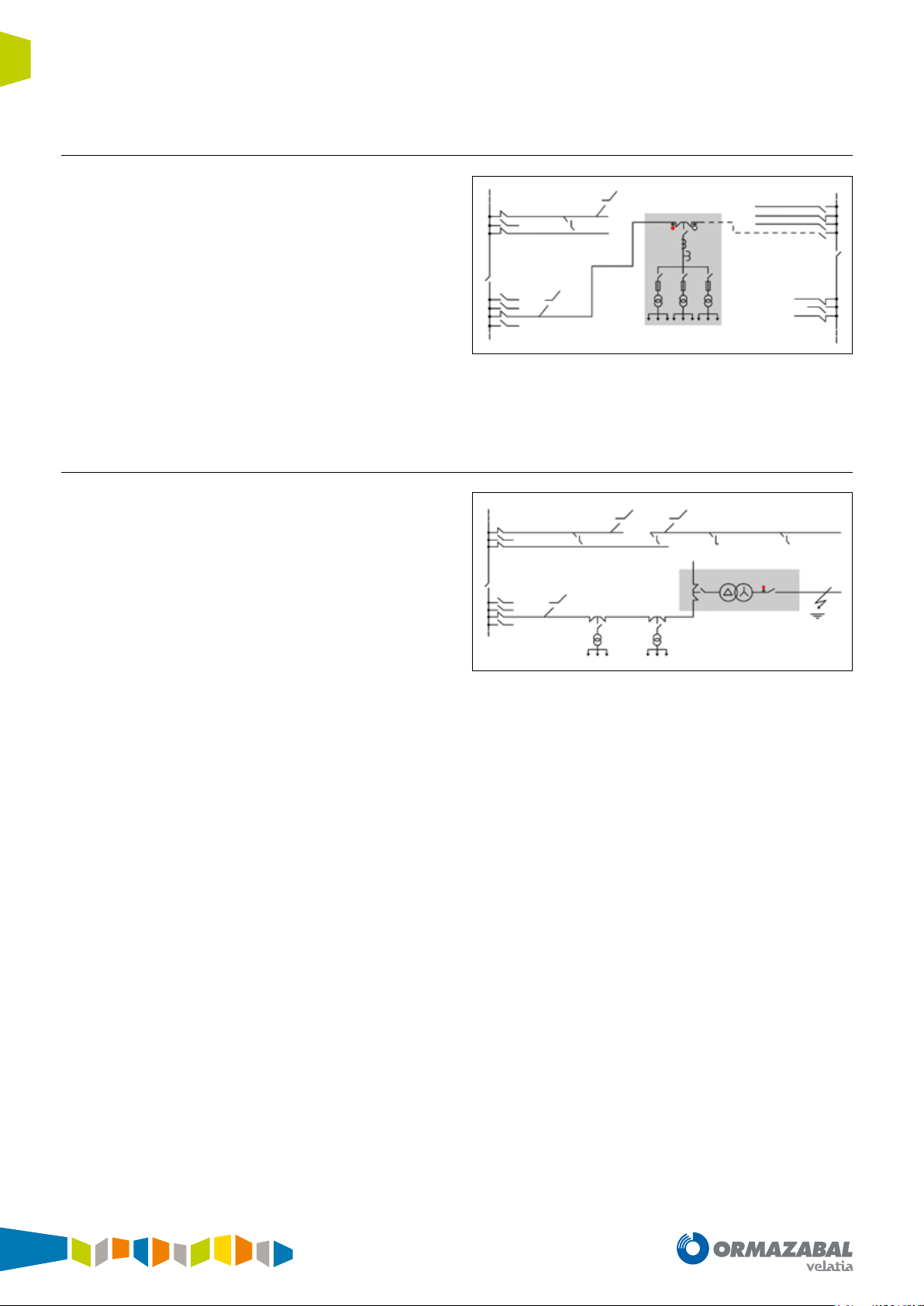

Figure 2.5. Automatic transfer

2.6. Detection of phase with earthing

In networks with isolated or resonant earthed neutral, the

fault currents are very low. In the event of a fault in a system

of this type, the fault current may not reach the calibrated

threshold for overcurrent protection, and therefore this

fault may not be detected.

Function 59 is used instead of programmed logic for

detecting this type of fault, analysing both the installation’s

neutral voltage and its current.

Figure 2.6. Detection of phase with earthing

16

IG-267-EN versión 01; 07/04/2017

General Instructions

ekor.rpa

2.7. Protection and control of MV interconnection stations

Applications

In MV customers where an ekor.rpa-100 relay is installed,

either in protection cubicles with circuit-breaker or fuses

which protect the MV outgoing, information on this

outgoing can be sent to the SCADA both by the web and

via the MODBUS-TCP communications protocol.

2.8. Energy balances

By including MV energy meterings in the ekor.rpa-100

relays, it is possible to analyse non-technical losses which

can be found between the Transformer Substation and

the LV consumption, in order to uncover possible fraudulent

use such as energy which has not been billed due to an

error in the LV equipment.

The accessible information would be as follows:

• Cubicle position

• Trips

• Alarms

• Meterings:

- Voltage

- Current

- Power

- Energy

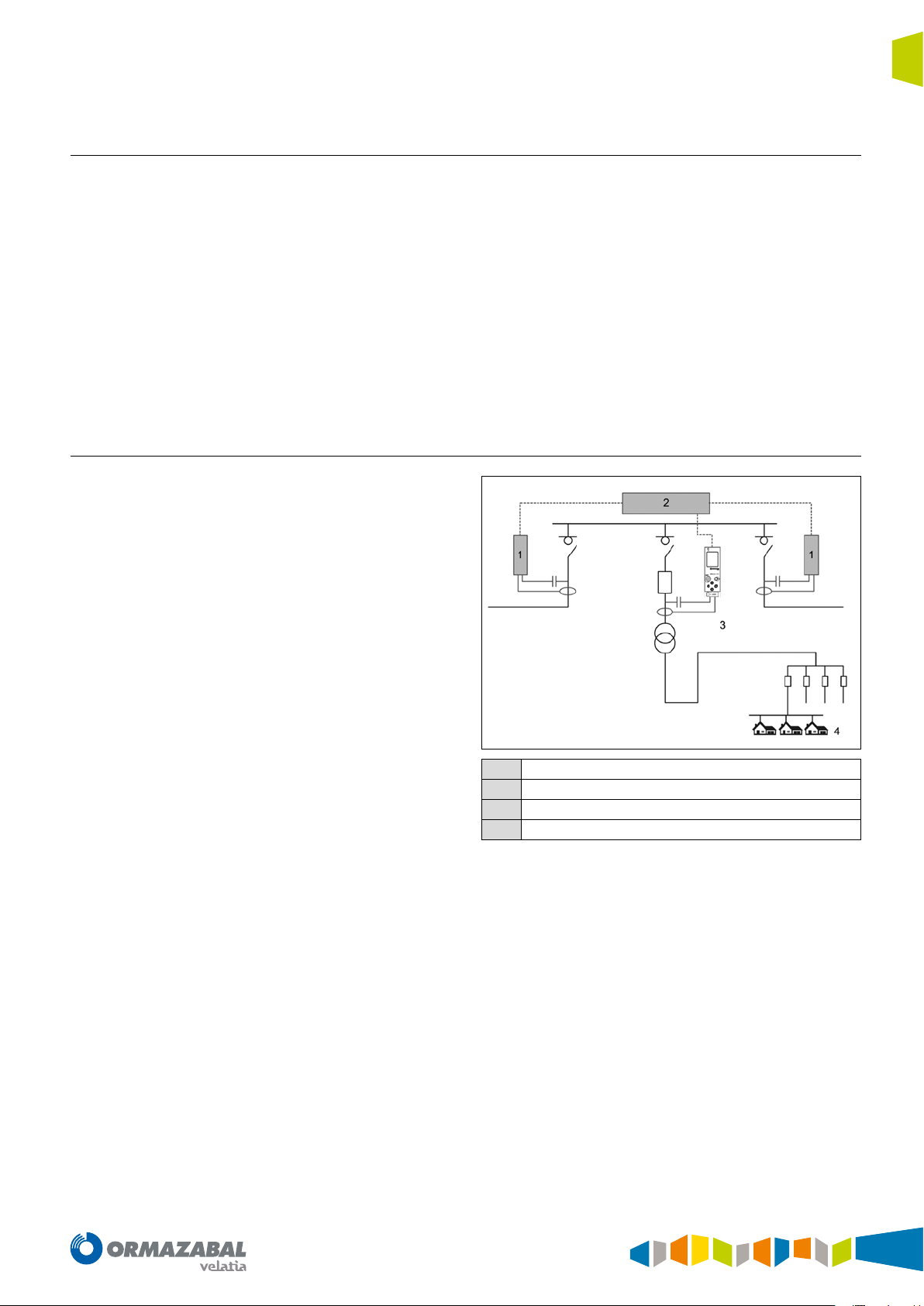

ekor.rci

1

ekor.ccp

2

ekor.rpa

3

Meters

4

Figure 2.7. ekor.rpa-100 unit measuring MV energies in a transformer

with private customers

IG-267-EN versión 01; 07/04/2017

17

Metering functions General Instructions

ekor.rpa

3. Metering functions

3.1. Current and voltage metering

The unit has four current reading inputs (IA, IB, IC and INS)

and three voltage reading inputs (VA, VB and VC). Each of

them are conditioned and digitised in order to carry out the

calculation.

The design of the equipment and sensors, along with their

integration in the cubicle, form an assembly which works

as a single unit to achieve maximum immunity and quality

of the signal to be measured, both in the 50 Hz and 60 Hz

networks.

The signal transduction and conditioning stages are

designed to ensure the sensor and relay assembly

reproduces both the magnitude and the phase of the

current and voltage signals of the distribution network.

This ensures optimal performance in real-time applications,

with protection algorithms, in all operation conditions and

in supply quality or load monitoring meterings.

The samples obtained for I

and VN, calculated by the sum

N

of samples of the corresponding phase signals, must be

added to the voltage and current inputs sampled directly.

These calculated signal characteristics are equivalent to

those obtained by vector sum of the conventional sensor

signals.

The meterings for supervision of current and voltage are

measured integrated for 1.28 seconds and represented in

phasorial mode (module + argument). Network load status

is therefore updated regularly.

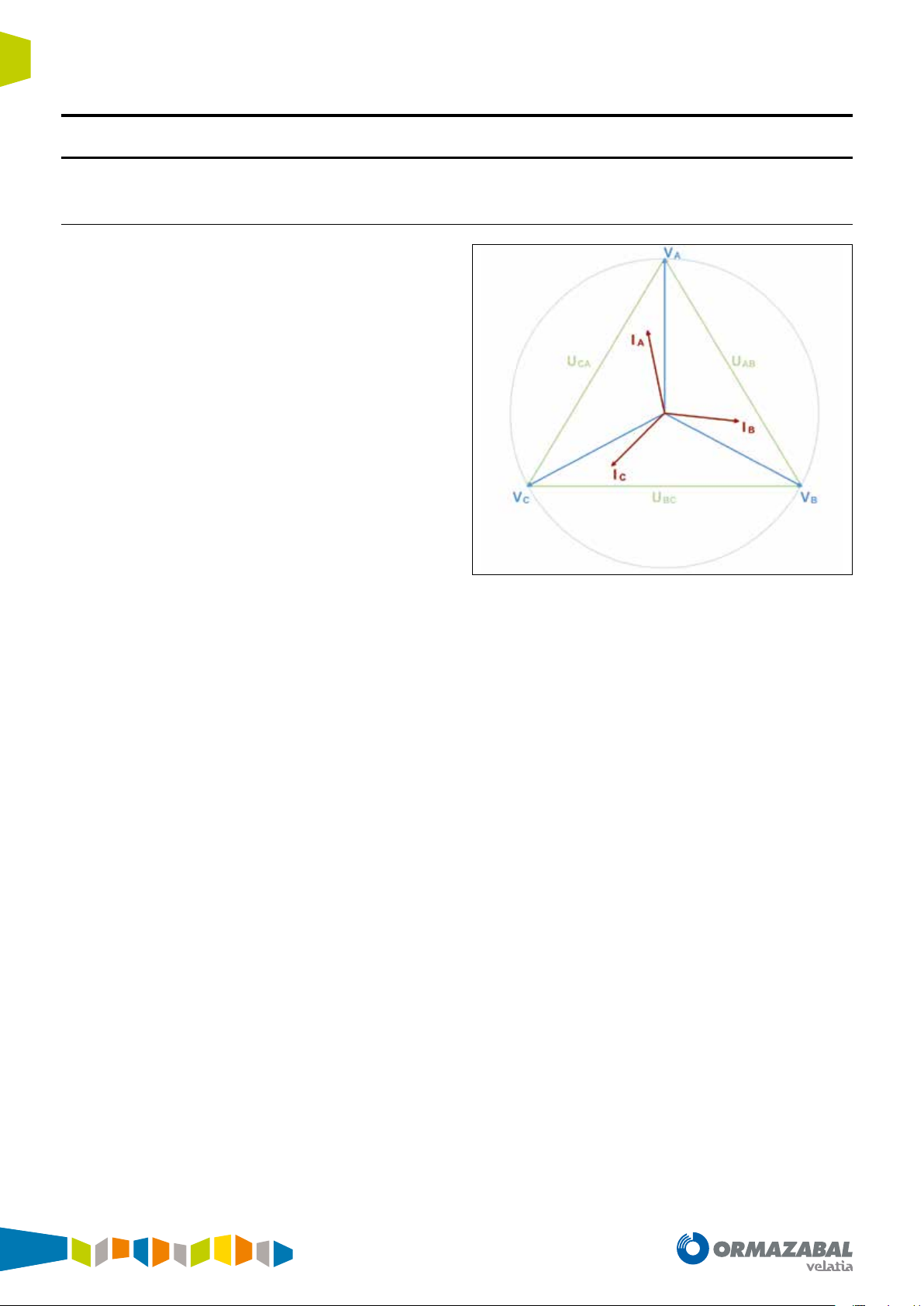

The current and voltage meterings are:

• Line currents I

• Line voltage: U

, IB and IC.

A

, UBC and UCA and Line voltages: VA, VB

AB

and VC.

• Residual currents and voltages. Represented as: I

N/INS

(3Io) and VN (3Vo).

Figure 3.1. Current and voltage metering

The final calibration is the overall calibration of sensors,

metering equipment, cabling and switchgear, and is

validated in an exhaustive test plan carried out in a

controlled environment which reproduces the reality of the

medium-voltage electrical distribution network.

All this process includes different scenarios:

• Maximum electromagnetic interference and temperature

rise scenarios of the assembly, carried out at rated

switchgear current.

• Maximum thermal variation scenarios, carried out in a

climate chamber between -10 °C and 60 °C.

• Scenarios with highly aggressive transient disturbance,

power and lightning impulse tests with medium-voltage

levels.

• etc.

These tests conclude in points such as: the ratio of the

number of turns of the current transformers, impedance

of the voltage reading inputs, etc. All this is tested and

validated on the final solution delivered to the customer.

18

IG-267-EN versión 01; 07/04/2017

General Instructions

ekor.rpa

3.2. Power meterings

Metering functions

The powers which are monitored (locally or remotely) are

1.28 second integrated meterings of the calculated RMS

instantaneous values.

Accredited meterings in precision class guarantee reliability

in the values obtained.

The equipment acts as a metering station for load analysis

or electrical supply quality monitoring tasks. The monitored

meterings for active and reactive power are single-phase

and three-phase, and three-phase only for apparent power.

3.3. Energy meter

The equipment is fitted with an "Active and reactive electrical

energy meter" which meets the particular requirements for

static energy meters. This is an indirect connection threephase meter which, along with the voltage and current

metering sensors, form a medium-voltage (MV) meter.

The energy meter accumulates 100 meterings of powers

P and Q integrated in a semicircle (1 second for 50Hz and

1.2 seconds for 60Hz). In total, there will be four meters:

three single-phase (A phase, B phase and C phase) and one

three-phase.

The meterings are made up of:

• Single-phase: Active PA, PB and PC and Reactive QA, QB

and QC.

• Three-phase: PT, QT and ST Powers and Power Factor

(P.F.).

Each meter has two active energy records (E+ and E-) and

four reactive energy records (Q1, Q2, Q3 and Q4), each of

them 32 bits. These registers have a bit to indicate overflow

and a reset option by command.

Active powers are expressed in kilovolts-hour (kWh) and

reactive powers are expressed in kilovolt amperes reactivehour (kVArh).

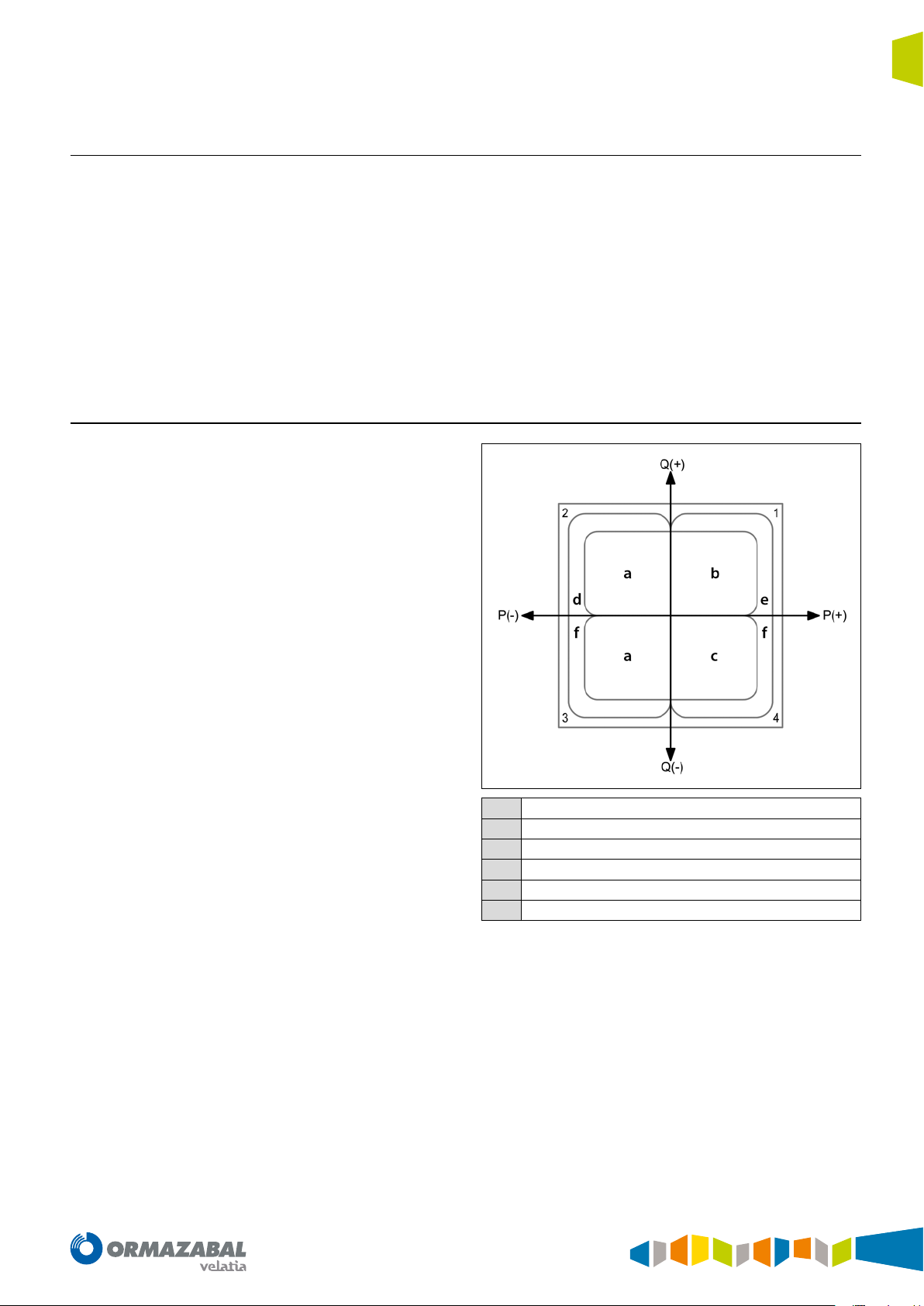

Reactive

a

Inductive

b

Capacitive

c

Generated

d

Consumed

e

Active

f

Active energy imported (in kWh): EA + , EB + , EC + and ET +

Active energy exported (kWh): EA - , EB - , EC - and ET Inductive reactive energy imported (kVArh): QA1, QB1, QC1 and QT1

Capacitive reactive energy imported (kVArh): QA2, QB2, QC2 and QT2

Inductive reactive energy exported (kVArh): QA3, QB3, QC3 and QT3

Capacitive reactive energy exported (kVArh): QA4, QB4, QC4 and QT4

Figure 3.2. Energies

IG-267-EN versión 01; 07/04/2017

19

Protection functions General Instructions

ekor.rpa

4. Protection functions

4.1. Overcurrent units

The ekor.rpa-100 systems are fitted with the following

overcurrent protection units:

Phases:

• Six phase overcurrent timed units (3 x 51.3 x 51(2)).

• Three phase overcurrent instantaneous units (3 x 50).

4.1.1. Timed overcurrent units

The phase, neutral and sensitive neutral timed units start

up if the fundamental value of the magnitude for each unit

exceeds the value 1.05 times the adjusted start-up, and are

reset when this value is below 0.95 times the adjusted value.

Tripping takes place if the unit is started up for the time set.

This time may be adjusted by selecting different types of

curve, in accordance with IEC and ANSI Standards.

The curves implemented in the ekor.rpa-100 units are:

IEC CURVES

• IEC DT: Defined time

• IEC NI: Normally inverse curve

• IEC VI: Very inverse curve

• IEC EI: Extremely inverse curve

• IEC LTI: Long time inverse curve

• IEC STI: Short time inverse curve

ANSI CURVES

• ANSI LI: Long time inverse curve

• ANSI NI: Normally inverse curve

• ANSI VI: Very inverse curve

• ANSI EI: Extremely inverse curve

These curves are detailed in the ANNEX section.

Neutral (Calculated):

• Two neutral timed overcurrent units (1 x 51N, 1 x 51(2)

N).

• A neutral instantaneous overcurrent unit (1 x 50N).

Sensitive neutral (measured):

• Two sensitive neutral timed overcurrent units (1 x 51NS,

1 x 51(2)NS).

• A sensitive neutral instantaneous overcurrent unit (1 x

50NS).

The settings for the timed units are:

• Enabling the unit: Enable/disable the unit (ON/OFF).

• Starting up the unit: Unit starting current. Variable

ranges in accordance with current transformers used.

• Time curve: Curve type (IEC DT, IEC NI, IEC VI, IEC EI, IEC

LTI, IEC STI, ANSI LI, ANSI NI, ANSI VI, ANSI EI).

• Time index: Time index, also known as time dial (from

0.05 to 1.60). This setting applies to all curve types

except for IEC DT.

• Fixed time: Unit tripping time (from 0.00 s to 100.00 s).

This setting only applies to IEC DT type curves.

• Torque control: Directional tripping mask (OFF,

FORWARD or REVERSE). To indicate the direction for

tripping:

- OFF: Regardless of the direction, the relevant

overcurrent unit will trip if the overcurrent conditions

are met.

- FORWARD: The corresponding overcurrent unit

will trip whenever the overcurrent conditions are

met, and the directional unit will give the FORWARD

signal.

- REVERSE: The corresponding overcurrent unit will

trip whenever the overcurrent conditions are met,

and the directional unit will give the REVERSE signal.

This setting will only be found in ekor.rpa-100 units

model 120.

20

IG-267-EN versión 01; 07/04/2017

General Instructions

ekor.rpa

4.1.2. Instantaneous overcurrent units

Protection functions

The phase, neutral and sensitive neutral instantaneous

units start up if the fundamental value of the magnitude for

each unit exceeds the value 1.00 times the adjusted startup, and are reset when this value is below 0.95 times the

adjusted value.

Tripping takes place if the unit is started up for the time set.

The settings for the instantaneous units are:

• Enabling the unit: Enable/disable the unit (ON/OFF).

• Starting up the unit: Unit starting current. Variable

ranges in accordance with current transformers used.

• Fixed time: Unit tripping time (from 0.00 s to 100.00 s).

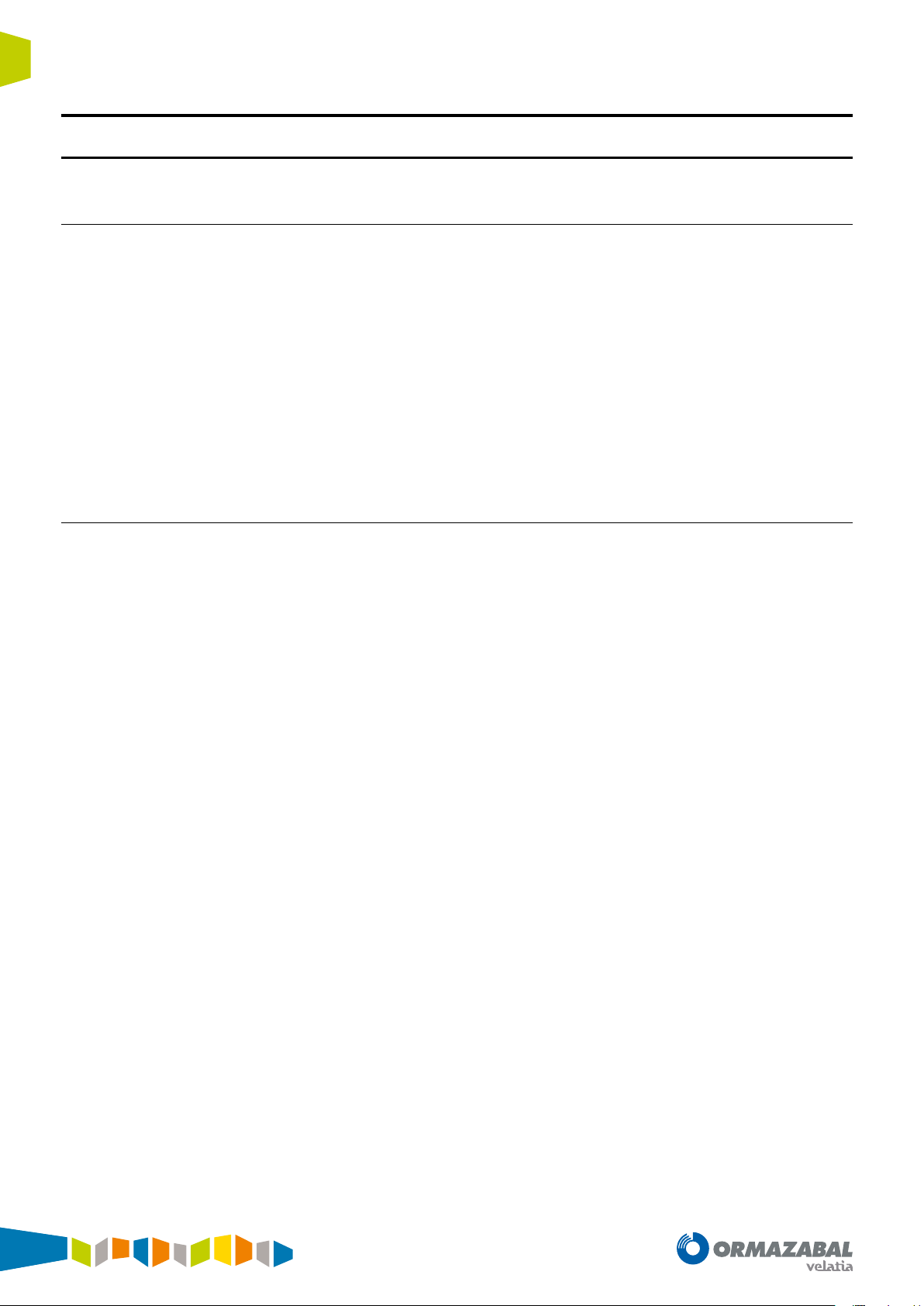

4.1.3. Block diagram

Any overvoltage unit complying with the diagram shown

below:

• Torque control: Directional tripping mask (OFF,

FORWARD or REVERSE). To indicate the direction for

tripping:

- OFF: Regardless of the direction, the relevant

overcurrent unit will trip if the overcurrent conditions

are met.

- FORWARD: The corresponding overcurrent unit

will trip whenever the overcurrent conditions are

met, and the directional unit will give the FORWARD

signal.

- REVERSE: The corresponding overcurrent unit will

trip whenever the overcurrent conditions are met,

and the directional unit will give the REVERSE signal.

This setting will only be found in ekor.rpa-100 units

model 120.

Metering

1

Input signal

2

Output signal

3

Settings

4

Figure 4.1. Block diagram

IG-267-EN versión 01; 07/04/2017

21

Protection functions General Instructions

ekor.rpa

Basically, the diagram shows that, whenever a magnitude

measured in real-time (Ix) exceeds the setpoint value (l

pick up

setting), a time counter counts down (counter: f (curve,

index, time), tripping when completely expired.

If the measured magnitude (Ix) drops below the setpoint

(I

) during timing, the unit and the meter are reset and

pick up

the unit remains idle.

All the units generate the following signalling:

• Pick-up: Activated when the measured magnitude (Ix)

exceeds a setpoint (I

setting) and disabled when the

pick up

metering value drops below the setpoint.

• Temporize: Activated when the time counter reaches

its end, and disabled when the metering value drops

below the setpoint.

• Trip: Activated when the temporize signal is activated,

and disabled when the metering value drops below the

setpoint.

4.2. Ultra-sensitive earth

This functionality is available in both directional and nondirectional ekor.rpa and corresponds to a particular case of

overcurrent detection for phase-to-earth faults. Primarily

used in networks with isolated neutral, resonant earthed

neutral or on highly resistive soils, where the phase-toearth fault current has a very low value.

Moreover, the overcurrent units can be blocked by the

maximum current blocking and second harmonic

blocking units detailed in the following sections.

Moreover, the overcurrent units can be blocked in three

different ways:

• Unit block: Blocks the unit, preventing start-up while

this input remains active.

• Timing Block: Freezes the time counter value while this

input is active.

• Trip Block: Allows the unit to advance, and blocks it

before the trip output.

The current flowing to earth is detected using a toroidalcore current transformer which covers the three phases.

In this way, the metering is independent from the phase

current, thus avoiding errors in the phase metering sensors.

Using this type of toroidal-core means the measured

neutral currents due to unbalanced phases are reliable in

very low primary amp values. For this type of configuration,

the unit allows a minimum trip setting of 0.3 primary amps

in its Sensitive Neutral channel.

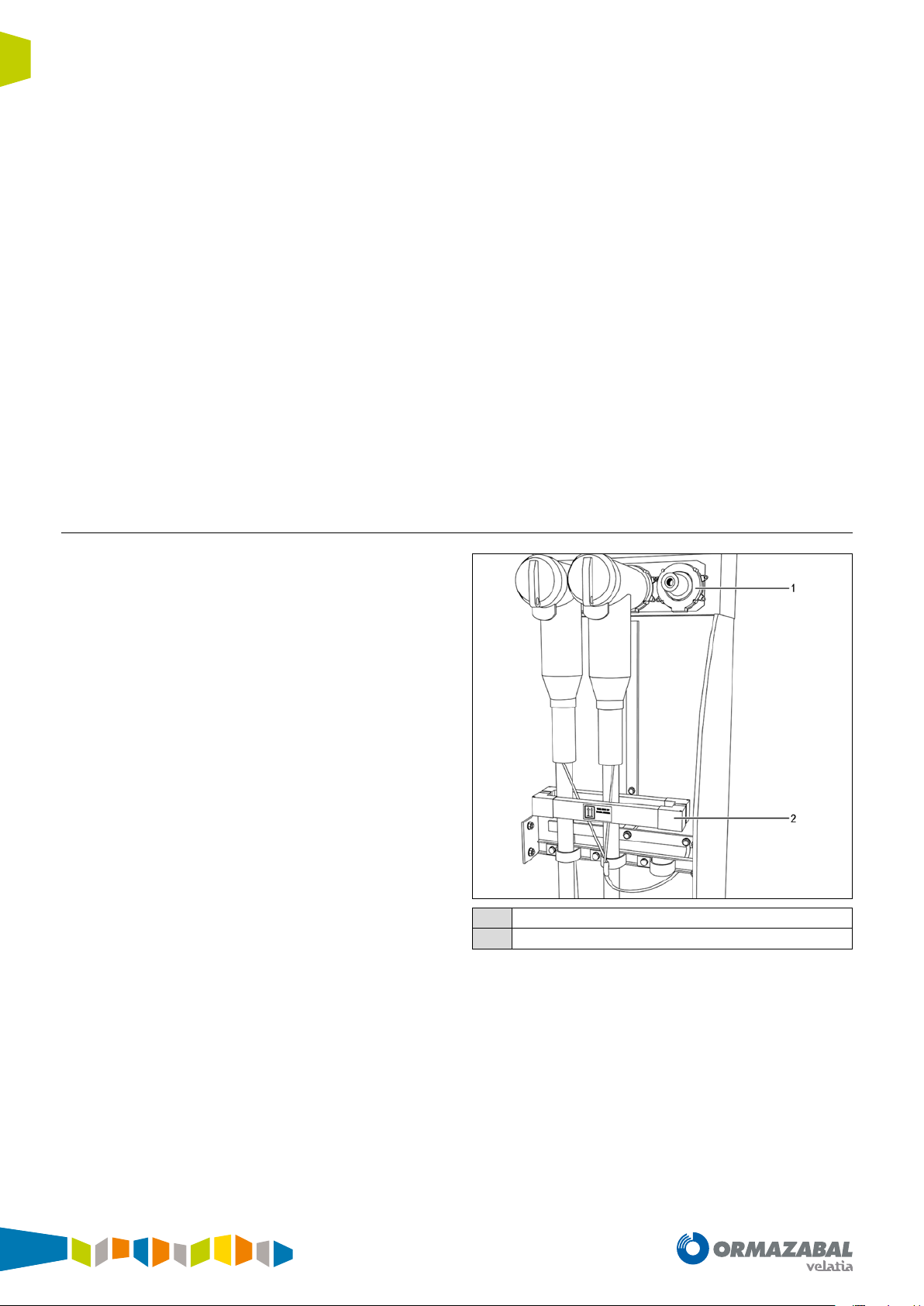

Voltage and current sensors

1

Zero-sequence transformers

2

Figure 4.2. Current sensors

22

IG-267-EN versión 01; 07/04/2017

General Instructions

ekor.rpa

4.3. Directional units

Protection functions

The directional units are combined with the overcurrent

units when taking a decision on tripping. In accordance with

the "torque control" direction setting (Forward or Reverse)

and the result of the direction of the fault, the overcurrent

units finish by tripping or not.

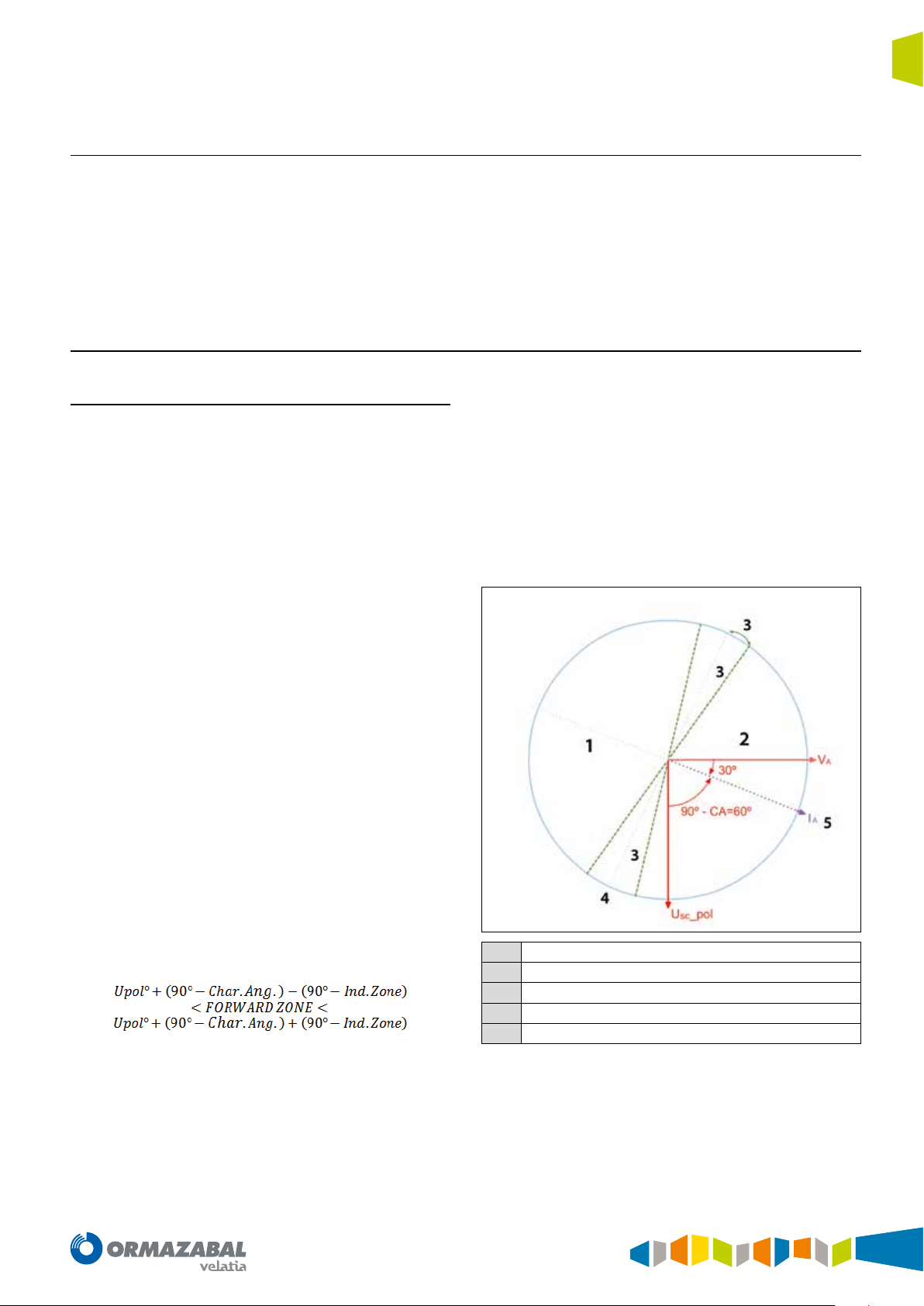

4.3.1. Phase directional units

Angular criterion

The phase directional units are units which, using the

angular criterion, determine the direction of each of the

3 phases. The polarisation voltage used for each phase is the

compound voltage corresponding to the other 2 phases.

These units determine direction based on:

• The calibrated settings.

• The phase difference existing between the polarisation

signal and the current signal.

The settings for the phase directional unit are:

The ekor.rpa-100 model 120 systems have the following

directional units:

• Three phase directional units (3 x 67)

• A neutral directional unit (1 x 67N)

• A sensitive neutral directional unit (1 x 67NS)

The Reverse direction zone will be the opposite of the

Forward zone. In other words, the above formula needs to

be turned around 180° in order to achieve the expression

which delimits the Reverse direction zone.

The directional units will indicate ndef direction if in the

indeterminate zone or polarisation voltage is below the

V

setting.

min

The figure shows an example of operation of the directional

unit of phase A:

• Characteristic phase angle: Characteristic angle

(from - 90.0° to 90.0°). This often corresponds to the

series impedance angle of the lines. Typical values in

distribution: 30° and 45°.

• Minimum phases voltage: Minimum polarisation

voltage (from 0.5 kV to 72.0 kV). Polarisation voltage

value as of which the directional unit considers the

angle reliable, and is capable of determining a direction.

• Indeterminate zone: Indeterminate zone angle (from

0.0° to 90.0°). Setting to establish the indetermination

zone which is close to the zero torque line.

The direction indicated by the units can be Forward, Reverse

or ndef (undefined).

The Forward direction zone is delimited by the following

formula:

Reserve

1

Forward

2

Indeterminate zone

3

Zero torque line

4

Maximum torque line

5

Figure 4.3. Phase A directional unit

IG-267-EN versión 01; 07/04/2017

23

Protection functions General Instructions

ekor.rpa

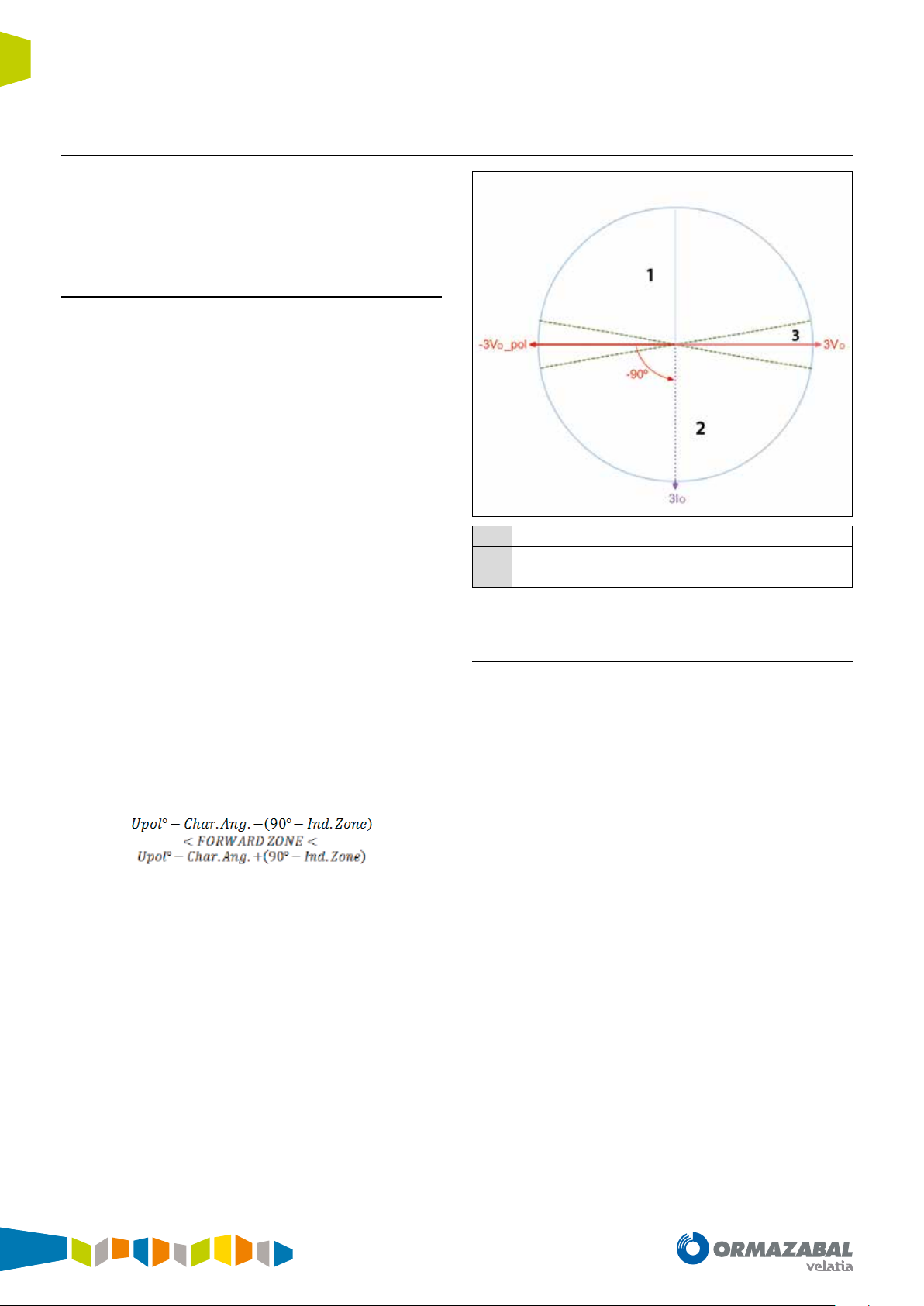

4.3.2. Neutral and sensitive neutral directional units

The neutral and sensitive neutral directional units include

two different criteria to determine direction: Directional

criterion and wattmetric criterion. The criterion is selected

through a setting in the unit itself.

Angular criterion

The angular criterion of the neutral and sensitive neutral

directional units is based on the phase difference between

the polarisation signal (-3V

(3Io).

The polarisation signal used is the 180° out-of-phase

residual voltage, i.e.- 3V

The settings for the neutral and sensitive neutral directional

unit, which apply to the angular criteria, are:

) and the residual current signal

o

.

o

• Characteristic neutral angle: Characteristic angle (from

- 90.0° to 90.0°). In distributions with earthed neutral,

this often corresponds to the earth impedance angle.

• Minimum neutral voltage: Minimum polarisation

voltage (from 0.5 kV to 72.0 kV). Polarisation voltage

value as of which the directional unit considers the

angle reliable, and is capable of determining a direction.

• Indeterminate zone: Indeterminate zone angle (from

0.0° to 90.0°). Setting to establish the indetermination

zone which is close to the zero torque line.

The direction indicated by the units can be Forward, Reverse

or ndef (undefined).

The Forward direction zone is delimited by the following

formula:

The Reverse direction zone will be the opposite of the

Forward zone. In other words, the above formula needs to

be turned around 180° in order to achieve the expression

which delimits the Reverse direction zone.

The directional units will indicate ndef direction if in the

indeterminate zone or polarisation voltage is below the V

min

setting.

The figure below shows an example of operation for the

neutral directional unit:

Reserve

1

Forward

2

Indeterminate zone

3

Figure 4.4. Neutral directional unit

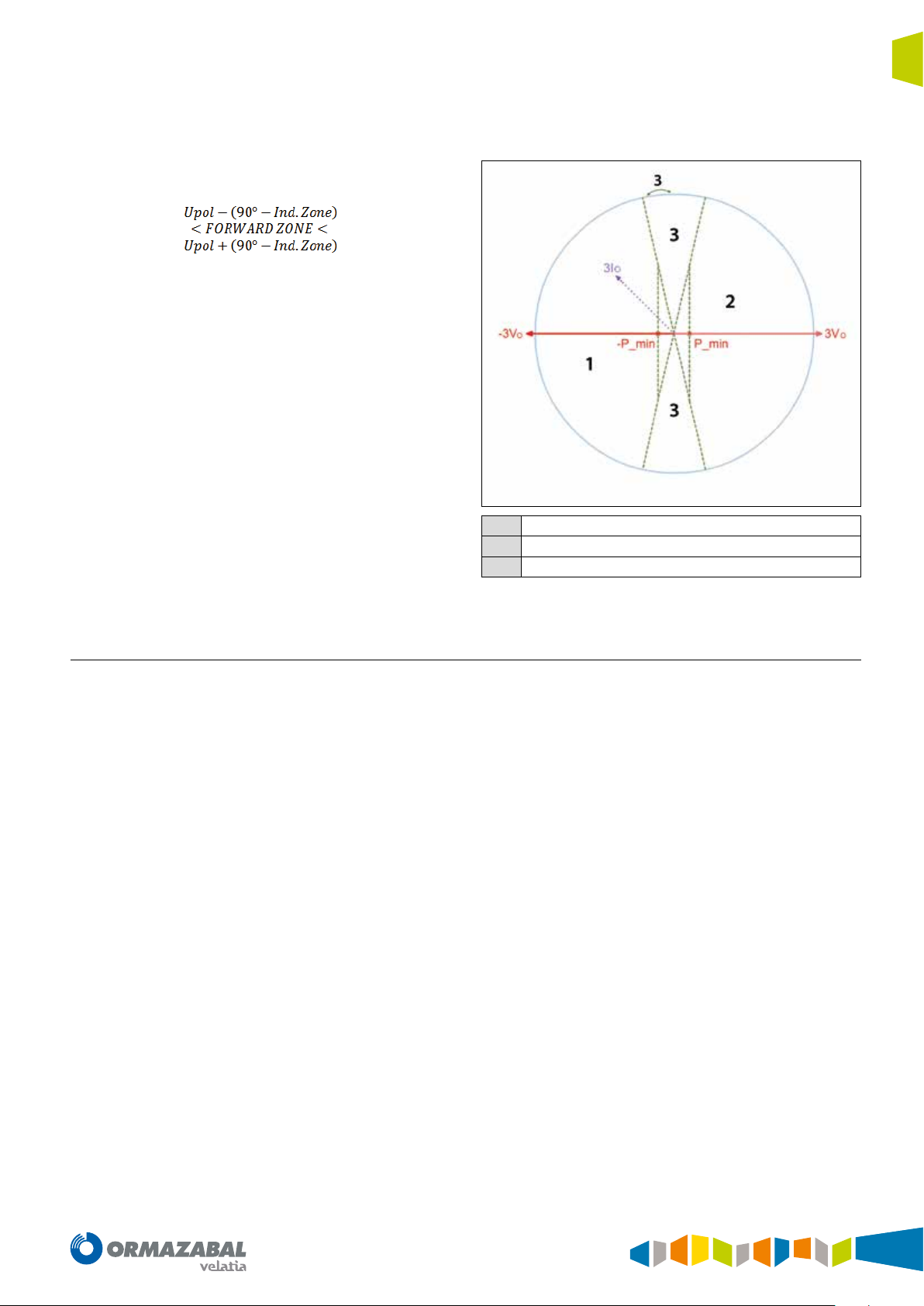

Wattmetric criterion

The wattmetric criterion of the neutral and sensitive neutral

directional units is based on the phase difference between

the polarisation signal (- 3V

) and the residual current signal

o

(3lo), along with the magnitude of the residual active power.

The settings for the neutral and sensitive neutral directional

unit, which apply to the wattmetric criteria, are:

• Minimum neutral active power: Minimum residual

active power. Minimum residual active power value (in

absolute value), as of which direction other than ndef

(i.e. Forward or Reverse) can be considered. Variable

ranges in accordance with current transformers used.

• Minimum neutral voltage: Minimum polarisation

voltage (from 0.5 kV to 72.0 kV). Polarisation voltage

value as of which the directional unit considers the

angle reliable, and is capable of determining a direction.

• Indeterminate zone: Indeterminate zone angle (from

0.0° to 90.0°). Angle formed by the 90° axis and the line

which delimits the indeterminate zone.

The direction indicated by the units can be Forward, Reverse

or ndef (undefined).

24

IG-267-EN versión 01; 07/04/2017

General Instructions

ekor.rpa

Protection functions

The unit will indicate Forward direction in the following

conditions:

• The residual current signal (3I

) drops in the following

o

zone:

The residual active power is lower than - P

min

.

The reverse direction zone will be the opposite of the

Forward zone. In other words, the above formula needs to

be turned around 180° in order to achieve the expression

which delimits the reverse direction zone. Furthermore,

residual active power must be greater than + P

min

.

The unit will give undefined direction if:

• The residual active power in absolute value is lower

than P

• The polarisation voltage value is lower than the V

min

.

min

setting.

• This is found in the indeterminate zone (see figure

below).

The figure below shows an example of operation for the

neutral directional unit with wattmetric criterion:

Reserve

1

Forward

2

Indeterminate zone

3

Figure 4.5. Neutral unit with wattmetric criterion

4.4. Thermal image unit

The ekor.rpa-100 model 120 systems are fitted with

the thermal image unit (49) for protection of lines and

transformers.

On certain occasions, the thermal overload of the element

to be protected cannot be detected by conventional

protection units. Furthermore, many of the elements

installed in the power system are being used ever-closer to

their thermal limits, making it necessary for the protection

devices used for these elements to have thermal units.

The thermal image unit is a unit which, in accordance with

the estimated thermal capacity value, generates alarm and

trip signals.

IG-267-EN versión 01; 07/04/2017

25

Protection functions General Instructions

ekor.rpa

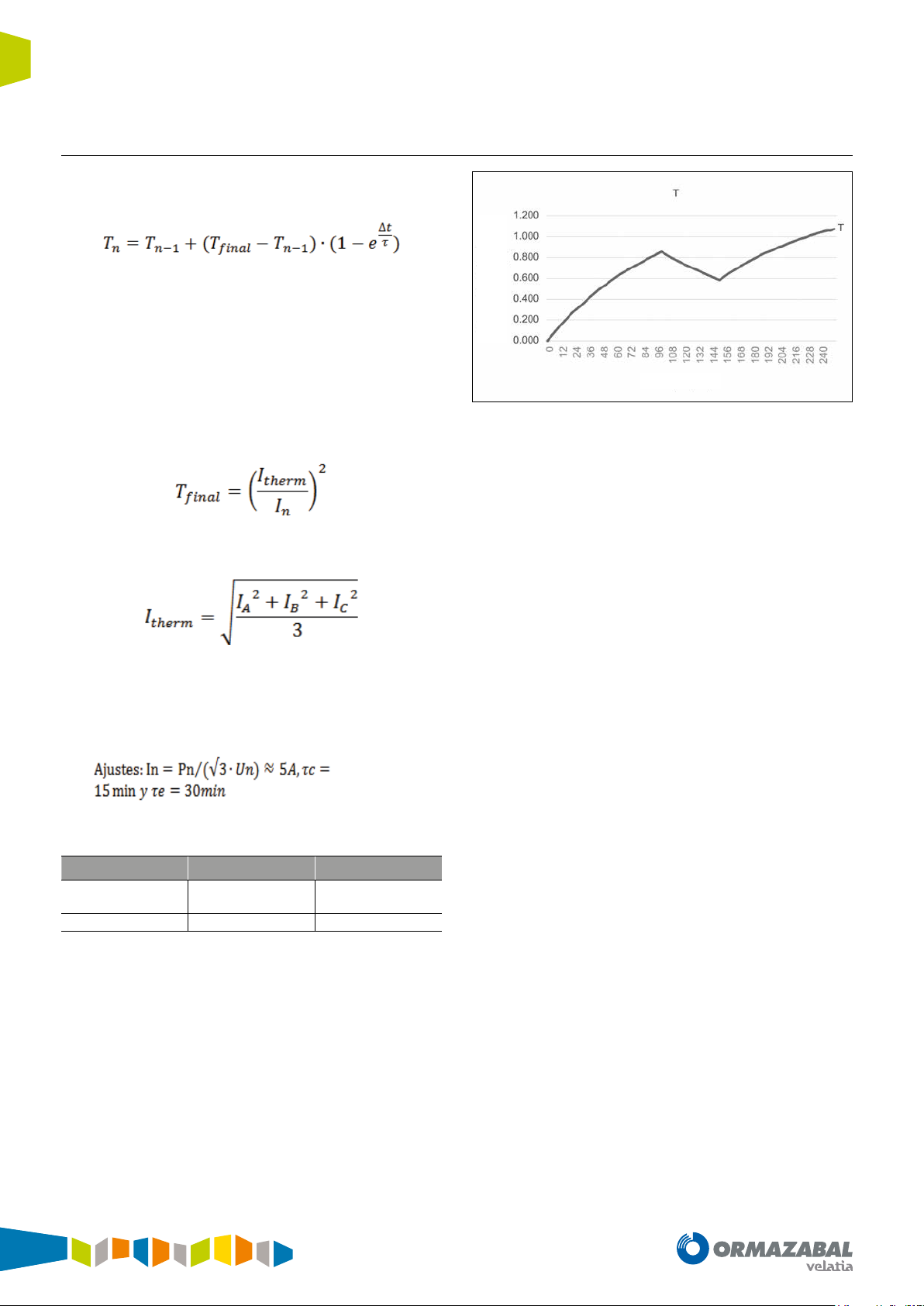

4.4.1. Estimated thermal capacity

The system estimates thermal capacity through the phase

currents (I

Where:

T

: Estimated thermal capacity at instant n

n

T

: Estimated thermal capacity at instant n-1

n-1

Δt: Time interval between consecutive n and n-1 instants

τ: Cooling or heating constant If T

constant will be applied in the formula If, on the other hand,

T

final

T

: Final thermal capacity This value is calculated based on the

final

, IB and IC), using the following formula:

A

< T

final

< T

, the cooling constant will be applied in the formula

n-1

, the temperature rise

n-1

adjusted rated current and the phase currents, in accordance

with the following formula:

capacity (T)

Estimated thermal

Time (min)

Figure 4.6. Estimated thermal capacity

Starting from an initial thermal capacity of 0 %, during the

first 100 min where current is 16 % higher than the rated

(5.8 A), estimated thermal capacity reaches a value of

84.6 %.

I

: The estimated mean thermal current based on the phase

therm

currents:

Example

The evolution of the thermal capacity estimated by the

system for a 250 kVA transformer in a 30 kV network

under the following conditions:

I

sequence read by the equipment:

therm

Interval 1 Interval 2 Interval 3

From 0 min

to 100 min

5.8 A 1.5 A 5.8 A

Table 4.1. I

read by the system

therm

From 100 min

to 150min

From 150 min

to 250min

In the next 50 min current drops to 30 % of rated current

(1.5 A), and this makes thermal capacity drop to 58.4 %.

A third interval identical to interval 1 has been chosen to

check the memory effect of the estimated thermal capacity.

In other words, a current which is 16 % higher than the rated

(5.8 A) for 100 min. It is observed that, after these 100 min,

thermal capacity reaches 106.3 %, thus exceeding 100 %

(typical trip level setting).

This difference in the estimated thermal capacity between

intervals 1 and 3 is due to the fact that previous statuses

are taken into account in the calculation. Hence, as the first

interval starts from a thermal capacity equal to 0 %, the third

interval starts from the thermal capacity accumulated up

to this moment, taking into account all the thermal stress

suffered by the element to be protected. This means the

estimated thermal capacities are different in these intervals.

26

IG-267-EN versión 01; 07/04/2017

General Instructions

ekor.rpa

4.4.2. Functionality

Protection functions

The thermal image unit starts up (with an alarm signal) if the

thermal capacity value exceeds the alarm level setting (%),

tripping whenever the trip level setting is exceeded (%).

Once the unit has tripped, this will reset when the thermal

capacity value drops below the trip reset level setting (%).

The settings for the thermal image unit are:

• Enabling the unit: Enable/disable the unit (ON/OFF).

• Temperature rise constant: Temperature rise constant

(from 3 min to 60 min).

• Cooling constant: Cooling constant (from 3 min to

180 min).

• Alarm level: Alarm threshold percentage. The thermal

capacity percentage from which an alarm situation is

considered (from 80 % to 100 %).

• Trip level: Trip threshold percentage. The thermal

capacity percentage from which a thermal overload is

tripped (from 100 % to 200 %).

• Trip reset level: Reset threshold. The thermal capacity

percentage below which the unit is reset (from 50 % to

99 %).

• Rated current: Rated current of the element to be

protected. Variable ranges in accordance with current

transformers used.

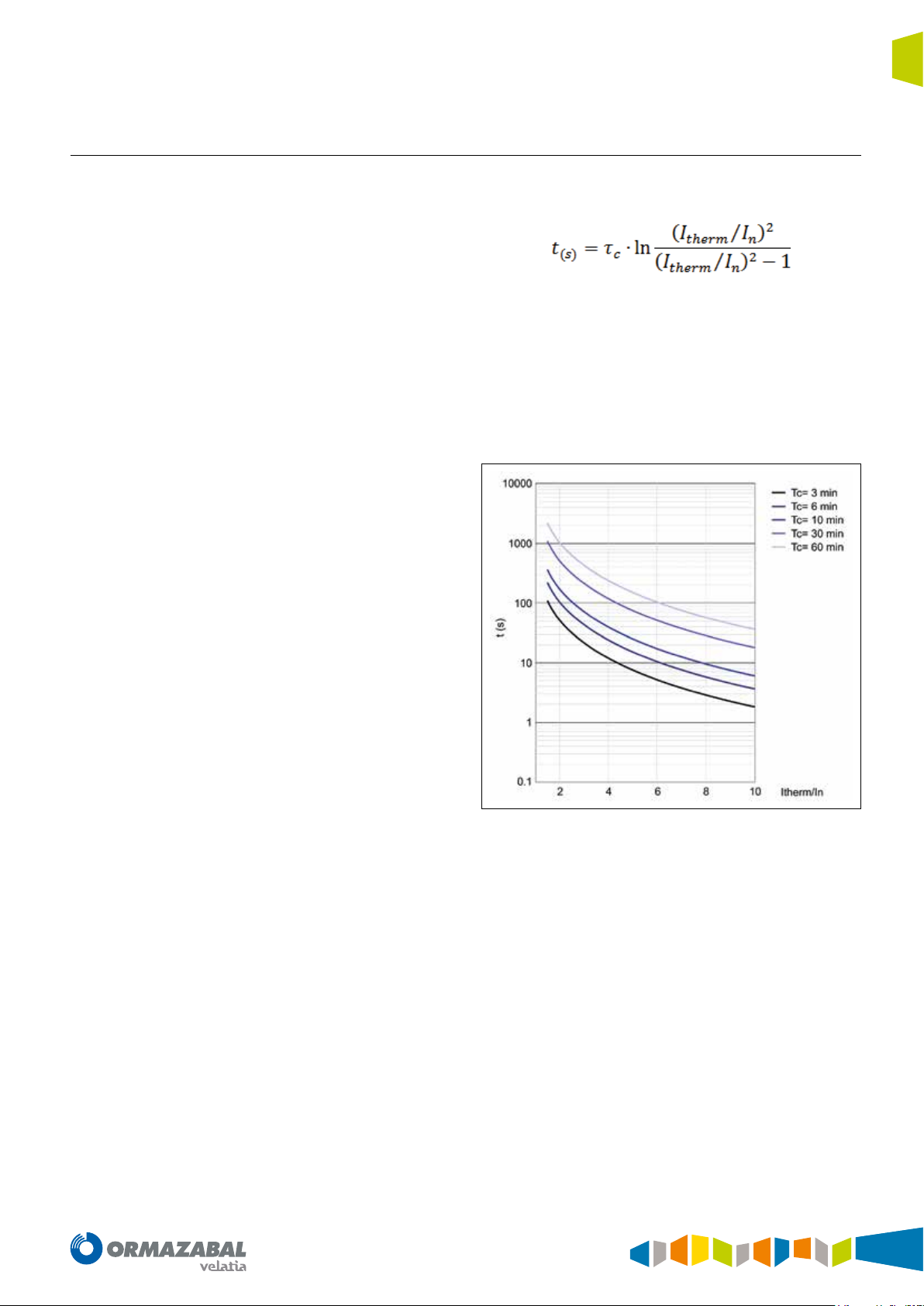

The time taken to reach tripping, based on a thermal

capacity equal to zero, given by the following formula:

Where:

t: Tripping time

τ

: Temperature rise constant

c

I

: Adjusted rated current

n

I

: The estimated mean thermal current based on the phase

therm

currents

The trip times for different temperature rise constants are

shown graphically below:

Figure 4.7. Trip time

IG-267-EN versión 01; 07/04/2017

27

Protection functions General Instructions

ekor.rpa

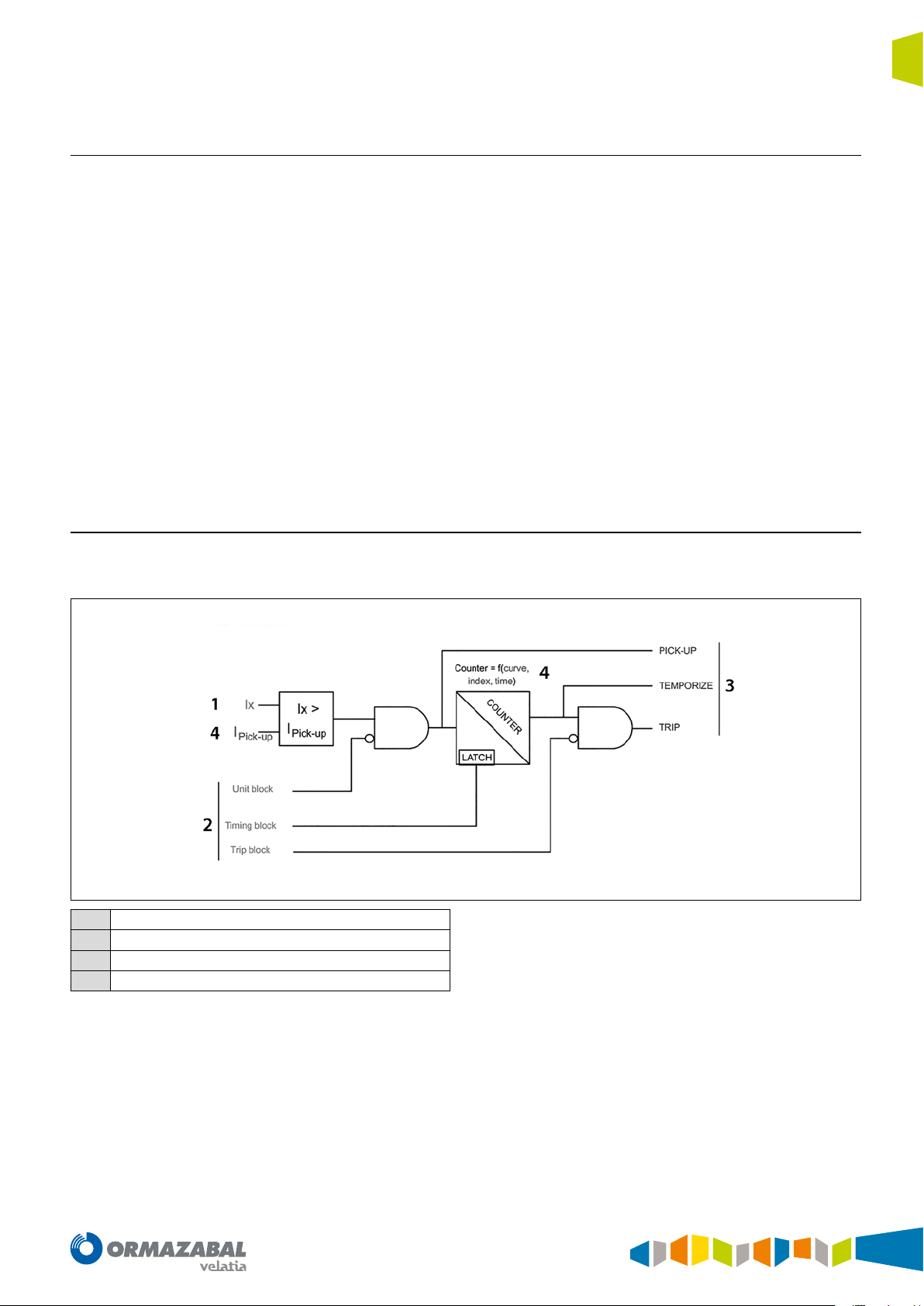

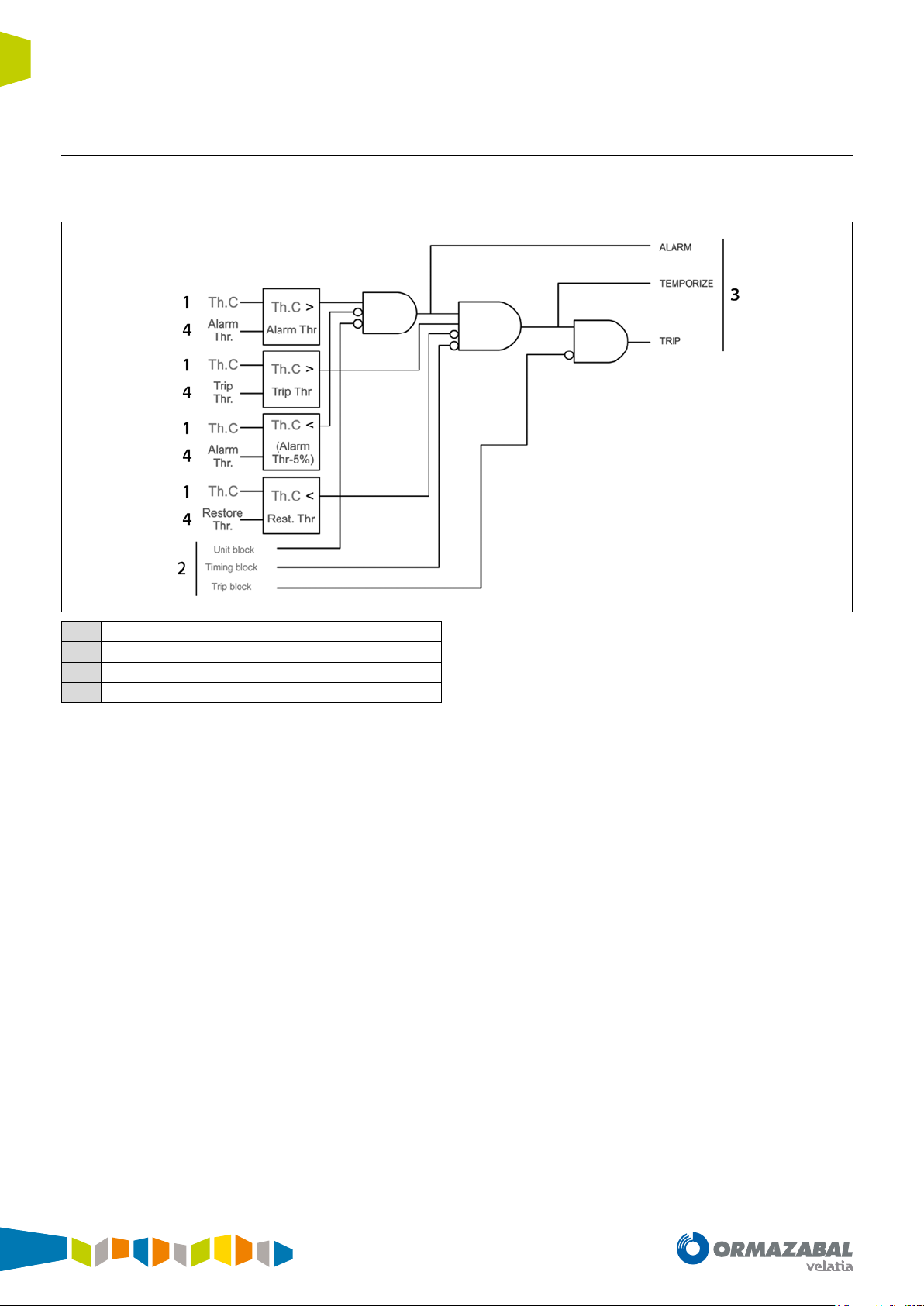

4.4.3. Block diagram

The thermal image unit complies with the following block

diagram :

Metering

1

Input signal

2

Output signal

3

Settings

4

Figure 4.8. Block diagram

The thermal image unit generates the following signal:

• Alarm: Activated when the estimated magnitude of

thermal capacity (Th. C) exceeds the “Alarm Threshold”

setting, and is disabled when estimated thermal capacity

(Th. C) drops below the “Alarm Threshold – 5%” setting.

• Temporize: Activated when the estimated magnitude

of thermal capacity (Th. C) exceeds the “Trip Threshold”

setting, and is disabled when estimated thermal capacity

(Th. C) drops below the “Restore Threshold” setting.

• Trip: Activated when the temporize signal is activated,

and disabled when the estimated thermal capacity (Th.

C) drops below the “Restore Threshold” setting.

Moreover, the thermal image unit can be blocked by the

maximum current blocking unit detailed in the following

sections.

The thermal image unit can be blocked in three different

ways:

• Unit Block: Blocks the unit, preventing start-up while

this input remains active.

• Timing Block: Blocks the unit, allowing it to run the

alarm signal but not allowing the temporize or trip signal.

• Trip Block: Allows the unit to advance, and blocks it

before the trip output.

28

IG-267-EN versión 01; 07/04/2017

General Instructions

ekor.rpa

4.5. Broken conductor unit

Protection functions

The ekor.rpa-100 model 120 systems are fitted with the

broken conductor unit (46BC).

Conventional protection functions cannot detect conditions

in which one of the conductors is broken.

4.5.1. Calculation of sequence currents

The broken conductor unit is supplied by the sequence

currents (I

, I2 and Io) previously calculated by the system.

1

The sequence current calculation is carried out in

accordance with these formulae:

The broken conductor unit (46 Broken Conductor) can

be used to detect broken conductors, by monitoring

the sequence currents, and another series of conditions

detailed in this section.

Where,

With the phase A sequence components known, the B

and C sequence components will be identical in modules,

displaced 120° in angle in the case of direct and inverse

sequence, and with the same angle in the case of zerosequence.

IG-267-EN versión 01; 07/04/2017

29

Protection functions General Instructions

ekor.rpa

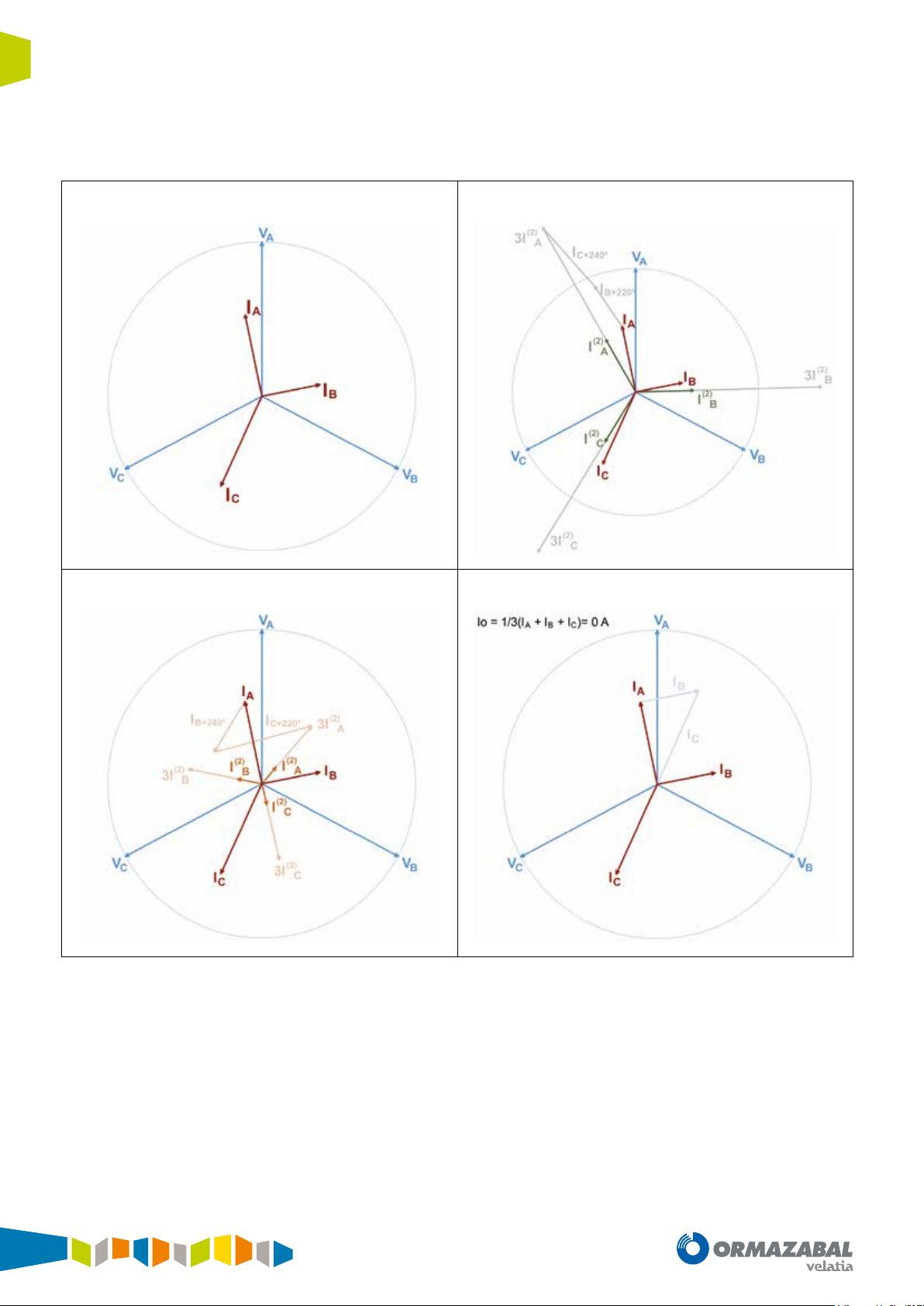

The following image shows an example of calculation of the

sequences based on an imbalanced system. It is observed

that the system has a large inverse component, but no zero-

Line currents Direct-sequence currents

sequence (situation which can come about in lines which

are not uniformly charged in the three phases):

Inverse-sequence currents Zero-sequence currents

Figure 4.9. Calculation of sequences

30

IG-267-EN versión 01; 07/04/2017

General Instructions

ekor.rpa

Protection functions

Another example which applies for the case of broken

conductors could be as follows: One of the phases with

no current (without the capacitive currents which can go

Line currents Direct-sequence currents

through the broken conductor) and the other two counterdirection phases:

Inverse-sequence currents Zero-sequence currents

Figure 4.10. Calculation of sequences

IG-267-EN versión 01; 07/04/2017

31

Protection functions General Instructions

ekor.rpa

4.5.2. Functionality

The broken conductor unit starts up when a series of

conditions are met, as detailed below, and is reset when any

of these conditions drops to 0. Tripping takes place if the

unit is started up for the time set.

The settings for the broken conductor unit are:

• Enabling the unit: Enable/disable the unit (ON/OFF).

• Base current: The magnitude to be used to calculate the

ratios. Can be I1 (direct sequence) or I

(primary rated

n

current of the current transformer). The In value will vary

in accordance with the current transformers used.

• Starting up the unit: Start-up value of I2 (inverse

sequence)/Ib (base current) (from 0.05 to 0.5 p.u.).

4.5.3. Block diagram

The broken conductor unit complies with the following

block diagram:

• Unit timing: Unit tripping time (from 0.05 s to 600.00 s).

• Minimum current threshold for phases: Phase current

value, below which it is considered that the line is open.

Although the line is actually open, there may be current

flowing through this phase (through capacitive elements

of the lines, as this line continues to supply some stations

located before the broken conductor). Variable ranges in

accordance with current transformers used.

• Maximum current threshold for neutral: Maximum

ratio of Io (zero-sequence)/Ib (base current ) as of which

it is considered a single-phase fault rather than an

broken conductor (from 0.00 to 0.5 p.u.). If the setting

is 0.00, the 46BC unit does not make any zero-sequence

current check.

Input signal

1

Output signal

2

Settings

3

Figure 4.11. Block diagram

32

IG-267-EN versión 01; 07/04/2017

General Instructions

ekor.rpa

The four conditions which make the broken conductor unit

start up are:

Protection functions

Figure 4.12. Conditions A, B, C and D

The broken conductor unit generates the following signal:

• Pick up: Activated when the four conditions come

about at the same time, and disabled when any of the 4

conditions are no longer met.

• Temporize: Activated when the Pick up signal remains

active for the time set, and disabled when any of the

4 conditions are no longer met..

• Trip: Activated when the Temporize signal is activated, and

disabled when any of the 4 conditions are no longer met.

4.6. Voltage units

The ekor.rpa-100 model 120 systems are fitted with the

following voltage protection units:

Phases:

1. Three phase overvoltage timed units (3 x 59_TEMP)

2. Three phase overvoltage instantaneous units

(3 x 59_INST)

3. Three phase undervoltage timed units

(3 x 27_TEMP)

4. Three phase undervoltage instantaneous units

(3 x 27_INST)

Moreover, the broken conductor unit can be blocked by the

maximum current blocking unit detailed in the following

sections.

The broken conductor unit can be blocked in three

different ways:

• Unit Block: Blocks the unit, preventing start-up while

this input remains active.

• Timing Block: Freezes the time counter value while this

input is active.

• Trip Block: Allows the unit to advance, and blocks it

before the trip output.

Neutral (calculated):

1. A neutral overvoltage timed unit (1 x 59N_TEMP)

2. A neutral overvoltage instantaneous unit

(1 x 59N_INST)

IG-267-EN versión 01; 07/04/2017

33

Protection functions General Instructions

ekor.rpa

4.6.1. Timed overvoltage units

The phase and neutral timed units start up if the

fundamental value of the magnitude (single or compound

voltage, which can be set by the user) for each unit is below

the value 1.05 times the adjusted start-up, and are reset

when this value exceeds 0.95 times the adjusted value.

Tripping takes place if the unit is started up for the time

set. This time may be adjusted by selecting different types

of curve, in accordance with IEC and ANSI Standards. The

curves implemented for the voltage units are identical to

those in the overcurrent units.

4.6.2. Instantaneous overvoltage units

The phase and neutral timed units start up if the

fundamental value of the magnitude for each unit exceeds

the value 1.00 times the adjusted start-up, and are reset

when this value is below 0.95 times the adjusted value.

Tripping takes place if the unit is started up for the time set.

The settings for the timed units are:

• Enabling the unit: Enable/disable the unit (ON/OFF).

• Working voltage: Selection of the magnitude for

working: Single or compound voltage (Phase to neutral

or Phase to phase).

• Starting up the unit: Unit starting voltage (from 0.5 kV

to 72.0 kV).

• Time curve: Curve type (IEC DT, IEC NI, IEC VI, IEC EI, IEC

LTI, IEC STI, ANSI LI, ANSI NI, ANSI VI, ANSI EI).

• Inverse curve time index: Time index, also known as

time dial (from 0.05 to 1.60). This setting applies to all

curve types except for IEC DT.

• Fixed time: Unit tripping time (from 0.00 s to 100.00 s).

This setting only applies to IEC DT type curves.

The settings for the instantaneous units are:

• Enabling the unit: Enable/disable the unit (ON/OFF).

• Working voltage: Selection of the magnitude for

working: Single or compound voltage (Phase to Phase or

Phase to Neutral).

• Starting up the unit: Unit starting voltage (from 0.5 kV

to 72.0 kV).

• Fixed time: Unit tripping time (from 0.00 s to 100.00 s).

34

IG-267-EN versión 01; 07/04/2017

General Instructions

ekor.rpa

4.6.3. Timed undervoltage units

Protection functions

The phase timed units start up if the fundamental value of

the magnitude (single or compound voltage, which can be

set by the user) for each unit is below the value 0.95 times

the adjusted start-up, and are reset when this value exceeds

1.05 times the adjusted value.

Tripping takes place if the unit is started up for the time

set. This time may be adjusted by selecting different types

of curve, in accordance with IEC and ANSI Standards. The

curves implemented for the voltage units are identical to

those in the overcurrent units.

4.6.4. Instantaneous undervoltage units

The phase instantaneous units start up if the fundamental

value of the magnitude (single or compound voltage, which

can be set by the user) for each unit is below the value 1.00

times the adjusted start-up, and are reset when this value

exceeds 1.05 times the adjusted value

Tripping takes place if the unit is started up for the time set.

The settings for the timed units are:

• Enabling the unit: Enable/disable the unit (ON/OFF).

• Working voltage: Selection of the magnitude for

working: Single or compound voltage (Phase to neutral

or Phase to phase).

• Starting up the unit: Unit starting voltage (from 0.5 kV

to 72.0 kV).

• Time curve: Curve type (IEC DT, IEC NI, IEC VI, IEC EI,

IEC LTI, IEC STI, ANSI LI, ANSI NI, ANSI VI, ANSI EI).

• Inverse curve time index: Time index, also known as

time dial (from 0.05 to 1.60). This setting applies to all

curve types except for IEC DT.

• Fixed time: Unit tripping time (from 0.00 s to 100.00 s).

This setting only applies to IEC DT type curves.

The settings for the instantaneous units are:

• Enabling the unit: Enable/disable the unit (ON/OFF).

• Working voltage: Selection of the magnitude for

working: Single or compound voltage (Phase to Phase or

Phase to Neutral).

• Starting up the unit: Unit starting voltage (from 0.5 kV

to 72.0 kV).

• Fixed time: Unit tripping time (from 0.00 s to 100.00 s).

IG-267-EN versión 01; 07/04/2017

35

Protection functions General Instructions

ekor.rpa

4.6.5. Block diagram

Any voltage unit complying with the diagram shown below.

Metering

1

Input signal

2

Output signal

3

Settings

4

Figure 4.13. Block diagram

The diagram represents, whenever the magnitude measured

in real time (Vx) is: a) higher in the case of overvoltage units:

59 or, b) lower in the case of undervoltage units: 27 than the

setpoint value (V

setting), a time counter counts down

pick up

(counter: ƒ (curve, index, time) tripping once completely

expired.

If the measured magnitude (Vx) drops (overvoltage units: 59)

or increases (undervoltage units: 27) over setpoint (V

pick up

),