Ormazabal cgm.3-l, cgm.3-p, cgm.3-s, cgm.3-s-pt, cgm.3-pti General Instructions Manual

...

cgm.3 system

Fully SF6 gas insulated medium

voltage switchgear up to 40.5 kV in

accordance with IEC Standards

General instructions

IG-136-EN, version 10; 23/06/2016

CAUTION!

When medium-voltage equipment is operating, certain components are live, other parts may be in movement and some may reach high

temperatures. Therefore, the use of this equipment poses electrical, mechanical and thermal risks.

In order to ensure an acceptable level of protection for people and property, and in compliance with applicable environmental

recommendations, Ormazabal designs and manufactures its products according to the principle of integrated safety, based on the

following criteria:

• Elimination of hazards wherever possible.

• Where elimination of hazards is neither technically nor economically feasible, appropriate protection functions are

incorporated in the equipment.

• Communication about remaining risks to facilitate the design of operating procedures which prevent such risks, training

for the personnel in charge of the equipment, and the use of suitable personal protective equipment.

• Use of recyclable materials and establishment of procedures for the disposal of equipment and components so that

once the end of their service lives is reached, they are duly processed in accordance, as far as possible, with the

environmental restrictions established by the competent authorities.

Consequently, the equipment to which the present manual refers complies with the requirements of section 11.2 of Standard IEC 62271-

1. It must therefore only be operated by appropriately qualified and supervised personnel, in accordance with the requirements of

standard EN 50110-1 on the safety of electrical installations and standard EN 50110-2 on activities in or near electrical installations.

Personnel must be fully familiar with the instructions and warnings contained in this manual and in other recommendations of a more

general nature which are applicable to the situation according to current legislation

The above must be carefully observed, as the correct and safe operation of this equipment depends not only on its design but also on

general circumstances which are in general beyond the control and responsibility of the manufacturer. More specifically:

[1].

• The equipment must be handled and transported appropriately from the factory to the place of installation.

• All intermediate storage should occur in conditions which do not alter or damage the characteristics of the equipment or

its essential components.

• Service conditions must be compatible with the equipment rating.

• The equipment must be operated strictly in accordance with the instructions given in the manual, and the applicable

operating and safety principles must be clearly understood.

• Maintenance should be performed properly, taking into account the actual service and environmental conditions in the

place of installation.

The manufacturer declines all liability for any significant indirect damages resulting from violation of the guarantee, under any jurisdiction,

including loss of income, stoppages and costs resulting from repair or replacement of parts.

Warranty

The manufacturer guarantees this product against any defect in materials and operation during the contractual period. If defects are

detected, the manufacturer may opt either to repair or replace the equipment. Improper handling of this equipment and its repair by the

user shall constitute a violation of the guarantee.

Registered trademarks and copyrights

All registered trademarks cited in this document are the property of their respective owners. The intellectual property of this manual

belongs to Ormazabal.

[1]

For example, in Spain the “Regulation on technical conditions and guarantees for safety in high-voltage electrical installations” –

Royal Decree 337/2014 is obligatory.

In view of the constant evolution in standards and design, the characteristics of the elements contained in this manual are subject

to change without prior notice. These characteristics, as well as the availability of components, are subject to confirmation by

Ormazabal.

General instructions

cgm.3 system

Fully SF6 gas insulated medium voltage switchgear up to 40.5 kV in accordance with IEC Standards

Contents

1 General description ......................................................... 6

1.1 Models .................................................................................6

1.2 Standards applied........................................................................7

1.3 Main components ........................................................................7

1.3.1 Gas tank .........................................................................8

1.3.2 Driving mechanism compartment ......................................................8

1.3.3 Base.............................................................................9

1.3.4 Name plate ......................................................................10

1.4 Characteristics table.....................................................................11

1.5 Dimensions and weights .................................................................12

1.6 Operating conditions ....................................................................13

3

2 Handling and transport ..................................................... 14

2.1 Lifting means...........................................................................14

3 Storage .................................................................. 16

4 Installation ............................................................... 17

4.1 Unpacking the equipment ................................................................17

4.2 Location of accessories during transport ...................................................17

4.3 Minimum installation distances............................................................18

4.4 Recommended cable connection trench ....................................................19

4.4.1 Cubicles with internal arc in gas tank up to 20 kA - 0.5 s ...................................19

4.4.2 Cubicles with classification of internal arc IAC up to 25 kA - 1 s ..............................22

4.5 Fastening to the floor ....................................................................26

4.5.1 Fastening to the floor on profile .......................................................26

4.5.2 Fastening to the floor by anchoring ....................................................26

4.6 Connecting the cubicles .................................................................29

4.7 Earthing the switchgear ..................................................................29

4.8 Cable connections ......................................................................30

4.8.1 Horizontal front connection ..........................................................30

4.8.2 Cable connection in fuse protection function 1400 mm high .................................31

4.9 Assembly and connection of measuring transformers in cgm.3-m ...............................33

IG-136-EN version 10; 23/06/2016

4

General instructions

cgm.3 system

Fully SF6 gas insulated medium voltage switchgear up to 40.5 kV in accordance with IEC Standards

5 Recommended sequence of operations ....................................... 34

5.1 Checking the gas pressure ...............................................................34

5.2 Voltage presence indicator ...............................................................34

5.3 Phase balance check ....................................................................35

5.4 Feeder function .........................................................................36

5.4.1 Mimic diagram ....................................................................36

5.4.2 Driving levers .....................................................................37

5.4.3 Opening operation from earthing position ...............................................37

5.4.4 Switch closing operation from the disconnected position ...................................38

5.4.5 Opening operation from closed position ................................................39

5.4.6 Earthing operation from the disconnected position ........................................40

5.4.7 Cable test........................................................................40

5.5 Busbar switch function ..................................................................41

5.5.1 Mimic diagram ....................................................................41

5.5.2 Driving lever......................................................................41

5.5.3 Switch closing operation from the disconnected position ...................................42

5.5.4 Opening operation from closed position ................................................43

5.6 Busbar switch function with earth connection ...............................................44

5.6.1 Mimic diagram ....................................................................44

5.6.2 Driving lever......................................................................44

5.6.3 Opening operation from earthing position ...............................................45

5.6.4 Connection of the switch-disconnector from the disconnected position ........................46

5.6.5 Opening operation from closed position ................................................46

5.6.6 Earthing operation from open position..................................................47

5.7 Busbar rise function with earth connection..................................................48

5.7.1 Mimic diagram ....................................................................48

5.7.2 Driving levers .....................................................................48

5.7.3 Earthing switch disconnection ........................................................49

5.7.4 Earthing switch connection ..........................................................49

5.8 Fuse protection function .................................................................51

5.8.1 Mimic diagram ....................................................................51

5.8.2 Driving lever......................................................................51

5.8.3 Opening operation from earthing position ...............................................52

5.8.4 Spring charge operation and closing of the switch - disconnector from disconnected position.......52

5.8.5 Opening operation from the switch-disconnector closed position .............................53

5.8.6 Earthing operation from the open position...............................................54

5.9 Fuse replacement sequence ..............................................................54

5.9.1 Selection of recommended fuses .....................................................57

IG-136-EN version 10; 23/06/2016

General instructions

cgm.3 system

Fully SF6 gas insulated medium voltage switchgear up to 40.5 kV in accordance with IEC Standards

5.10 Circuit-breaker function with AV / RAV driving mechanism ....................................58

5.10.1 Mimic diagram ...................................................................58

5.10.2 Spring charge and driving levers .....................................................58

5.10.3 Opening operation from earthing position ..............................................59

5.10.4 Closing operation from open position .................................................60

5.10.5 Opening operation from closed position ...............................................61

5.10.6 Earthing Operation from the open position .............................................62

6 Safety elements ........................................................... 64

6.1 Acoustic earthing prevention alarm ........................................................64

6.2 Interlocks ..............................................................................64

6.2.1 Locking with a padlock..............................................................65

6.2.2 Locking with a lock.................................................................65

5

7 Maintenance .............................................................. 66

7.1 Voltage presence indicator test ............................................................66

7.2 Acoustic earthing prevention alarm test ....................................................67

7.3 Specific maintenance for the cgm.3-v cubicle ...............................................68

8 Spares and accessories .................................................... 69

9 Environmental information .................................................. 71

IG-136-EN version 10; 23/06/2016

General description

6

1 General description

General Instructions

cgm.3 system

Fully SF6 gas insulated medium voltage switchgear up to 40.5 kV in accordance with IEC Standards

The cgm.3 system by Ormazabal, designed following the

requirements indicated by regulations of the International

Electrotechnical Commission (IEC), is made up of different

unifunctional and multifunctional switchgear models,

with full SF6 gas insulation, which can be used to configure

different secondary distribution configurations in medium

voltage up to 40.5 kV

1.1 Models

Unifunctional switchgear Function

cgm.3-l

cgm.3-s

cgm.3-s-pt

cgm.3-p

cgm.3-v

cgm.3-rb

Feeder

Busbar switch

Busbar switch with earth connection on the right (-ptd) or on the

left (-pti)

Fuse protection

Vacuum circuit-breaker

Busbar rise

[1]

.

cgm.3-rc / -r2c

cgm.3-m

Cable/double cable rise

Metering

Multifunctional switchgear Functions

cgm.3-2lp

cgm.3-2lv

[1] Further information at www.ormazabal.com.

2 feeder functions and 1 fuse protection

2 feeder functions and 1 vacuum circuit-breaker

IG-136-EN version 10; 23/06/2016

General Instructions

General description

cgm.3 system

Fully SF6 gas insulated medium voltage switchgear up to 40.5 kV in accordance with IEC Standards

1.2 Standards applied

Standard Description

IEC 62271-1 Common specifications for high-voltage switchgear and controlgear standards.

IEC 62271-100 High-voltage alternating current circuit-breakers.

IEC 62271-102 Alternating current disconnectors and earthing switches.

IEC 62271-103 High-voltage switches for rated voltages above 1 kV up to and including 52 kV.

IEC 62271-105 Alternating current switch-fuse combinations.

7

IEC 62271-200

Alternating current metal-enclosed switchgear and controlgear for rated

voltages above 1 kV and up to and including 52 kV.

IEC 62271-206 / IEC 61243-5 Voltage presence indicating systems.

IEC 60529 Protection grades for enclosures.

IEC 60282-1 Current-limiting fuses.

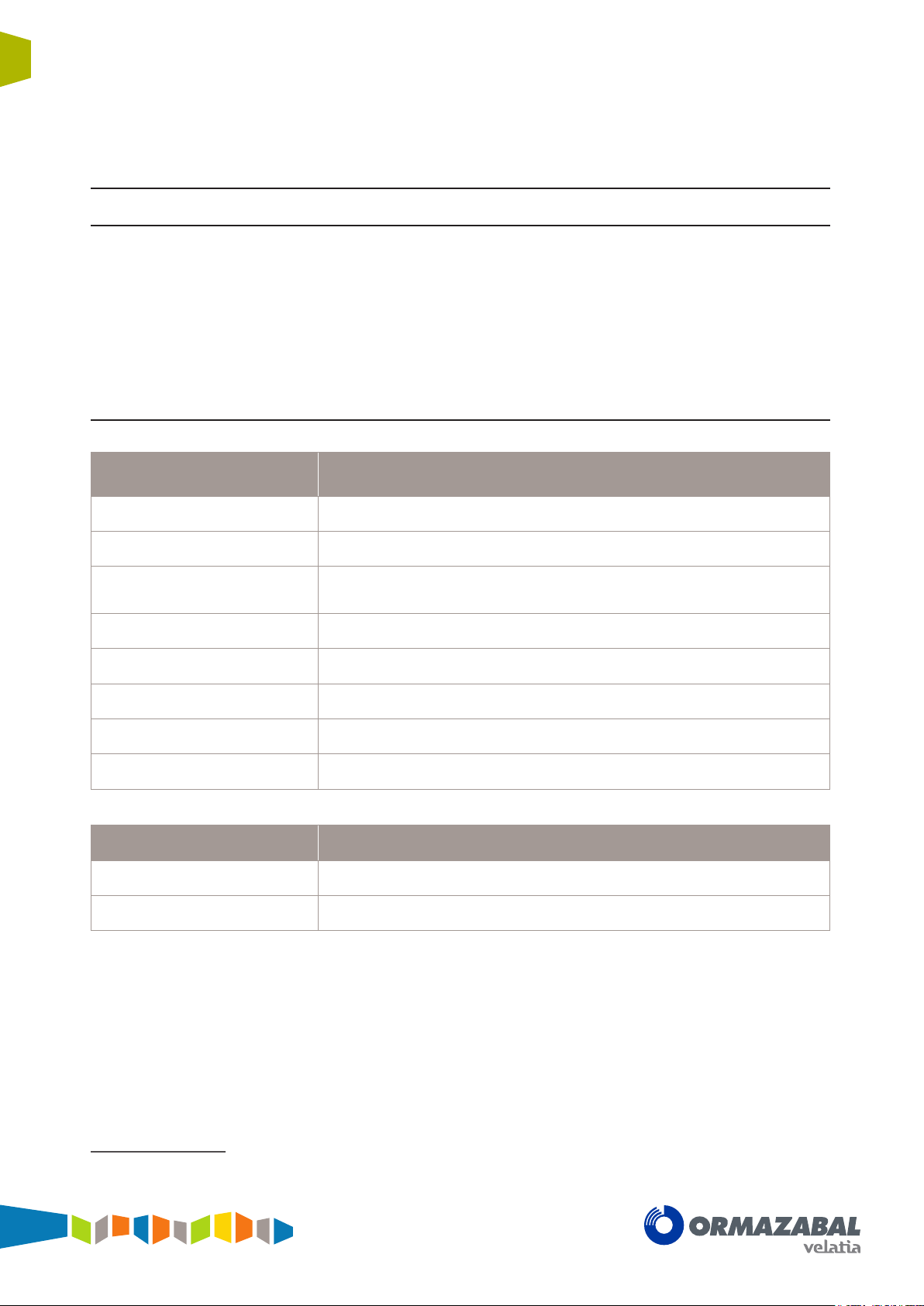

1.3 Main components

1. Gas tank

1.1. Side connection female bushings

2. Driving mechanism area

2.1.Name plate

2.2.Operating sequence plate

2.3. Driving shafts (see mimic diagram of each model).

2.4. ekor.vpis / ekor.ivds* Voltage presence detection unit

2.5. ekor.sas* acoustic earthing prevention alarm unit.

3. Base

3.1 Cable compartment access cover

3.2 Medium-voltage cable fastening support

3.3.Gas relief compartment

3.4.Earth collector

3.5 Front cable connection bushings

* Optional elements.

Figure 1.1 Main elements of cgm.3 cubicles

IG-136-EN version 10; 23/06/2016

General description

8

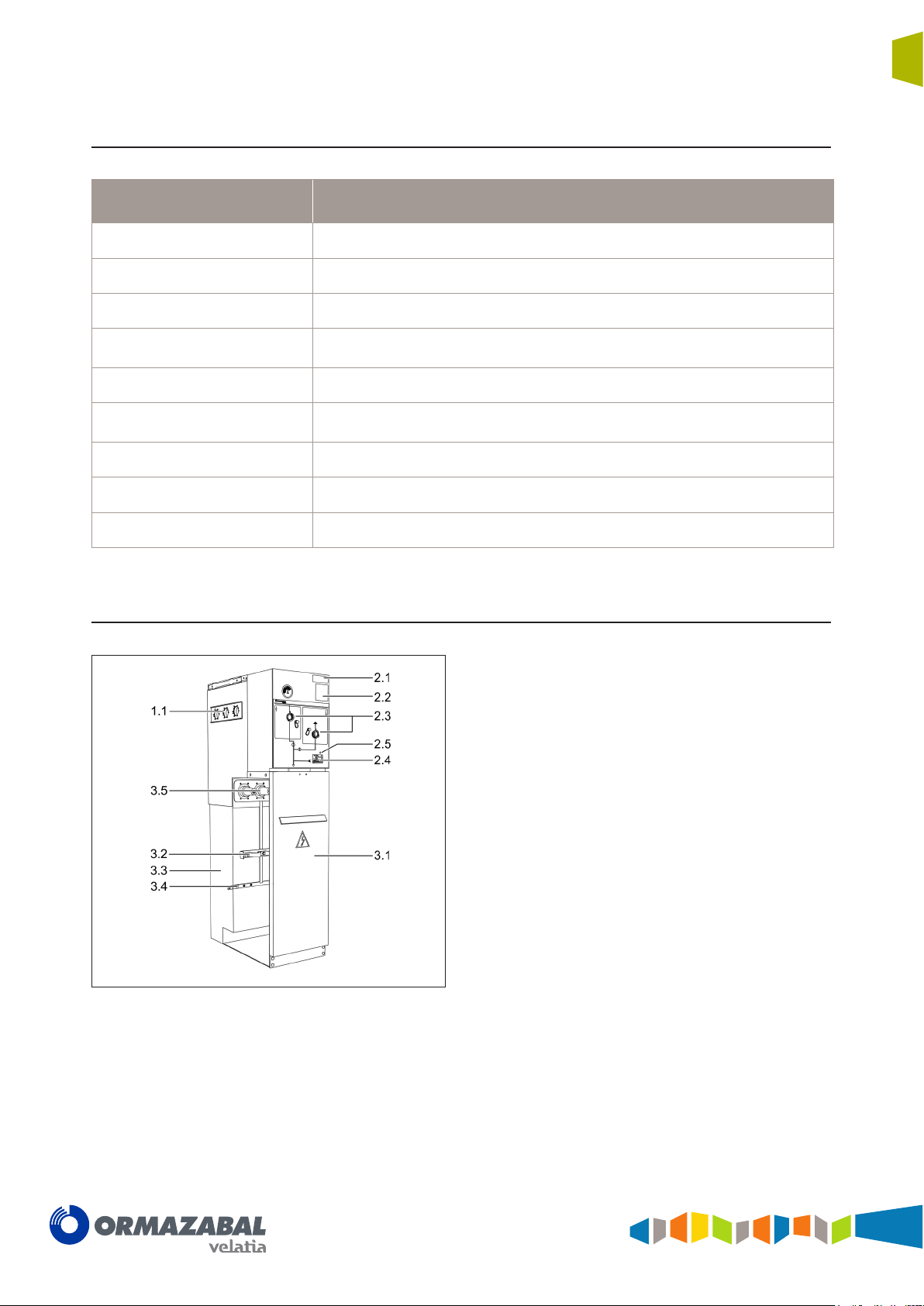

1.3.1 Gas tank

General Instructions

cgm.3 system

Fully SF6 gas insulated medium voltage switchgear up to 40.5 kV in accordance with IEC Standards

Sealed compartment which houses the busbar and the

switching and breaking elements, where the insulating

medium is SF6.

Each gas tank has a pressure relief device to facilitate gas

relief in the event of internal arc.

Figure 1.2 Gas tank for cgm.3-l

1.3.2 Driving mechanism compartment

Thanks to the hermetically-sealed nature of the gas

tank containing all the medium voltage elements, the

equipment is expected to have a minimum service life of

30 years, without replenishing the gas, in accordance with

Standard IEC 62271-1.

This is the compartment in which the switch-disconnector,

earthing switch or circuit-breaker is driven, depending on

the type of function.

The mimic diagram for the main medium voltage circuit is

displayed on the cover of this compartment.

B

BM Motorised tilting

BR-A Accumulation of energy with latch

BR-AM Accumulation of energy with motorised latch

AV Circuit-breaker without reclosing

AMV Motorised circuit-breaker without reclosing

RAV Circuit-breaker with reclosing option

RAMV Motorised circuit-breaker with reclosing option

These elements are operated independently, i.e., their

actuation speed does not depend on the speed of the

manual operation.

The B, BM, BR, AR and BR-AM driving mechanisms can

be replaced by upgrading in any of the three possible

Tilting

The mimic diagram includes all the position indicators for

the driving elements.

The cgm.3 system has, in line with the cubicle model, the

following types of driving mechanism:

l, s, s-pt, rb-pt, v, 2lp, 2lv

l, s, s-pt, 2lp, 2lv

p, 2lp

l, p, 2lp

v, 2lv

v, 2lv

v, 2lv

v, 2lv

positions (closed – opened – earth). Whilst the driving

mechanism is withdrawn, these positions of the switch can

be blocked using a coupling device, whether in service or

not.

IG-136-EN version 10; 23/06/2016

General Instructions

General description

cgm.3 system

Fully SF6 gas insulated medium voltage switchgear up to 40.5 kV in accordance with IEC Standards

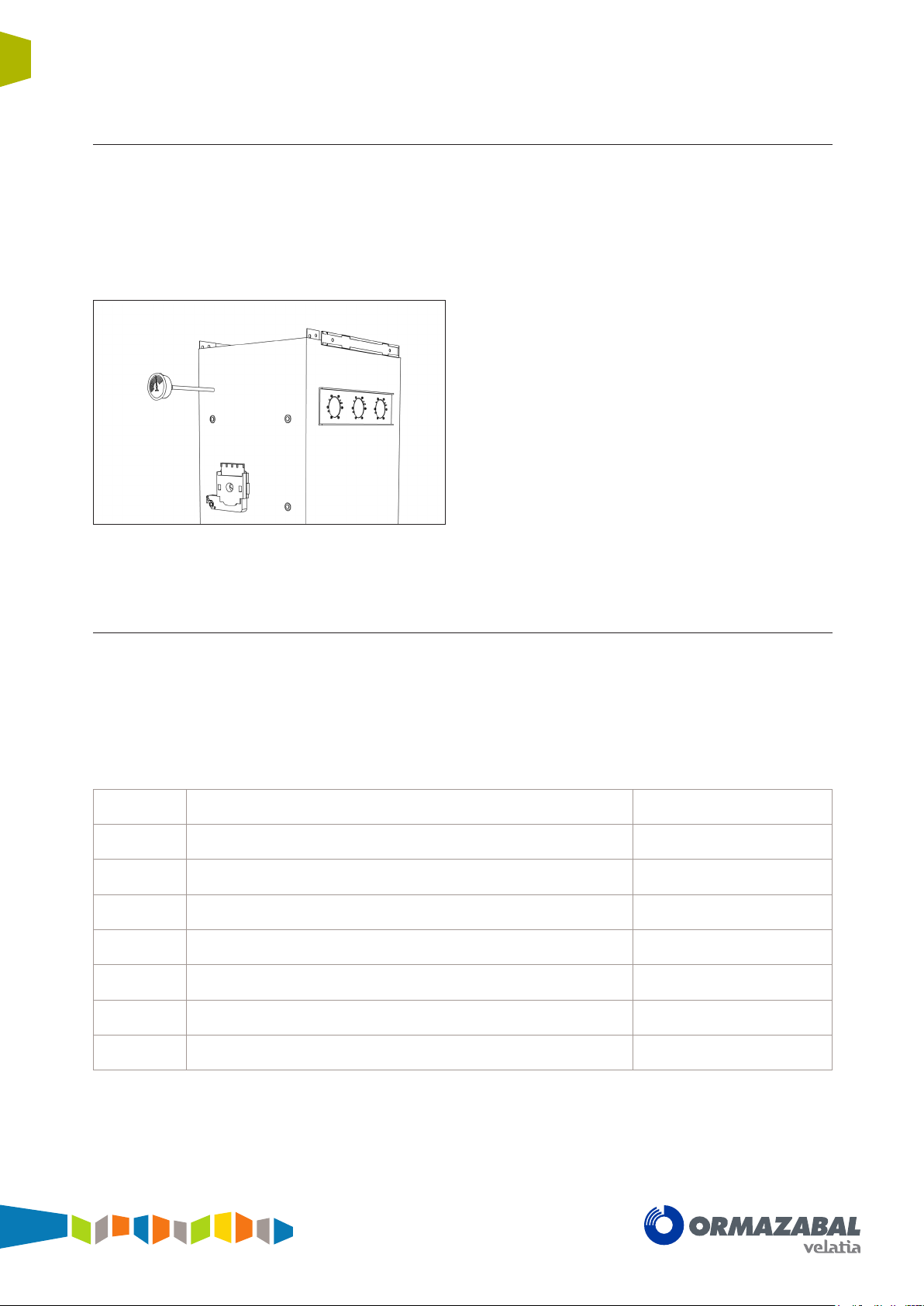

1.3.3 Base

Made up of the cable compartment and the gas relief

compartment:

Cable compartment

This is located in the lower front section of the cubicle

and has a cover interlocked with the earthing switch, thus

allowing front access to the medium voltage cables.

As standard, designed to contain up to:

• Two shielded screw-in terminals (reduced)

per phase or one terminal (reduced) plus

surge arrester (reduced) with space for the

corresponding incoming power cables.

• Cable ties for the power cables.

• Earthing bars.

As an option:

9

• Two symmetric terminals or symmetric terminal

plus symmetric surge arrester.

• Metallic voltage transformers.

Gas relief compartment

The cgm.3 system by Ormazabal is designed and

constructed to withstand at least the thermal and dynamic

effects of an arc of 16 kA for 0.5 seconds should a defect

result in an internal arc in the gas compartment. The

system conducts the gases generated in a fully controlled

manner to avoid any possible injury to people in the

equipment operation area.

Figure 1.3 Cable compartment

Optionally, a chimney can be positioned in the

rear of the cubicle to redirect the gases to the

top section. Please check with Ormazabal.

IG-136-EN version 10; 23/06/2016

10

General description

Fully SF6 gas insulated medium voltage switchgear up to 40.5 kV in accordance with IEC Standards

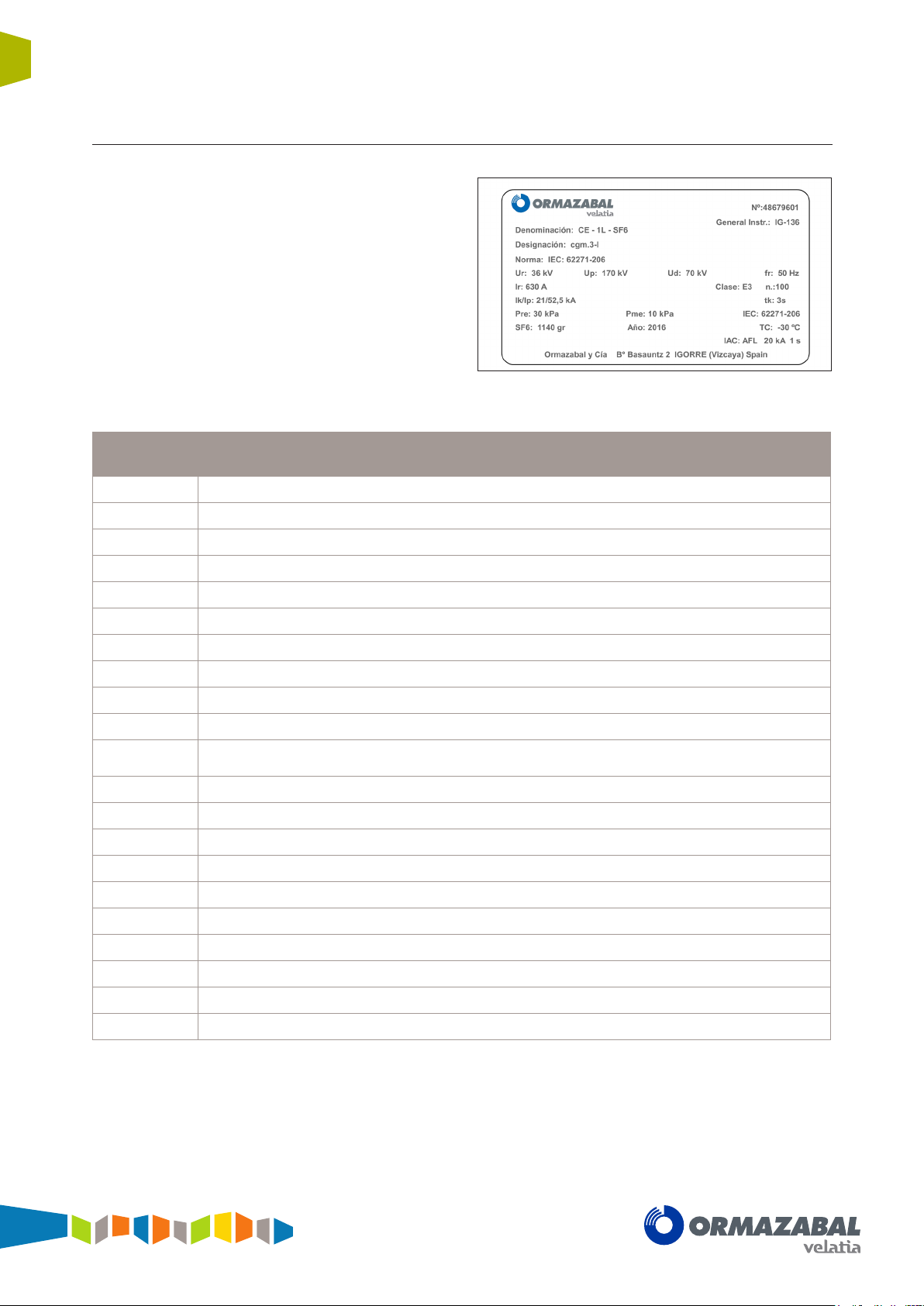

1.3.4 Name plate

Every unit includes a name plate, with some of the

following data:

Name plate

General Instructions

cgm.3 system

Figure 1.4 Example of name plate

Nº Cubicle serial number

(*)

Type Cubicle system Ormazabal

Designation Cubicle model

Standard Standards applied to the equipment

Name Equipment name

U

r

U

p

U

d

f

r

I

r

Instructions

Manual

Equipment rated voltage (kV)

Lightning impulse withstand voltage (kV)

Industrial frequency withstand voltage (kV)

Equipment rated frequency (Hz)

Equipment rated current (A)

General Instructions Manual (IG) for the system

Class Driving mechanism class according to IEC 62271-103

N Number of mainly active load breaking operations

/ I

I

k

t

k

P

re

P

me

SF

Year

TC

IAC

p

6

Short-time withstand current/Short-time withstand peak value

Short-time withstand current time

Gas pressure inside the tank (MPa)

Minimum operating gas pressure (MPa)

Weight of insulating fluid (g)

Year of manufacture

Minimum working temperature

Classification of internal arc

(*)

In the event of incident, this number should be reported to Ormazabal.

IG-136-EN version 10; 23/06/2016

General Instructions

General description

cgm.3 system

Fully SF6 gas insulated medium voltage switchgear up to 40.5 kV in accordance with IEC Standards

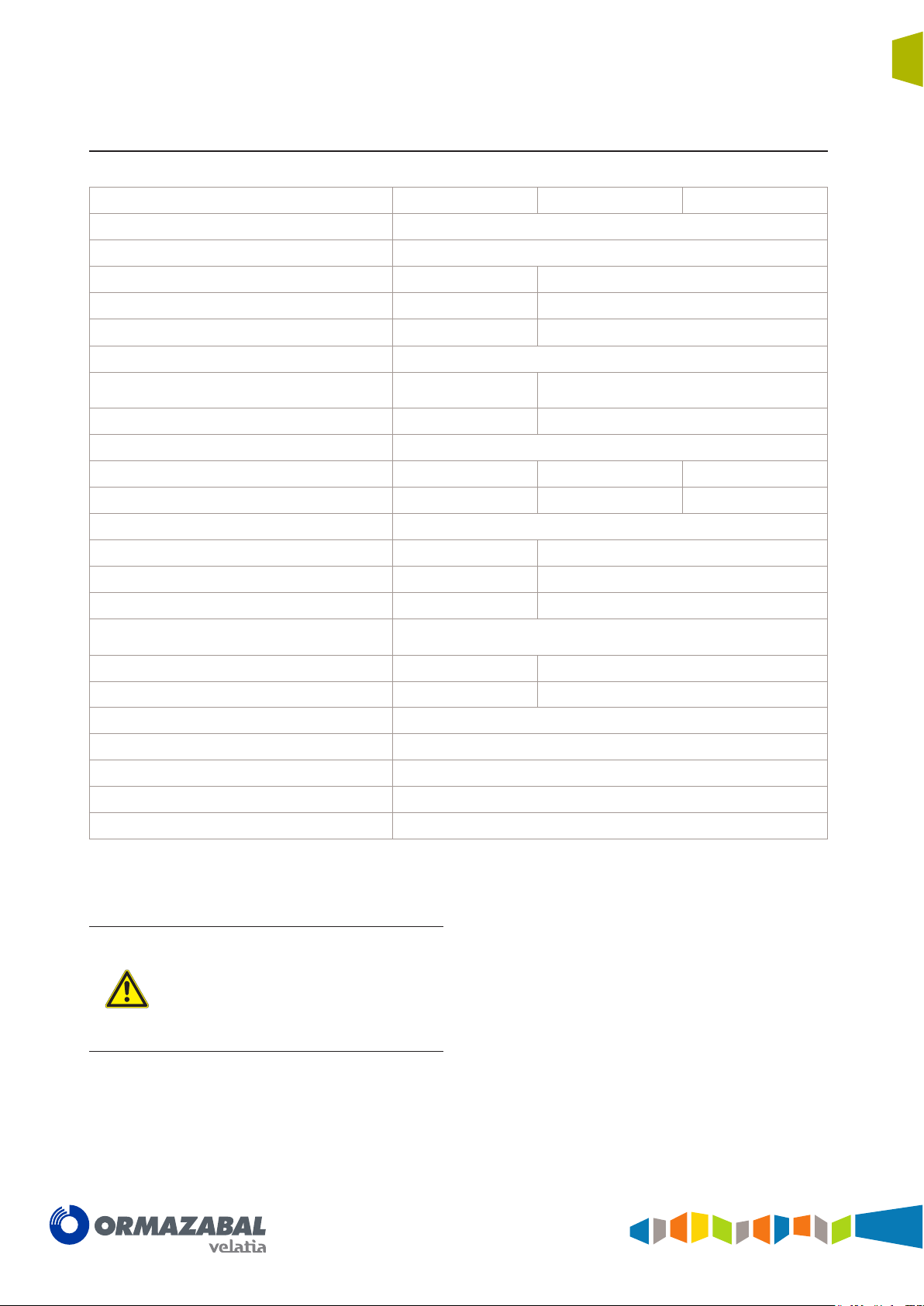

1.4 Characteristics table

Rated voltage [kV] 36 38.5 40.5

Frequency [Hz] 50 / 60

Rated current [A]

Busbars and cubicle interconnection 400 / 630 630

Feeder 400 / 630 630

Output to transformer 200 200

Rated short-term withstand current [kA]

= (x) s

With t

k

Peak value 40 / 52* / 62.5 52* / 62.5

Rated insulation level [kV]

Industrial frequency rated withstand voltage (1 min) 70 / 80 80 / 90 95 / 118

16 / 20* (1 / 3 s)

25 (1 s)

20* (1 / 3 s)

25 (1 s)

11

Lightning impulse rated withstand voltage 170 / 195 180 / 210 185 / 215

Internal arc in tank

Front accessibility 16 / 20* kA (0.5 s) 20* kA (0.5 s)

Front and side accessibility 16 / 20* / 25 kA (1 s) 20* / 25 kA (1 s)

Front, side and rear accessibility*** 16 / 20* / 25 kA (1 s) 20* / 25 kA (1 s)

Internal arc classification in accordance with

IEC 62271-200

IAC AF/AFL

IAC AFLR

Protection grade: Gas tank IP X8

Protection grade: External enclosure IP 2XD

Standard unit colour [RAL] grey 7035 / blue 5005

Category of loss of service continuity [LSC] LSC2

Compartmenting class PM

(*) Tests conducted with current 21 kA/54.6 kA

(**) With gas exhaust upwards via the chimney

The values set out in this table are general

for the cgm.3 system and are only valid once

conrmed by Ormazabal. Some cubicle

models can withstand partial values. For more

detailed information, check the table for each

cubicle model in the CA-112 catalogue by

Ormazabal.

16 / 20* / 25 kA (1 s) 20* / 25 kA (1 s)

16 / 20* / 25 kA (1 s) 20* / 25 kA 1 s

IG-136-EN version 10; 23/06/2016

12

General description

Fully SF6 gas insulated medium voltage switchgear up to 40.5 kV in accordance with IEC Standards

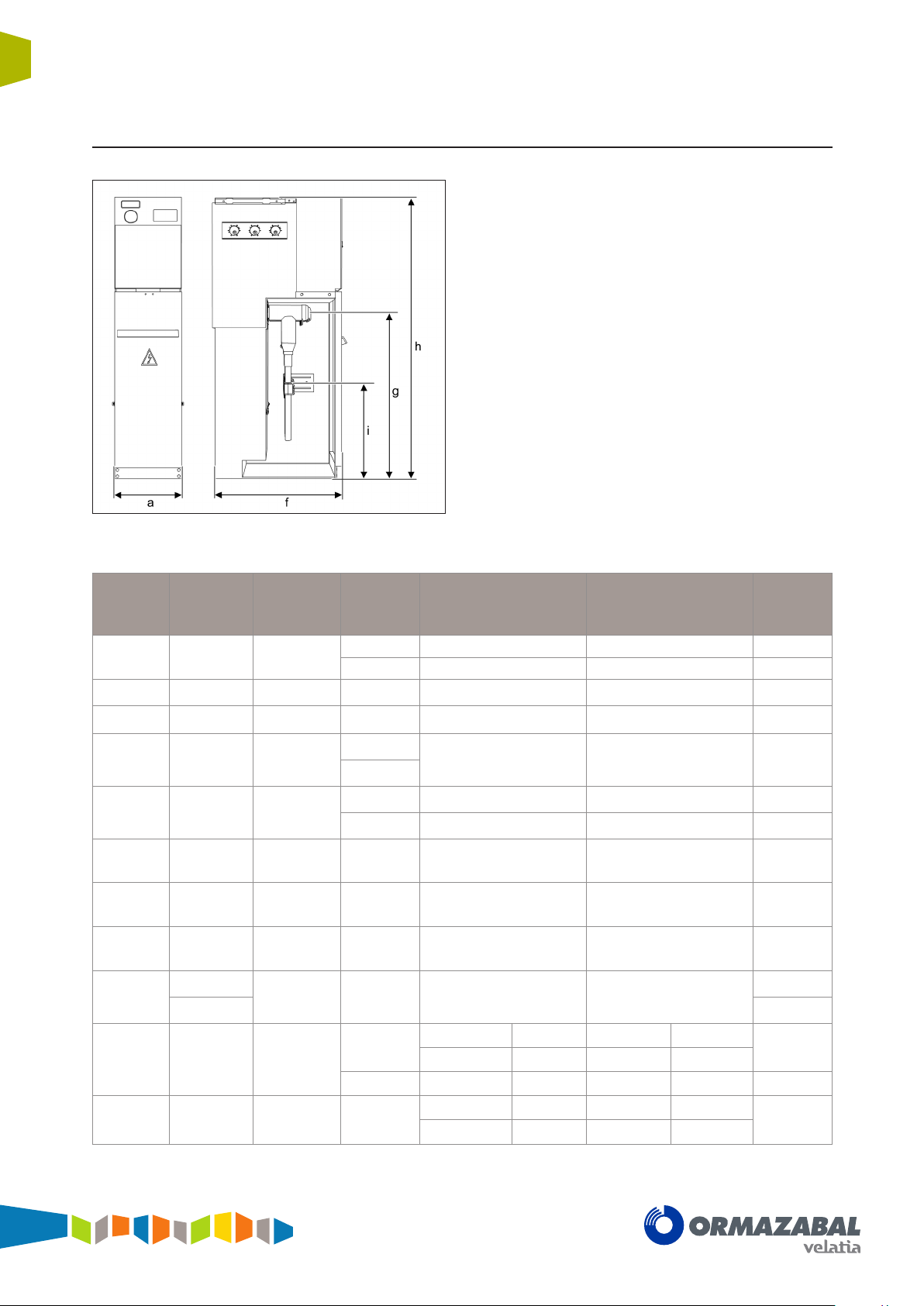

1.5 Dimensions and weights

General Instructions

cgm.3 system

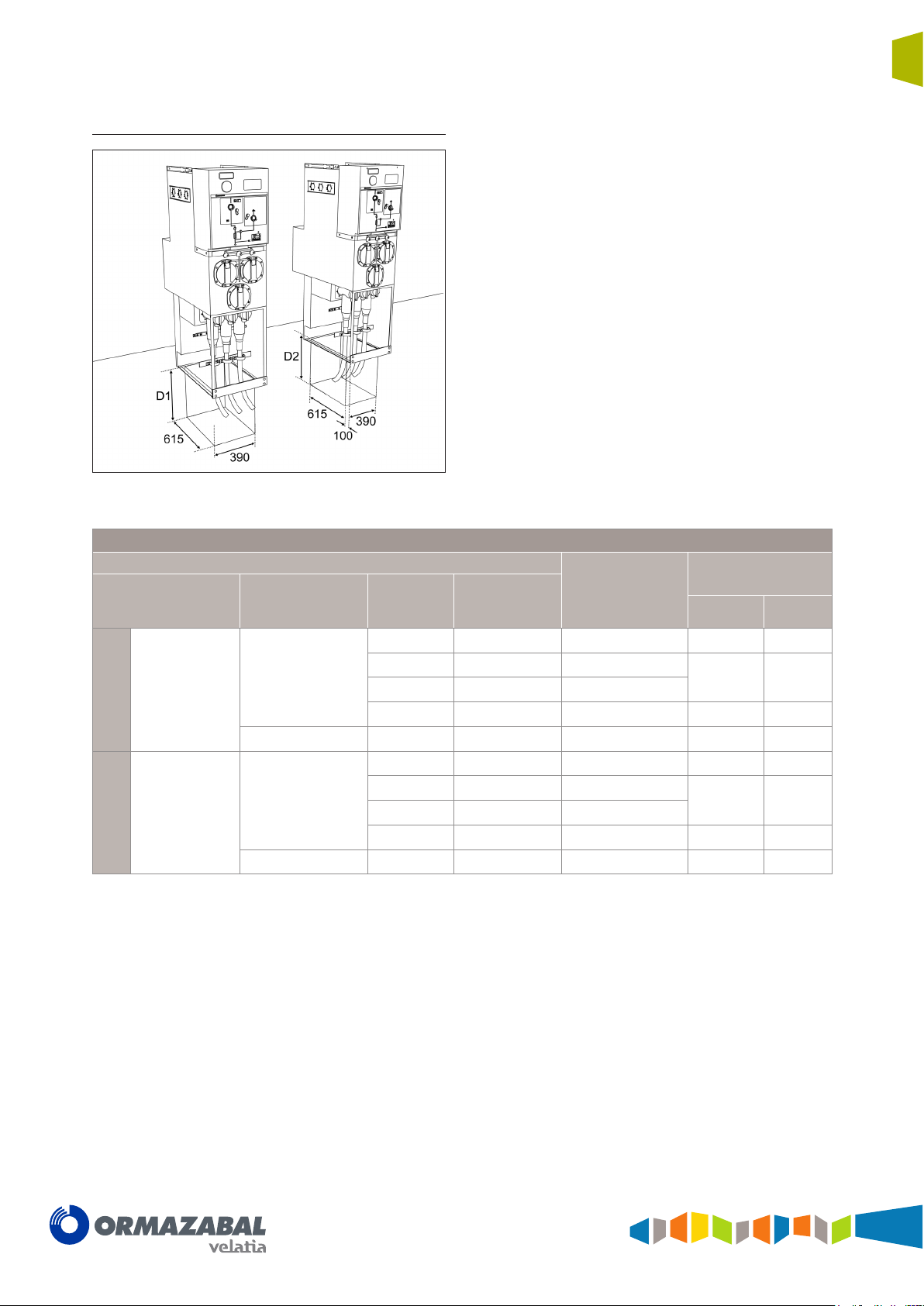

Figure 1.5 Dimensions cgm.3

Cubicle

-l

-s

-s-pt

-p

-v

-rci

-rcd

-r2c

-rb

-rb-pt

Width (a)

[mm]

418 850

418 850 1745 - - 143

600 850 1745 - - 185

480 1010

[2]

600

367 831 1745 1590 1087 42

550 831 1745 1590 1087 65

418 850

1100

-m

900 300

-2lp

-2lv

1316 1010

1436 850 1745

Depth (f)

[mm]

[1]

850

[1]

1160 1950 - -

[1]

Height

(h) [mm]

1400 697 234 147

1745 1042 580 162

1400

1745

1400 350 20 240

1745 695 282 255

1745 1042 580 158

1400

1745 1042 525 580 234 490

Bushings height (g)

[mm]

180 - 128 215

-l -p -l -p

697 180 234 - 128

Cable fastening

-l -v -l -v

1042 695 580 282

height (l)

[mm]

Weight

[kg]

258

460

547

[1]

In the case of double symmetrical terminal, the Switchgear is an extra 80 mm deep.

[2]

As an option, there is also available a 595 mm wide model of the cgm.3-v cubicle. Please check with Ormazabal.

IG-136-EN version 10; 23/06/2016

General Instructions

General description

cgm.3 system

Fully SF6 gas insulated medium voltage switchgear up to 40.5 kV in accordance with IEC Standards

1.6 Operating conditions

Installation Indoor

Maximum ambient temperature + 40 ºC

Minimum ambient temperature – 5 ºC / - 30 ºC

Maximum mean ambient temperature, measured over a 24-hour period + 35 ºC

Maximum mean relative humidity, measured over a 24-hour period < 95%

Maximum mean relative humidity, measured over a 1-month period < 90%

Maximum mean vapour pressure, measured over a 24-hour period 2.2 kPa

Maximum mean vapour pressure, measured over a 1-month period 1.8 kPa

Maximum height above sea level 2000 m

13

(a)

Solar radiation Negligible

Ambient air pollution (dust, smoke, corrosive and/or flammable gases, vapours or

salt)

Vibrations caused by causes external to the switchgear or by seismic movements

(a)

1000 m for metering function and non-shielded connectors. For higher installation altitudes, check with Ormazabal.

(b)

Unless indicated otherwise, It is assumed that there are no specific user requirements.

The specications refer to the section "Normal

service conditions for indoor cubicles" in

Standard IEC 62271-1 "Common specications

for high-voltage cubicles".

For special service conditions: ambient

temperature above + 40 ºC, installation over

2000 m above sea level, signicant pollution

level, or others different to those described,

check with Ormazabal.

Insignificant

Insignificant

(b)

IG-136-EN version 10; 23/06/2016

14

Handling and transport

Fully SF6 gas insulated medium voltage switchgear up to 40.5 kV in accordance with IEC Standards

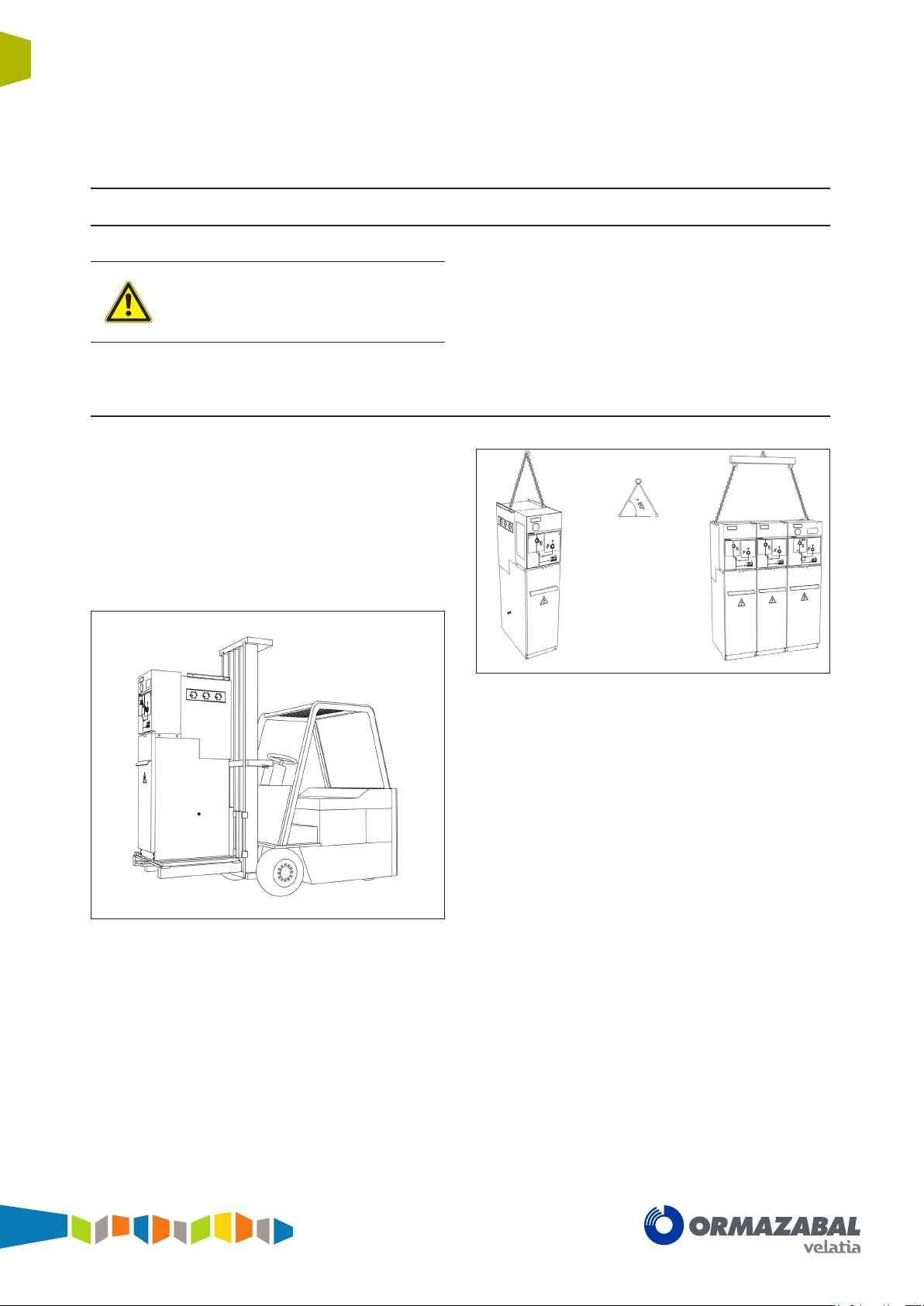

2 Handling and transport

Important: During transport, the switchgear

must be perfectly seated and xed so that it

cannot move about and possibly damage the

equipment.

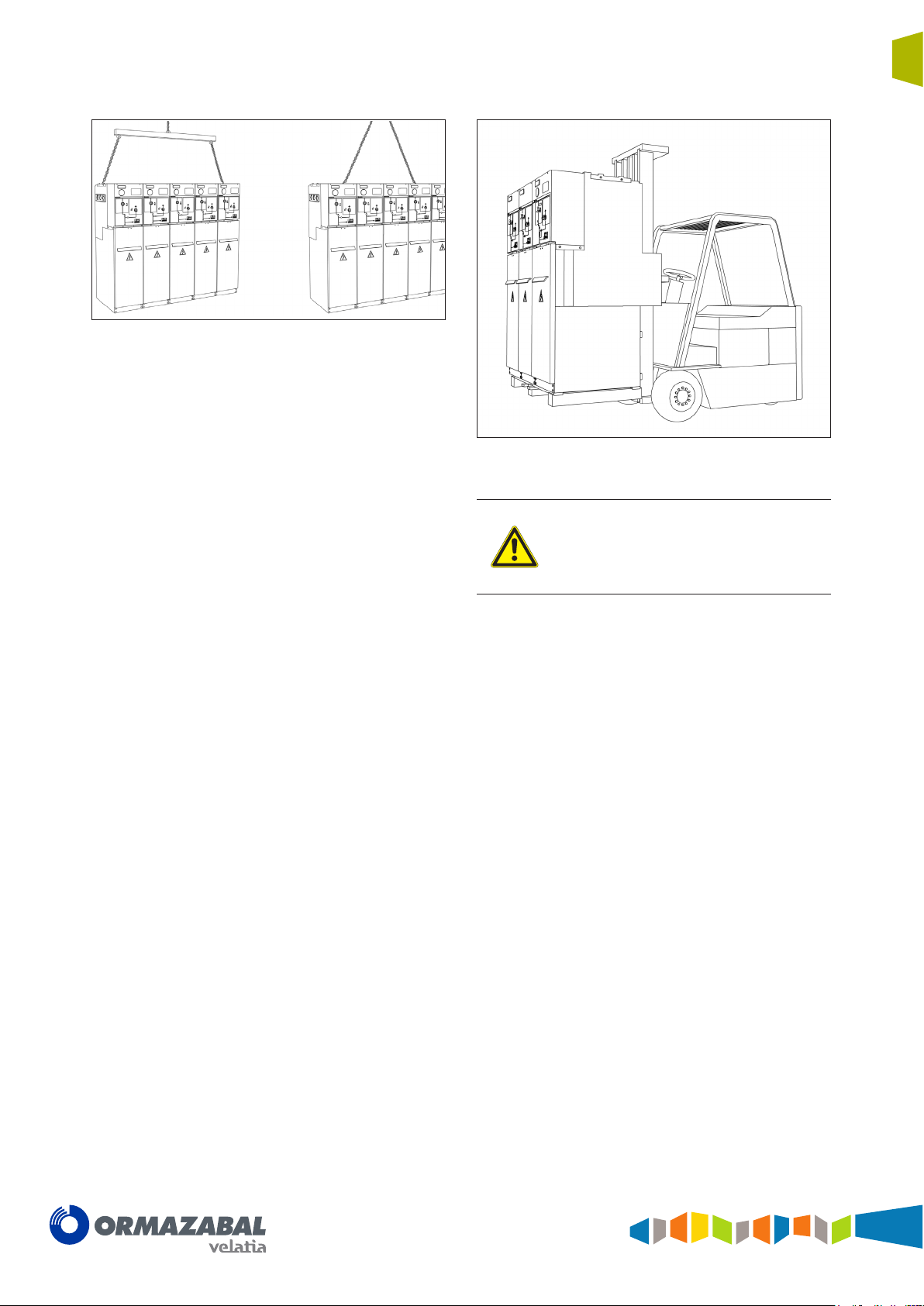

2.1 Lifting means

The switchgear must always be kept upright, directly

on the ground or on a pallet depending on the type of

handling involved.

General instructions

cgm.3 system

To handle assemblies of up to 4 cgm.3 functional units,

one of the following methods must be used:

[5]

1. Using a forklift truck or pallet-jack

Figure 2.1 Lifting a cgm.3 modular cubicle using a fork-lift

truck.

.

Figure 2.2 Lifting a cgm.3 modular cubicle with chains.

3. If it is not possible to use the aforementioned methods,

rollers may be used underneath the switchgear.

Another option is to slide the cubicles over rods

(these same rods can be used to help get over the

cable trench).

4. To handle sets of 5 functional cgm.3 units (consisting

of either coupled modules or compact assemblies

associated with modules), use lifting systems (slings,

lifting beam, etc.) with a pull angle greater than

65º and less than 115º in order to prevent possible

damage to the cubicles during hoisting.

2. Lifting using slings or chains fixed to the lifting

supports on the sides of the top of the cubicle. The

angle of pull should be as vertical as possible (with an

angle greater than 60º from the horizontal).

[5]

Position the rear of the cubicle facing the driver, to avoid damaging the front.

IG-136-EN version 10; 23/06/2016

General instructions

Handling and transport

cgm.3 system

Fully SF6 gas insulated medium voltage switchgear up to 40.5 kV in accordance with IEC Standards

Figure 2.3 Lifting a cgm.3 assembly with 5 functional units.

Figure 2.4 Lifting a cgm.3 assembly with a forklift truck.

15

The use of lifting beams is required for cubicle

assemblies with control boxes. As the sole

exception, slings may be used if the cubicles

of the assembly have identical height control

boxes installed.

IG-136-EN version 10; 23/06/2016

16

Storage

3 Storage

General instructions

cgm.3 system

Fully SF6 gas insulated medium voltage switchgear up to 40.5 kV in accordance with IEC Standards

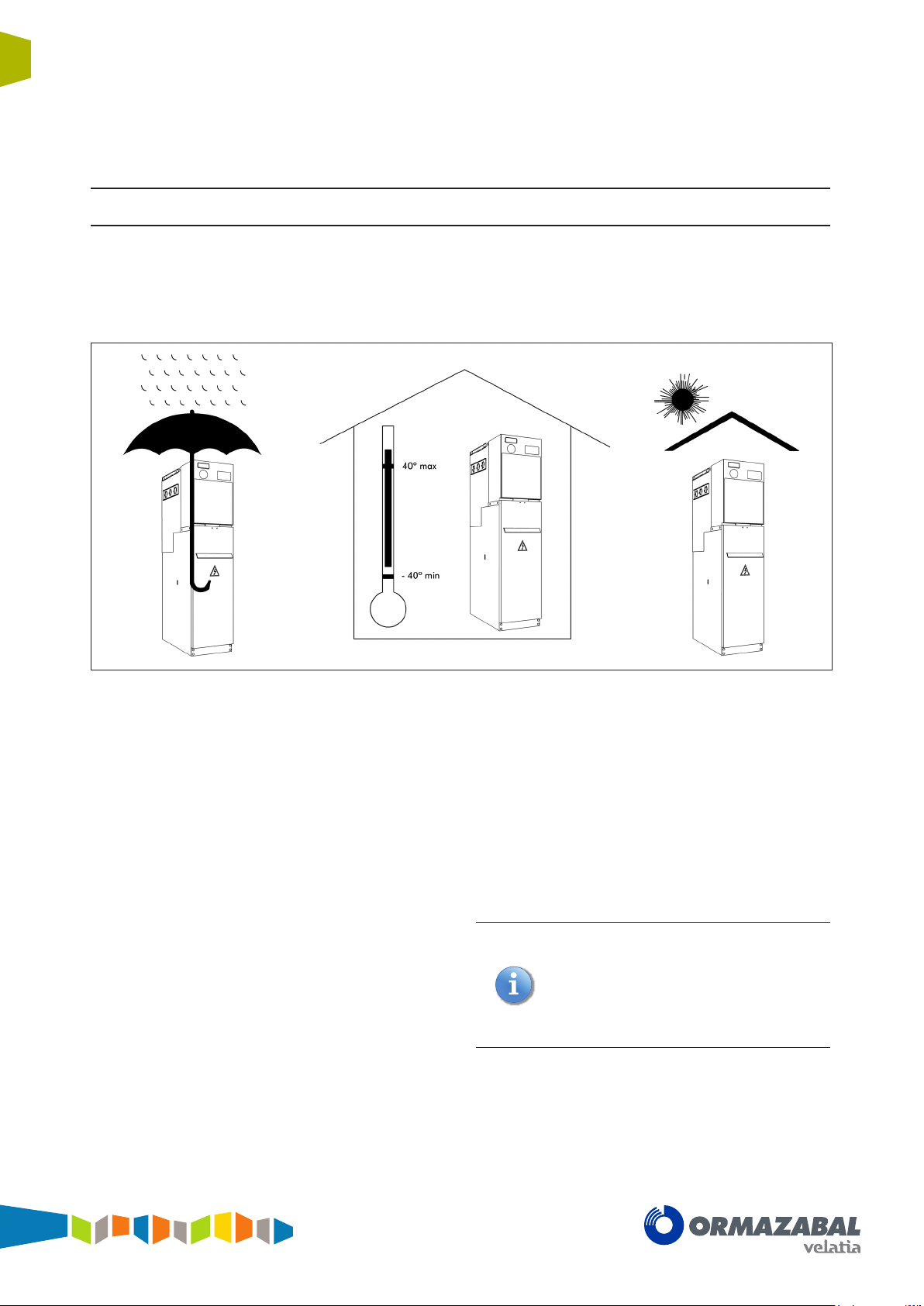

If it needs to be stored, the equipment must be placed on

dry ground or on top of damp-proof insulating material, still

in its original packaging.

Storage must always be INDOORS, with the following

conditions recommended:

1. Ambient air temperature should not exceed 40 ºC and

its mean value, measured in a period of 24 hours,

should not exceed 35 ºC.

2. The ambient air temperature should not drop below

- 5 ºC. There are also cubicles with storage

temperature up to - 40 ºC.

3. The switchgear must be protected from direct solar

radiation.

4. Altitude, both in transport and in storage, must not

exceed 2000 m.

5. The environmental air must not have any significant

contamination from dust, smoke, corrosive and/or

inflammable gases, vapours or salt.

After prolonged storage, clean all the insulating parts

carefully before commissioning the equipment. The

enclosure should be cleaned with a clean, dry lint-free

cloth.

a) the mean relative humidity value, measured over

a period of 24 hours, must not exceed 95%.

b) the mean water steam pressure value, measured

in a period of 24 hours, must not exceed 2.2 kPa.

c) the mean relative humidity value, measured over

a period of one month, must not exceed 90%.

d) the mean water steam pressure value, measured

in a period of one month, must not exceed

1.8 kPa.

7. During transport, vibrations caused by external

factors or seismic movements must be insignificant.

Any other conditions must be made known

beforehand, since the equipment

must be factory-set at atmospheric pressure in

the nal destination.

Otherwise the gauge may show an erroneous

reading, even though

the unit's interior pressure value is correct.

6. The switchgear must be protected from the rain, and

the humidity conditions should be as follows:

IG-136-EN version 10; 23/06/2016

General instructions

cgm.3 system

Fully SF6 gas insulated medium voltage switchgear up to 40.5 kV in accordance with IEC Standards

4 Installation

4.1 Unpacking the equipment

Installation

17

The switchgear of the cgm.3 system is supplied protected

in plastic as standard.

On receiving the equipment, check that the goods supplied

correspond to the order and associated documentation. If

this is not the case, contact Ormazabal immediately.

The disassembly process for the equipment is as follows:

1. Using a blade, cutter or similar tool, cut the cellophane

the cubicle is wrapped in

2. Completely remove the cellophane.

3. Detach the white polystyrene corner pieces.

4. Unscrew the fixings between the base and the pallet.

5. Remove the pallet, handling the cubicle as indicated

in section 2.1.

[6]

.

6. Unpack the accessory box located at the rear or on

7. Remove the self-adhesive protective plastic from the

8. Dispose of any waste in an environmentally-friendly

It is advisable to make a visual inspection of the equipment

to check whether it has suffered any damage in transit. If

damaged, contact Ormazabal immediately.

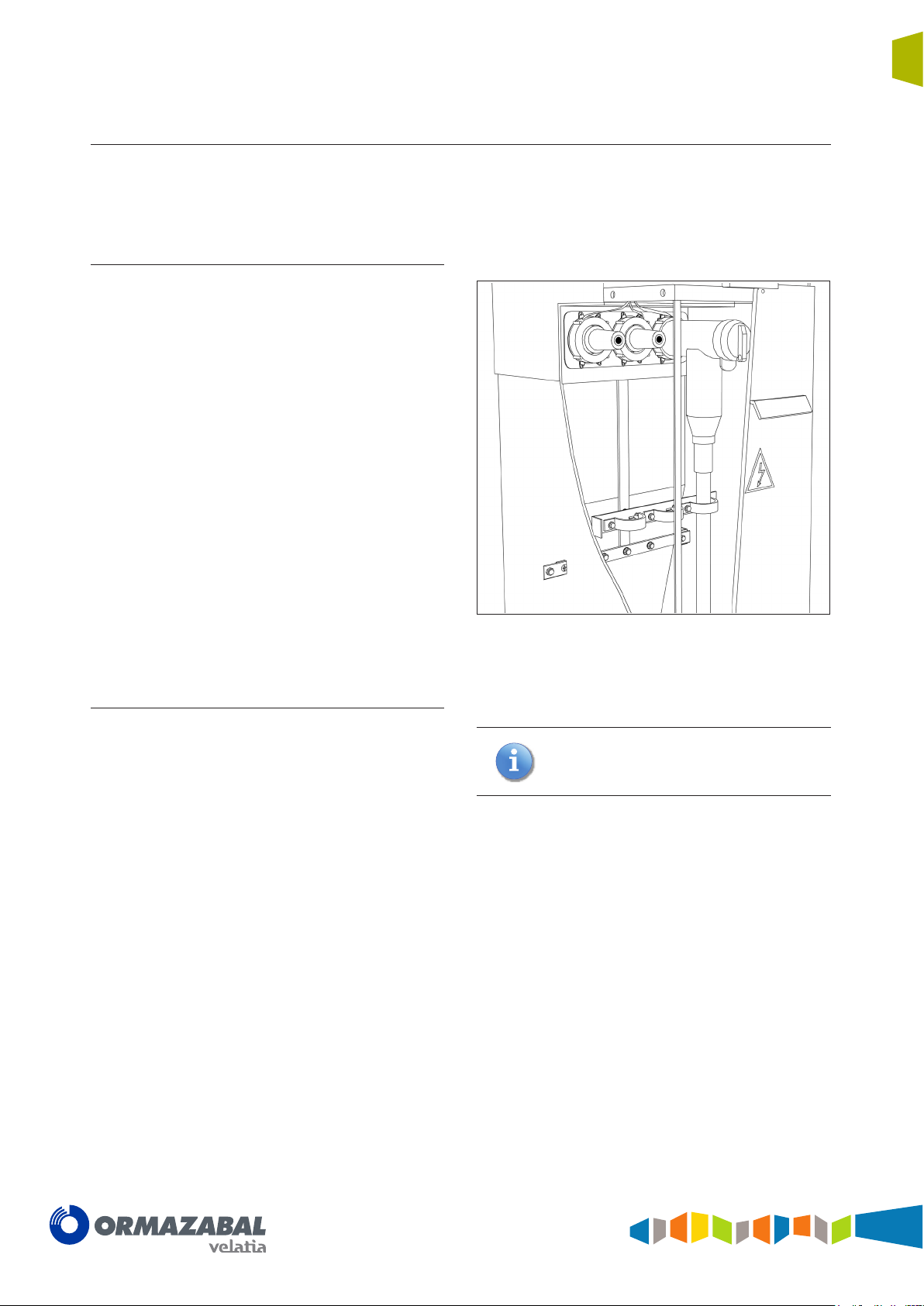

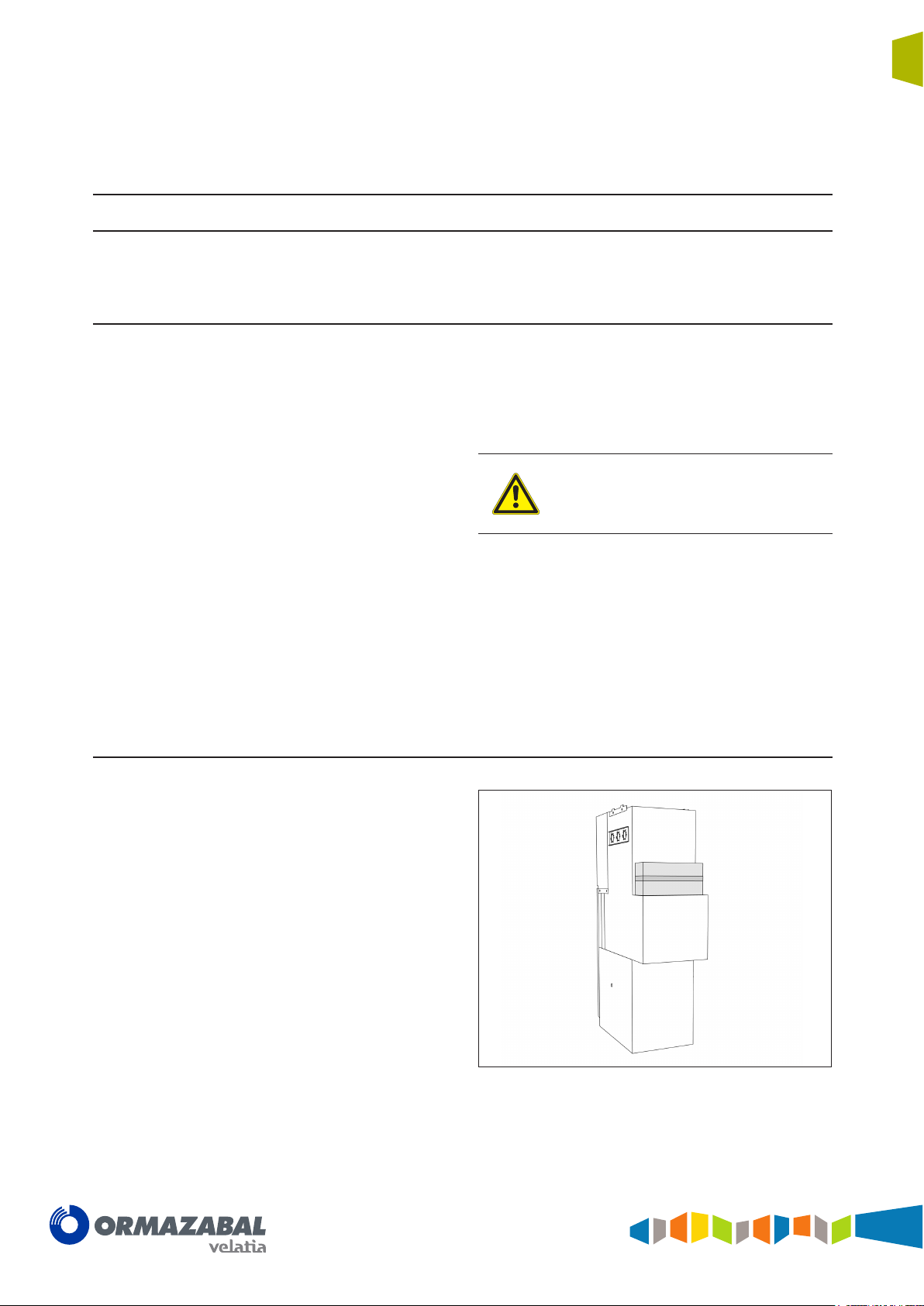

4.2 Location of accessories during transport

A number of accessories are supplied with the cubicles,

located as indicated in the figures below:

top of the cubicle.

cable compartment cover.

The self-adhesive plastic must be removed

from the cable compartment cover so that the

equipment enclosure's earth connection may

have the proper electrical continuity.

manner.

Figure 4.1 Location of accessories in cgm.3-p cubicles

[6]

It is advisable to cut the cellophane at the rear of the cubicle or at the corner to avoid scratching the surface.

IG-136-EN version 10; 23/06/2016

18

Installation

Fully SF6 gas insulated medium voltage switchgear up to 40.5 kV in accordance with IEC Standards

Figure 4.2 Location of accessories in cgm.3-l and cgm.3-v

cubicles

General instructions

cgm.3 system

Depending on the cubicle model, the accessory box

contains some of the following items:

• General Instructions Document IG-136 by

Ormazabal.

• Driving lever

• Spring charge lever

• Cubicle connecting kit:

- ormalink

- Springs

- Syntheso grease

- Earthing bar

• End plug kit:

- Cubicle end assembly

- Nylon thread

- Plastic plugs

- Side cover

• Floor fastening assembly

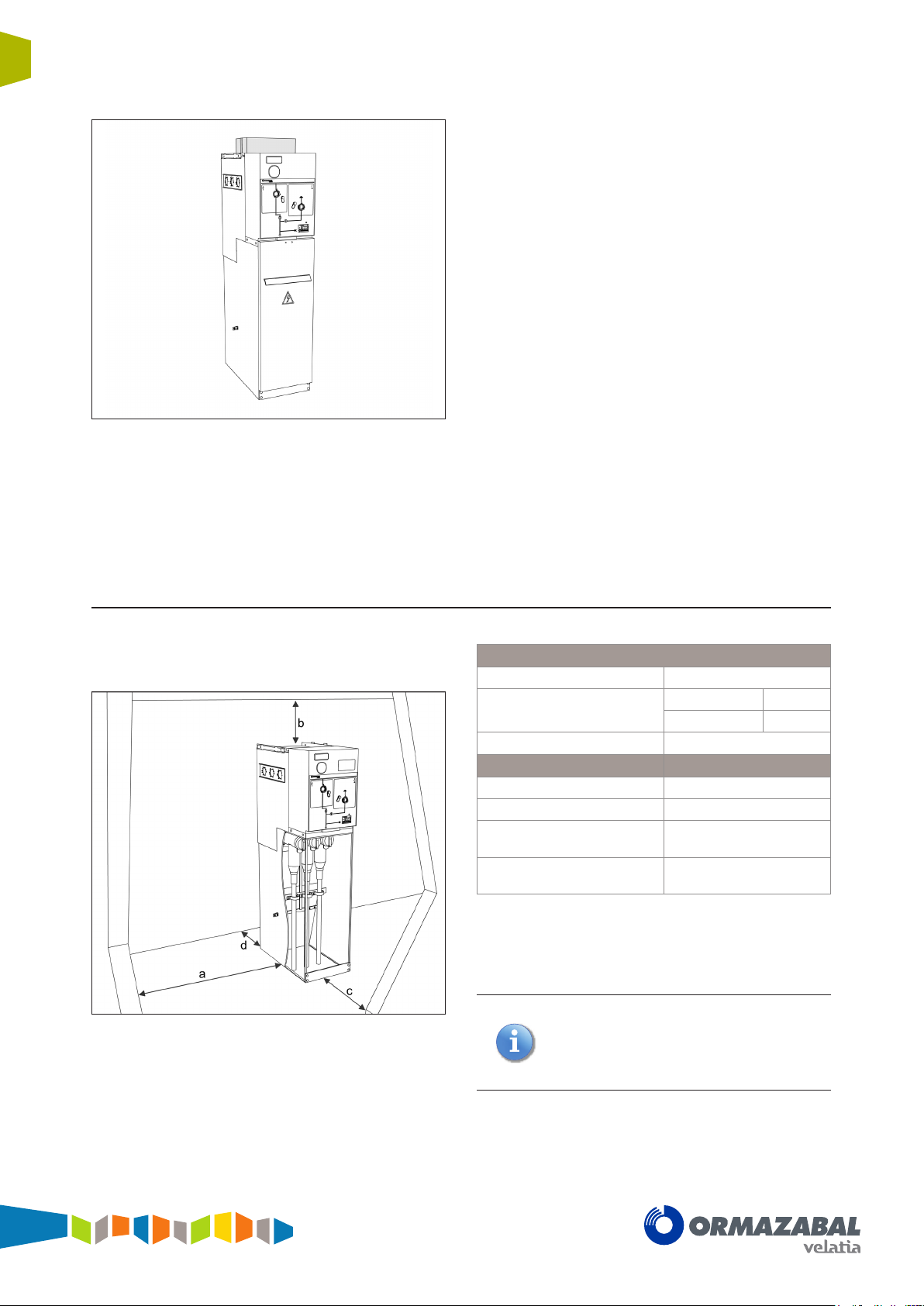

4.3 Minimum installation distances

The minimum distances to the walls and ceiling which

must be maintained in the installation are as follows:

Figure 4.3 Minimum installation distances

Minimum distances [mm]

Side wall (a) 100

Roof (b)

Front clearance (c) 500 (*)

Height 1400 mm 600

Height 1745 mm 550

Function Rear wall (d)

cgm.3-l / -s / -v / -2lv / -rb / -rc

cgm.3-p / -2lp

cgm.3-m without IAC

classification

cgm.3-m with IAC

classification

(*) An operating clearance of at least 1000 mm is recommended.

(**) Cubicles with classification IAC AFLR: d = 800 mm.

(***) Diagrams combined with p and 2lp cubicles.

(****) For classification IAC 21 kA – 1 s.

The measurements indicated in the table

have been obtained in accordance with the

dimensions of the test room for the gas insulated

modules, in accordance with Annex AA of

Standard IEC 62271-200.

100 / 160(***)

0

0

100 / 150(****)

[7]

For any doubts, please ask Ormazabal.

The space required to extend the assembly with an

additional cubicle is 250 mm plus the width of the new

cubicle

[7]

.

IG-136-EN version 10; 23/06/2016

General instructions

cgm.3 system

Fully SF6 gas insulated medium voltage switchgear up to 40.5 kV in accordance with IEC Standards

4.4 Recommended cable connection trench

Installation

19

Minimum recommended dimensions based on the trench

dimensions used in the tests in accordance with Standard

4.4.1 Cubicles with internal arc in gas tank

[8]

up to 20 kA

Feeder function, busbar rise and cable rise

The dimensions of the trench depend on the minimum

radius of curvature of the cables used.

Front and rear

cable input or output

Side cable input or

(D1)

output (D2)

IEC 62271-200. In accordance with the radius of curvature

of the cables used, these dimensions may vary

[9]

- 0.5 s

[10]

.

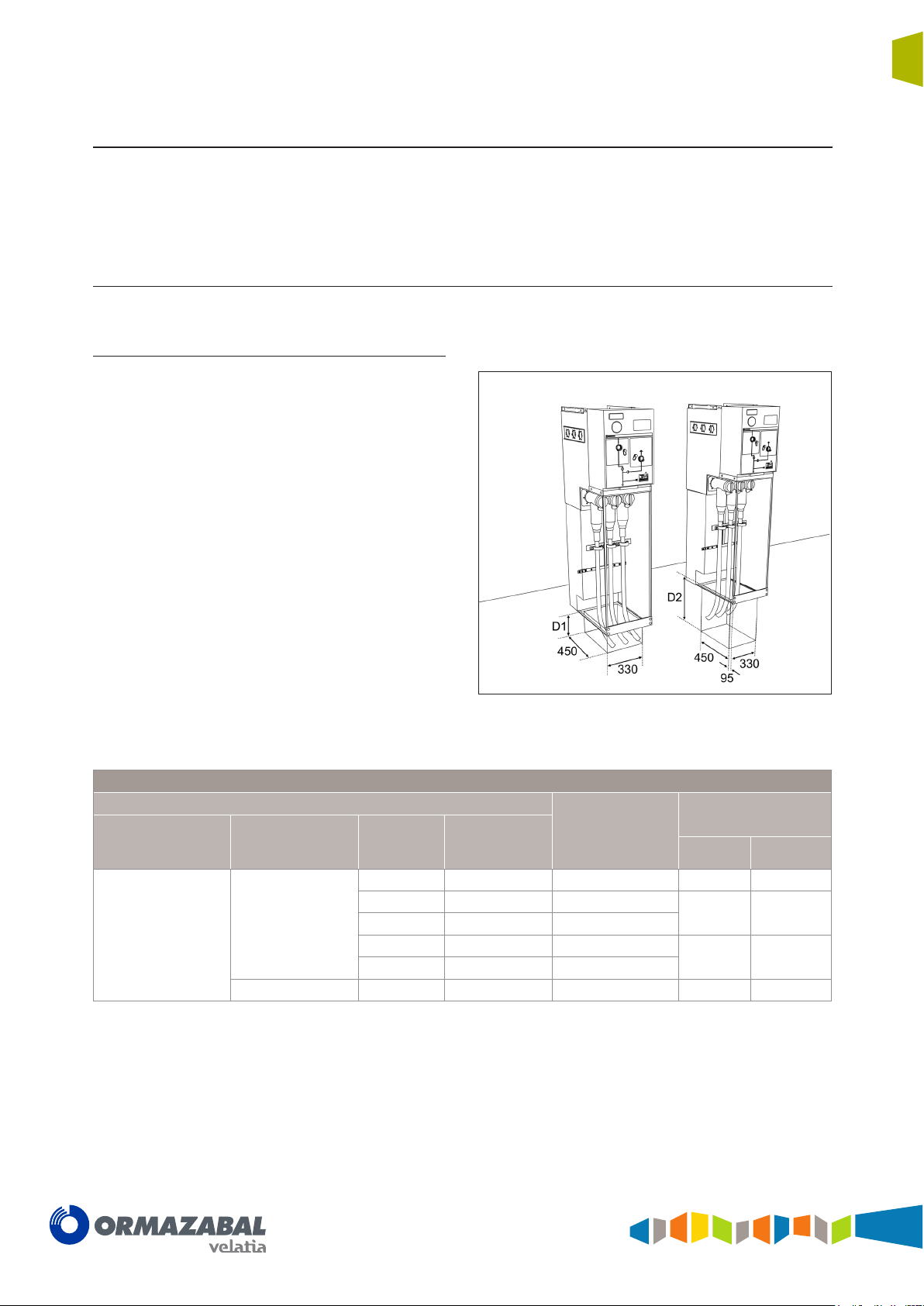

Figure 4.4 Dimensions [mm] of the cable trench for cgm.3-l,

Trench necessary for the feeder, busbar rise and cable rise function

Cable data

Cable insulation Cable type

Dry insulation

Check against the data of the manufacturer of the cable used.

(*)

[9]

Tests conducted with a current of 21 kA.

[10]

In each case, bear in mind which cable is to be used in that particular installation.

Single-core 18/30 kV

3-core 18/30 kV < 150 92.7 805 650 650

Cable section

[mm

< 150 41 555 200 500

185 43 590

240 45.2 640

300 47.5 685

400 48 745

2

]

Cable diameter

[mm]

cgm.3-rb and cgm.3-rc

Approximate radius

of curvature*

[mm]

Minimum depth

D1 [mm] D2 [mm]

200 550

300 660

IG-136-EN version 10; 23/06/2016

20

Installation

Fuse protection function

General instructions

cgm.3 system

Fully SF6 gas insulated medium voltage switchgear up to 40.5 kV in accordance with IEC Standards

Front and rear cable input

or output (D1)

Side cable input or

output (D2)

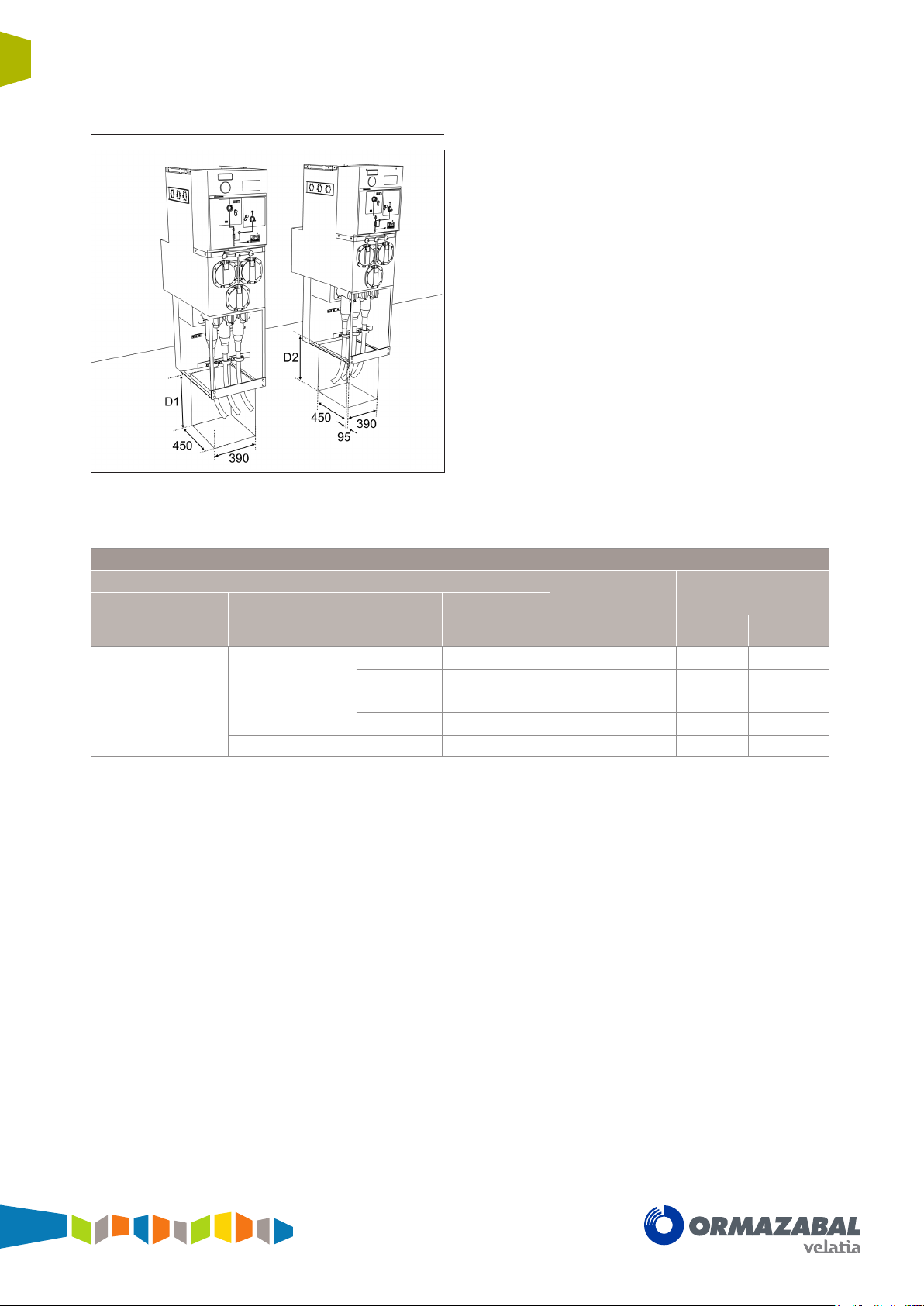

Figure 4.5 Dimensions [mm] of the cable trench for cgm.3-p

Trench necessary for the fuse protection function

Cable data

Cable insulation Cable type

Dry insulation

(*) Check against the data of the manufacturer of the cable used.

Single-core 18/30 kV

3-core 18/30 kV < 95 86 735 1050 1050

Cable section

2

]

[mm

< 50 35 430 500 500

70 36.5 460

95 38 500

150 41 555 600 600

Cable diameter

[mm]

Approximate radius

of curvature*

[mm]

Minimum depth

D1 [mm] D2 [mm]

550 550

IG-136-EN version 10; 23/06/2016

General instructions

cgm.3 system

Fully SF6 gas insulated medium voltage switchgear up to 40.5 kV in accordance with IEC Standards

Circuit-breaker function with AV / RAV

driving mechanism

Front and rear cable input

or output (D1)

Side cable input or

output (D2)

Installation

21

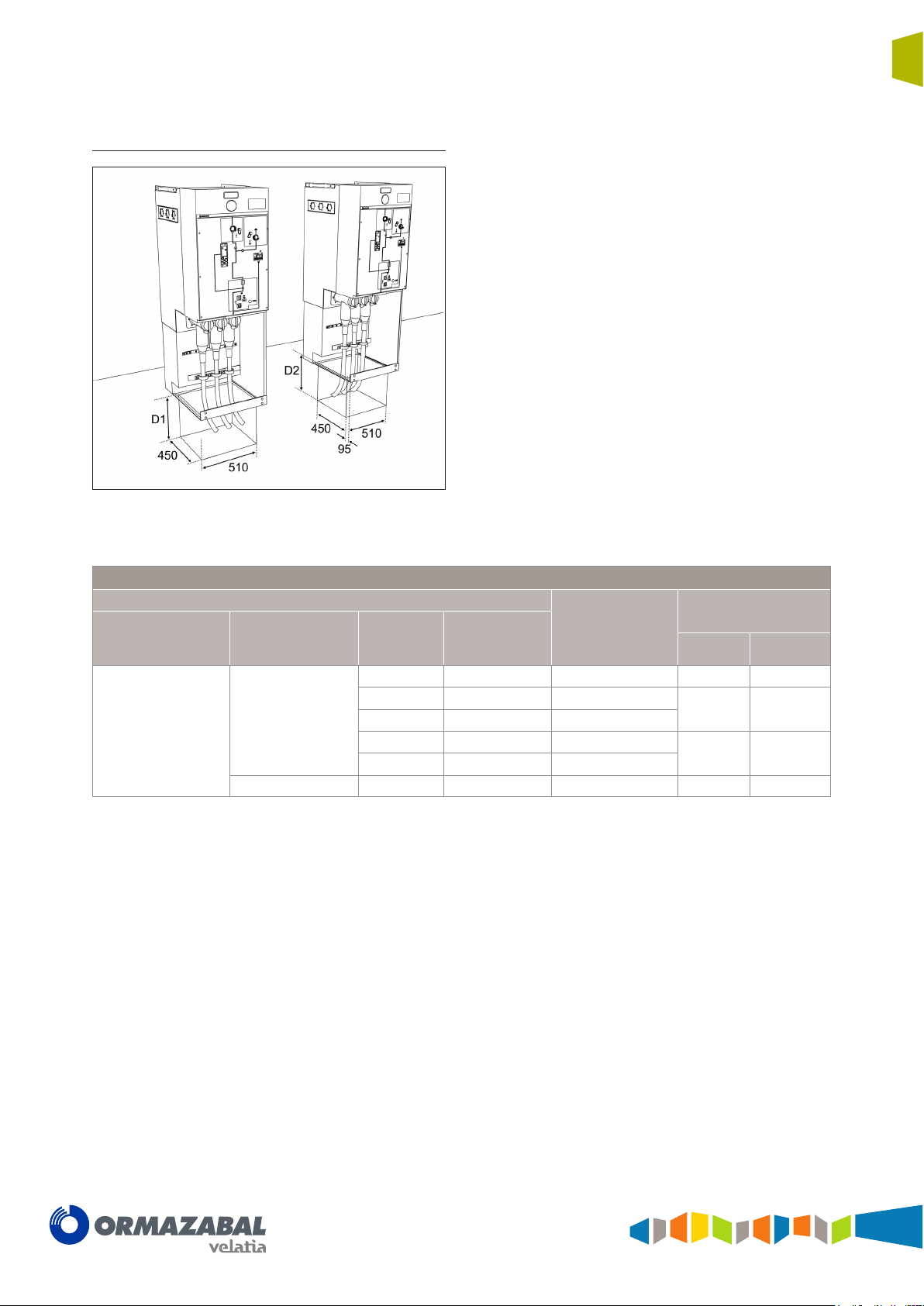

Figure 4.6 Dimensions [mm] of the cable trench for cgm.3-v

with AV / RAV driving mechanism.

Trench necessary for the circuit-breaker function with AV / RAV driving mechanism

Cable data

Cable insulation Cable type

Dry insulation

(*) Check against the data of the manufacturer of the cable used.

(**) 150 mm2 cable only valid up to 21 kA.

Single-core 18/30 kV

3-core 18/30 kV < 150 92.7 805 850 850

Cable section

2

]

[mm

<150 (**) 41 555 400 400

185 43 590

240 45.2 640

300 47.5 685

400 48 745

Cable diameter

[mm]

Approximate radius

of curvature*

[mm]

Minimum depth

D1 [mm] D2 [mm]

400 500

500 600

IG-136-EN version 10; 23/06/2016

22

Installation

Fully SF6 gas insulated medium voltage switchgear up to 40.5 kV in accordance with IEC Standards

4.4.2 Cubicles with classification of internal arc IAC up to 25 kA - 1 s

Feeder function, busbar rise and cable rise

Front and rear

cable input or output

(D1)

Side cable input or

output (D2)

General instructions

cgm.3 system

Trench necessary for the feeder, busbar rise and cable rise function

Cable data

Cable insulation Cable type

Dry insulation

Height 1400 mm(***)

Dry insulation

Height 1745 mm

(*) Check against the data of the manufacturer of the cable used.

(**) 150 mm2 cable only valid up to 21 kA.

(***) Exclusively for cgm.3-l and cgm.3-2lp cubicles.

Single-core 18/30 kV

3-core 18/30 kV < 150 92.7 805 950 950

Single-core 18/30 kV

3-core 18/30 kV < 150 92.7 805 650 650

Cable section

2

]

[mm

< 150 (**) 41 555 500 800

185 43 590

240 45.2 640

300 47.5 685

400 48 745

< 150 (**) 41 555 370 500

185 43 590

240 45.2 640

300 47.5 685

400 48 745

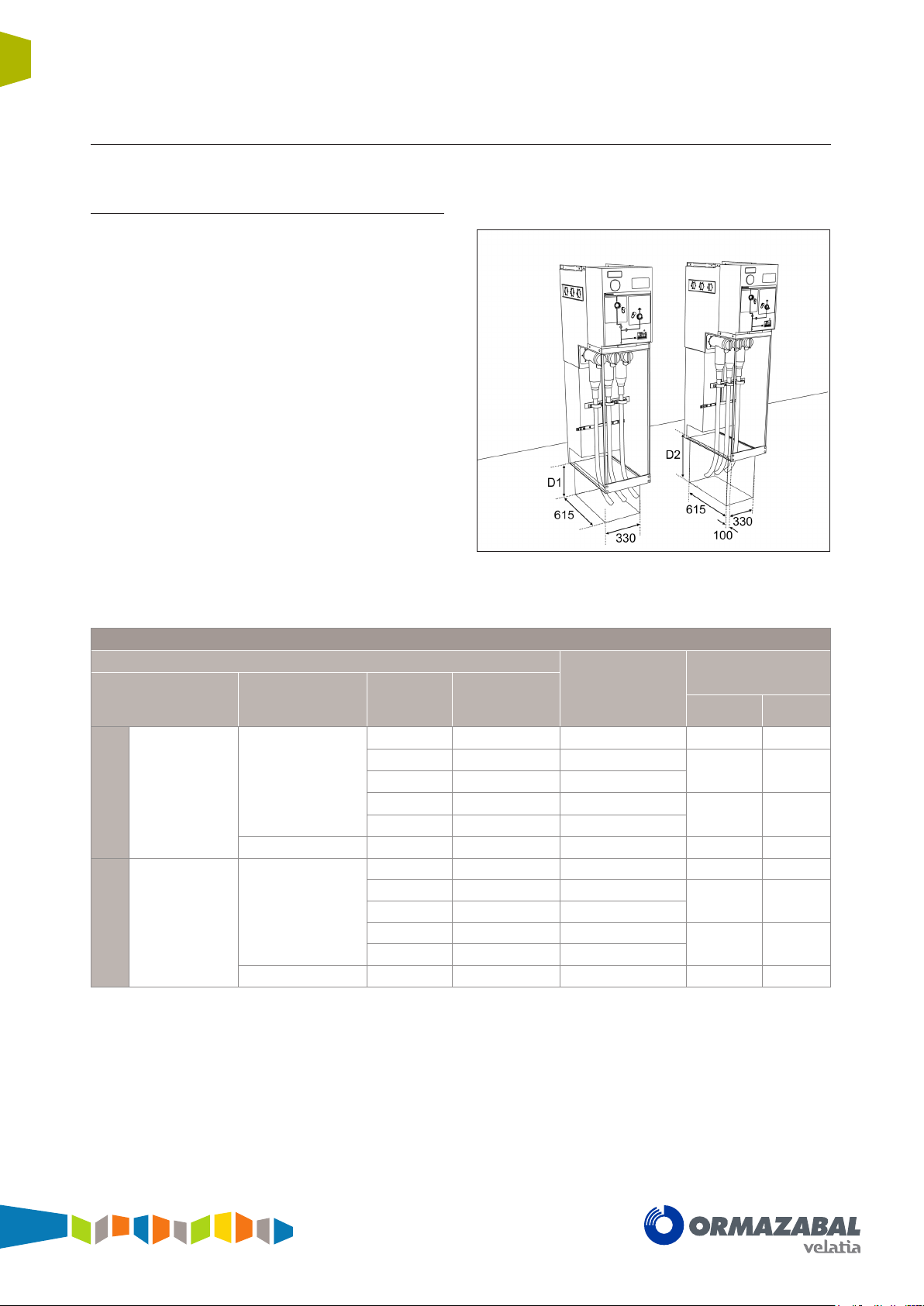

Figure 4.7 Dimensions [mm] of the cable trench for cgm.3-l,

Cable diameter

[mm]

cgm.3-rb and cgm.3-rc

Approximate radius

of curvature*

[mm]

Minimum depth

D1 [mm] D2 [mm]

550 900

650 1000

370 550

370 660

[11] In each case, bear in mind which cable is to be used in that installation.

IG-136-EN version 10; 23/06/2016

General instructions

cgm.3 system

Fully SF6 gas insulated medium voltage switchgear up to 40.5 kV in accordance with IEC Standards

Fuse protection function

Front and rear cable input

or output (D1)

Side cable input or

output (D2)

Installation

23

Figure 4.8 Dimensions [mm] of the cable trench for cgm.3-p.

Trench necessary for the fuse protection function

Cable data

Cable insulation Cable type

Dry insulation

Height 1400 mm

Dry insulation

Height 1745 mm

(*) Check against the data of the manufacturer of the cable used.

Single-core 18/30 kV

3-core 18/30 kV < 95 86 735 1400 1400

Single-core 18/30 kV

3-core 18/30 kV < 95 86 735 1050 1050

Cable section

2

]

[mm

< 50 35 430 800 800

70 36.5 460

95 38 500

150 41 555 950 950

< 50 35 430 500 500

70 36.5 460

95 38 500

150 41 555 600 600

Cable diameter

[mm]

Approximate radius

of curvature*

[mm]

Minimum depth

D1 [mm] D2 [mm]

900 900

550 550

IG-136-EN version 10; 23/06/2016

Loading...

Loading...