ORLIGNO 500

INSTRUCTION MANUAL

& SERVICE MANUAL

MANUAL INSTRUCTION

CONTENTS

1. Boiler application ................................................................3

2. Description of the controller .......................................................3

2.1. Lightning up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3. Controller’s menu description .....................................................6

3.1. Menu handling.........................................................6

3.2. Alarm status and safety devices ........................................11

4. Feed system ...................................................................12

4.1. Feed system-alarm status ..............................................12

4.2. Feed system protection ...............................................12

5. Maintenance ...................................................................13

2 3

1. Boiler application

Low temperature pellet boiler Orligno 500 produced by Eko-Vimar Orlański Ltd. is adapted for

central heating installations also for hot utility water heating.

Main fuel use in ORLIGNO 500 is pellet with 6-8 mm diameter and length 10-50 mm.

Capacious pellet hopper lets for very long boiler operation without need to rell the hopper.

Boiler is adapted for installation in open or pressurized system with pressure vessel allowing to

work with working pressure.

2. Description of the controller

Boiler controller is a modern microprocessor system which controls not only the boiler but also

central heating system and hot domestic water.

Device controls quantity of feed fuel through periodic operation of feeder’s engine and amount

of supplied air for burning process. Thanks to semiconductor transmitters power of the blower is

uently adjusted thus increasing reliability of control system of feeder’s engine.

Automatic burning up. Controller enables automatic burning up of the fuel on the burner.

Measurement of fumes temperature. Controller enables reading fumes temperature, it is

necessary for boiler operation with automatic igniting . Measurement of fumes temperature is

important for control and boiler adjustment.

Thanks to advanced algorithm and possibility to adjust many parameters; system can be easily

adapted to the heating system needs.

Controller is equipped with output test function that enables to check correct electric connections

and executive devices (pump, blower, feeder, mixing valve’s actuator ) before boiler is put into

action.

Alphanumeric display makes easier to communicate between user and controller, easy

handling.

New intuitive controller’s menu with 6 languages at choice: polish, english, german, french,

lithuanian and russian.

Pic. 1. Controller’s menu.

4 5

2.1. Burning up

1. Pour the pellets into the hopper and tightly close the lid. ..

2. Connect the main power plug into the 230V/50 socket.

ATTE NTI ON!

Socket should be protected with min. 10A fuse and 20 mA RCD (residual current

device).

3. Start the controller.

To start the controller it is necessary to press the „ON/OFF/ESC” button for 3 seconds. The same

operation with turning off the controller. Present status is shown on the display:

OFF – (active control of alarm parameters, manual mode of blower and feeder)

ON

ATTE NTI ON!

When „OFF” is shown on the display device is in standby mode and is still live. In

case of alarm controller will activate all pumps or feeders.

ATTE NTI ON!

It is forbidden to use for boiler lightning up any ammable substances.

If boiler is in idle time or maintenance is made it’s essential to unplug the boiler from the main power.

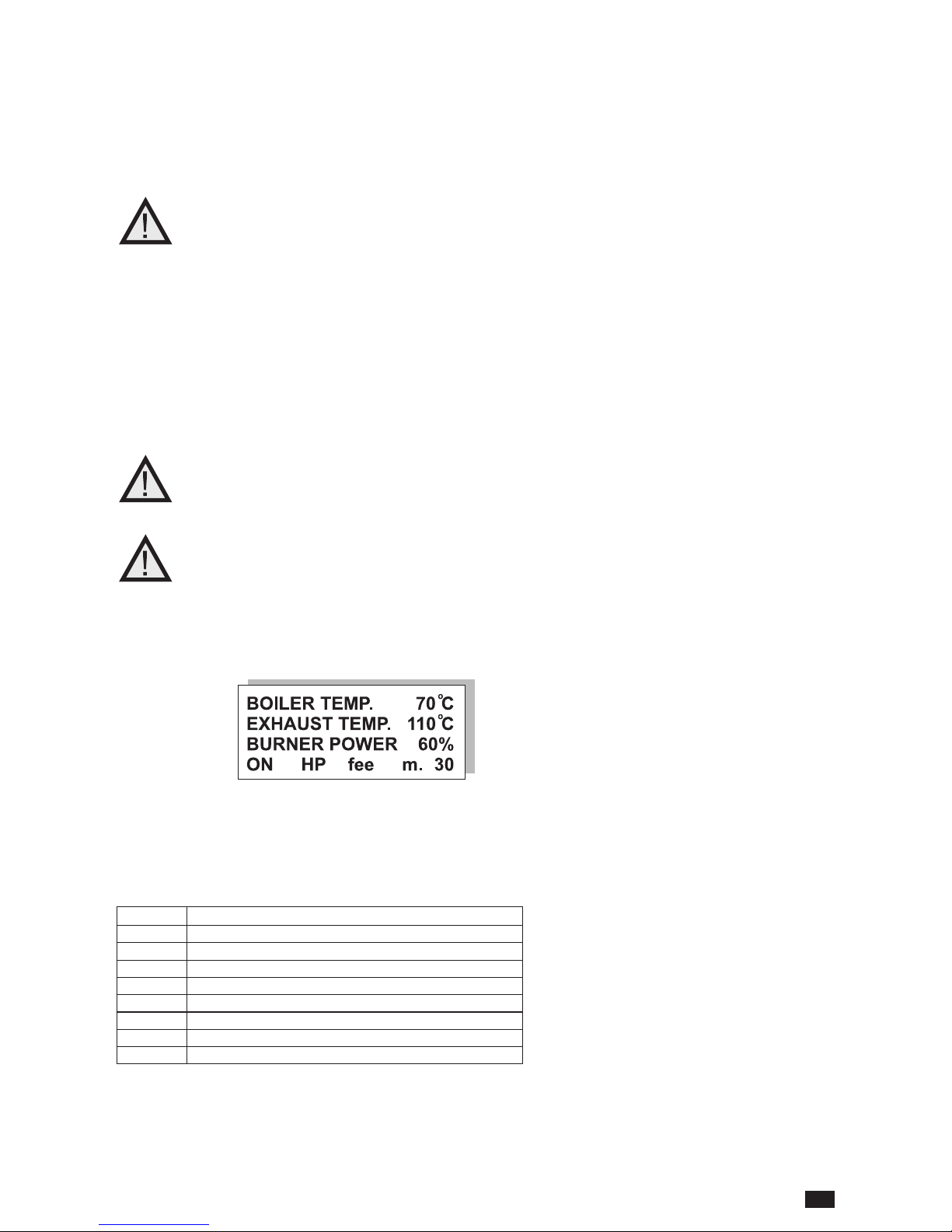

Display shows current state of individual devices. Picture shows main menu view.

Last line on display shows through abbreviations active devices.

Pic. 2. Main display.

ABBR.

DESCRIPTION

HP central heating pump operation

WP hot water pump operation

BU buffer pump operation

LIG heating element operation

fee feeder operation

fa 20 blower operation, current blower output

M0 mixing valve closing

M1 mixing valve opening

Tab 1. Abbreviation table with devices names.

After pouring the pellets it is recommended to manually start the feeder in order to transport fuel

to the burner.

Go to menu MANUAL MODE, which is displayed below:

To turn on/off the feeder press

.

To turn on/off the blower press .

Feeders should work until lling the burner with fuel. Next switch the controller in ON mode, fuel

will be automatically light up.

3. Controller’s menu description

3.1. Menu handling

Controller has two types of menus: SIMPLE MENU and ADVANCED MENU.

ATTENTION !

To change type of menu: SIMPLE or ADVANCED press at the same time i

buttons. After 10 minutes of inaction from user menu will automatically be changed

on SIMPLE.

ATTENTION !

Instruction manual contains all control parameters available both in SIMPLE or

ADVANCED menu. Parameters from ADVANCED menu are written in italics.

To go in to the main menu press „ENTER” button.

-main menu, written with capital letters, buttons and are for move within main menu, to go in to

submenu press „ENTER”. To go out from submenu press „ESC”. Main menu is shown on pic.1

-submenu is for displaying and changing operation parameters. In order to change the parameter press

„ENTER” . Changing parameter will be displayed periodically. Changing parameter on different one press

or . To withdraw from changed parameter press „ESC”. To accept the changes press „ENTER” .

Rys 3. Manual mode.

Całe menu zostało przedstawione pkt. 2. Opis regulatora.

6 7

Menu Boiler

Boiler can operate in one of two operation modes: manual and auto.

Pic. 1. Main Menu

Pic. Menu BOILER

ATTENTION !

Operation modes decide only about setting method of the boiler temperature.

PARAMETERS

Auto mode – recommended mode. Boiler’s temperature is automatically set depending on heat

demand.

Manual mode – Boiler’s temperature is set by user.

Service – parameter informing about next boiler maintenance.

Hysteresis (only in ADVANCED menu) – parameter deciding about required difference between

actual boiler’s temperature and set one to start the burner.

Menu heating

Menu for central heating settings. Menu HEATING is shown on picture.

Pic. Menu HEATING CIRCUIT

PROGR. H.W. (PROGRAMMED HOT WATER)

Hot water tank need to be equipped with temperature sensor.

PARAMETERS:

Programmable hot water temperature (progr. h.w.) – hot water temperature kept in the tank.

Hot water – parameter for turning on/off hot water function.

Priority (only in ADVANCED menu) – with priority parameter “on” during hot water heating rest of the

pumps in the installation are off in order to faster heat the water.

Hysteresis (only in ADVANCED menu) – temperature value that need to decrease temperature of hot

water to start heating hot water and temp. value that need to increase to turn off hot water heating.

Boiler h.w. + (only in ADVANCED menu) – temperature value that need to increase to programmed

temperature during hot water heating. i.e. if programmed temp of hot water = 60ºC and “boiler h.w.+” =

10 ºC then programmed temperature during heating hot water is 70ºC.

PARAMETERS

Progr. – kept temperature in heating circuit ( radiators, underoor heating) during demand from room

thermostat.

Heating – parameter for turning off/on heating.

Reduction (only in ADVANCED menu) – parameter for adjusting the temperature value .

ATTE NTI ON!

In case if mixing valve with actuator is not installed in central heating circuit,

parameters „progr” and „ reduction” are turned off.

ATTE NTI ON!

In case if mixing valve with actuator is not installed in central heating circuit, during

the rst start of the boiler, parameter „mixer” need to changed on „no” in SERVICE

menu.

Menu hot water

Pellet boiler is perfectly matched for hot water heating both during the heating season and summer

season. Menu HOT WATER is shown below:

Pic.7 Menu HOT WATER.

8 9

ADVANCED PRIORITY OF HOT WATER

Controller can operate in two modes of hot water heating ( known only in gas and oil boilers): hot water

priority ( recommended) and without priority. During boiler operation with priority mode with hot water

heating, works only hot water pump reaching set temp. much faster.

In order to avoid temperature drop in the house during hot water heating and the pump works longer than

20 minutes ( pre-set) and programmed temperature of hot water is not reached; central heating pump

will start working on 5 minutes.

Parameters availab le in s er vic e menu: „ stop central heat ing pum p with h ot water pump” ( stop HP/HWP)

and „ work central heating pump with hot water pump ”( work HP/HWP).

Pic.8 Pump operation during hot water heating in priority mode

Input menu

Input menu shows temperatures from all connected sensors to the controller . Input menu view is shown

below:

Pic. 9 Input menu.

Buffer menu

Menu for adjustment of buffer parameters. Buffer menu view is shown below:

Pic.:Buffer menu

PARAMETERS

Programmed top – programmable temperature in the upper part of the buffer.

Programmed down – programmable temperature in the upper part of the buffer.

OPERATION DESCRIPTION

Buffer pump will be on, when temperature in upper part of the buffer drops below programmed

temperature.

Buffer charging lasts until both programmed temperatures are reached.

ATTE NTI ON

Buffer menu is only available in ADVANCED menu..

PARAMETERS

Burner power – available in two modes: auto (recommended) and manual. In auto mode: controller

selects burner power accordingly to energy demand of the house.

Programmed power – in auto mode is displayed actual power of the burner , in manual mode burner

power can be set as a constant.

ATTE NTI ON!

Burner menu is only available in ADVANCED menu.

Language menu

Controller is equipped with multilingual menu: polish, english, german, french, lithuanian and russian.

Language selection is made in Language menu.

10 11

3.2. Alarm status and safety devices

Alarm status is indicated with blinking backlight on the controller’s display. After pressing „ENTER”, type

of alarm is displayed. Types of alarms:

-boiler overheating;

Alarm is indicated after exceeding 97ºC (pre-set) on the boiler. Controller will activate all connected

pumps until temperature will decrease.

ATTE NTI ON!

With temperature 2ºC lower than alarm temperature, pumps are activated in a

initial alarm mode. If temperature do not exceed alarm temperature it will not be

remembered in controller’s memory.

-no fuel/re;

Alarm is activated in case of lack of fuel or re in the burner.

-feeder overheating;

Alarm is activated when permissible feeder’s temperature is exceeded.

ATTE NTI ON!

After noticing alarm status, it is recommended to determine cause and remove it.

-thermal boiler protection independent from boiler’s controller In case of exceeding boiler’s

temperature of 94ºC thermal boiler protection will turn off blower.

ATTE NTI ON!

After alarm occured it is recommended to determine cause of alarm, remove it and

manually unblock thermostat.

4. Feed system

4.1. Feed system –alarm status

In case of exceeding 60°C in the feed system, alarm is activated with blinking display „feeder

overheating”.

ATTE NTI ON!

After alarm occured it is recommended to determine cause of alarm and remove it.

4.2. Feed system protection

Feed system is designed in such a way that ame from burner is not able to get to the pellet hopper. Safe

feeding is assured by system of two feeders jointed together with exible, vertical chute. Fuel feeding is

continually monitored by boiler’s controller.

Proper feeders cooperation guarantees that vertical chute is always empty – it is a burn-back

protection.

Pic. 11. Feed system section

1. Pellet container

2. Motoreductor of a feeder no 1

3. Motoreductor of a feeder no 2

4. Feeder no 1

5. Feeder no 2

6. Fan

7. Burner

8. Heater

12 13

5. Maintenance.

Ash created during pellet burning is deposited in the bottom chamber. Bottom chamber needs to

be cleane d once a month wi th tools: scr a per, cle a ning shiel d . It is advi sabl e t o cl ean heat exchan g er

at least once a month to assert permeability of pipes.

If fumes temperature exceeds max. value which will be displayed it is necessary to clean heat

exchanger pipes and boiler.

Once a week burner need to be checked thoroughly because of possibility of depositing unburned

parts of pellets (especially when pellet quality is bad) which may block pellet feeding and cause

uncontrolled burning.

Attention!

If unproper pellet issue will repeat it is necessary to fully open blower’s screen.

a) disassembly the door

b) loosen the adjusting nut

c) turn the hinge at 360°

d) tighten up an adjusting nut.

Steps for door correct regulation:

adjusting nut

Warning!

Regulation should be made on both upper and bottom hinges at the same time. All

threaded door parts should be greased periodically (for exemple with a grease or an

oil) as well as hinges.

In order to clean heat exchanger:

1. Open upper door

2. Unscrew two nuts with M13 wrench ( they secure heat exchanger’s plate behind which

horizontal pipes are placed).

3. Remove turbulators and clean pipes with shield and turbulators with brush.

4. Place turbulators back into the heat exchanger.

Attention!

If unproper pellet issue will repeat it is necessary to fully open blower’s screen.

SERVICE MANUAL

CONTENTS

1. Installation .....................................................................15

2. Recommended controller’s settings ...............................................16

3. Block diagram ..................................................................16

4. Technical data ..................................................................17

4.1. Dimensions...........................................................17

4.2. Boiler technical data ...................................................17

4.3. Controller’s technical data..............................................18

4.4. Electric data of gear-motors ...........................................19

4.5. Mechanical data of gear-motors ........................................19

4.6. Heater’s technical data ................................................19

5. Boiler’s electric scheme..........................................................20

6. Boiler connection ...............................................................22

6.1. Connection scheme ...................................................22

6.2. Hydraulic connections ................................................23

6.3. Cooling coil ..........................................................23

7. Boiler tightness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8. Ventilation .....................................................................24

8.1. Supply air ventilation ..................................................24

8.2. Exhaust ventilation....................................................24

9. Chimney connection ............................................................24

10. Troubleshooting ................................................................25

11. Ending .......................................................................26

14 15

1. Installation

Boilers should be installed according to binding rules and norms. The requirements of norm PN 87/B

02411 according building of solid fuel boiler room and the norm PN 91/B 02413 according open system

boilers’ production should be taken into account.

These norms and rules should be followed, however, caution is required as national rules in countries to

which the product is sold may replace above mentioned norms.

In case of boiler assembly outside Poland, rules and norms should be followed according to solid fuel

boiler assembly in countries in which the boiler is sold. Boiler ORLIGNO 500 is adjusted for installation

in pressurized systems.

Eko-Vimar Orlanski Ltd. recommends to use stainless steel ue liners that protect the chimney from

damaging effect of wood tar.

Company Eko-Vimar Orlanski does not take responsibility for not complying to above recommendation

and damage resulting from it.

During boiler transport, boiler ue may be disassembled by unscrewing nuts (8xM8) and detaching ue

from the ange.

At the bottom chamber wrapped in a foil are ceramic moulders which need to be placed on the burner

as shown on below picture.

Pic 2. Ceramics layout on the burner

2. Recommended controller’s settings

Lp.

Description

Programmed parameter

1. Boiler operation Auto mode

2. Heating temperature

60°C

3. Underoor heating temperature max

45°C

4. Thermostat

-15°C

5. Hot water temperature

45°C

6. Priority yes

7. Hysteresis

2°C

8. Boiler h.w.

+10°C

9. Buffer upper temperature

60°C

10. Buffer down temperature

80°C

3. Block diagram

Rys 2. Controller’s block diagram.

16 17

4. Technical data.

4.1. Dimensions.

4.2. Boiler technical data.

L.p. Description j.m. Value

1. Boiler output kW 25

2. Power range kW from 7 to 25

3. Boiler class acc. norm

EN 303-5

3 (highest)

4. Efciency % ~92

5. Fuel: pellets

lenght

diameter

moisture content

mm

mm

%

10-50

6-8

8-12

6. Fuel consumption:

nominal

minimal

kg/h

kg/h

5,5

1,5

4.3. Controller’s technical data .

L.p. Description j.m. Value

1. Power AC ~V/Hz 230/50±10%

2. Power consumption (controller) VA <5

OUTPUT LOAD

3. Central heating pump W 100

4. Hot water pump W 100

5. Buffer pump W 100

6. Heater W 400

7. Blower W 150

8. Gear-motor 1 W 200

9. Gear-motor 2 W 150

10. Mixing valve actuator

W

50

11. Boiler temp. range

ºC

60-85

12. Hot water temp. range

ºC

35-70

13. Measurement accuracy

ºC

±2

14. Ambient temperature

ºC

0-60

15. Moisture content

%

5-95 without condensation

16.

Alarm temp. - range

ºC

80-95

18 19

L.p. Description j.m. Value

7. Approximate heating space m

2

to 250

8. Max working pressure bar 2,5

9. Max water temp. °C 85

10. Min. return water temp. °C 60

11. Flue diameter mm 160

12. Required chimney draught mbar from 0,1 to 0,2

13. Fumes temp:

nominal

minimal

°C 160

130

14. Fumes ow:

nominal

minimal

kg/s

kg/s

0,02

0,01

15. Weight kg 320

16. Water capacity l 60

17. Hopper capacity l 255

18. Loading opening dimensions width/lenght mm 260/432

19. Cooling coil water temperature °C 10

20. Min water pressure in cooling coil bar 2

21. Voltage/Frequency AC V/Hz 230/50

22. Auxiliary power W 250

23. Recommended capacity of accumulation tank litres 1000-2000

4.4. Electric data of gear-motors.

Lp. Description j.m.

Value

1. Type – motor with gear - -

2. Voltage AC ~V/Hz 230/50

3. Pole number P 2

4.

Motor characteristic without load

Power

Input power

Rotation speed

Start voltage

A

W

rot/min

V

0,65 ± 15%

72 ± 15%

5,4 ± 10%

161 MAX

5.

Load characteristic – after 1 min since start of motor

Limit load

Acceptable load

Start load

Nm

Nm

Nm

33 MIN

25 MlN

20 MIN

6. Max current A 1,2 MAX

7.

Dielectric resistance

Motor resistant voltage: 1500V RMS through 1 min

(1800V RMS through 1 sec) measured between coil and motor’s core (test

current 3 mA

- -

8.

Insulation coefcient 100 MΩ minimum at 500V of voltage measured

between coil and cover

- -

9. Thermal protection: Motor protected up 120°C - -

10. Insulation class klasa „E”

4.5. Heater’s technical data

L.p. Description j.m. Value

1. Lubrication – Mineral oil and grease - -

2. Noisness (without load) dB 25 MAX

3. Weight kg 2,2

4. Shaft position - horizontal - -

5. Shift - 1 : 532

L.p. Description j.m. Value

1. Type - GLO 120 - 400 - -

2.

Input voltage range ( cooperate with adapter 230/120

VAC )

V-AC 120 -15%/+10% (102 – 132)

3.

Current

A/ V-AC 3,3 - 4,2/120

4. Heater power W 400

6. Heater temperature °C 1200

7. Time for warm. up to 1200°C sek. >12

9. Heater material: ceramic – recrystallised Si3N4 - -

10. Safety norm CSA - -

4.6. Heater’s technical data

20 21

5. Boiler’s electric scheme.

Pic.3 Electric scheme.

Electric connection of equipment to the boiler’s controller.

Low-voltage contact

Tco - temperature sensor connection for central heating

Tcwu - sensor connection for hot water pump

Tbg- sensor connection in upper part of the buffer

Tbd- sensor connection in down part of the buffer

Rpok- room thermostat connection

High-voltage contact

M.co- mixing valve’s actuator connection

P. cw u - hot water pump connection

P. bu - buffer pump connection – pump responsible for maintaining right return temperature to the boiler

P. co - central heating pump connection

Room thermostat

Controller enables to cooperate with any room thermostat with closing contact.

Room thermostat should be installed in a representative room in the house with respect to temperature

at 1,5-2m height.

One shouldn’t install room thermostat close to any heat source ( TV, radiator), direct sun radiation or

places exposed to draught.

Pic.4 Room thermostat connection.

NO

COM

NC

Room thermostat ex.

EUROSTER, AURATON

Boiler controller

Pellets control

Room thermostat

6. Boiler connection.

6.1. Connection scheme.

Pic.4 Boiler connection scheme.

Connection scheme

1. Pellet boiler ORLIGNO 500

2. Buffer-boiler pump

3. Supply manifold

4. Three-way mixing valve 230V

5. Circulation pump

6. Differential valve

7. Return manifold

8. Radiator

9. Hot water pump

10. Hot water tank

11. Hot water outlet

12. Cold water inlet

13. Pressure tank

14. Safety group

15. Buf fer tank

16. Set of solar collectors

17. central heating sensor

18. Upper part sensor

19. Down part sensor

20. Solar collector pump

21. Hot water measurement

22 23

Return from installation

Supply to installation. – DN 50

Cooling coil tappings– 2 × DN 20

Drain valve – DN 15

6.2. Hydraulic connections.

6.3. Cooling coil

In connection with thermostatic valve BVTS it protects the boiler from overheating. Cooling coil needs to

be connected to cold water installation through thermostatic valve BVTS. Cooling coil outlet should be

directed to drains.

Pic. 5 BVTS connection scheme

7. Boiler tightness

It is very important to assure boiler tightness especially: door tightness. Leakiness causes that fumes

may get out to the boiler room and lead to uncontrolled burning. To assure proper door tightness, rope

need to be checked periodically and in case of damage - replaced. Insulation rope in bottom door need

to greased at least once a month with oil or graphite grease.

8. Ventilation

According to european safety regulations each boiler room should have supply-exhaust ventilation

ensuring correct boiler operation and user’s safety. Lack of ventilation or its obstruction is the main

reason of incorrect boiler operation (i.e. boiler cannot reach set temperature). Exhaust ventilation

removes from boiler room used air and harmful gases. Boiler room with natural draught cannot have

installed mechanical ventilation.

8.1. Supply air ventilation.

1. Ventilating duct section should have at least 50% area of chimney’s section and not less than 20 x 20

cm. Duct should be placed 1m above the oor.

2. Ventilating duct should have installed device for air ow control; device shouldn’t limit duct section

above 1/5.Ventilating duct should be made of non-inammable material.

8.2. Exhaust ventilation

1. Exhaust duct should be made of bricks with section of at least 25% of chimney section not less 14 x 14

cm. Inlet hole cannot have any devices that reduce its section. Outlet hole should be placed close to the

ceiling led out 1,5 m above the roof. Ventilating duct should be made of non-inammable material.

2. Height of the boiler room min. 2,2 m.

9. Chimney connection

Chimney ducts should be installed according to binding rules and norms in countries to which boilers

are sold.

Part of chimney system connection boiler with chimney is called ue. In order to lower ow resistance of

exhaust gases this part should lead as a straight pipe with, if necessary, joints up to 45°

Because of exhaust gases temperature ORLIGNO 500’s need to be connected to chimney system

protected against condensate soaking.

30 cm above the oor closing door should be installed with tight closing.

Chimney section should be round or close to square shape because of low ow resistance. Minimal ue

diameter at least 160 mm

Chimney should lead above the roof. Chimney outlet location is dependent on roof slope and its

combustibility.

Eko-Vimar Orlański Ltd. recommends to install draught regulator which stabilizes chimney draught.

24 25

Symptom Reason Action

Alarm: No re/fuel Lack of re Rell hopper acc. to point „Lightning up”

Boiler

cannot reach

programmed

temp.

Wrong lightning up Check „Lightning up”

Too moisture pellet

Check moisture – use pellet with required

parameters

Clogged primary air channels Call service – after-warranty service

Clogged heat exchanger’s pipes

Clean pipes or call service – after warranty

service

Damaged gasket on blower’s or

burner’s ange

Replace – after-warranty service

Damaged blower Replace – after-warranty service

Boiler is fuming

Clogged or unproper chimney Get the chimney-sweeper opinion

Strong wind forces fumes into the

chimney

Consider installation of devices regulating

chimney draught

Door is fuming

Gasket leak Regulate the door’s hinges

Damaged rope Replace the rope – after-warranty service

Controller doesn’t

work

No voltage in the grid

Check the protection devices in the electric

installation

Damaged wire Wire and connection control

Damaged controller Call the service

Loud blower

operation

Damaged bearings Call the service - replace the blower

Damaged capacitor Call service – replace the capacitor

Loosen xing of blower Fixing control, screw in

Dirty rotor blades Control, cleaning

10. Troubleshooting

11. Ending

Present appliance is marked according to European Directive 2002/96/EC on waste electrical and

electronic equipment.

Symbol placed on the components or attached documents means that appliance is not classied as a

household waste.

Scrapping should take place in special collection point in order to reuse electrical and electronic

components.

26 27

EKO-VIMAR ORLAŃSKI Sp. z o.o.

48-385 Otmuchów, ul. Nyska 17b

POLSKA / woj. opolskie

T +48 77 400 55 80-81, 400 55 91

F +48 77 439 05 03, 400 55 96

E biuro@orlanski.pl

www.orlanski.pl

Loading...

Loading...