Orlaco 0506911, 0516911, 0506952, 0516951, 0516961 Installation Manual

...

Camera PTZ

PAL/NTSC Alu/SSt

Installation Manual

Manual No. IM0973142, R1-4

Article no. 0506911, 0516911

0506952, 0516951

0506961, 0516961

09/2014

English

Article no. 0506952; Camera PTZ PAL Alu

0516951; Camera PTZ PAL Alu RS485

0506961; Camera PTZ NTSC Alu

0516961; Camera PTZ NTSC Alu RS485

Article no. 0506911; Camera PTZ PAL Sst

0516911; Camera PTZ PAL Sst RS485

2 IM0973142 R1-4 IM0973142 R1-4 3

CORRECT

INCORRECT

INCORRECT

U-Bolt of all clips on

dead end of rope

Staggered clips

U-Bolt of all clips on

live end of rope

Installation Manual

Camera PTZ PAL/NTSC Alu/SSt

Article no. 0506911; Camera PTZ PAL Sst

Article no. 0516911; Camera PTZ PAL Sst RS485

Article no. 0506952; Camera PTZ PAL Alu

Article no. 0516951; Camera PTZ PAL Alu RS485

Article no. 0506961; Camera PTZ NTSC Alu

Article no. 0516961; Camera PTZ NTSC Alu RS485

Safety

In order to guarantee safe operation, these safety instructions must be read before you start using this equipment.

• Do not open the enclosure. The camera and the P&T enclosure are

pressurised. This can cause damage, short-circuiting or electrical

shocks.

• Do not expose the equipment to extreme temperatures. This can cause

deformation of the enclosure or damage to internal components.

• Repairs or adjustments to the equipment may only be undertaken by

Orlaco.

• The equipment must be assembled as shown in this manual.

• If there have been alterations or changes to this equipment that have

not been specifically approved by Orlaco, use of this equipment is not

permitted.

Statement related to Machine-directive 2006/42/EC:

Orlaco, under it’s role as manufacturers product-responsibility has

studied the impact of the Machine Directive onto the design of this

Pan/Tilt unit. We can make the following statement:

There is no risk that we aware of in the PTZ that is in conflict with the

Machine Directive and this device is safe to use under 2006/42/EC

machinery directive. :

2 safety measurements are in place to comply to the rules set out in the

directive:

1. Holes that are big enough to allow bodyparts in (see directive

for definition) are designed in a way that they cannot and will not

pinch the body-parts in normal operation of the PTZ as described

in this manual.

2. In the rare occasion that the device is hitting or pinching a

mechanical part or bodypart the electronics and integrated

sensors makes sure the stepping motors are stopped

automatically to prevent any damage similar to the way car

windows are functioning.

Before you start using this equipment, please read this manual carefully

and follow all instructions. This installation manual describes the functions of the equipment, outlines the connection options and explains how

to put the equipment into operation. We recommend that you keep this

manual in a safe place for reference purposes.

If you have any questions or issues concerning the operation of this

equipment, consult the relevant section in the manual or contact the

Orlaco Products BV Service department.

The camera and monitor systems from Orlaco comply with the latest CE,

ADR, EMC and mirror-directive regulations. All products are manufactured in accordance with the ISO 9001 quality management, ISO/TS16949

quality automotive and ISO 14001 environmental management.

Installation Manual

1. Introduction

PTZ (Pan Tilt Zoomcamera) unit.

Pan & Tilt unit including camera. The PTZ unit functions via two stepper

motors. These stepper motors are controlled by the integrated microcontroller and input commands RS232 RS485/Visca-, Pelco D protocol/P

9600 Baud rate. Commands for the PTZ unit are sent via, amongst other

things, the Monitor 7” RLED Serial or Monitor 12” Serial. Weather-,

shock-, vibration-, corrosionproof.

2. Configuration

The space required for panning and tilting is:

Panning: 315mm.

Tilting: 370mm.

See also figure 10, page 7. When positioning the PTZ unit, account must

be taken of the space required for panning and tilting. There must be no

obstacles in this space.

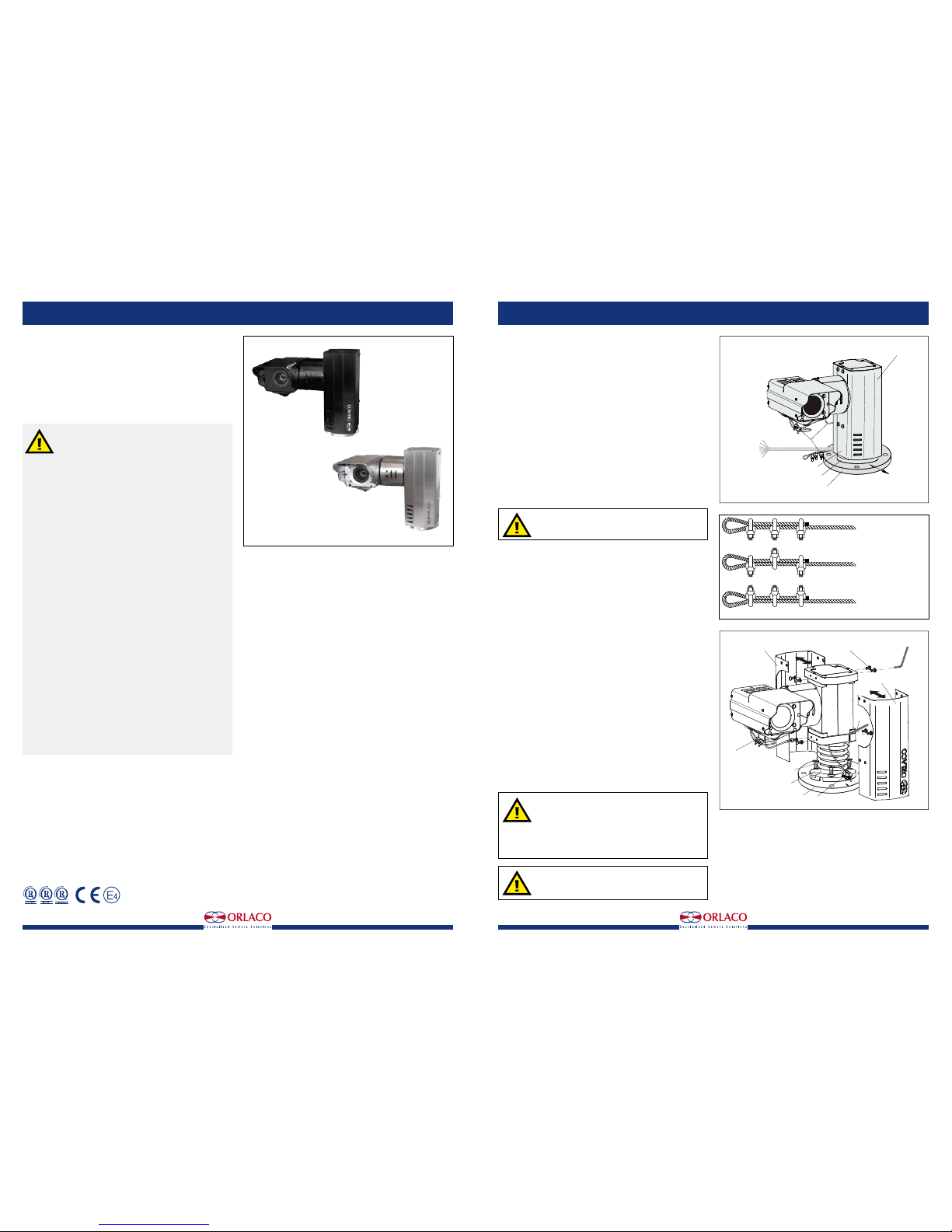

3. Mounting

The PTZ unit has a base. Mount the PTZ unit upright.

The PTZ unit may not be mounted hanging or at a right

angle! This would put too much pressure on the base

and mechanical components.

First demount two coverplates of the PTZ unit, see figure 3.

To affix the PTZ unit, use a pole bracket or a wall bracket. Or mount the

PTZ unit directly to a metal surface.

Note the starting position of the camera; this is indicated as the zero position in figure 1.

Use a Allen key to secure the PTZ unit with three M8 x 20mm Stainless

steel bolts(included). The base of the PTZ unit has three recessed holes.

Mount the bolts (Hexagon socket countersunk head screws) from the upper side of the base. For details of the size of the attachment points, see

figures 5 and 6. Mount the two cover plates back to the PTZ unit.

3.1. Mounting safety cables

Mount the fall protection to a fixed point. Use three cable clamps for

attachment. These cable clamps must to be installed correctly; see figure

2. Mount the safety cable from the camera to a fixed mounting point on

the same surface and height as the Base plate, see figure 4.

4. Operation

4.1 Overpressure in the enclosure

The enclosure of the Camera and PTZ unit has a 1,4-bar overpressure.

4.2 Switching on and off

First of all, position the PTZ unit in the zero position as indicated in

figure 1.

The PTZ unit configuration is switched on by connecting the connector

cables to the power supply. It is switched off by disconnecting the connecting cable from the power supply. See figure 7.

Ensure that the PTZ unit and other components of

the installation are closed so that it is not possible to

come into contact with moving parts.

Ensure that all parts are firmly fixed, stable and

secure.

Check that the power and connector cables are suitable for the system power supply.

Do not get too close to the PTZ unit when the system

is switched on. There is a risk of injury.

Contens page

1. Introduction 3

2. Configuration 3

3. Mounting 3

3.1. Mounting safety cables 3

4. Operation 3

4.1 Overpressure in the enclosure 3

4.2 Switching on and off 3

5. Electrical installation 4

5.1. Pan & Tilt (PTZ) cable specifications 4

5.2. Example configuration 4

6. Instructions for use 5

7. Troubleshooting 5

8. Maintenance and cleaning 6

9. Technical specifications 6

9.1 Camera PAL 6

9.2 PTZ PAL 6

9.3 General PAL 6

9.4 Camera NTSC 7

9.5 PTZ NTSC 7

9.6 General NTSC 7

10. Dimensions 7

11. Visca protocols 8

10.1 Orlaco Pan/Tilt command set 8

10.2 Old Pan/Tilt commands 8

10.3 New pan/Tilt commands 8

12. Generic Serial commands 8

13. Pan/Tilt serial commands 8

12.1 Old Pan/Tilt commands 9

12.2 New pan/Tilt commands 9

14. Additional serial commands 10

15. Disposal 11

16. General terms and conditions 11

17. Release notes 11

Available documentation

DS0506910 Camera PTZ SSt (0516910)

DS0506951 Camera PTZ Alu (0516950

DS0506960 Camera PTZ NTSC Alu (0516960)

UM0972080 Monitor 7" RLED/LEDD

Figure 1

Figure 3

Horizontal zero position

view direction

Cover plate

Cable Base

art. no 1221300

length 5,5m

Open

wired

Cable

fall protection

Base

Base plate

Cover plate

Cover plate

3 Bolts M8 x 20mm

Base

Base plate

Socket head wrench

Socket head wrench

M5 Socket head screw

Fall protection

Fall protection

Figure 2

4 IM0973142 R1-4 IM0973142 R1-4 5

Installation Manual

5. Electrical installation

The PTZ unit must be connected by trained electricians. Under no circumstances should you make

connections that are not described in this manual.

5.1 PTZ Cable specifications. Cable Base, Art no 1221300

1 = Coax core Video

2 = Coax shielding Video GND

3 = Red Camera power, 18...30V/DC (fuse 315mA)

4 = Black Camera 0V

5 = Red/White Pan/Tilt power (fuse 500mA)

6 = Black/White Pan/Tilt 0V

7 = Green Serial 1 RS-232 TX

8 = Grey Serial 2 RS-232 RX

9 = Black/Gray Serial 0V

1 = Red/blue N.C.

2 = Black/blue N.C.

3 = Blue N.C.

4 = Brown N.C.

5 = Shield N.C.

5.2 Example configuration

The following products are required for basic operation of the

PTZ unit,

see figure 7.:

PTZ unit Art Nr 0506910.

Monitor RLED 7", Art no 0208632.

Installation Manual

6. Instructions for use

Using the Monitor: See User Manual IM0972080 Monitor 7" RLED/LEDD

for detailed instructions about how to use the Monitor

To set the PTZ unit and the autofocus function, go to the camera settings

area via the service menu; then select ‘Pan/tilt’ to operate the PTZ unit

from the keyboard and select ‘AFZ’ for the zoom camera functions. See

figure 8.

7. Troubleshooting

power

power

display RLED 7” serial

0208632

handheld control serial

0506950

interface control panel serial

05029**

multi cable

40m

1220150

Junctionbox

0504791

Camera PTZ Sst

0506910

optional

Cable Base

Art.No. 1221300

Lenght 3,6m

Figure 7

R = 50,0

M8 x 1,25 (3x)

horizontal zero position

Cable

120°

90°

30°

120°

Base

back side

Base plate

Top side

150

120° (3x)

M8 (3x)

R = 50,0

∅12 (4x)

Figure 6

Problem

1. Monitor does not work.

2. Monitor has no picture.

3. Camera does not work.

5. PTZ does not work.

Possible cause

System is not switched on.

System is not connected or the supplied voltage

of the vehicle to which the system is connected

is too low (flashing LED on camera).

Fuse of the vehicle’s supply voltage is defective.

Other cause.

Monitor is not or incorrectly connected to the

control box.

Camera is not functioning.

Other cause.

Camera is not or incorrectly connected.

The camera is defective.

Other cause.

PTZ not or incorrectly connected to the camera.

Other cause.

Solution

Connect the Power cable to the right power

supply.

Connect the system and measure the vehicle’s

supplied voltage when the system is switched

on.

Replace the fuse.

Contact your Orlaco dealer.

Check the connection of the Monitor

See problem 3.

Contact your Orlaco dealer.

Check the connection of the PTZ to the operating panel and make sure the red LED on the

camera is lit.

Contact your Orlaco dealer.

Contact your Orlaco dealer.

Check the connection of the Monitor to the

camera.

Contact your Orlaco dealer.

Figure 8

R = 50,0

M8 x 1,25 (3x)

horizontal zero position

Cable

120°

90°

30°

120°

Base

back side

Figure 5

Camera cable

Top view

Base Plate

∅2 safety cable

from the camera

length 360-370

between camera

and wire rope

clamp

60 ±10

wire rope clamps (3x)

fixed mounting point

Camera cable

Top view

Base Plate

∅2 safety cable

from the camera

length 360-370

between camera

and wire rope

clamp

60 ±10

wire rope clamps (3x)

Mount the safety cable from

the camera on a fixed

mounting point on the same

surface and height as

the Base plate

Base plate

fixed mounting point

Base

Figure 4

Loading...

Loading...