Orion Welders - mPulse Getting Started

Follow these steps before welding. ese are also great

troubleshooting steps to follow if you feel like your welds are not

consistent or not looking the way you think they should.

STEP 1: Check the Gas Pressure

• Gas is at 8 - 12 psi

STEP 2: Shape the Electrode

• Hold the dremel in one hand (close to the body for support)

and the electrode in the other hand.

• Place the electrode on the diamond disk at a 45 degree angle

and spin it to sharpen.

• Make sure the striations in the electrode are horizontal.

STEP 3: Verify Electrode Length

• e electrode should stick out of the Stylus Cone 4 - 6 mm

(1/8 - 1/4”). Make sure the Stylus Cone is pushed in all the

way (you will feel it click into place and bottom-out).

STEP 5: Welder Settings and when to use the Reset Button

• Before beginning any weld, double check the energy level.

• Verify Energy and that the play button is showing before

beginning a weld. *Settings on p.2

STEP6: How to Touch the Electrode to the Work piece

• Clip the alligator clip to the workpiece.

• Rest your hands on the table under the darkening lens.

• Position the work piece so that it is right under the electrode

then look through the lens.

• Lightly lift your fingers up and touch the work piece to the

electrode (the electrode will retract after it is touched).

• Hold the work piece steady after touching the electrode - if

you pull the work piece away after touching the electrode, it

will not weld. If you follow the electrode with the work piece

while it is retracting, the electrode will stick to the work piece.

STEP 4: Verify the Darkening Lens Setup

• Darkening Lens cable is securely connected to the welder.

• Electrode is centered in your field of view and in focus.

• Electrode is at a height where you can rest your hands on the

baseplate and lift your work piece up with your fingers.

STEP7: How to Set up the Work pieces for Welding.

• When closing a jump ring, or welding two pieces together;

make sure the two sides are pushed together and flush

before welding.

• When adding material, touch the wire to the work piece at a

45-degree angle then enter the electrode in at a 90-degree

angle. Touch the electrode between the work piece and the

wire.

OrionWelders.com

Orion Welders - mPulse

General Settings for specific metals and applications Specifications

Remember:

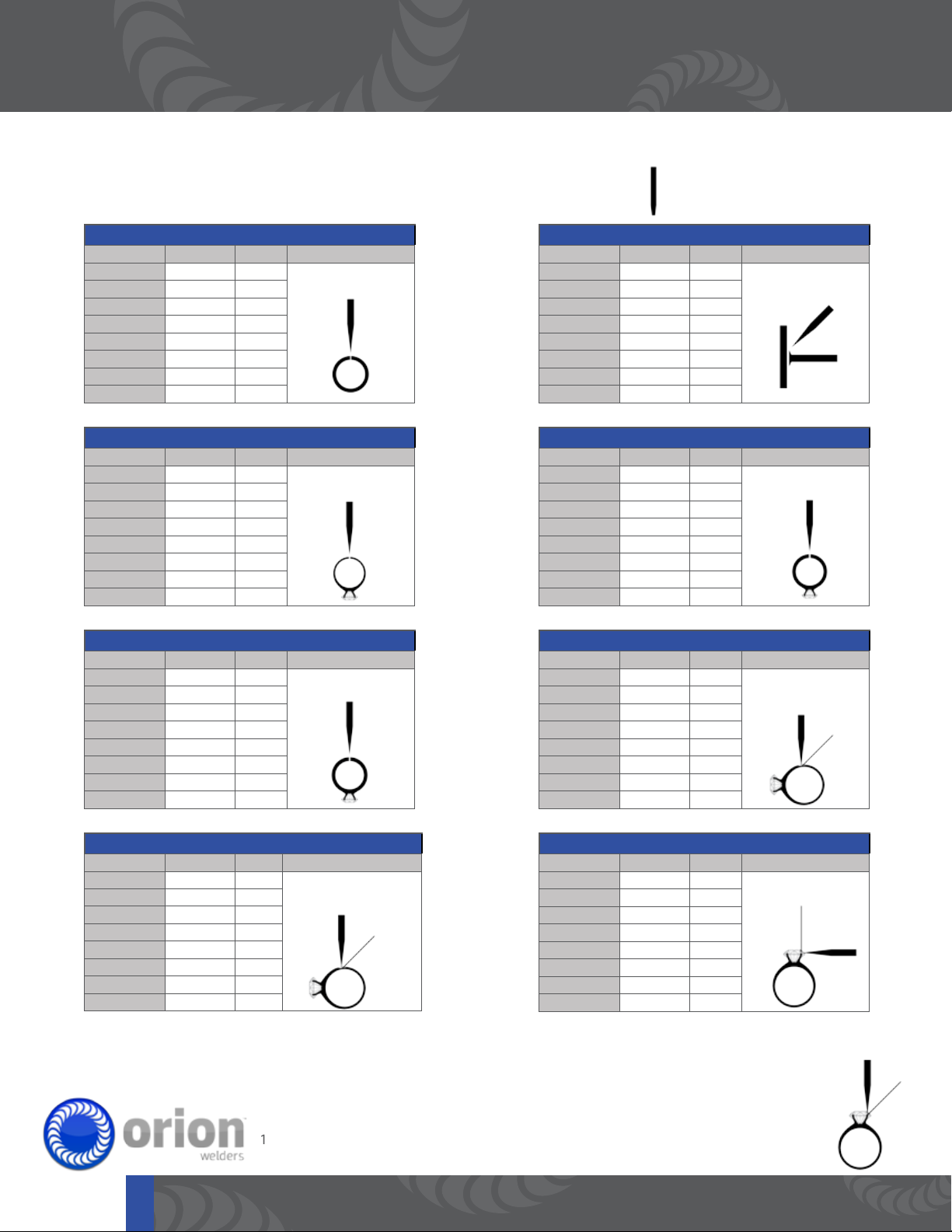

2. The image to the right is an example of what a blunt electrode should look like:

1. When in doubt, start with your energy lower then work your way up.

General Settings - 26 AWG wire/chain/jump ring

Metal Tip Shape Energy Notes

14k Gold Sharp 10 ws

24k Gold Sharp 7.5 ws

Silver Sharp 10 ws

Platinum Sharp 10 ws

Stainless Steel Sharp 7.5 ws

Palladium Sharp 7.5 ws

Titanium Sharp 10 ws

Brass Sharp 10 ws

Butt weld with 90 degree

electrode angle

General Settings - 0.5mm thick Ring

Metal Tip Shape Energy Notes

14k Gold Sharp 12.5 ws

24k Gold Sharp 10 ws

Silver Sharp 17.5 ws

Platinum Sharp 15 ws

Stainless Steel Sharp 15 ws

Palladium Sharp 15 ws

Titanium Sharp 15 ws

Brass Sharp 15 ws

Butt weld with 90 degree

electrode angle

General Settings - 2mm thick Ring

Metal Tip Shape Energy Notes

14k Gold Sharp 30 ws

24k Gold Sharp 30 ws

Silver Blunt 30 ws

Platinum Sharp 30 ws

Stainless Steel Sharp 30 ws

Palladium Sharp 30 ws

Titanium Sharp 30 ws

Brass Sharp 30 ws

Butt weld with 90 degree

electrode angle

General Settings - Earring Post

Metal Tip Shape Energy Notes

14k Gold Sharp 10 ws

24k Gold Sharp 10 ws

Silver Sharp 12.5 ws

Platinum Sharp 12.5 ws

Stainless Steel Sharp 7.5 ws

Palladium Sharp 7.5 ws

Titanium Sharp 12.5 ws

Brass Sharp 10 ws

T joint with 45 degree

electrode angle

General Settings - 1mm thick Ring

Metal Tip Shape Energy Notes

14k Gold Sharp 22.5 ws

24k Gold Sharp 20 ws

Silver Semi Blunt 30 ws

Platinum Sharp 25 ws

Stainless Steel Sharp 22.5 ws

Palladium Sharp 20 ws

Titanium Sharp 25 ws

Brass Sharp 25 ws

General Settings - Add Material (30 AWG laser wire)

Metal Tip Shape Energy Notes

14k Gold Sharp 12.5 ws

24k Gold Sharp 12.5 ws

Silver Sharp 15 ws

Platinum Sharp 15 ws

Stainless Steel Sharp 10 ws

Palladium Sharp 10 ws

Titanium Sharp 15 ws

Brass Sharp 12.5 ws

Butt weld with 90 degree

electrode angle

Wire at 45 degree angle.

Electrode touching work

piece next to wire.

General Settings - Add Material (24 AWG wire)

Metal Tip Shape Energy Notes

14k Gold Sharp 17.5 ws

24k Gold Sharp 15 ws

Silver Sharp 20 ws

Platinum Sharp 20 ws

Stainless Steel Sharp 15 ws

Palladium Sharp 15 ws

Titanium Sharp 20 ws

Brass Sharp 17.5 ws

Wire at 45 degree angle.

Electrode touching work

piece next to wire.

Orion Welders

1-877-786-9353

1693 American Way #5

Payson, UT 84651 USA

General Settings - Retip Prong (26 AWG wire)

Metal Tip Shape Energy Notes

14k Gold Sharp 10 ws

24k Gold Sharp 7.5 ws

Silver Sharp 10 ws

Platinum Sharp 10 ws

Stainless Steel Sharp 7.5 ws

Palladium Sharp 7.5 ws

Titanium Sharp 10 ws

Brass Sharp 10 ws

The above method will allow the user to attach the wire to the

prong tip. If the user desires to add metal to the tip without

the wire staying attched, use a 30 AWG wire and position the

electrode and 30 AWG wire as seen in the picture to the right.

This method will allow the user to add a little bit of metal at a

time, covering the top of the prong with every weld.

Butt weld with 90 degree

OrionWelders.com

electrode angle

Wire at 45 degree angle.

Electrode touching work

piece next to wire.

Loading...

Loading...