ORION TELESCOPES & BINOCULARSinstruction Manual SkyQuest xx12g, SkyQuest xx14g, SkyQuest xx16g Instruction Manual

INSTRUCTION MANUAL

Orion® SkyQuest™ XXg

GoTo Truss Tube Dobsonians

#10148 XX12g, #8964 XX14g, #8968 XX16g

XX14g

Providing Exceptional Consumer Optical Products Since 1975

Customer Support:

www.OrionTelescopes.com/contactus

Corporate Offices:

89 Hangar Way, Watsonville CA 95076 - USA

IN 461 Rev. D 06/13

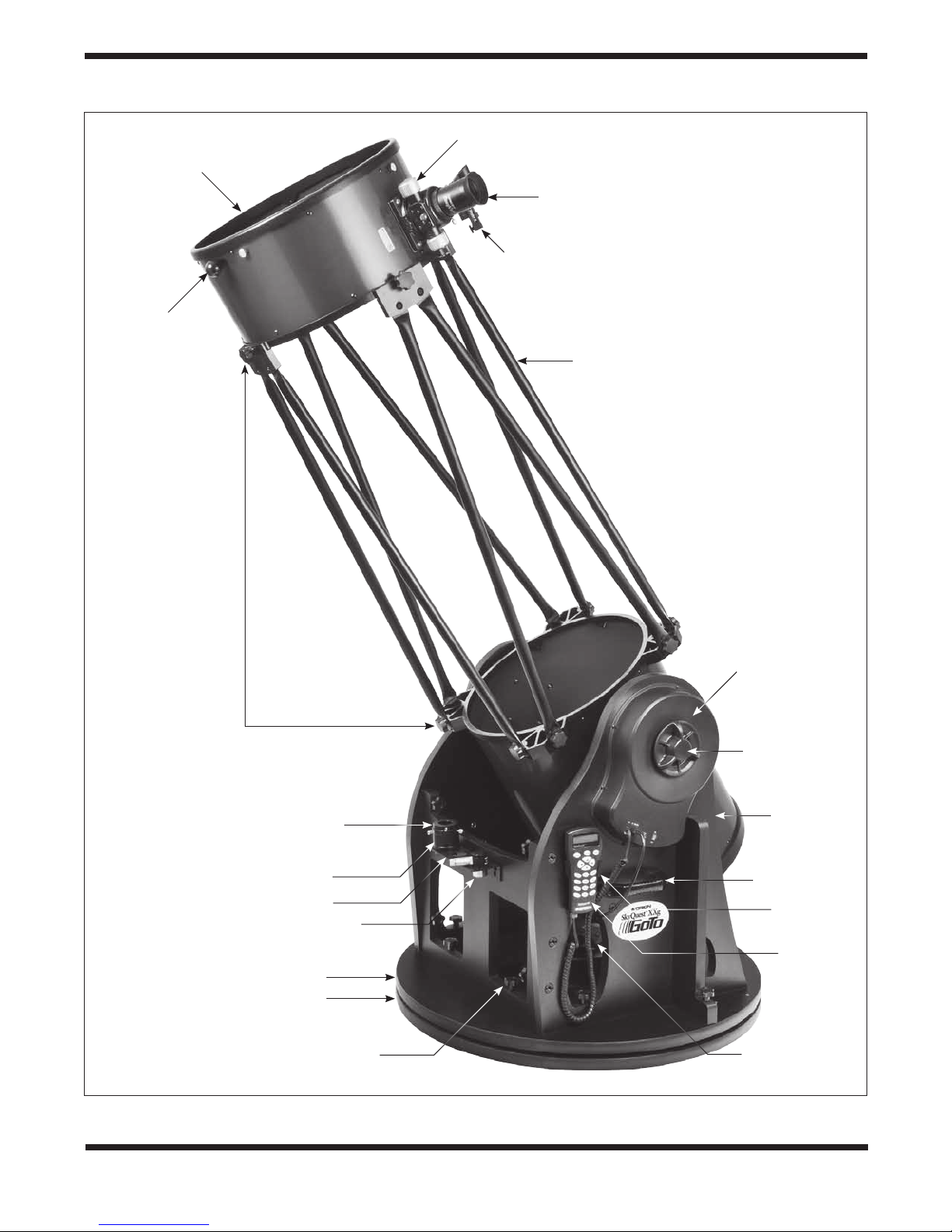

Upper optical

tube section

Navigation

knob

2" Dual-speed

Crayford focuser

2" DeepView eyepiece

EZ Finder II

Truss poles

Captive

clamping

knobs (x12)

1.25" eyepiece adapter

2" extension adapter

Eyepiece rack

12.5mm Illuminated Plössl

Top groundplate

Bottom groundplate

Captive base

connecting bolts (x12)

Figure 1. Overview of SkyQuest XXg Dobsonian (16" shown)

Altitude motor and

encoder housing

Altitude

clutch knob

Lower optical

tube section

Handle

Hand controller

bracket

GoTo hand

controller

Azimuth motor and

encoder housing

2

Congratulations on your purchase of an Orion SkyQuest XXg GoTo Dobsonian. These revolutionary Dobs

combine large-aperture optical performance with state-of-the-art computerized GoTo pointing capability. Moreover, these big telescopes were designed by Orion to be remarkably transportable – both their

base and optical tube break down into easily manageable components that can fit into any standard size

vehicle. Setup for an observing session takes just minutes, and the views are spectacular! We know you

will enjoy many years of rewarding observations with your SkyQuest XXg GoTo Truss Dobsonian.

Please read these instructions thoroughly before beginning assembly and subsequent use of the telescope.

1. Unpacking

Table of Contents

1. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3. The GoTo Hand Controller . . . . . . . . . . . . . . . . . 15

4. Collimating the Optical System . . . . . . . . . . . . . 16

5. Using Your Telescope . . . . . . . . . . . . . . . . . . . . . 18

6. Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . 22

WARNING: Never look directly at the Sun through your

telescope or its finder scope – even for an instant – without a professionally made solar filter that completely covers the front of the instrument, or permanent eye damage

could result. Young children should use this telescope

only with adult supervision.

The SkyQuest XX12g is packed in three boxes, one containing the optical tube assembly (OTA), truss poles, and accessories; a second containing the unassembled Dobsonian

base; and third containing the primary mirror and mirror cell.

The XX14g ships in four boxes, with the truss poles and counterweights contained in a separate box. The XX16g is packaged in five boxes, with the base components divided into two

separate boxes to keep the weight and size of the individual

boxes more manageable.

Before beginning assembly, unpack each box and confirm

that all of the parts in the Parts List below are present. The

parts are listed by the box they should arrive in, but some of

the parts may be in different boxes than indicated below. Be

sure to check all boxes carefully, as some parts are small. If

anything appears to be missing or broken, immediately call

Orion Customer Support (800-676-1343) or email support@

telescope.com for assistance.

3

Parts List

Box #1: Optical Tube Assembly and Accessories

(Figure 2)

Qty. Description

1 Lower optical tube section

1 Upper optical tube section

2 Optical tube dust covers (one for each tube section)

4 Truss pole pairs (XX12g only)

1 DeepView 28mm eyepiece, 2"

1 Eyepiece extension adapter, 2" (not shown)

1 Illuminated 12.5mm Plössl eyepiece, 1.25"

1 EZ Finder (with bracket)

1 Collimation cap

1 Eyepiece rack

2 Eyepiece rack wood screws (20mm long, color black)

2 Hex keys (2mm, 2.5mm)

1 Tube connecting knob

1 SynScan AZ Hand controller

1 Hand controller cable (coiled)

1 Azimuth motor connection cable

1 RS-232 computer interface cable

1 Hand controller bracket (with 2 mounting screws)

3 Counterweight mounting bolts (XX14g, XX16g)

1 Cooling accelerator fan with battery holder

(XX12g only)

1 Instruction manual (not shown)

1 Starry Night CD-ROM

Lower

optical tube

section

Upper

optical tube

section

a.

Figure 2. Contents of the optical tube box. a) The larger

components. b) Accessories and hardware.

b.

Cooling fan and

mounting screws

(XX12g only)

Battery pack

(XX12g only)

Starry Night

Special Edition

CD-ROM

EZ Finder II

Hex keys

Bracket for hand

controller and

mounting screws

Tube

connecting

bolt

Quick collimation cap

Dust covers

12.5mm Illuminated

Plössl eyepiece

with illuminator arm

DeepView 28mm

2" eyepiece

Eyepiece

rack

mounting

screws

Eyepiece rack

Counterweight

mounting bolts

(XX14g and

XX16g only)

4

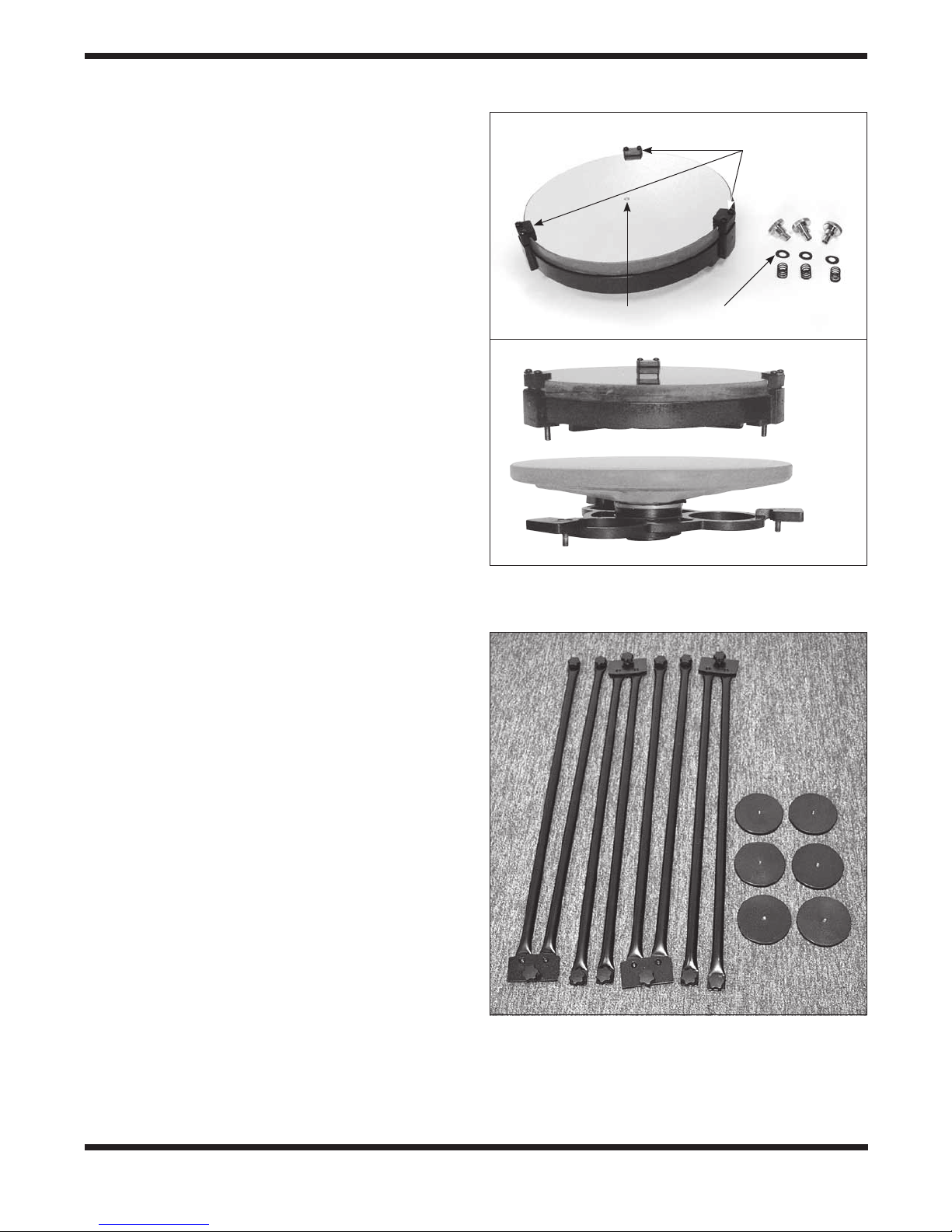

Box #2: Primary Mirror and Cell (Figure 3)

Qty. Description

1 Parabolic primary mirror (XX12g, flat back; XX14g and

XX16g, convex back)

1 Mirror support cell

3 Collimation knobs

3 Nylon washers (3/4" outer diameter)

3 Springs

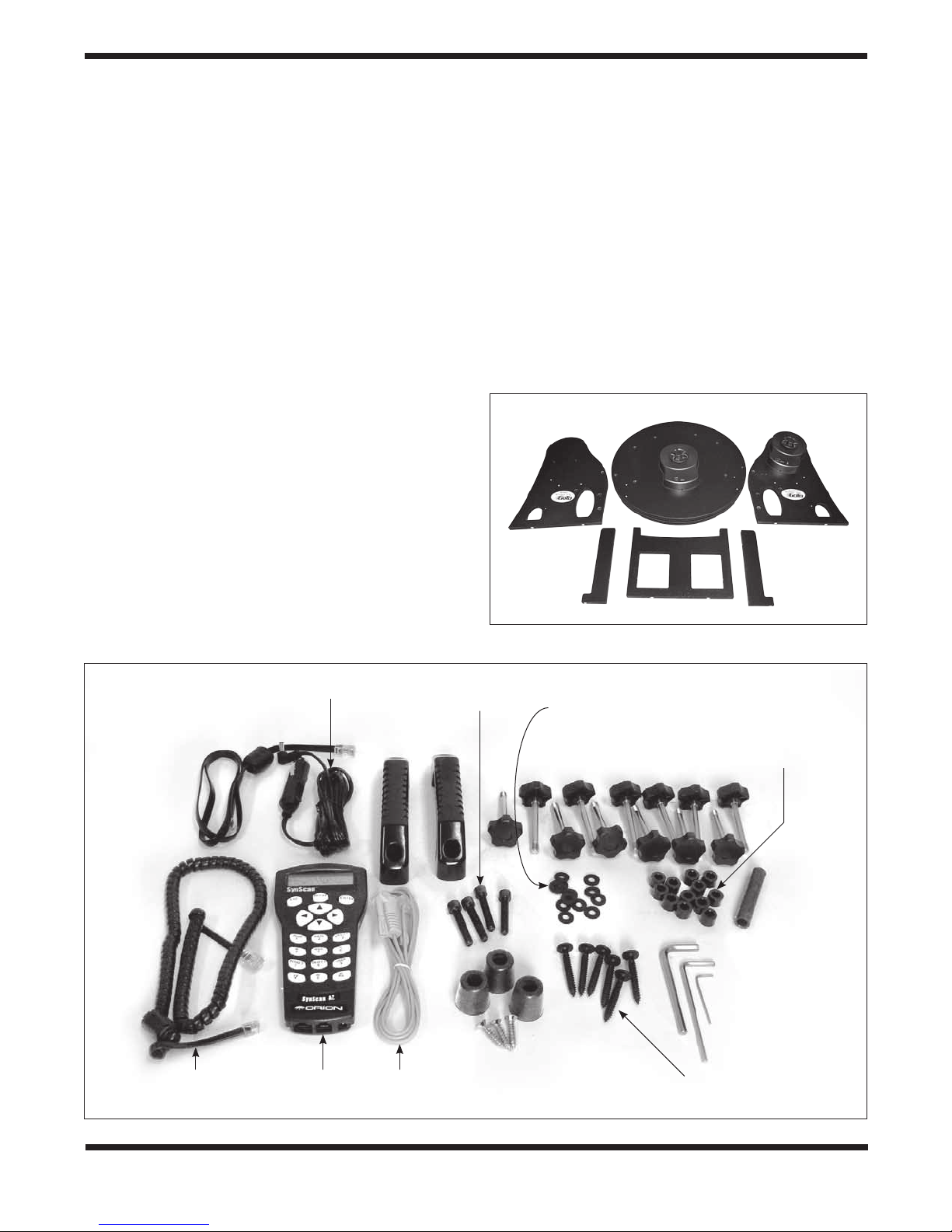

Box #3: Truss Pole Assemblies and

Counterweights (XX14g and XX16g) (Figure 4)

Qty. Description

4 Truss pole pairs

6 Counterweights, 2.2 lbs. each (XXX14g only)

9 Counterweights, 2.2 lbs. each (XXX16g only)

Primary mirror in

mirror support cell

(XX12g)

a.

b.

Mirror

retaining

clips

Collimation

knobs

Springs

WashersCenter mark

XX12g

XX14g

and

XX16g

Figure 3. Contents of the primary mirror box. a) The primary

mirror, mirror cell, and collimation hardware for the XX12g. b) The

primary mirrors and mirror support cells for the XX12g (top) and

XX14g/XX16g are quite different.

Figure 4. Contents of the truss pole and counterweight box.

(The XX16g contains nine counterweights.) For the XX12g, the

truss poles are included in the optical tube box, and there are no

counterweights.

5

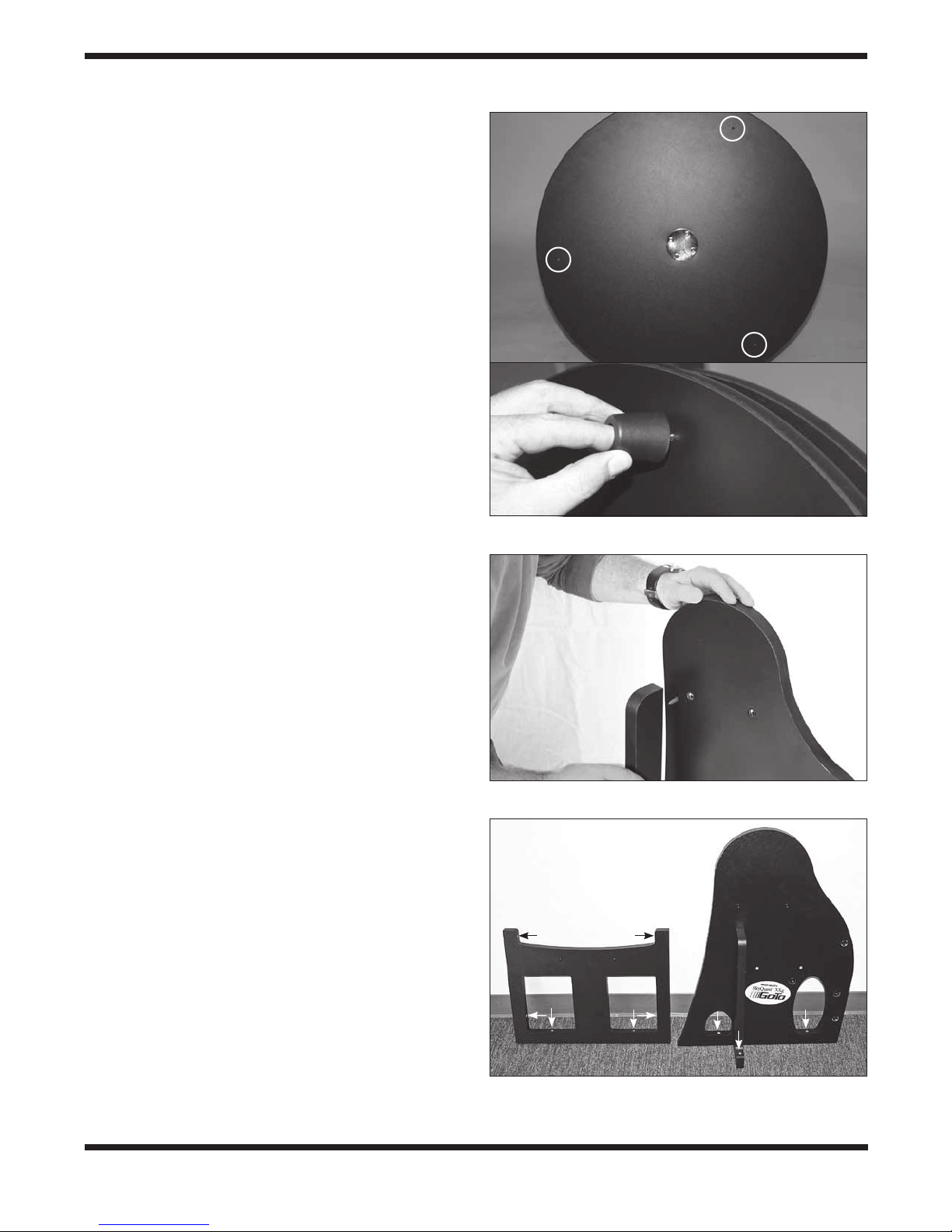

Box #4: Dobsonian Base (Figure 5)

Qty. Description

1 Left side panel (with altitude motor and encoders pre-

installed)

1 Right side panel

1 Front panel

2 Side braces

1 Groundplate assembly (with azimuth motor and

encoders pre-installed) This is contained in a separate

box (Box #5) for the XX16g.

6 Base assembly wood screws (coarse thread, 47mm

long)

12 Base connecting bolts with hand knobs

12 Rubber retaining washers

12 Spacers for connecting bolts

1 Insertion tube for rubber retaining washers (~3" long)

2 Carrying handles

4 Handle mounting bolts (socket head cap screws,

25mm long)

3 Hex keys (size 2mm, 4mm, 6mm)

3 Plastic feet (XX12g only; feet are pre-installed on

XX14g and XX16g)

3 Feet wood screws (1" long; XX12g only)

Box #5: Dobsonian Base (XX16g only)

Qty. Description

1 Groundplate assembly (with azimuth motor and

encoders pre-installed)

Right side panel

Groundplate assembly

Left side panel

b.

Azimuth motor

connection cable

DC power cable

Handles

a.

Figure 5. Contents of the base box(es). a) The larger components,

b) Hand controller, cables, and other hardware.

Mounting bolts

for handles

Side brace Side brace

Front panel

Rubber retaining

washers

Base connecting

bolts (x12)

Spacers for

connecting

bolts (x12)

Insertion tube

Hex keys

Coil cable for

hand controller

Hand

controller

6

RS-232

cable

Feet (x3) and mounting screws

(Feet come pre-installed on

XX14g and XX16g)

Base assembly

wood screws (x6)

2. Assembly

Now that you have unpacked the boxes and familiarized yourself with all the parts, it is time to begin assembly.

Initial Assembly of the GoTo Dobsonian Base

The GoTo bases of the SkyQuest XXg Dobs are shipped partially assembled for your convenience. All the motors, optical

encoders, and gears are pre-installed at the factory. The two

round groundplates are preassembled and should not be

taken apart.

When fully assembled, the SkyQuest XXg GoTo Truss Tube

Dobsonians are big telescopes. But we designed them to

break down into easily manageable components, none of

which is too big or too heavy for a reasonably fit individual

to lift and carry (but for the XX16g a helper would be great!).

In fact, both the base and the optical tube can be quickly

disassembled into smaller components for transport and/

or storage, then reassembled – all without tools! We’ll get

to the tube later, but for the base you’ll see that it has four

main components: the groundplate assembly (top and bottom

groundplates and installed azimuth motor housing), the left

side panel with installed altitude motor housing, the right side

panel, and the front panel.

For the initial assembly of the base, you will need a Philips

screwdriver.

1. To install the feet (XX12g only; feet are pre-installed at

the factory on the XX14g and XX16g), turn the groundplate assembly upside-down and gently rest it on the azimuth motor housing on a clean, flat surface. Carpet is

good, or you may want to place a cloth under the azimuth

motor housing to avoid scratching it. Locate the three

starter holes on the perimeter of the bottom groundplate (Figure 6a). Insert the screws through the feet and

thread them into the predrilled starter holes (Figure 6b)

with a Phillips screwdriver until tight.

2. Connect the side braces to the side panels using three

base assembly screws for each panel (Figure 7). The

brace should be attached to the outside surface of the

side panel – the outside of the left side panel has the

altitude motor housing attached. The screws go through

the holes in the side panels and thread into the starter

holes in the side braces. Use the included 4mm hex key

to firmly tighten the screws, but be careful not to strip the

holes by over-tightening!

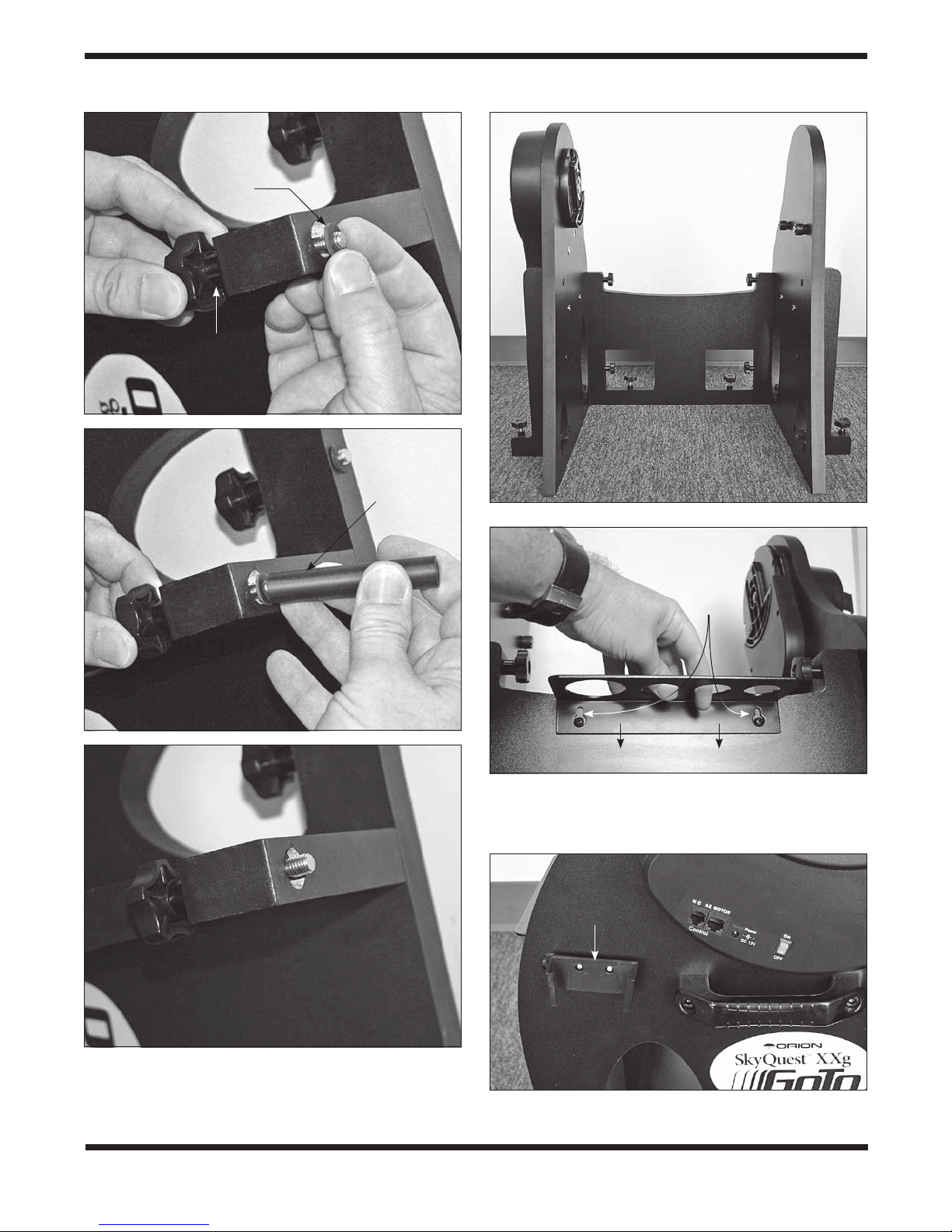

3. Now you will install the captive connecting bolts, each of

which is already fitted with a black hand knob. There are

12 connecting bolts altogether; refer to Figure 8 for locations. Start with the front panel, which has through holes

for six connecting bolts.

First, slide a spacer onto a collecting bolt. Then insert

the connecting bolt into the through hole, in the direction

indicated in Figure 8. Holding the knob with one hand,

use your other hand to press a rubber washer over the

threaded (protruding) end of the bolt. It will be a tight fit;

you may have to work the washer a bit to get it on. Push

the washer up on the bolt as far as you can with your

a.

b.

Figure 6. a) Starter holes for feet on bottom baseplate.

b) Attaching the base feet.

Side

panel

Side

brace

Figure 7. Attach a side brace to the outside of each side panel

using three base assembly wood screws and the 4mm hex key.

Figure 8. Locations for connecting bolts in the front and side panels

(one side panel not shown). Connecting bolts should be inserted in

the predrilled holes in the direction indicated by the arrows.

7

a.

Rubber

washer

Spacer (Don’t

forget this!)

b.

Insertion

tube

Figure 10. The completed side panel and front panel assembly.

Keyholes

c.

Figure 11. Place the large opening of the “keyhole” slots in the

eyepiece rack over the mounting screw heads, then push the rack

downward. To do this, leave the screw heads about 1/8" out from

the panel. After the rack is installed, you can tighten the screws to

secure it in place.

Hand controller

bracket

Figure 9. a) Place a rubber washer on the threaded end of the

connecting bolt and push it on as far as you can with your fingers.

b) Then use the included insertion tube to push the washer past

the threads and up into the counterbored hole in the wood. c) The

recessed washer will keep the bolt captive in the hole.

8

Figure 12. Find the two pilot holes and attach the hand controller

bracket – but don’t overtighten the screws!

Figure 13. The altitude motor housing has jacks for the hand

controller (HC) cable, azimuth motor connection cable, and power

cable as well as an ON/OFF switch.

fingers (Figure 9a). Then place the insertion tube on the

bolt (Figure 9b) and use it to push the washer farther

up on the bolt, into the counterbored hole in the wood

(Figure 9c). The washer will keep the bolt captive when

it is fully disengaged from the mating part of the base.

Repeat this procedure for the other five connecting bolts

to be installed in the front panel, and for the six additional connecting bolts that attach the side panels and side

braces to the top groundplate.

4. Now attach the front brace to the two side panels with the

four appropriate captive connecting bolts. Use the hand

knob to screw each bolt into the threaded metal receptacle recessed in the side panel. The side panels should

be oriented so the side braces are facing outward. The

front panel should be oriented so that the two pilot holes

for the eyepiece rack face outward. Do not completely

tighten the connecting bolts yet. The completed assembly should look like Figure 10.

5. Place the assembled side panel/front panel structure on

the top groundplate, aligning the protruding connecting

bolts with the threaded inserts in the groundplate. Turn

the connecting bolt hand knobs to fasten the side panel/

front panel structure to the groundplate. Firmly tighten all

12 connecting bolts installed in steps 3 and 4. To avoid

stripping the threads, do not overtighten.

6. Attach a handle on each of the two side panels. Insert

a large socket head cap screw through the holes in the

handle and into the predrilled hole in the side panel. The

hole has a flanged threaded metal insert in it. Use the

6mm hex key to thread the screw into the insert until tight.

Refer to Figure 1 for handle placement.

7. The aluminum eyepiece rack holds three 1.25" eyepieces

and one 2" eyepiece in a convenient place on the base,

within easy reach while you are observing. To attach the

eyepiece rack, locate the two small pilot holes on the

front panel. Thread the small Phillips-head screws into

the holes until the screw head is about 1/8" from the

panel’s surface. Now place the wide part of the “keyhole”

on the eyepiece rack over the screw heads and slide it

downward until it stops (Figure 11). Tighten the screws

to secure the rack in place.

8. The XXg base includes a bracket that holds the hand

controller when it’s not in use. The bracket mounts on

the left side panel adjacent to the altitude motor housing

(Figure 12). Locate the two small pilot holes and attach

the bracket using the small screws included with the

bracket until just barely tight. Do not over-tighten these

screws or you will strip the holes!

9. Now install the azimuth motor connection cable. It is a

flat cable that has an 8-pin RJ-45 plug on both ends.

Plug one end into the jack on the azimuth motor housing on the top groundplate; plug the other end into the

jack labeled AZ MOTOR on the altitude motor housing

(Figure 13).

10. Finally, connect the GoTo hand controller. Plug the wide

RJ-45 connector on the coiled hand controller cable into

the corresponding port on the hand controller. Plug the

smaller RJ-12 connector into the port labeled HC on the

altitude motor housing. Refer to the SynScan GoTo Hand

Controller manual.

Initial Assembly of the Optical Tube

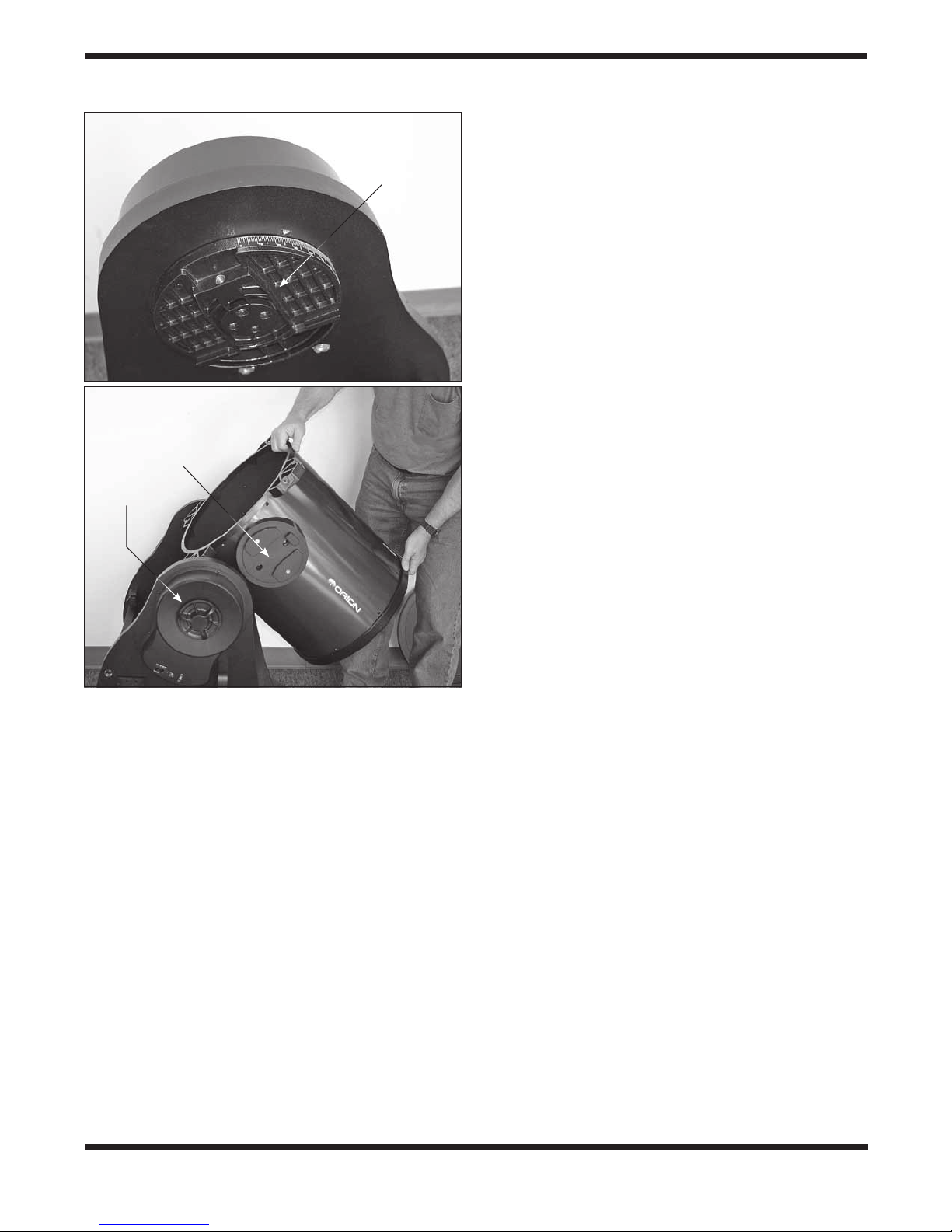

The primary mirror is shipped in its metal support cell separately from the optical tube, to prevent possible damage to

both the mirror and the optical tube. Once the primary mirror

is installed, there will be no need to remove it except if cleaning is necessary (see “Care & Maintenance”). First, the mirror

will be installed in the lower tube section, then the truss poles

and upper tube section will be attached.

The primary mirror of the XX12g has the typical flat back side,

whereas the thinner primaries of the XX14g and XX16g have

a “conical,” or convex back with raised “ribs” radiating from the

center for added strength. The reduced-mass design of these

larger mirrors allows more-efficient equilibration to outdoor

ambient temperature. All the primary mirrors have a small

adhesive ring placed in the exact center (Figure 3a); it aids

in achieving a precise collimation, which will be covered later.

The ring, which has no effect on the image rendered by the

telescope, should NOT be removed.

9

Figure 14. To remove the rear end ring, unthread the screws that

connect it to the tube.

Figure 15. Thread the three hex-head counterweight mounting

bolts (XX14g and XX16g only) into the holes in the counterweight

support plates as shown. Tighten using an adjustable or 16mm

crescent wrench.

1. To install the mirror cell in the optical tube, the rear end

ring attached to the lower tube section must first be

removed. This is done by unthreading and removing the

Phillips-head screws that attach the end ring to the tube

(Figure 14), and then pulling the end ring off of the tube.

Warning: Once the rear end ring is removed from

the tube, the raw edge of the tube itself will be

exposed. Be careful not to cut or otherwise hurt

yourself on the tube’s edge. Also, be careful not

to pinch your fingers between cell and tube when

re-attaching the assembled mirror cell!

2. Next, for the XX14g and XX16g, thread the three counterweight mounting bolts into their respective holes in the

rear end ring, as shown in Figure 15. Use an adjustable

wrench or a 16mm crescent wrench to tighten the bolts.

Do not install the counterweights yet.

3. Next, assemble the telescope’s rear end ring to the primary mirror cell. Find a clean, flat surface, and turn the

mirror cell over so that the mirror is facing downward.

For the XX14g and XX16g, we recommend placing a

soft towel on a flat surface and placing the mirror face

down on the towel, because the aluminized outer edge

of the mirror will contact the surface. With the XX12g mirror on the other hand, the aluminized mirror itself will not

Spring

a.

b.

Collimation

knob

c.

Figure 16. Shown for XX12g. a) Place the three springs on the

exposed threaded shafts of the mirror cell. b) Lower the rear end

ring onto the mirror cell so that the threaded shafts pass through

the end ring, and the end ring rests on the springs. c) Thread the

collimation knobs, with nylon washers attached, through the rear end

ring and onto the threaded shafts. Make sure the knobs have at least

three full turns of engagement on the shafts.

Figure 17. Locate the area of tube that is bulging out and

preventing the end ring from fully seating. Press on this bulge to

allow the mirror cell to seat properly on the tube. Be careful not to

pinch fingers!

Shaft

Nylon

washer

10

a.

Altitude axis

trunnion

b.

a.

Altitude side

bearing (dovetail)

Altitude

clutch knob

Figure 18. a) Altitude axis trunnion on left side panel. b) Grasp

both ends of the lower tube section to lift it, then lower it into the

base, sliding the dovetail slot in the tube’s left altitude bearing into

the mating part of the trunnion.

make contact with the surface; only the mirror retaining

clips will. Place the three springs onto the three exposed

threaded shafts (Figure 16a). (The XX12g mirror is

shown, but the procedure is similar for the XX14g and

XX16g.) Lower the end ring onto the mirror cell so the

threaded shafts pass through it, and the end ring rests on

the springs (16b). Add a nylon washer to each collimation knob and thread the collimation knobs through the

end ring and onto the threaded shafts (16c). Make sure

the knobs have at least three full turns of engagement

on the shafts. The mirror cell is now almost ready to be

installed onto the lower tube section.

4. Check to make sure that the three mirror retaining clips

are properly tensioned (XX12g only, Figure 3a). If they

are too tight, the pinching of the mirror’s edge will distort the images you see through the telescope. But if they

are too loose, the mirror could shift or even fall out if it is

tilted severely. With the mirror in its cell facing up, use a

Phillips screwdriver to loosen the two screws on one of

the clips until you can easily move the small metal plate

underneath the screw heads. Then gradually tighten both

screws just until the metal plate is no longer loose – no

tighter! Repeat this with the other two retaining clips. Now

the clips are properly tensioned.

5. Assembling the end ring (and mirror assembly) back onto

the tube can be a bit tricky. This is because the large

diameter and thin metal of the tube will cause the tube

to become somewhat out of round once the end ring is

removed. To assemble the rear end ring (with mirror and

mirror cell now connected) to the tube, stand the lower

section of the tube up vertically so the raw edge of the

tube is up. Line up the threaded holes in the edge of the

end ring with the holes in the end of the tube. Then, lower

the entire assembly onto the tube. (Be careful to avoid

finger pinching during this step!) There may be a bulge in

the perimeter of the tube that prevents the end ring from

fully seating onto the tube (Figure 17). Press against this

bulge, and the entire mirror cell assembly should seat

onto the tube. Now, replace the Phillips screws that fasten the rear end ring to the tube.

Before assembling the rest of the optical tube, you should consider how you want to mount the optical tube on the base. We

recommend mounting the lower tube section onto the base

first, THEN adding the counterweights, then the truss poles

and upper tube section. Alternatively, you could complete the

assembly of the entire optical tube first, then hoist the whole

thing onto the base. But for that we strongly recommend getting a second person to help with the lifting – at least for the

XX14g and XX16g. For these instructions, we will outline the

procedure for installing the lower tube section on the mount

first, then building the rest of the OTA from there.

Mounting the Lower Tube Section (Only) on

the Base

1. Loosen the altitude clutch knob slightly so the altitude

trunnion can rotate with relatively little resistance.

Note: To keep the bottom tube section as light as

possible for lifting during installation, do not install

the counterweights until after the tube is installed

on the base (see step 4 below).

2. The left altitude side bearing on the optical tube has a

dovetail slot that slides onto the altitude axis trunnion on

the inside of the left side panel (Figure 18a). We recommend orienting the trunnion such that the threaded

hole for the tube connecting knob is at about a 45-degree

angle from horizontal. If the altitude trunnion is oriented

differently, you’ll have to adjust the angle of the telescope

tube accordingly to mount it. Grasp the tube section as

shown in Figure 18b and lift it. Slide the tube’s dovetail

altitude bearing into the mating receptacle of the altitude

trunnion on the base. Once seated in the base, the tube

will freely rotate to a vertical position due to its bottomheavy imbalance. Maintain your grip on the tube and

gently guide it to the resting, vertical position.

11

Altitude

motor/encoder

housing

Tube

connecting

knob

Figure 19. Secure the tube to the base with the tube connecting

knob.

3. Now insert and tighten the tube connecting knob to

secure the tube in place (Figure 19).

4. For the XX14g and XX16g, before assembling the rest

of the optical tube, it is recommended that you install the

counterweights on the rear cell so that the tube, when

assembled, will be properly balanced rather than frontheavy. (The XX12g does not utilize counterweights.)

Without counterweights, the fully assembled tube could

swing forward rapidly, possibly damaging the tube and

mirrors.

There are six counterweight disks for the XX14g and nine

for the XX16g, each weighing 2.2 lbs. For the XX14g, two

counterweights are to be threaded onto each bolt, while

for the XX16g three counterweights should be installed on

each bolt (Figure 20). Tilt the lower tube section as needed to access the counterweight mounting bolts on the rear

cell, and thread the counterweights onto each of the three

mounting bolts. Spin them clockwise until they stop.

5. Now, attach the four truss pole assemblies to the lower

tube section. Connect the eight captive clamping knobs

on the ends of the pole assemblies to the lower truss sup-

Counterweight

Counterweight

mounting bolts

Figure 20. Installing counterweights (XX14g and XX16g only).

Thread two (for XX14g) or three (for XX16g) 2.2-lb. counterweights

onto each counterweight mounting bolt for proper tube balance.

Truss pole

assembly

Clamping

knobs

12

Lower

truss

Lower tube

section

Figure 21 The clamping knobs on the ends of the truss pole

assemblies thread into the holes in the lower truss support ring on

the lower tube section.

Focuser

support

ring

Focuser

Left side

bearing

Figure 22. The upper tube section should be oriented relative to

the lower tube section as shown. Note the orientation of the focuser

on the upper tube section relative to the side bearing on the lower

tube section.

port ring on the lower optical tube section (Figure 21).

This is done by simply threading the knobs into the holes

in the support ring. Do not completely tighten the knobs

just yet.

6. Attach the upper tube section to the four truss connectors at the top of the poles. Orient the upper tube section

as shown in Figure 22. Hold the upper tube section with

one hand while threading the knobs in the truss connectors into the holes in the upper truss support ring. If necessary, you can slightly adjust the position of the truss

connector with respect to the pole ends in order to have

Truss

connector

Truss

poles

a. b.

Figure 23. The position of the truss connectors relative to the pole

ends can be adjusted to register the truss connectors with the upper

truss support ring.

Registration

flats

Upper truss

support ring

Figure 24. When the truss clamping knob is tightened, it will clamp

the truss connector against the registration flats on the upper truss

support ring.

Button head cap screw

Truss connector knob

Truss

connector

the knobs and holes line up (Figure 23). When tightened,

the knob will clamp the truss connector against the registration flats on the upper truss support ring (Figure 24).

Repeat this for the other three truss connectors. Firmly

tighten the knobs.

7. Now go back and firmly tighten the eight clamping knobs

on the lower truss support ring.

If, after assembling, the truss poles are loose within the truss

connectors, use the supplied 4mm hex key to tighten the button head cap screws that connect the poles to the truss connectors (see Figure 23). This should rarely need to be done.

The telescope is now assembled.

13

Accessory Installation

Now that the base is assembled and the optical tube assembled and mounted, all that remains is to attach the EZ Finder

II reflex sight and pop an eyepiece into the focuser.

EZ Finder II

Using the included dovetail mounting bracket, the EZ Finder II

will slip neatly into the dovetail base pre-installed on the upper

tube section adjacent to the focuser. Just slide the dovetail

mounting bracket into the telescope’s dovetail mounting base

and tighten the thumbscrew on the base to secure the mounting bracket. Make sure the sight tube of the EZ Finder II is

forward (closest to front opening of telescope).

Operating the EZ Finder II

Before installing the EZ Finder II on the telescope, you’ll need

to insert the included 3-volt lithium battery.

1. Insert a small, flat-blade screwdriver into the notch in the

battery casing and gently pry it off (Figure 26).

2. Slide the CR2032 3V lithium battery under the retaining

clip with the positive (+) side facing down (touching the

clip).

3. Then press the battery casing back on.

Should the battery die, replacement CR2032 batteries are

available at many stores where small batteries are sold.

The EZ Finder II works by projecting a tiny red dot (it is not

a laser beam) onto a lens mounted in the front of the unit.

When you look through the EZ Finder II, the red dot will

appear to float in space, helping you to pinpoint your target

object (Figure 25). The red dot is produced by a light-emitting

diode (LED) near the rear of the sight. Turn the power knob

(see Figure 26) clockwise until you hear the “click” indicating

that power has been turned on. Look through the back of the

reflex sight with both eyes open to see the red dot. Position

your eye at a comfortable distance from the back of the sight.

In daylight you may need to cover the front of the sight with

your hand to be able to see the dot, which is purposefully

quite dim. The intensity of the dot is adjusted by turning the

power knob. For best results when stargazing, use the dimmest possible setting that allows you to see the dot without

difficulty. Typically a dimmer setting is used under dark skies

and a brighter setting is needed under light-polluted skies or

in daylight.

Figure 25. The EZ Finder II superimposes a tiny red dot on the

sky, showing right where the telescope is aimed.

Power knob

Altitude

adjustment

knob

Figure 26. The EZ Finder II reflex sight.

Thumbscrews

Sight

tube

Azimuth

adjustment

knob

Battery

casing

Dovetail

mounting

bracket

and altitude (up/down) adjustment knobs (see Figure 26)

to position the red dot on the object in the eyepiece. When

the red dot is centered on the distant object, check to make

sure that the object is still centered in the telescope’s field of

view. If not, re-center it and adjust the EZ Finder II’s alignment

again. When the object is centered in the eyepiece and on

the EZ Finder’s red dot, the EZ Finder II is properly aligned

with the telescope. Once aligned, the EZ Finder II will usually

hold its alignment even after being removed and remounted.

Otherwise, only minimal realignment will be needed. At the

end of your observing session, be sure to turn the power knob

to the Off position.

Aligning the EZ Finder II

When the EZ Finder II is properly aligned with the telescope,

an object that is centered on the EZ Finder II’s red dot should

also appear in the center of the field of view of the telescope’s

eyepiece. Alignment of the EZ Finder II is easiest during daylight, before observing at night. Aim the telescope at a distant

object such as a telephone pole or roof chimney and center it

in the telescope’s eyepiece. The object should be at least 1/4

mile away. Now, with the EZ Finder II turned on, look though it.

The object should appear in the field of view. Without moving

the main telescope, use the EZ Finder II’s azimuth (left/right)

14

Using Eyepieces

The final step in the assembly process is to insert an eyepiece into the telescope’s focuser. First, take the cover cap

off the focuser drawtube. To use the 2" DeepView eyepiece,

loosen the two thumbscrews on the 2" accessory collar (on

the end of the focuser drawtube) and remove the 1.25" adapter. Then place the 2" eyepiece directly into the 2" accessory

collar and secure it with the two thumbscrews loosened previously (Figure 27). If you cannot achieve focus, you may need

to install the included 2" extension adapter on the focuser,

then insert the eyepiece into it. The other eyepiece and 1.25"

1.25" adapter

thumbscrew

2" collar

thumbscrews

Coarse

focus

knob

Figure 27. Detail of the dual-speed focuser.

Focuser cap

Drawtube tension setscrew

1.25" adapter

2" accessory collar

Fine

focus

knob

Coarse

focus knob

Focus lock

thumbscrew

adapter can be placed in the eyepiece rack until they are

needed.

To install the 1.25" Illuminated Plössl eyepiece instead of the

2" DeepView eyepiece, keep the 1.25" adapter in the focuser,

and make sure the two thumbscrews on the 2" collar are tightened. Now, loosen the thumbscrew on the 1.25" adapter, do

not loosen the two thumbscrews on the 2" collar. Insert the

1.25" eyepiece into the 1.25" eyepiece adapter, and secure it

by retightening the thumbscrew on the 1.25" eyepiece adapter (Figure 27). The other eyepiece can be placed in the eye-

piece rack until it is needed.

The basic assembly of your SkyQuest XXg Dobsonian is now

complete. It should appear as shown in Figure 1. Keep the

dust cap in place on the bottom tube section when the telescope is not in use, to minimize the accumulation of dust on

the primary mirror. It is also a good idea to store eyepieces in

an eyepiece case and to replace the cover cap on the focuser

when the telescope is idle.

Tips for Transporting Your XXg

The SkyQuest XXg Dobsonians are big scopes, but they were

designed with portability in mind. For all three telescopes, the

optical tube and the GoTo base break down without tools into

manageable components for transporting to and from your

favorite observing site in a standard-sized vehicle, or for more

convenient storage in your home or garage.

A fit individual should have no trouble setting up, dismantling,

or carrying the individual components of an XXg Dobsonian

short distances without assistance. Of course, having a helper will facilitate these activities, but if or when you find yourself

on your own for an evening observing session, you should

be just fine! The larger XX16g could be more of a challenge

for one person, especially if you are of slight build. Its heaviest component, the groundplate assembly, weighs 61 lbs.,

so keep that in mind. The good news is that the groundplate

assembly can be rolled on its edge like a big wheel! But lifting

it to get it into and out of a car requires some muscle if you’re

doing it by yourself. With a helper, however, it should be no

problem.

For the XX16g, an optional transport solution is available

that allows the telescope to be rolled while fully assembled.

Featuring 10" pneumatic tires, this transport solution is particularly useful for moving the telescope from, say, a garage

out onto the driveway or into the backyard observing spot. It

obviates the need to disassemble the telescope just to move

it a short distance! Visit OrionTelescopes.com or call Orion

customer service at 800-676-1343 for details.

The optical tube disassembles into a small front tube section

including the secondary mirror and focuser, rear tube section housing the primary mirror cell, and four truss-pole pairs.

We recommend dismantling the optical tube in reverse order

from the way it was assembled. That is, remove the upper

tube section first, then the truss tube assemblies, then the

counterweights, and finally, remove the lower tube section

from the base.

The base disassembles into four separate components: the

groundplate assembly (top and bottom groundplates with azimuth motor and encoders installed), left side panel (with altitude motor and encoders installed), right side panel, and front

panel. All the hardware has hand knobs for tool-free manipulation and is captive so that nothing will drop off and get dirty

or lost in the dark.

Before transporting the telescope, remove the EZ Finder II

(with bracket) and any eyepiece from the focuser. The eyepiece rack can also be removed from the base, if you wish.

This will prevent these accessories from getting damaged

during transport. These items can be placed in an optional

accessory case.

If possible, transport the bottom tube section containing the

primary mirror in an upright position, i.e., with the rear end ring

resting on the ground. Doing so will reduce stress on the mirror

support system. We recommend transporting the tube assembly in the optional padded case set for proper protection.

Each time you assemble the optical tube for an observing

session, you should check the optical collimation. It may not

need any adjustment, but it could require a minor tweak to

dial it in precisely. See the section on collimation for details on

how to collimate the optics.

3. The GoTo

Hand Controller

SkyQuest XXg telescopes feature the SynScan hand controller, which contains an extensive database of stars, deep-sky

objects, and solar system denizens – nearly 43,000 in all. The

features and functionality of the SynScan controller are covered in detail in a separate manual entitled SynScan GoTo

Hand Controller. Please refer to that manual before beginning

your explorations with the SkyQuest XXg.

15

Primary mirror

center mark

(XX12g

only)

b.

c.

a.

d.

Figure 28. Collimating the optics. (a) When the mirrors are properly aligned, the view down the focuser drawtube should look like this. (b)

With the collimation cap in place, if the optics are out of alignment, the view might look something like this. (c) Here, the secondary mirror is

centered under the focuser, but it needs to be adjusted (tilted) so that the entire primary mirror is visible. (d) The secondary mirror is correctly

aligned, but the primary mirror still needs adjustment. When the primary mirror is correctly aligned, the “dot” will be centered, as in (e).

e.

4. Collimating the

Optical System

To get the sharpest images, your telescope’s optical system must be in precise alignment. The process of aligning

the primary and secondary mirrors with each other and with

the mechanical axis of the telescope is called collimating.

Collimating is relatively easy to do and can be done in daylight or at night.

Because the primary mirror is shipped separately from the

optical tube, the telescope’s optics must be collimated before

it can be used. Most of the adjustments will be to the tilt of the

primary mirror, as the secondary mirror has been pre-aligned

at the factory. It is also good idea to check the collimation

(optical alignment) of your telescope before each observing

session and make any necessary adjustments.

To check collimation, remove the eyepiece and look down the

focuser drawtube. You should see the secondary mirror centered in the drawtube, as well as the reflection of the primary

mirror centered in the secondary mirror, and the reflection of

the secondary mirror (and your eye) centered in the reflection

of the primary mirror, as depicted in Figure 28a. If anything

is off-center, as in Figure 28b, proceed with the following collimation procedure.

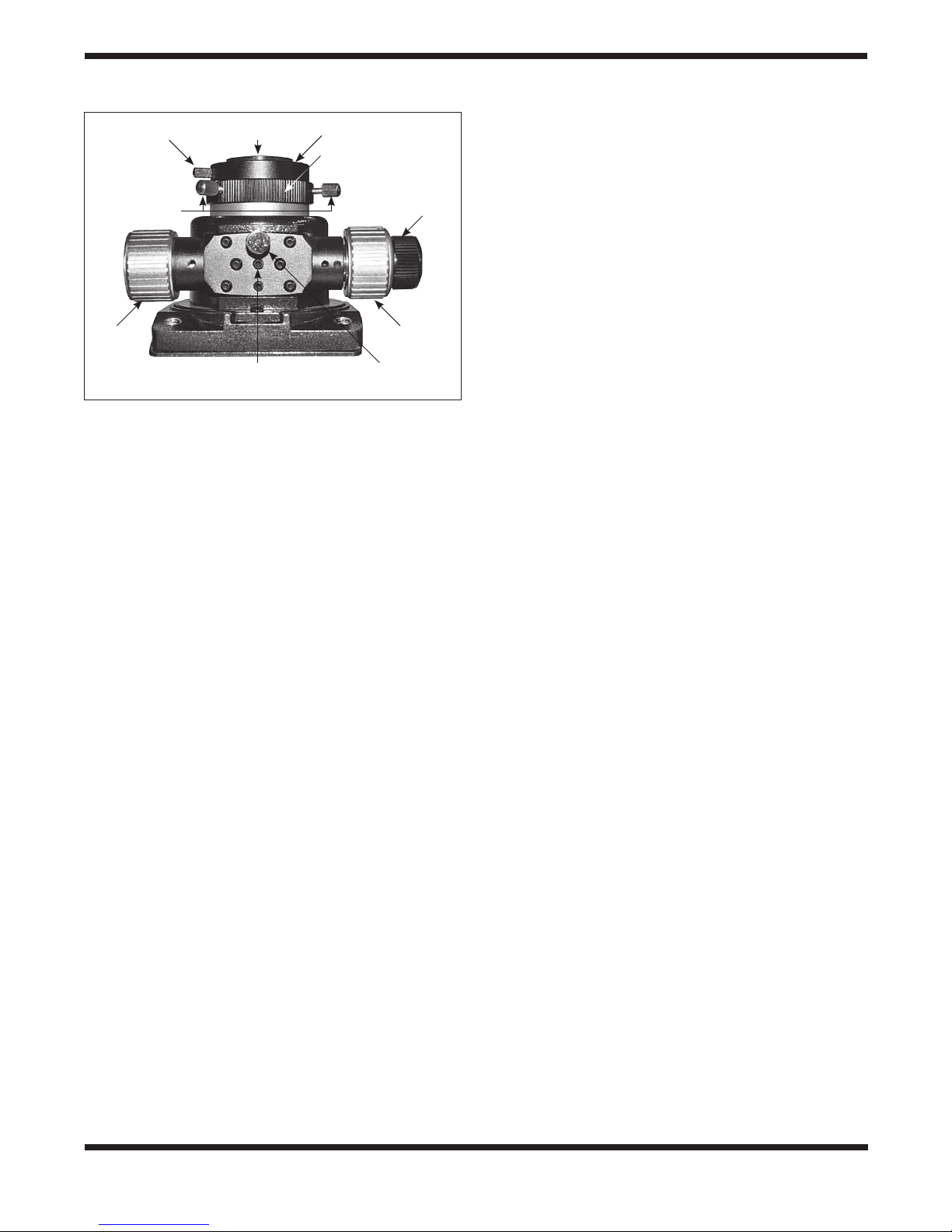

The Collimation Cap and Mirror Center Mark

Your XXg comes with a collimation cap. This is a simple cap

that fits on the focuser drawtube like a dust cap, but has a

hole in the center and a reflective inner surface. The cap

helps center your eye so that collimating is easier to perform.

Figures 28b-e assume you have the collimation cap in place.

As an additional aid in collimating, the primary mirror of

the XXg has a tiny adhesive ring marking its exact center

(Figure 3a). This center ring will not affect the images you

see when observing with the telescope in any way (since

it lies directly in the shadow of the secondary mirror), but it

will greatly facilitate collimating when using the supplied collimation cap or other, more sophisticated collimation devices,

such as the Orion LaserMate Deluxe II laser collimator.

Preparing the Telescope for Collimating

Once you get the hang of collimating, you will be able to do it

quickly even in the dark. For now, it is best to collimate in daylight, preferably in a brightly lit room and aimed at a white wall.

It is recommended that the telescope tube be oriented horizontally. This will prevent any parts from the secondary mirror

from falling down onto the primary mirror and causing damage if something comes loose when you are making adjustments. Place a sheet of white paper inside the optical tube

directly opposite the focuser. This will provide a bright “background” when viewing into the focuser. When properly set up

for collimation, your telescope should resemble Figure 29.

16

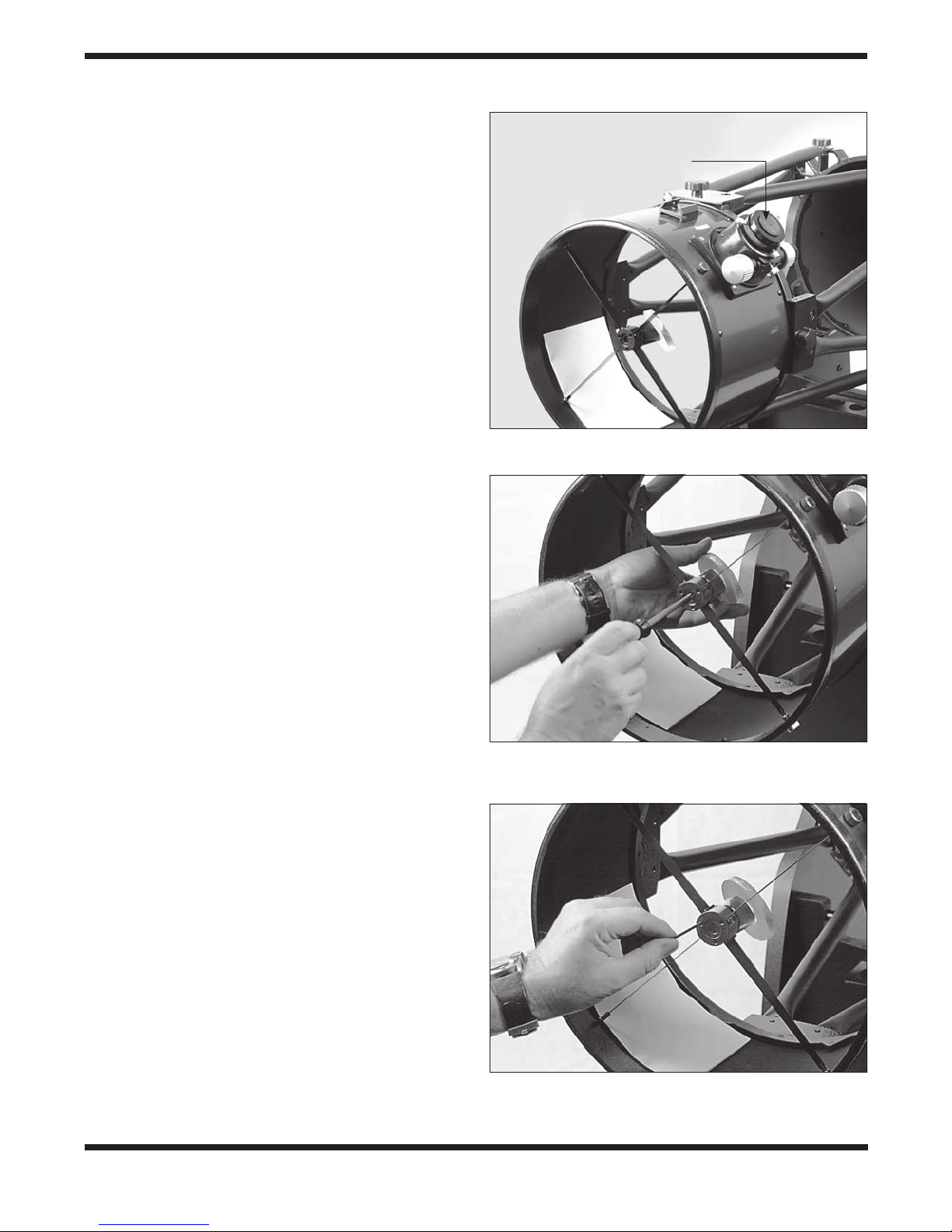

Aligning the Secondary Mirror

With the collimation cap in place, look through the hole in the

cap at the secondary (diagonal) mirror. Ignore the reflections

for the time being. The secondary mirror itself should be centered in the focuser drawtube. If it isn’t, as in Figure 28b, its

position must be adjusted. This positional adjustment of the

secondary mirror will rarely, if ever, need to be done.

To adjust the secondary mirror left-to-right in the focuser drawtube, use the included 2mm hex key to loosen the three small

alignment setscrews in the center hub of the 4-vaned spider

several turns. Now, grasp the mirror to prevent it from rotating

(be careful not to touch the surface of the mirror), while turning the center screw with a Phillips screwdriver (Figure 30).

Turning the screw clockwise will move the secondary mirror

toward the front opening of the optical tube, while turning

the screw counter-clockwise will move the secondary mirror

toward the primary mirror. When the secondary mirror is centered left-to-right in the focuser drawtube, rotate the secondary mirror holder until the reflection of the primary mirror is as

centered in the secondary mirror as possible. It may not be

perfectly centered, but that is OK for now. Tighten the three

small alignment setscrews equally to secure the secondary

mirror in that position.

Note: When making these adjustments, be careful not to

stress the spider vanes or they may bend.

Collimation cap

Figure 29. The SkyQuest optical tube properly set up for

collimation.

The secondary mirror should now be centered in the focuser

drawtube. Now we will shift our attention to the reflections

within the secondary mirror in order to properly adjust the tilt

of the secondary mirror. Adjusting the tilt of the secondary

mirror and the tilt of the primary mirror are the two collimation

adjustments that will be done most often.

If the entire primary mirror reflection is not visible in the secondary mirror, as in Figure 28c, you will need to adjust the tilt

of the secondary mirror. This is done by alternately loosening

one of the three secondary mirror alignment setscrews while

tightening the other two (Figure 31). Do not make excessive

turns of these setscrews or force them past their normal travel. A simple 1/2 turn of the screw can dramatically change the

tilt of the secondary mirror. The goal is to center the primary

mirror reflection in the secondary mirror, as in Figure 28d.

Don’t worry that the reflection of the secondary mirror (the

smallest circle, with the collimation cap “dot” in the center) is

off-center. You will fix that in the next step.

Aligning the Primary Mirror

The final adjustment is made to the tilt of the primary mirror.

It will need adjustment if, as in Figure 28d, the secondary

mirror is centered under the focuser and the reflection of the

primary mirror is centered in the secondary mirror, but the

small reflection of the secondary mirror (with the “dot” of the

collimation cap) is off-center.

Figure 30. To center the secondary mirror under the focuser, hold

the mirror holder in place with one hand while adjusting the center

bolt with a Phillips screwdriver. Do not touch the mirror’s surface!

Figure 31. Adjust the tilt of the secondary mirror by adjusting one

or more of the three alignment setscrews with a 2mm hex key.

17

The tilt of the primary mirror is adjusted with the three large

Out of collimation Collimated

spring-loaded collimation knobs on the rear end of the optical tube (Figure 32). The three smaller thumbscrews lock the

mirror’s position in place. These thumbscrews must be loosened before any collimation adjustments can be made to the

primary mirror.

To start, turn the smaller thumbscrews counterclockwise a

few turns each. Use a screwdriver in the slots, if necessary.

Now, try tightening or loosening one of the collimation knobs

Look into the focuser and see if the secondary mirror reflection has moved closer to the center of the primary mirror. You

can easily determine this with the collimation cap and mirror

center mark by simply watching to see if the “dot” of the collimation cap is moving closer or further away from the “ring”

on the center of the primary mirror. If turning the one knob

does not seem to bring the dot closer to the ring, try using one

of the other collimation knobs. It will take some trial-and-error

using all three knobs to properly align the primary mirror. Over

time you will get the feel for which collimation screws to turn to

move the image in a given direction.

When you have the dot centered as much as is possible in the

ring, your primary mirror is collimated. The view through the

collimation cap should resemble Figure 28e. Re-tighten the

locking thumbscrews in the bottom of the mirror cell.

A simple star test will tell you whether the optics are accurately collimated.

Collimation

knob

Locking

thumbscrew

Figure 32. The tilt of the primary mirror is adjusted by turning one

or more of the three larger thumbscrews. (XX12g shown)

Star-Testing the Telescope

When it is dark, point the telescope at a bright star high in the

sky and center it in the eyepiece’s field of view. Slowly de focus

the image with the focusing knob. If the telescope is correctly collimated, the expanding disk should be a perfect circle

(Figure 33). If the image is unsymmetrical, the telescope is

out of collimation. The dark shadow cast by the secondary mirror should appear in the very center of the out-of-focus circle,

like the hole in a doughnut. If the “hole” appears off center, the

telescope is out of collimation.

If you try the star test and the bright star you have selected is

not accurately centered in the eyepiece, then the optics will

always appear out of collimation, even though they may be

perfectly aligned. It is critical to keep the star centered, so over

time you will need to make slight corrections to the telescope’s

position in order to account for the sky’s apparent motion.

Figure 33. A star test will determine if a telescope’s optics are

properly collimated. An unfocused view of a bright star through

the eyepiece should appear as illustrated on the right if the optics

are perfectly collimated. If the circle is unsymmetrical, as in the

illustration on the left, the scope needs collimation.

5. Using Your Telescope

Using the Clutch Tensioning Knobs

The XXg Dobs all now feature large clutch tensioning knobs

on both the altitude and azimuth axes. Located on the altitude and azimuth motor/encoder housings (Figure 34), these

knobs allow the user to adjust the amount of tension (friction) in both the altitude and azimuth motion for moving the

telescope by hand. Rotating the knob clockwise increases

the tension, while turning it counterclockwise decreases the

tension. The closed-loop encoder system of the XXg Dobs

allows the scope to be moved manually without losing the initial GoTo star alignment. The clutch knobs allow you to set the

amount of motion tension on each axis independently to the

level you desire for smooth manual slewing of the telescope.

18

Alt

a. b.

Figure 34. a) The redesigned altitude (Alt) and (AZ) azimuth motor/encoder housings of the XXg Dobs feature large manual clutch knobs for

adjustable motion tension. b) Rotate the clutch knob to adjust the friction of motion for slewing the telescope by hand.

Clutch tensioning knobs

AZ

If a clutch tension it is set too loose, the scope may not slew

on that axis, or may slew intermittently. In that case you

should tighten the clutch knob(s) a little until a normal slewing

motion is achieved. If you add significant weight to the front of

the telescope, such as a heavy eyepiece and finder scope or

a full-aperture glass solar filter, the scope could become “front

heavy.” In that case you may have to tighten the altitude clutch

knob some so that the tube doesn’t slip when moving in the

up/down direction.

Focusing the Telescope

The SkyQuest XXg Dobsonians come standard with a 2"

dual-speed (11:1) Crayford focuser (Figure 27). The focuser

has coarse focus knobs and a fine focus (11:1) knob for very

precise focusing. The focuser allows use of 2" or 1.25" eyepieces and the Crayford design prevents image shift while

focusing.

To focus, with an eyepiece in the focuser and secured with the

thumbscrews, move the telescope so the front end is pointing

in the general direction of an object at least 1/4-mile away.

Now, with your fingers, slowly rotate one of the coarse focus

knobs until the object comes into sharp focus. Go a little bit

beyond sharp focus until the image just starts to blur again,

then reverse the rotation of the knob, just to make sure you’re

close to the focus point.

Now, use the fine focus knob to achieve precise focus. Eleven

turns of the fine focus knob are equivalent to one turn of the

coarse focus knobs, so much finer adjustment is possible

than with just the coarse focus knobs alone. You’ll find this is

a great convenience, especially when attempting to focus at

high magnifications. If you have trouble focusing, rotate the

coarse focusing knob so the drawtube is inward as far as it

will go. Now look through the eyepiece while slowly rotating

the focusing knob in the opposite direction. You should soon

see the point at which focus is reached. The thumbscrew on

the bottom of the focuser body (Figure 27) will lock the focuser drawtube in place, if desired. This is usually not necessary, however. Before focusing, remember to first loosen this

thumbscrew.

If you find the drawtube tension when focusing is either too

tight (i.e., focus knob is difficult to turn) or too loose (i.e.,

drawtube moves by itself under the weight of the eyepiece),

you can adjust it by tightening or loosening the drawtube tensioning setscrew on the focuser, which is located just below

the focus lock thumbscrew (see Figure 27). Adjust this setscrew with the included 2.5mm hex key. Do not loosen the

setscrew too much as there must be some tension to keep the

drawtube secure within the focuser. The other setscrew below

the drawtube tensioning setscrew does not affect drawtube

tension and should not be adjusted.

19

If an image does not come into focus with a particular eyepiece

because you run out of outward focus travel, you may need to

use the included 2" extension adapter. This adapter threads

onto the focuser drawtube. First, you’ll need to remove the 2"

accessory collar from the drawtube by unthreading it (Figure

35a). Then thread the 2" extension adapter into the drawtube

(Figure 35b). Insert a 2" eyepiece into the extension adapter

and secure it with the two thumbscrews. Or, to use 1.25" eyepiece with the extension adapter, insert and secure the 1.25"

adapter in the extension adapter, then insert the eyepiece into

the 1.25" adapter.

Viewing with Eyeglasses

If you wear eyeglasses, you may be able to keep them on

while you observe, if your eyepieces have enough eye relief

to allow you to see the whole field of view. You can try this by

looking through the eyepiece first with your glasses on and

then with them off, and see if the glasses restrict the view

to only a portion of the full field. If they do, you can easily

observe with your glasses off by just refocusing the telescope

as needed. If you suffer from severe astigmatism, however,

you may find images noticeably sharper with your glasses on.

Magnification

Magnification, or power, is determined by the focal length of

the telescope and the focal length of the eyepiece. Therefore,

by using eyepieces of different focal lengths, the resultant

magnification can be varied.

2" accessory

collar

a.

2" extension

adapter

b.

Figure 35. (a) Removing the 2" accessory collar, (b) Thread the

2" extension adapter into the focuser drawtube.

20

Magnification is calculated as follows:

Telescope Focal Length (mm)

Eyepiece Focal Length (mm)

= Magnification

The XX12g, for example, has a focal length of 1500mm. So,

the magnification with the supplied 28mm 2" eyepiece is:

1500mm

28mm

= 54x

The magnification provided by the 12.5mm illuminated eyepiece is:

1500mm

12.5mm

= 120x

The maximum attainable magnification for a telescope is

directly related to how much light its optics can collect. A telescope with more light-collecting area, or aperture, can yield

higher magnifications than a smaller-aperture telescope. The

maximum practical magnification for any telescope, regardless of optical design, is about 50x per inch of aperture. This

translates to about 600x for the XX12g. Of course, such high

magnification will only yield acceptable images if atmospheric

conditions are extremely favorable.

More typically, useful magnifications will be limited to 200x

or less, regardless of aperture. This is because the Earth’s

atmosphere distorts light as it passes through. On nights of

good “seeing,” the atmosphere will be still and will yield the

least amount of distortion. On nights of poor seeing, the atmo-

sphere will be turbulent, which means different densities of

air are rapidly mixing. This causes significant distortion of the

incoming light, which prevents sharp views at high magnifications.

Keep in mind that as magnification is increased, the brightness of the object being viewed will decrease; this is an inherent principle of the physics of optics and cannot be avoided.

If magnification is doubled, an image appears four times dimmer. If magnification is tripled, image brightness is reduced by

a factor of nine!

The SkyQuest XXg Dobs are designed to accept eyepieces

with a barrel diameter of either 1.25" or 2". At low magnifications, 2" eyepieces can provide a wider field of view than standard 1.25" eyepieces. A wider field can be desirable for viewing extended deep-sky objects that are too large to fit within a

narrower field of view.

Using a Light Shroud

We highly recommend using a light shroud over the open

truss tube portion of the optical tube assembly when observing. Usually made of breathable, stretchy, opaque black fabric, a shroud blocks stray light from entering the optical path

at oblique angles, thus improving image contrast. Use of the

shroud will also lessen the accumulation of dust and dirt on

the mirrors during use, and will help prevent dew from forming

on them. A custom-designed light shroud is available for each

of the SkyQquest XXg Dobsonians from Orion.

21

6. Specifications

SkyQuest XX12g GoTo

Primary mirror 305mm diameter, parabolic, center-marked

Focal length 1500mm

Focal ratio f/4.9

Focuser Dual-speed Crayford (11:1), accepts 2" and

1.25" eyepieces with included adapter

Optical tube material Rolled steel

Azimuth bearing Thrust needle bearing

Altitude bearing Ball bearing

Eyepieces 28mm DeepView, 2" barrel; 12.5mm

Illuminated Plössl, 1.25" barrel

Eyepiece

magnifications 54x and 120x

Finder scope EZ Finder II Reflex Sight

Eyepiece rack Holds three 1.25" eyepieces and one 2"

eyepiece

Mirror coatings Enhanced aluminum (94% reflectivity) with

SiO2 overcoat

Minor axis of

secondary mirror 70mm

Optical tube weight

(assembled) 47 lbs.

Base weight 89 lbs.

Tube length 58.3"

Operation Northern or Southern hemisphere

Power requirement 12V DC 2.1 Amp (tip positive)

Motor type DC servo with optical encoders for altitude

and azimuth axes

Slew speeds Rate 0 = 1.0X

Rate 1 = 2X

Rate 2 = 16X

Rate 3 = 32X

Rate 4 = 50X

Rate 5 = 200X

Rate 6 = 400X

Rate 7 = 600X

Rate 8 = 800X

Rate 9 = 1000X

Tracking rates Sidereal (default), Lunar, Solar.

Alignment method Brightest Star, Two Star

Database Over 42,900 objects including:

Complete Messier & Caldwell catalogs, 7840

NGC objects, 5386 IC objects, 29523 SAO

stars, 8 planets, Moon, 212 named stars,

55 well-known double stars, 20 well-known

variable stars, 25 user-defined objects.

SkyQuest XX14g GoTo

Primary mirror 356mm diameter, parabolic, center-marked

Focal length 1650mm

Focal ratio f/4.6

Focuser Dual-speed Crayford (11:1), accepts 2" and

1.25" eyepieces with included adapter

Optical tube material Rolled steel

Azimuth bearing Thrust needle bearing

Altitude bearing Ball bearing

Eyepieces 28mm DeepView, 2" barrel; 12.5mm

Illuminated Plössl, 1.25" barrel

Eyepiece

magnifications 59x and 132x

Finder scope EZ Finder II Reflex Sight

Eyepiece rack Holds three 1.25" eyepieces and one 2"

eyepiece

Mirror coatings Enhanced aluminum (94% reflectivity) with

SiO2 overcoat

Minor axis of

secondary mirror 80mm

Optical tube weight

(assembled) 64 lbs.

Base weight 94 lbs.

Tube length 61"

Operation Northern or Southern hemisphere

Power requirement 12V DC 2.1 Amp (tip positive)

Motor type DC servo with optical encoders for altitude

and azimuth axes

Slew speeds Rate 0 = 1.0X

Rate 1 = 2X

Rate 2 = 16X

Rate 3 = 32X

Rate 4 = 50X

Rate 5 = 200X

Rate 6 = 400X

Rate 7 = 600X

Rate 8 = 800X

Rate 9 = 1000X

Tracking rates Sidereal (default), Lunar, Solar.

Alignment method Brightest Star, Two-Star

Database Over 42,900 objects including:

Complete Messier & Caldwell catalogs, 7840

NGC objects, 5386 IC objects, 29523 SAO

stars, 8 planets, Moon, 212 named stars,

55 well-known double stars, 20 well-known

variable stars, 25 user-defined objects.

22

SkyQuest XX16g GoTo

Primary mirror 406mm diameter, parabolic, center-marked

Focal length 1800mm

Focal ratio f/4.4

Focuser Dual-speed Crayford (11:1), accepts 2" and

1.25" eyepieces with included adapter

Optical tube material Rolled steel

Azimuth bearing Thrust needle bearing

Altitude bearing Ball bearing

Eyepieces 28mm DeepView, 2" barrel; 12.5mm

Illuminated Plössl, 1.25" barrel

Eyepiece

magnifications 64x and 144x

Finder scope EZ Finder II Reflex Sight

Eyepiece rack Holds three 1.25" eyepieces and one 2"

eyepiece

Mirror coatings Enhanced aluminum (94% reflectivity) with

SiO2 overcoat

Minor axis of

secondary mirror 91mm

Optical tube weight

(assembled) 69 lbs.

Base weight 105 lbs.

Tube length 68"

Operation Northern or Southern hemisphere

Power requirement 12V DC 2.1 Amp (tip positive)

Motor type DC servo with optical encoders for altitude

and azimuth axes

Slew speeds Rate 0 = 1.0X

Rate 1 = 2X

Rate 2 = 16X

Rate 3 = 32X

Rate 4 = 50X

Rate 5 = 200X

Rate 6 = 400X

Rate 7 = 600X

Rate 8 = 800X

Rate 9 = 1000X

Tracking rates Sidereal (default), Lunar, Solar.

Alignment method Brightest Star, Two-Star

Database Over 42,900 objects including:

Complete Messier & Caldwell catalogs, 7840

NGC objects, 5386 IC objects, 29523 SAO

stars, 8 planets, Moon, 212 named stars,

55 well-known double stars, 20 well-known

variable stars, 25 user-defined objects.

23

One-Year Limited Warranty

This Orion product is warranted against defects in materials or workmanship for a period of one year from

the date of purchase. This warranty is for the benefit of the original retail purchaser only. During this warranty period Orion Telescopes & Binoculars will repair or replace, at Orion’s option, any warranted instrument that proves to be defective, provided it is returned postage paid. Proof of purchase (such as a copy

of the original receipt) is required. This warranty is only valid in the country of purchase.

This warranty does not apply if, in Orion’s judgment, the instrument has been abused, mishandled, or

modified, nor does it apply to normal wear and tear. This warranty gives you specific legal rights. It is not

intended to remove or restrict your other legal rights under applicable local consumer law; your state or

national statutory consumer rights governing the sale of consumer goods remain fully applicable.

For further warranty information, please visit www.OrionTelescopes.com/warranty.

Orion Telescopes & Binoculars

Corporate Offices: 89 Hangar Way, Watsonville CA 95076 - USA

Customer Support: www.OrionTelescopes.com/contactus

© Copyright 2013 Orion Telescopes & Binoculars

Loading...

Loading...