Orion Car Audio HCCA62, HCCA52 User Manual

Component Speaker

HCCA52

HCCA62

OWNER'S MANUAL

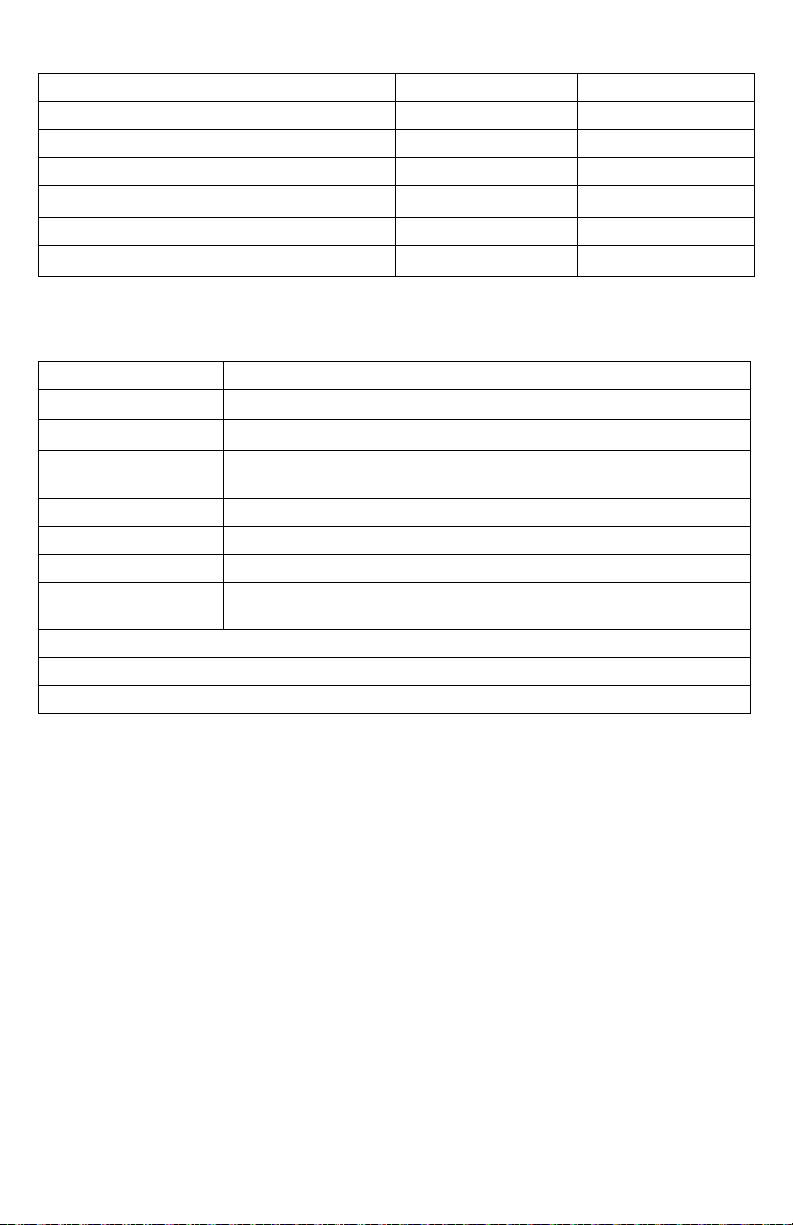

MODEL

TABLE OF CONTENTS

English . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Français . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Español . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Deutsch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Italiano . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Português . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Practice Safe Sound™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

What’s in the Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Tools of the Trade. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Finding Speaker Mounting Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Door Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Rear Deck Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installing the Mid/Woofers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installing the Tweeter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installing the Crossover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . back cover

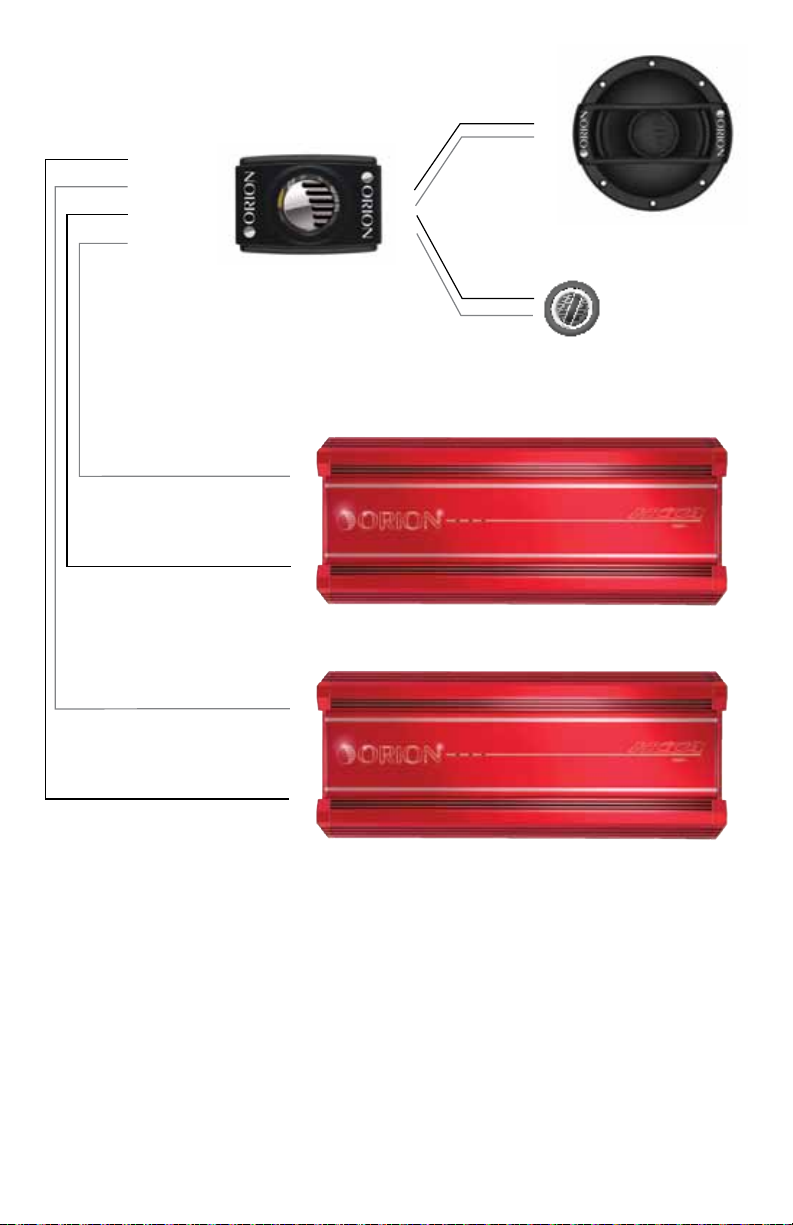

INTRODUCTION

Thank you for your purchase of the Orion HCCA Component Loudspeaker system. These

speakers represent a combination of incredible performance and value. The HCCA die-cast

components feature Kevlar treated paper cones and silk dome tweeters. Capable of maintaining

their balance and clarity at exceptionally high output levels, they are the perfect complement

to the HCCA subwoofers. The crossovers feature tweeter level adjustment, and are biampable

for extreme system designs. These high-performance components are built with 4 ohm voice

coils, to get the most out of your amplifier. The components are available in a standard 5 1/4"

and 6-1/2” sizes to fit most applications.

We at Orion strive to give you all the latest up to date information about this product. What

we can’t give you in this manual is personal installation or technical experience. If you have

questions concerning the use or application of this product, please refer to the nearest Authorized

Orion Dealer for assistance or call the Orion technical support hot-line at 1-800-876-0800. As we

are always finding new ways to improve our product, the features and specifications are subject

to change without notice.

© 2010 directed electronics—all rights reserved 1

PRACTICE SAFE SOUND™

Continuous exposure to sound pressure levels over 100dB may cause permanent hearing loss.

High powered automotive sound systems can generate sound pressure levels in excess of 130dB.

When playing your system at high levels, please use hearing protection and prevent long term

exposure.

Model Number: _____________________________

Date of Purchase: _____________________________

WHAT’S IN THE BOX

Included in this box are all the necessary mounting hardware and cables for your basic

installation. Listed below is a detailed list of the components included in this system package.

Quantity Description

1 Owner's Manual

2 HCCA Tweeter Elements

2 Surface mount hardware

2 Flush mount hardware

2 HCCA mid/woofer

2 Passive crossovers

4 Cables (speakers to crossover)

4 Cables (crossover to amplifier)

1 Mounting template

2 Grilles

Mounting screws

TOOLS OF THE TRADE

Listed are the majority of the tools required to perform the installation. Having the proper tools

will make the installation much easier. It is very difficult when you get half way through the

installation and discover that you require a specific tool to get yourself through a particular part

of the installation. Some of these tools are necessities. Some make the job much easier.

o Marking Pen o Electric Drill

o 1/4" Drill Bit o Phillips Screwdriver

o 1/8" Drill Bit o Volt/Ohm Meter (Optional)

o 3/8" Drill Bit o Needle Nose Pliers

o Hole Saw Arbor o Assorted Tin Snips

o Wire Crimpers o Wire Strippers

o 5-5/8" Hole Saw (6-1/2" woofer install.)

o 4-3/4" Hole Saw (5-1/4" mid/woofer install.)

o 2" or 2-1/8" Hole Saw (for flush mount tweeter installation.)

INSTALLATION

The performance of the HCCA Component Loudspeaker is directly proportional to the quality of

installation. Care taken during the installation process will be rewarded with years of satisfying

performance. If you are unsure about your installation capabilities, please refer to your local

Authorized Orion Dealer for technical assistance. Orion dealers are trained professionals

dedicated to extracting the maximum performance out of your Orion system. If you decide to

install this speaker system yourself, please read the entire installation section before starting

your installation.

2 © 2010 directed electronics—all rights reserved

FINDING SPEAKER MOUNTING LOCATIONS

Choosing the correct speaker locations will have the greatest effect on the sound quality of the

system. Different considerations are needed when choosing the locations that best suit your

needs. The locations must be large enough for the speakers to fit. Care is needed to ensure that

the location you have chosen will not affect any of the mechanical or electrical operations of

the vehicle.

Determining the best location for the speakers will depend on your cosmetic needs and your

vehicle's interior. If minimal intrusion in your vehicle is desired, factory speaker locations may

be the ticket for you. Placing the speaker in the factory location can often give very desirable

results.

DOOR MOUNTING

When checking for possible speaker locations in the doors, check the operation of the window

and all assemblies. There is also a stabilizer stop bar in between the door and the door jamb.

This bar prevents the door from opening too far. Many shade tree installers overlook this and

check for clearance only when the door is fully open.

REAR DECK MOUNTING

In rear deck installations, check the operation of the trunk suspension springs or tension bars.

These tension bars move in the opening and closing of the trunk. You cannot be too cautious

during this part of the installation, In addition, do not locate the speakers too close to the back

of the rear deck. Installing the far screws will only be possible with the removal of the rear

window.

INSTALLING THE MID/WOOFERS

Step 1: Determine where the speakers will be mounted. Make sure there is a flat area large

Step 2: Check to make sure the space you have chosen for the speakers will not interfere with

Step 3: Using the supplied template guide, mark the mounting hole and mounting screw hole

Step 4: Cut the holes for the speaker. When using correctly sized factory locations, this step

• 5-5/8” Hole Saw (6-1/2” mid/woofer installation)

• 4-3/4" Hole Saw (5-1/4" mid/woofer install.)

WARNING: Check for clearance of window mechanisms and electrical wires BEFORE you drill.

Step 5: Run the speaker wire to the speakers. Make sure to keep wires away from sharp metal

Step 6: Pre-drill mounting screw holes using a 1/8" drill bit.

WARNING: Check for clearance of window mechanisms and electrical wires BEFORE you drill.

© 2010 directed electronics—all rights reserved 3

enough for the speakers to fit properly. An uneven mounting surface can damage the

driver.

the operation of the vehicle.

locations with a pen for each speaker.

can be passed. A hole can be cut either with a pair of metal tin snips, an air or jig saw,

or with a hole saw corresponding to the size of the midrange listed below.

or other edges. When passing through metal, use a protective grommet.

Step 7: Pull the wire through the speaker opening and connect to the speaker. Be sure to

observe proper mid/woofer polarity during this process.

Step 8: Mount the speaker- Place the speaker and the grille in the

installation hole. Align the mounting screw holes and drive in the four

mounting screws.

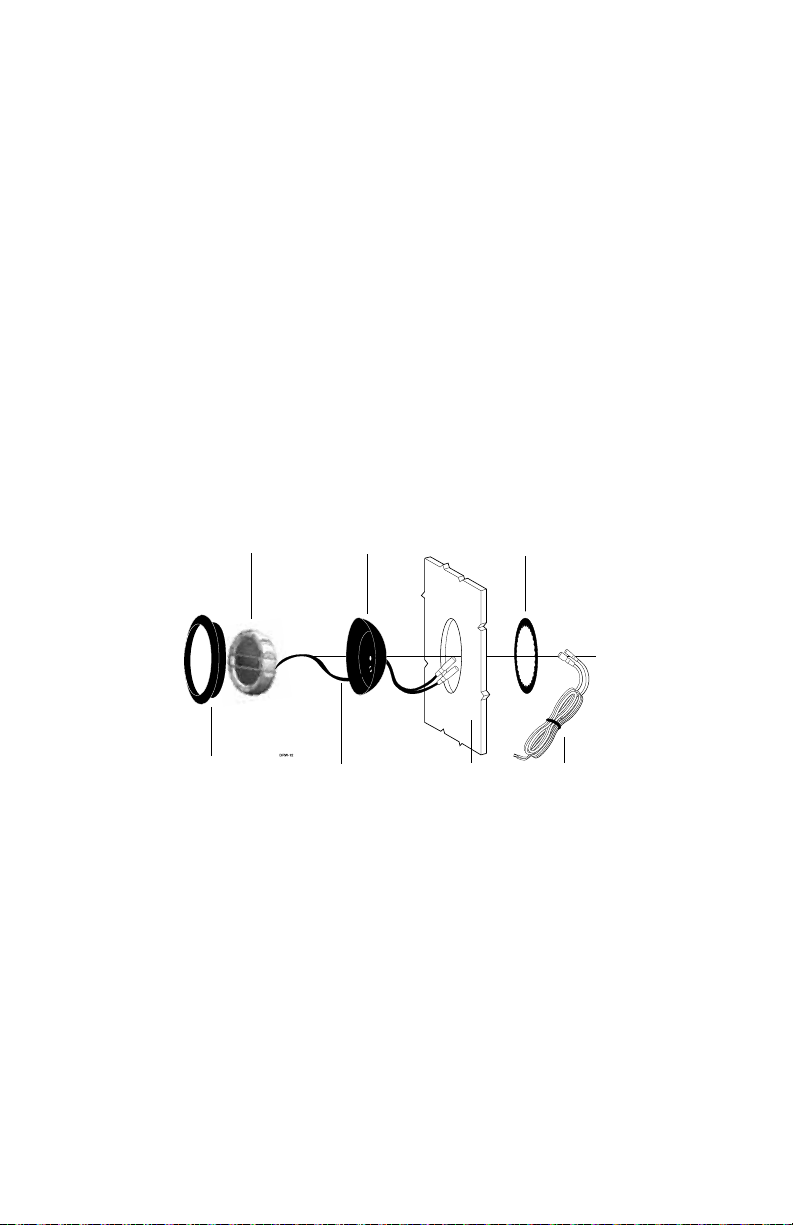

INSTALLING THE TWEETER

SURFACE MOUNTING

Step 1: Determine the tweeter mounting location, then route the wires from the crossover to

the tweeter location.

Step 2: Place the provided template or tweeter cup against the panel and mark the two holes

at the rear of the housing.

Step 3: Drill the smaller holes using a 1/8" drill bit. These are the mounting screw holes.

WARNING: Check for clearance of window mechanisms and electrical wires BEFORE you drill.

Step 4: Drill the larger off-center hole using a 3/8" drill bit, insert a grommet and route the

speaker wire from the crossover through the grommet.

Step 5: After removing the surface mount tweeter assembly trim ring, route the tweeter wires

through the larger hole in the housing and connect to the speaker wires from the

crossover. (See Figure 4.)

Step 6: Insert the excess speaker wire into the hole and position the housing so the housing

will not pinch the wires after final mounting.

Step 7: Attach the housing using the supplied screws of the correct length for a solid mount.

Step 8: Insert the tweeter into the housing and attach the surface mount trim ring.

SURFACE

TRIM RING

MOUNTING SCREWS SURFACE MOUNT HOUSING

MOUNT

Figure 2

Figura 2

Abbildung 2

4 © 2010 directed electronics—all rights reserved

TWEETER

TWEETER

WIRE PANEL WIRING HARNESS

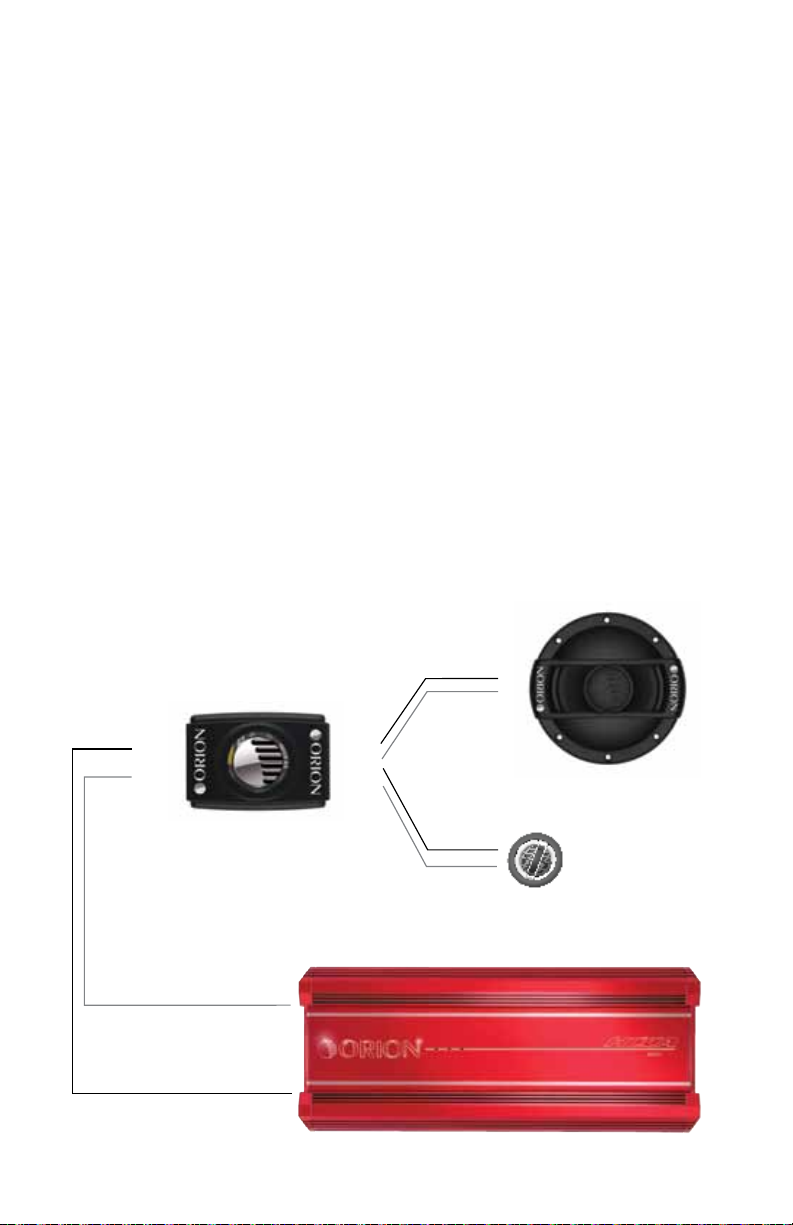

FULL FLUSH MOUNTING

Step 1:. Determine where the tweeter will be mounted. Make sure there is a flat area large

enough for the tweeter and no obstructions behind the area.

Step 2: Using the back half of the tweeter housing, mark with a pen the hole needed for the

tweeter.

Step 3: Be sure the hole is large enough for the tweeter housing, but not so large that the

flange will not cover the hole..

Step 4: Cut the hole for the tweeter. When using factory locations, this step can be skipped.

A hole can be cut either with a pair of metal tin snips or a 2" hole saw for hard

materials.

WARNING: Check for clearance of window mechanisms and electrical wires BEFORE you drill.

Step 5: Install tweeter in flush mount housing.

Step 6: Connect the speaker wires observing the correct polarity.

Step 7: Install tweeter and housing in the hole cut for mounting, so that the trim ring is flat

with the front of the surface.

Step 8: Use the supplied pressure ring to secure the housing to the surface.

TWEETER

TWEETER

CUP

PRESSURE

RING

Figure 3

Figura 3

Abbildung 3

FLUSH

MOUNT

TRIM RING

TWEETER WIRE PANEL

WIRING HARNESS

INSTALLING THE CROSSOVER

Step 1: Find a location for the crossover away from any factory or after market electrical wires.

Step 2: Remove top cover of crossover housing. Don’t lose it.

Step 3: Mark with a marking pen the two mounting holes.

Step 4: Remove crossover and pre-drill mounting holes using a 1/8” drill bit.

WARNING: Check for clearance of window mechanisms and electrical wires BEFORE you drill.

Step 5: Mount the crossover using the supplied #8 screws.

© 2010 directed electronics—all rights reserved 5

It is recommended to mount the passive crossover close to the amplifier. In the event you

decide to upgrade and bi-amplify the system, mounting the passive crossover close to the

amplifier would simplify the installation upgrade.

Step 6: Connect the wires. Make sure the speaker wires for the mid/woofer go to the woofer output

and the tweeter to the tweeter output. Be sure to observe the correct polarity. Changing the

polarity of the tweeter may be necessary for optimum sound quality.

Step 7: Re-install the crossover cover.

NOTE: The crossover has a parallel and a bi-wire/bi-amp input. To access these settings remove

the top cover of the crossover. This is accomplished with a small flat head screw driver. There

is a small notch just to the left of the output plug on the crossover. Insert the screwdriver and

gently pry. Be very cautious not to insert the screwdriver too far or you could cause physical

damage to the board and void your warranty. The parallel/bi-wire switch is right next to the

input plug. When selecting parallel, it does just that, wires the input in parallel (meaning the

positive terminals are common and the negative terminals are common). You would use this

selection when using a single channel to power the tweeter and the mid/woofer. It does not

matter which positive and which negative you use since they are wired in parallel, although

the tweeter positive and woofer negative are on opposite ends of the plug to make the wiring

easier. Parallel wiring is also probably the most popular wiring method.

The bi-wire/bi-amp selection is for using two separate channels for powering the tweeter and

the mid/woofer. When using this selection one channel would use the positive and negative

for the tweeter and the other channel would use the positive and negative for the mid/

woofer. There is also a tweeter level switch for adjusting the tweeter. Moving this adjustment

will change the output gain of the tweeter. Where the adjustment should be depends on the

location of the tweeter and your preference. Adjustments can be made from +3dB to -6dB in 3

dB steps. Tweeter phase can be changed by reversing the polarity of the tweeter output wire

connections on the crossover. If the tweeter is within 6" of the woofer center the tweeter should

be in phase with the woofer. If the tweeter is further than 6" from the center of the woofer,

both in phase and out of phase should be tried to see which is best

Parallel Wiring

Figure 4

Figura 4

Abbildung 4

-

input

+

+

_

6 © 2010 directed electronics—all rights reserved

To woofer

output

To tweeter

_

+

_

+

Bi-Amp Wiring

Figure 5

Figura 5

Abbildung 5

w -

w +

T -

T +

outputinput

To woofer

_

+

_

To tweeter

+

_

+

_

Note: The tweeter positive is the wire marked with the stripe.

Note: Le câble positif du haut-parleur d'aigus est rayé.

Nota. El positivo del tweeter es el cable que tiene la franja.

Hinweis: Der positive Hochtönerdraht ist mit dem Streifen markiert.

Nota: il filo positivo del tweeter è contrassegnato da una striscia.

Nota: O cabo positivo do tweeter está marcado com a listra.

+

© 2010 directed electronics—all rights reserved 7

SPECIFICATIONS

Model HCCA52 HCCA62

Nominal Impedance 4 ohms 4 ohms

Power Continuous/Maximum 50/100 60/120

Frequency Response 75Hz - 20kHz 55Hz - 20kHz

Sensitivity 85 dB 86 dB

Mounting Depth 1.9" (49 mm) 2.125" (54mm)

Mounting Diameter 4.6" (116.5 mm) 5.625" (143mm)

FEATURES

Cone paper & Kevlar blend – moisture and UV resistant

Surround polyester foam

Magnet Neodymium

Voice Coil CCAW wire – copper clad aluminum wire for best power handling

Tweeter dome–silk - Ferrofluid

Spider single flat interlaced Conex

Tinsel leads woven to spider

Custom crossover with 12dB high pass, 6dB low pass, tweeter level adjustments, multi

Custom grills

Custom tweeter mounting kits including swivel

Custom Cast Aluminum Basket: Shallow mounting depth

and light weight moving parts

stage tweeter protection, and mid/mid-bass zobel circuit.

NOTE: All Specifications are subject to change without notice.

8 © 2010 directed electronics—all rights reserved

Loading...

Loading...