Orion Car Audio CO124S, CO104S, CO154S User Manual

OWNER'S MANUAL

Subwoofer

MODEL

CO104S

CO124S

CO154S

TABLE OF CONTENTS

English . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Français . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Español. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Deutsche . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Italiano. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Português . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Practice Safe Sound™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Whats in the box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Tools of the Trade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Finding Speaker Mounting Locations . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . 2

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Wiring Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Enclosure Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Back cover

INTRODUCTION

Thank you for your purchase of the Orion Cobalt Subwoofers. These woofers

represent a combination of incredible performance and value. We at Orion strive to

give you the latest up to date information about this product. What we can’t give you

with the manual is personal installation or technical experience. If you have questions

concerning the use or application of this product please refer to the nearest ORION

dealer for assistance, visit www.orioncaraudio.com, or call the technical support

hotline at 1-800-876-0800. As we are always finding new ways to improve our product,

the features and specifications are subject to change without notice.

PRACTICE SAFE SOUND™

Continuous exposure to sound pressure levels over 100dB may cause permanent

hearing loss. High powered automotive sound systems can generate sound pressure

levels in excess of 130dB. When playing your system at high levels, please use hearing

protection and prevent long term exposure.

Model Number: _______________

Serial Number: _______________

Date of Purchase: _______________

© 2007 directed electronics—all rights reserved 1

WHAT’S IN THE BOX

Included in this box are all the necessary mounting hardware and cables for your basic

installation. Listed below is a detailed list of the components included in this system

package.

Quantity Description

1 Installation and Operation Manual

1 OrionTM Cobalt woofer

1 Mounting template Mounting screws

INSTALLATION

The performance of these Cobalt subwoofers is directly proportional to the quality

of the installation. Care taken with the installation process will be rewarded by

years of satisfying performance. If you are unsure of your installation abilities, please

refer to your local authorized ORION dealer for assistance. Orion dealers are trained

professionals dedicated to extracting the maximum performance out of your Orion

system. If you decide to install this speaker system yourself, please read the entire

section on sealed and vented enclosures before starting the installation. .

TOOLS OF THE TRADE

Listed are the majority of the tools required to perform the installation. Having the

proper tools will make the installation much easier. It is very difficult when you get

half way through the installation and discover that you require a specific tool to

get yourself through a particular part of the installation. Some of these tools are

necessities. Some make the job much easier.

• Marking Pen • Electric Drill and assorted Bits

• Phillips Screwdriver • Wire Strippers

• Allen Wrenches • Volt/Ohm Meter (Optional)

• Table Saw • Jig Saw

• Wire Cutters • Wire Crimpers

FINDING SPEAKER MOUNTING LOCATIONS

Choosing the correct speaker locations will have the greatest effect on the

sound quality of the system. Different considerations are needed when choosing

the locations that best suit your needs. The locations must be large enough for

the speakers to fit. Care is needed to ensure that the location you have chosen

will not affect any of the mechanical or electrical operations of the vehicle.

Determining the best location for the speakers will depend on your cosmetic needs

and your vehicle's interior. If minimal intrusion in your vehicle is desired, factory

speaker locations may be the ticket for you. These woofers are too large to fit most

factory locations and typically need enclosures to perform correctly.

2 © 2007 directed electronics—all rights reserved

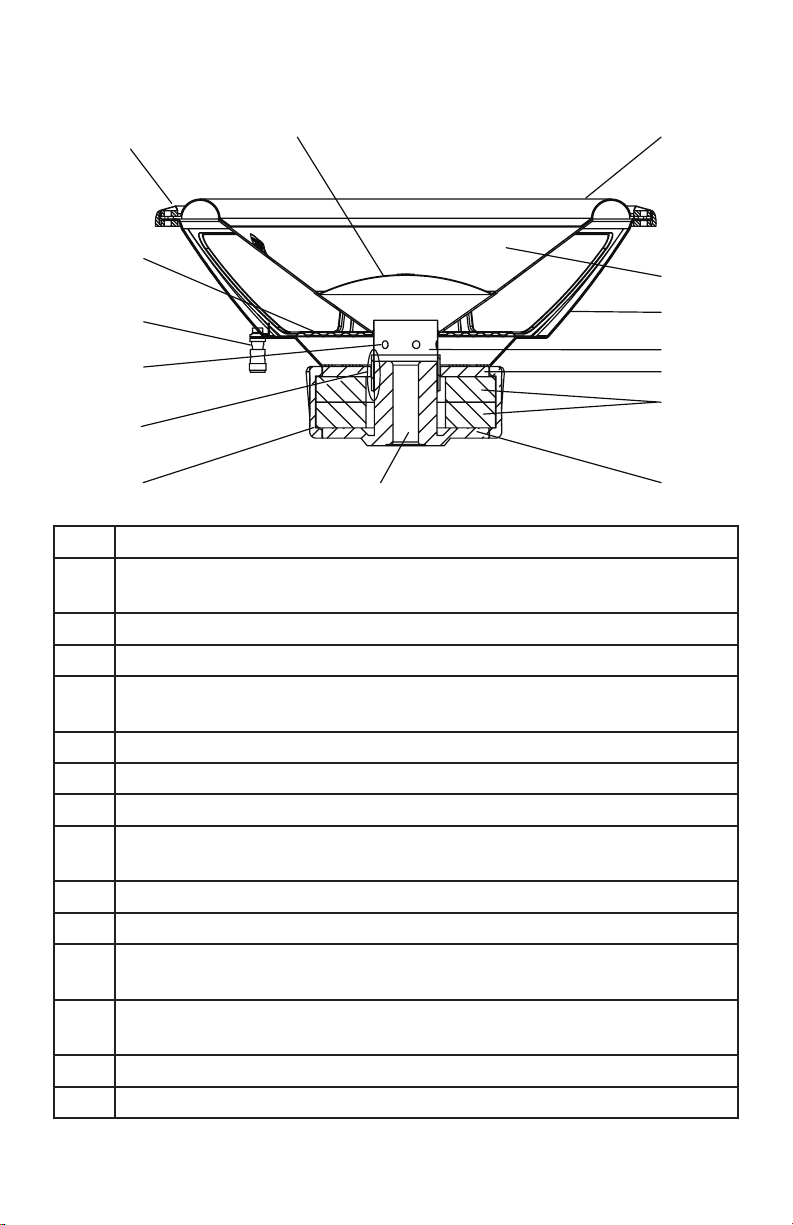

FEATURES

13

12

15

14

11

10 9

1 2

3

6

5

7

4

8

1 Polypropylene dust cap - moisture and UV resistant.

2 Oversized NBR (Nitrile-butadiene Rubber) surround for linear

controlled long excursion.

3 Vented paper cone - moisture and UV resistant.

4 Custom stamped steel frame.

5 Vented Kapton voice coil former (10” & 12" uses 1.5" voice coil

former, 15” use a 2" voice coil former).

6 8mm steel front plate.

7 Large 2 stack ceramic magnets.

8 8mm steel back plate/pole piece T yoke assembly.

9 .75" vent. Part of the enhanced voice coil cooling system (forced

10 PVC magnet protector.

11 High temperature Copper 4 ohm voice coil.

12 Venting in voice coil former. Part of the enhanced voice coil cooling

13 Interlaced Conex spider with stitched and looped tinsel leads

14 Push Terminals.

15 Reversible PVC mounting gasket.

convection).

system (forced convection).

attached.

© 2007 directed electronics—all rights reserved 3

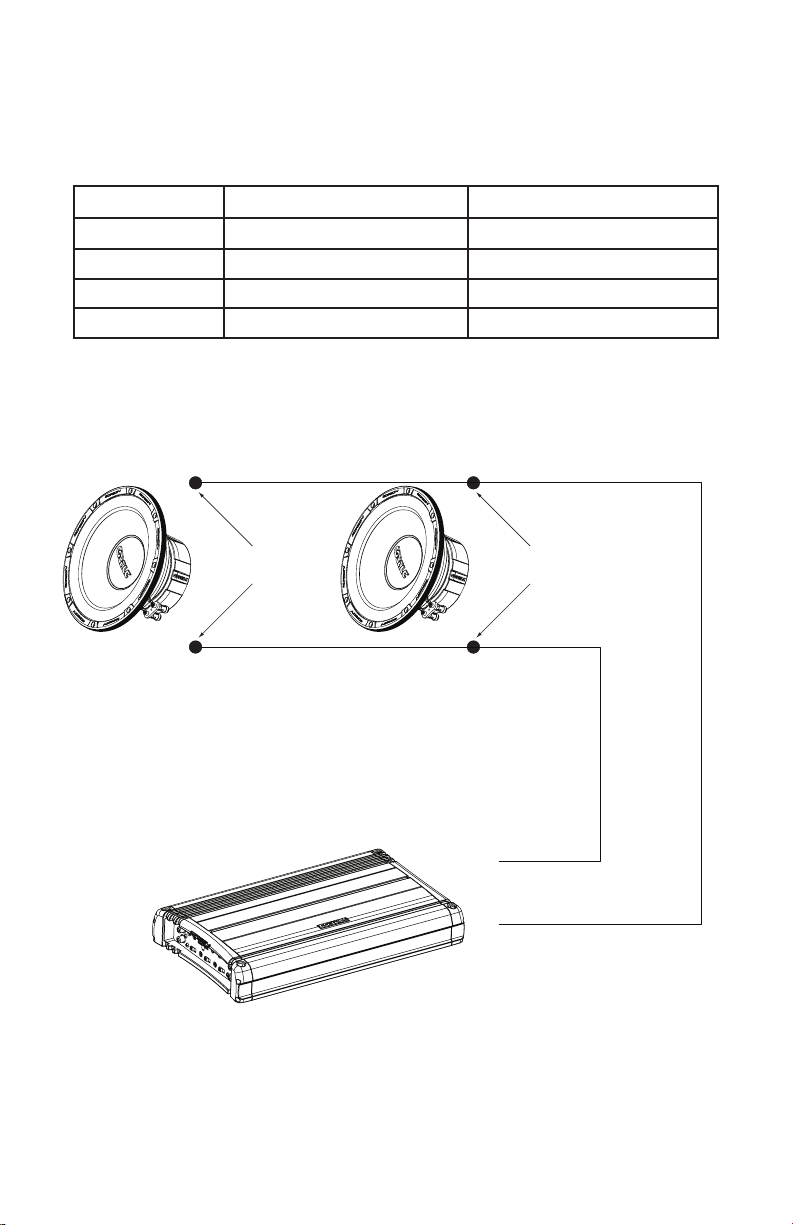

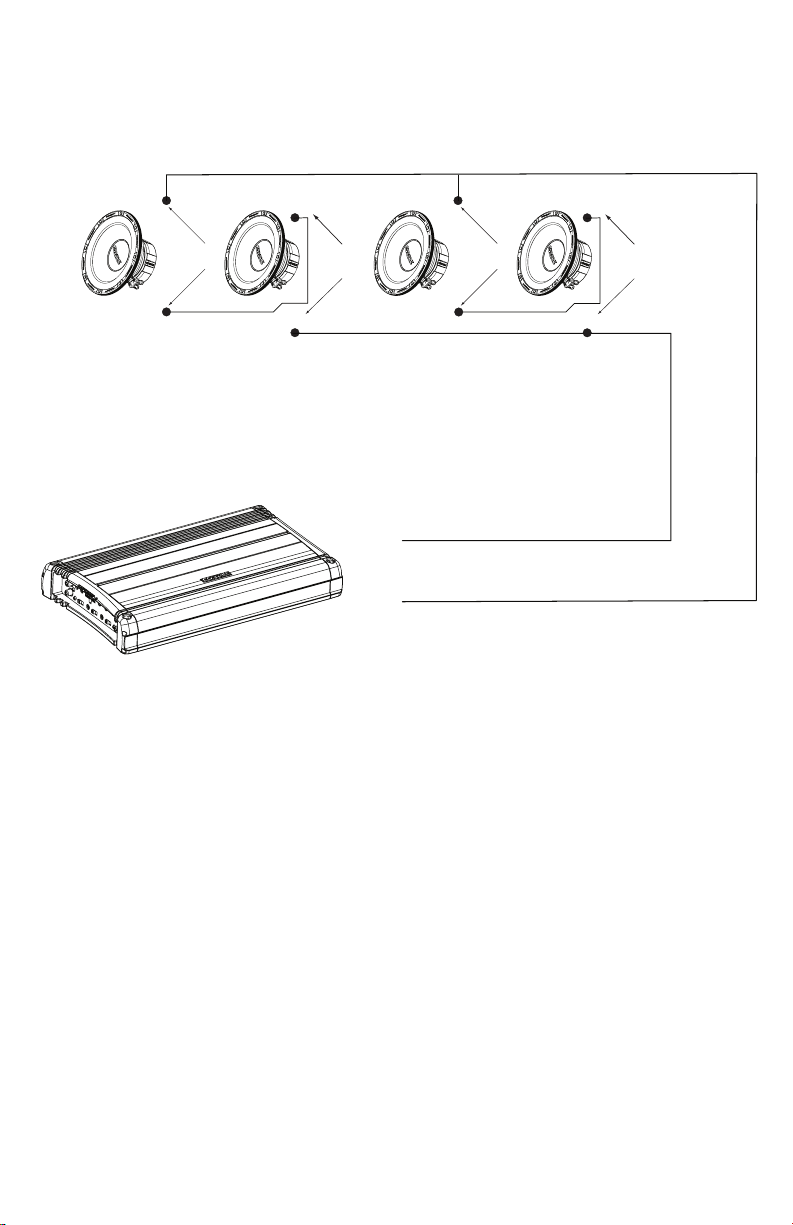

WIRING CONFIGURATIONS

+

+

+

4 ohm

_

_

_

4 ohm

Figure 2

Figura 2

Abbildung 2

The following illustrations provide guidelines on properly connecting your

Orion Cobalt woofer to an Orion Cobalt amplifier for maximum performance.

Recommended Amplifier Power

Continuous Power (RMS) Peak Power (Watts)

1 woofer 100 to 300 200 to 600

2 woofers 200 to 600 400 to 1200

3 woofers 300 to 900 600 to 1800

4 woofers 400 to 1200 800 to 2400

Parallel—Two Speakers ( 4 ohm voice coils)

Two 4 ohm voice coil woofers with the two woofers in parallel results in a 2 ohm load

to the amplifier..

1. Connect the speaker in parallel by connecting the two positive (+) terminals

together and the two negative (-) terminals together.

2. Wire the positive (+) terminals of the woofers to the positive (+) terminal on

the amplifier. Wire the negative (-) terminals of the woofers to the negative (-)

terminal on the amplifier.

4 © 2007 directed electronics—all rights reserved

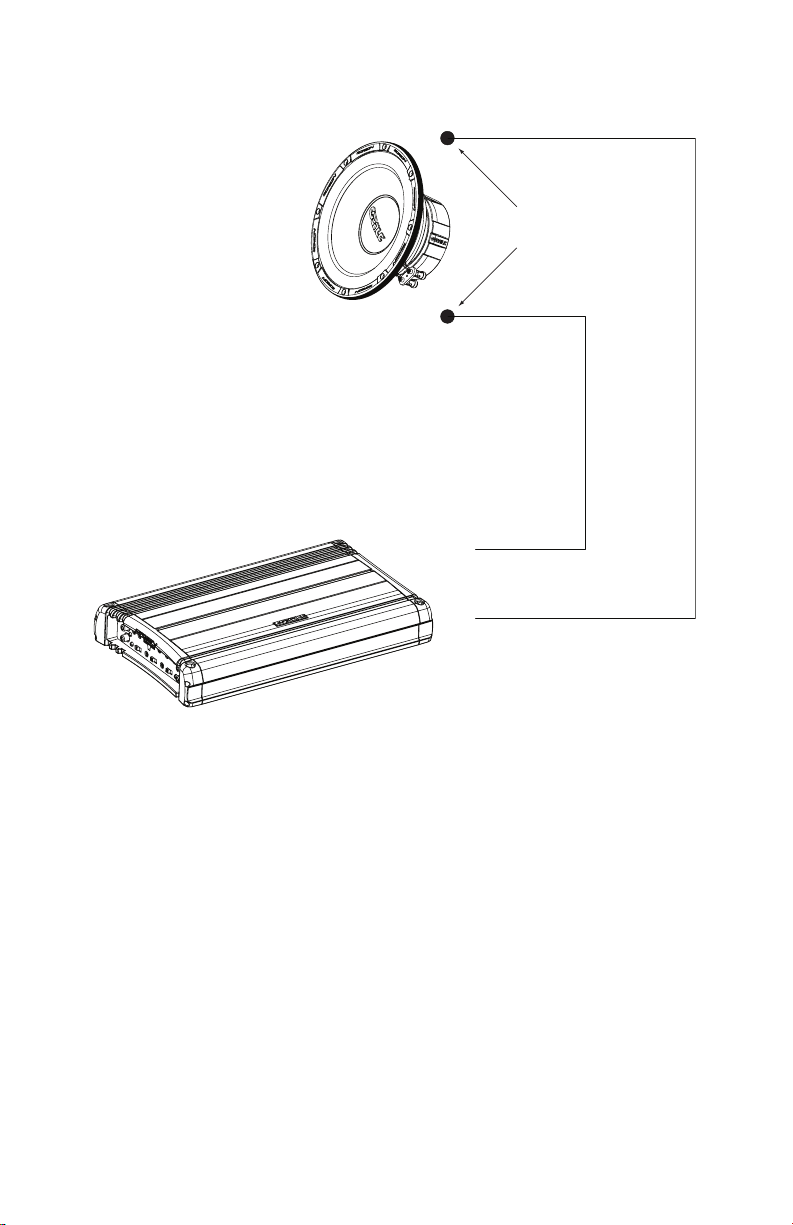

One Speaker (4 ohm voice coil)

+

+

4 ohm

_

_

Figure 3

Figura 3

Abbildung 3

One 4 ohm voice coil woofer results in a 4 ohm load to the amplifier.

1. Connect the speaker by connecting the positive (+) terminal of the woofer to

the positive (+) terminal on the amplifier. Wire the negative (-) terminal of the

woofer to the negative (-) terminal on the amplifier.

© 2007 directed electronics—all rights reserved 5

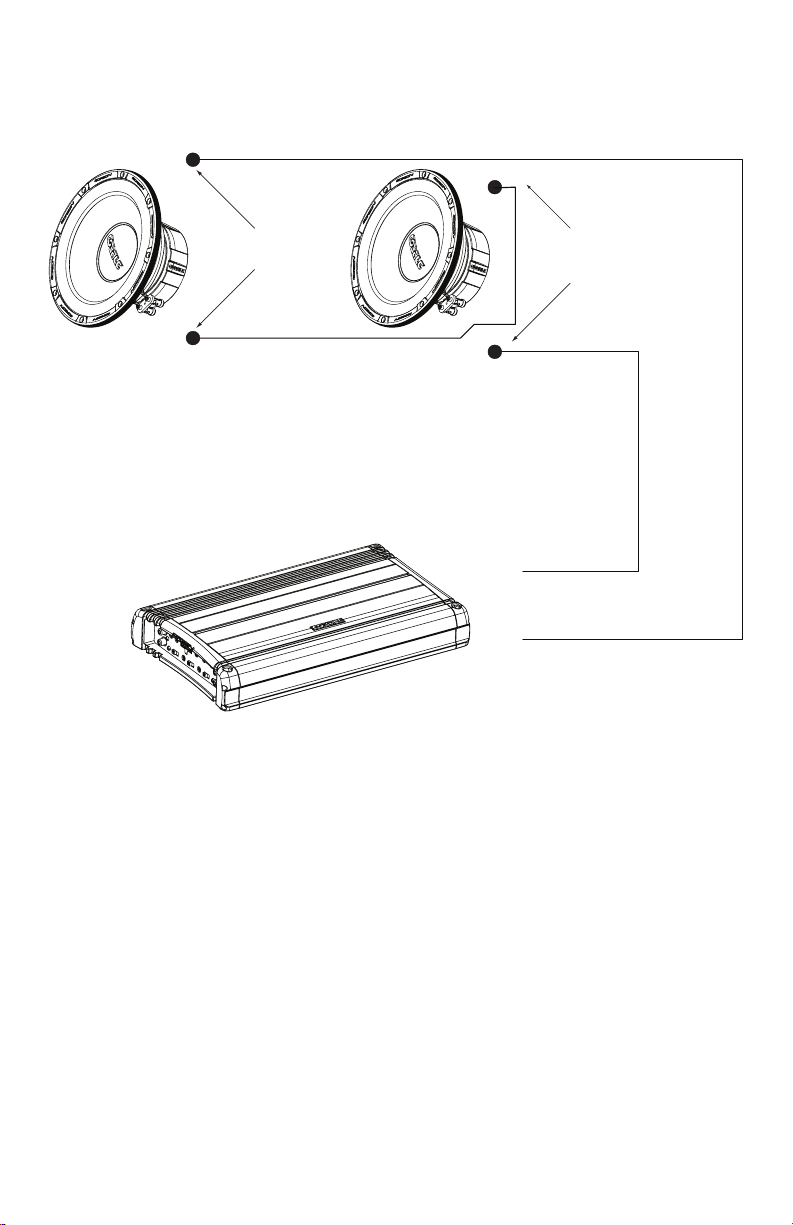

Series—Two Speakers (Single 4 ohm voice coils)

+

+

+

4 ohm

_

_

_

4 ohm

Figure 4

Figura 4

Abbildung 4

Two single 4 ohm voice coil subwoofers with the voice coils connected in series to

result in an 8 ohm load to the amplifier.

1. Connect the woofers in series by connecting the negative (-) terminal of the first

woofer voice coil to the positive (+) terminal of the second woofer voice coil.

2. Wire the positive (+) terminal of the first woofer voice coil to the positive (+)

terminal on the amplifier. Wire the negative (-) terminal of the second woofer

voice coil to the negative (-) terminal on the amplifier.

6 © 2007 directed electronics—all rights reserved

Series/Parallel - 4 Speakers (Single 4 Ohm Coils)

+

+

+

4 ohm

_

_

_

4 ohm

+

+

4 ohm

_

4 ohm

_

1 2 3 4

Figure 5

Figura 5

Abbildung 5

4 single 4 ohm voice coil subwoofers with the voice coils of each pair of speaker wired

in series and then all 4 speakers wired in parallel to result in a 4 ohm load on the

amplifier.

1. Connect the negative (-) terminal from speaker 1 to the negative terminal on

speaker 3 and then hook that wire to the negative (-) terminal on the amplifier.

2. Connect the positive (+) terminal from speaker 1 to the negative (-) terminal on

speaker 2.

3. Connect the positive (+) terminal from speaker 3 to the negative (-) terminal on

speaker 4.

4. Connect the positive (+) terminal from speaker 2 to the positive (+) terminal on

speaker 4 and then hook that wire to the positive (+) terminal on the amplifer.

© 2007 directed electronics—all rights reserved 7

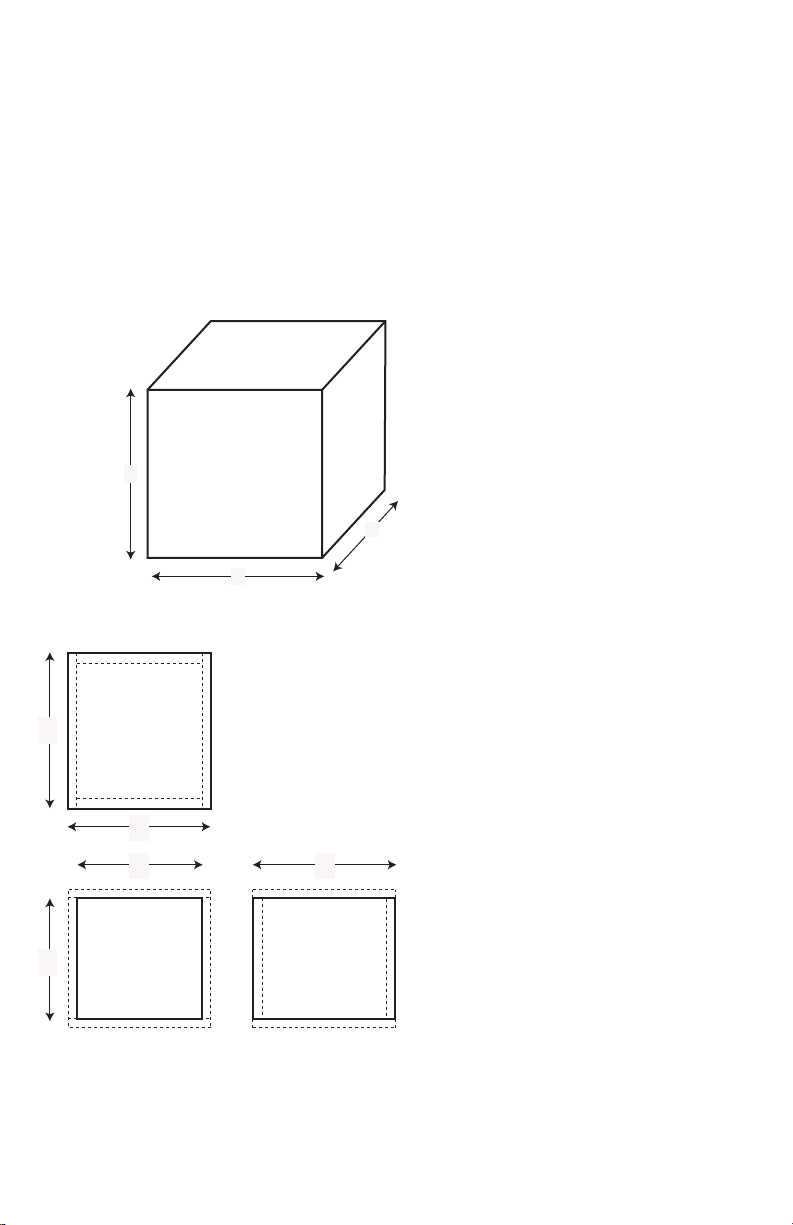

ENCLOSURE RECOMMENDATIONS

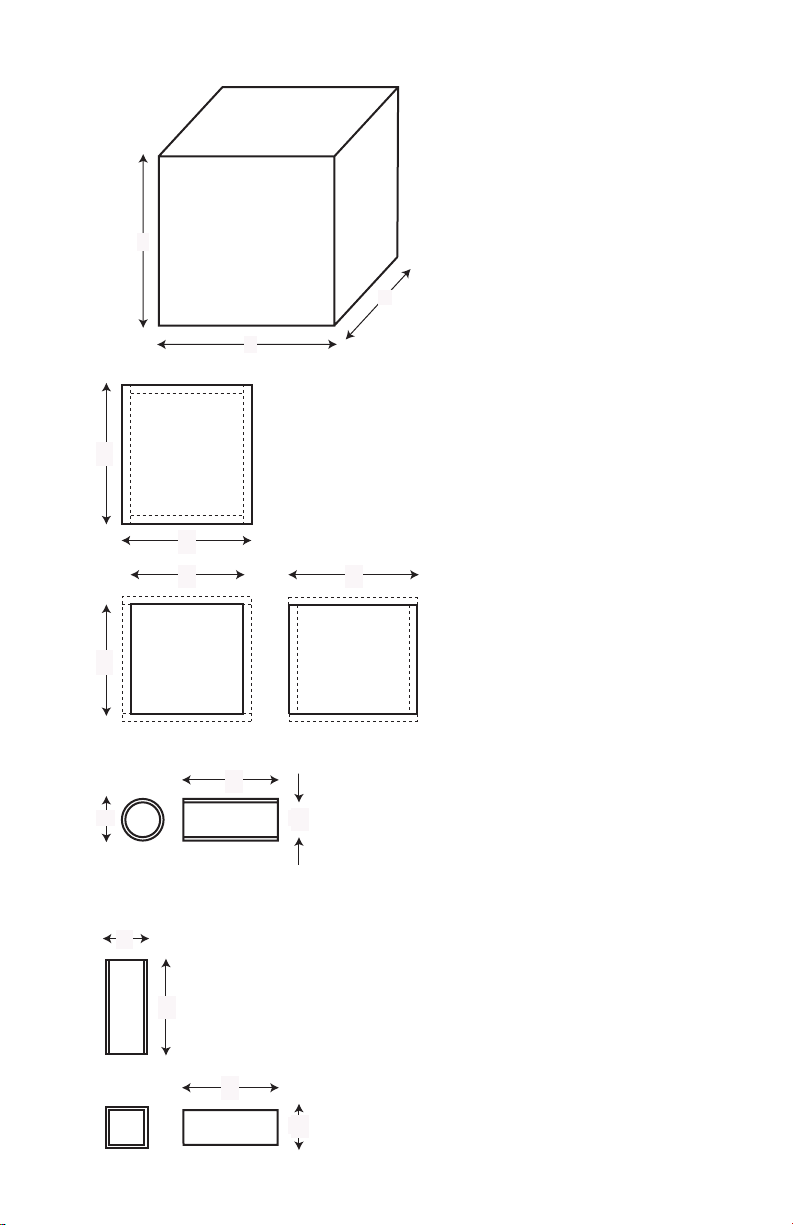

c

b

—Box Parts—

Box Shape: Square Prism

1 Top, 1 Bottom:

depth (c) = 11.5 in

width (b) = 12.5,

thickness = 0.75 in

1 Front, 1 Back:

height (a) = 12.5 in

width (d) = 11,

thickness = 0.75 in

2 Sides: height (a) = 12.5 in

depth (c) = 11.5,

thickness = 0.75 in

—Driver Mounting—

Front

Top &

Bottom

a

d

Front &

Back

c

Sides

A

B

C

External Dimensions

A = 14 in

B = 12.5 in

C = 11.5 in

Internal Dimensions

A = 12.5 in

B = 11 in

C = 10 in

Wall Thickness

Front = 0.75 in

Side = 0.75 in

Figure 6

Figura 6

Abbildung 6

Enclosure Details

1. External dimensions calculated for 3/4” building material

2. Includes speaker displacement

3. Volumes given are net tuning volume

4. Enclosures include a minimal amount of damping material. Just enough material

to line the inside of the enclosure is required.

Cobalt CO104S Sealed Enclosure Recommendations

8 © 2007 directed electronics—all rights reserved

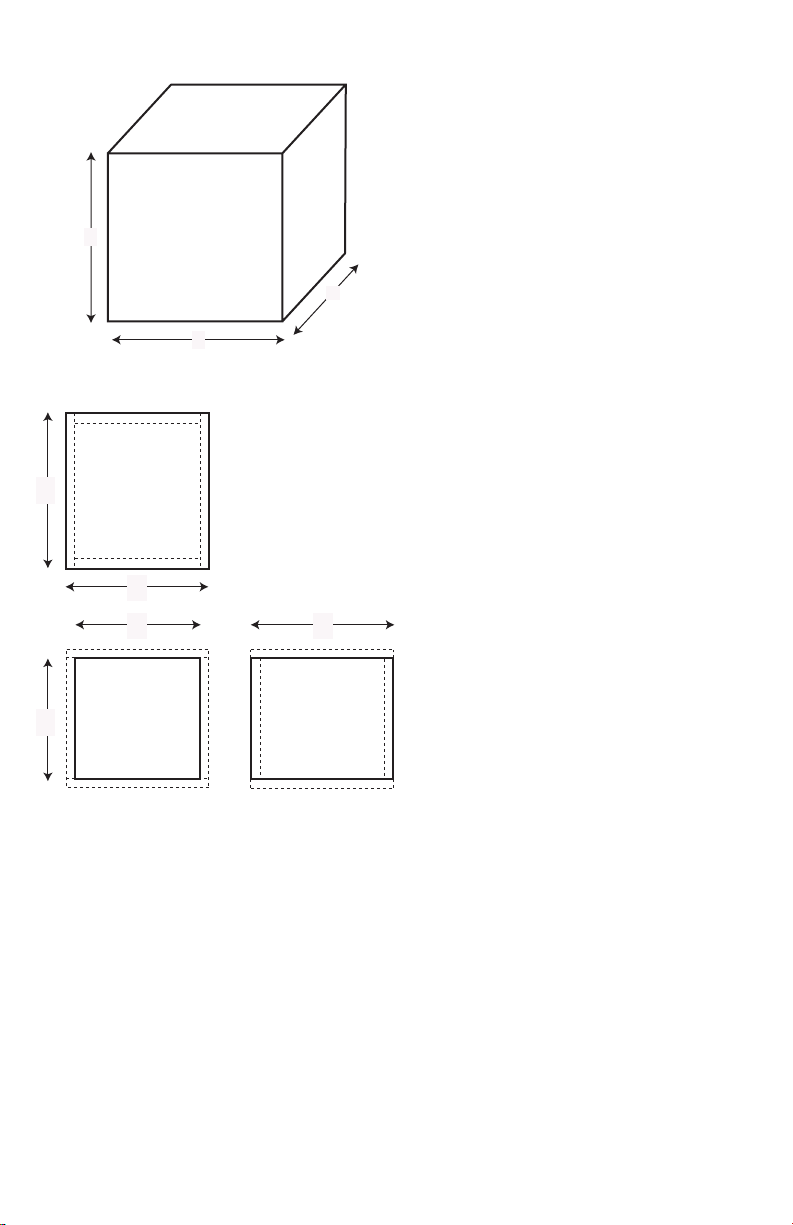

Cobalt CO104S Vented Enclosure Recommendations

—Box Parts—

Box Shape: Square Prism

1 Top, 1 Bottom:

depth (c) = 12 in

width (b) = 14.25,

thickness = 0.75 in

1 Front, 1 Back:

height (a) = 14.25 in

width (d) = 12.75,

thickness = 0.75 in

2 Sides:

height (a) = 14.25 in

depth (c) = 12,

thickness = 0.75 in

—Driver Mounting—

Front

Vent Parts --- Round

1 Duct: outside diameter (e) = 3.25 in

inside diameter (g) = 3 in

length (h) = 9.5 in

Vent Parts --- Square

1 Top, 1 Bottom:

width (e) = 3,

length (h) = 10 in

thickness = 0.125 in

2 Sides:

height (g) = 2.75,

length (h) = 10 in

thickness = 0.125 in

c

b

Top &

Bottom

a

e

d

Front &

Back

c

Sides

h

h

VENT Round

- OR -

VENT Square

e

h

g

g

A

B

C

External Dimensions

A = 15.75 in

B = 14.25 in

C = 12 in

Internal Dimensions

A = 14.25 in

B = 12.75 in

C = 10.5 in

Wall Thickness

Front = 0.75 in

Side = 0.75 in

Figure 7

Figura 7

Abbildung 7

© 2007 directed electronics—all rights reserved 9

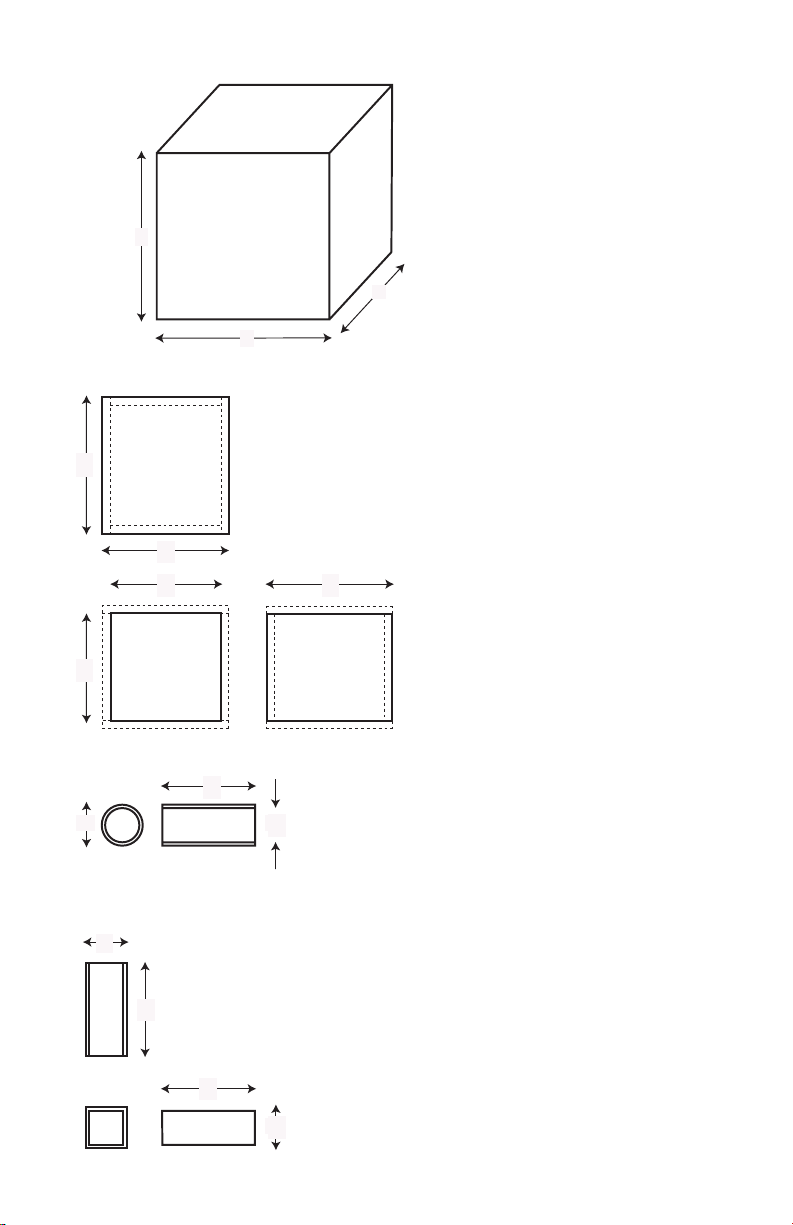

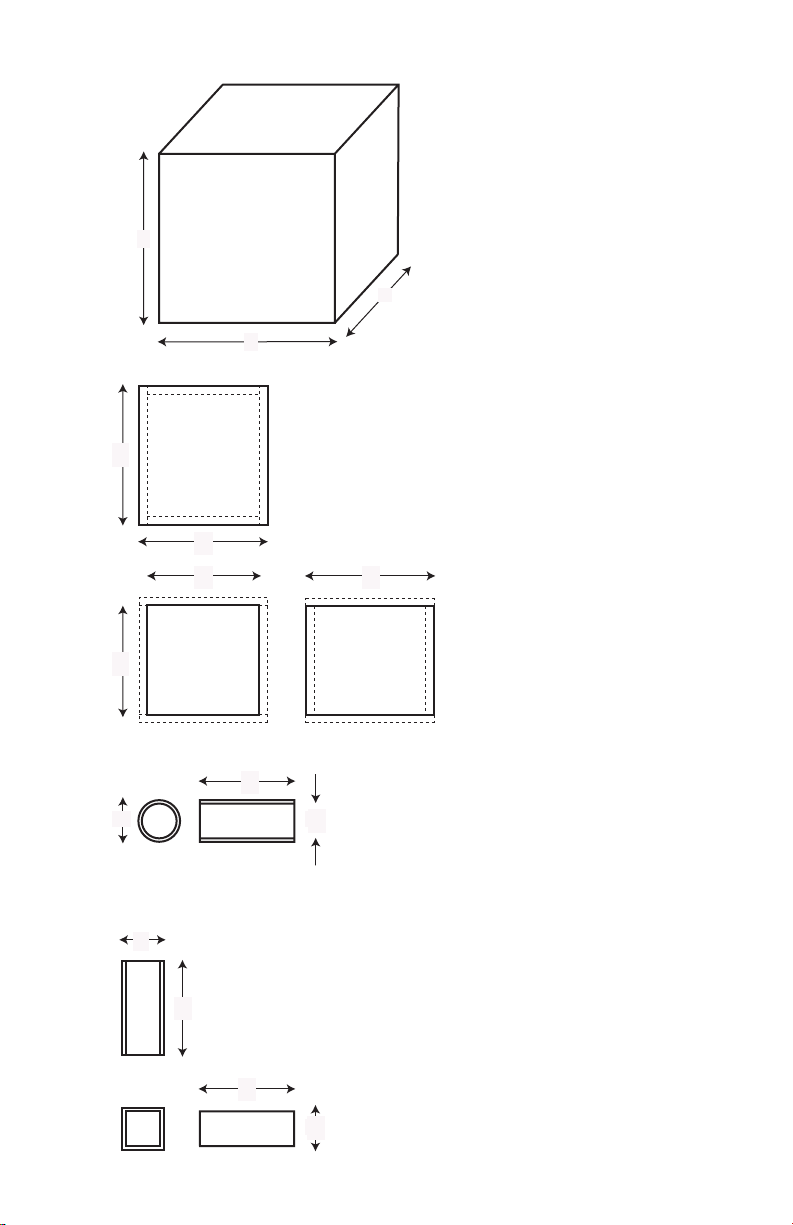

Cobalt CO124S Sealed Enclosure Recommendations

c

b

—Box Parts—

Box Shape: Square Prism

1 Top, 1 Bottom:

depth (c) = 12 in

width (b) = 14.75,

thickness = 0.75 in

1 Front, 1 Back:

height (a) = 14 in

width (d) = 13.25,

thickness = 0.75 in

2 Sides:

height (a) = 14 in

depth (c) = 12,

thickness = 0.75 in

Driver Mounting

Mounting: Front

Top &

Bottom

a

d

Front &

Back

c

Sides

A

B

C

External Dimensions

A = 15.5 in

B = 14.75 in

C = 12 in

Internal Dimensions

A = 14 in

B = 13.25 in

C = 10.5 in

Wall Thickness

Front = 0.75 in

Side = 0.75 in

Figure 8

Figura 8

Abbildung 8

10 © 2007 directed electronics—all rights reserved

Cobalt CO124S Vented Enclosure Recommendations

—Box Parts—

Box Shape: Square Prism

1 Top, 1 Bottom:

depth (c) = 13 in

width (b) = 16.75,

thickness = 0.75 in

1 Front, 1 Back:

height (a) = 16.5 in

width (d) = 15.25,

thickness = 0.75 in

2 Sides:

height (a) = 16.5 in

depth (c) = 13,

thickness = 0.75 in

Driver Mounting

Mounting: Front

Vent Parts --- Round

1 Duct:

outside diameter (e) = 4.25 in

inside diameter (g) = 4 in

length (h) = 10 in

Vent Parts --- Square

1 Top, 1 Bottom:

width (e) = 3.75,

length (h) = 10 in

thickness = 0.125 in

2 Sides:

height (g) = 3.5,

length (h) = 10 in

thickness = 0.125 in

c

b

Top &

Bottom

a

e

d

Front &

Back

c

Sides

h

h

VENT Round

- OR -

VENT Square

e

h

g

g

A

B

C

External Dimensions

A = 18 in

B = 16.75 in

C = 13 in

Internal Dimensions

A = 16.5 in

B = 15.25 in

C = 11.5 in

Wall Thickness

Front = 0.75 in

Side = 0.75 in

Figure 9

Figura 9

Abbildung 9

© 2007 directed electronics—all rights reserved 11

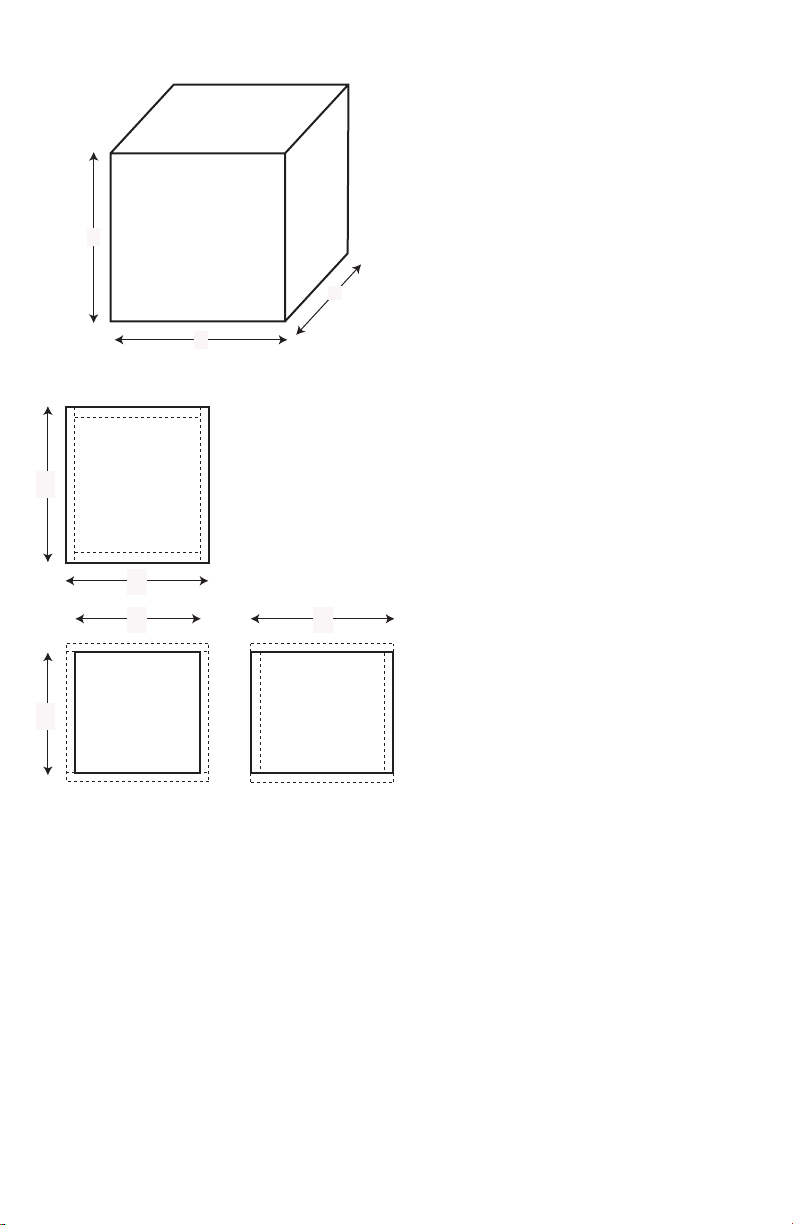

Cobalt CO154S Sealed Enclosure Recommendations

c

b

—Box Parts—

Box Shape: Square Prism

1 Top, 1 Bottom:

depth (c) = 11.5 in

width (b) = 17.5,

thickness = 0.75 in

1 Front, 1 Back:

height (a) = 23.5 in

width (d) = 16,

thickness = 0.75 in

2 Sides:

height (a) = 23.5 in

depth (c) = 11.5,

thickness = 0.75 in

Driver Mounting

Mounting: Front

Top &

Bottom

a

d

Front &

Back

c

Sides

A

B

C

External Dimensions

A = 25 in

B = 17.5 in

C = 11.5 in

Internal Dimensions

A = 23.5 in

B = 16 in

C = 10 in

Wall Thickness

Front = 0.75 in

Side = 0.75 in

Figure 10

Figura 10

Abbildung 10

12 © 2007 directed electronics—all rights reserved

Cobalt CO154S Vented Enclosure Recommendations

—Box Parts—

Box Shape: Square Prism

1 Top, 1 Bottom:

depth (c) = 13 in

width (b) = 17.5,

thickness = 0.75 in

1 Front, 1 Back:

height (a) = 23.5 in

width (d) = 16,

thickness = 0.75 in

2 Sides:

height (a) = 23.5 in

depth (c) = 13,

thickness = 0.75 in

Driver Mounting

Mounting: Front

Vent Parts --- Round

1 Duct: outside diameter (e) = 4.25 in

inside diameter (g) = 4 in

length (h) = 7 in

Vent Parts --- Square

1 Top, 1 Bottom:

width (e) = 4.25,

length (h) = 7 in

thickness = 0.125 in

2 Sides:

height (g) = 4,

length (h) = 7 in

thickness = 0.125 in

c

b

Top &

Bottom

a

e

d

Front &

Back

c

Sides

h

h

VENT Round

- OR -

VENT Square

e

h

g

g

A

B

C

External Dimensions

A = 25 in

B = 17.5 in

C = 13 in

Internal Dimensions

A = 23.5 in

B = 16 in

C = 11.5 in

Wall Thickness

Front = 0.75 in

Side = 0.75 in

Figure 11

Figura 11

Abbildung 11

© 2007 directed electronics—all rights reserved 13

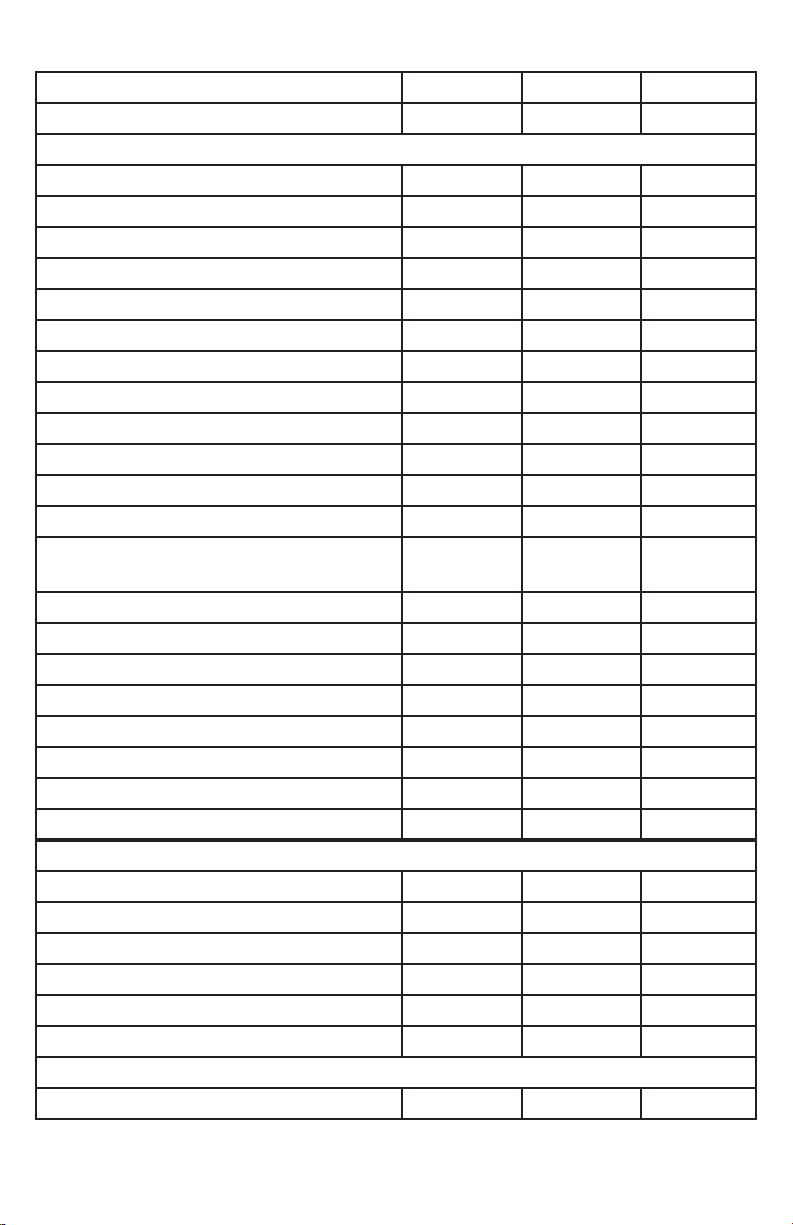

SPECIFICATIONS

Directed Part Number CO104S CO124S CO154S

Model Number 32100 32105 32115

Thiele/Small Parameters

Fs (free-air resonance, Hz) 39.2 25.6 25.2

Vas (equivalent compliance, cu. ft.) 1.080 4.017 7.098

Vas (equivalent compliance, liters) 30.600 113.790 201.070

Qms (Q, mechanical) 3.53 4.72 6.08

Qes (Q, electrical) 0.68 0.55 0.51

Qts (total driver Q) 0.57 0.49 0.47

Re (DC resistance, ohms) 3.6 3.55 3.77

Z (nominal impedance, ohms) 4 4 4

Le (inductance, mh) 1.38 1.37 1.61

Efficiency (1W @ 1M, dB) 86.1 87.2 89.9

Xmax (one way linear excursion, in.) 0.406 0.410 0.453

Xmax (one way linear excursion, mm) 10.2925 10.4075 11.5

Pe (continuous power handling,

watts)

Peak power handling (music, watts) 400 500 600

Mms (total moving mass, grams) 101.00 127 195

Cms (mechanical compliance, mm/N) 0.180564 0.294721 0.211994

Bl (motor strength, Tesla-M) 10.88 11.61 14.82

Sd (effective radiating area, sq. cm.) 346.361 522.792 819.398

Sd (effective radiating area, sq. in.) 53.706 81.064 127.055

Frequency range (Hz) 39 - 250Hz 25 - 250Hz 25 - 250Hz

Energy Bandwidth Product (EBP) 58 47 49

Driver Physical Dimension

Speaker Displacement (cu ft) 0.048 0.061 0.116

Speaker Outer Diameter (inches/mm) 10.31/ 262 12.40/ 315 15.40/ 391

Mounting hole diameter (inches/mm) 9.23/ 232 10.91/ 277 13.82/ 351

Mounting depth (inches/mm) 5.12/ 130 5.51/ 140 6.46/ 164

Magnet Weight (Oz) 38.60 41 70

Basket diameter (inches/mm) 10.16/258 12.21/310 15.16/385

Recommended Enclosures

Typical sealed enclosure (cu. ft.) 0.75 1 2

200 200 250

Specifications subject to change without notice

14 © 2007 directed electronics—all rights reserved

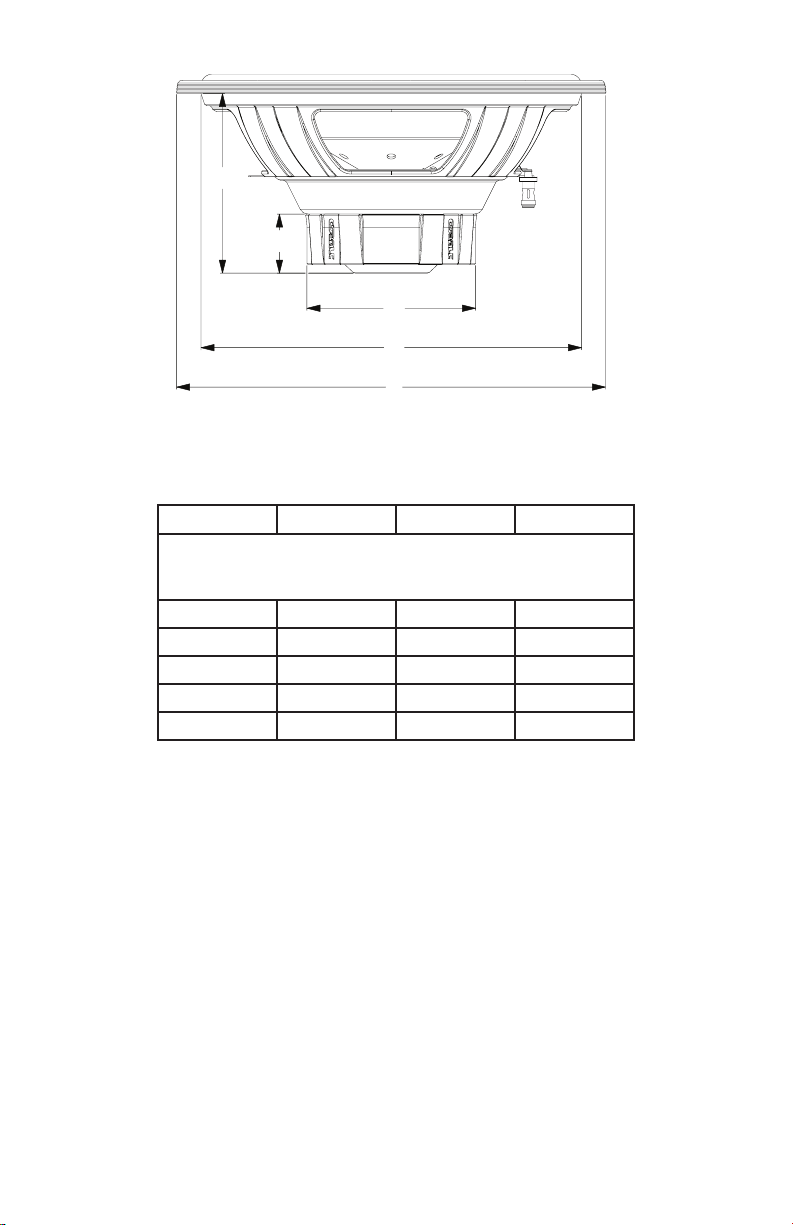

D

A

E

C

B

Figure 12

Figura 12

Abbildung 12

CO104S CO124S CO154S

Dimensions inches/mm, Dimensions po/mm, Dimensiones

plg./mm, Abmessungen Zoll/mm, Dimensioni

pollici/millimetri, Dimensões polegadas/mm

A 5.12/130 5.51/140 6.46/164

B 1.97/50 1.97/50 2.01/51

C 4.96/126 5.00/127 5.71/145

D 9.13/232 10.91/277 13.82/351

E 10.16/258 12.20/310 15.16/385

© 2007 directed electronics—all rights reserved 15

Loading...

Loading...