Page 1

INSTRUCTION MANUAL

Orion® SkyQuest

XT6 Classic, XT8 Classic

& XT10 Classic

Dobsonian Reflecting Telescopes

Providing Exceptional Consumer Optical Products Since 1975

OrionTelescopes.com

Customer Support (800)676-1343

E-mail: support@telescope.com

Corporate Offices (831) 763-7000

89 Hangar Way, Watsonville, CA 95076

IN 165 Rev. D 05/08

Page 2

Secondary mirror with

4-vane spider (not shown)

EZ Finder II

Eyepiece

Focus knob

Optical tube

Altitude side bearing

Right side panel

Front brace

Handle

Eyepiece Rack

(optional)

Top baseplate

Ground baseplate

Figure 1.

CorrecTension Friction

Optimization System

Pull loop

Left side panel

The SkyQuest XT Dobsonian (XT6 pictured)

2

Page 3

Welcome to an exciting new world of adventure! Your SkyQuest Dobsonian is a high-quality optical instrument designed to

bring you dazzling views of the outer reaches of our universe. Easy enough for kids to use, and portable enough for anyone to carry, the SkyQuest will provide fun and entertainment for the entire family. Whether you are brand-new to amateur

astronomy or a seasoned stargazer, get ready for many evenings of enjoyment and fascination. Before venturing into

the night with your new telescope, we recommend that you read through this instruction manual. Not only does it provide

accurate directions for assembly and use, but it also serves as a guide for your first explorations in the sky.

Table of Contents

1. Unpacking.............................3

2. Assembly .............................4

3. Using Your Telescope ....................7

4. Collimation (Aligning the Mirrors) ..........10

5. Astronomical Observing .................12

6. Care and Maintenance ..................16

7. Specifications .........................17

1. Unpacking

The telescope will arrive in two boxes, one containing the

optical tube assembly and accessories, the other containing

the unassembled Dobsonian base. Be careful unpacking the

boxes. We recommend keeping the original shipping containers. In the event that the telescope needs to be shipped to

another location, or returned to Orion for warranty repair, having the proper shipping containers will help ensure that your

telescope will survive the journey intact.

Make sure all the parts in the Parts List below are present. Be

sure to check boxes carefully, as some parts are small. If anything appears to be missing or broken, immediately call Orion

Customer Support (800-676-1343) for assistance.

WARNING: Never look directly at the Sun

through your telescope or its finder scope—

even for an instant—without a professionally

made solar filter that completely covers the front

of the instrument, or permanent eye damage

could result. Young children should use this

telescope only with adult supervision.

Parts List

Box #1: Optical Tube Assembly and Accessories

Qty. Description

1 Optical tube assembly

1 Dust cover

1 25mm Sirius Plössl eyepiece, 1.25" barrel diameter

1 EZ Finder II (with bracket)

1 Collimation cap

2 Spring coils

2 Pull loops

4 Nylon spacers (black)

2 1/4" washers (black)

2 Phillips-head screws (black, length 1-3/4")

2 Screws with round knob attached

Box #2: Dobsonian Base

Qty. Description

1 Left panel

1 Right panel

1 Front brace

1 Top baseplate

1 Ground baseplate

12 Base assembly screws (length 2")

1 Hex key (size 4mm)

3 Plastic feet

3 Feet attachment wood screws (length 1")

1 Self-adhesive rubber bumper

1 Large hex-head bolt (length 3")

2 3/8" washers

1 3/8" lock nut

1 Nylon spacer (white)

1 T-nut

1 Handle

2 Socket-head cap screws, 5/16" (black)

2 5/16" washers (black)

2 5/16" nuts (black)

1 Hex key (6mm)

3

Page 4

F

G

C

C

B

D

J

A

I

H

K

L

E

Figure 3. Set the optical

tube on the “cradle” of the

base so that the altitude side

bearings on the tube rest on

the white plastic “pads,” and

the finder is facing away from

the front brace (Part B).

3. Attach the two sides (C) with the front brace attached to

the top baseplate (D) with the remaining six base assembly

screws in the predrilled holes. Tighten all six screws.

4. Tighten the six side panel screws installed earlier.

5. Insert the white nylon bushing (E) into the hole in the center of the top baseplate (D). Tap the nylon bushing in so it

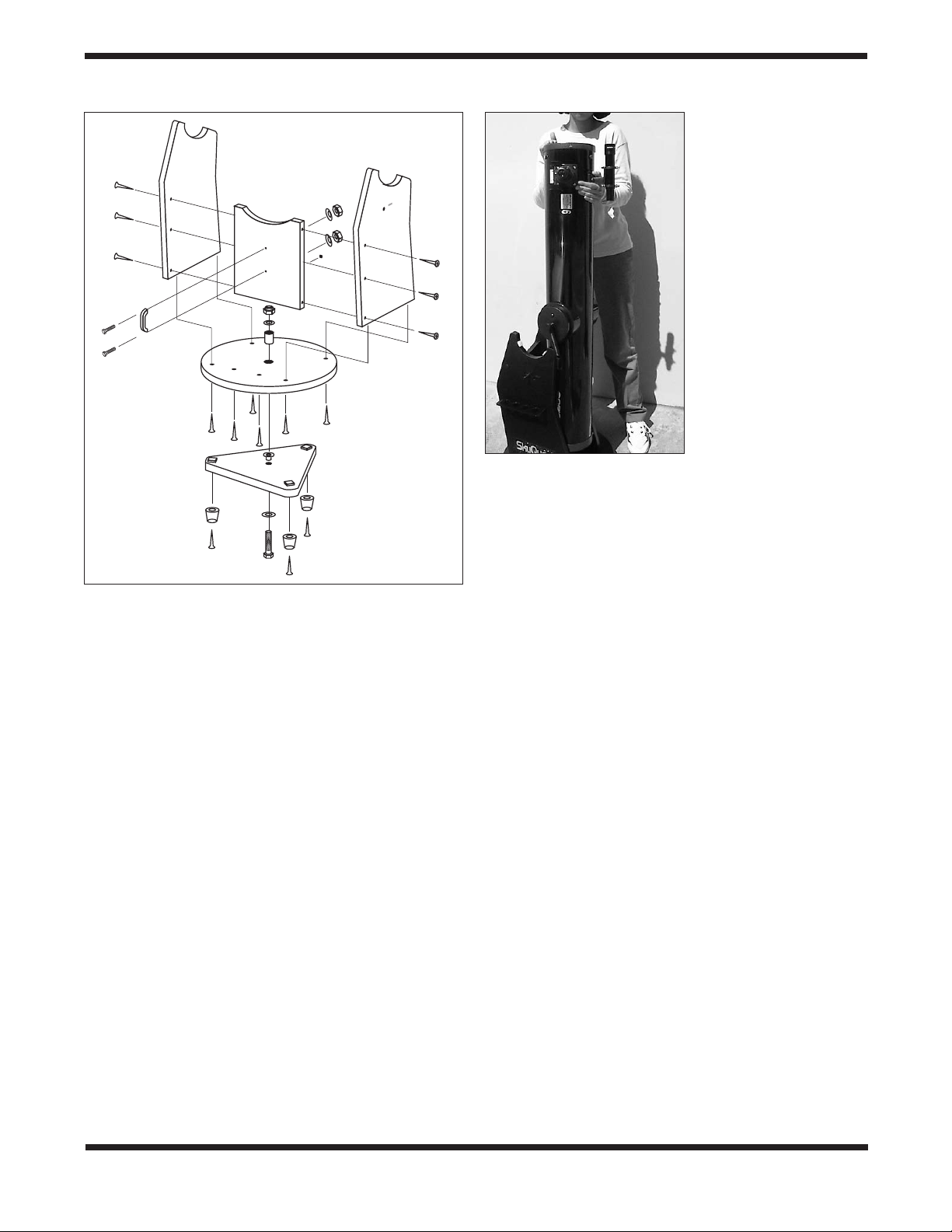

Figure 2. Exploded view of the SkyQuest XT Dobsonian base.

goes all the way into the top baseplate. The nylon bushing

should be flush with the top surface of the top baseplate.

2. Assembly

Now that you have unpacked the boxes and familiarized yourself with all the parts in front of you, it’s time to begin assembly.

The optics of the telescope are already installed in the tube,

so most of the required assembly concerns the Dobsonian

base.

Assembly of the Dobsonian Base

Refer to Figure 2 during base assembly. The base need only

be assembled once, unless you disassemble it for long-term

storage. The assembly process takes about 30 minutes and

requires a Phillips screwdriver, an adjustable crescent wrench,

and the provided hex keys.

Note: When tightening the base assembly screws, tighten them until firm, but be careful not to strip the holes

by over-tightening. If you use an electric screwdriver, do

the final tightening with a standard screwdriver to avoid

6. Insert the T-nut (K) into the center hole of the ground baseplate (A) so the nut’s flanged top is on the same side of the

baseplate as the Teflon pads. Thread the large hex-head

bolt (G) with a 3/8" washer (F) attached up through the

ground baseplate and through the T-nut until it is tight. Now

position the top baseplate (D) (with side panels attached)

over the ground baseplate and lower it so the bolt goes

through the nylon spacer in the center hole of the top

baseplate. Now thread the remaining 3/8" washer (H) and

lock nut (I) onto the bolts shaft. You might need to hold the

bolts head in place with another crescent wrench or pliers.

Tighten the lock nut with the wrench just enough to allow

a slight separation of the top and bottom baseplates when

the mount is lifted. The purpose of the lock nut is merely to

keep the two baseplates from coming apart when moving

the telescope.

Note: Overtightening the lock nut (I) will make the mount

difficult to rotate in the azimuthal (horizontal) direction.

stripping.

1. Screw the plastic feet into the underside of the ground

baseplate (A) using the self-tapping wood screws provided, with a Phillips screwdriver. Insert the screws through

the feet and thread them into the predrilled starter holes.

2. Loosely attach the front brace (B) to the two side panels

(C) with six of the base assembly screws in the predrilled

holes. Use the 4mm hex key to tighten the screws. The side

panels should be oriented so the SkyQuest label is facing

outward. Do not completely tighten the screws yet.

7. Attach the handle (J) to the front brace (B) with the two

black socket-head screws. Insert the screws through the

handle and into the predrilled holes. Place the 5/16" washers and 5/16" nuts on the protruding ends of the screws.

Tighten the nuts with a crescent wrench while holding the

bolts stationary with the 6mm hex key.

8. Lift the optical tube and set the altitude bearings on either

side of the tube in the “cradle” of the base (Figure 3). The

unique flange design of the altitude bearing allows for automatic left-to-right centering of the optical tube in the cradle.

4

Page 5

a. b.

Figure 4. Position the tube on the mount pointed vertical. Place

the rubber bumper “stop” where the mirror cell contacts the front

base to cushion the impact.

Once in the cradle, the tube should pivot freely up and

down with gentle hand pressure. Note that the tube will

not yet be properly balanced, since the eyepiece and EZ

Finder II are not in place, and the CorrecTension system

has not been installed.

9. The rubber bumper (L) provides a convenient “stop” for the

telescope’s altitude motion; it prevents the telescope mirror cell from being knocked against the hard surface of the

base’s front brace. Remove the backing from the rubber

bumper and position the bumper so it is positioned in the

spot where the optical tube (mirror cell) contacts the front

base as shown in Figure 4a and 4b. Press firmly so the

adhesive holds the bumper securely in place.

Installing the Optional Eyepiece Rack

The aluminum eyepiece rack is an optional accessory for

SkyQuest Dobsonians. On the XT6 it holds three 1.25" eyepieces in a convenient place on the base; on the XT8 and

XT10 it holds three 1.25" eyepieces and one 2" eyepiece.

These eyepieces will be within easy reach while you’re

observing. About halfway down the left side panel of the base

you will notice two predrilled starter holes, about 6" apart.

Take the black wood screws and thread them into the starter

holes with a Phillips screwdriver. Then you can “keyhole” the

eyepiece rack onto the wood screws and continue tightening

the screws (Figure 5). If you want to be able to remove the

rack, do not tighten the screws too tightly. Be certain that the

screws are loose enough that you can lift the rack and remove

it from the screws through the larger part of the keyhole. If

you want to have the rack permanently attached, thread the

screws tightly.

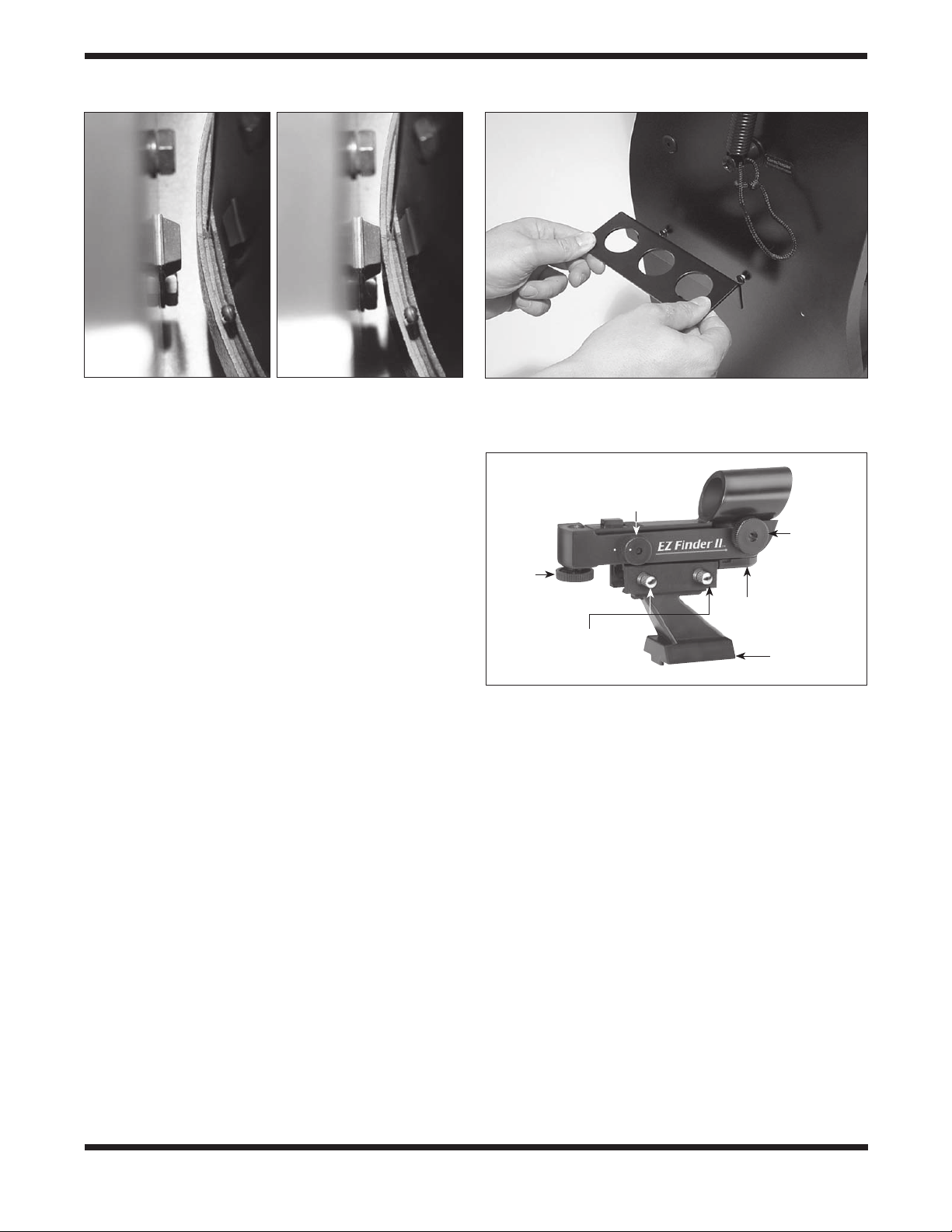

Installing the EZ Finder II

Using the included dovetail mounting bracket, the EZ Finder

II will slip neatly into the dovetail base preinstalled on your

SkyQuest optical tube. To attach the dovetail mounting bracket

to the EZ Finder II, loosen the two thumbscrews on the bottom

rail of the EZ Finder II. Slide the EZ Finder II onto the bracket

and tighten the two thumbscrews (See Figure 6). Then simply

Figure 5. Using the two supplied screws, install the optional

aluminum eyepiece rack in the predrilled holes about halfway down

the left side panel of the base. (XT6 eyepiece rack shown)

Power

knob

Azimuth

adjustment

Altitude

adjustment

knob

Battery

casing

Thumbscrews

knob

Dovetail

mounting

bracket

Figure 6. The EZ Finder II

slide the dovetail mounting bracket into the telescope’s dovetail mounting base and tighten the thumbscrew on the base to

secure the mounting bracket.

Operation

The EZ Finder II works by projecting a tiny red dot (it’s not a

laser beam) onto a lens mounted in the front of the unit. When

you look through the EZ Finder II, the red dot will appear to

float in space, helping you locate even the faintest of deep

space objects. The red dot is produced by a light-emitting

diode (LED) near the rear of the sight. A 3-volt lithium battery

provides the power for the diode.

Turn the power knob (see Figure 6) clockwise until you hear

the “click” indicating that power has been turned on. Look

through the back of the reflex sight with both eyes open to

see the red dot. Position your eye at a comfortable distance

from the back of the sight. In daylight you may need to cover

the front of the sight with your hand to be able to see the

dot, which is purposefully quite dim. The intensity of the dot

is adjusted by turning the power knob. For best results when

stargazing, use the dimmest possible setting that allows you

to see the dot without difficulty. Typically a dimmer setting is

5

Page 6

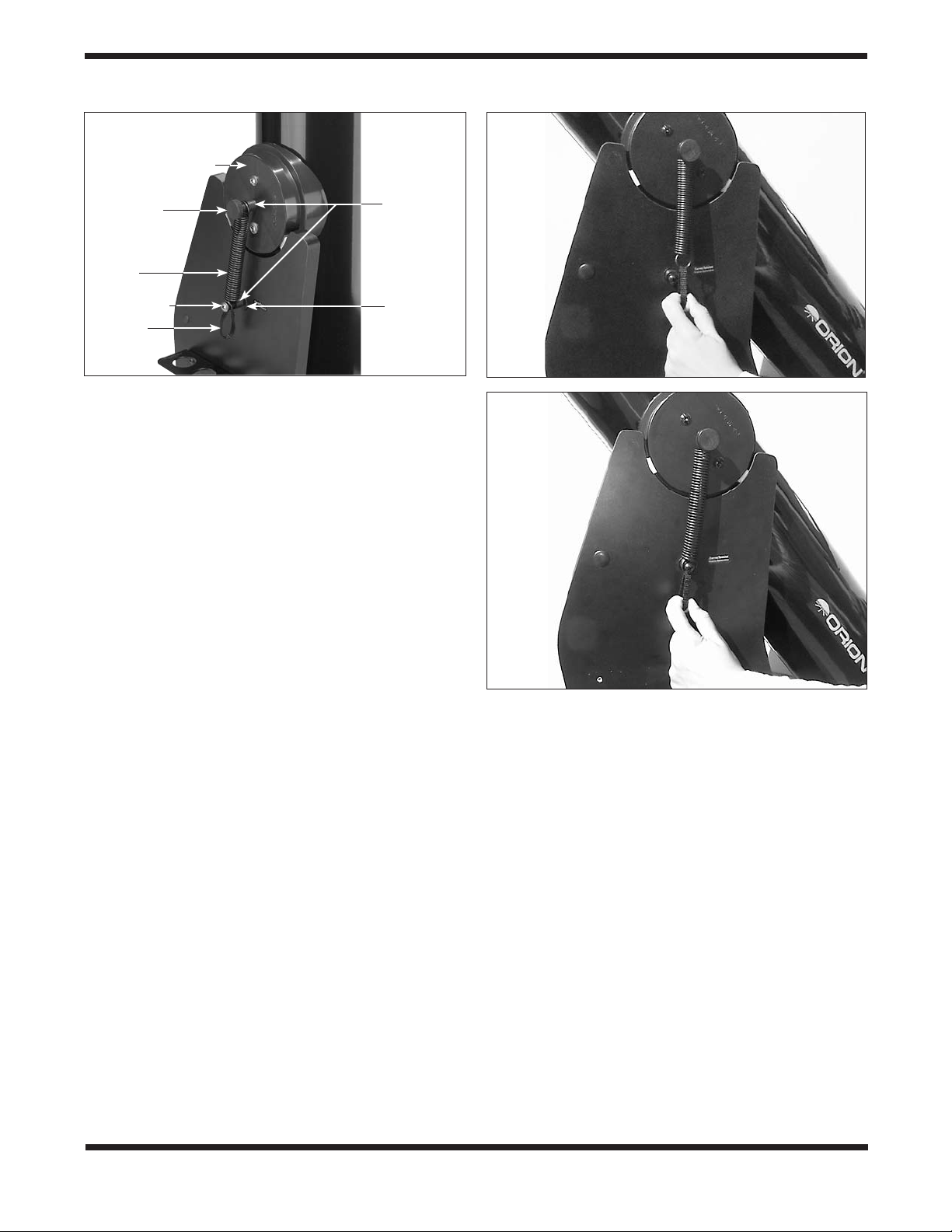

Altitude side bearing

Screw with

round knob

Spring

Phillips-head

screw (black)

Pull loop

Black nylon

spacers

1/4" washer

(black)

Figure 7. Close-up view of the CorrecTension system, which pulls

the tube assembly down onto the altitude bearing pads.

used under dark skies and a bright setting is used under lightpolluted skies or daylight.

At the end of your observing session, be sure to turn the power

knob counterclockwise until it clicks off. When the white dots

on the EZ Finder II’s body and power knob are lined up, the EZ

Finder II is turned off.

Installing the CorrecTension (XT) Friction

Optimization System

Perhaps the most exciting feature of the SkyQuest Dobsonians

is the CorrecTension Friction Optimization system. Because of

their light weight, 10" and smaller Dobsonians have always

been plagued by insufficient friction on the altitude bearing

surfaces. As a result, such telescopes move up and down

much too freely. This causes problems when the observer tries

to accurately center and track an object for viewing, especially

at higher powers. Also, the telescope becomes very sensitive

to balance, requiring additional equipment such as counterweight systems or adjustable side bearings to compensate.

SkyQuest Dobsonians employ a simple yet effective remedy

for the friction problem that obviates the need for such cumbersome countermeasures. CorrecTension Friction Optimization

utilizes a spring coil to “pull” the tube assembly down onto the

altitude bearing pads, thereby increasing the friction by just

the right amount. With CorrecTension, you can change eyepieces, or add a barlow lens or solar filter without having to

tediously adjust the telescope’s balance as you would with

other Dobsonians. The altitude friction will roughly equal the

azimuth friction, ensuring optimal performance.

To install the CorrecTension assembly, follow these steps while

referring to Figure 7:

1. Put one of the black nylon spacers on a black Phillips-head

screw. The spacer should be oriented so the narrow end

seats against the head of the screw. Slip one of the black

1/4" washers over the end of the screw. Now, thread the

screw into the hole in the base side panel just below the

cradle. The screw will thread into the preinstalled insert in

a.

b.

Figure 8. (a) To attach the spring to the base, grip the pull loop

with your index finger and pull down on the spring. (b) While pulling

down, slip the end ring of the spring over the bolt head and onto the

narrow part of the nylon spacer, then release the pull loop.

the hole. Use a Phillips screwdriver to tighten the screw.

Repeat this procedure on the opposite side panel.

2. Next, insert one of the screws with a round plastic knob

attached through the end ring of one of the springs. Slip

a black nylon spacer onto the screw. Orient the spacer so

the narrow end is closest to the knob. Thread the entire

assembly into the hole in the center of the telescope’s

altitude side bearing until tight. The end ring of the spring

should seat onto the narrow end of the spacer. Repeat this

procedure for the other altitude side bearing.

3 Attach a pull loop to the free end of each spring. Slide the loop

through the opening in the ring on the end of the spring.

4. Now, pull each spring down using the pull loop, and position the spring’s end ring over the head of the Phillips

screw (installed in Step 1) and onto the narrow part of the

nylon spacer, as shown in Figure 8b. You needn’t attach

both springs simultaneously; one at a time is fine.

6

Page 7

2" eyepiece adapter

Altitude

Azimuth

Figure 9. The SkyQuest has two axes of motion: altitude (up/

down) and azimuth (left/right).

The CorrecTension system is now installed and engaged.

If you wish to remove the telescope from the base, you will

first need to disconnect the springs from the “posts” on the

Dobsonian base. The springs will remain captive on the altitude side bearings, so they will not get lost.

Inserting an Eyepiece

The final step in the assembly process is to insert an eyepiece

into the telescope’s focuser. Take the cover cap off the end of

the focuser drawtube.

For the XT6: Loosen the two thumbscrews on the eyepiece

holder and insert the eyepiece. Then secure it in place with the

thumbscrews.

For the XT8 and XT10: There are three thumbscrews on

the focuser, one holds the eyepiece, and two hold the 1.25"

adapter. To insert the eyepiece, loosen the thumbscrew that is

on the 1.25" adapter itself (it will be highest up on the focuser).

Insert the eyepiece into the adapter and secure it by tightening the thumbscrew.

The assembly of your SkyQuest Dobsonian is now complete.

It should appear as in Figure 1. The dust cover on the front of

the telescope should always remain in place when the telescope is not in use. It is also a good idea to store eyepieces in

an eyepiece case and to replace the cover cap on the focuser

when the telescope is idle.

3. Using Your Telescope

It is best to get a feel for the basic functions of the SkyQuest

Dobsonian during the day, before observing astronomical

objects at night. This way you will not have to fumble around

Focus knobs

Tension adjustment screw

Figure 10. The 2" Crayford focuser (XT8 and XT10)

trying to orient yourself in the dark! Find a spot outdoors

where you have plenty of room to move around the telescope,

and where you have a clear view of some object or vista that is

at least 1/4-mile away. It is not critical that the base be exactly

level, but it should be placed on somewhat flat ground or pavement to ensure smooth movement of the telescope.

1.25" eyepiece

adapter

Focus lock

thumbscrew

Remember, never point the telescope at or near the

Sun without using a proper solar filter over the front

aperture!

Altitude and Azimuth

The Dobsonian base of the SkyQuest permits motion of the

telescope along two axes: altitude (up/down) and azimuth

(left/right) (Figure 9). This is very convenient, since up/down

and left/right are the most “natural” ways that people aim. As a

result, pointing the telescope is exceptionally easy.

Simply take hold of the end of the tube and move it left or

right so the base rotates about its central azimuth bolt, and

move it up or down so the altitude side bearings rotate in the

base’s cradle. Both motions can be made simultaneously and

in a continuous manner for easy aiming. Move the telescope

gently—let it glide. In this way you can point the telescope to

any position in the night sky, from horizon to horizon.

Focusing the Telescope

Insert the 25mm eyepiece into the focuser and secure with the

thumbscrew(s). Move the telescope so the front (open) end is

pointing in the general direction of an object at least 1/4-mile

away. Now, with your fingers, slowly rotate one of the focusing

knobs until the object comes into sharp focus. Go a little bit

beyond sharp focus until the image just starts to blur again,

then reverse the rotation of the knob, just to make sure you’ve

hit the exact focus point.

If you have trouble focusing, rotate the focusing knob so the

drawtube is in as far as it will go. Now look through the eyepiece while slowly rotating the focusing knob in the opposite

direction. You should soon see the point at which focus is

reached.

The 2" Crayford focuser of the XT8 and XT10 models features

a thumb screw on the bottom of the focuser body (Figure 10)

7

Page 8

Naked-eye view

View through and telescope

Figure 11. The view through a reflector telescope is upside

down.

which will lock the focuser drawtube in place once the telescope is properly focused.

If you find the drawtube tension when focusing is either too

tight (focus knob is difficult to turn) or too loose (image shifts

when focusing or drawtube moves inward by itself), the tension can be adjusted for optimal performance. On the XT8 &

XT10, the focusing tension adjustment set screw is a 3mm

socket head set screw located below the focus lock thumb

screw (Figure 10). A 3mm hex key is required for adjustment

of focus tension. Due to the rack-and-pinion focuser design on

the XT6, tension adjustment should not normally be needed

as it has been pre-adjusted at the factory.

Note: The image in the main telescope will appear upsidedown (rotated 180°). This is normal for reflector telescopes.

(see Figure 11)

Aligning the EZ Finder II

When the EZ Finder II is properly aligned with the telescope,

an object that is centered on the EZ Finder II’s red dot should

also appear in the center of the field of view of the telescope’s

eyepiece. Alignment of the EZ Finder II is easiest during daylight, before observing at night. Aim the telescope at a distant

object such as a telephone pole or roof chimney and center it

in the telescope’s eyepiece. The object should be at least 1/4

mile away. Now, with the EZ Finder II turned on, look though

the EZ Finder II. The object should appear in the field of view.

Without moving the main telescope, use the EZ Finder II’s azimuth (left/right) and altitude (up/down) adjustment knobs (see

Figure 6) to position the red dot on the object in the eyepiece.

When the red dot is centered on the distant object, check to

make sure that the object is still centered in the telescope’s

field of view. If not, recenter it and adjust the EZ Finder II’s

alignment again. When the object is centered in the eyepiece

and on the EZ Finder’s red dot, the EZ Finder II is properly

aligned with the telescope.

Once aligned, EZ Finder II will usually hold its alignment even

after being removed and remounted. Otherwise, only minimal

realignment will be needed.

Replacing the Battery

Should the battery ever die, replacement 3-volt lithium batteries are available from many retail outlets. Remove the old

battery by inserting a small flat-head screwdriver into the slot

on the battery casing (Figure 6) and gently prying open the

case. Then carefully pull back on the retaining clip and remove

the old battery. Do not overbend the retaining clip. Then slide

the new battery under the battery lead with the positive (+)

end facing down and replace the battery casing.

Aiming/Pointing the Telescope

Now that the EZ Finder II is aligned, the telescope can be

quickly and accurately pointed at anything you wish to

observe. The EZ Finder II has a much wider field of view than

the telescope’s eyepiece, and therefore it is much easier to

first center an object in the EZ Finder II. Then, if the EZ Finder

II is accurately aligned, the object will also be centered in the

telescope’s field of view.

Start by once again moving the telescope until it is pointed

in the general direction of the object you want to see. Some

observers find it convenient to sight along the tube to do this.

Now, look in the EZ Finder II. If your general aim is accurate,

the object should appear somewhere in the EZ Finder II. Make

small adjustments to the telescope’s position until the object

is centered on the red dot of the EZ Finder. Now, look in the

telescope’s eyepiece and enjoy the view!

Magnification

Magnification of the telescope can be changed by using

additional eyepieces (optional). To switch eyepieces, simply

loosen the thumbscrew(s) on the focuser drawtube and lift the

eyepiece out of the focuser. Insert your new eyepiece in the

focuser and tighten the thumbscrews. If you are careful not to

bump the telescope your object should remain in the field of

view. With higher powers notice that the object veing viewed is

now larger, but somewhat dimmer.

The SkyQuest is designed to accept any eyepiece with a barrel diameter of 1.25". The XT8 and XT10 can also accept 2"

eyepieces. Magnification, or power, is determined by the focal

length of the telescope and the focal length of the eyepiece.

Therefore, by using eyepieces of different focal lengths, the

resultant magnification can be varied.

Magnification is calculated as follows:

Magnification=

Telescope Focal Length (mm)

Eyepiece Focal Length (mm)

The 6", 8" and 10" SkyQuest Dobsonians all have a focal length

of 1200mm. So, the magnification with the supplied 25mm eyepiece is:

1200mm

25mm

= 48x

The maximum attainable magnification for a telescope is directly

related to how much light its optics can collect. A telescope with

8

Page 9

a.

b.

c.

Figure 12. Picking up and carrying

the SkyQuest as a single unit (with

tube held captive on the base) requires

some caution. (a) First, position the tube

vertically. Then, grasp the handle on the

base with one hand while supporting the

tube with the other. (b) With knees bent,

slowly lift the base while supporting the

tube with one hand. This ensures that

the tube will not swing down and impact

the ground. (c) As you lift, the whole

assembly will tilt down, becoming nearly

parallel with the ground, at which time you

can let go of the tube with your supporting

hand. Make sure you are comfortable with

the weight of the whole assembly before

attempting to carry it!

more light-collecting area, or aperture, can yield higher magnifications than a smaller aperture telescope. The maximum

practical magnification for any telescope, regardless of optical

design, is about 60x per inch of aperture. This translates to about

360x for the SkyQuest XT6 and 480x for the XT8.

Keep in mind that as magnification is increased, the brightness

of the object being viewed will decrease; this is an inherent

principle of the physics of optics and cannot be avoided. If

magnification is doubled, an image appears four times dimmer. If magnification is tripled, image brightness is reduced by

a factor of nine!

Note About High Magnifications:

Maximum magnifications are achieved only under the most

ideal viewing conditions at the best observing sites. Most of the

time, magnifications are limited to 200x or less, regardless of

aperture. This is because the Earth’s atmosphere distorts light

as it passes through. On nights of good “seeing,” the atmosphere will be still and will yield the least amount of distortion.

On nights of poor seeing, the atmosphere will be turbulent,

which means different densities of air are rapidly mixing. This

causes significant distortion of the incoming light, which prevents sharp views at high magnifications.

Tube Balance

Dobsonians are designed to balance with standard supplied

accessories, such as an eyepiece and EZ Finder II. But what

if you want to use a larger finder scope or a heavier eyepiece?

The telescope will no longer be properly balanced, and will not

hold its position properly. This makes the telescope difficult to

use, since it is critical that it hold its position (when not purposefully moved) to keep objects centered in the field of vision.

Traditional Dobsonian designs expect the user to compensate for heavier accessories by adding weight to the opposite

end of the telescope tube. Such counterweighting systems

can be expensive and unwieldy. The CorrecTension Friction

Optimization system of the SkyQuest Dobsonians, however,

solves the finicky balance problem. The spring coils pull the

tube down onto the base, thereby increasing the friction on the

altitude bearing pads. With CorrecTension, the added weight

of small front-end loads will not adversely affect the balance of

the telescope.

If you install an array of heavier accessories onto your SkyQuest’s optical tube, you may need at

some point to counterbalance the telescope with a counterweight system.

Carrying the Telescope

Moving the SkyQuest is easy to do. Because the springs of the

CorrecTension system hold the optical tube captive on the base,

the entire telescope can be carried as one unit (6" and 8" models

only). This requires some caution, however. If the telescope is

lifted improperly, the front of the tube could swing down and hit

the ground.

First, point the optical tube straight up (vertical). Remove any

eyepieces from the telescope and optional eyepiece rack, and

place them in an eyepiece case. Grasp the handle on the front

of the base with one hand while supporting the telescope tube

vertically with the other (see Figure 12). Now, lift the telescope

from the handle. Once the telescope is in the horizontal position, you can carry the entire unit with one hand. The handle

position properly balances the load for easy carrying.

If you wish to carry the optical tube and base separately, simply disengage the CorrecTension springs by unhooking them

from the posts on the base, using the pull loops. The springs

remain captive on the telescope side bearings. Now the base

and tube are disengaged and can be transported separately.

Note: The SkyQuest may be too heavy for some users to

lift and carry as one unit. Do not strain yourself! If the load

seems too heavy, disengage the springs and carry the

base and tube separately.

When putting the SkyQuest into a vehicle, common sense prevails. It is especially important that the optical tube does not

knock around; this can cause the optics to become misaligned,

and could dent the tube. We recommend transporting and storing the tube assembly in a padded case for proper protection.

4. Collimation

Collimation is the process of adjusting the mirrors so they are

correctly aligned with one another. Your telescope’s optics

were aligned at the factory, and should not need much adjustment unless the telescope is handled roughly. Accurate mirror

9

Page 10

drawtube

Reflection

of primary

mirror clip

b.

c.

a. d.

e.

Figure 13. Collimating the optics. (a) When the mirrors are properly aligned, the view down the focuser drawtube should look like this (b)

With the collimation cap in place, if the optics are out of alignment, the view might look something like this. (c) Here, the secondary mirror is

centered under the focuser, but it needs to be adjusted (tilted) so that the entire primary mirror is visible. (d) The secondary mirror is correctly

aligned, but the primary mirror still needs adjustment. When the primary mirror is correctly aligned, the “dot” will be centered, as in (e).

alignment is important to ensure the peak performance of your

telescope, so it should be checked regularly. Collimation is relatively easy to do and can be done in daylight.

To check collimation, remove the eyepiece and look down the

focuser drawtube. You should see the secondary mirror centered

in the drawtube, as well as the reflection of the primary mirror centered in the secondary mirror, and the reflection of the secondary

mirror (and your eye) centered in the reflection of the primary mirror, as in Figure 13a. If anything is off-center, as in Figure 13b,

proceed with the following collimation procedure.

adversely affects the optical performance of the telescope

or the image quality. That might seem counterintuitive, but

it’s true!

Aligning the Secondary Mirror

With the collimation cap in place, look through the hole in the

cap at the secondary (diagonal) mirror. Ignore the reflections

for the time being. The secondary mirror itself should be centered in the focuser drawtube, in the direction parallel to the

length of the telescope. If it isn’t, as in Figure 13b, it must be

adjusted. This adjustment will rarely, if ever, need to be done. It

The Collimation Cap and Mirror Center Mark

Your SkyQuest XT comes with a collimation cap. This is a simple cap that fits on the focuser drawtube like a dust cap, but has

a hole in the center and a silver bottom. This helps center your

eye so that collimation is easy to perform. Figures 13a through

13e assume you have the collimation cap in place.

In addition to providing the collimation cap, you’ll notice a tiny

ring (sticker) in the exact center of the primary mirror. This

“center mark” allows you to achieve a very precise collimation of the primary mirror; you don’t have to guess where the

center of the mirror is. You simply adjust the mirror position

(described below) until the reflection of the hole in the collimation cap is centered inside the ring. This center mark is also

required for best results with other collimating devices, such

as Orion’s LaserMate Laser Collimator, obviating the need to

remove the primary mirror and mark it yourself.

Note: The center ring sticker need not ever be removed

from the primary mirror. Because it lies directly in the

shadow of the secondary mirror, its presence in no way

helps to adjust the secondary mirror in a brightly lit room with

the telescope pointed toward a bright surface, such as white

paper or wall. Placing a piece of white paper in the telescope

tube opposite the focuser (i.e., on the other side of the secondary mirror) will also be helpful in collimating the secondary

mirror. Using a 2mm hex key, loosen the three small alignment

set screws in the center hub of the 4-vaned spider several

turns. Now hold the mirror holder stationary (be careful not

to touch the surface of the mirrors), while turning the center

screw with a Phillips head screwdriver (see Figure 14). Turning

the screw clockwise will move the secondary mirror toward

the front opening of the optical tube, while turning the screw

counter-clockwise will move the secondary mirror toward the

primary mirror.

Note: When making these adjustments, be careful not to

stress the spider vanes or they may bend.

When the secondary mirror is centered in the focuser drawtube, rotate the secondary mirror holder until the reflection of

the primary mirror is as centered in the secondary mirror as

10

Page 11

Figure 14. To center the secondary mirror under the focuser,

hold the secondary mirror holder in place with one hand while

adjusting the center bolt with a Phillips screwdriver. Do not touch the

mirror’s surface!

Figure 16. The three small thumbscrews that lock the primary

mirror in place must first be loosened before any adjustments can be

made.

Figure 15. Adjust the tilt of the secondary mirror by loosening or

tightening the three alignment set screws with a 2mm hex key.

possible. It may not be perfectly centered, but that is OK. Now

tighten the three small alignment screws equally to secure the

secondary mirror in that position. If the entire primary mirror

reflection is not visible in the secondary mirror, as in Figure

13c, you will need to adjust the tilt of the secondary mirror.

This is done by alternately loosening one of the three alignment setscrews while tightening the other two, as depicted in

Figure 15. The goal is to center the primary mirror reflection

in the secondary mirror, as in Figure 13d. Don’t worry that the

reflection of the secondary mirror (the smallest circle, with the

collimation cap “dot” in the center) is off-center. You will fix that

in the next step.

Adjusting the Primary Mirror

The final adjustment is made to the primary mirror. It will need

adjustment if, as in Figure 13d, the secondary mirror is centered under the focuser and the reflection of the primary mirror

is centered in the secondary mirror, but the small reflection of

the secondary mirror (with the “dot” of the collimation cap) is

off-center.

The tilt of the primary mirror is adjusted with three springloaded collimation thumbscrews on the back end of the optical

tube (bottom of the primary mirror cell); these are the larger

Figure 17. The tilt of the primary mirror is adjusted by turning

one or more of the three larger thumbscrews.

thumbscrews. The other three smaller thumbscrews lock the

mirror’s position in place; these thumbscrews must be loosened before any collimation adjustments can be made to the

primary mirror.

To start, turn the smaller thumbscrews a few turns each

(Figure 14). Use a screwdriver in the slots, if necessary.

Now, try tightening or loosening one of the larger collimation thumbscrews with your fingers (Figure 17). Look into the

focuser and see if the secondary mirror reflection has moved

closer to the center of the primary. You can tell this easily with

the collimation cap and mirror center mark by simply watching

to see if the “dot” of the collimation cap is moving closer or

farther away from the ring on the center of the primary mirror. When you have the dot centered as much as possible in

the ring, your primary mirror is collimated. The view through

the collimation cap should resemble Figure 13e. Retighten the

locking thumbscrews.

A simple star test will tell you whether the optics are accurately

collimated.

Star-Testing the Telescope

When it is dark, point the telescope at a bright star and accurately center it in the eyepiece’s field of view. Slowly de-focus

11

Page 12

Figure 18. A star test will determine if a telescope’s optics are

Out of collimation Collimated

properly collimated. An unfocused view of a bright star through

the eyepiece should appear as illustrated on the right if the optics

are perfectly collimated. If the circle is unsymmetrical, as in the

illustration on the left, the scope needs collimation.

the image with the focusing knob. If the telescope is correctly

collimated, the expanding disk should be a perfect circle

(Figure 18). If the image is unsymmetrical, the scope is out

of collimation. The dark shadow cast by the secondary mirror

should appear in the very center of the out-of-focus circle, like

the hole in a donut. If the “hole” appears off-center, the telescope is out of collimation.

If you try the star test and the bright star you have selected is

not accurately centered in the eyepiece, the optics will always

appear out of collimation, even though they may be perfectly

aligned. It is critical to keep the star centered, so over time you

will need to make slight corrections to the telescope’s position

in order to account for the sky’s apparent motion.

Note About the Collimatable 2" Focuser

(XT8 and XT10)

The 2" focuser of the SkyQuest XT8 can be collimated using

three pairs of push-pull screws located at the base of the

focuser. The focuser was collimated at the factory however,

and should never need to be adjusted. Focuser collimation is

only required under very rare circumstances, but has been

made available for this telescope should such a need arise.

5. Astronomical Observing

For many users, the SkyQuest XT telescope will be a major

leap into the world of amateur astronomy. This section is

intended to get you ready for your first voyage through the

night sky.

Site Selection

Pick a location away from streetlights and bright yard lighting.

Avoid viewing over rooftops and chimneys, as they often have

warm air currents rising from them, which distort the image

seen in the eyepiece.

Similarly, you should not observe through an open window

from indoors. Better yet, choose a site out-of-town, away from

any “light pollution”. You’ll be stunned at how many more stars

you’ll see! Most importantly, make sure that any chosen site

has a clear view of a large portion of the sky.

Cooling the Telescope

All optical instruments need time to reach “thermal equilibrium”

to achieve maximum stability of the lenses and mirrors, which

is essential for peak performance. When moved from a warm

indoor location to cooler air outside(or vice-versa), a telescope

needs time to cool (or warm) to the outdoor temperature. The

bigger the instrument and the larger the temperature change,

the more time will be needed.

Allow at least 30 minutes for your SkyQuest XT to equilibrate.

If the scope experiences more than a 40° temperature change,

allow an hour or more. In the winter, storing the telescope in a

shed or garage greatly reduces the amount of time needed for

the optics to stabilize. It also is a good idea to keep the scope

covered until the Sun sets so the tube does not heat greatly

above the temperature of the outside air.

The XT8 and XT10 have the ability to mount a small fan to

make cooling the tube faster. On the bottom of the mirror cell

there are four holes where a fan can be screwed on.

Seeing and Transparency

Atmospheric conditions play a huge part in quality of viewing.

In conditions of good “seeing,” star twinkling is minimal and

objects appear steady in the eyepiece. Seeing is best overhead, worst at the horizon. Also, seeing generally gets better

after midnight, when much of the heat absorbed by the Earth

during the day has radiated off into space. Typically, seeing

conditions will be better at sites that have an altitude over about

3000 feet. Altitude helps because it decreases the amount of

distortion-causing atmosphere you are looking through.

A good way to judge if the seeing is good or not is to look at

bright stars about 40° above the horizon. If the stars appear to

“twinkle,” the atmosphere is significantly distorting the incoming light, and views at high magnifications will not appear

sharp. If the stars appear steady and do not twinkle, seeing

conditions are probably good and higher magnifications will

be possible. Also, seeing conditions are typically poor during

the day. This is because the heat from the Sun warms the air

and causes turbulence.

Good “transparency” is especially important for observing faint

objects. It simply means the air is free of moisture, smoke,

and dust. All tend to scatter light, which reduces an object’s

brightness.

One good way to tell if conditions are good is by how many

stars you can see with your naked eye. If you cannot see

stars of magnitude 3.5 or dimmer then conditions are poor.

Magnitude is a measure of how bright a star is, the brighter a

star is, the lower its magnitude will be. A good star to remember for this is Megrez (mag. 3.4), which is the star in the Big

Dipper connecting the handle to the “dipper.” If you cannot see

Megrez, then you have fog, haze, clouds, smog, light pollution, or other conditions that are hindering your viewing. (See

Figure 19)

Let Your Eyes Dark-Adapt

Do not expect to go from a lighted house into the darkness

of the outdoors at night and immediately see faint nebulas,

galaxies, and star clusters — or even very many stars, for that

12

Page 13

1.9

1.9

1.7

4.9

2.4

3.4

2.5

2.4

Figure 19. Megrez connects the Big Dipper’s handle to it's “pan”.

It is a good guide to how conditions are. If you can not see Megrez

(a 3.4 mag star) then conditions are poor.

matter. Your eyes take about 30 minutes to reach perhaps 80%

of their full dark-adapted sensitivity. Many observers notice

improvements after several hours of total darkness. As your

eyes become dark-adapted, more stars will glimmer into view

and you will be able to see fainter details in objects you view

in your telescope. So give yourself at least a little while to get

used to the dark before you begin observing.

To see what you are doing in the darkness, use a red light

flashlight rather than a white light. Red light does not spoil

your eyes’ dark adaptation like white light does. A flashlight

with a red LED light is ideal, or you can cover the front of a

regular flashlight with red cellophane or paper. Beware, too,

that nearby porch and streetlights and automobile headlights

will spoil your night vision.

Tracking Celestial Objects

The Earth is constantly rotating about its polar axis, completing one full rotation every 24 hours; this is what defines a “day.”

We do not feel the Earth rotating, but we can tell that it is at

night by seeing the apparent movement of stars from east to

west. This movement translates into a rate of approximately

.25° per minute, or 15 arc-seconds per second. (There are 60

arc-minutes in 1°, and 60 arc-seconds in one arc-minute.) This

is called the sidereal rate.

When you observe any astronomical object, you are watching

a moving target. This means the telescope’s position must be

continuously updated over time to keep an object in the field

of view. This is easy to do with the SkyQuest XT because of its

smooth motions on both axes. As the object moves off toward

the edge of the field of view, you just lightly nudge the telescope to bring it back to the center.

You will notice that it is more difficult to “track” objects when

the telescope tube is aimed nearly straight up. This is inherent

to the basic design of the Dobsonian, and stems from the fact

that there is very little mechanical leverage to move in azimuth

when the tube is in a near vertical position. To gain more leverage, try grasping the tube close to the altitude side bearings

with both hands.

Remember that objects appear to move across the field of

view faster at higher magnifications. This is because the field

of view becomes narrower.

Eyepiece Selection

By using eyepieces of varying focal lengths, it is possible to

attain many magnifications with the SkyQuest XT. The telescope comes with one high-quality Sirius Plössl eyepiece: a

25mm, which gives a magnification of 48x. Other eyepieces

can be used to achieve higher or lower powers. It is quite common for an observer to own five or more eyepieces to access

a wide range of magnifications. This allows the observer to

choose the best eyepiece to use depending on the object

being viewed.

Whatever you choose to view, always start by inserting your

lowest-power (longest focal length) eyepiece to locate and

center the object. Low magnification yields a wide field of view,

which shows a larger area of sky in the eyepiece. This makes

acquiring and centering an object much easier. If you try to

find and center objects with high power (narrow field of view),

it’s like trying to find a needle in a haystack!

Once you’ve centered the object in the eyepiece, you can

switch to higher magnification (shorter focal length eyepiece),

if you wish. This is especially recommended for small and

bright objects, like planets and double stars. The Moon also

takes higher magnifications well.

Deep-sky objects, however, typically look better at medium or

low magnifications. This is because many of them are quite

faint, yet have some extent (apparent width). Deep-sky objects

will often disappear at higher magnifications, since greater

magnification inherently yields dimmer images. This is not

the case for all deep-sky objects, however. Many galaxies are

quite small, yet are somewhat bright, so higher power may

show more detail.

The best rule of thumb with eyepiece selection is to start with a

low power, wide field, and then work your way up in magnification. If the object looks better, try an even higher magnification.

If the object looks worse, then back off the magnification a

little by using a lower-power eyepiece.

Using 2" Eyepieces (XT8 and XT10)

The SkyQuest XT8 and XT10 Crayford focusers are capable

of accepting optional 2" eyepieces. To use 2" eyepieces you

must remove the 1.25" adapter from the focuser by turning

the two thumbscrews that hold it in place. Once this adapter

is removed, inser t a 2” eyepiece directly into the eyepiece

holder and use the same thumbscrews to secure the larger

eyepiece.

2" eyepieces are desirable because they provide a wider field of

view than 1.25" eyepiece. Many observers own at least one 2"

eyepiece to yield the largest field of view possible for looking at

wide deep-sky objects, such as open star clusters or gaseous

nebulae. You’ll be stunned at the large fields of view that 2" eyepieces deliver. You’ll feel like you’re floating in space!

Now that you are all set up and ready to go, one critical

decision must be made: what to look at?

A. The Moon

With is rocky and cratered surface, the Moon is one of the

most interesting and easy subjects to view with your scope.

The best time to view it is during its partial phases when

13

Page 14

shadows fall on the craters and canyon walls to give them definition. While the full moon may look like a tempting target, it

is not optimal for viewing! The light is too bright and surface

definition is low.

Even at partial phases the Moon is very bright. Use of an

optional Moon filter to helps to dim the glare. It simply threads

onto the bottom of the eyepiece. You’ll find the Moon filter

improves viewing comfort, and helps bring out the subtle features of the lunar surface.

B. The Sun

You can change your nighttime telescope into a daytime Sun

viewer by installing an optional full-aperture solar filter over the

front opening of the telescope. The primary attraction is sunspots, which change shape, appearance, and location daily.

Sunspots are directly related to magnetic activity in the Sun.

Many observers like to make drawings of sunspots to monitor

how the Sun is changing from day to day.

Important Note: Do not look at the Sun with any optical

instrument without a professionally made solar filter, or

permanent eye damage could result. Also, be sure to cover

the finder scope, or better yet, remove it altogether.

C. The Planets

The planets don’t stay put like the stars, so to find them you

should refer to the Learning Center at our website telescope.

com and choose “In the Sky”, or to charts published monthly in

Astronomy, Sky & Telescope, or other astronomy magazines.

Venus, Mars, Jupiter, and Saturn are the brightest objects

in the sky after the Sun and the Moon. Your SkyQuest XT is

capable of showing you these planets in some detail. Other

planets may be visible but will likely appear starlike. Because

planets are quite small in apparent size, optional higher power

eyepieces are recommended and often needed for detailed

observations. Not all the planets are generally visible at any

one time.

JUPITER The largest planet, Jupiter, is a great subject for

observation. You can see the disk of the giant planet and

watch the ever-changing positions of its four largest moon:

Io, Callisto, Europa, and Ganymede. Higher power eyepieces

should bring out the cloud bands on the planet’s disk and the

Great Red Spot.

SATURN The ringed planet is a breathtaking sight. The tilt

angle of the rings varies over a period of many years; sometimes they are seen edge-on, while at other times they are

broadside and look like giant “ears” on each side of Saturn’s

disk. A steady atmosphere (good seeing) is necessary for a

good view. Look closely and you should see the Cassini division, a thin, dark gap in the rings. You should also see one or

more of Saturn’s moons, which look like faint stars. The brightest is the moon Titan.

VENUS At its brightest, Venus is the most luminous object in

the sky, excluding the Sun and the Moon. It is so bright that

sometimes it is visible to the naked eye during full daylight!

Ironically, Venus appears as a thin crescent, not a full disk,

when at its peak brightness. Because it is so close to the Sun,

it never wanders too far from the morning or evening horizon.

No surface markings can be seen on Venus, which is always

shrouded in dense clouds.

MARS The Red Planet makes a close approach to Earth

every two years. Observing Mars is most favorable at these

times. You should see salmon-colored disk with some distinct

dark patches, and you may be able to spot a whitish polar ice

cap. To see surface detail on Mars, you will need a high power

eyepiece and very steady air!

D. The Stars

Stars will appear as tiny points of light. Even powerful telescopes cannot magnify stars to appear as anything more than

pinpoints. You can, however, enjoy the different colors of the

stars and locate many pretty double and multiple stars. The

famous “Double-Double” in the constellation Lyra and the gorgeous two-color double star Albireo in Cygnus are favorites.

Defocusing a star slightly can help bring out its color.

E. Deep-Sky Objects

Under dark skies, you can observe a wealth of fascinating

deep-sky objects; that is, objects that reside outside of our

solar system. These include gaseous nebulas, open and

globular star clusters, and a variety of different types of galaxies. The large apertures of SkyQuest XT Dobsonians are

particularly well suited to gathering light, which is critical for

observing these usually faint celestial entities. For deep-sky

observing it is important that you find an observing site well

away from light pollution. Take plenty of time to let your eyes

adjust to the darkness. As you become more experienced and

your observing skills get sharper, you will be able to ferret out

more and more subtle details and structure from these fascinating objects. Do not expect to see color in deep-sky objects,

however, as human eyes are not sensitive to color from faint

light.

How to Find Deep-sky Objects: Starhopping

Starhopping, as it is called by astronomers, is perhaps the

simplest way to hunt down objects to view in the night sky. It

entails first pointing the telescope at a star close to the object

you wish to obser ve, and then progressing to other stars

closer and closer to the object until it is in the field of view

of the eyepiece. It is a very intuitive technique that has been

employed for hundreds of years by professional and amateur

astronomers alike. Keep in mind, as with any new task, that

starhopping may seem challenging at first, but will become

easier over time and with practice.

To starhop, only a minimal amount of additional equipment is

necessary. A star chart or atlas that shows stars to at least

magnitude 5 is required. Select one that shows the positions

of many deep-sky objects, so you will have a lot of options to

choose from. If you do not know the positions of the constellations in the night sky, you will need to get a planisphere to

identify them.

Start by choosing bright objects to view. The brightness of

an object is measured by its visual magnitude; the brighter

an object, the lower its magnitude. Choose an object with a

visual magnitude of 9 or lower. Many beginners start with the

Messier objects, which represent some of the best and bright-

14

Page 15

Figure 20. Starhopping is a good way to locate hard-to-find

objects. Refer to a star chart to map a route to the object that uses

bright stars as guideposts. Center the first star you’ve chosen

in the EZ Finder II and telescope eyepiece (1). Now move the

scope carefully in the direction of the next bright star (2), until it is

centered. Repeat (3&4). The last hop (5) should place the desired

object in the eyepiece.

est deep-sky objects, first catalogued about 200 years ago by

the French astronomer Charles Messier.

Determine in which constellation the object lies. Now, find the

constellation in the sky. If you do not recognize the constellation on sight, consult a planisphere. The planisphere gives an

all-sky view and shows which constellations are visible on a

given night at a given time.

Now look at your star chart and find the brightest star in the

constellation that is near the object that you are trying to find.

Using the EZ Finder II, point the telescope at this star and

center it on the red dot. Next, look again at the star chart and

find another suitably bright star near the bright star currently

centered in the finder. Keep in mind that the field of view of

the EZ Finder II is 10°, so you should choose a star that is no

more than 10° from the first star, if possible. Move the telescope slightly, until the telescope is centered on the new star.

Continue using stars as guideposts in this way until you are

the approximate position of the object you are trying to find

(Figure 20). Look in the telescope’s eyepiece, and the object

should be somewhere within the field of view. If it’s not, sweep

the telescope carefully around the immediate vicinity until the

object is found.

If you have trouble finding the object, start the starhop again

from the brightest star near the object you wish to view. This

time, be sure the stars indicated on the star chart are in fact

the stars you are centering in the EZ Finder II and telescope

eyepiece. Remember the telescope and the EZ Finder II will

give you inverted images, keep this in mind when you are starhopping from star to star.

Note About Astrophotography

SkyQuest Dobsonians are designed for visual, not photographic use. The Dobsonian mount is not an equatorial-type

mount, so it cannot be motor driven for long exposure astrophotography. SkyQuests have also been optically optimized

for visual use, since photographic optimization degrades visual performance.

With that in mind, however, it is possible to do some simple

astrophotography with a SkyQuest. With the use of afocal photography techniques (where the camera is simply placed to

the eyepiece to take a picture) and digital cameras, it is possible to take pictures of bright objects. Certain photographic

aids, such as the Orion SteadyPix, can help in taking photos

by the afocal method.

6. Care and Maintenance

If you give your telescope reasonable care, it will last a lifetime.

Store it in a clean, dry, dust free place, safe from rapid changes in temperature and humidity. Do not store the telescope

outdoors, although storage in a garage or shed is OK. Small

components like eyepieces and other accessories should be

kept in a protective box or storage case. Keep the caps on the

front of the scope and on the focuser when it is not in use. For

maximum protection during storage, we recommend placing

the telescope in a case to prevent any dust and moisture from

accumulating on exposed surfaces.

The telescope requires very little mechanical maintenance.

The optical tube is made of steel and has a smooth painted

finish that is fairly scratch-resistant. If a scratch does appear

on the tube, it will not harm the telescope. If you wish, you may

apply some auto touch-up paint to the scratch. Smudges on

the tube can be wiped off with a soft cloth and a household

cleaner.

Cleaning Lenses

Any quality optical lens cleaning tissue and optical lens cleaning fluid specifically designed for multi-coated optics can be

used to clean the exposed lenses of your eyepieces. Never use

regular glass cleaner or cleaning fluid designed for eyeglasses

Before cleaning with fluid and tissue, blow any loose particles

off the lens with a blower bulb or compressed air. Then apply

some cleaning fluid to a tissue, never directly on the optics.

Wipe the lens gently in a circular motion, then remove any

excess fluid with a fresh lens tissue. Oily fingerprints and

smudges may be removed using this method. Use caution;

rubbing too hard may scratch the lens. On larger lenses, clean

only a small area at a time, using a fresh lens tissue on each

area. Never reuse tissues.

Cleaning Mirrors

You should not have to clean the telescope’s mirrors very often;

normally once every year or so. Covering the telescope with

the dust cover when it is not in use will help prevent dust from

accumulating on the mirrors. Improper cleaning can scratch

mirror coatings, so the fewer times you have to clean the mir-

15

Page 16

rors, the better. Small specks of dust or flecks of paint have

virtually no effect on the visual performance of the telescope.

The large primary mirror and the elliptical secondary mirror of

your telescope are front-surface aluminized and overcoated

with hard silicon dioxide, which prevents the aluminum from

oxidizing. These coatings normally last through many years of

use before requiring re-coating, which is easily done.

To clean the secondary mirror, it must be removed from the

telescope. Do this by holding the secondary mirror holder stationary with your fingers (don’t touch the mirror itself) while

unthreading the Phillips head screw in the center hub of the

4-vaned spider. Completely unthread the screw from the holder, and the holder will come loose in your fingers. Be careful

not to lose the spring on the Phillips head screw.

Handle the mirror and its holder carefully. You do not need to

remove the secondary mirror from its holder for cleaning. To

clean the secondary mirror, follow the procedure described

below for cleaning the primary mirror.

To clean the primary mirror, carefully remove the mirror cell

from the telescope. To do this, you must remove the screws

that connect the entire mirror cell to the steel tube. These

screws are located on the outer edge of the mirror cell.

Now, remove the mirror from the mirror cell by removing the

three mirror clips that secure the mirror in its cell. Use a Phillips

head screwdriver to unthread the mirror clip anchor screws.

Next, hold the mirror by its edge, and remove it from the mirror cell. Be careful not to touch the aluminized surface of the

mirror with your fingers. Set the mirror on a clean, soft towel.

Fill a clean sink, free of abrasive cleanser, with room-temperature water, a few drops of liquid dishwashing detergent, and

if possible, a capful of rubbing alcohol. Submerge the mirror

(aluminized face up) in the water and let it soak for several

minutes (or hours if it is a very dirty mirror). Wipe the mirror

underwater with clean cotton balls, using extremely light pressure and stroking in straight lines across the surface. Use one

ball for each wipe across the mirror. Then rinse the mirror

under a stream of lukewarm water. Any particles on the surface can be swabbed gently with a series of clean cotton balls,

each used just one time. Dry the mirror in a stream of air (a

“blower bulb” works great), or remove any stray drops of water

with the corner of a paper towel. Water will run off a clean surface. Dry the bottom and the edges with a towel (not the mirror

surface!). Cover the mirror surface with tissue, and leave the

entire assembly in a warm area until it is completely dry before

reassembling the telescope.

7. Specifications

SkyQuest XT 6"

Primary mirror

focal length: 1200mm, standard optical glass

Primary mirror diameter: 150mm

Focal Ratio: f/8.0

Focuser: Rack and pinion, accepts 1.25"

eyepieces

Optical tube material: Rolled steel

Eyepiece: 25mm Sirius Plössl, fully coated

with multi-coatings, 1.25" barrel

diameter

Magnification with

supplied eyepiece: 48x

Reflex Sight: EZ Finder II

Reflex Sight Bracket: Plastic bracket with dovetail base

Mirror coatings: Aluminum with SiO2 overcoat

Minor axis of

secondary mirror: 34.5mm

Optical tube weight: 13.5 lbs.

Base weight: 20.9 lbs.

Tube length: 45.5"

Tube outer diameter: 7.25"

SkyQuest XT 8"

Primary mirror

focal length: 1200mm, standard optical glass

Primary mirror diameter: 203mm

Focal Ratio: f/5.9

Focuser: Crayford, accepts 2" eyepieces

and 1.25" eyepieces with adapter

Optical tube material: Rolled steel

Eyepiece: 25mm Sirius Plössl, fully coated

with multi-coatings, 1.25" barrel

diameter

Magnification with

supplied eyepiece: 48x

Reflex Sight: EZ Finder II

Reflex Sight Bracket: Plastic bracket with dovetail base

Mirror coatings: Aluminum with SiO

Minor axis of

secondary mirror: 47.0mm

Optical tube weight: 20.3 lbs.

Base weight: 20.7 lbs.

Tube length: 46.5"

Tube outer diameter: 9.25"

overcoat

2

16

Page 17

SkyQuest XT 10"

Primary mirror

focal length: 1200mm

Primary mirror diameter: 254mm, BK7 optical glass

Focal Ratio: f/4.7

Focuser: Crayford, accepts 2" and 1.25"

eyepieces with included adapter,

collimatible

Optical tube material: Rolled steel

Eyepiece: 25mm Sirius Plössl, fully coated

with multi-coatings, 1.25" barrel

diameter

Magnification with

supplied eyepiece: 48x

Reflex Sight: EZ Finder II

Reflex Sight Bracket: Plastic bracket with dovetail base

Mirror coatings: Aluminum with SiO

overcoat

2

Minor axis of

secondary mirror: 63.0mm

Optical tube weight: 30.8 lbs.

Base weight: 22.6 lbs.

Tube length: 47.25"

Tube outer diameter: 12.0"

17

Page 18

One-Year Limited Warranty

This Orion SkyQuest XT telescope is warranted against defects in materials or workmanship for a period

of one year from the date of purchase. This warranty is for the benefit of the original retail purchaser only.

During this warranty period Orion Telescopes & Binoculars will repair or replace, at Orion’s option, any

warranted instrument that proves to be defective, provided it is returned postage paid to: Orion Warranty

Repair, 89 Hangar Way, Watsonville, CA 95076. If the product is not registered, proof of purchase (such

as a copy of the original invoice) is required.

This warranty does not apply if, in Orion’s judgment, the instrument has been abused, mishandled, or

modified, nor does it apply to normal wear and tear. This warranty gives you specific legal rights, and

you may also have other rights, which vary from state to state. For further warranty service information,

contact: Customer Service Department, Orion Telescopes & Binoculars, 89 Hangar Way, Watsonville, CA

95076; (800)-676-1343.

Orion Telescopes & Binoculars

89 Hangar Way, Watsonville, CA 95076

Customer Support Help Line (800)‑676‑1343 • Day or Evening

18

Loading...

Loading...