Orion D5000, WCC D2400, WestCoast Customs WCC-D5000, WestCoast Customs WCC-D2400 User Manual

Page 1

Warranty

LIMITED TWO YEAR CONSUMER WARRANTY:

Directed Electronics, Inc. promises to the original purchaser, to replace this product should it prove to be

defective in workmanship or material under normal use, for a period of two years from the date of

purchase from the dealer as indicated by the date code marking of the product PROVIDED the product

was installed by an authorized Directed dealer. During this two-year period, there will be no charge for this

replacement PROVIDED the unit is returned to Directed, shipping pre-paid. If the unit is installed by

anyone other than an authorized Directed dealer, the warranty period will be one year from the date of

purchase by the dealer as indicated by the date code marking of the product. This warranty is nontransferable and does not apply to any unit that has been modified or used in a manner contrary to its

intended purpose, and does not cover damage to the unit caused by installation or removal of the unit.

During this one-year period, there will be no charge for this replacement PROVIDED the unit is returned

to Directed, shipping pre-paid. This warranty is void if the product has been damaged by accident or

unreasonable use, neglect, improper service or other causes not arising out of defects in materials or

construction. Units which are found to be damaged by abuse resulting in thermally damaged voice coils

are not covered by this warranty but may be replaced at the absolute/sole discretion of Directed. ALL

WARRANTIES INCLUDING BUT NOT LIMITED TO EXPRESS WARRANTY, IMPLIED WARRANTY,

WARRANTY OF MERCHANTABILITY, FITNESS FOR PARTICULAR PURPOSE, AND WARRANTY OF NONINFRINGEMENT OF INTELLECTUAL PROPERTY ARE EXPRESSLY EXCLUDED TO THE MAXIMUM

EXTENT ALLOWED BY LAW, AND DIRECTED NEITHER ASSUMES NOR AUTHORIZES ANY PERSON TO

ASSUME FOR IT ANY LIABILITY IN CONNECTION WITH THE SALE OF THE PRODUCT. DIRECTED HAS

ABSOLUTELY NO LIABILITY FOR ANY AND ALL ACTS OF THIRD PARTIES INCLUDING ITS

AUTHORIZED DEALERS OR INSTALLERS. Unit must be returned to Directed, postage pre-paid, with bill

of sale or other dated proof of purchase bearing the following information: consumer's name, telephone

number, and address, authorized dealer's name and address, and product description. Note: This warranty

does not cover labor costs for the removal and reinstallation of the unit. IN ORDER FOR THIS

WARRANTY TO BE VALID, YOUR UNIT MUST BE SHIPPED WITH PROOF OF INSTALLATION BY AN

AUTHORIZED DIRECTED DEALER. ALL UNITS RECEIVED BY DIRECTED FOR WARRANTY REPAIR

WITHOUT PROOF OF DIRECTED DEALER INSTALLATION WILL BE COVERED BY THE LIMITED 1 YEAR

PARTS AND LABOR WARRANTY. Note: This warranty does not cover labor costs for the removal and

reinstallation of the unit. BY PURCHASING THIS PRODUCT, THE CONSUMER AGREES AND CONSENTS

THAT ALL DISPUTES BETWEEN THE CONSUMER AND DIRECTED SHALL BE RESOLVED IN

ACCORDANCE WITH CALIFORNIA LAWS IN SAN DIEGO COUNTY, CALIFORNIA.

© 2004 Directed Electronics, Inc. All rights reserved. G46000.05 12-04

CCllaassss DD mmoonnoo bblloocckk

aammpplliiffiieerrss

CCllaassss DD mmoonnoo bblloocckk

aammpplliiffiieerrss

Page 2

CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

What’s in the Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Practice Safe Sound™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Limited Two-Year Consumer Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Record Your Serial Number and Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

End Panel Layouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

CEA Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Amplifier Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Signal Input and Output Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Input Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Phase Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Auxiliary Output Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Internal Crossover Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Low-Pass Crossover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

High-Pass Crossover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Fine Tuning the Crossovers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Adjusting INTELLi Q . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Infinite Baffle Example High-Pass Set at 30Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Sealed Example High-Pass Set at 20Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Sealed Example High-Pass Set at 30Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Vented Example High-Pass Set at 30Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Remote Gain Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Amplifier Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Power Connections for the WCC-D2400 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Power Connections for the WCC-D5000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Speaker Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Bridging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Amplifier Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Choosing Mounting Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Passenger Compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Trunk Compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

General Precautions and Installation Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Tools of the Trade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Step By Step Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Set Up and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Testing the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Adjusting the Sound of the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Troubleshooting Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

1

©2004 Directed Electronics, Inc.

Page 3

INTRODUCTION

Thank you for your purchase of a West Coast Customs by Orion power amplifier. Each WCC

amplifier is designed to be the leader in its class offering the most power, advanced features, and extreme ease of use. In high-end sound systems or high SPL systems, WCC amplifiers will give you years of trouble-free performance.

● WCC-D2400 - 1200 Watt single-channel Class D amplifier with built-in fully vari-

able high-pass, low-pass, or band-pass crossover with INTELLi Q. Equipped with

optional remote gain, the D2400 is capable of one-channel operation with a maximum power of 1200 Watts into 1W.

● WCC-D5000 - 2500 Watt single-channel Class D amplifier with built-in fully vari-

able high-pass, low-pass, or band-pass crossover with INTELLi Q. Equipped with

optional remote gain, the D5000 is capable of one-channel operation with a maximum power of 2500 Watts into 1W.

The installation of all WCC components will determine the overall performance result.

Improper installation will not only limit the performance of your WCC system but also

potentially compromise the reliability of this amplifier. To ensure proper sonic results and

component reliability, please refer to your authorized dealer for installation assistance or

advice. If you decide to perform the installation yourself, be sure to read the entire manual before beginning the installation.

What’s in the Box

● (1) Amplifier

● (1) Spare fuse(s) (WCC-D2400 only)

● (1) Allen wrench 2.5mm

● (1) Allen wrench 3mm

● (4) #8 self-tapping black Phillips head pan head screws

● (1) Amplifier installation and operation manual

PRACTICE SAFE SOUND™

Continuous exposure to sound pressure levels over 100dB may cause permanent hearing

loss. High power automotive sound systems can generate sound pressure levels in excess of

130dB. When playing your system at high levels, please use hearing protection and avoid

long term exposure.

2

©2004 Directed Electronics, Inc.

Page 4

LIMITED TWO-YEAR CONSUMER WARRANTY

Directed Electronics, Inc. promises to the original purchaser, to replace this product should

it prove to be defective in workmanship or material under normal use, for a period of two

years from the date of purchase by the dealer as indicated by the date code marking of the

product PROVIDED the product was installed by an authorized Directed dealer. During this

two year period, there will be no charge for this replacement PROVIDED the unit is

returned to Directed, shipping pre-paid. If the unit was installed by anyone other than an

authorized Directed dealer, the warranty period will be 1 year from date of purchase by the

dealer as indicated by the date code marking of the product. During this 1 year period,

there will be no charge for this replacement PROVIDED the unit is returned to Directed,

shipping pre-paid. This warranty is non-transferable and does not apply to any unit that has

been modified or used in a manner contrary to its intended purpose, and does not cover

damage to the unit caused by installation or removal of the unit. This warranty is void if the

product has been damaged by accident or unreasonable use, neglect, improper service or

other causes not arising out of defects in materials or construction. ALL WARRANTIES

INCLUDING BUT NOT LIMITED TO EXPRESS WARRANTY, IMPLIED WARRANTY, WARRANTY OF MERCHANTABILITY, FITNESS FOR PARTICULAR PURPOSE, AND WARRANTY

OF NON-INFRINGEMENT OF INTELLECTUAL PROPERTY ARE EXPRESSLY EXCLUDED TO

THE MAXIMUM EXTENT ALLOWED BY LAW, AND DIRECTED NEITHER ASSUMES NOR

AUTHORIZES ANY PERSON TO ASSUME FOR IT ANY LIABILITY IN CONNECTION WITH

THE SALE OF THE PRODUCT. DIRECTED HAS ABSOLUTELY NO LIABILITY FOR ANY AND

ALL ACTS OF THIRD PARTIES INCLUDING ITS AUTHORIZED DEALERS OR INSTALLERS.

Unit must be returned to Directed, postage pre-paid, with: consumer's name, telephone

number, and address, authorized dealer's name and address, and product description. IN

ORDER FOR THIS WARRANTY TO BE VALID, YOUR UNIT MUST BE SHIPPED WITH

PROOF OF INSTALLATION BY AN AUTHORIZED DIRECTED DEALER. ALL UNITS

RECEIVED BY DIRECTED FOR WARRANTY REPAIR WITHOUT PROOF OF DIRECTED

DEALER INSTALLATION WILL BE COVERED BY THE LIMITED 1 YEAR PARTS AND

LABOR WARRANTY. BY PURCHASING THIS PRODUCT, THE CONSUMER AGREES AND

CONSENTS THAT ALL DISPUTES BETWEEN THE CONSUMER AND DIRECTED SHALL BE

RESOLVED IN ACCORDANCE WITH CALIFORNIA LAWS IN SAN DIEGO COUNTY, CALIFORNIA.

NOTE: This warranty does not cover labor costs for the removal and reinstallation of the

unit.

Record Your Serial Number and Date

Model: __________________________________________________

Serial Number: __________________________________________________

Date of Purchase: __________________________________________________

Purchased from: __________________________________________________

3

©2004 Directed Electronics, Inc.

Page 5

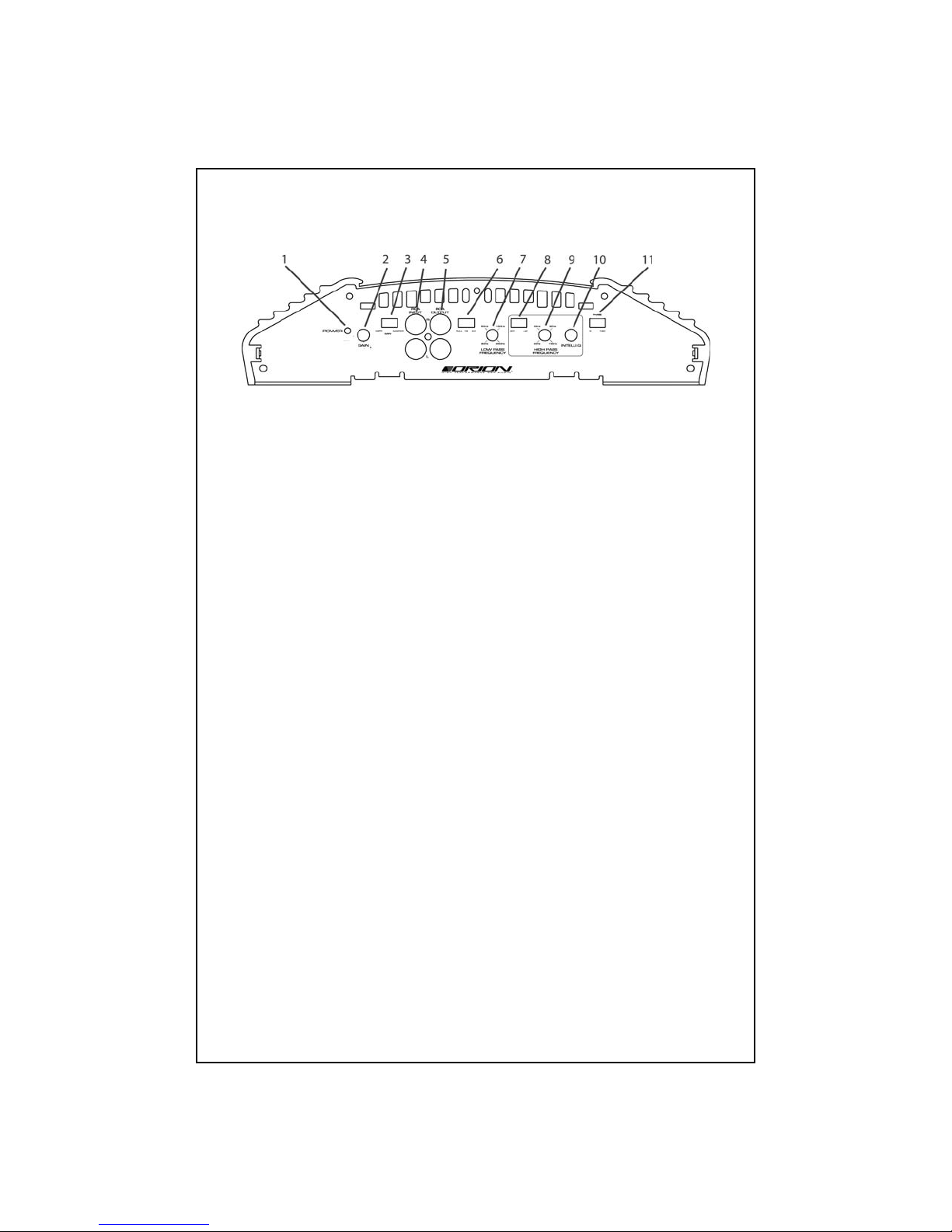

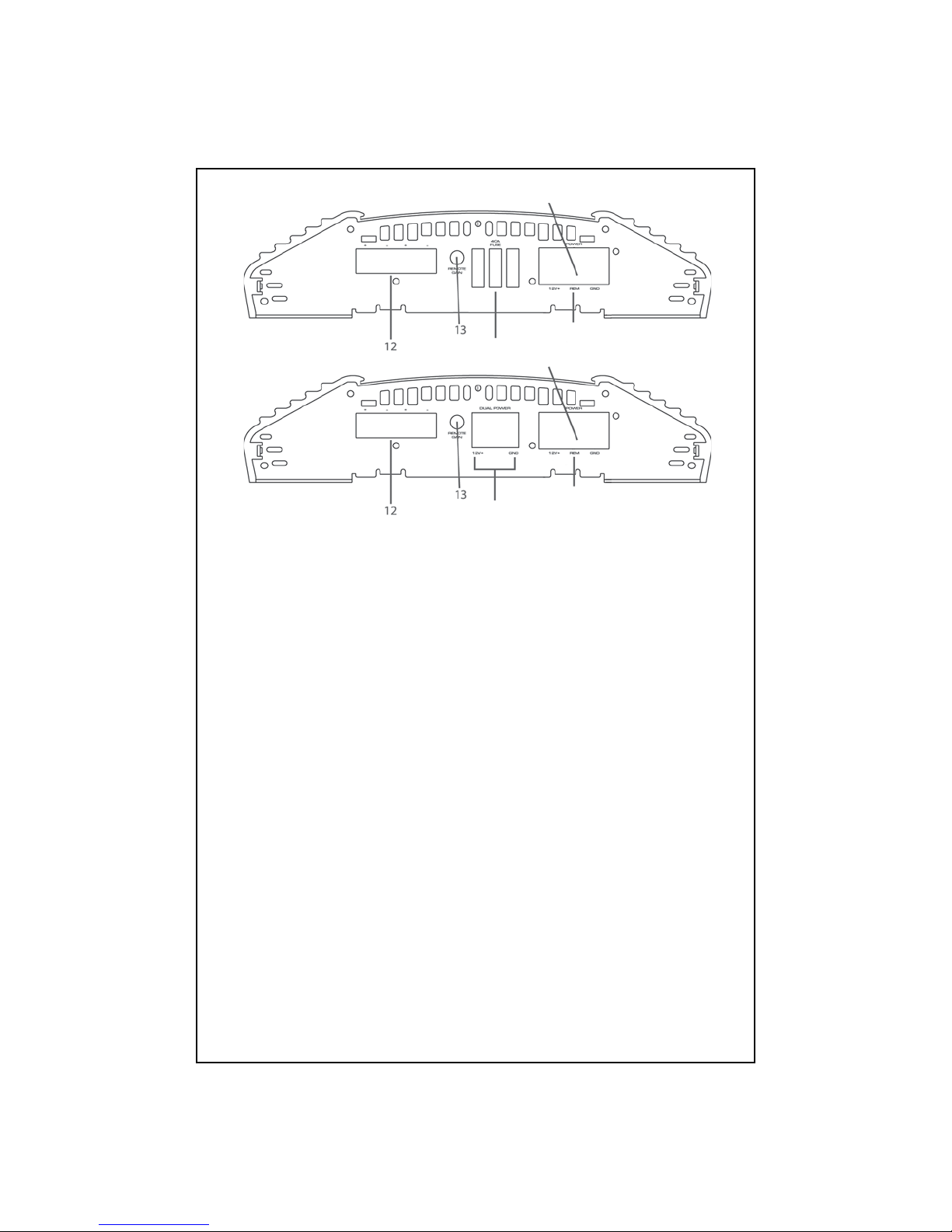

END PANEL LAYOUTS

1. Power LED - when lit indicates that the amplifier is on.

2. Gain Control - continuously adjusts from 200mV to 5V for full power output.

3. Copy/Gain/Master Switch - determines the configuration of the RCA outputs.

4. RCA Inputs - accepts RCA input from a source unit, preamplifier, or equalizer.

5. RCA Outputs - provides easy connection to additional amplifiers.

6. Low-Pass Crossover Switch - activates low pass crossover.

7. Low-Pass Frequency Control - adjusts the frequency of the low-pass crossover.

8. High-Pass Crossover Switch - activates high pass crossover (part of Intelli-Q

function).

9. High-Pass Frequency Control - adjusts the frequency of the high-pass crossover.

10. INTELLi Q Control - continuously adjusts the "Q" boost of the high-pass

crossover from 0 to 10dB of boost.

11. Phase Control Switch - Allows for adjustment of phase and makes bridging

amplifiers possible.

4

©2004 Directed Electronics, Inc.

Page 6

5

©2004 Directed Electronics, Inc.

12. Speaker Connections - accepts up to 12-gauge speaker wire.

13. Remote Gain Jack - connects optional RGC-1 (remote gain control).

14. 3 ATC Fuses (WCC-D2400) - protects the amplifier from over current situations.

15. Power Connections - accepts up to 4 AWG power and ground cables.

16. Additional Power Connectors (WCC-D5000) - accepts secondary power and

ground cables.

17. REM Remote Turn-on Input - turns on the amplifier when fed 12 V+.

WCC-D2400

15

14

15

WCC-D5000

16

17

17

Page 7

6

©2004 Directed Electronics, Inc.

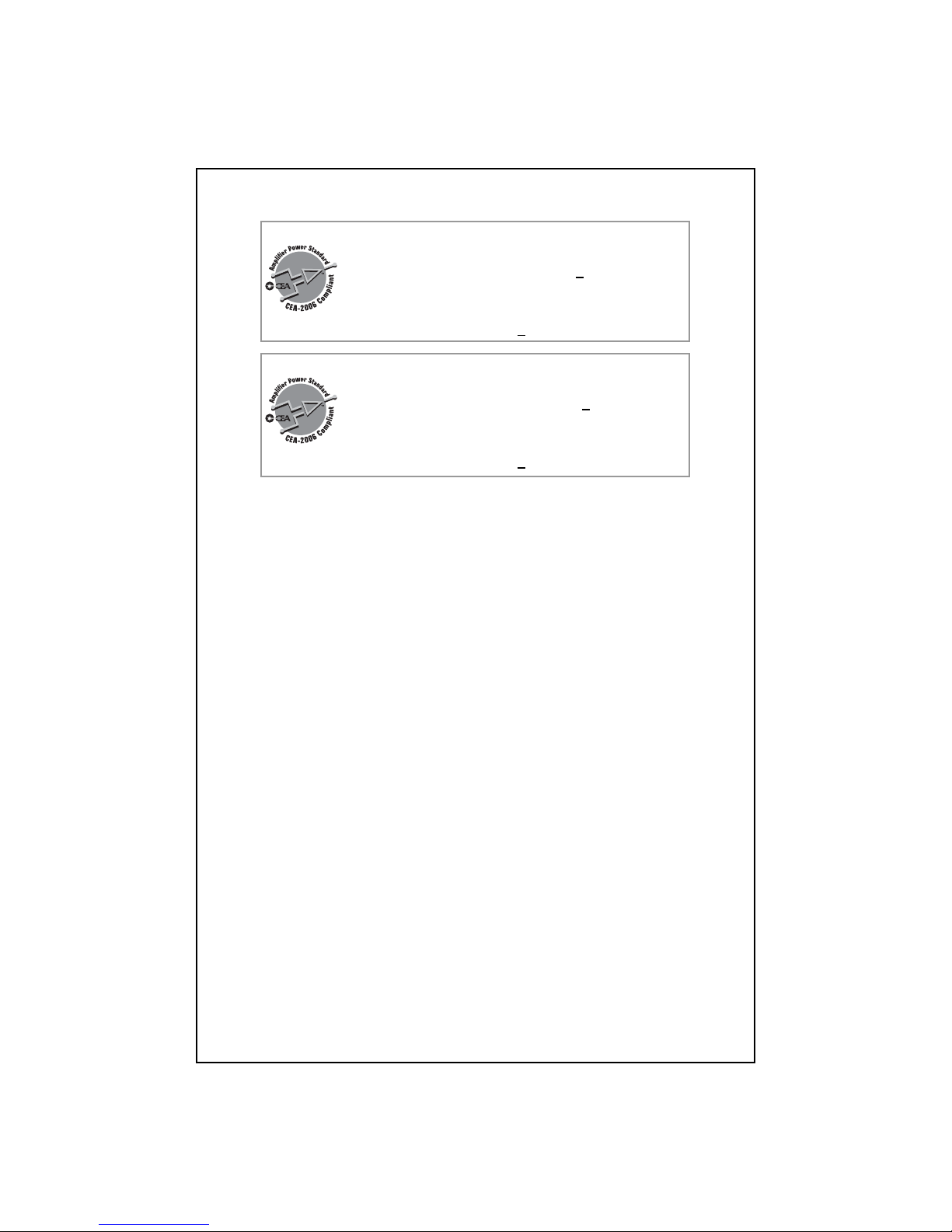

CEA SPECIFICATIONS

WCC-D2400D

Power Output: 475 Watts RMS x 1 at 4 ohms and < 1% THD+N

Signal to Noise Ratio: -60 dBA (reference 1 Watt into 4 ohms)

Additional Power: 1160 Watts RMS x 1 at 1 ohm and <

1% THD+N

WCC-D5000

Power Output: 1000 Watts RMS x 1 at 4 ohms and <

1% THD+N

Signal to Noise Ratio: -50 dBA (reference 1 Watt into 4 ohms)

Additional Power: 2350 Watts RMS x 1 at 1 ohm and <

1% THD+N

Page 8

7

©2004 Directed Electronics, Inc.

SPECIFICATIONS

1. Continuous 4W load 20Hz to 200Hz, < 0.05% THD, with input voltage at 13.8VDC.

2. Continuous 2W load 20Hz to 200Hz, < 0.1% THD, with input voltage at 13.8VDC.

Amplifier Section WCC-D2400 WCC-D5000

Power Output 4W

(Watts)

1

425 x 1 1000 x 1

Power Output 2W

(Watts)

2

725 x 1 1700 x 1

Power Output 1W

(Watts)

1200 x 1 2500 x 1

Externally

Bridgeable

yes no

Remote Gain

Function

yes yes

Distortion at Rated

Power

< 0.9% THD+N < 0.9% THD+N

Frequency

Response

20Hz to 200Hz

+0, -1dB

20Hz to 200Hz

+0, -1dB

Linear Bandwidth

10Hz to 500Hz

±3dB

10Hz to 500Hz

±3dB

Damping Factor > 50 > 50

Input Sensitivity 200mV to 5V rms 200mV to 5V rms

Input Impedance

40kW 40kW

Fuse Type (3) 40 Amp ATC None

Dimensions 18.7"x10.5"x2 27.2"x10.5"x2.3"

Weight 16 lbs. 24 lbs.

Crossover Section

Low Pass Crossover

Continuously

variable/

2ndOrder/

4thOrder

Continuously

variable/

2ndOrder/

4thOrder

Low Pass Frequency

Range

30Hz to 250Hz 30Hz to 250Hz

High Pass Filter

Continuously

variable/

2

nd

Order/

4thOrder

Continuously

variable/

2

nd

Order/

4thOrder

High Pass

Frequency

10Hz to 150Hz 10Hz to 150Hz

INTELLI Q 0–10dB boost 0–10dB boost

Page 9

8

©2004 Directed Electronics, Inc.

AMPLIFIER SETTINGS

Signal Input and Output Configurations

The input section of the amplifier consists of a phase switch that sets the output configuration, gain controls, and RCA inputs. The input section makes it easy to adapt this amplifier

to most system configurations.

Input Gain

The WCC-D2400 and WCC-D5000 amplifiers have level adjustments to allow for easy integration with any source unit. The input sensitivity can be adjusted from 200mV to 5V. Refer

to Testing the System and Adjusting the Sound of the System sections of this guide for

detailed instructions on setting the gain.

Phase Switches

● 0° - leaves output unaffected. The output signal is in phase with the input signal.

● 180° - inverts the output. The channel is 180° output of phase. This configuration

is useful for inverting the phase of subwoofers to improve staging in a vehicle.

This is also used when bridging two amplifiers into one speaker (D2400 only).

Auxiliary Output Configurations

The auxiliary outputs on WCC amplifiers offer easy, unlimited system expansion. Routing

signal from a source unit, pre-amplifier, or equalizer is a matter of connecting RCAs to the

RCA Inputs and the RCA outputs to your next WCC amplifier in the signal chain. When the

switch is in the COPY position, the RCA output is an identical copy of the input signal. The

signal passes through a buffer stage so that several amplifiers can be daisy chained without

signal loss or overloading of the source unit. This maximizes the signal output and minimizes the potential for system noise.

When the switch is in the GAIN position, the RCA outputs are buffered through the gain

stage of the amplifier. When the first amplifier in the signal chain is set this way, a remote

gain controller (RGC-1) can be connected to the amplifier and act as a PRE-AMP controlling

the overall level of the system. Following amplifiers are configured in the COPY mode with

their gains set to zero as the GAIN amp is now controlling the gain level for all subsequent

amps. This eliminates the need to gain match multiple amplifiers.

When the switch is in the MASTER position, the RCA outputs are buffered through the gain

stage of the amplifier and filtered through the crossover sections of the amplifier. When set

this way, the amplifier's gain and crossover settings are sent to other amplifiers down the signal chain. This can be useful for configuring multiple subwoofer amplifiers easily in a large

SPL system. All subsequent amplifiers after the master amp will be in the COPY position and

have their gains set to zero and all crossovers turned off. The master amplifier will control

all the functions of the slave amps via the MASTER RCA output signal.

Internal Crossover Configurations

The crossover section of the WCC-D2400 and WCC-D5000 amplifiers is continuously variable

and extremely flexible. In addition to the variable built-in low-pass filters, the high-pass

crossover incorporates the INTELLi Q feature. This circuit is designed to optimize the performance of WCC subwoofers in all types of enclosures.

Page 10

9

©2004 Directed Electronics, Inc.

When using WCC loudspeakers, minor deviations from the recommended frequency ranges

can provide superior results depending on your speaker locations and your vehicle acoustics.

Setting crossover frequencies higher than recommended will not cause damage and may

provide superior sonic results depending on your system's performance goals. Refer to your

loudspeaker owner's manual for assistance in choosing the proper crossover frequencies for

your system.

WARNING! DO NOT set crossover frequencies lower than the speakers recommended

operating range. This can cause driver failure that is not covered by the manufacturer's warranty.

Low-Pass Crossover

When the switch is to the left (OFF position), the low-pass crossover is bypassed. When the

switch is in the middle (12 position), the low-pass crossover is active with a 2nd order (12dB

per octave) slope. When the switch is to the right (24 position), the low-pass crossover is

active with a 4th order (24dB per octave) slope. The low-pass crossover is continuously variable from 30Hz to 250Hz.

High-Pass Crossover

When the switch is to the left (OFF position), the high-pass crossover is bypassed. When the

switch is to the right (ON position), the high-pass crossover is active with a 2nd order (12dB

per octave) slope. The high-pass crossover is continuously variable from 10Hz to 150Hz and

is optimized for use as a subsonic filter. Additionally, boost can be added at the high-pass

crossover frequency for improved bass output while still protecting the woofer from excessive excursion. The INTELLi Q adjustment allows up to 10 dB of boost at the selected

crossover frequency.

WARNING! Exercise caution when setting INTELLi Q. Maximum boost can potentially

cause woofer damage due to over-excursion.

Fine Tuning the Crossovers

The low-pass and high-pass crossover sections are each marked at four frequency points for

ease of system adjustment. The low-pass crossover section is marked at 30Hz, 50Hz, 150Hz,

and 250Hz. The high-pass crossover section is marked at 20Hz, 33Hz, 90Hz and 150Hz.

Specific crossover points can be chosen based on the recommended operational bandwidth

of your speakers.

Adjusting INTELLi Q

Incorporated in the high-pass crossover, INTELLi Q maximizes the performance of a subwoofer. The high-pass subsonic filter removes unwanted bass output from the woofer,

increasing the output of a subwoofer by as much as 3 dB due to the increased mechanical

power handling. Depending on the enclosure, using INTELLi Q can increase the low frequency response by an additional 10dB! The type of enclosure used and the woofer's excursion capability determine acceptable boost levels. Listed below are recommended boost levels for different enclosure designs.

Page 11

10

©2004 Directed Electronics, Inc.

Infinite Baffle Example High-Pass Set at 30Hz

By removing low frequency signal that the woofer cannot produce, the woofer can play its

capable range louder. The first example is an infinite baffle situation. The left graph displays

the frequency response of a 12-inch woofer in an infinite baffle application without the

high-pass filter, with the filter and with the filter and the INTELLi Q set to +3dB. As you can

see, with +3dB of boost and the high pass filter set to 30Hz, the woofer has more output

down to 25Hz and less overall excursion when compared to the non-high-pass response.

Maximum physical excursion capability of the woofer is 15mm.

NOTE: The left graph is the response; the right graph is the driver excursion. These des-

ignations apply to the following graphs as well.

Enclosure Type Boost Levels

0dB +3dB +6dB +10dB

Infinite Baffle Tune above High X-Max Not Not

Fs of woofer Drivers--Tune Recommended Recommended

above Fs of

woofer

Sealed Tune above Tune above High X-Max Not

Fs of woofer Fs of woofer Drivers--Tune Recommended

above Fs of

woofer

Ven te d Tune to port Tune to port Tune to port High X-Max

frequency frequency frequency Drivers--Tune to

port frequency

Sealed Band-pass Tune above Tune above High X-Max Not

Fs of woofer Fs of woofer Drivers--Tune Recommended

above Fs of

woofer

Vented Band-pass Tune to port Tune to port Tune to port High X-Max

frequency frequency frequency Drivers--Tune to

port frequency

Aperiodic Set crossover Set crossover Set crossover Not

to Fs of to Fs of to Fs of Recommended

woofer woofer woofer

Page 12

11

©2004 Directed Electronics, Inc.

Sealed Example High-Pass Set at 20Hz

This sealed example is the same 12-inch woofer in the recommended sealed enclosure. Up

to 6 dB of boost is capable if 20 Hz was used. With +6dB of boost, the woofer has more output down to 15 Hz.

Sealed Example High-Pass Set at 30Hz

In this example, the frequency has been increased to 30 Hz. Up to 6 dB of boost is capable

at this frequency. With +6dB of boost, the woofer has more output down to 23 Hz. The

overall usable output is increased.

Vented Example High-Pass Set at 30Hz

Vented enclosures benefit most from the INTELLi Q. Up to 10 dB of boost is capable at the

box tuning frequency of 30 Hz. With +10dB of boost, the woofer has more output down to

22 Hz. The excursion below the tuning frequency has been greatly reduced.

Page 13

12

©2004 Directed Electronics, Inc.

Remote Gain Operation

The remote gain port provides easy remote access to the internal gain structure of the

power amplifier. The RGC-1 plugs into the amplifier via the 1/8" mini jack plug. The RGC-1

can be installed in the front of the vehicle to control the amplifier gain level. The RGC-1 can

be used as a bass level control when used on an amplifier dedicated to subwoofers.

In addition, one RGC-1 can be used on multiple sub amplifiers. Plug the RGC-1 into the first

amp that must have its RCA output selection switch in the MASTER position. The RGC-1

information will now be sent to subsequent amps via the MASTER signal.

Note: The RGC-1 is not supplied with the amplifier (order Orion p/n 58000).

AMPLIFIER WIRING

Power Connections for the WCC-D2400

● WCC-D2400 Fuse Size: 3 x 40 AMP ATC

● Power connections accept up to 4 AWG wire.

● 4 AWG power and ground wire recommended for optimal performance.

● Connect 12V+ to the battery through fuse holder. This connection provides +12V

main power to the amplifier.

● Power wire must be fused no more than 18" from battery.

● Ground amplifier to a good chassis ground as close as possible to the amplifier.

● Connect REM terminal to remote turn-on lead from source unit. This connection

provides +12V power to turn-on the amplifier.

● Add extra ground wire between the negative terminal of the battery and the

chassis.

Power Connections for the WCC-D5000

● Power connections accept up to 4 AWG wire.

● Dual 4 AWG power and ground wire required for proper performance.

● Connect 12V+ to the battery through power distribution and fuse holder. This

connection provides +12V main power to the amplifier.

● Power wires must be fused no more than 18" from battery.

● Terminate both grounds of the amplifier to a good chassis ground as close as pos-

sible to the amplifier.

● Connect REM terminal to remote turn-on lead from source unit. This connection

provides +12V power to turn-on the amplifier.

● Add an extra ground wire between the negative terminal of the battery and the

chassis. Either dual 4 AWG or single 1/0 AWG is recommended.

NOTE: The addition of a ground wire from the battery to the chassis of the vehicle

improves the ability of the battery to supply power to the amplifier. This is recommended because the current delivery of the factory electrical system was designed

only to accommodate electronics supplied by the auto manufacturer.

WARNING! The WCC-D5000 has two separate four-gauge power and ground inputs.

Both pairs of connections must use 4 AWG power wire for proper operation.

Failure to do this may damage the amplifier and is not covered under warranty. The WCC-D5000 cannot be operated in a bridge or strapped configuration, attempting to do so will damage the amplifier.

Page 14

13

©2004 Directed Electronics, Inc.

Speaker Connections

The WCC-D2400, and WCC-D5000 amplifiers offer two positive and two negative output terminals for ease of connecting the speakers to the amplifier. Since these are mono amplifiers, the

speaker connectors are paralleled internally. Each amplifier is stable to 1W.

Bridging

For bridging into a single speaker load, the WCC-D2400 has the ability to be bridged with

another amplifier of the same model. To do this you must utilize the COPY/GAIN/MASTER

switch settings. For the MASTER amplifier, set the switch setting to MASTER. This will route

the signal through RCA to the other (slave) amplifier. Refer to Auxiliary Output

Configuration section of this guide. To set the PHASE switch on the (slave) amp, move the

phase switch from 0 to 180, exactly opposite of the master amp. Refer to the Phase Switches

section of this guide.

On the (slave) amplifier be sure to turn off all crossovers. For the speaker connections, connect the positive (+) speaker lead from the speaker to the positive (+) speaker terminal of

the master amplifier. On the negative (-) speaker connection, take the negative (-) speaker

terminal of the master amplifier and connect it directly to the negative (-) speaker terminal

of the (slave) amplifier. The remaining positive (+) speaker terminal of the (slave) amplifier

must be connected to the negative (-) speaker lead from the speaker. The impedance of the

speaker must not exceed 2W.

NOTE: For best results, connect both negative speaker terminals on the master amp to

both negative terminals on the slave amp using at least 12 AWG cable.

WARNING! The WCC-D5000 is not designed to work in a bridged or strapped configura-

tion. Attempting to apply these configurations will damage the amplifier

and will not be covered under warranty.

Page 15

14

©2004 Directed Electronics, Inc.

AMPLIFIER INSTALLATION

Choosing Mounting Locations

The location of your amplifier will depend on several important issues. Due to the low profile size of the WCC amplifiers, there are many possible installation locations that will yield

satisfactory amplifier performance. Always mount the amplifier in a place that protects the

amplifier from the elements. In addition, mount the amplifier on a stable, flat surface.

NOTE: Mounting amplifiers upside down is not recommended and may cause premature

thermal shutdown.

WARNING! Do not mount any amplifier in the engine compartment. Amplifiers are not

designed to endure the harsh environment of the exterior elements.

Passenger Compartment

If you are going to mount the amplifier in the passenger compartment, make sure you have

adequate room for ventilation. The amplifiers have been designed to make under-seat

mounting possible. When mounting your amplifier under a seat or similar area, keep a minimum of 1" of clearance around the amplifier for adequate cooling.

Trunk Compartment

Mounting your amplifier in the trunk provides excellent performance as long as you do not

restrict the airflow around the heatsink of the amplifier. For optimal results, mount the

amplifier with as much clearance as possible. This type of mounting will yield the best cooling due to the convection effect of the amplifier chassis.

General Precautions and Installation Tips

WARNING! Be careful not to cut or drill into gas tanks, fuel lines, brake lines, hydraulic

lines, vacuum lines, or electrical wiring when working on your vehicle.

Disconnect the vehicle's ground wire at the battery before making or breaking connections

to the audio system's power supply terminals.

Do not use this amplifier unmounted. Failing to securely mount the amplifier can result in

damage or injury, particularly in the event of an accident. An unmounted amplifier becomes

a dangerous projectile in the event of a crash. Never mount the amplifier where it might

get wet. Mount the amplifier so the wire connections will not be pulled. Route the wires

where they will not be scraped, pinched or damaged in any fashion.

The +12V power supply wire must be fused as close as possible to the battery terminal, ideally within 18". Use the recommended fuse size or circuit breaker listed in the Power

Connections section of this manual.

If you need to replace the fuse plugged into the side of the amplifier, replace the fuse with

the same size ATC / MAXI type fuse that came with the amplifier. If you are not sure as to the

correct value, refer to the Power Connections section of this manual for details. Using a higher current fuse may result in damage to the amplifier that is not covered under warranty.

NOTE: Make sure all the equipment in the system is turned off when making or break-

ing connections to the input RCAs or speaker terminals. Turn on the system and

slowly turn up the volume control only after double checking all wire connections.

Page 16

15

©2004 Directed Electronics, Inc.

Power for systems with a single amplifier can be supplied by most automotive electrical systems. Systems with multiple amplifiers may require a higher capacity battery, alternator or

the use of a storage capacitor. We strongly recommend the use of a Directed Audio

Essentials power capacitor with an extra battery in larger stereo systems.

WCC amplifiers generate a certain amount of heat as part of normal operation. Be sure the

area around the amplifier is unobstructed to allow adequate air circulation. Remember,

beach blankets, last week's laundry, school books and homework papers located on top of

the amplifier do not improve air flow and may become damaged.

Tools of the Trade

Listed below are the majority of the tools required to perform an installation. Having the

proper tools will make the installation that much easier. Some of these tools are necessities;

some will just make the job easier.

● Allen Wrenches (2.5mm and 3mm)

● DMM or VOM

● Electric drill with assorted drill bits

● Grommets

● Heat shrink tubing

● Marking pen

● Nylon tie straps

● Phillips and flat blade screw drivers

● Pliers (standard and needle nose)

● Reference CD with 1 kHz Sine Wave at 0dB level (all bits high)

● RTA (real time analyzer)

● Soldering iron and solder

● Utility knife

● Wire brush or sandpaper for chassis grounding

● Wire crimper

● Wire cutters

● Wire strippers

Step By Step Installation

Step 1 Determine the location for the amplifier. Refer to the Choosing Mounting

Locations section of this guide for detailed information.

Step 2 Decide on the system configuration for your amplifier. For system sugges-

tions, refer to the Speaker Connections section of this guide.

Step 3 Run all the wires from the amplifier location to the speakers, source unit, and

battery. Do not connect the battery at this time. Be sure to run RCAs and

power and speaker wires away from factory electrical wires and system as

they pose a great potential for induced system noise.

Step 4 Pre-drill amplifier mounting holes. Be sure to "think before you drill". Gas

tanks, fuel lines, and other obstructions have a nasty way of hiding themselves. For best results use a marking pen to mark the mounting holes and

pre-drill these holes with a standard 1/8" drill bit.

Step 5 Mount the amplifier. Make sure the amplifier is mounted on a flat surface. If

this is not possible, do not over tighten the screws so that the chassis of the

Page 17

16

©2004 Directed Electronics, Inc.

amplifier is twisted or bent.

Step 6 Turn the vehicle's key switch to the off position.

Step 7 Disconnect the vehicle's battery ground terminal.

Step 8 Connect power wires to the amplifier (ground first, then 12 V(+) and REM).

Step 9 Connect the RCA and speaker wires to the amplifier. Check the quality of

your speakers and signal connections. This will determine the ultimate performance of your WCC amplifier. Refer to the Signal Input and Output Level

Controls and Speaker Connections sections of this guide for correct wiring

instructions.

Step 10 Reconnect the ground terminal to the battery after power, speaker, and RCA

connections are completed.

Step 11 Set crossovers. Refer to the Internal Crossover Configuration section of this

manual for detailed instructions.

Step 12 Once satisfied that all connections and settings are correct, install the fuse

located near the vehicle's battery and proceed to the Testing the System section of this manual.

WARNING! Never exceed the recommended fuse size of this amplifier. Failure to do so will

result in the voiding of your warranty and possible damage to the amplifier.

SET UP AND TROUBLESHOOTING

Testing the System

After you have completed the installation, you need to test the system. This will help ensure

years of trouble-free operation. Please refer to the listed steps below when testing the

sound of your WCC system.

Step 1 Check all the wiring connections to be sure they are correct and secure.

Step 2 Turn the signal source volume control all the way down. Set any tone con-

trols to their flat or defeated positions. This includes the loudness control.

Step 3 Turn the level controls of the amplifier to their minimum positions.

Step 4 Turn the source unit on. Check to see if the power LED located on the con-

nection side of the amplifier is on. If not, please refer to the Power

Connections and the Troubleshooting Tips sections of this manual for instruc-

tions.

Step 5 If using an aftermarket source unit, turn the level controls of the amplifier

about one quarter of a turn. Slowly increase the volume level of the source

unit to so that you can hear the output of the system. If no sound is heard or

if the output is distorted, turn the system off immediately. Refer to the Power

Connections and the Troubleshooting Tips sections of this manual to solve

your installation problems.

Step 6 Check to make sure the output for each channel is correct. If the active

crossovers are used, check to make sure that each output is correct from the

amplifier. When using active crossovers on midrange and tweeters, do not

use crossover frequencies lower than recommended. If the system is not configured properly, refer to the Internal Crossover Configuration section of this

manual and take corrective action.

Step 7 If the output is clear and undistorted, continue to the Adjusting the Sound

of the System section of this manual.

Page 18

17

©2004 Directed Electronics, Inc.

Adjusting the Sound of the System

Once you have checked the system's operation, adjust the sound of the system. Adjusting

the sound of the system is accomplished by setting the level controls and adjusting the

internal crossovers.

Step 1 Turn the signal source volume control all the way down. Set any tone con-

trols to their flat or defeated positions. This includes the loudness control.

Step 2 Turn the level controls of the amplifier to their minimum positions.

Step 3 Choose music with high dynamic content that you like, with which you are

familiar, and will be used most often in the system.

Step 4 Turn the source unit's volume control up to its highest undistorted output

level. If you lack test equipment, this point occurs between 3/4 to full volume

depending on the quality of your source unit. Listen for any audible distortion. If any distortion is audible, reduce the volume of the source unit until

you have an undistorted output. Leave the volume control at this position

during your system tuning.

Step 5 While listening to your chosen dynamic music, turn up the level control cor-

responding to the midrange output until you hear slight distortion and turn

the level control back slightly for an undistorted output. Depending on your

system, the midrange and tweeter output may be on the same output channels.

Step 6 Turn up the level control corresponding to the tweeter output until you hear

slight distortion and turn back the level control slightly for an undistorted

output. Depending on your system the midrange and tweeter output may be

on the same output channels.

Step 7 Fine-tune the output level between midrange and tweeters. Refer to the

Internal Crossover Configuration section of this manual for detailed instructions.

Step 8 Repeat Steps 5-7 for the rear speakers. If you do not have rear speakers con-

tinue to Step 10.

Step 9 Set levels between the front and rear midrange and tweeters for optimum

front/rear balance.

Step 10 Turn up the level control corresponding to the woofer output until you hear

slight distortion and turn back the level control slightly for an undistorted

output.

Step 11 Fine-tune the output level between satellite speakers and the woofers. Refer

to the Internal Crossover Configuration section of this manual for detailed

instructions. If using an RGC-1, adjust the level to the output of the woofer

to match the sonic requirements of the system.

Step 12 Enjoy your awesome West Coast Customs by Orion sound system.

Page 19

18

©2004 Directed Electronics, Inc.

Troubleshooting Tips

Symptom Probable Cause Action To Take

No output

Low or no remote turn-on Check remote turn-on voltage

at voltage amplifier and repair

as needed.

Fuse blown Check power wire's integrity

and check for speaker shorts. Fix

as needed and replace fuse.

Power wires not connected Check power wire and ground

connections and repair or

replace as needed.

Audio input not connected Check RCA connections and

repair or replace as needed.

Speaker wires not Check speaker wires and repair

connected or replace as needed.

Speakers are blown Check system with known work

ing speaker and repair or

replace speakers as needed.

Audio cycles

on and off

Thermal protection engages Make sure there is proper venti

when amplifier heat sink lation for amplifier and improve

temperature exceeds 90°C ventilation as needed.

(190°F)

Loose or poor audio input Check RCA connections and

repair or replace as needed.

Loose power connections Check power wire and ground

connections and repair or

replace as needed.

Distorted output

Amplifier level sensitivity Readjust gain. Refer to the

set too high exceeding Adjusting the Sound of the

maximum capability of System section of this manual

amplifier for detailed instructions.

Impedance load to amplifier Check speaker impedance load,

too low if below 1W, rewire the speakers

to achieve higher impedance.

Shorted speaker wires Check speaker wire connections

and fix or replace as needed.

Speaker not connected Check speaker wiring and repair

to amplifier properly or replace as needed. Refer to

the Speaker Connections section

of this guide for detailed

instructions.

Page 20

Symptom Probable Cause Action To Take

Distorted output

Internal crossover not set Readjust crossovers. Refer to the

properly for speakers Internal Crossover Configuration

section of this guide for detailed

instructions.

Speakers are blown Check system with known work

ing speakers and fix or replace

as needed.

Poor bass response

Speakers wired with wrong Check speaker polarity and fix

polarity causing cancellation as needed.

at low frequencies

Crossover set incorrectly Reset crossovers. Refer to the

Internal Crossover Configuration

section of this guide for detailed

instructions.

Impedance load at amplifier Check speaker impedance load,

is too low if below 1W, rewire speakers to

achieve higher impedance.

Battery fuse

blowing

Short in power wire or Check power and ground conincorrect wiring nections and replace or repair as

needed.

Fuse used is smaller than Replace with proper fuse size.

recommended

Actual current exceeds fuse Check speaker impedance load.

rating If below 1W, rewire speakers to

achieve higher impedance.

Amplifier fuse

blowing

Fuse used is smaller than Replace with proper fuse size.

recommended

Impedance load at Check speaker impedance load.

amplifier too low If below 1W, rewire speakers to

achieve higher impedance.

Speaker is blown with Check system with known work

shorted outputs ing speakers and fix or replace

as needed.

Actual current exceeds Check speaker impedance load.

fuse rating If below 1W, rewire speakers to

achieve higher impedance.

19

©2004 Directed Electronics, Inc.

Page 21

NOTES

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

20

©2004 Directed Electronics, Inc.

Loading...

Loading...