Page 1

System Manager TS II

In-House Technical Guide

VCB-X Controller Code: SS1051 Version 2.0 and up

VCM-X Controller: SS1026 & Y200920 Version 2.0 and up;

VCM-X Modular Controller: Tulsa - SS1030; Coil - SS1034

VCM-X WSHP Controller: Tulsa - SS1032; Coil - SS1033

VAV/Zone Controller: SS1001, SS1005, SS1025

VCM Controller: SS1016

Page 2

Table of Contents

OVERVIEW ........................................................................................................................................................ 4

COMPONENTS AND WIRING ............................................................................................................................ 5

Flush Wall Mount Dimensions and Components .........................................................................................................................6

Surface Mount Components and Dimensions ..............................................................................................................................7

SMTS II to VCM Controller Wiring ................................................................................................................................................8

SMTS II to VCM-X Controller Wiring ............................................................................................................................................9

SMTS II to VCB-X Controller Wiring...........................................................................................................................................10

SMTS II to VAV/Zone Controller Actuator Package Wiring ........................................................................................................11

NAVIGATION .................................................................................................................................................. 12

Main Screen Icons and Button Functions...................................................................................................................................12

MAIN SCREEN FUNCTIONS ........................................................................................................................... 14

Logging In...................................................................................................................................................................................14

Editing Passcodes ......................................................................................................................................................................15

Setting The System Clock ..........................................................................................................................................................16

System Manager Settings ..........................................................................................................................................................17

Alarm Polling ..............................................................................................................................................................................18

Unit Selection .............................................................................................................................................................................19

VCM, VCM-X & VCB-X CONTROLLERS........................................................................................................... 19

Viewing Status Screens .............................................................................................................................................................19

Viewing & Enabling/Disabling VCM & VCM-X Alarms ................................................................................................................21

Viewing & Enabling/Disabling VCB-X Alarms ............................................................................................................................22

Viewing and Setting Schedules .................................................................................................................................................23

Viewing and Setting and Holidays ..............................................................................................................................................24

Forcing Schedules......................................................................................................................................................................24

VCM & VCM-X CONTROLLERS ....................................................................................................................... 25

Accessing and Entering VCM / VCM-X Setpoints ......................................................................................................................25

VCM / VCM-X Confi guration Setpoints ......................................................................................................................................26

VCM / VCM-X Temperature Setpoints ........................................................................................................................................32

VCM / VCM-X Static Setpoints ...................................................................................................................................................35

VCM / VCM-X Staging Delays Setpoints....................................................................................................................................37

VCM / VCM-X Miscellaneous Setpoints .....................................................................................................................................38

VCM / VCM-X Calibration Setpoints...........................................................................................................................................40

VCM / VCM-X Relay Outputs Setpoints .....................................................................................................................................41

VCB-X CONTROLLERS ................................................................................................................................... 42

Accessing and Entering VCB-X Setpoints..................................................................................................................................42

VCB-X Confi guration Setpoints ..................................................................................................................................................43

VCB-X Temperature Setpoints ................................................................................................... ................................................50

VCB-X Static Setpoints ..............................................................................................................................................................54

VCB-X Staging Delays Setpoints ...............................................................................................................................................56

VCB-X Miscellaneous Setpoints.................................................................................................................................................59

VCB-X Relay Outputs Setpoints.................................................................................................................................................62

www.orioncontrols.com

WattMaster Controls Inc.

8500 NW River Park Drive · Parkville , MO 64152

Toll Free Phone: 866-918-1100

PH: (816) 505-1100 · FAX: (816) 505-1101 ·

E-mail: mail@wattmaster.com

Visit our web site at www.orioncontrols.com

Form: OR-SMTSII-In-House-TGD-01E

Copyright April 2015 WattMaster Controls, Inc.

AAON® is a registered trademark of AAON, Inc., Tulsa, OK.

WattMaster Controls, Inc. assumes no responsibility for errors or

omissions.

This document is subject to change without notice.

Page 3

Table of Contents

VAV/ZONE CONTROLLERS ............................................................................................................................. 63

Viewing VAV/Box Status Screens...............................................................................................................................................63

Viewing Alarm Status .................................................................................................................................................................63

Enabling/Disabling VAV/Zone Alarms ........................................................................................................................................63

Accessing and Entering VAV/Zone Setpoints .............................................................................................................................64

VAV/Zone Confi guration Setpoints .............................................................................................................................................65

V AV/Zone Temperature Setpoints ................................................................................................ ..............................................66

VAV/Zone Damper/Airfl ow Setpoints ................................................................................................................. .........................67

V A V/Zone Alarm Settings ...........................................................................................................................................................68

VAV/Zone Miscellaneous Setpoints ............................................................................................................................................69

VAV/Zone Calibration Setpoints .................................................................................................................................................69

APPENDIX ...................................................................................................................................................... 70

Troubleshooting - System Manager TS II LEDs, Buttons, Dipswitches & Jumpers ...................................................................70

System Confi guration .................................................................................................................................................................71

Alarm Polling Setup Using Prism 2 ............................................................................................................................................75

Military Time Conversion ............................................................................................................................................................76

INDEX ............................................................................................................................................................. 77

Page 4

Overview

System Manager TS II

Zone

Zone

Features

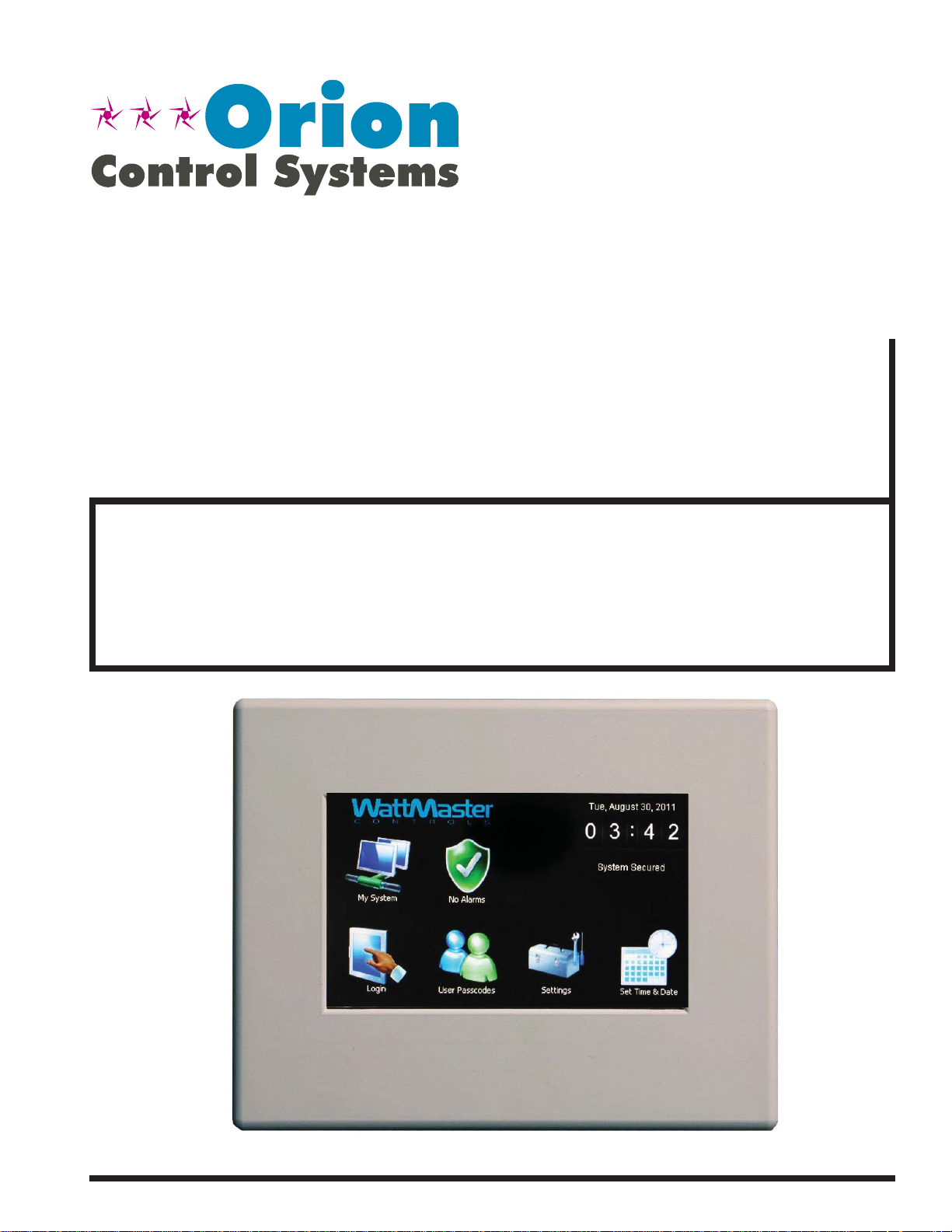

The OE392-10 System Manager TS II (Touch Screen) provides a direct,

graphic-enhanced, menu-driven link to enable you to view the status and

adjust the setpoints of most controllers on the Orion Controls System.

(See Figure 1.)

The System Manager TS II provides the following useful functions:

• Provides a 4.3” 480 x 272 WQVGA RGB TFT LCD Graphical

Touch Screen LCD display with 16 million colors

• Utilizes a graphical touch screen menu system with easyto-understand menu trees and icons and non-cryptic, plain

English language messages

• Makes entering data quick and easy with instructions on each

confi guration and setpoint screen

• Graphic programming and status screens provide easy setup

and operation without the need for specialized training

• Provides protection from unauthorized users through integral

multi-level passcode authorization programming

• Comes equipped with real-time clock backup power supply

for short power losses

• Provides icons to indicate alarm conditions

System Requirements

• The System Manager TS II is packaged and assembled as fl ush

wall mount. Surface mount components are also included for

your convenience.

• If using the surface mount version, you will need a double

duplex outlet box (by others).

• The System Manager TS II only works with the following

VAV/Zone Controller EPROMs: SS1001, SS1005, SS1025

• The System Manager TS II only works with the following

VCM, VCM-X, VCM-X Modular, VCM-X WSHP, and

VCB-X Controller EPROMs: All standard SS1016, SS1026,

SS1030, SS1032, SS1033, SS1034, SS1051 and later

*• USB-Link, CommLink, or MiniLink Polling Device

*NOTE: Alarm polling must fi rst be set up in Prism 2. This requires a

personal computer with Prism 2 software and a USB-Link or

CommLink and a MiniLink Polling Device. Ongoing alarm

polling on the System Manager TS II Main Scr een requires

a MiniLink to be connected to the system.

• LEDs behind plastic panel indicate power, communications,

and operation

• Plastic enclosure allows for easy fl ush wall mounting in

hollow drywall or surface mounting on solid wall surface

NOTE: Screens in this manual referring to VCM-X also apply

to VCM controllers.

Figure 1: System Manager TS II

4

Revised 4/25/14

SMTS Technical Guide

Page 5

Components and Wiring

Mounting, Wiring, Initializing, and Updating

Environmental Requirements

The System Manager TS II needs to be installed in an environment that

can maintain a temperature range between 14°F and 158°F with less

than 90% RH levels (non-condensing).

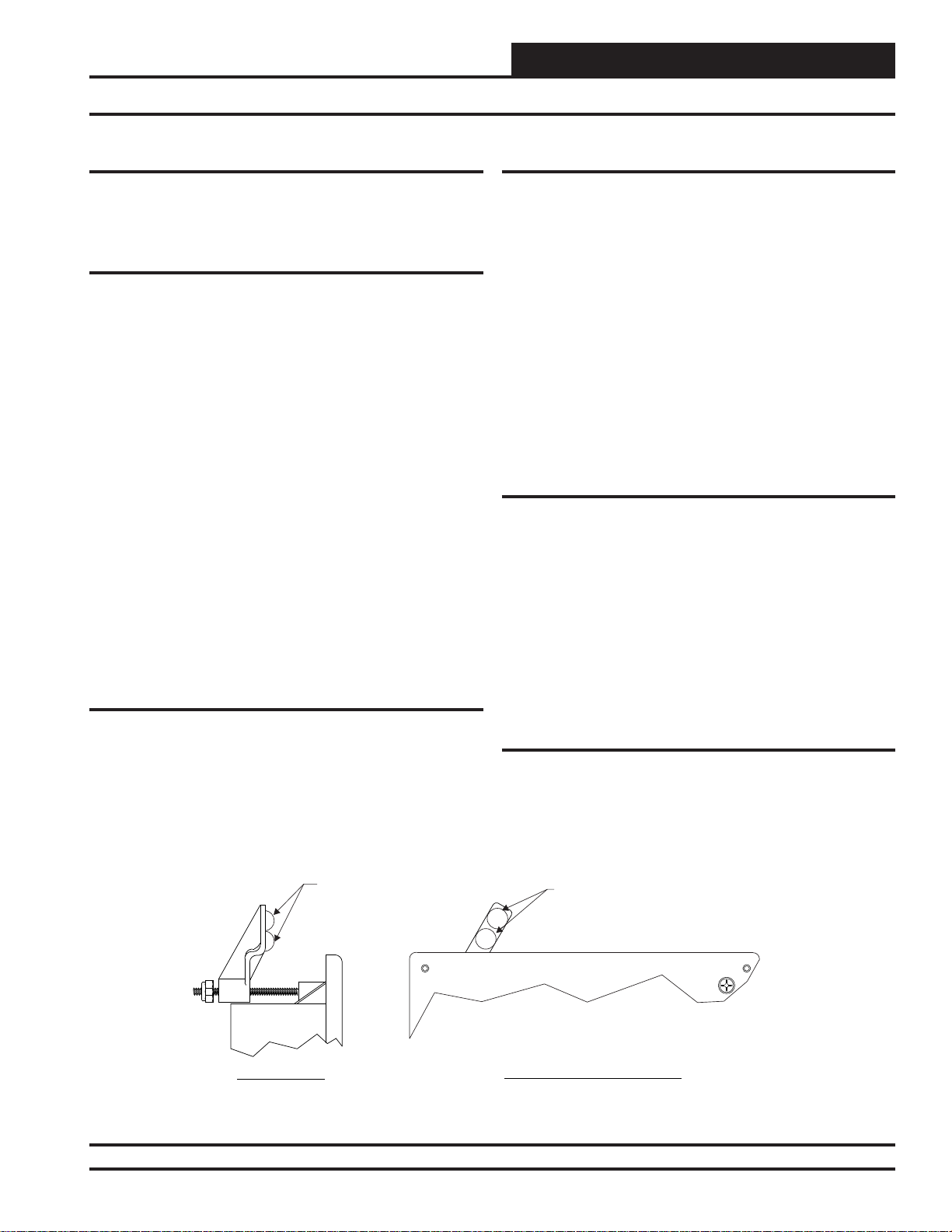

Mounting

The System Manager TS II is housed in a plastic enclosure designed

for mounting in hollow drywall construction or a control panel cover

with the fl ush wall mount version (shown in Figure 3) or on a concrete,

brick, or other solid wall surface with the surface mount version (shown

in Figure 4).

The fl ush wall mount version has integral wingnut paddles that are tight-

ened after installation to grip the drywall and hold the System Manager

TS II in place. For mounting in a control panel cover or other thin material, (4) adhesive backed rubber pads are provided to assist in securing

the System Manager TS II into the cutout in the panel. These pads are

applied to the wingnut paddles to provide a non-slip mounting against

the panel’s sheet metal surface. See Figur e 2 for pad placement details.

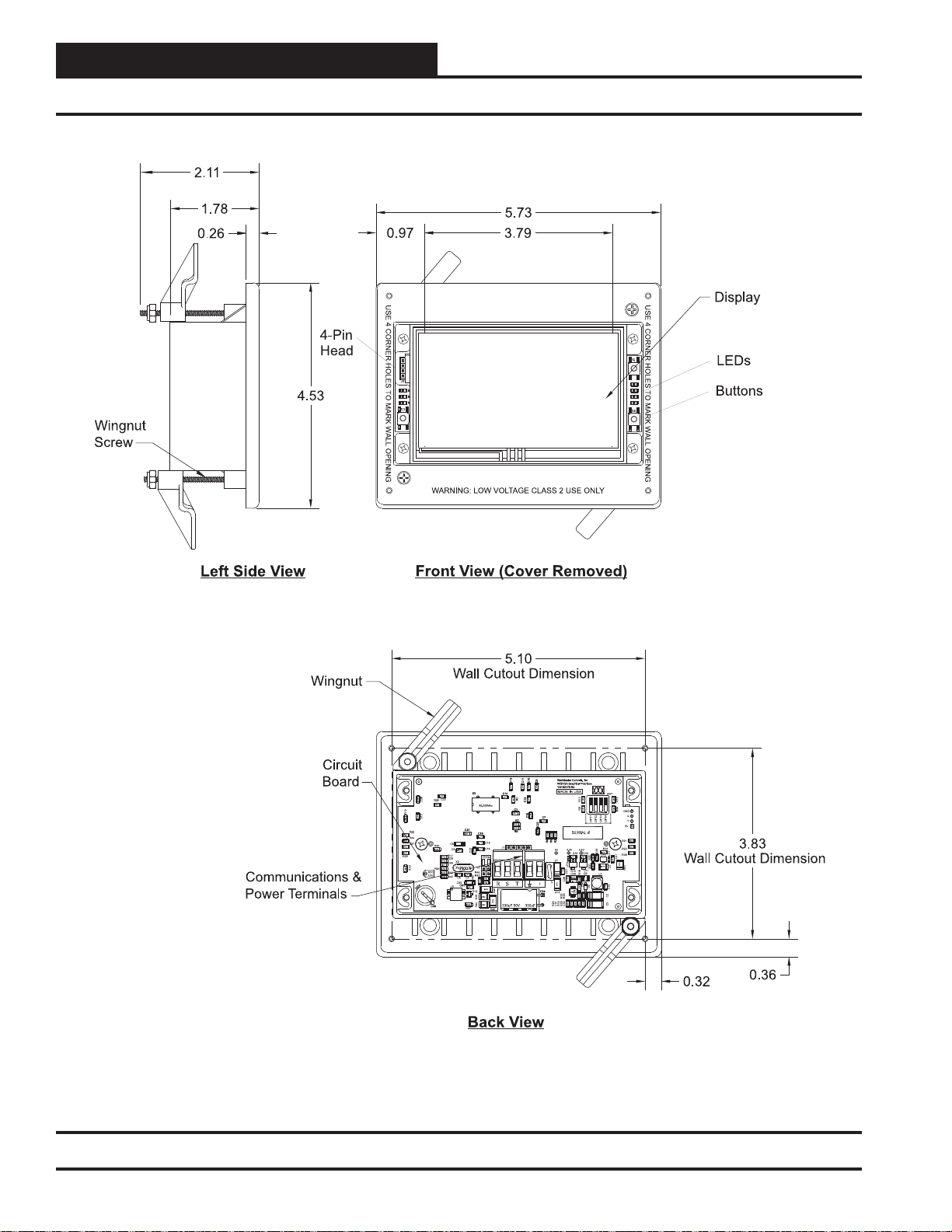

The surface mount version is designed to be installed in a double duplex

outlet box (by others). Both mounting styles of the System Manager

TS II feature an integral, magnetically-secured face plate which can be

easily removed for reset of the display when required.

The System Manager TS II should be mounted at approximately eye

level to allow for ease of programming and reading of the display. The

System Manager TS II is typically mounted in the building manager’s

or superintendent’s offi ce or in an equipment room, but is also quite

suitable for mounting in any location or with most decors.

Care

Wiring

The System Manager TS II is connected to the local communications

loop of the Orion system via 18 AWG 2-conductor, twisted pair with

shield wire connected to the T , SHLD & R communication terminals on

the back of the System Manager TS II. The communications wire used

can be either our WattMaster # WR-LL-WG-18 communications wire

or Belden #82760 wire or its equivalent.

The System Manager TS II also requires that 24 VAC (6 VA) power be

supplied (by others) to its + and – wiring terminal located on the back

of the System Manager TS II.

See Figur es 5-8 for wiring details. These wiring diagrams depict wiring

the System Manager TS II to the VCM-X Controller , VCM Controller,

VCB-X Controller and VAV/Zone Controller. The System Manager TS II

can also be wired to the local loop terminals on the MiniLink PD, Power

Comm Board, or any other add-on controller’s local loop terminals. It

will still require a transformer to be wired as shown in Figures 5, 6 & 7.

Dipswitch and Jumper Settings

If you are using a VCB-X Controller set at high speed, Dipswitch OPT1

should be set to ON; in all other instances, it should be set to OFF . As of

April 2014, Dipswitch OPT4 should be set to ON by default. Previous

versions should be set to OFF. If you see your screen is not centered

correctly, switch OPT4 to the opposite position. Dipswitches OPT2

and OPT3 should always be set to OFF. See Figures 5-8, pages 8-11

for details.

If you have a Stand-Alone system (no CommLink or MiniLink, the

TERM Jumpers must be ON. For applications with CommLink(s) and/

or MiniLink(s), the TERM Jumpers must be OFF. See Figures 5-8,

pages 8-11 for details.

The System Manager TS II should be cleaned with a soft, dust-free cloth.

Do not use any liquid to clean your System Manager TS II. You should

press the < Suspend> button located behind the cover to temporarily

freeze the touch pad before you attempt to clean your screen. See the

Troubleshooting section on page 70 for details.

Rubber Pads

USE 4

Left Side View

Technical Support

Call (866) 918-1100 to talk to a WattMaster Controls T echnical Support

Representative. Support is available Monday through Friday, 7:00 AM

to 5:00 PM central standard time.

Place (2) On Each Paddle Arm

As Shown When Mounting In Sheet Metal

Panel Or Other Thin Mounting Material. Pads

Are Not Required For Drywall Mounting

Front View (Cover Removed)

Rubber Pads

Figure 2: System Manager TS II - Control Panel Mounting Pad Placement Detail ( Flush Wall Mount)

SMTS II Technical Guide

Revised 4/21/14

5

Page 6

Components and Wiring

Wall Mount Dimensions and Components

Figure 3: System Manager TS II Dimensions and Components ( Flush Wall Mount)

6

SMTS II Technical Guide

Page 7

Components and Wiring

Surface Mount Components and Dimensions

Figure 4: System Manager TS II Dimensions and Components ( Surface Mount)

SMTS II Technical Guide

7

Page 8

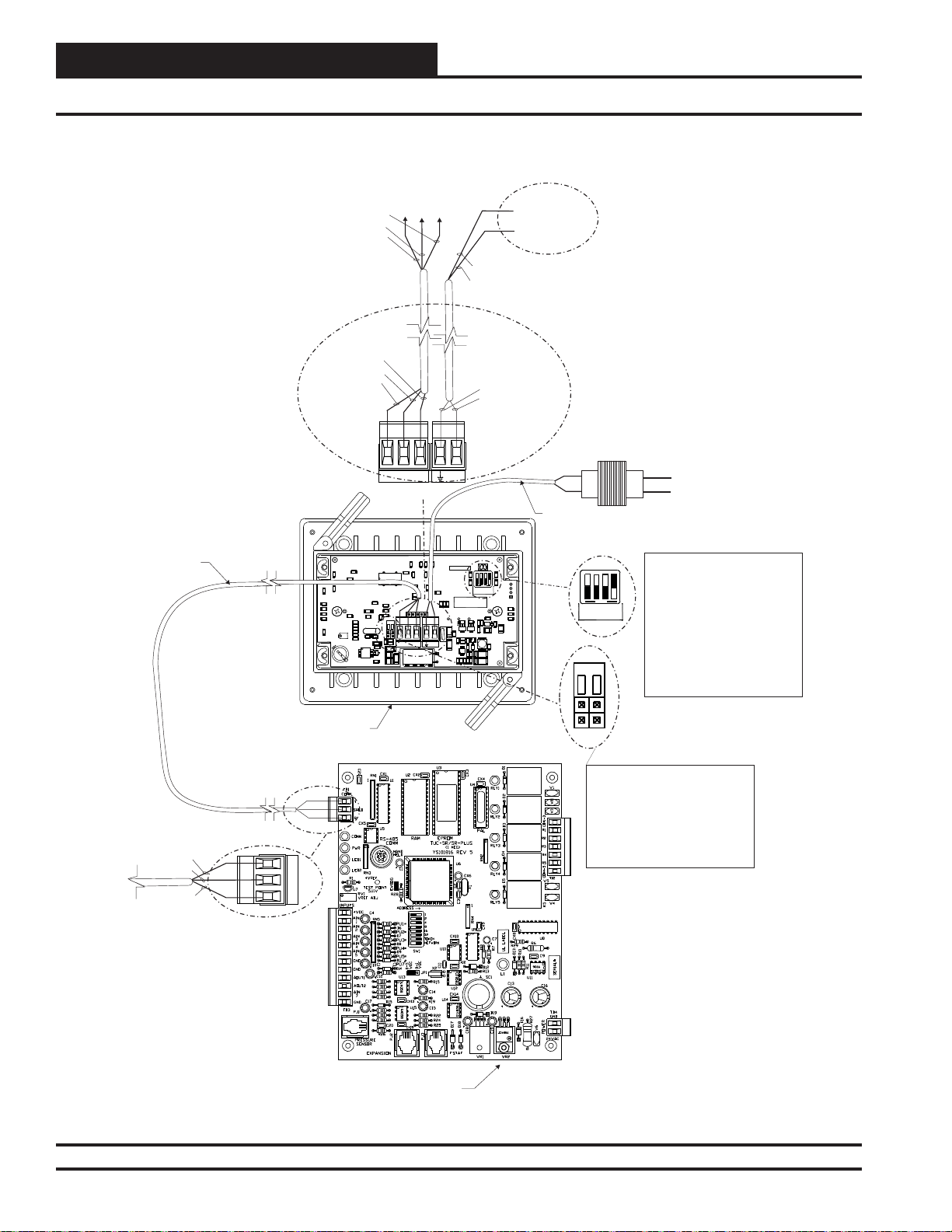

Components and Wiring

SMTS II to VCM Controller Wiring

On VCM

On VCM

To T Terminal

To S Terminal

T

C13

C11

C10

C9

C13

C11

C10

C9

.1uF

.1uF

.1uF

.1uF

X3

X3

C14

C14

.1uF

.1uF

R1

R1

1002

C12

C12

66.000Mhz

C1

C1

.1uF

.1uF

C15

C15

R7

R7

1002

1002

R9

R9

C19

C19

.1uF

.1uF

C18

J1

.1uF

.1uF

C16

C17

TERM

8.00Mhz

J3

R46

R43

1002

R47

1002

1002

RRSST

+

1002

D12

1002

R49

1002

R44

R48

1002

R45

330uF 50V 330uF

C24

C24

Run 2 Conductor

Twisted Pair W/Shield

Cable. WattMaster

WR-LL-WG-18 Cable

Or Equivalent From

System Manager To

VCM Controller

BLACK (R)

BARE (S)

WHITE (T)

WHITE (T)

BARE (S)

BLACK (R)

.1uF

.1uF

.1uF

C23

R20

C26

1002

C25

R10

.1uF

1002

R22

1002

R24

1002

R27

R36

1002

1002

1002

R29

R12

R14

1002

RTC

CAL

C39

C39

C20

C20

.1uF

C6

C8

.1uF

R17

1002

R26

1002

X2

C45

.1uF

1002

1002

R40

.1uF

.1uF

1002

R42

C5 C4

C50

C51

C51

L5

.1uF

1002

R37

C7

C7

.1uF

1002

1002

R6R5R2

R6R5R2

V1

On VCM

To R Terminal

+

WattMaster Controls, Inc

WattMaster Controls, Inc

WQVGAGraphical Interface

WQVGAGraphical Interface

YS102178 R4

YS102178 R4

MADE IN USA

1002

5V 3.3V 2.5V

D1

U10

.1uF

C27

.1uF

C28

1002

R11

R33

1002

R25

C31

R19U9R28

C32 R30

BROWN (GND)

RED (24 VAC)

BROWN (GND)

RED (24 VAC)

SW1

R13R8

1002 1002

1002 1002

R34 R16

GND

OFF

OPT4

OPT3

OPT2

OPT1

5V

SERIAL#

R21

R23

R35

1002

C36

C34 C40

R39

D11

.1uF

U13

.1uF

.1uF

.1uF

C41

1002

R32R31

1002

1002

L4

1002

R41

U11

R15

Q2

L1

C29

R18

1002

.1uF

.1uF

.1uF

C30

D2

C35

LTC3824

C2C3

1002

1002

.1uF

.1uF

1002

1002 1002

To (24 VAC)

Transformer -

To (24 VAC)

Transformer +

24 VAC Transformer

5 VA Minimum

Line Voltage

Run 2 Conductor 20 Ga. Minimum Cable From

System Manager TS Terminals To 24 VAC

NOTE: Dip Switches OPT1,

R

T

1002

1002

1002

OFF

OPT2

OPT1

OPT2 & OPT3.Should Be

Set To Off As Of April 2014,

OPT4 Should Be Set To ON

OPT4

OPT3

By Default. Previous Versions

Should Be Set To OFF. If You

See Your Screen Is Not

TERM

Centered Correctly, Switch

OPT4 To The Opposite

Position.

System Manager TS

Back View

WHITE (T)

BARE (S)

BLACK (R)

T

S

R

VCM Controller

Front View

Figure 5: System Manager TS II to VCM Controller Wiring

NOTE: For Stand-Alone

Installations (No CommLink

or MiniLink), Both TERM

Jumpers Must Be ON.

For All Applications With

CommLink(s) Or MiniLink(s),

Both Jumpers Must Be OFF.

8

Revised 4/21/14

SMTS II Technical Guide

Page 9

Components and Wiring

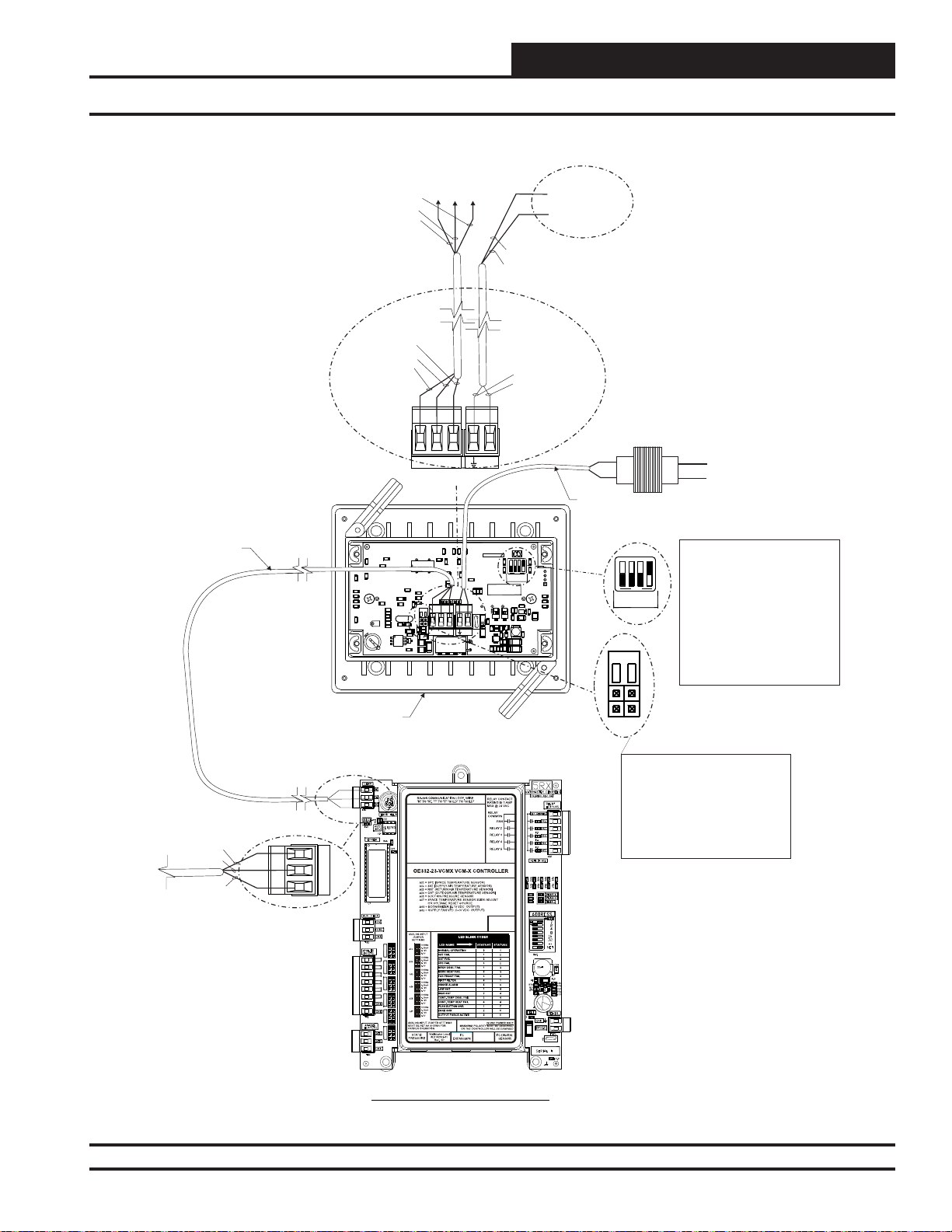

SMTS II to VCM-X Controller Wiring

Run 2 Conductor

Twisted Pair W/Shield

Cable. WattMaster

WR-LL-WG-18 Cable

Or Equivalent From

System Manager To

VCM-X Controller

BLACK (R)

BARE (S)

WHITE (T)

WHITE (T)

BARE (S)

BLACK (R)

.1uF

.1uF

.1uF

C23

R20

C26

1002

C25

R10

.1uF

1002

R22

1002

R24

1002

R27

R36

1002

1002

1002

R29

1002

1002

R12

.1uF

1002

R14

1002

RTC

1002

CAL

1002

C39

C39

On VCM-X

To T Terminal

To S Terminal

On VCM-X

On VCM-X

To R Terminal

To (24 VAC)

Transformer -

To (24 VAC)

Transformer +

BROWN (GND)

RED (24 VAC)

BROWN (GND)

RED (24 VAC)

24 VAC Transformer

5 VA Minimum

T

+

Line Voltage

Run 2 Conductor 20 Ga. Minimum Cable From

System Manager TS Terminals To 24 VAC

WattMaster Controls, Inc

WattMaster Controls, Inc

C13

C11

C10

C9

C13

C11

C10

C9

WQVGAGraphical Interface

WQVGAGraphical Interface

.1uF

.1uF

.1uF

.1uF

YS102178 R4

YS102178 R4

C14

C14

.1uF

R1

R1

1002

C1

C1

.1uF

R7

R7

1002

1002

R9

R9

J1

330uF 50V 330uF

MADE IN USA

1002

1002

5V 3.3V 2.5V

D1

1002

V1

R11

R25

C31

R19U9R28

SW1

R13R8

1002 1002

1002 1002

R34 R16

GND

OFF

R

T

OPT4

OPT3

OPT2

OPT1

5V

SERIAL#

.1uF

U10

.1uF

R15

C27

C29

.1uF

1002

.1uF

C28

LTC3824

R33

.1uF

1002

C32 R30

C34 C40

1002

R21

1002

R35

R23

1002

1002

C36

R39

D11

.1uF

U13

.1uF

.1uF

C41

1002

R32R31

1002

1002

L4

1002

R41

U11

Q2

L1

R18

.1uF

.1uF

C30

D2

C35

C2C3

1002

1002

.1uF

1002

1002 1002

TERM

OFF

OPT2

OPT1

.1uF

C12

C12

.1uF

C15

C15

C7

C7

.1uF

1002

R6R5R2

R6R5R2

+

C24

C24

X3

X3

66.000Mhz

C20

C20

.1uF

C19

C19

.1uF

.1uF

C18

C6

.1uF

.1uF

C16

C8

.1uF

C17

R17

TERM

R26

X2

C45

8.00Mhz

J3

R46

R40

.1uF

.1uF

R43

R42

C5 C4

1002

R47

1002

1002

C50

RRSST

C51

C51

L5

.1uF

1002

D12

R48

1002

1002

R49

1002

1002

R44

R37

R45

NOTE: Dip Switches OPT1,

OPT2 & OPT3.Should Be

Set To Off As Of April 2014,

OPT4 Should Be Set To ON

OPT4

OPT3

By Default. Previous Versions

Should Be Set To OFF. If You

See Your Screen Is Not

Centered Correctly, Switch

OPT4 To The Opposite

Position.

System Manager TS

Back View

WHITE (T)

BARE (S)

BLACK (R)

T

S

R

AI1 SET AI2 SET AI3 SET

AI1

AI2

AI3

AI4

AI5

AI4 SET AI5 SET AI7 SET

AI7

VCM-X Controller - Front View

Figure 6: System Manager TS II to VCM-X Controller Wiring

NOTE: For Stand-Alone

Installations (No CommLink

or MiniLink), Both TERM

Jumpers Must Be ON.

For All Applications With

CommLink(s) Or MiniLink(s),

Both Jumpers Must Be OFF.

SMTS II Technical Guide

Revised 4/21/14

9

Page 10

Components and Wiring

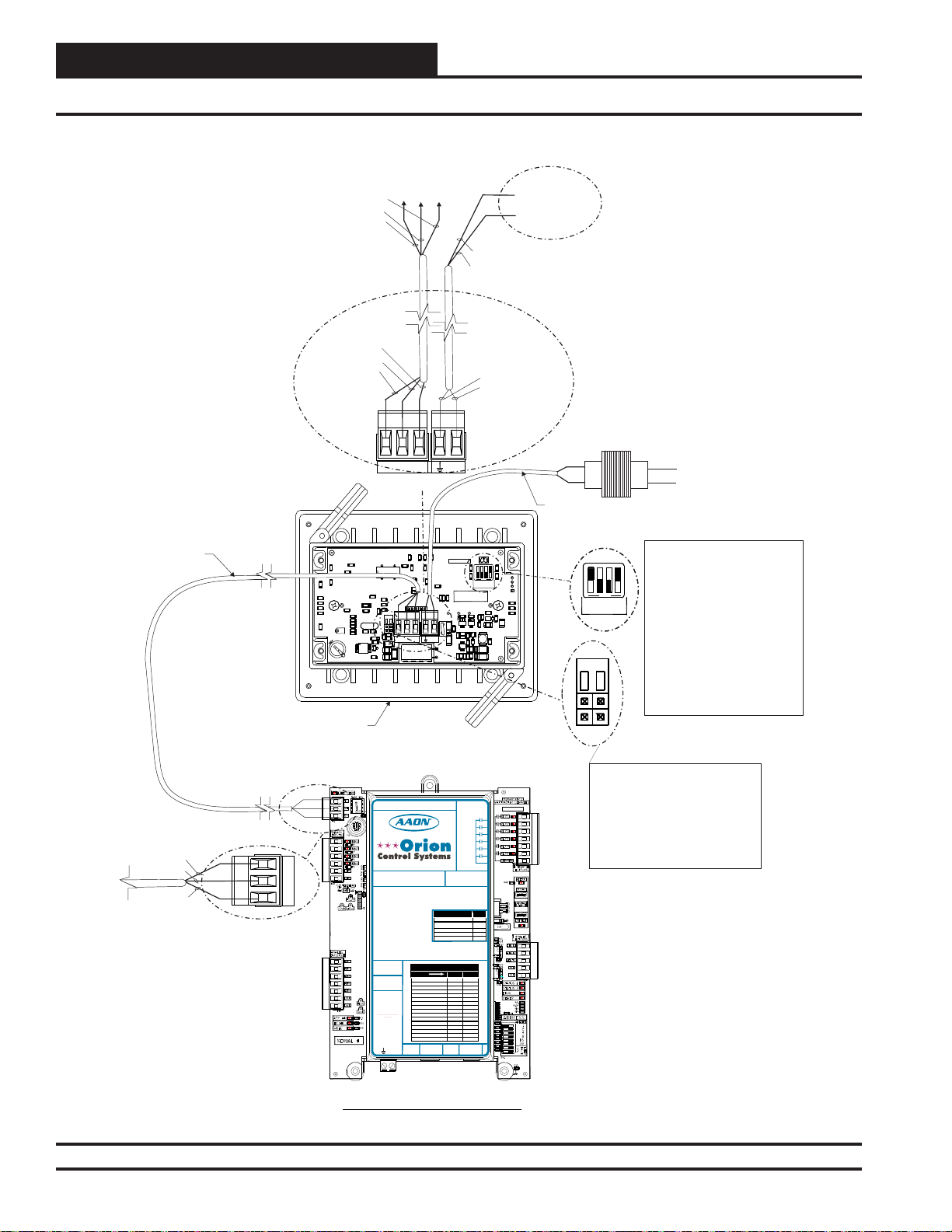

SMTS II to VCB-X Controller Wiring

Run 2 Conductor

Twisted Pair W/Shield

Cable. WattMaster

WR-LL-WG-18 Cable

Or Equivalent From

System Manager To

VCB-X Controller

BLACK (R)

BARE (S)

WHITE (T)

WHITE (T)

BARE (S)

BLACK (R)

.1uF

.1uF

R20

C26

1002

C25

R10

.1uF

1002

R22

1002

R24

1002

R27

R36

1002

1002

1002

R29

R12

R14

1002

RTC

CAL

C39

C39

System Manager TS

Back View

On VCB-X

To T Terminal

On VCB-X

To S Terminal

To R Terminal

On VCB-X

To (24 VAC)

Transformer -

To (24 VAC)

Transformer +

BROWN (GND)

RED (24 VAC)

BROWN (GND)

RED (24 VAC)

24 VAC Transformer

5 VA Minimum

T

+

Line Voltage

Run 2 Conductor 20 Ga. Minimum Cable From

System Manager TS Terminals To 24 VAC

WattMaster Controls, Inc

WattMaster Controls, Inc

C13

C11

C10

C9

C13

C11

C10

C9

WQVGAGraphical Interface

WQVGAGraphical Interface

.1uF

.1uF

.1uF

.1uF

YS102178 R4

YS102178 R4

C14

C14

.1uF

R1

R1

1002

C1

C1

.1uF

R7

R7

1002

1002

R9

R9

330uF 50V 330uF

MADE IN USA

1002

1002

5V 3.3V 2.5V

D1

.1uF

C28

1002

V1

R11

R33

R25

C31

R19U9R28

C32 R30

SW1

R13R8

1002 1002

1002 1002

R34 R16

GND

OFF

R

T

OPT4

OPT3

OPT2

OPT1

5V

SERIAL#

C34 C40

.1uF

U10

R15

C27

C29

.1uF

1002

.1uF

LTC3824

.1uF

1002

1002

R21

1002

R35

R23

1002

1002

C36

R39

D11

.1uF

U13

.1uF

.1uF

C41

1002

R32R31

1002

1002

L4

1002

R41

U11

Q2

L1

R18

.1uF

.1uF

C30

D2

C35

C2C3

1002

1002

.1uF

1002

1002 1002

OPT1

TERM

.1uF

C12

C12

.1uF

C15

C15

C7

C7

.1uF

1002

R6R5R2

R6R5R2

+

C24

C24

X3

X3

.1uF

C23

66.000Mhz

C20

C20

.1uF

C19

C19

.1uF

.1uF

C18

C6

J1

.1uF

.1uF

C16

C8

.1uF

C17

R17

1002

TERM

R26

1002

X2

C45

.1uF

8.00Mhz

J3

1002

1002

R46

R40

.1uF

.1uF

R43

1002

R42

C5 C4

1002

R47

1002

1002

C50

RRSST

C51

C51

L5

.1uF

1002

D12

R48

1002

1002

R49

1002

1002

R44

R37

R45

NOTE: Dip Switch OPT1

SW1

Should Be Set To ON When

VCB-X Is Set To High Speed.

OFF

OPT4

OPT3

OPT2

OPT2 & OPT3

Set To Off

. As Of April 2014,

OPT4 Should Be Set To ON

By Default. Previous Versions

Should Be Set To OFF. If You

See Your Screen Is Not

Should Be

Centered Correctly, Switch

OPT4 To The Opposite

Position.

WHITE (T)

BARE (S)

BLACK (R)

RS-485 COMMUNICATION LOOP. WIRE

“R”TO “R”, “T” TO “T” “SHLD” TO “SHLD”

www.aaon.com

T

S

R

www.orioncontrols.com

VCB-X CONTROLLER

Orion No.:OE335-23-VCBX-A

ANALOG INPUTS

AI1= SPC (SPACE TEMPERATURE SENSOR)

AI2

= SAT(SUPPLYAIR TEMPERATURE SENSOR)

AI3

= OAT(OUTDOOR AIR TEMPERATURE SENSOR)

AI4

= DCT(DIGITAL COMP. DISCHARGETEMPERATURE SENSOR)

AI5

= SPACETEMPERATURE SLIDE OFFSET

BINARYINPUTS

BI1

= EMERGENCYSHUTDOWN

BI2

= PROOF OF FLOW

BI3

= DIRTYFILTER

Bi4

= COILTEMPERATURE SWITCH

G OUTPUTS

ANALO

AO1

= FAN VFD

AO2

= ECONOMIZER

AO3

= SCR OR MODULATING HW HEATING

TRIAC OUTPUT

TR1

= DIGITALCOMP. UNLOADER

(24 VAC & UNLOADTERMINALS)

WattMaster Label

#LB102093-01-A

Rev.: 1A

24 VAC POWER

ONLY

WARNING!

POLARITYMUST

BE OBSERVED

OR THE

CONTROLLER

WILLBE

DAMAGED

GND

+24VAC

RELAYCONTACT

RATING IS 1AMP

MAX @ 24 VAC

RELAY2

RELAY3

RELAY4

RELAY5

RELAY6

RELAY

COMMON

AAON No.:

V04740

ALERTLED BLINKCODES BLINKS

NORMALOPERATION 0

MISSINGOR SHORTED

DISCHARGETEMP. SENSOR

IN30 MIN. CUTOFF PERIOD 3

INHIGH TEMP. CUTOFF 4

COMPRESSORLOCKED OUT 6

STATUSLED BLINKCODES

LEDNAME STATUS1 STATUS2

NORMALOPERATION 0 1

SATFAIL 1 2

OATFAIL 2 2

SPCFAIL 3 2

AIRFLOWSENSOR FAIL 7 2

MECHCOOL FAIL 1 3

MECHHEAT FAIL 2 3

FANPROOF FAIL 3 3

DIRTYFILTER 4 3

EMERGENCYSHUTDOWN 5 3

LOWSAT 1 4

HIGHSAT 2 4

CONT.TEMP COOL FAIL 3 4

CONT.TEMP HEAT FAIL 4 4

PUSHBUTTON OVR 1 5

OUTPUTFORCE ACTIVE 0 6

E-BUS

EXPANSION

EXPANSION

FAN

E-BUS

VCB-X Controller - Front View

Figure 7: System Manager TS II to VCB-X Controller Wiring

Revised 4/21/14

10

SMTS II Technical Guide

NOTE: For Stand-Alone

Installations (No CommLink

MADE IN USA

or MiniLink), Both TERM

Jumpers Must Be ON.

For All Applications With

CommLink(s) Or MiniLink(s),

Both Jumpers Must Be OFF.

1

Page 11

Components and Wiring

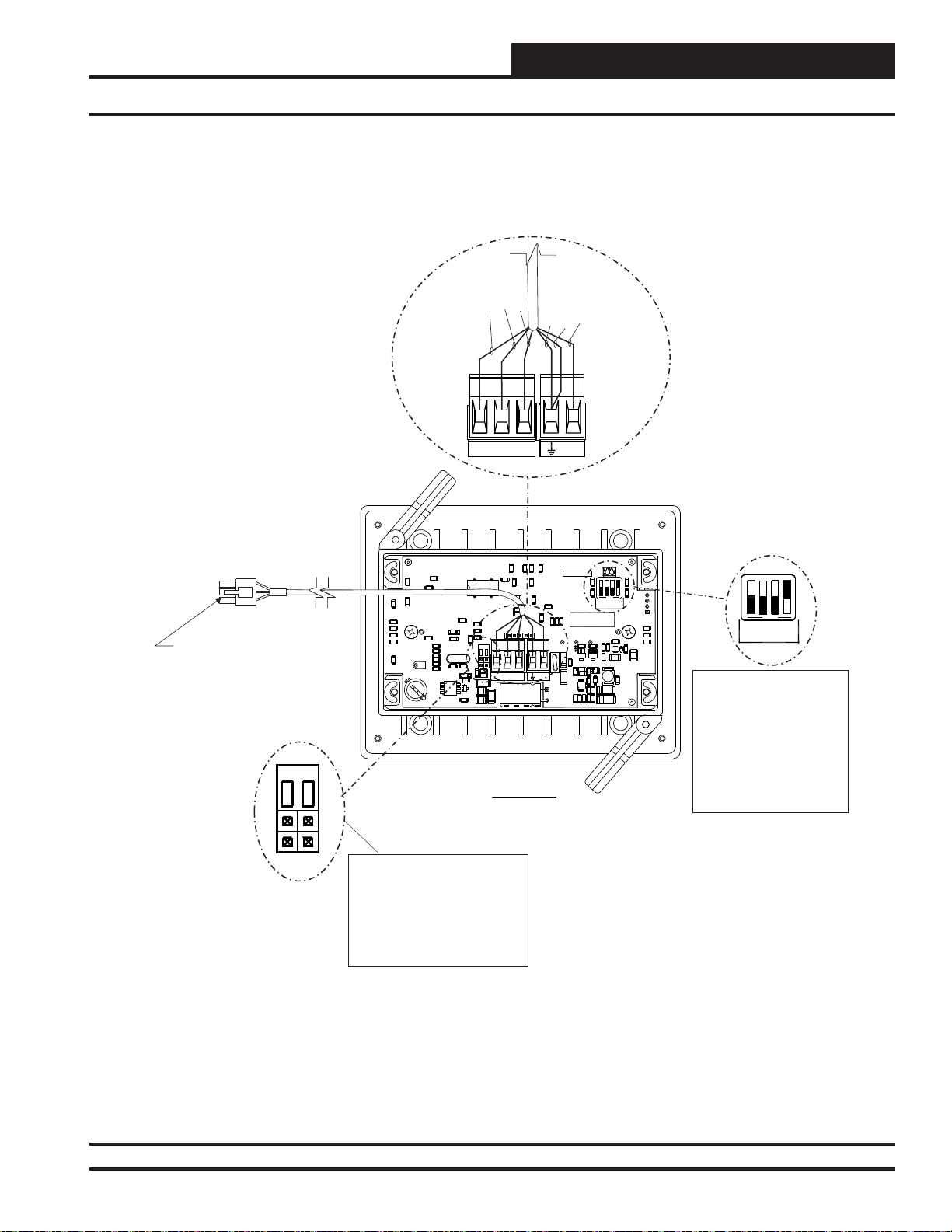

SMTS II to VAV/Zone Controller Actuator Package Wiring

BARE (S)

WHITE (T)

BLACK (R)

RED (24 VAC)

GREEN (GND)

BROWN (GND)

+

Power/Comm Pigtail Cable From

VAV/Zone Controller Actuator

Package Or Power/Comm

Distribution Board

TERM

X3

X3

C14

C20

C20

.1uF

.1uF

.1uF

1002

R37

66.000Mhz

C19

C19

.1uF

.1uF

.1uF

.1uF

C17

8.00Mhz

J3

R46

R43

R47

D12

R49

R44

C18

C16

TERM

1002

1002

1002

RRSSTT+

1002

R48

1002

1002

1002

R45

C14

.1uF

J1

330uF 50V 330uF

.1uF

.1uF

.1uF

C23

R20

C26

1002

C25

R10

.1uF

1002

R22

1002

R24

1002

1002

1002

R29

1002

C6

R27

R36

1002

C8

.1uF

R17

1002

R26

1002

X2

C45

R12

.1uF

1002

R14

RTC

1002

R40

.1uF

CAL

1002

R42

C5 C4

C50

C51

C51

L5

C39

C39

Back View

NOTE: For Stand-Alone

Installations (No CommLink

or MiniLink), Both TERM

Jumpers Must Be ON.

For All Applications With

CommLink(s) Or MiniLink(s),

Both Jumpers Must Be OFF.

WattMaster Controls, Inc

C13

C13

.1uF

1002

C1

C1

.1uF

R7

R7

1002

1002

R9

R9

WattMaster Controls, Inc

C11

C10

C9

C11

C10

C9

WQVGAGraphical Interface

WQVGAGraphical Interface

.1uF

.1uF

.1uF

YS102178 R4

YS102178 R4

MADE IN USA

.1uF

R1

R1

C12

C12

.1uF

C15

C15

C7

C7

.1uF

C22

C22

.1uF

1002

1002

1002

R6R5R2

R6R5R2

5V 3.3V 2.5V

D1

.1uF

C28

1002

V1

C24

C24

R11

R33

R25

C31

R19U9R28

C32 R30

U10

C27

.1uF

LTC3824

1002

SERIAL #

C34 C40

.1uF

R15

C29

1002

.1uF

.1uF

1002

SW1

R13R8

1002 1002

1002 1002

R34 R16

GND

OFF

R

T

OPT4

OPT3

OPT2

OPT1

5V

1002

R21

1002

R35

R23

1002

1002

C36

R39

D11

.1uF

U13

.1uF

.1uF

C41

1002

R32R31

1002

1002

L4

1002

U11

Q2

R18

.1uF

C30

1002

.1uF

1002 1002

R41

L1

.1uF

D2

C35

C2C3

1002

NOTE: Dip Switches OPT1,

OPT2 & OPT3.Should Be

Set To Off As Of April 2014,

OFF

OPT4

OPT3

OPT2

OPT1

OPT4 Should Be Set To ON

By Default. Previous Versions

Should Be Set To OFF. If You

See Your Screen Is Not

Centered Correctly, Switch

OPT4 To The Opposite

Position.

Figure 8: System Manager TS II Wiring to Power/Comm Distribution Board or VA V/Zone Actuator Package

Wiring

SMTS II Technical Guide

Revised 4/21/14

11

Page 12

Zone

Navigation

Main Screen Icons and Button Functions

Zone

Icons and Button Functions

System settings and screens are easily accessible by simply touching one

of the six icons on the Main Screen. The subscreens contain yellow highlighted data entry boxes with accessible number keypads for data entry

and screen maneuvering buttons such as

NOTE: Do not attempt to make changes to the Touch Screen

while the Unit Controller is initializing. This can cause

programming errors.

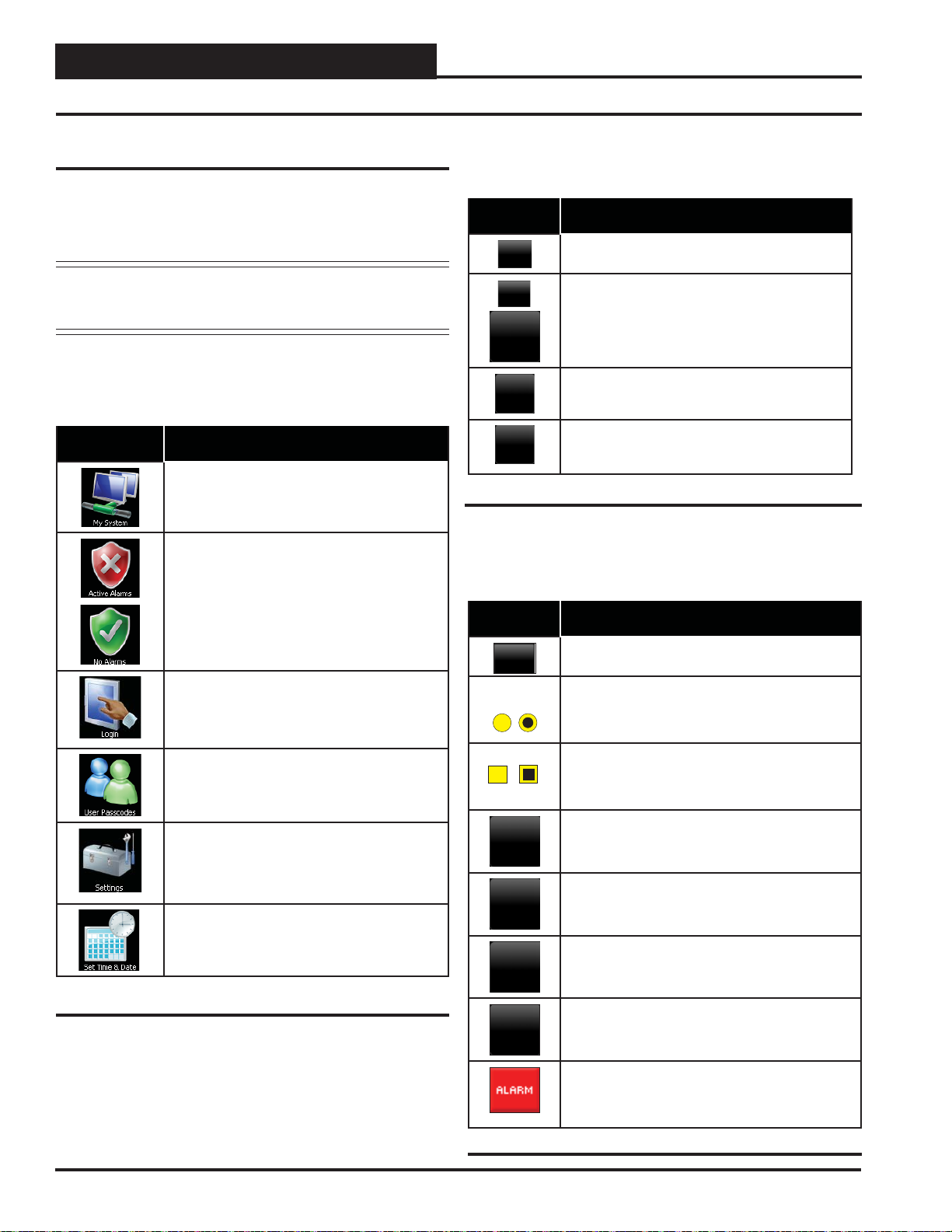

Main Screen Icons

There are six Main Screen icons. See Table 1 for a list of the Main

Screen icons and their functions.

Icon Main Screen Icons

The < My System> icon takes you to a Unit

Selection Screen which takes you directly to the

selected controller’s Status Screen.

When bright red, the < Alarms> icon takes

you to the Alarms Screen. When bright green,

no alarms are present. This icon is only useful

when your SMTS II is set for multiple managers

or network mode and you have confi gured alarm

polling using Prism 2 software.

<Esc>, <Back>, and <OK>.

Navigation Buttons

See Table 2 for a list of Navigation buttons and their functions.

Button Function

Use the < Esc> (Escape) key to exit from data

entry without saving any new data.

Use the small < Back> button located in the top

right corner of a Data Entry Screen to return to the

controller’s Status Screen. Use the large < Back>

button located at the bottom left of other screens to

return to the previous screen.

Use the < +> key to step to the next screen.

Use the < -> key to step to the previous screen.

Back

Back

Esc

+

-

Table 2: Navigation Button Functions

Selection, Confi guration, and Setpoint Buttons

See Table 3 for a list of Selection, Confi guration, and Setpoint buttons

and their functions.

Button Function

The < Login> icon takes you to the Login Screen

where you enter your passcode.

The < User Passcodes> icon takes you to the

System Manager Passcode Levels Screen if you

are a Level 3 user.

The < Settings> icon takes you to the System

Settings Screen where you can change the Backlight settings, set the System Manager address,

and enable alarm polling. System settings are

only accessible to a Level 3 user.

The < Set Time & Date> icon takes you to the

Set Time and Date Screen. Any level of user can

set the time and date.

Table 1: Main Screen Icon Functions

OK

Setpoints

Overrides

Schedules

Holidays

Use the < OK> key to save the data you just se-

lected or entered.

Touch the grey radio button to make your selection.

A white circle will designate that the item is

selected. You can only select one radio button item

per screen.

Touch the grey square selection box to make your

selection. A white square will designate that the item

is selected. You can make numerous square box

item selections per screen.

The < Setpoints> button, appearing on the control-

ler’s Status Screen, takes you directly to the controller’s Temperature Setpoint Screen.

The <Overrides> button, appearing on various

controllers’ Status Screens, takes you directly to the

controller’s Force Schedules Screen.

The < Schedules> button, appearing on various

controllers’ Status Screens, takes you directly to the

controller’s Schedule Screen.

The < Holidays> button, appearing on various

controllers’ Status Screens, takes you directly to the

controller’s Holidays Screen.

The < Alarm> button, appearing on the controller’s

Status Screen, takes you directly to the controller’s

Alarms Screen. If red, alarm(s) are present. If black,

no alarm(s) are present.

12

Revised 10/2/12

Table 3: Confi guration Selection Buttons

SMTS II Technical Guide

Page 13

Navigation

Main Screen Icons and Button Functions

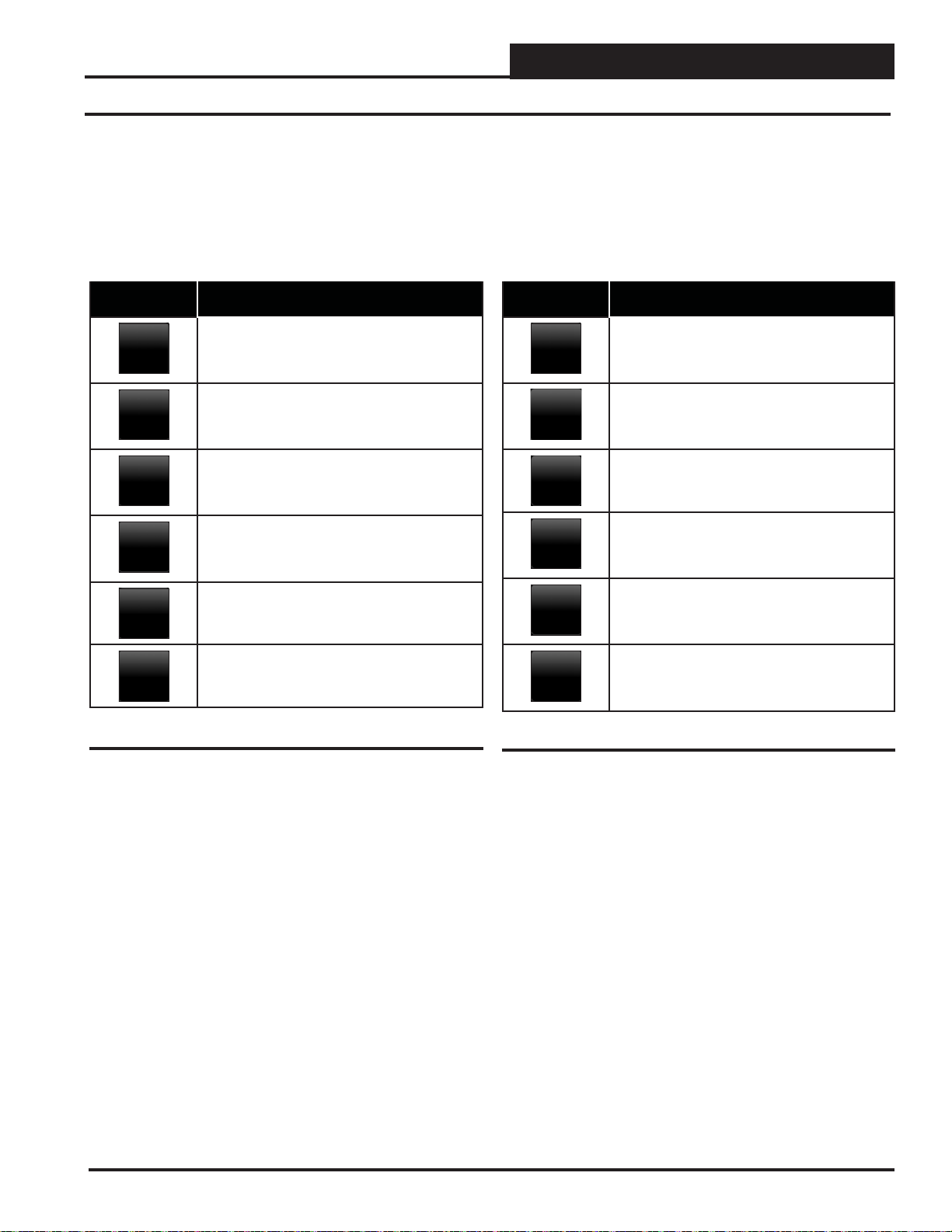

VCM, VCM-X & VCB-X Setpoint Buttons

The VCM, VCM-X & VCB-X Setpoint Buttons are located at the bottom of each controller’s Setpoints Screen. See Table 4 for a list of the

Setpoint buttons and their functions. Level 1 and Level 2 users can view

these screens and change occupied heating and cooling setpoints, but

only a Level 3 user can make changes to all setpoints.

Button Function

The < Temps> button, located at the bottom

Temps

Static

Staging

Misc

Relays

Config

of the controller’s Setpoints Screen, takes you

directly to the controller’s Temperature

Setpoints Screens.

The < Static> button, located at the bottom

of the controller’s Setpoints Screen, takes you

directly to the controller’s Static & Air Setpoints

Screens.

The < Staging> button, located at the bottom of

the controller’s Setpoints Screen, takes you

directly to the controller’s Staging Delays

Screens.

The < Misc> button, located at the controller’s

Setpoints Screen, takes you

directly to the controller’s Miscellaneous Set-

points Screens.

The <Relays> button, located at the bottom

of the controller’s Setpoints Screen, takes you

directly to the controller’s Outputs Screens.

The < Confi g> button, located at the

controller’s Setpoints Screen, takes you directly

to the controller’s Confi guration Screens.

VAV/Zone Setpoint Buttons

The VAV/Zone Setpoint Buttons are located at the bottom of the VAV/

Zone Setpoints Screen. See Table 5 for a list of the Setpoint buttons and

their functions. Level 1 and Level 2 users can view these screens and

change occupied heating and cooling setpoints, but only a Level 3 user

can change all setpoints.

Button Function

The < Temps> button, located at the bottom

Temps

Damper

Alarms

Misc

Calibrate

Config

the controller’s Setpoints Screen, takes you

directly to the controller’s Temperature Setpoints

Screens.

The < Damper/Airfl ow> button, located at the

bottom of the controller’s Setpoints Screen, takes

you directly to the controller’s Damper/Airfl ow

Setpoints Screens.

The < Alarms> button, located at the bottom

of the controller’s Setpoints Screen, takes you

directly to the controller’s Alarm Settings Screen.

The < Misc> button, located at the bottom

of the controller’s Setpoints Screen, takes you

directly to the controller’s Miscellaneous

Setpoints Screen.

The < Calibrate> button, located at the bottom

of the controller’s Setpoints Screen, takes you

directly to the controller’s Calibration Setpoints

Screen.

The < Confi g> button, located at the bottom

of the controller’s Setpoints Screen, takes you

directly to the controller’s Confi guration Setpoints

Screens.

Table 4: VCM, VCM-X & VCB-X Setpoint Icons

Table 5: VAV/Zone Setpoint Icons

SMTS II Technical Guide

13

Page 14

Main Screen Functions

Logging In

Zone

Zone

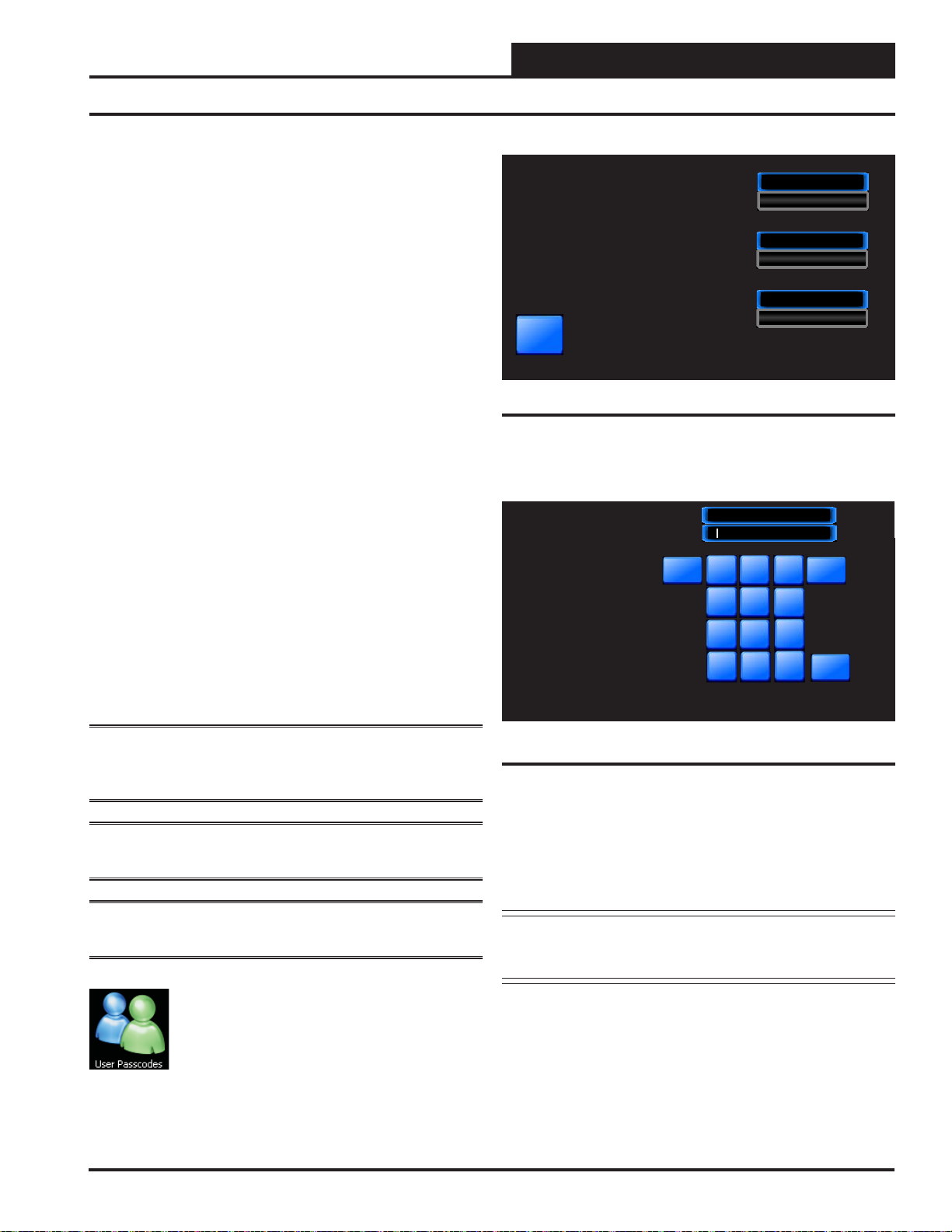

First Things First

The fi rst thing you need to do when setting up your Touch Screen is

to Login. The second thing you need to do is establish user passcodes.

The third thing you need to do is set the clock. After you complete

these simple tasks, you are ready to set your system’s settings,

view controller status screens, and change schedules and setpoints.

NOTE: Do not attempt to make changes to the Touch Screen

while the Unit Controller is initializing. This can cause

programming errors.

Main Screen

Once you have connected your System Manager TS II to a controller

and have powered it up with the proper power supply, the Main Screen

will appear. See Figure 9.

Entering Your System Manager

Passcode

NOTE: There are three available passcode levels. Level 1 defaults to

1111, Level 2 defaults to 2222, and Level 3 defaults to 3333. These defaults

can be changed by anyone who logs in at Level 3.

When you power-up your System Manager TS II, the message

Secured is displayed on the bottom left corner of the Main Screen.

Touch the

< Login> icon found on bottom left of the

Main Screen and type the default Level 3 passcode of

“3333” using the number keypad to gain access to all

setpoint and confi guration items. See Figure 10.

Esc

Currently: ****

2

1

4

5

7

8

-

0

3

6

9

.

DATA ENTRY

Enter the 4 digit Passcode

for the required Level.

Level #1:

Can change space setpoints.

Level #2:

Can change schedules.

Level #3:

Can change all setpoints.

System

<<

OK

Figure 9: Main Screen

Figure 10: Login Screen

NOTE: For security reasons, the current passcode characters

displayed at the top of the screen are never shown and

appear as asterisks.

Touch <OK>. Touch <Esc> if you accessed this screen by mistake and

do not wish to change the current access level.

The Login Screen will automatically close, and the passcode will be

tested against all previously defi ned passcodes to determine the pass-

code’s access level.

If 3333 is still the active Level 3 code, the status message System

Access Level 3 will now be displayed on the bottom left corner of

the Main Screen.

NOTE: System Access will automatically default to System

Secured after time set for Backlight Timeout in the

System Manager Settings Screen (see Figure 15, page

19). If timeout is set to zero, the passcode will timeout

after two minutes.

14

Revised 10/2/12

SMTS II Technical Guide

Page 15

Main Screen Functions

Editing Passcodes

Passcode Clearance Levels

Below is a list of the passcode levels, default codes, and actions that can

be performed at the various levels.

Level 0—No Passcode Needed, System

Secured

Level 0 users can view temperatures and status points. They

can also change the system date and time, but no changes

to any controller setpoints can be made.

Level 1—Default: 1111

Level 1 users can view temperatures and change space

temperature setpoints. No changes to schedules or other

settings can be made.

Level 2—Default: 2222

Level 2 users can change space temperature setpoints and

operating schedules but not confi guration settings.

Level 3—Default: 3333

Level 3 users have system manager access and can change

all setpoints and confi gurations, including default pass-

codes. Level 3 users can also access force modes. This

Level is normally reserved for qualifi ed HVAC service

personnel.

Edit Passcodes

Passcode Levels

You can limit access to critical settings

by giving the user access only to those

items needed to maintain comfort levels

or to modify operating hours.

All critical setpoints and configurations

are protected by Level #3 and should not be

accessed except by a service technician.

Back

{ Can change Space Setpoints }

{ Can change Schedules & Holidays }

{ Can change All Setpoints }

1111

Level #1 Passcode

2222

Level #2 Passcode

3333

Level #3 Passcode

Figure 11: System Manager Passcode Levels Screen

To change a passcode, touch the blue highlighted box containing the

current passcode. The keypad will appear with instructions for changing

the passcode. See Figure 12.

Esc

Currently: 1111

2

1

4

5

7

8

-

0

<<

3

6

9

OK

.

DATA ENTRY

Enter the 4 digit Passcode

for Level 1.

Level #1:

Can temporarily override schedules.

Level #2:

Can change schedules and holidays.

Level #3:

Can change user passcodes and

access force modes.

WARNING: MAKE SURE YOU CHANGE ALL PASSCODES AS SOON AS POSSIBLE TO SECURE THE

SYSTEM!

NOTE: Only a Level 3 user ( system manager level) can change Level

1, 2, and 3 passcodes.

NOTE: Do not use the same passcode for all 3 levels. If you do, each

passcode will default to Level 1.

From the Main Screen, touch the

< User Passcodes>

icon. The System Manager Passcode Levels Scr een will

appear. See Figure 11.

SMTS II Technical Guide

Figure 12: Change Passcode Screen

The current passcode will appear on the top menu bar. Type in the new

four-digit passcode. You cannot use the period or minus characters in

your passcode. Use the <<<> key if you make a mistake. Touch <Esc>

to return to the previous screen without changing the passcode. When

you have typed in the new passcode, touch <OK>. The System Manager

Passcode Levels Screen should display the passcode you entered.

NOTE: If you change the Level 3 passcode, make sure to write

it down. If you should happen to forget the Level 3

passcode, contact WattMaster Technical Support.

Touch <Back> to return to the Main Screen.

15

Page 16

Main Screen Functions

Setting the System Clock

Zone

Zone

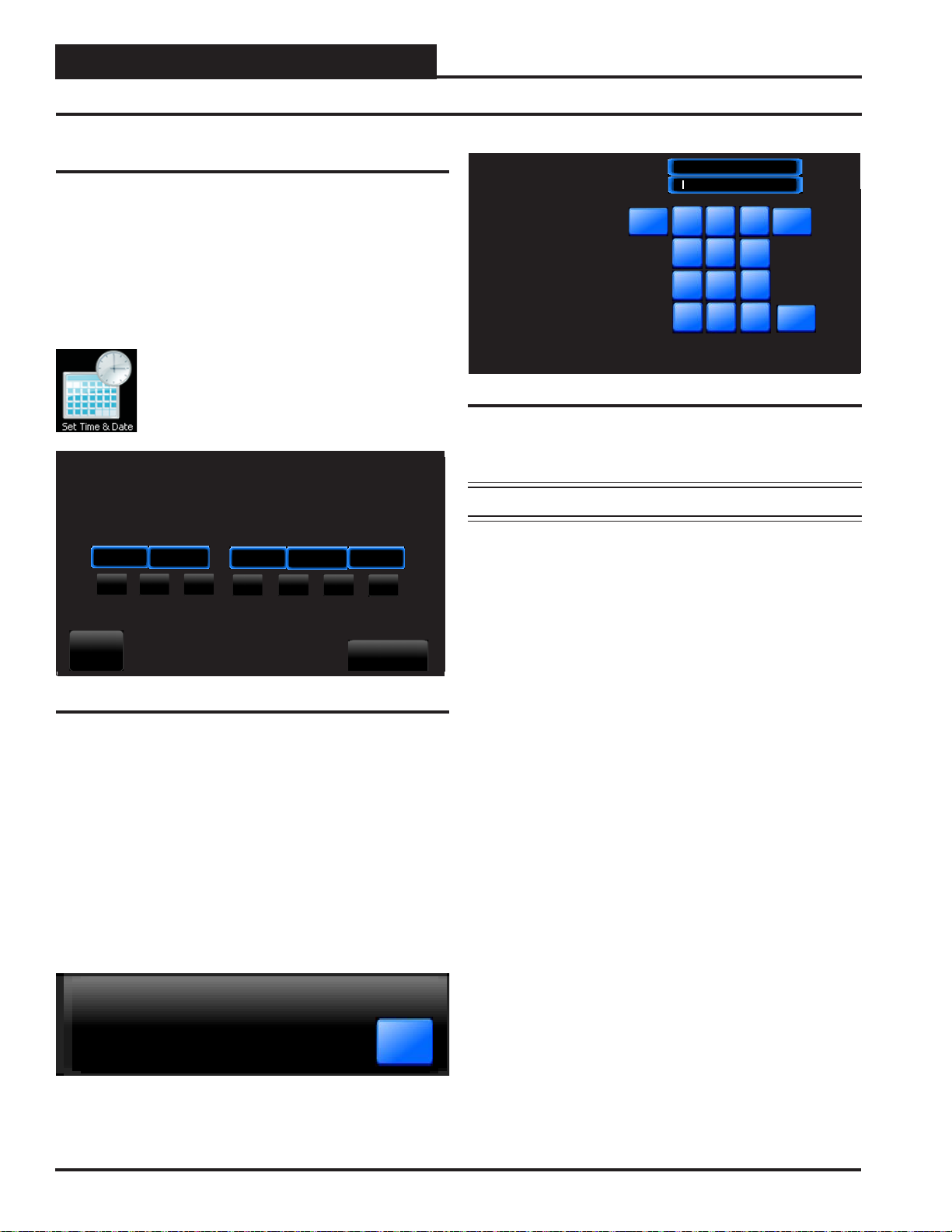

Set Time and Date

When you fi rst power up your System Manager TS II, you will need

to change the day of the week, the time, and the month, day, and year

to the current time and date. If your system has been turned off or has

been down for a long time, you may have to do the same, although the

time and date can maintain itself for several days. Any level of user can

change the time and date settings.

The day of the week, the time, and the date appear at the top right on

the Main Screen. See Figure 9.

From the Main Screen, touch the < Set Time & Date>

icon. The Set Time & Date Screen will appear. See

Figure 13.

System Manager Settings

Set Time & Date

Hour Minute

14

Sun

12

Mon

Tue

Month

Wed

Day Year

Thu

Sun

Thu

16

Fri

Sun

12

Sat

Sat

Sun

Fri

1

DATA ENTRY

Set Clock Hour

Enter the Current Hour in

24 hour military format.

Example:

5:00 AM = 5

5:00 PM = 17

Hi Limit: 23

Lo Limit: 0

Esc

Currently: 10

2

1

4

5

7

8

-

0

<<

3

6

9

OK

.

Figure 14: Set Clock Hour

Set Clock Hour: Touch the number buttons to enter the current hour in

24 hour military format. Valid entries are from 0-23. Press <OK>.

NOTE: See Appendix for Military Time Conversion table.

Set Clock Minute: Touch the number buttons to enter the current

minutes. Valid entries are from 0-59. Press

Set Clock Month: Touch the number buttons to enter the current

month. Valid entries are from 1-12. Press <OK>.

<OK>.

Back

Broadcast

Figure 13: Set Time & Date Screen

In the example above, the current time and date is 2:12 PM, January 16,

2012. There is no day of the week selected yet.

Set Day of the Week: Select the day of the week by simply touching

your selection. The day of the week text will change from white to blue.

Set Hour, Minute, Month, Day, and Year: Touch the blue high-

lighted box to have each selection screen appear. See Figur es 13 & 14.

Read the instructions on each screen for entering data.

Broadcast: When you are fi nished setting the clock, touch the

<Broadcast> button to broadcast the Time and Date to all Units. The

following message will appear:

Time & Date Broadcast to All Units.

OK

Set Clock Day: Touch the number buttons to enter the current day of

the month. Valid entries are from 1-31. Touch <OK>.

Set Clock Year: Touch the number buttons to enter the current year.

Valid entries are from 0-99. Touch <OK>. Note: The year is based on

the current century; therefore, 12 = 2012. If you enter more than two

digits, e.g. 2012, the system will not recognize your entry.

16

SMTS II Technical Guide

Page 17

Main Screen Functions

System Manager Settings

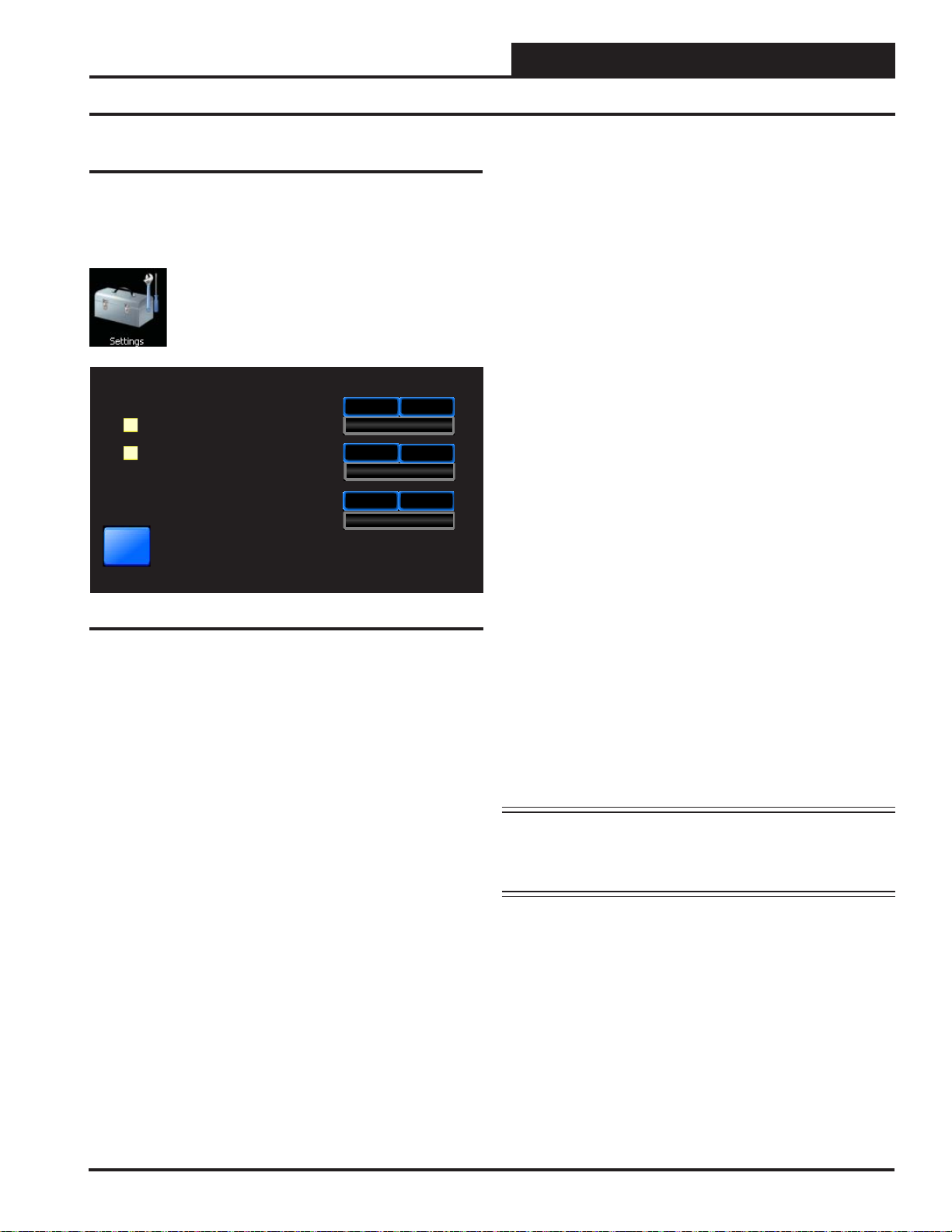

System Manager Settings

Additional system settings are available under the <Settings> icon.

These include setting the Backlight Timeout, the Backlight Intensity

Percentage, the System Manager Address, Alarm Polling, and One to

One Unit Connection.

From the Main Screen, touch the < Settings> icon.

The System Manager Settings Screen will appear. See

Figure 15.

System Manager Settings

30

30

Minutes

Alarm Polling Enabled

One to One Unit Connection

Back

Figure 15: System Manager Settings Screen

Backlight Timeout

3050

Backlight Intensity

3063

System Manager Address

System Manager Version: 2.00

%

System Manager Address: Enter the address of the System Manager

TS II. 0 = Stand Alone Mode. 63 = Network System. 1-60 = Multiple

Managers based on the following defi nitions:

• Stand Alone—If your System Manager TS II is connected to

one controller and you are not using a CommLink or MiniLink

anywhere on the loop, your system is Stand Alone. If your System

Manager TS II is connected to more than one controller daisychained together and you are not using a CommLink or MiniLink

anywhere on the loop, your system is Interconnected. If you have

either a Stand Alone or Interconnected system, you must enter

<0> for Stand Alone Mode. In order to view all controllers on an

Interconnected System, make sure that One to One Unit Connec-

tion, described below, is not selected.

• Network—If you are using this System Manager TS II on a com-

munications loop that has a MiniLink or CommLink installed and

you have a single System Manager TS II for your entire system,

you must enter <63> for Network System.

• Multiple Managers—If you are using this System Manager TS

II on a communications loop, have a MiniLink or CommLink installed, and have more than one System Manager TS II, then you

need to operate in Multiple Managers Mode. Enter the address

<1-60> at which you want this particular System Manager TS II

to be set. When more than one System Manager TS II is used on

a local loop, each must be set with a unique address different from

any other device on that loop. If you want one of the System Manager TS II’s to be able to indicate alarms for the entire system, you

must enter <63> for Network System for that particular System

Manager TS II.

Backlight Timeout: This setting is actually a setting for three separate

functions—Backlight Timeout, Main Screen Timeout, and Passcode

Timeout. To set the Backlight Timeout, enter the amount of time you

wish the screen to maintain the active intensity level after the last touch

pad activity occurs. The High limit is 30 and the Low limit is 0. 0 =

No Timeout. The System Manager TS II will return to the Main Screen

display at the same rate as the Backlight Timeout, except that if set

to 0, the Main Screen will display after 2 minutes. The Passcode will

timeout at the same rate as the Backlight Timeout, except that if set to

0, the Passcode will timeout after 2 minutes and will return to System

Secured Setting.

Backlight Intensity Percentage: Enter the percentage of light level

you wish to maintain whenever touch pad activity occurs. The High limit

is 100 and the Low limit is 0.

Alarm Polling Enabled: If you wish for the system to poll for alarms,

touch the black box to the left of this item to select it. The box will

turn white and the system will immediately check all loops for alarms.

Touch <Cancel> to stop the process. If you wish to have Alarm Polling

Disabled, you must now touch the white box to deselect this option. The

box will return to its previously fully black state.

NOTE: For the System Manager TS II to poll for alarms, you

must also confi gure the unit(s) to poll for alarms on the

MiniLink Polling Device Setpoints Screen using Prism

2. See the Appendix in this guide for more information.

One to One Unit Connection: If your System Manager TS II is

directly connected to only one unit, you may wish to select this option

to bypass the Unit Selection Screen and go directly to the unit’s Status

Screen. The controller must be set to address #1 for this to work. Touch

the black box to the left of this item on the screen to select it. The box

will turn white. If you wish to deselect this option, simply touch the

box again.

System Manager V ersion: The version number of the System Man-

ager software appears on the bottom menu bar. This version number is

important to know for troubleshooting purposes.

SMTS II Technical Guide

17

Page 18

Main Screen Functions

Polling for Alarms

Zone

Zone

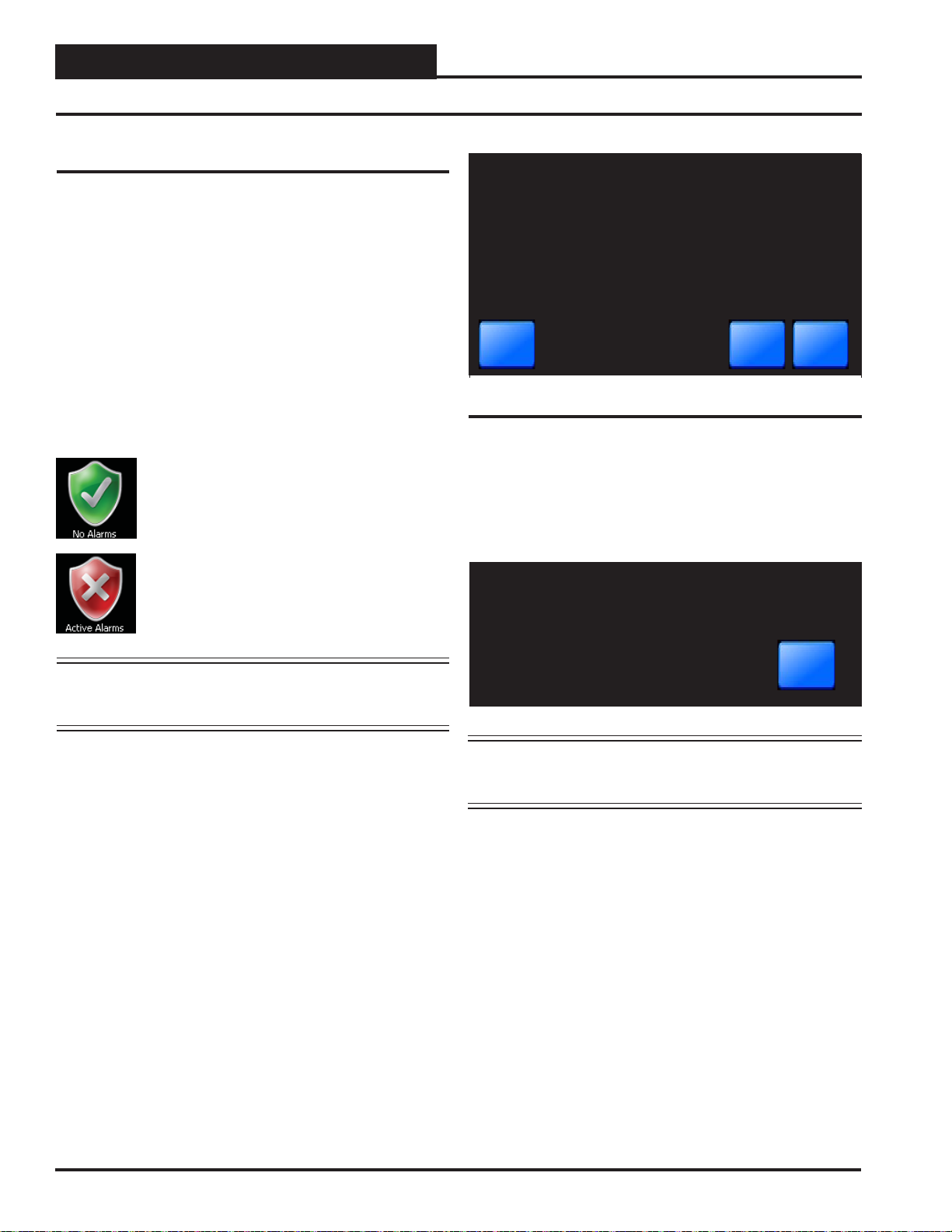

Alarm Polling

In order for Alarm Polling to appear on the Main Scr een, you must have

the following items in place:

1. Alarm Polling Enabled must be selected in the Systems

Settings Screen (see Figure 15, page 17).

2. You must have a MiniLink connected to your system and

have your System Manager TS II set to Network Mode.

3. You must confi gure each unit to poll for alarms on the

MiniLink Polling Device Setpoint Screen using Prism 2.

See the Appendix in this guide for more information.

The < Alarms> icon on the Main Screen allows you to check for

alarms, review alarms, and clear alarms. Only a Level 3 user can clear

the alarm log.

A green

Screen when no alarms are present. This icon changes to

a red < Active Alarms> icon when alarms are present.

To check for alarms, review alarms, or clear alarms,

from the Main Screen, touch the < Active Alarms>

icon. The System Alarm Status Screen will appear. See

Figure 16.

< No Alar ms> icon appears on the Main

System Alarm Status

Checking

Back

Clear All

Next Unit

Figure 16: System Alarm Status Screen

Next Unit: Touch <Next Unit> to access the next unit’s alarms.

Clear All: Touch <Clear All> to clear all alarms logs. Active alarms

will remain. You must be a Level 3 user to access this option. When all

alarms have cleared, the following message will appear on the screen:

All alarms cleared.

Any remaining active alarms will re-appear.

NOTE: Even if you don’t set up Alarm Polling using Prism 2,

a controller’s fi rst status screen will still alert you of an

active alarm.

OK

NOTE: Y ou can also view alarms while in individual controller’s

status screens. For more information, see pages 21, 22

& 63.

18

SMTS II Technical Guide

Page 19

VCM, VCM-X & VCB-X Controllers

Selecting Units and Viewing VCM, VCM-X & VCB-X Status Screens

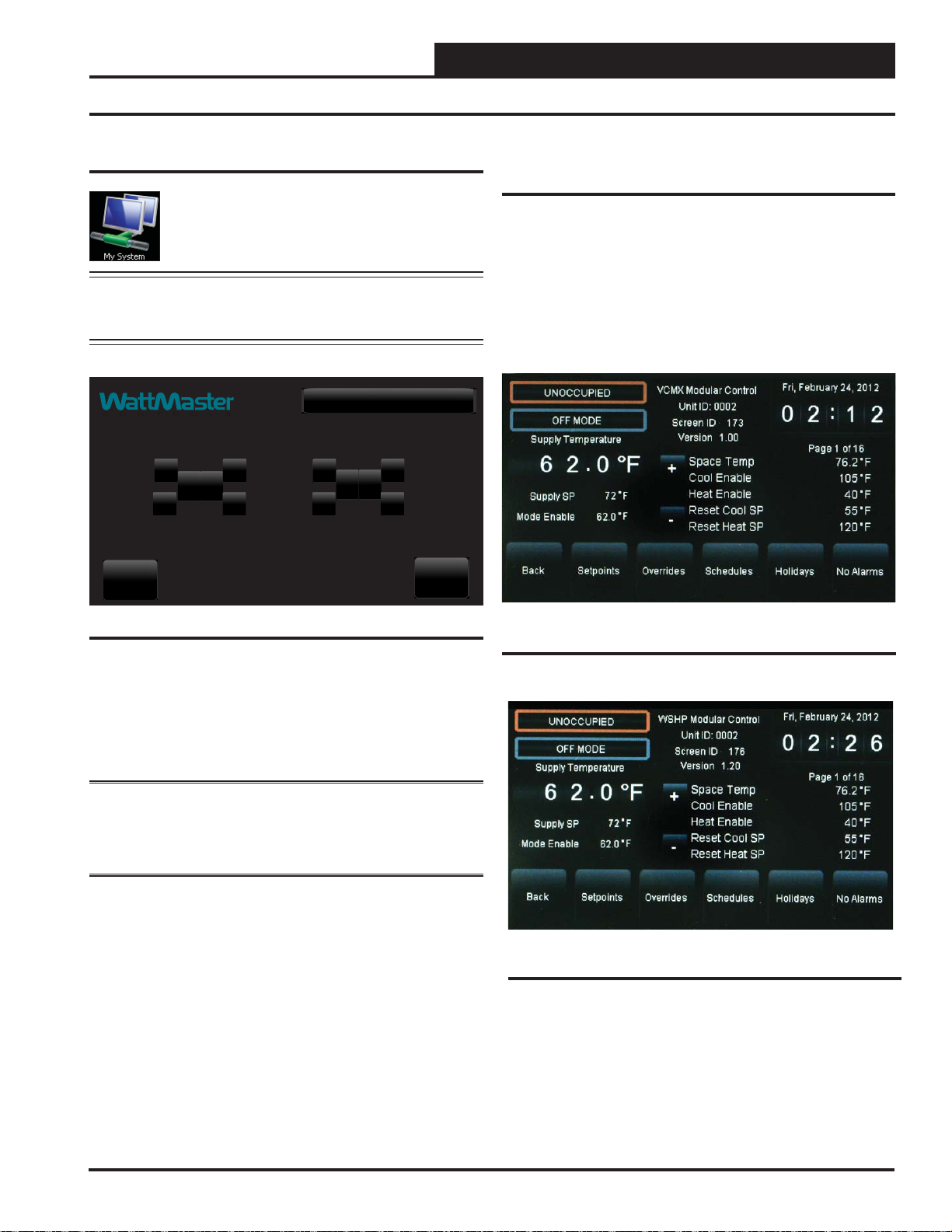

My System Unit Selection

From the Main Screen, touch the < My System> icon.

The Selected Unit Screen will appear. See Figure 17.

NOTE: If you have chosen the One to One Unit Connection

in the System Manager Settings Screen, this screen will

not appear. Instead, the unit’s Status Screen will appear.

Selected Unit [Loop 1 - Unit 1]

+ + + +

1

0

10

- - - -

Back

GO

Viewing VCM, VCM-X & VCB-X Status

Screens

Figures 18, 19, 20 & 21 depict the fi rst Controller Status Screens.

Notice that the controller is identifi ed by loop number and unit number

- in this case, 0102 represents Loop 1, Unit 2. Images vary based on

controller type.

While in the Status Screen, touch the <+> and <-> buttons to view more

status screens displaying relays and operating setpoints. These screens

roll back to the fi rst Status Screen.

Figure 17: Unit Selection Screen

In Figure 17, Loop 1 and Unit 1 are selected as indicated in the fi gure

with white text. They also appear in the Top Menu Bar in brackets.

Use the <+> and <-> buttons to move up and down through the loops

and units. Enter the desired Loop # and Unit # and then touch <GO>

to access the unit’s Status Screen.

NOTE: Instructi ons f or confi gurations and setpoints are included in

this guide separately for V CM/VCM- X Controllers, VCB-X Controllers,

and V A V/Zone Controllers. See page 25 for VCM/VCM-X Controllers,

page 42 for VCB-X Controllers, and page 63 for V A V/Zone Controllers.

Figure 18: VCM-X & VCM-X Modular Controller

Status Screen 1

Figure 19: VCM-X WSHP Controller (Tulsa) Status

Screen 1

SMTS II Technical Guide

19

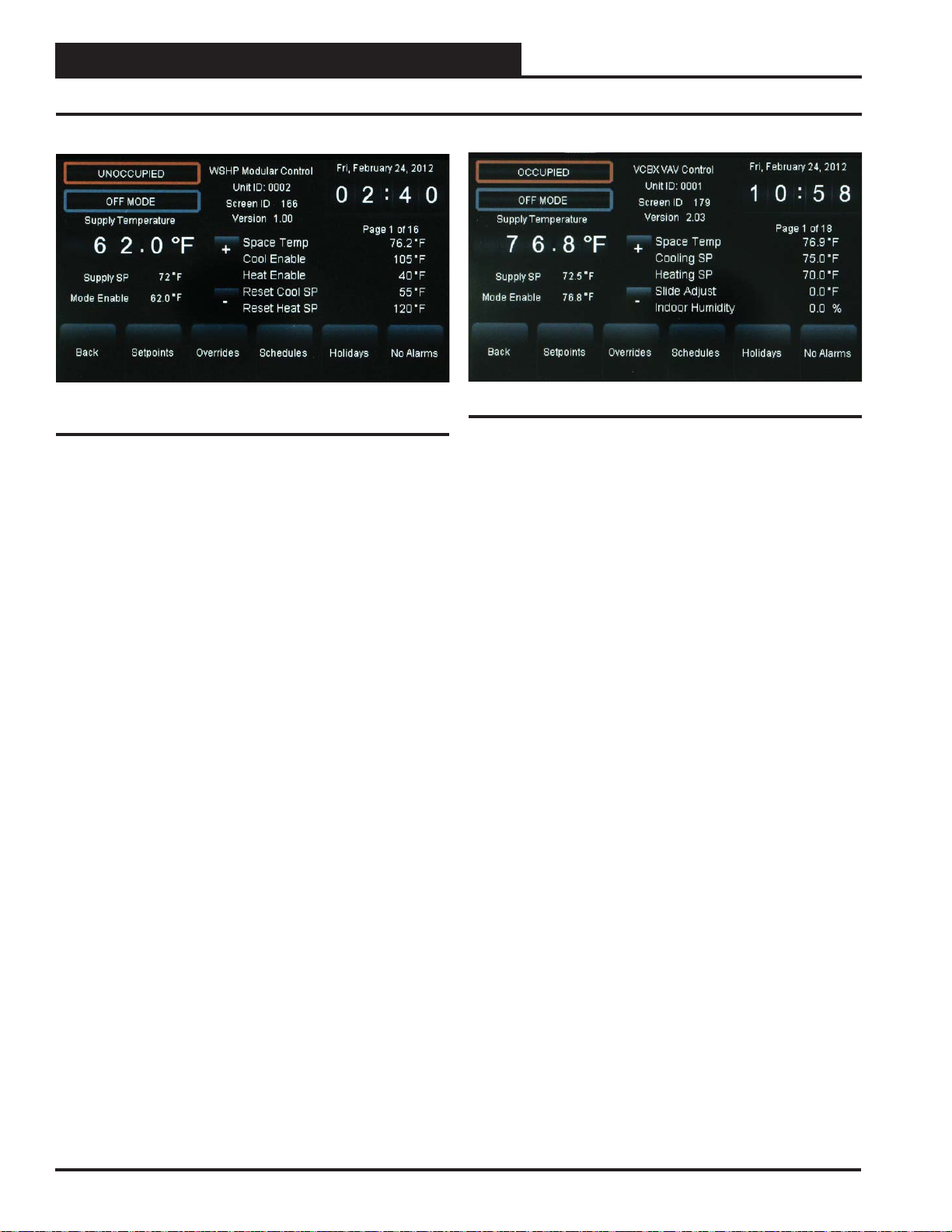

Page 20

Zone

VCM, VCM-X & VCB-X Controllers

Viewing VCM, VCM-X & VCB-X Status Screens

Zone

Figure 20: VCM-X WSHP Controller (Coil) Status

Screen 1

Figure 21: VCB-X Controller Status Screen 1

20

SMTS II Technical Guide

Page 21

VCM, VCM-X & VCB-X Controllers

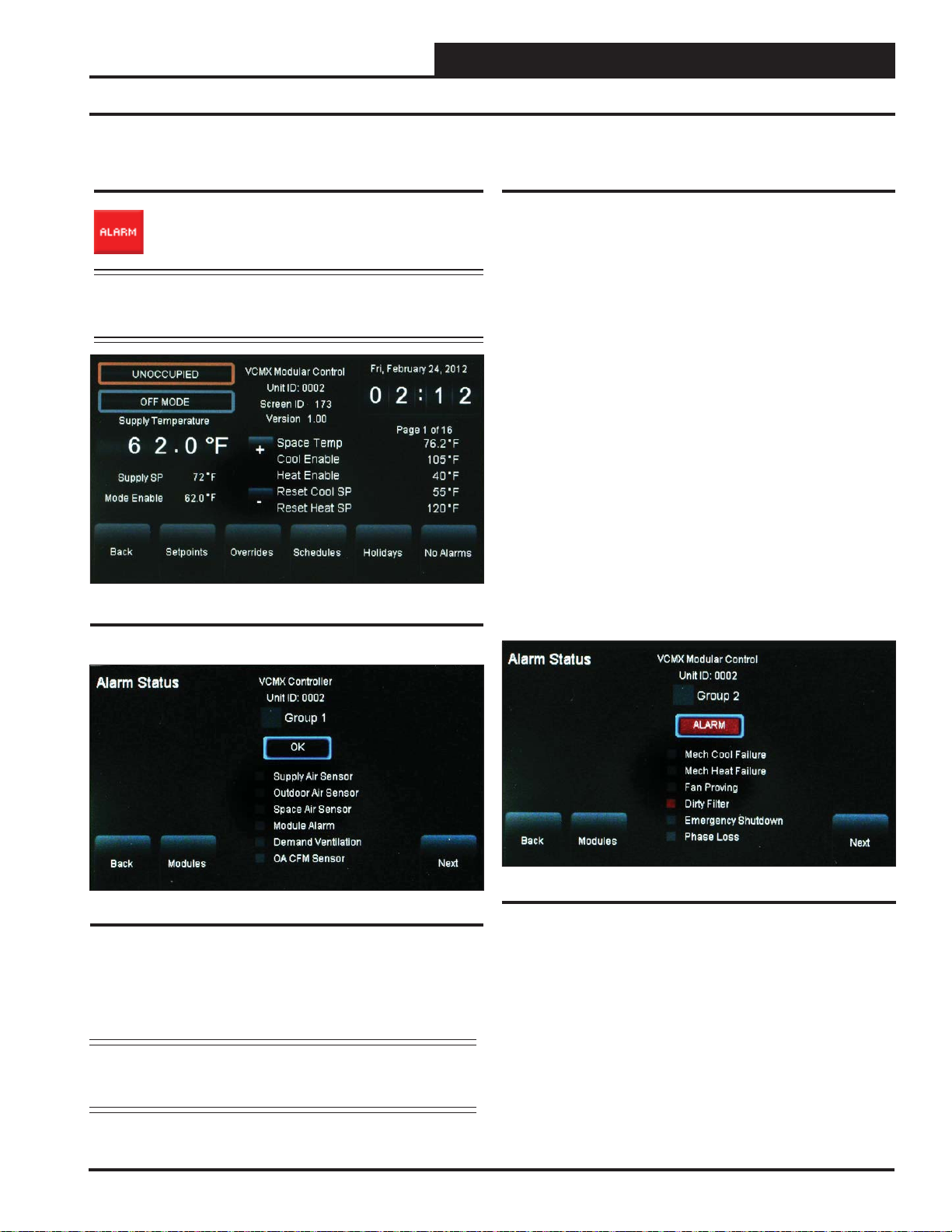

Viewing and Enabling/Disabling VCM, VCM-X & Module Alarms

Viewing VCM, VCM-X & Module

Alarm Status

To view alarm status, touch the <ALARM> button on the

unit’s fi rst Status Scr een. See Figure 22. The Alarm Status

Screen will display. See Figure 23.

NOTE: The < ALARM> button only appears on the screen if the

unit has an active alarm condition. Only a Level 3 user

has the option to enable or disable each type of alarm.

Figure 22: VCM-X Controller Status Screen 1

Enabling/Disabling VCM, VCM-X &

Module Alarms

Alarm confi guration is accessed by touching the <ALARM> button on

the lower right of the unit’s fi rst Status Screen. See Figure 22. Only a

Level 3 user can confi gure alarms. Touch the <Next> button to go to

the next Alarm Status Screen.

In addition to simply viewing alarms, the Alarm Status Screen can also

be used for enabling and disabling alarms that will be emailed or texted.

The emailing and texting feature will only work if Prism 2 is running

and has emailing capability.

The alarms must fi rst be confi gured using Prism 2 software. See the

Appendix in this guide for instructions.

Once the alarm settings have been established in Prism 2, the settings

you choose in the Alarm Status Screen will be stored in the controller

so that you will not have to reconfi gure the alarms for that controller in

Prism 2. Once confi guration is complete, Prism 2 does not have to be

running in order to view alarms on individual Alarm Status Screens in

the System Manager TS II. However, as mentioned previously, Prism 2

does have to be running for emailing or texting alarms to occur.

To enable an alarm category—Sensors, Mechanical, Fail Modes—simply

touch the black square next to Group 1, Group 2, and/or Group 3. A white

box designates that the alarm category is enabled. To disable an alarm

category, simply touch the square again. A grey box designates that the

alarm category is disabled. See Figure 23 for an example.

Figure 23: VCM-X Controller Alarm Status Screen

Touch the

the <Modules> button to go to the Head Pressure Module Alarms

Screen, Dual/Full Digital Module Alarms Screen, and Heat Pump

Module Alarms Screen.

<Next> button to go to the next Alarm Status Screen. Touch

NOTE: Even if you don’t set up Alarm Polling using Prism 2,

a controller’s fi rst status screen will still alert you of an

active alarm.

SMTS II Technical Guide

Figure 24: VCM-X Controller Alarm Screen

In the example above (Figure 24), there is an ALARM (designated by the

word ALARM in red.) There is a red box in front of Dirty Filter , designating the alarm. If there is no alarm condition, the word OK appears in a

box below the Group Number (as shown in Figure 23).

Touch the <Next> button to go to the next Alarm Status Screen. Touch

the <Modules> button to go to the Head Pressure Module Alarms

Screen, Dual/Full Digital Module Alarm Scr een, and Heat Pump Module

Alarms Screen.

21

Page 22

Zone

VCM, VCM-X & VCB-X Controllers

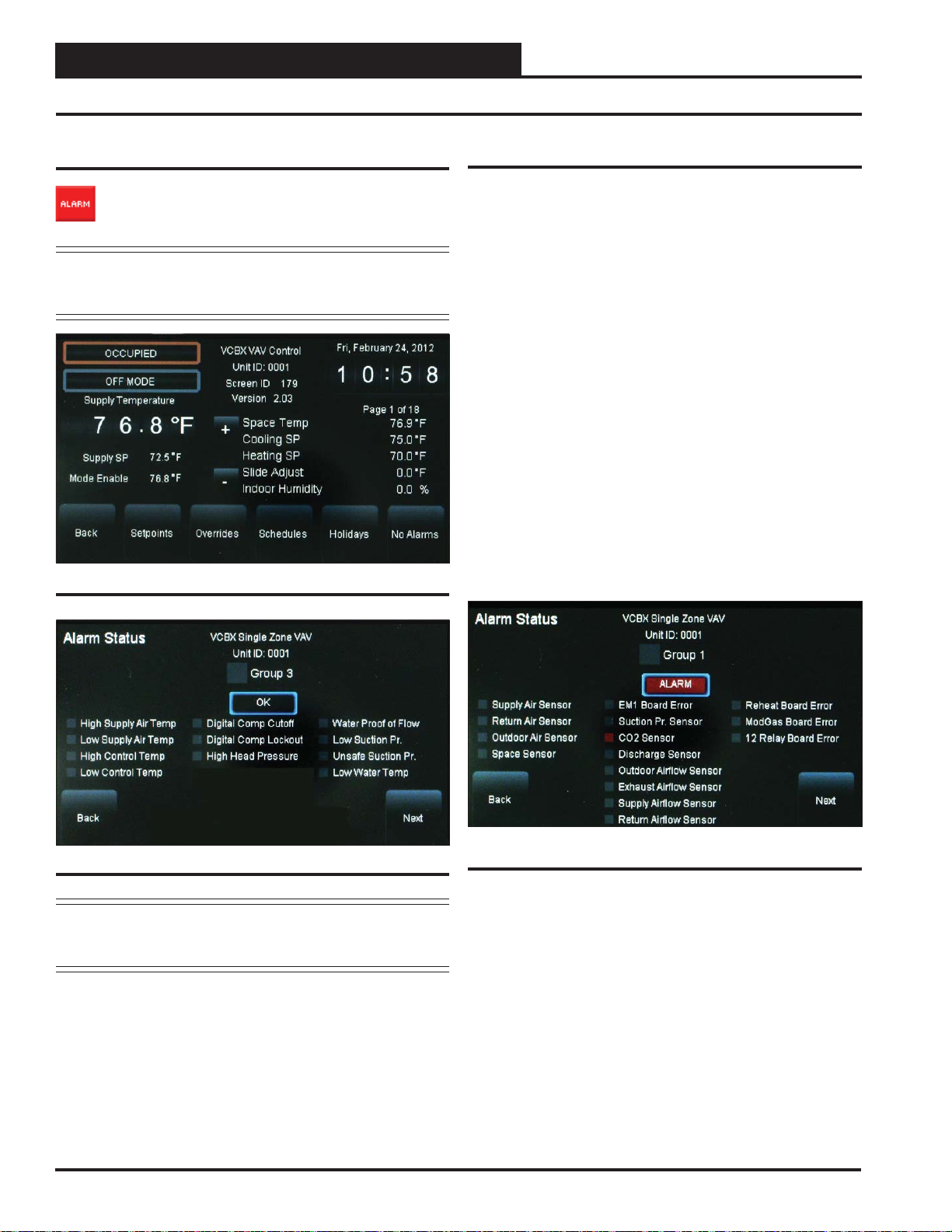

Viewing and Enabling/Disabling VCB-X Alarms

Zone

Viewing VCB-X Alarm Status

To view alarm status, touch the <ALARM> button on the

unit’s fi rst Status Screen. See Figure 25. The Alarm Status

Screen will display. See Figure 26.

NOTE: The < ALARM> button only appears on the screen if the

unit has an active alarm condition. Only a Level 3 user

has the option to enable or disable each type of alarm.

Figure 25: VCB-X Controller Status Screen 1

Enabling/Disabling VCB-X Alarms

Alarm confi guration is accessed by touching the <ALARM> button on

the lower right of the unit’s fi rst Status Screen. See Figure 25. Only a

Level 3 user can confi gure alarms.

In addition to simply viewing alarms, the Alarm Status Screen can also

be used for enabling and disabling alarms that will be emailed or texted.

The emailing and texting feature will only work if Prism 2 is running

and has emailing capability.

The alarms must fi rst be confi gured using Prism 2 software. See the

Appendix in this guide for instructions.

Once the alarm settings have been established in Prism 2, the settings

you choose in the Alarm Status Screen will be stored in the controller

so that you will not have to reconfi gure the alarms for that controller in

Prism 2. Once confi guration is complete, Prism 2 does not have to be

running in order to view alarms on individual Alarm Status Screens in

the System Manager TS II. However, as mentioned previously, Prism 2

does have to be running for emailing or texting alarms to occur.

To enable an alarm category—Sensors, Mechanical, Fail Modes—simply

touch the black square next to Group 1, Group 2, and/or Group 3. A white

box designates that the alarm category is enabled. To disable an alarm

category, simply touch the square again. A grey box designates that the

alarm category is disabled. See Figure 26 for an example.

Figure 26: VCB-X Controller Alarm Status Screen

NOTE: Even if you don’t set up Alarm Polling using Prism 2,

a controller’s fi rst status screen will still alert you of an

active alarm.

Touch the

<Next> button to go to the next Alarm Status Screen.

22

Figure 27: VCB-X Controller Alarm Screen

In the example above (Figure 27), there is an ALARM (designated by

the word ALARM in red.) There is a red box in front of CO2 Sensor,

designating the alarm. If there is no alarm condition, the word OK appears in a box below the Group Number (as shown in Figure 26).

Touch the <Next> button to go to the next Alarm Status Screen.

SMTS II Technical Guide

Page 23

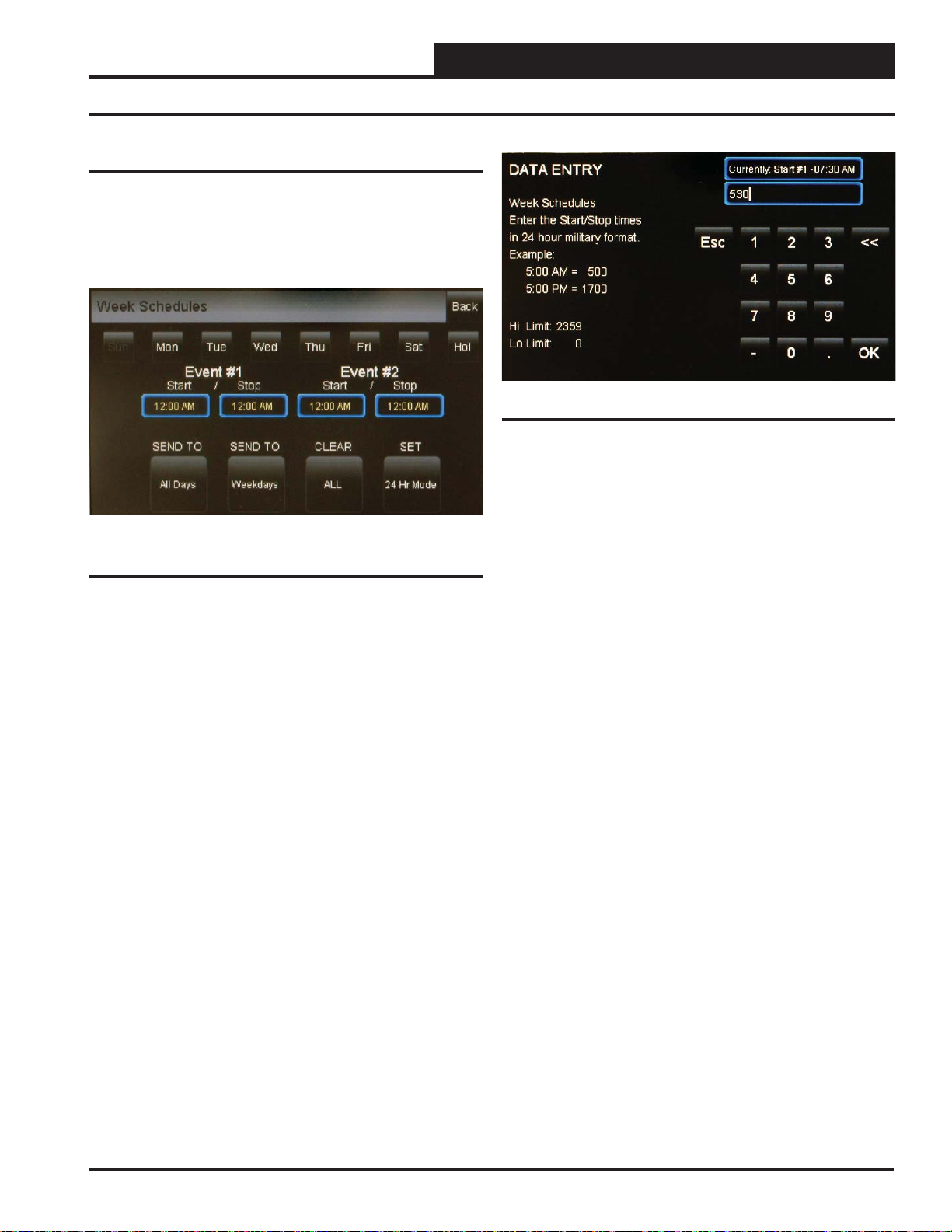

VCM, VCM-X & VCB-X Controllers

Viewing and Setting Schedules

To view and set schedules for VCM, VCM-X, and VCB-X controllers,

touch the <Schedules> button found at the bottom of the Status Scr een

(Figure 22 & 25). The Schedules Screen will appear. See Figure 28.

The default day will be Sunday and the default event start/stop times

will be midnight.

Viewing and Setting Schedules

Figure 29: Schedule Times Screen

Touch <OK> to save the time you entered or touch <Esc> to exit the

Schedule Times Screen without changing the time and return to the

Schedules Screen (Figure 28).

Figure 28: VCM / VCM-X / VCB-X Controller

Schedules Screen

A Level 2 user can set two schedules per day for individual days of the

week, all weekdays, weekends, and holidays. All times are entered in

military time format.

If you wish to enter a schedule for a certain day of the week, fi rst touch

the day of the week at the top of the screen. Otherwise, the day defaults

to Sunday. Touch the start and stop time for each Event and enter the

desired times. See Figure 29. All times must be entered in military time

format. See the Military Time Table - Table 8 - in the Appendix.

To eliminate a schedule from any event, simply enter a zero for the

Start and Stop time for that day. The screen will display 12:00 am for

both the Start and Stop times, indicating that the equipment will not

activate on that day.

Once back at the Schedules Screen, you can continue setting schedules

day by day or use following options:

SEND TO <All Days> - Touch this button to send the schedule appearing

on the screen to all days of the week, except for holidays.

SEND TO <Weekdays> - Touch this button to send the schedule to

weekdays only. You will need to set up a separate schedule for Saturday

and Sunday when selecting this option.

CLEAR <All Schedules> - Touch this button to clear all schedules.

SET <24 Hr Mode> - Touch this button to have the system run con-

tinuously, 24 hours a day, 7 days a week including holidays. All event

times will display 11:59 PM.

SMTS II Technical Guide

23

Page 24

Zone

VCM, VCM-X & VCB-X Controllers

Zone

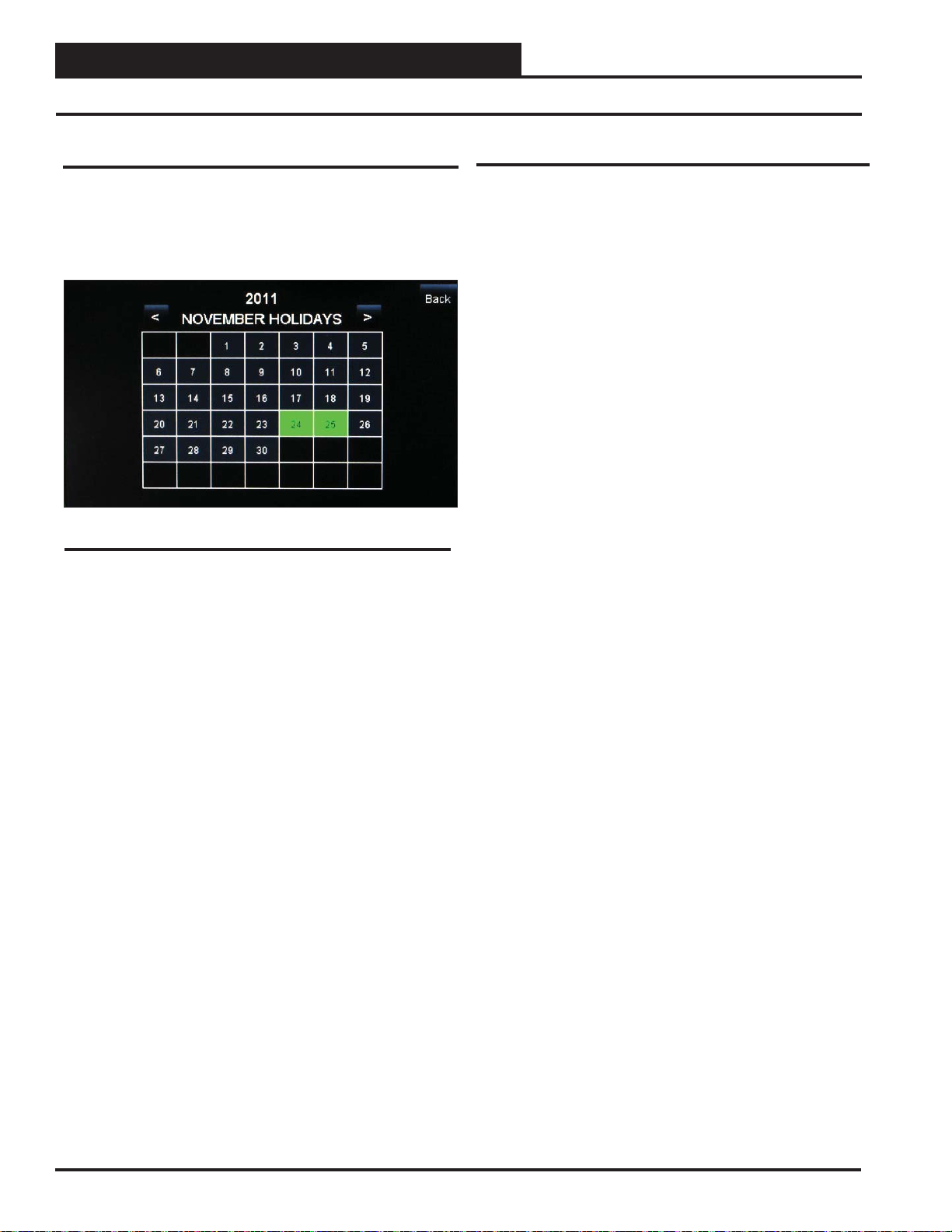

Viewing and Setting Holidays and Forcing Schedules

Viewing and Setting Holidays

To view and set holidays for a VCM/VCM-X/VCB-X controller, touch

the

< Holidays> button found at the bottom of the Status Screen (Figures

22 & 25). The Holidays Schedule Screen will appear . See Figure 30. The

holidays in the screen will initially not be set. You can only set holidays

for the current year. You must be a Level 2 user in order to set holidays.

Figure 30: Holidays Schedule Screen

Simply touch the day(s) of the month to select holidays. Touch the

<<> button to go back one month and the <>> button to go forward

one month.

Schedule Override

To Force Schedules, from the VCM, VCM-X or VCB-X Main Status

Screen, touch the Occupied/Unoccupied wording located below the time

and date display. The following options will appear:

Schedule Auto Mode

Touch the radio button to select the schedule option. Default is Schedule

AUTO Mode. This selection will remain in effect unless it is changed

again on this screen. Schedule overrides do not automatically time out

after a certain period of time.

Schedule AUT O Mode—Select this to restore normal

schedule operations.

Schedule FORCED ON—Select this to Force the unit into

continuous Occupied Mode operation.

Schedule FORCED OFF—Select this to Force the unit

into continuous Unoccupied Mode operation.

There are 14 holiday periods available for each year. These holiday periods can be a single day or they can span days, weeks, or even months.

For example, if you want to schedule a summer break, you need only

schedule one holiday period to defi ne a two or three month break from

operating in the occupied mode.

Every defi ned holiday uses the Holiday operating schedule programmed

in the controller’s Schedules Screen.

Holidays can only b e pr ogrammed for the c urrent year. You cannot progra m

ho lid ays be for e th e n ext yea r oc curs . Holidays do not automatically adjust for

the new year, so you will need to access this screen after the new year and

make necessary adjustments to the days that fl oat, such as Memorial Day.

24

SMTS II Technical Guide

Page 25

VCM & VCM-X Controllers

Accessing and Entering VCM & VCM-X Setpoints

Accessing and Entering VCM & VCM-X

Setpoints

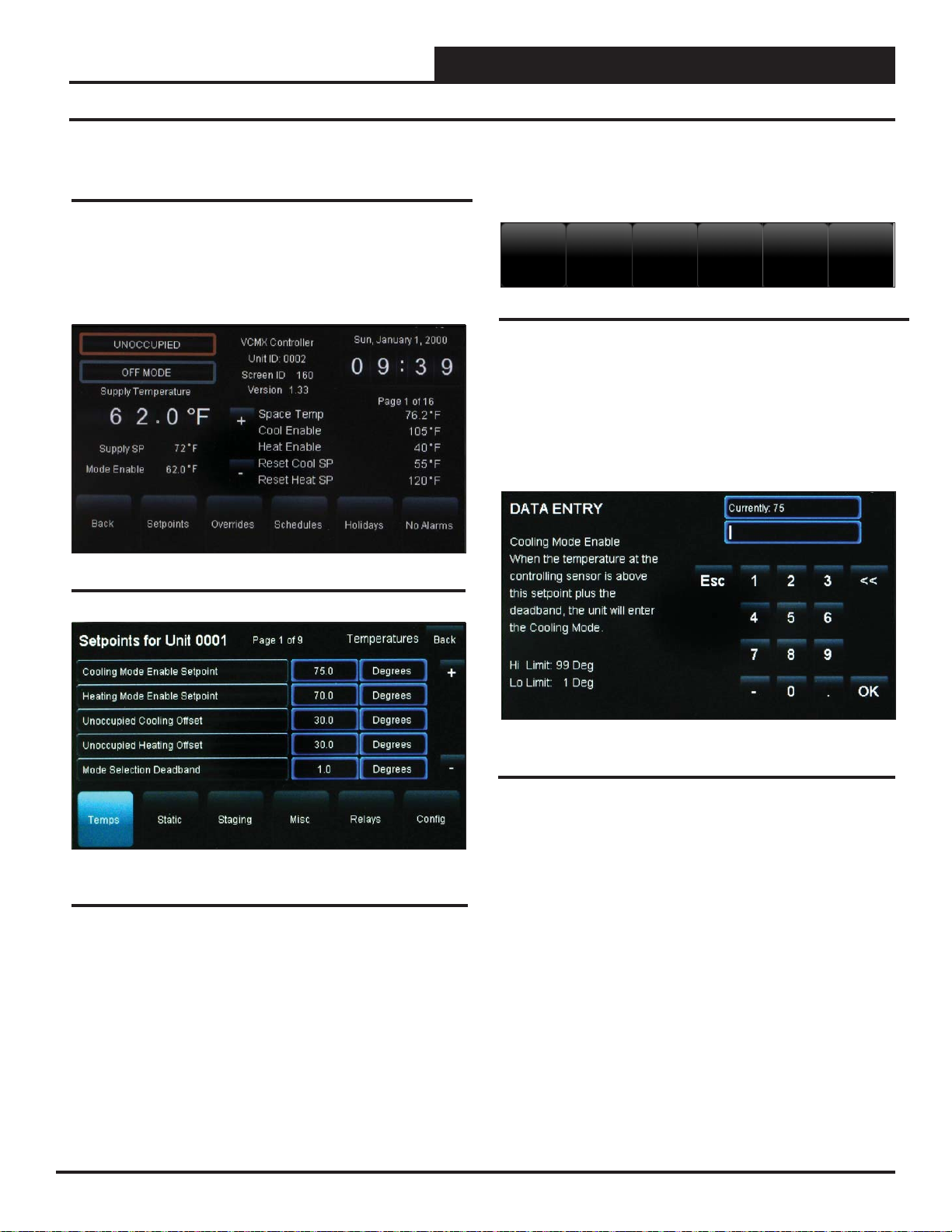

While in the VCM-X Status Screen (see Figure 31), touch the < Set-

points> button found on the bottom menu bar . The VCM-X Controller’s

Temperature Setpoints Screen will appear. See Figure 32.

Level 1 and Level 2 users can change occupied space temperature set-

points, but only Level 3 users can change all setpoints.

Figure 31: VCM-X Controller Status Screen

Individual setpoint and confi guration buttons are located at the bot-

tom of the Setpoint Screens. See Figure 33. Simply touch a specifi c

button to access that category.

Temps

Static

Staging

Misc

Relays

Config

Figure 33: VCM / VCM-X Setpoint Buttons

Within each Setpoint Screen, touch the < Status> button to return

to the Status Screen or touch < Home> to return to the Main Screen.

Use the <+> and <-> buttons to scroll through the setpoints and

confi gurations. Simply touch the blue highlighted box to change the

setpoint. Each setpoint data entry screen will provide a defi nition of

the setpoint and specifi c instructions for entering the setpoint and

will include the setpoint range as in the example below, Figure 34.

Figure 32: VCM-X Controller Temperature Setpoints

Screen

SMTS II Technical Guide

Figure 34: VCM-X Cooling Mode Setpoint Data Entry

Screen

Touch <OK> to have the system accept the new value. If you enter

a setpoint that is not in the valid range, the setpoint will remain as is

and will not change.

Each setpoint data entry screen is self-explanatory; however, each

setpoint and confi guration is explained in the next section, Confi gur-

ing VCM-X Setpoints. To easily reference a particular setpoint or

confi guration, refer to the Index.

25

Page 26

VCM & VCM-X Controllers

VCM & VCM-X Confi guration

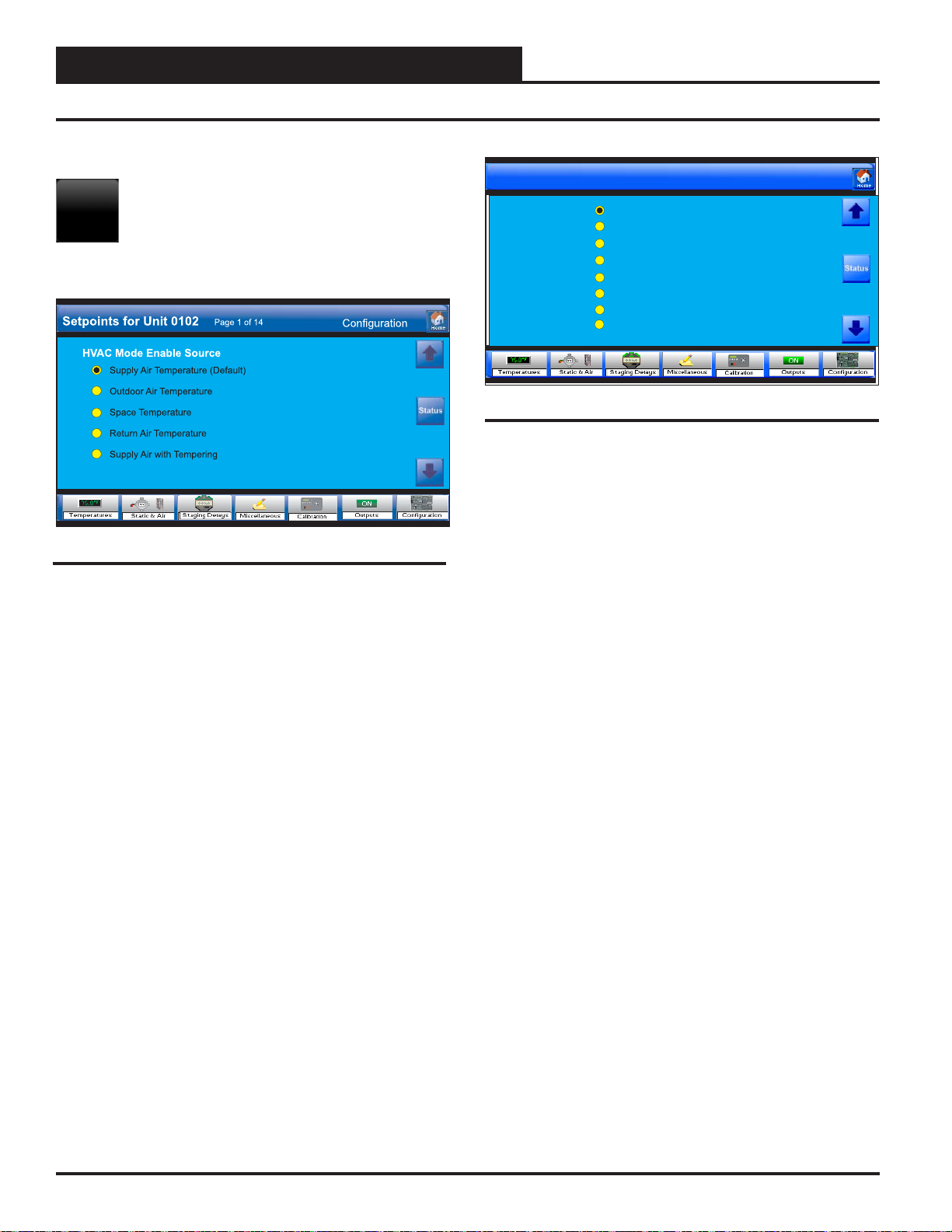

VCM-X Confi guration

Touch the < Confi guration> button to access the

Config

ton next to your selection. For screens with square buttons, touch one or

more square buttons to make your confi guration selections for the unit.

Figure 35: VCM-X Confi guration Screen 1

HVAC Mode Enable Source

Touch the radio button to select the Temperature Sensor that will determine the Heating, Cooling, or Vent Mode of operation. The available

selections are as follows:

Supply Air Temperature—This is typical for VAV

applications. Occupied Cooling with Morning Warm-up.

Outdoor Air Temperature—This is for 100% Outdoor

Air (MUA) units. Dehumidifi cation utilizing a Dewpoint

Calculation if equipped with an Outdoor Air Humidity

Sensor.

Space Temperature—This is for any unit that conditions

a space and is not 100% Outdoor air. Occupied/Unoccu pied Heating, Cooling, and Vent Modes of operation.

Return Air Temperature—This selection can be used

when an Average Building Temperature (the Return Air

Temperature) needs to determine Heating, Cooling, and

Vent Modes of operation.

Confi guration Setpoints Screens.

For screens that contain radio buttons, touch the radio but-

Setpoints for Unit 0102

Reset Source

Page 2 of 14

No Reset

Space Temperature

Return Air Temperature

External Analog Input

Fan VFD Signal Percentage

Outdoor Air Temperature

Single Zone VAV

Single Zone VAV w/CV Heat

Configuration

Figure 36: VCM-X Confi guration Screen 2

HVAC Reset Source

The Supply Air Heating and Cooling Temperature Setpoints can be reset

using various input sources. Default is No Reset. Touch the radio button

to select the desired Reset Source for Supply Air Temperature Reset.

The Single Zone VAV option should be selected in applications where

the Supply Fan VFD speed is reset based on the Space Temperature. If

you select No Reset, then neither the Supply Air Setpoint nor Supply

Fan VFD Reset will occur. The available selections are as follows:

No Reset

Space T emperature

Return Air Temperature

External Analog Input

Fan VFD Signal Percentage

Outdoor Air Temperatur

Single Zone VAV

Single Zone VAV w/ CV Heat

Supply Air w/ Supply Air Tempering—This selection is

for VAV “cooling only” applications where because of cold

outdoor temperatures, even at minimum damper position,

you may need to enable heat to maintain the cooling near its

Cooling Supply Air Setpoint. When heat is enabled during

this sequence, it will control to a non-adjustable setpoint