Page 1

www.orioncontrols.com

Operator Interfaces

Technical Guide

For MUA II D Controllers

( SS1013 or Y200405 MUA II D Controller Code)

(Use SS1010 System Manager Code & SS1009 Service Tool Code)

Page 2

Table Of Contents

Introduction ..................................................................................................................................................... 3

Modular Service Tool .................................................................................................................................................................. 3

Modular System Manager........................................................................................................................................................... 3

System Connections........................................................................................................................................ 4

Modular Service Tool .................................................................................................................................................................. 4

Modular System Manager........................................................................................................................................................... 5

General Programming Information ................................................................................................................. 6

Operator Interfaces Comparison ................................................................................................................................................ 6

Modular System Manager........................................................................................................................................................... 7

Modular Service Tool .................................................................................................................................................................. 7

System Manager Passcodes ...................................................................................................................................................... 9

Scheduling ................................................................................................................................................................................ 10

Setting Time & Date...................................................................................................................................................................11

Space Sensor Overrides ........................................................................................................................................................... 12

Alarm Search ............................................................................................................................................................................ 12

Programming The MUA II D Controller ......................................................................................................... 13

Configuration ............................................................................................................................................................................ 13

Setpoints................................................................................................................................................................................... 14

Status........................................................................................................................................................................................ 18

Scheduling ................................................................................................................................................................................ 19

Outputs Force ........................................................................................................................................................................... 20

Notes:............................................................................................................................................................. 21

WattMaster Controls Inc.

WattMaster Controls Inc.

8500 NW River Park Drive · Parkville , MO 64152

8500 NW River Park Drive · Parkville , MO 64152

Toll Free Phone: 866-918-1 100

Toll Free Phone: 866-918-1 100

PH: (816) 505-1100 · F AX: (816) 505-1 101 · E-mail: mail@wattmaster .com

PH: (816) 505-1100 · F AX: (816) 505-1 101 · E-mail: mail@wattmaster .com

Visit our web site at www.orioncontrols.com

Visit our web site at www.orioncontrols.com

Form: OR-SMST-TGD-01B

Form: OR-MUAIID-SMST -TGD-01C

Copyright 2002 W attMaster Controls, Inc.

Copyright 2004 W attMaster Controls, Inc.

AAON® is a registered trademark of AAON, Inc., T ulsa, OK.

AAON® is a registered trademark of AAON, Inc., T ulsa, OK.

WattMaster Controls, Inc. assumes no responsibility for errors, or omissions.

WattMaster Controls, Inc. assumes no responsibility for errors, or omissions.

This document is subject to change without notice.

This document is subject to change without notice.

Page 3

Introduction

Technical Guide

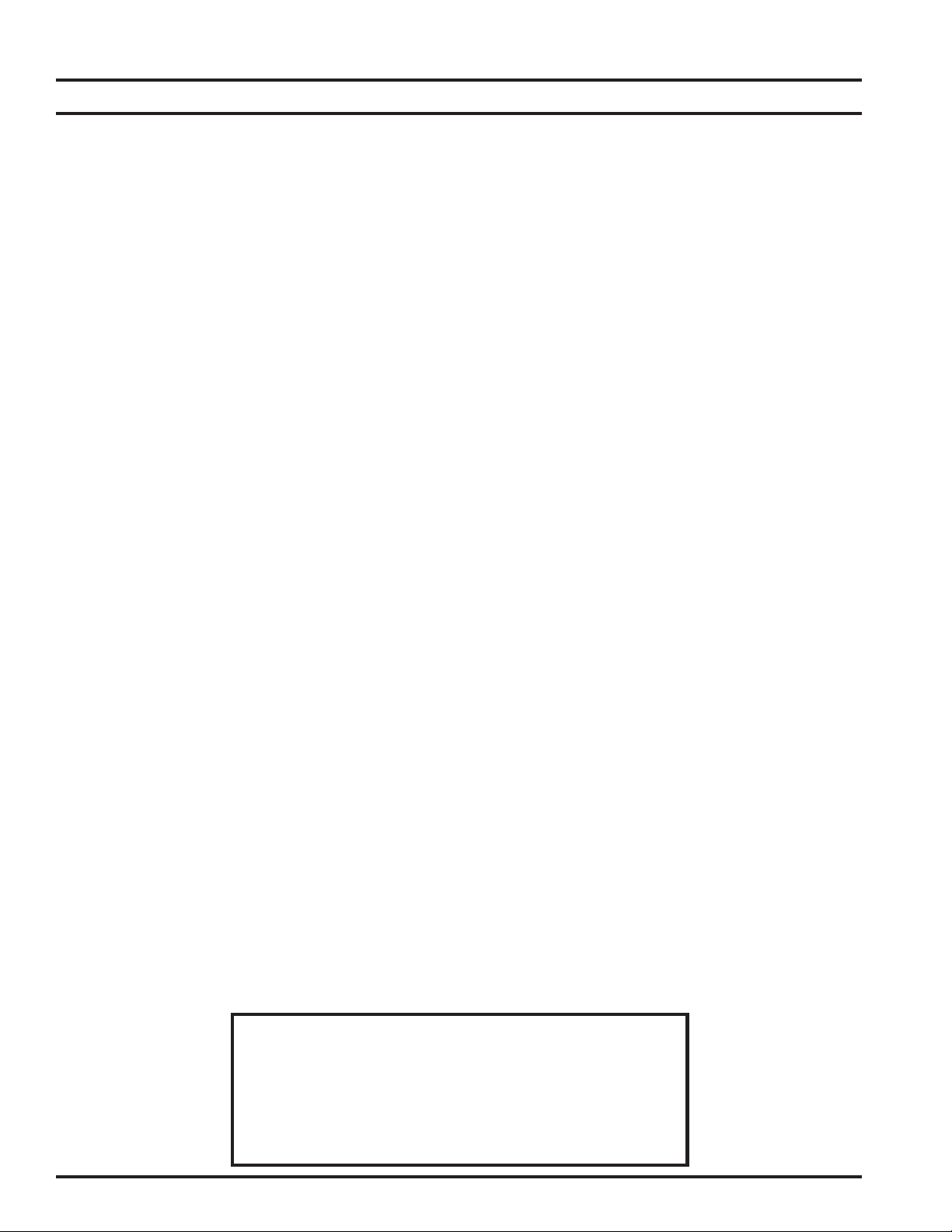

Modular Service Tool

2.02"

4.75”

Mode

Selection

STATUS

SETPOINTS

SCHEDULES

OVERRIDES

ALARMS

CONFIGURATION

BALANCE - TEST

ON

1.63"

Figure 1: Modular Service Tool Dimensions

Description

The MUA II D Modular Service Tool is a system operator interface

that provides a direct link to enable the system operator to view the

status, configure and to adjust the setpoints of any controller on the

control system communications loop. The Service Tool is housed in

an attractive beige colored plastic enclosure. The display area is covered with a clear plastic bezel for protection of the display screen. The

Service T ool has a four line by 20 character display panel with adjustable contrast control and a 27 key membrane keypad for data selection

and entry. All keypad operations are simple and straight forward, utilizing non-cryptic plain English language messages. Menu driven programming allows for easy setup and operation without the need for

specialized training. The Wendy’s Modular Service Tool is supplied

with (4) AA (1.5V) Volt alkaline batteries a wall mount DC power

supply and a communication cable terminated with an 8 pin DIN connecter for connection to the Service T ool. The cable allows the user to

setup and program any MUA II D controller with a 8 pin DIN connector socket by simply plugging in the service tool to the socket on the

controller.

The Service Tool is designed to be carried by the system installer or

service technician. Its rugged plastic housing, provides superior protection for the electronic components housed inside. The MUA II D Modular

Service Tool is a top quality service tool that will stand up to the demands of the typical job site environment for many years.

UP

PREV

ESC

13

4

708

DEC

NEXT

DOWN

CLEAR

ENTER

2

5

6

9

MINUS

-

10.00”

Modular System Manager

9.00"

13

2

5

6

4

708

9

DEC

MINUS

-

UP

PREV

ESC

DOWN

ENTER

Figure 2: Modular System Manager Dimensions

Description

The MUA II D Modular System Manager provides a direct link to enable the system operator to view the status and to adjust the setpoints of

any controller on the control system communications loop. The System

Manager is designed to be used with the MUA II D controllers. The

System Manager is housed in an attractive beige colored plastic enclosure. The System Manager is equipped with a four line by 20 character

backlighted display panel and a 24 key membrane keypad for data selection and entry. All keypad operations are simple and straight forward, utilizing non-cryptic plain English language messages. Menu

driven programming allows for easy setup and operation without the

need for specialized training. The System Manager also has 2 integral

LED’s for user notification of system alarm conditions and override

initiations. Protection from unauthorized users is provided by the System Manager’s integral multi-level passcode authorization programming.

On a Networked System the Modular System Manager is connected to

the communications and power loop of the system via modular cables

that simply plug into the System Manager board and the Power/Comm

Distribution Board. This virtually eliminates wiring errors and makes

installation fast and easy. When it is to be connected to a Stand Alone

system, a cable with modular connectors on one end and stripped wire

ends on the other end is provided to facilitate connecting communications and power to the System Manager from the 24 VAC power source

and the HVAC unit controller communication wiring terminals.

The System Manager is designed for wall mounting. Mounting holes

are provided to attach the System Manager to a standard handy box. It

is recommended that the System Manager be mounted at approximately

eye level to allow for ease of programming and reading of the display.

The System Manager is typically mounted in the building manager or

superintendent’s office or in an equipment room. The attractive enclosure is quite suitable for mounting in any location or with most decors.

STATUS

SETPOINTS

NEXT

SCHEDULES

CLEAR

OVERRIDES

ALARMS

6.25"

1.81"

Operator Interfaces 3

Page 4

Technical Guide

System Connections

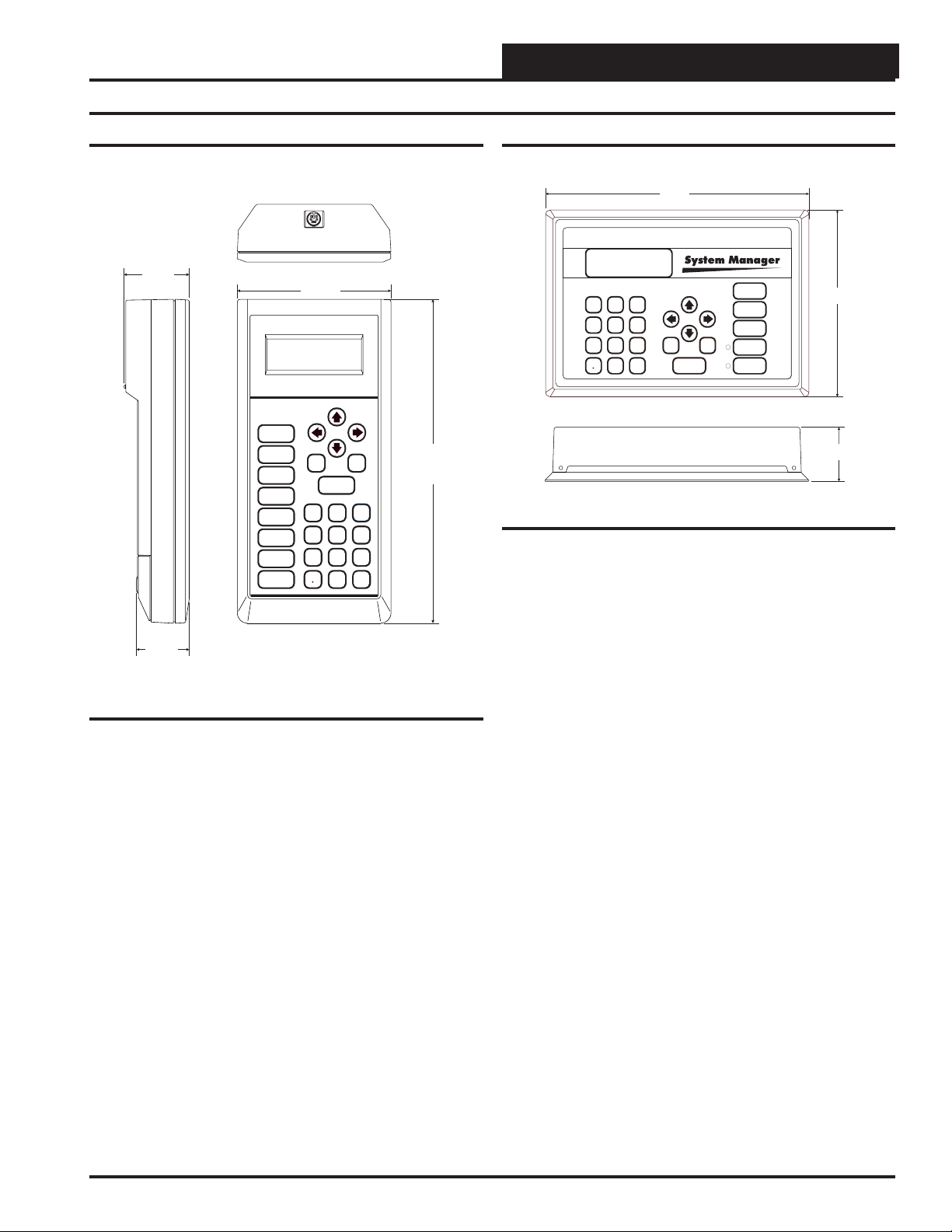

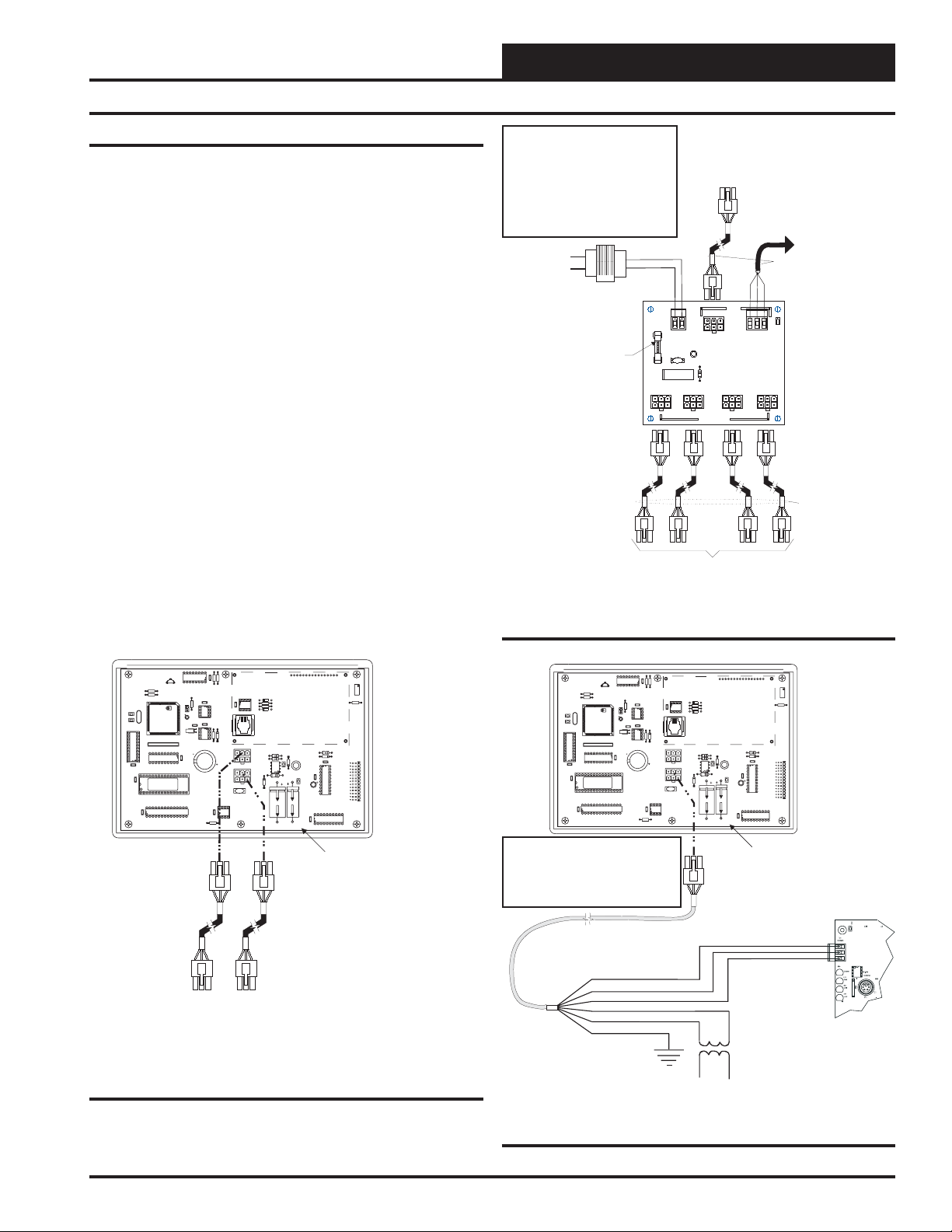

Modular Service Tool

Wether you have a Stand Alone, Interconnected or Networked Orion

Controls System, the Modular Service T ool always connects to an HV AC

unit controller via a prefabricated cable that is supplied with the service

tool. The Modular Service Tool cable is terminated on both ends with a

mini DIN connector. Attach one end to the Modular Service Tool and

the other end to the mini DIN connector on the HV AC unit controller. If

this is an Interconnected System, all controllers that are interconnected

Male DIN Connector

with communications cable can be programmed from any HVAC unit

controller on the loop. If this is a Networked System, all controllers on

the entire Networked System can be programmed from one HVAC unit

controller.

Be sure that the Modular Service Tool has fresh batteries installed or

that it is connected to a power source using the supplied power pack

before attempting any programming of the controller. See Figure 3 for

connection details.

Female DIN Connector

Connector Cable

Selection

SETPOINTS

SCHEDULES

OVERRIDES

CONFIGURATION

BALANCE - TEST

Mode

PREV

STATUS

13

ALARMS

4

708

DEC

ON

Typical Controller Board

The Modular Service Tool Can Be

Connected To The VAV/CAV

Controller Or The VAV/Zone

Controller By Plugging One End

Of The Supplied Cable Into the

Modular Service Tool DIN

Connector And The Other End

Into The DIN Connector On The

Controllers.

Modular Service Tool

UP

NEXT

DOWN

CLEAR

ESC

ENTER

2

5

6

9

MINUS

-

Be Sure The Modular Service

Tool Is Connected To The

Supplied Power Pack Or Has

Fresh Batteries Installed Before

Attempting Programming Of The

Controller. Be Sure The Power Is

Turned Off On The Modular

Service Tool Before Connecting

The Cable To The Controller.

Figure 3: Modular Service Tool

4

Power On Button

Operator Interfaces

Page 5

Technical Guide

U13

V62C518256L-70P

74HC573

CX8

RN1

YS101830PREV.

2PMODULARPSYSTEM

MANAGER

PCB80C552-5-16WPP442860=2/5

PDfD9722V7Y

R1

R4

24C128

74HC259

U14

CX9

470uF50v

1000uF10v

470uF50v

R12

R11

COMMOUT

COMMIN

74HC540

CX10

74HC923

82B715

RS-485P

V62C518256L-70P

75176

YS101830PREV.

2PMODULARPSYSTEM

PDfD9722V7Y

74HC259

470uF50v

1000uF10v

1000uF10v

COMMOUT

COMMIN

74HC540

CX14

82B715

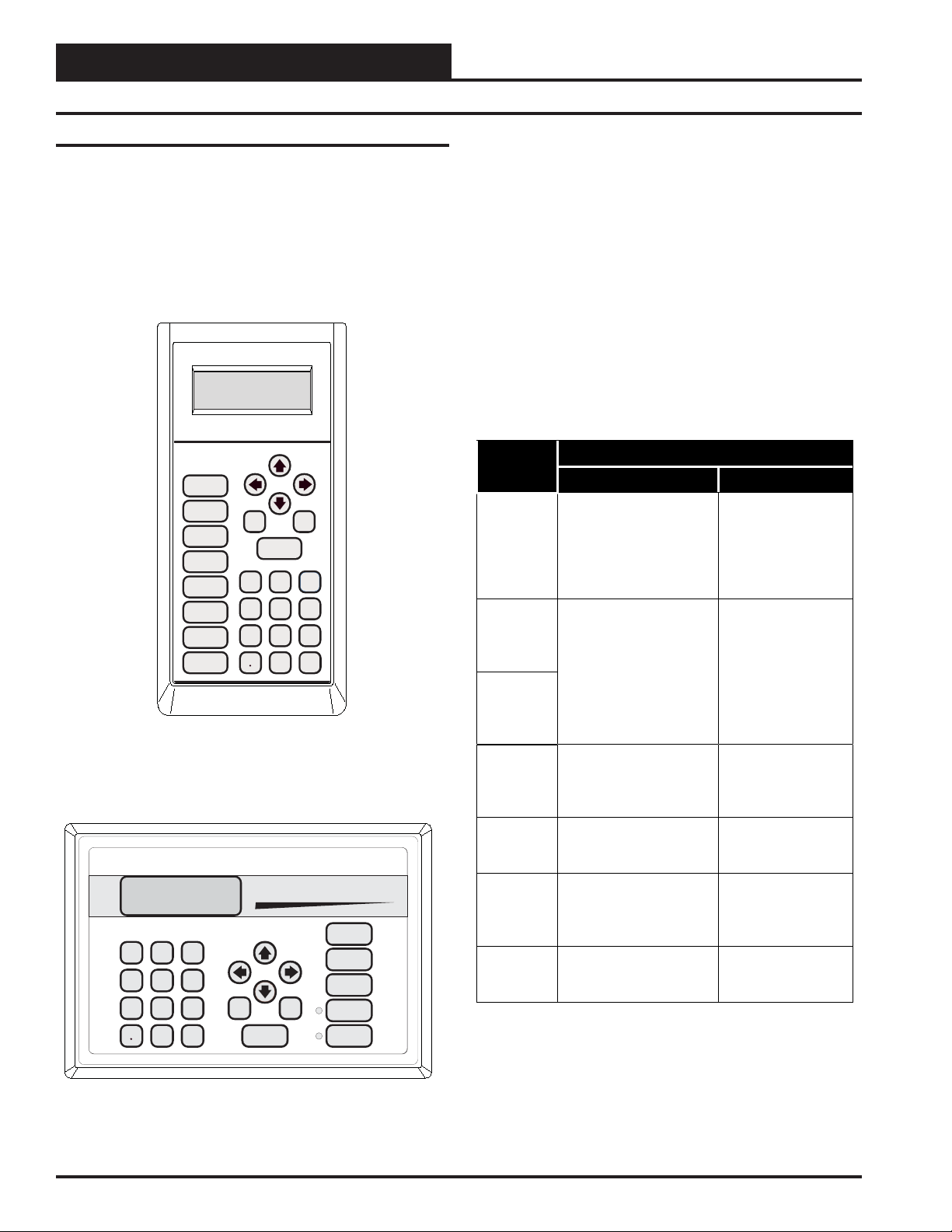

Modular System Manager

As previously described, when you are connecting the Modular System

Manager to a Networked System, the Modular System Manager is connected to the communications and power loop of the system via modular cables. These cables simply plug into the System Manager board

and to any device with modular connectors on any local loop on the

system. Devices with modular connectors include the Power/Comm Distribution Board, VAV/Zone controller and the Modular Polling device.

By using these plug in connections wiring errors are virtually eliminated and system installation is fast and easy. See Figure 4 for typical

connection information. See Figure 5 for typical Power/Comm board

wiring and connection information.

When the System Manager is to be connected to a Stand Alone system,

a 12 ft. cable with modular connectors on one end and stripped wire

ends on the other end is provided for this purpose. This is used to facilitate connecting communications and power wiring to the Modular System Manager from a 24 VAC power source and to the HVAC unit controller communication wiring terminals. See Figure 6 for wiring details. If the supplied cable wire is not long enough for your installation,

a standard modular cable of the correct length can be purchased through

WattMaster and one of the modular connectors can be cutoff to allow

for the transformer and communication terminal wiring connections. It

is recommended that you do not splice the communications wire if at all

possible. The transformer should be rated at 6 VA minimum power

output.

WARNING!

DO NOT GROUND THE 24V TRANSFORMER

THAT IS TO BE USED WITH THE

POWER/COMM BOARDS. GROUNDING OF

THE TRANSFORMER WILL DAMAGE THE

POWER/COMM BOARD AND ALL BOARDS

CONNECTED TO IT.A SEPARATE

TRANSFORMER MUST BE USED FOR EACH

POWER/COMMBOARD. NO EXCEPTIONS.

DO NOT CONNECT ANY OTHER DEVICES

TO THE TRANSFORMER USED FOR THE

POWER/COMM BOARD!

Line Voltage

24VAC

24VAC Transformer (By Others)

Size For Total Load Of Devices

Connected To Board

25

F1

4 Amp Slow Blow Fuse

4A

Power/ Cable To Power/Comm

Comm Other Distribution Board,

System Manager, MiniLink Or Other VAV/Zone Controllers

On Local Loop

Power/Comm Cable Power/Comm Distribution Board,

System Manager, MiniLink Or Other

VAV/Zone Controller On Local Loop. If This Is The First

Power/Comm Board On The Local Loop,

Connection Is Not Required.

TB2

VAC

24

LD1

POWER

V1

D1

P1

From Other

Polling Device

Connect To VAV/CAV Controller

If This Is First Power/Comm Board

On Local Loop - Otherwise No

Connection Is Required.

Local Loop RS-485

9600 Baud

All Comm Loop Wiring Is

Straight Thru

TtoT

C1

P5

RtoR

SHLD to SHLD

Local Loop RS-485

9600 Baud

COMMPIN

TB1

P2

SHLD

T

R

POWER& COMM

DIST.BOARD

YS101856

REV.0

R1

P4

P3

OUT

POWER& COMM

Polling Device

Figure 5: Typical Power/Comm Board Wiring

YS101830PREV.

2PMODULARPSYSTEM

MANAGER

U1

74HC259

CX2

U2

R3

R1

R4

PCB80C552-5-16WPP442860=2/5

PDfD9722V7Y

C1

X1

C2

U7

PAL

U8

CX7

CX11

U11

CX12

V62C518256L-70P

U12

R2

EWDOG

CX4

U3

R3

PHILIPS

24C128

U4

PHILIPS

CX5

CX6

R9

D3

C3

8583

X2

U6

RN1

74HC573

P1

CX8

P2

SC1

EPROM

VAR1

RAM

CX13

U13

75176

RS-485P

COMM

R14

Power/Commr Cables To

Power/Comm

Board, MiniLink Polling Device

Or VAV/Zone Controllers On

Local Loop.

DSPY1

U3

CX3

D1

R5

82B715

R6

D2

PJ1

COMMOUT

R11

R12

U9

9936

COMMIN

D6

MC34064A

R13

470uF50v

C7

470uF50v

All Modular Power/Comm

Cables Are To Be

WattMaster Part Number

PCC-xx Or PCCE-xx

Cables.

Distribution

RV1

R7

R10

D5

D4

L1

CX10

C4

74HC923

C5

U10

CX9

1000uF10v

C6

C8

1000uF10v

CX14

P3

74HC540

U14

Modular System Manager

Back of Front Cover

YS101830PREV.

2PMODULARPSYSTEM

MANAGER

U1

74HC259

CX2

U2

R3

R1

R4

PCB80C552-5-16WPP442860=2/5PDfD9722V7Y

C1

X1

C2

U7

PAL

U8

CX7

CX11

U11

CX12

V62C518256L-70P

U12

Note: If Desired A Power/Comm Board As

Used With The Networked System Can

Be Installed And Wired Instead Of Using

The Pigtail Cable Wiring Shown Below.

See The Networked System Wiring

Diagram For Details.

Use Supplied Modular

Cable With Stripped Ends

For Connection To Terminal

Block And Transformer

WHITE (T)

DRAIN WIRE (SHLD)

BLACK (R)

RED (24 VAC)

BROWN (GND)

GREEN (GND)

R2

EWDOG

CX4

U3

R3

PHILIPS

24C128

U4

PHILIPS

CX5

CX6

R9

D3

C3

8583

X2

U6

RN1

CX8

74HC573

SC1

EPROM

RAM

CX13

75176

RS-485P

COMM

R14

DSPY1

U3

CX3

D1

R5

82B715

R6

D2

PJ1

COMMOUT

P1

P2

VAR1

U13

D5

R11

R12

L1

U9

C4

9936

COMMIN

D6

MC34064A

R13

CX9

1000uF10v

470uF50v

C8

C7

1000uF10v

470uF50v

RV1

R7

R10

D4

CX10

74HC923

C5

U10

C6

P3

74HC540

CX14

U14

Modular System Manager

Back of Front Cover

T

SHLD

R

Controller Board

Figure 4: Modular System Manager - Networked

Operator Interfaces

Class 2 Transformer

Rated For 6 VA Minimum

Figure 6: Modular System Manager - Stand Alone

5

Page 6

Technical Guide

General Programming Information

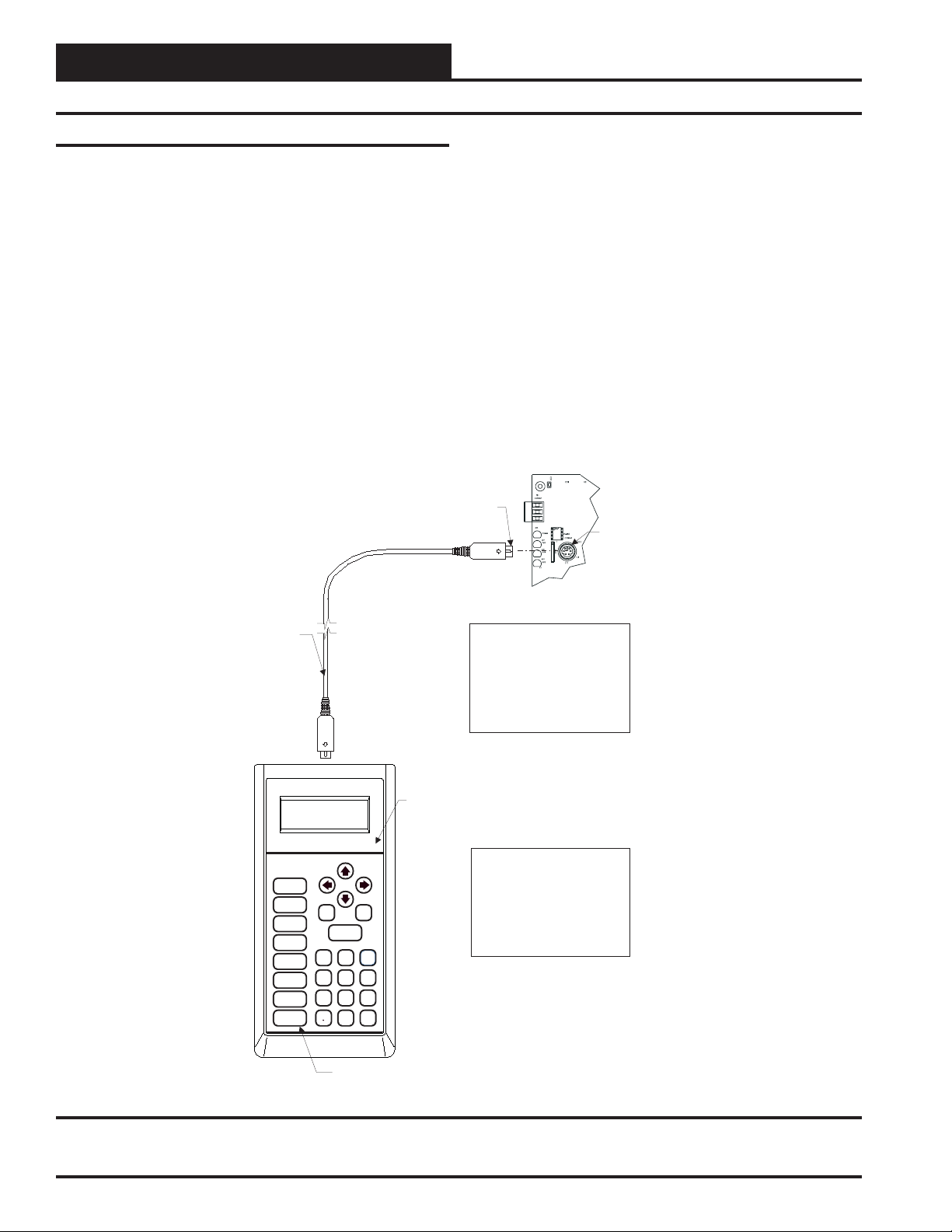

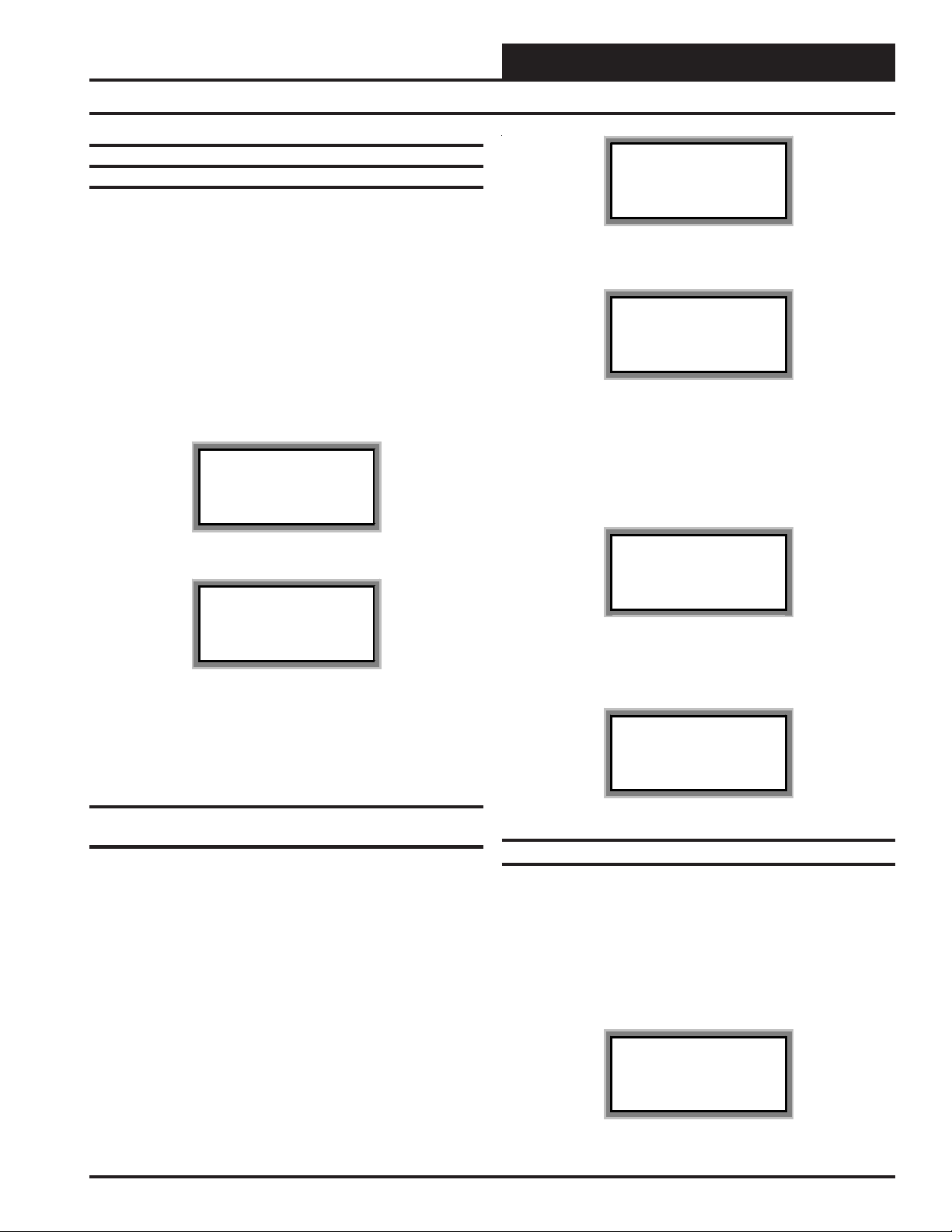

Operator Interfaces Comparison

In order to configure and program the Orion System controllers you

must have a central operators interface or a personal computer with the

Prism computer front end software installed. Two different central operators interfaces are available for programming of the Orion Controls

System. Y ou may use either the Modular Service Tool and/or the Modu-

lar System Manager to access the status and setpoints of any controller on your communications loop.

Mode

Selection

STATUS

SETPOINTS

SCHEDULES

OVERRIDES

ALARMS

CONFIGURATION

BALANCE - TEST

ON

Modular Service Tool

13

2

MINUS

PREV

6

9

-

4

708

DEC

5

UP

ENTER

DOWN

NEXT

CLEAR

2

5

6

9

MINUS

-

PREV

ESC

13

4

708

DEC

System Manager

UP

NEXT

DOWN

ENTER

CLEAR

ESC

STATUS

SETPOINTS

SCHEDULES

OVERRIDES

ALARMS

The Modular Service Tool or the System Manager allow the user to

view any temperature or output condition and change any setpoint to

fine tune the operations of the total system. All keypad operations are

simple and straightforward, utilizing non-cryptic plain English messages.

Display Screens & Data Entry Keys

The System Manager display screens and the Modular Service Tool

display screens are very similar. For most setpoints and modes the only

difference between using the Service T ool and the System Manager is a

few differences in the function of the keypads. The Modular Service

Tool has 2 extra function keys (“Configuration” and “Balance-Test”)

that are not available on the System Manager. Where a dif ference in the

keypad input or the screens displayed exists between the two operators

interfaces, both screens or keypads will be shown. See the chart below

for a list of the keypad descriptions and functions.

Keypad

Description

ESC

ENTER

Clear

Minus

DEC

⇐ ⇒

⇑

⇓

System Manager Modular Service Tool

Used to exit from screens

or from data entry. Use

this s creen to return to the

main menu from any

screen in the system

This key is used to close a

data entry field and

advance to the next item

or screen

If a data entry mistake is

made, press this key to

clear the data entry field

and start over

If the a setpo i nt with a

negative value is required,

press this key for the

minus sign

Press this key when

entering data that requires

a decim al po int

Ste p s the user to the nex t

controller on the loop on

interconnected or

networked systems

Steps the user backward or

forward th rou gh the

screens

Key Function

Same function as

System Manager but

also turns off the

power to the Se rvic e

Tool when on the

main menu screen

Same function as

System M an age r

Same function as

System M an age r

Same function as

System M an age r

Same function as

System M an age r

Same function as

System M an age r

Same function as

System M an age r

6

Modular System Manager

Operator Interfaces

Page 7

Modular System Manager

System Manager Initialization Screens

When the System Manager is powered up, the first screen displays the

current version of the software installed in your System Manager and

whether your system is configured for Network or Stand-Alone operation. The System Manager will try to detect the type of installation you

have by scanning the communications loop. See the screens below. If it

is configured for Stand-Alone operation, only the HVAC unit controller

that the System Manger is connected to is available for programming.

On a Networked System, all controllers on the communications loop

are available for programming by entering their loop address (ID). If an

Interconnected System is connected to the System Manager all controllers that are connected to the communication loop are available for programming.

Initializing

System Manager vX.XX

Wattmaster Controls

Network Mode

Technical Guide

1) Set Time & Date

2) Communications

->) Next Menu

ESC) Exit Menu

Press the “2” key on the keypad to enter the communications screen.

THIS ACTION REQUIRES

PASSCODE CLEARANCE

Enter Passcode: xxxx

Enter the seven digit passcode “2337377” to access the next screen.

These seven digits spell the word “ADDRESS” on your telephone keypad if you forget what they are. Once on the screen shown below, use

the keypad to enter the correct mode for your installation. The screen

will now show “Stand Alone System” or “Multiple MGRS” or “Network System” depending on what you selected.

System Manager vX.XX

Monday Operations

09/09/99 04:26 PM

Outdoor Air 87°F

The screen above will appear a few seconds later. If this is a Stand

Alone system, the outdoor air temperature will not be shown on the

display. If you believe your system is incorrectly configured, please follow the instructions that follow. If your system is configured correctly

proceed to the Menu Screens section of this manual.

Configuring The System Manager For Network

Or Stand-Alone Operation

The System Manager can operate as a Stand Alone interface with the

HVAC unit controller and does not require any other communications

devices to read or reset any available values. T o verify if it is currently

configured for Stand Alone operation, cycle power to the System Manager and monitor the LCD initialization screen. If it is configured for

Stand Alone you will see the words “Stand Alone Mode” on the bottom

line of the display. If you are using this System Manager on a communications loop and have installed a MiniLink or CommLink II communications interface, then you need to operate in Network Mode and the

bottom line should display the words “Network Mode”.

If your display indicates a different mode than the one you need, press

the “Enter” key and the following screen will appear.

0) Stand Alone

1-60) Multiple MGRS

63) Network System

Enter Mode Of Op:.xx

Once you have the correct mode displayed, press the ENTER key. The

following screen will appear to telling you that you have changed the

system mode. Press any key on the keyboard to exit this screen.

You Have Changed The

System Mode

Press Any Key To

Continue

Modular Service Tool

The Modular Service Tool is very similar to the System Manager in its

operations as stated previously . Two exceptions to this are that the Service Tool unlike the System Manager does not check the system to determine whether it should be in Network or Stand Alone Mode and it

does not have any passcoding capability.

After connecting the Service Tool to the controller with the supplied

cable, press the “On” key. The following screen will appear.

Service Tool vX.XX

Monday Operations

09/09/02 04:26 PM

Stand Alone Mode

Operator Interfaces

7

Page 8

Technical Guide

General Programming Information

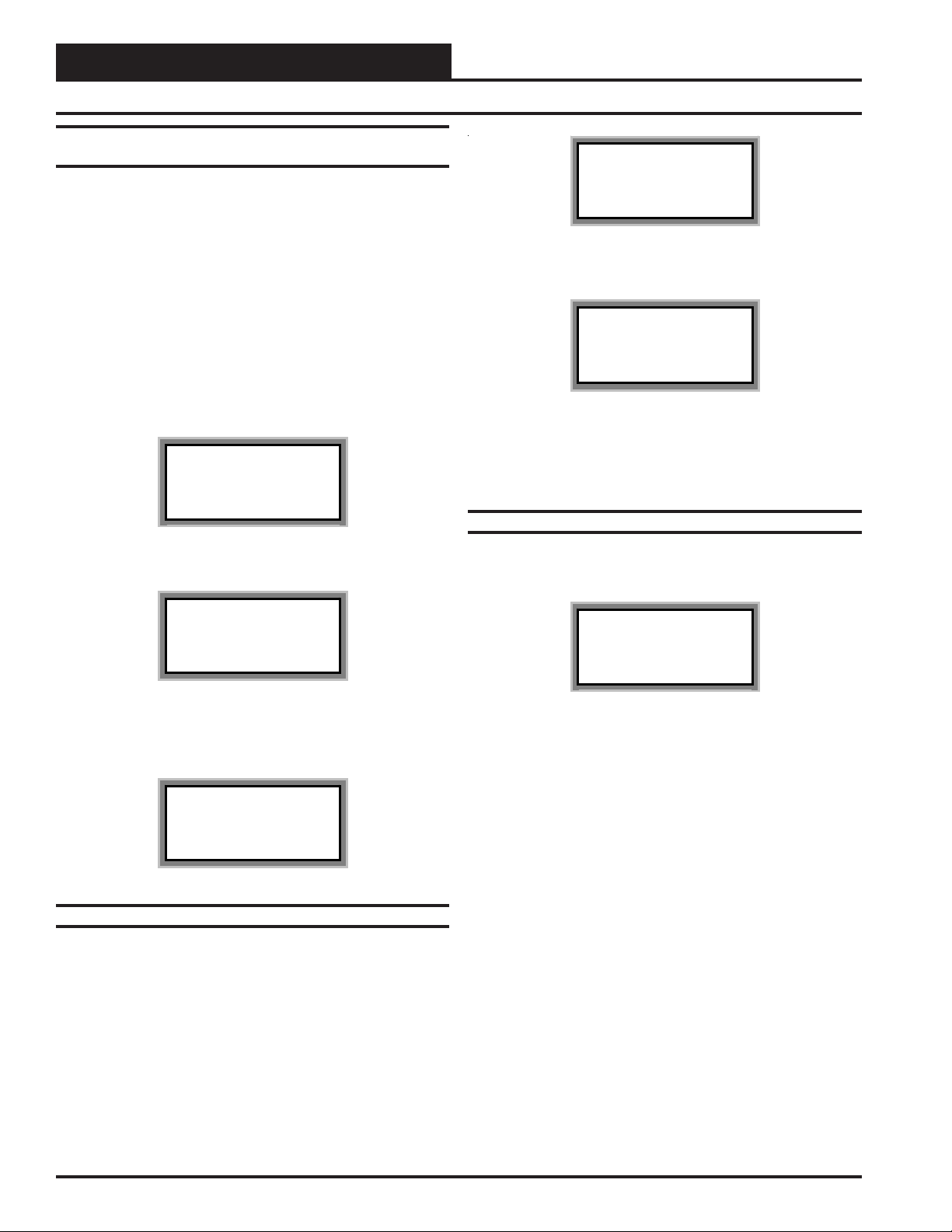

Configuring The Modular Service Tool For

Network Or Stand-Alone Operation

As with the System Manager described previously, you must determine

if the mode displayed is correct for your system. If it is configured for

Stand Alone you will see the words “Stand Alone Mode” on the bottom

line of the display. This is the factory default setting. If you are using

this tool on a system or controller that does not have a CommLink or

MiniLink installed, then this is the correct setting and you can proceed

to desired screen by pressing the menu key or any function key. If you

are using this Service Tool on a communications loop with and have

installed a MiniLink or CommLink II communications interface, then

you need to operate in network mode and the bottom line should display the words “Network Mode”.

If your display indicates a different mode than the one you need, press

the "Enter" key and the following screen will appear.

1) Set Time & Date

2) Communications

3) Energy Saving

ESC) Exit Menu

1) Set Time & Date

2) Communications

3) Energy Saving

ESC) Exit Menu

When this screen appears press the “3” key to access the Energy Saving

screen. The following screen will appear.

Energy Saving

Automatic Power Down

Minutes: xx

Press ESC to Exit

Enter the number of minutes you want the Service Tool to stay active

before it automatically powers down. To cancel the automatic power

down enter “99”. After you have entered this number between 1 and 99

minutes, press “ESC” to exit as the screen instructs you.

Unit Selection

Press the “2” key on the keypad to enter the communications screen.

0) Stand Alone

1) Network System

Enter Mode Of Op:.xx

As the screen indicates, press “0” or “1” keys to select the proper

mode of operation. When you are finished press “Enter” to move

back to the main menu screen.

You Have Changed The

System Mode

Press Any Key To

Continue

Setting The Energy Saving Timer

The Modular Service Tool has a built in timer that can be programmed

to shut the Service T ool off after a specified period of time if no buttons

are pressed. This is a very useful feature if you are powering the Service

Tool from the internal batteries. To access this setting from the main

status screen press "Enter".

With both the Modular Service Tool and the Modular System Manager

You must enter the ID (Address) of the controller you wish to program

Unit Selection

Enter Unit ID#

Selected ID#: xxxx

With the main menu screen displayed, press the function key associated

with the operation (setpoints, configuration, etc.) you want to perform.

The screen shown above will appear asking you to enter a unit I.D.#

(controller address). Put in the ID# of the controller you wish to communicate with then press the “ENTER” key.

If this is Network System (the system has a CommLink), the Unit ID is

actually two separate numbers, combined into one value. The first part

of the number contains the Loop Address at which the controller is

located. The second part of the number contains the actual controller

address. See Examples #1 & #2 below.

If this is a Stand Alone System (system without a CommLink) this will

be a number between 1 and 59. It is recommended the address be set to

1. See example #3 below.

EXAMPLE #1

You would like to view the 3rd controller on the 5th loop. Enter “503”

as the Unit ID.

8

Operator Interfaces

Page 9

Technical Guide

EXAMPLE #2

Y ou would like to view the 12th controller on the 24th loop. Enter “2412”

as the Unit ID

EXAMPLE #3

You would like to view the only controller on the loop. Enter 1 as the

Unit ID. No loop number is required since there is only one loop.

Hit the “Enter” key after entering the unit ID. If you are using the Modular

Service T ool you will be taken directly to the first screen for the operation you are trying to program.

System Manager Passcodes

Anytime you enter a unit ID with the Modular System Manager you

will be asked for a passcode. Passcodes are not required to view Status

Screens. The screen below will appear if this action requires passcode

clearance.

THIS ACTION REQUIRES

PASSCODE CLEARANCE

Enter Passcode: xxxx

The System Manager has two levels of user access. Level 1 users are

limited to viewing or changing the Time and Date and Operating Schedules. Level 2 users have complete system access. Any status or setpoint

field can be read or reset from the System Manager.

These two levels of passcodes are programmable by any Level 2 user.

The default Level 1 passcode is “111 1” and the default Level 2 passcode

is “2222.”

If you wish to change either Level 1 or Level 2 passcodes please see the

instructions that follow.

From the main status screen press "Enter", The following screen will

appear.

1) Set Time & Date

2) Communications

->) Next Menu

ESC) Exit Menu

Press ">", to proceed to the next menu and the following screen will

appear.

1) Change Passcodes

2) Loop Search

<-) Prev. Menu

ESC) Exit Menu

Press the “1” key on the keypad to enter the Change Passcode screen.

THIS ACTION REQUIRES

PASSCODE CLEARANCE

Enter Passcode: xxxx

Enter the default Level 2 passcode “2222” to access the next screen.

You must use the Level 2 passcode to change passcodes. Level 1

passcodes will not allow changing passcodes!

Enter New Passcode

Level 1.....: xxxx

Level 2.....: xxxx

[Must Be 4 Digits]

Operator Interfaces

This screen allows you to enter new Level 1 or Level 2 passcodes. The

actual digits in your passcodes are never displayed. An “X” is used as a

place holder for each digit entered. Passcodes must always be four digits in length, so the usable range of numbers is 1000 to 9999.

Caution: If you change the Level 2 passcode and cannot

remember what it is, you will be locked out of

your system!

9

Page 10

Technical Guide

General Programming Information

Scheduling

The MUA II D controller scheduling screens are accessed by pressing

the “Schedule” button on either the System Manager or the Modular

Service T ool. Press the number button for the scheduling function you

wish to view.

1)Schedule Overrides

2)Week Schedules

3)Holidays

ESC) Exit Menu

Week Schedules

Event #1

MUA II Sched ID 59

Sunday Event #1

Start Time : xxxx

Stop Time : xxxx

Event #2

Note: The second line displays which day of the week is cur-

rently being programmed. This automatically increments

as you finish the Event #2 screen and continue to the

next days Event #1 screen.

Caution: The controller ships with all schedules set to zero so

that the controller will not attempt to heat or cool

before the user has configured his system.

Holiday Start/Stop Day Selection

MUA II Hldy ID 59

Holiday # 1

Start Mon/Day: xxxx

[ July 4

MUA II Hldy ID 59

Holiday # 1

Stop Mon/Day: xxxx

[ July 4

th

= 704 ]

th

= 704 ]

MUA II Sched ID 59

Sunday Event #2

Start Time : xxxx

Stop Time : xxxx

If you are using the internal scheduling capability of the V AV/CA V controller, set the schedule hours and holiday periods from the menu shown

above. You can also force the unit to operate continuously in occupied

or unoccupied mode by selecting the Schedule Override menu item and

entering the desired command.

If you are using an external contact closure to signal the occupied mode,

you must access the Week Schedule screens and set all start and stop

times to zero to prevent the internal schedule from bringing the equipment on when you don’t want it to operate.

The screens will step through the Start T ime and then the S top T ime for

each day of the week. You can quit at any point in the process by pressing the “Escape” key. There are two Start/Stop events available per day

so the screen will show which event is being programmed. If you need

only one event, leave Event #2 times to ZERO.

All times are in 24-hour military format, so 5:00 PM would be entered

as 1700.

If both the Start and Stop T imes are ZERO, the schedule is in a continuous OFF mode. (Use for Remote Signal Contact)

The screens will step through the fourteen possible holidays, one period at a time. Line 2 shows which holiday is currently being programmed. Since a holiday period can encompass more than one day,

you need to program the day the holiday starts and the day the holiday

ends. If your holiday only lasts one day simply set both the Start Day

and the Stop Day to the same value. Remember to combine the month

and day into a single four-digit value.

EXAMPLE: 704 = July 4th (Note : Leading zero not required)

1225 = December 25

th

Holiday Start/Stop Times

MUA II Hldy ID 59

Holiday Schedule

Start Event #1: xxxx

Stop Event #1: xxxx

MUA II Hldy ID 59

Holiday Schedule

Start Event #2: xxxx

Stop Event #2: xxxx

If both the Start and Stop Times are 2359, the schedule is in a continuous ON mode.

10

The fourteen holidays all use the same Start and Stop times which are

entered on this screen and then next. It is entered in 24-hour military

format, the same as a regular week schedule.

Operator Interfaces

Page 11

Technical Guide

Normally the holidays will operate in an unoccupied mode or a reduced

schedule mode. There are two start/stop events available on holidays to

match the standard schedule number of events.

Schedule Override

Schedule Override

Enter Override : x

[0=Auto 1=ON 2=OFF]

If you want to force the unit to operate in a continuous Occupied or

Unoccupied mode, select this menu item to activate the desired method.

If a Schedule Override is active, all other methods of schedule control

are ignored. (Push-Button, Internal or Remote)

As you can see on the last line of the display you enter a ‘1’ to run

continuously in the Occupied Mode or a ‘2’ to run continuously in the

Unoccupied Mode.

T o restore normal schedule operations, make sure a ‘0’ is entered here.

This override remains in effect until canceled by the user and does not

time-out like the Output Overrides do after 10 minutes of no communications.

For the Service T ool, from the main screen press “Enter” and the fol-

lowing screen will appear.

1) Set Time & Date

2) Communications

3) Energy Saving

ESC) Exit Menu

Press 1 to enter the Set Time and Date Menu.

Programming Times

Although the times are displayed on the Main Screen in a standard 12hour format, they are programmed using the 24-hour military format. If

the VAV/CA V controller was configured to use its own Internal Schedules, the Occupied/Unoccupied modes are calculated on the basis of the

current real time clock reading.

Program Time/Date

Day (Sunday=0): x

Enter Hr. (0-23): xx

Enter Minutes : xx

Note: Do not use the Force OFF mode in place of setting all

the week schedules to ZERO if you are using a Remote

Signal for your scheduling since the Override has priority over the Remote Signal.

Setting Time & Date

Both the Modular Service Tool and Modular System Manager are

equipped with a real time clock chip allowing it to maintain the correct time. Once the correct time and date are entered, the information

is broadcast globally to all controllers on the entire system. The System Manager will also broadcast this information once every day at

midnight to synchronize all the controllers on the system.

From the main System Manager screen press “Enter” and the following screen will appear.

1) Set Time & Date

2) Communications

->) Next Menu

ESC) Exit Menu

Press 1 to enter the Set Time and Date Menu.

Day Enter the Day of the Week (0 to 6)

Sunday = 0

Hours (Hr) Enter Hours in 24-Hour Military Format

(1700 = 5:00 PM)

Minutes - Enter the Minutes

(0 to 59)

Programming Date

Program Time/Date

Month (1-12): xx

Day (1-31): xx

Year (00-99): xx

Month Enter the Month (1 to 12)

Day Enter the Day of the Month (1 to 31)

Year Enter the current Year with two digits (00 to 99)

Space Sensor Overrides

When a space sensor with override option is used the System Manager

or Modular Service Tool can determine and report any units which are

currently operating in an override condition. This function requires that

a polling device is installed on the loop where the controllers are located.

Operator Interfaces

T o access the Space Sensor Overrides screen, press the “Override” button located on the System Manager or Modular Service Tool. A screen

will appear asking you to enter a unit ID. Enter an ID for any active

11

Page 12

Technical Guide

General Programming Information

controller on the system and press "Enter". The following screen will

appear.

Overrides Screen

SEARCHING!

After the System Manager or Modular Service T ool completes its search,

it will list the first unit on the system that is currently in the override

mode. Press the previous or next button to scroll through all units that

are in the Override Mode.

Overrides Screen

Loop = 1 Unit = 59

Override Unit

Alarm Search

The System Manager or the Modular Service T ool can be used to search

for all active alarms on the system. From either of the operators interfaces press the “Alarm” key. The Unit Selection screen below will be

displayed. Enter the Unit ID of any unit on the system and press “Enter”.

The following screen will appear. The operators interface will search

for any active alarms on the entire system.

Alarm Screen

SEARCHING!

After the System Manager or Modular Service T ool completes it’s search,

it will list the first unit on the system that currently has an active alarm.

Press “Enter” to scroll through all the alarms on that particular unit. T o

move to the next unit or back to the previous unit use the “Prev” or

“Next” arrows to move between units with alarms.

Alarm Search Screen

Loop = 1 Unit = 59

Space Sensor Failure

T o clear any alarms that are found you must fix the problem indicated in

the alarm. Once the problem is fixed, the alarm will clear from the screen

the next time the unit is polled.

Unit Selection

Enter Unit ID#

Selected ID#: xxxx

12

Operator Interfaces

Page 13

Programming The MUA II D Controller

Technical Guide

Configuration

In order to correctly setup the MUA II D controller you must first configure several parameters in regard to the type of HV AC unit and system

you have installed. Most of these values and operating parameters are

only set once, at the initial system setup and are never changed.

System Manager Instructions

From any menu screen press the “Setpoint” key. The unit selection screen

will appear requesting that you enter the unit ID number. Enter the cor rect unit ID number of the MUA II D controller you want to configure

and hit the “Enter” key. You will see the screen shown below.

1)Change Setpoint

2)Configure Unit

3)Damper Force

ESC) Exit Menu

Press “2” on the keypad to enter Configuration Screen #1.

Modular Service Tool Instructions

From any menu screen press the “Configuration” key. The unit selection screen will appear requesting that you enter the unit ID number.

Enter the correct unit ID number of the MUA II D controller you want

to configure and hit the “Enter” key. You will then see unit configuration screen #1.

Configuration Screen #1

MUA II Cnfg IDxxxx

Proof Of Flow Switch

Installed: NO

(0=No 1=Yes)

If you need proof of airflow before allowing any heating or cooling

stages to operate, install a differential pressure switch with a contact

closure that is connected to analog input #7 and select this option. If

this option is not selected, the air handler assumes there is adequate

airflow anytime the fan is running and ignores this signal defaulting

input #7 to space humidity.

Configuration Screen #2

temperatures for control of the HVAC unit, the setting should be set to

0=No. If you have an Outside Air Humidity Sensor installed and wish

to use dewpoint calculations for unit control, select 1=Y es. If you have

a sensor installed and do not select 1=Yes, the sensor readings will be

ignored.

Configuration Screen #3

MUA II Cnfg IDxxxx

Heat In Dehumidify

Installed : Yes

(0=No 1=Yes)

If you need to allow heat during dehumidification, select this option. If

this option is not selected, the controller assumes that only reheat will

be allowed during dehumidification mode.

Configuration Screen #4

MUA II Cnfg IDxxxx

Is External Heat

Reverse Actn: Yes

Use Left/Right Arrow

If you need the modulation of the external heat to be reverse acting,

select this option. If this option is not selected, the controller assumes

the modulation will be direct acting.

Configuration Screen #5

MUA II Cnfg IDxxxx

If External Heat

Output Range.: 0

(0=2-10V 1=0-10V)

If you have an external heat device to be controlled by the MUA II D

controller, you can select between the voltage ranges that will be used

to control the device. The available options are 2-10 VDC and 0-10

VDC.

Configuration Screen #6

MUA II Cnfg IDxxxx

OA Humidity Sensor

Installed: NO

(0=No 1=Yes)

This configuration screen allows the user to indicate whether an Outside Air Humidity Sensor is to be installed and used to calculate

dewpoint settings. If you either don’t have an Outside Air Humidity

Sensor installed or have one installed but wish to use only drybulb

Operator Interfaces

MUA II Cnfg IDxxxx

Broadcast Outside

Temperature:_NO

(0=No 1=Yes)

If you have other unit controllers on the system, you can elect to broadcast the Outside Air Temperature to these units by selecting 1=Yes on

this screen. If you don’t have other controllers or they have their own

Outside Air Temperature Sensors, select 0=No on this screen.

13

Page 14

Technical Guide

Programming The MUA II D Controller

Configuration Screen #7

MUA II Cnfg IDxxxx

Broadcast Humidity

Reading :_NO

[0=No 1=Yes]

If you have other unit controllers on the system, you can elect to broadcast the Outside Humidity to these units by selecting 1=Yes on this

screen. If you don’t have other controllers or they have their own Outside Humidity Sensors, select 0=No on this screen.

Configuration Screen #8- #27

MUA II Cnfg IDxxxx

Stage Configurations

Rly #xx: Not Used

Select Using ‘0’ Key

The first relay on the controller is always reserved for the Supply Fan.

The remaining four relays on the main board and the additional 16 relays on the expansion relay modules can be configured by pressing the

left or right arrow key to change the relay to the desired configuration.

Press “1” on the keypad to enter the first unit setpoint screen.

Modular Service Tool Instructions

From any menu screen press the “Setpoint” key. The unit selection screen

will appear requesting that you enter the unit ID number. Enter the cor rect unit ID number of the MUA II D controller you want to change

setpoints and press the “Enter” key. You will then see setpoint screen

#1.

Setpoint Screen #1

MUA II Spts IDxxxx

Supply Air Temp

Setpoint.....: xxx°F

The Supply Air Setpoint is the desired temperature to be delivered by

the MUA II D at any time during the occupied mode of operation

Description Minimum De fault Maximum

Supply Air Temp Setpoint 50° F 70° F 90° F

Setpoint Screen #2

Possible Relay Descriptions:

Not Used

HeatStage

CoolStage

Gas Reheat

External Heat

The MUA II D controller does not require whether you start configuring your heating or cooling stages first nor does it require that you utilize consecutive relays until all heating or cooling stages have been

defined. This method allows the greatest flexibility in the field, but it

requires close attention to the wiring of the heating and cooling stages

to prevent incorrect and possibly harmful operation. The controller assumes that there will only be one relay configured for Hot Gas Reheat

and one relay for External Heat Enable, although it doesn’t prevent

multiple relays from being selected.

Setpoints

System Manager Instructions

From any menu screen press the “Setpoint” key. The unit selection screen

will appear requesting that you enter the unit ID number. Enter the cor rect unit ID number of the MUA II D controller you want to change

setpoints for and hit the “Enter” key. You will see the screen shown

below.

MUA II Spts IDxxxx

Staging Deadbands

Cooling....: xxx°F

Heating....: xxx°F

The Cooling Deadband added to the Supply Air Setpoint gives the

Cooling Mode Setpoint. When the Outside Air T emperature rises above

this setpoint, the MUA II D will go to Cooling Mode. The Heating

Deadband subtracted to the Supply Air Setpoint gives the Heating

Mode Setpoint. When the Outside Air Temperature drops below this

setpoint, the MUA II D will go to Heating Mode.

Description Minimum Default Maximum

Cooling Deadband 2° F 5° F 20° F

Hea ting D ead ban d 2° F 5° F 20° F

Setpoint Screen #3

MUA II Spts IDxxxx

Unoccupied Deadbands

Cooling....: xxx°F

Heating....: xxx°F

14

1)Change Setpoint

2)Configure Unit

3)Damper Force

ESC) Exit Menu

The Uncoccupied Cooling Deadband added to the Supply Air Setpoint

gives the Unoccupied Cooling Mode Setpoint. When the Space Air

Temperature rises above this setpoint, the MUA II D will go to Unoccupied Cooling Mode. The Unoccupied Heating Deadband subtracted

Operator Interfaces

Page 15

Technical Guide

from the Supply Air Setpoint gives the Unoccupied Heating Mode

Setpoint. When the Space Air T emperature drops below this setpoint,

the MUA II D will go to Unoccupied Heating Mode.

If the default setpoint of 30° F is used it will cancel the corresponding

unoccupied cooling or unoccupied heating mode.

Descriptio n Minimum Default Maximum

Unoccupied Cooling

Deadband

Unoccupied Heating

Deadband

Cooling

Deadband

Setpoint

Heatling

Deadband

Setpoint

30° F 30° F

30° F 30° F

Setpoint Screen #4

MUA II Spts IDxxxx

Systems With Re-heat

Dewpoint Control

Setpoint...: xxx°F

The systems capable of dehumidification will enter this mode of operation when the Outside Air Dewpoint rises above the Dewpoint Setpoint.

Description Minimum Default Maximum

Dewpoint Setpoint 40° F 55° F 80° F

Setpoint Screen #5

Setpoint Screen #6

MUA II Spts IDxxxx

Heat Delay During

Dehumidifcation

Will Occur..: xxxMin

If heating during dehumidification is configured, this is the amount of

time the heating call will be delayed after the dehumidification is activated.

Description Minimum Default Maximum

Heat Delay 0 Min 2 Min 10 Min

Setpoint Screen #7

MUA II Spts IDxxxx

Alarm Limits

Hi SAT Limit.: xxx°F

Lo SAT Limit.: xxx°F

If the Supply Air Temperature ever rises above the Hi SAT Limit or

drops below the Lo SAT Limit for a user defined period of time, an

alarm is generated.

Description Minimum Default Maximum

Hi SA T Limit 50° F 150° F 150 ° F

Lo SAT Limit 0° F 0° F 70° F

MUA II Spts IDxxxx

Enthalpy Staging

Deadband....: xxxBTU

Hysterisis..: x.xBTU

The Enthalpy Deadband if the amount Enthalpy in the Outside Air

needed to activate an extra stage of cooling. The Enthalpy Hysterisis

is use to avoid unnecessary cycling of the cooling stages when the Out-

side Enthalpy is close to the setpoint.

Description Minimum Default Maximum

Enthalpy Deadband 3 BTU 5 BTU 20 BTU

Entha lpy Hysterisis 0.5 BT U 1 BTU 2.5 BTU

Setpoint Screen #8

MUA II Spts IDxxxx

Supply Air Alarms If

Out Of Range For

xxx Minutes

This is the amount of time the Supply Air Temperature must be outside

either the Hi or Lo SAT Limit setpoint before it generates an alarm.

Description Minimum Default Maximum

Min utes 0 Min 30 Min 300 M in

Operator Interfaces

15

Page 16

Technical Guide

Programming The MUA II D Controller

Setpoint Screen #9

MUA II Spts IDxxxx

Set Sat Temp Reset

SPC= xxx Spt= xxx

SPC= xxx Rst= xxx

A Type III Thermistor Sensor connected to AIN 1 can be used to reset

the Supply Air Temperature. This screen allows the user to set the temperature that the reset will begin at and the new reset Supply Air Temperature range.

Description Minimum Default Maximum

Minim um Range 40° F 0° F 100° F

Maxim um R a nge 40° F 0° F 100° F

Reset SAT S pt SAT Spt Spt + 50° F

Setpoint Screen #10

MUA II Spts IDxxxx

Set Dewpoint Reset

HUM= xxx Spt= xxx

HUM= xxx Rst= xxx

An Indoor Humidity Sensor connected to AIN7 can be used to reset the

Dewpoint Setpoint. This screen allows the user to set the relative humidity percentage that the reset will begin at, and the new reset Dewpoint

Setpoint percentage range.

Description Minimum Default Maximum

Minimum Range 0% 0% 100%

Maximum Range 0% 0% 100%

Reset 35° F 55° F Dewpoint Spt

MUA II Spts IDxxxx

Heating Stage Delays

Staging Up : xx Min

Staging Down: xx Min

MUA II Spts IDxxxx

Heating Stage Delays

Min Run Time: xx Min

Min Off Time: xx Min

Both the Heating Stages and the DX Cooling Stages utilize S taging Up

and Down delay periods between stages and Minimum Run T imes and

Off Times.

Both modes have their own set of staging and run delay times. The

Heating timer screens look exactly the same as the cooling except they

reference the Heating instead of Cooling.

See the Sequence of Operation Manual for information on how these

delays and run times are used.

Description Minimum Default Maximum

Cooling Stage U p 3 Min 3 Min 15 Min

Cooling Stage Down 1 Min 1 Min 15 Min

Cooling Min R un T ime 5 M in 5 Min 15 Min

Cooling Min Off Time 3 Min 3 Min 15 Min

Heating Stage U p 3 Min 3 Min 15 Min

Heating Stage Down 1 Min 1 Min 15 Min

Heating Min Run Time 2 Min 2 Min 15 Min

Heating Min Off Time 1 Min 1 Min 15 Min

Setpoint Screen #11-14

MUA II Spts IDxxxx

Cooling Stage Delays

Staging Up : xx Min

Staging Down: xx Min

MUA II Spts IDxxxx

Cooling Stage Delays

Min Run Time: xx Min

Min Off Time: xx Min

16

Setpoint Screen #15

MUA II Spts IDxxxx

External Mod Heat

DeadBand.....: xxx°F

The External Heat Pr oportional deadband is the range through which

the external heating device will proportionally modulate.

Description Minimum Default Maximum

Proportional Band 1° F 5° F 30° F

Operator Interfaces

Page 17

Technical Guide

Setpoint Screen #16

MUA II Spts IDxxxx

Push-Button Override

Duration : x.x Hr

If the Space T emperature sensor contains the optional push-button override then this is the amount of time the unit will revert to occupied

operation whenever the button is pressed during the unoccupied mode.

Description Minimum Default Maximum

Dura tion 0.0 Hr 2.0 Hr 8.0 Hr

Setpoint Screen #17

MUA II Spts IDxxxx

Maximum Slide Offset

Effect on Spt: x°F

If Space Temperature is used as the controlling sensor for the HVAC

unit and it is supplied with the optional Setpoint Slide Adjust, this is

the maximum amount the user can adjust the heating and cooling setpoints up or down as the slide is moved from the center position to its

full up or down position.

Description Minimum Default Maximum

Effect on Spt

F0° F10° F

0°

Setpoint Screen #18

MUA II Spts IDxxxx

AHU Scheduled By

Schedule Number: x

0=AHU 1-7=Scheduler

Setpoint Screen #19

MUA II Spts IDxxxx

Fan Time Delay

Before Activation

Can Occur..:XXX Sec

This is the time delay that occurs before the fan is activated when the

unit switches into the occupied mode from unoccupied mode.

Description Minimum Default Maximum

Fan Time Delay Before

1 Secon d 60 Seco nd 180 Se c on d

Activatio n Can O c cur

Setpoint Screen #20

MUA II Spts IDxxxx

Sensor Calibration

SAT: xx.x° xx.x

OAT: xx.x° xx.x

The Thermistor Type III temperature sensors connected to the MUA II

D controller can be calibrated using this screen. Enter a Positive value

to increase a reading and a Negative value to decrease a reading.

Description Minimum Default Maximum

Supply Sensor - SAT -100.0° F 0.0° F +100.0° F

Outdoor Sensor - OAT -100.0° F 0.0° F +100.0° F

°

°

Setpoint Screen #21

MUA II Spts IDxxxx

Sensor Calibration

Reset Sensor

SPC: xx.x° xx.x

°

Normally, the MUA II D controller will use its own internal time clock

and week schedules to set the occupied mode of operation. If you have

several air handlers you can connect an external scheduling device to

the communications loop and program the air handler for the desired

schedule to follow. If the MUA II D controller is using its internal schedule, enter a ‘0’ for the Schedule Number.

Description Minimum Default Maximum

Schedule Number 0 0 7

Operator Interfaces

If you are using a temperature sensor connected to analog input #1 on

the MUA II D controller for resetting the Supply Air Temperature, the

Thermistor Type III temperature sensor connected to the MUA II D

controller can be calibrated using this screen. Enter a Positive value to

increase a reading and a Negative value to decrease a reading.

Description Minimum Default Maximum

Rese t Sensor - R S T -100 .0° F 0.0° F +100.0° F

17

Page 18

Technical Guide

Programming The MUA II D Controller

Status

The MUA II D controller status screens are accessed by pressing the

“Status” button on either the System Manager or the Modular Service

Tool. Following are the available status screens and a description of

their functions.

Status Screen 1

MUA II vx.xx IDxxxx

OCCUPIED

Vent Mode

Normal Operation

Line 2 Line displays one of the following:

Unoccupied Mode Remote Occupied

Occupied Mode Override Mode

Holiday Operations FORCED OCCUPIED

FORCED UNOCCUPIED FORCED OUTPUT

PUSH-BUTTON OVERRIDE

Line 3 Line displays one of the following:

Vent Mode Cooling Mode

Heating Mode Dehumidification

Line 4 Line displays one of the following:

Normal Operation

Fan Starting Delay

Status Screen 2

Status Screen 4

MUA II vx.xx IDxxxx

Dewpoint...: xxx.x°F

Dewpnt..Spt: xxx.x°F

Outdoor.RH.: xxx.x%

Line 2 - Current Outside Air Dewpoint

Line 3 - Current Dewpoint Setpoint

Line 4 - Current Outside Humidity

Status Screen 5

MUA II vx.xx IDxxxx

Enthalpy...: xx.xBTU

Enthlpy Spt: xx.xBTU

Enthalpy Db: xx.xBTU

Line 2 - Current Air Enthalpy

Line 3 - Current Enthalpy Setpoint

Line 4 - Current Enthalpy Deadband

Status Screen 6

MUA II vx.xx IDxxxx

Space..Temp: xxx.x°F

Reset...Hum: xxx.x%

MUA II vx.xx IDxxxx

Supply Air: xxx.x°F

Supply..Spt: xxx.x°F

Line 2 - Current Supply Air Temperature

Line 3 - Current Supply Air Setpoint

Line 4 - Blank Line

Status Screen 3

MUA II vx.xx IDxxxx

Outdoor.Air: xxx.x°F

Cooling.Spt: xxx.x°F

Heating.Spt: xxx.x°F

Line 2 - Current Outdoor Air Temperature

Line 3 - Current Cooling Mode Setpoint.

Line 4 - Current Heating Mode Setpoint

18

Line 2 - Current Reset Temperature reading

Line 3 - Current Reset Humidity reading

Line 4 - Blank Line

Status Screen 7

MUA II vx.xx IDxxxx

ModGas.Heat: xxx.x%

Mod..Reheat: xxx.x%

Extrnl Heat: xxx.x%

Line 2 - Current MODGAS II position

Line 3 - Current REHEAT II position

Line 4 - Current External Heat position

Operator Interfaces

Page 19

Technical Guide

Status Screen 8-27

MUA II vx.xx IDxxxx

Fan Relay : OFF

Cool Stage1 : OFF

Heat Stage1 : OFF

Line 2 - Current Supply Fan Relay Status

The letters FRC will appear before the colon if this

relay is in a force mode.

Line 3 - Current Configurable Relay Status

Description of relay and what it is configured for and it’s

current status. The letters FRC will indicate the relay is

forced to its current condition.

Line 4 - Current Configurable Relay Status

Description of relay and what it is configured for and it’s

current status. The letters FRC will indicate the relay is

forced to its current condition.

Status Screen 28

MUA II vx.xx IDxxxx

NO ALARMS

Scheduling

The MUA II D controller scheduling screens are accessed by pressing

the “Schedule” button on either the System Manager or the Modular

Service T ool. Press the number button for the scheduling function you

wish to view. All Scheduling, Holiday Functions, Schedule Overrides,

Time & Date Functions and Alarm Search Functions are identical to

these functions as detailed in the scheduling portion of this manual. See

pages 10 through 11 of this manual for complete information in regards

to programming these functions for the MUA II D controller.

1)Schedule Overrides

2)Week Schedules

3)Holidays

ESC) Exit Menu

Line 2 - Blank Line.

Line 3 - NO ALARMS is displayed if none detected. If there are

one or more alarms active, the possible messages are

shown below:

NO SUPPLY SENSOR

BAD OUTDOOR AIR TEMP

NO RELATIVE HUMIDITY

FAN PROVING ALARM!

LO SUPPLY AIR ALARM!

HI SUPPLY AIR ALARM!

Line 4 - Blank Line.

Operator Interfaces

19

Page 20

Technical Guide

Programming The MUA II D Controller

Outputs Force

Output Force settings are available for testing or troubleshooting the

system. These Force settings can only be accessed and programmed

from the Modular Service T ool, the System Manager does not allow for

programming of this function.

Caution: The Output Force settings should only be applied by

qualified service personnel. Serious damage to the

HVAC unit could result from improper use of these

Outputs Force settings.

To access the Output Force settings simply press the “Balance-Test”

key on the Modular Service Tool. You will then see the unit ID screen.

Enter the unit ID of the MUA II D controller you wish to access and

press "Enter". The Output Force settings are only available for the MUA

II D controller.

Unit Does Not

Support The Function

Press Any Key To

Continue

If you entered the unit ID of a MUA II D controller the following screen

will be displayed.

AHU Fan Override

Enter Override...: 0

[0=Auto 1=ON 2=OFF]

The first Outputs Force screen allows the AHU Fan Relay to be set for

Auto, ON or OFF by entering a 0, 1 or 2 as desired. The default setting

is 0=Auto. After completion of all troubleshooting or testing procedures all relays should be changed back to this setting. The 1=ON setting will force the relay to the ON (energized) position. The 2=OFF

selection will force the relay to the OFF (de-energized) position.

The next screen displays the Relay Overrides for Relay 2. After pressing the "Enter" key the next relay will be displayed. All 20 Relay Over ride screens (including the AHU fan relay) are available by pressing the

"Enter" key after each setting is made.

Relay Overrides

Relay 2 Override: 0

[0=Auto 1=ON 2=OFF]

After the screen for relay 20 is displayed, the first Analog Output Override screen will be displayed.

Analog Output 1 Screen

1)Outputs Force

2)Dampers Force

Press the “1” key to access the Outputs Force screen.

Mod External Heat

Analog Output #1

Override Volts: -1.0

[-1.0=Auto]

The default setting for normal operation is -1.0 volts. Voltages between

0 to 10.0 can be set for the Analog Output Override. Press “Enter” after

making a setting change.

20

Operator Interfaces

Page 21

Notes:

Technical Guide

Operator Interfaces

21

Page 22

Notes:

Technical Guide

22

Operator Interfaces

Page 23

Notes:

Technical Guide

Operator Interfaces

23

Page 24

Form: OR-MUAIID-SMST-TGD-01C Printed in the USA December 2004

All rights reserved Copyright 2004

WattMaster Controls Inc. • 8500 NW River Park Drive • Parkville, Mo. • 64152

Phone (816) 505-1100 www.orioncontrols.com Fax (816) 505-1101

Loading...

Loading...