Page 1

FACTORY CONTROLS SYSTEM

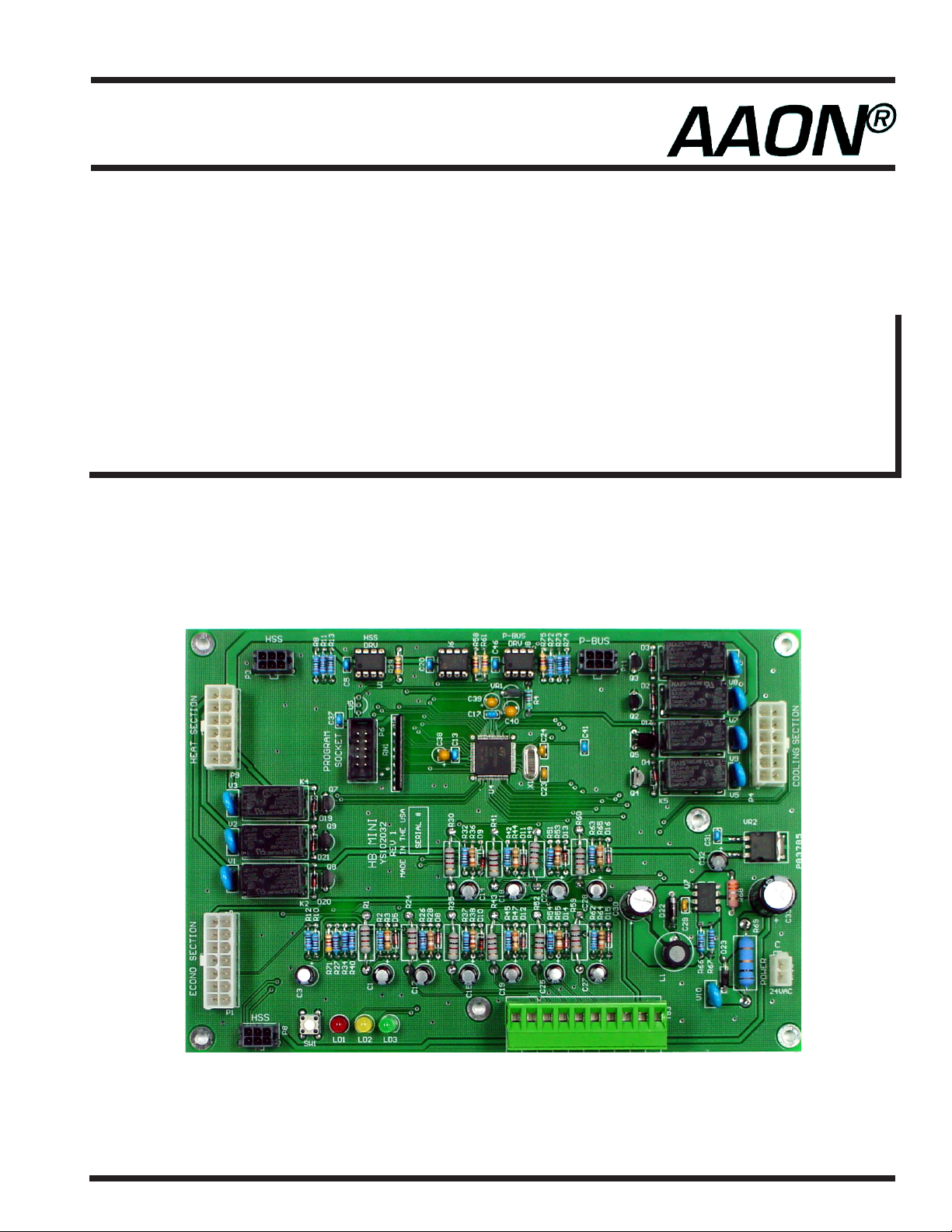

HB Mini - Controller

Technical Guide

Page 2

Table Of Contents

Controller Overview ........................................................................................................................ 3

General ...................................................................................................................................................................................... 3

Inputs ......................................................................................................................................................................................... 3

Outputs ...................................................................................................................................................................................... 3

Controller Sequence Of Operation ................................................................................................. 4

Fan Mode ................................................................................................................................................................................... 4

Heating Mode ............................................................................................................................................................................ 4

Cooling Mode ............................................................................................................................................................................ 4

Lockout Modes ......................................................................................................................................................................... 4

Controller Installation & Wiring ...................................................................................................... 5

Controller Mounting ................................................................................................................................................................. 5

Important Wiring Considerations............................................................................................................................................ 5

Programming With The HB Service Tool...................................................................................... 11

Entering Passcodes ................................................................................................................................................................ 11

General Procedures ................................................................................................................................................................11

Module Selection Screens..................................................................................................................................................11

HB Mini Controller Status & Setpoints ................................................................................................................................. 12

Main Status Screens.......................................................................................................................................................... 12

Fan Module Status Screens .............................................................................................................................................. 13

Cooling Module Status Screens ........................................................................................................................................ 13

Cooling Module Setpoint Screens ..................................................................................................................................... 14

Heating Module Status Screens........................................................................................................................................ 15

Heating Module Setpoint Screens..................................................................................................................................... 16

Alarm Module Status Screens........................................................................................................................................... 16

HVAC Test Module Screens .............................................................................................................................................. 17

Troubleshooting ............................................................................................................................ 19

Using LEDs To Verify Operation ............................................................................................................................................ 19

HB Mini Controller Fault Condition Operation ................................................................................................................... 19

Appendix ........................................................................................................................................ 20

Notes: ............................................................................................................................................ 22

WattMaster Controls Inc.

8500 NW River Park Drive · Parkville , MO 64152

Toll Free Phone: 866-918-1100

PH: (816) 505-1100 · FAX: (816) 505-1101 · E-mail: mail@wattmaster.com

Visit our web site at www.wattmaster.com

Form: AA-HBM-TGD-01A Copyright 2005 WattMaster Controls, Inc.

AAON® is a registered trademark of AAON, Inc., Tulsa, OK.

WattMaster Controls, Inc. assumes no responsibility for errors, or omissions.

This document is subject to change without notice.

Page 3

Controller Overview

Technical Guide

General

The HB Mini Controller is designed to work with a normal 24 VAC

Thermostat. Single or Multi-stage Thermostats can be used. When a

Single Stage Thermostat is used, an auto-staging feature is built-in for

Multi-stage HB units.

The HB Mini Controller also monitors equipment safeties, logs information and locks out the equipment in the event of multiple failures.

Terminal block style connections are provided for field wiring of the

Thermostat. All other inputs and outputs are connected via a wiring

harness on the HB unit. A list of all available inputs and outputs follows.

Inputs

G, Y1, Y2, W1, W2, W3

Outdoor Air Temperature Sensor

Heat Safety Monitor (monitors main and auxiliary limit thermostats)

High Pressure Switch

Low Pressure Switch

Clogged Filter Switch

Outputs

Supply Fan High Speed Relay

Supply Fan Low Speed Relay

Cool-1 Relay

Cool-2 Relay

Heat-1 Relay

Heat-2 Relay

Heat-3 Relay

C1, C2: Clogged Filter Switch 24 VAC Output Terminals

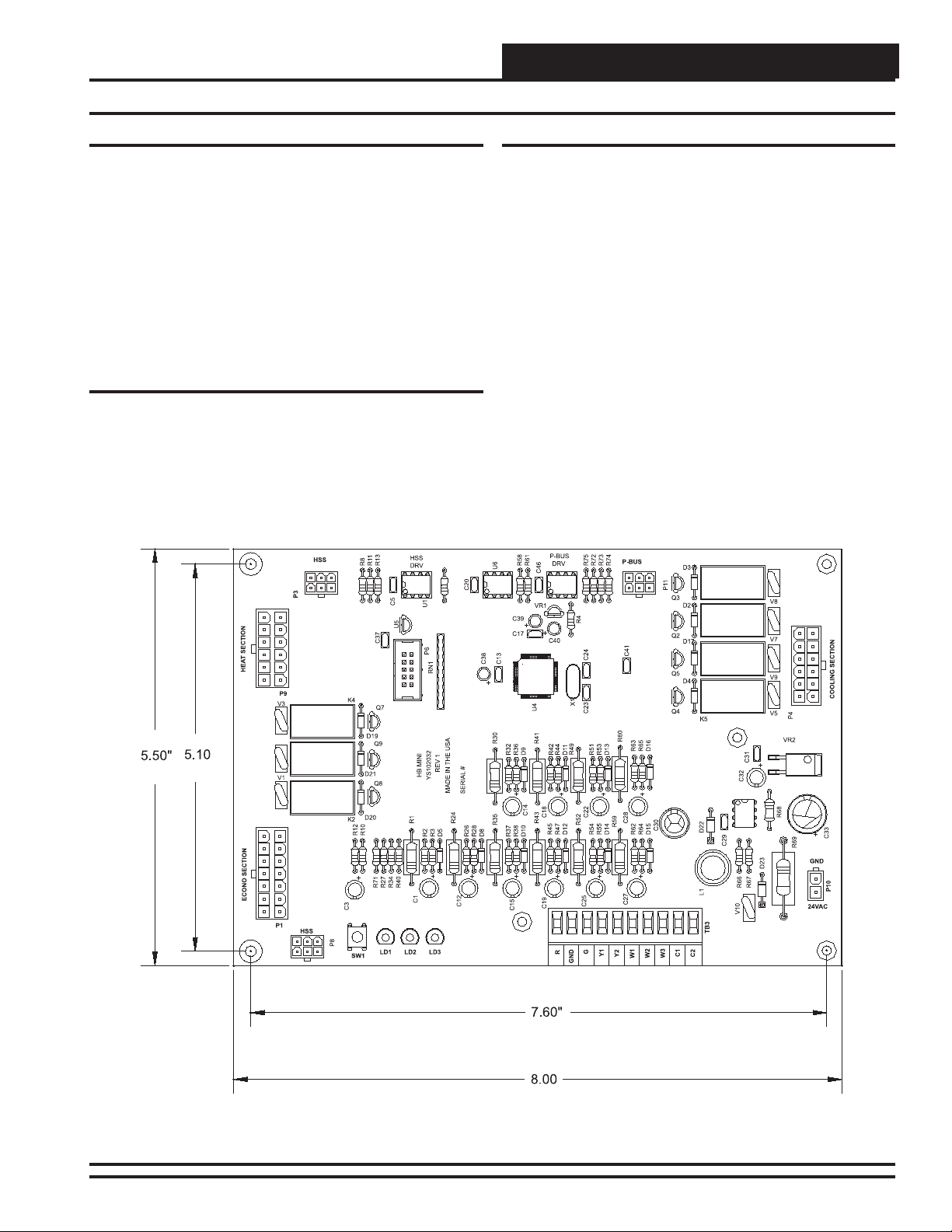

Figure 1: HB Mini Controller Dimensions

HB Mini Controller 3

Page 4

Technical Guide

Controller Sequence Of Operation

Fan Mode

The HB Mini Controller controls the 2 Speed Supply Fan . On a call for

"G" the Supply Fan runs at Low Speed. Minimum on and off times are

maintained in the event of a short cycled call for "G".

Heating Mode

On a call for "W1" the Supply Fan runs at High Speed (maintained

during the Heating mode) and Heat Stage 1 is energized. On a call for

"W2", Heat Stage 2 is energized after the stage up delay. If "W2" is

called without "W1", Heat Stage 1 is energized and then Heat Stage 2 is

energized after the Auto Stage Up Delay period. On a call for "W3",

Heat stage 3 is energized after the Stage Up delay. If "W3" is called

without "W1" or "W2", Heat Stages 1, 2 and 3 will energize based on

Auto Stage Up Delays.

Cooling Mode

If the HB Mini Controller is configured for 1 stage of Cooling, on a call

for "Y1" the Supply Fan runs at High speed and Cool Stage 1 will

energize. If the HB Mini Controller is configured for 2 stages of Cooling, on a call for "Y1" the Supply Fan runs at Low Speed and Cool

Stage 1 is energized. On a call for "Y2" the Supply Fan runs at High

Speed and Cool Stage 2 is energized after the Stage Up Delay. If "Y2"

is called without "Y1", Cool stage 1 is energized and then Cool stage 2

is energized after the Auto Stage Up Delay.

Lockout Modes

Heating Mode is locked out if the HSM (Heat Safety Monitor) trips 3

times during a call for Heating. To reset the lockout condition, either

remove the call for Heating or cycle power to the HB Mini Controller.

Heating Mode is also locked out if the Outdoor Air Temperature is above

the OAT Heat Lockout setpoint temperature.

Cooling Mode is locked out if the LPS (Low Pressure Switch) trips 3

times during a call for Cooling. To reset the lockout condition, either

remove the call for Cooling, or cycle power to the HB Mini Controller.

Cooling Mode is also locked out if the Outdoor Air Temperature is

below the OAT Cool Lockout setpoint temperature or if the OAT Sensor is bad or missing.

4

HB Mini Controller

Page 5

Controller Installation & Wiring

Technical Guide

Controller Mounting

It is important to mount the controller in a location that is free from

extreme high or low temperatures, moisture, dust and dirt. Be careful

not to damage the electronic components when mounting the controller. The HB Mini Controller mounts in the HB unit control panel using

the 4 plastic standoffs located on the HB control enclosure mounting

base.

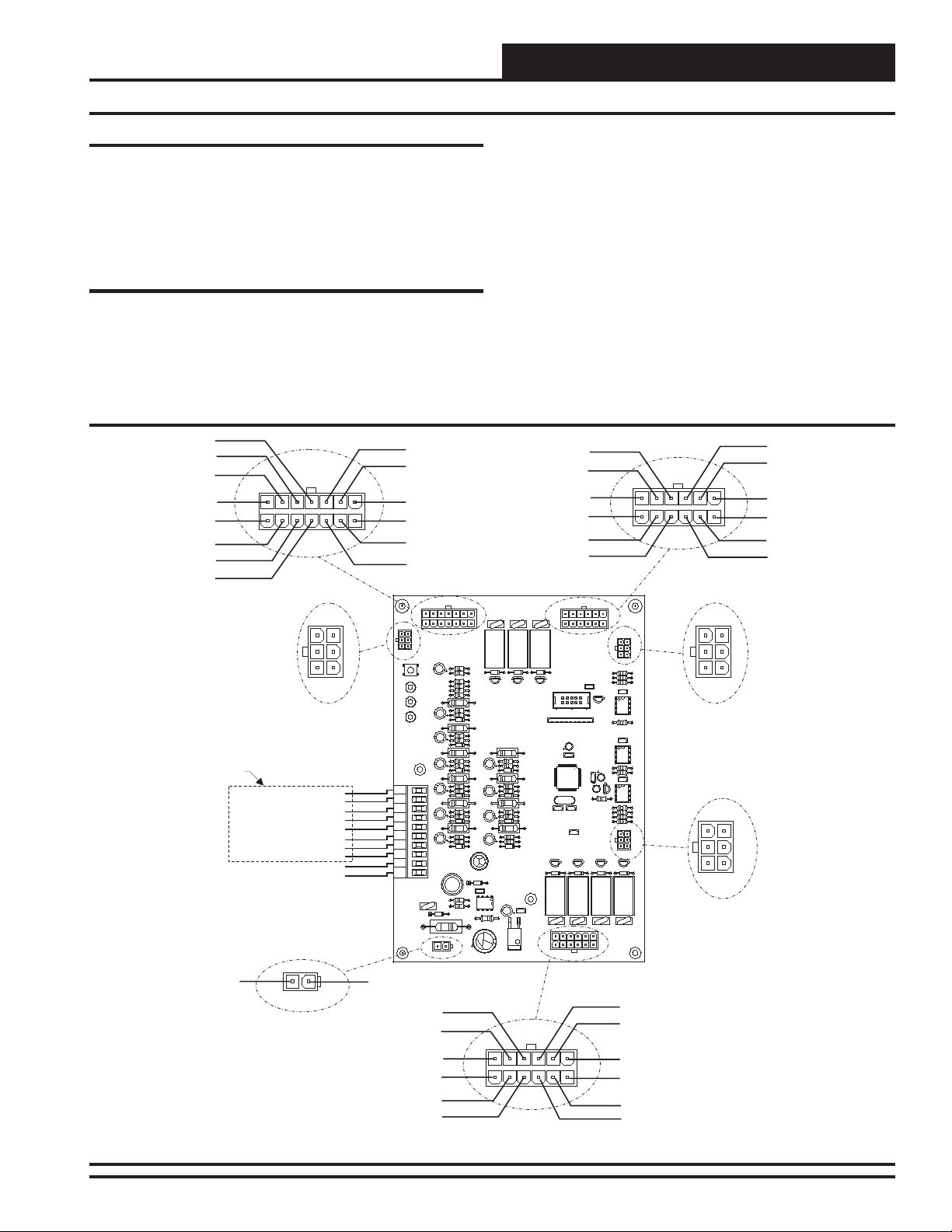

Important Wiring Considerations

Please carefully read and apply the following information when wiring

the HB Mini Controller.

1. All 24 VAC wiring must be connected so that all ground

wires remain common. Failure to follow this procedure

can result in damage to the controller and connected

devices.

PIN11 - 24 VAC

PIN12 - RAB

PIN13 - CO2

PIN14 - GND

PIN7-24VAC

PIN6 - GND

PIN5 - OAT

PIN4-24VAC

HIGH SPEED

SERIAL

COMMUNICATIONS

CONNECTOR

See Thermostat

Wiring Diagrams

For Complete Wiring

Connection Details

(C1) CLOGGED FILTER SWITCH 24 VAC OUTPUT

(C2) CLOGGED FILTER SWITCH 24 VAC OUTPUT

PIN2-24VAC

Figure 2: HB Mini Controller Wiring

ECONO SECTION

P1

P8

(R) FROM THERMOSTAT

(C) FROM THERMOSTAT

(G) FROM THERMOSTAT

(Y1) FROM THERMOSTAT

(Y2) FROM THERMOSTAT

(W1) FROM THERMOSTAT

(W2) FROM THERMOSTAT

(W3) FROM THERMOSTAT

24VAC

GND

P10

HSS

(GND)

PIN1 - GND

PIN10 - HPS

PIN11 - LO_SPD

PIN12 - FAN

PIN6 - COND

PIN5 - GND

PIN4 - LL_TMP

PIN10 - GND

PIN9 - ECONO POS

PIN8 - CFS

PIN1 - SW_24VAC

PIN2 - GND

PIN3 - SPARE IN

ECONO SECTION

P1

HSS

P8

C3

SW1

R71

LD1 LD2 LD3

R27

R34

R40

C1

C12

C15

C19

R

C

C25

G

Y1

Y2

C27

W1

W2

W3

C1

C2

L1

TB3

V10

R66

R67

D23

24VAC

GND

P10

C29

R69

C33

2. All wiring is to be in accordance with local and national

3. Minimum wire size for 24 VAC thermostat wiring should

4. Minimum wire size for all sensors should be 24 gauge.

5. Be sure that all wiring connections are properly inserted

6. Be sure all modular wiring harness connectors are seated

PIN10 - COM_23

PIN11 - COM_23

PIN12 - GND

PIN6 - COM_1

PIN5 - HEAT_1

PIN4 - GND

V1

K2

R12

D20

D21

R10

R1

R2

R3

D5

R24

R26

R28

D8

R35

R37

R38

D10

R43

C18

R45

R47

D12

R52

C22

R54

R55

D14

R59

C28

R62

R64

D15

C30

D22

R68

P4

D19

Q8

Q9

HB MINI

YS102032

REV 1

MADE INTHE USA

SERIAL#

R30

R32

R36

D9

C14

R41

R42

R44

D11

R49

R51

R53

D13

R60

R63

R65

D16

C32

C31

VR2

COOLING SECTION

electrical codes and specifications.

be 22 gauge.

and tightened into the terminal blocks. Do not allow wire

strands to stick out and touch adjoining terminals which

could potentially cause a short circuit.

firmly in their respective modular connectors on the HB

Mini circuit board.

V3

Q7

U4

X1

C23

Q4

K5

V5

P4

HEATSECTION

P9

K4

RN1

Q5

D4

V9

COOLING SECTION

HEAT SECTION

P9

P3

P3

HSS

R8

C37

P6

C38

C13

C40

C24

C41

D17

R11

R13

C5

U5

HSS

DRV

U1

C20

U6

C17

C39

R58

R61

VR1

C46

P-BUS

DRV

R4

R75

R72

R73

R74

P-BUS

P11

Q2

Q3

D3

D2

P11

V7

V8

PIN9 - LPS

PIN8 - COOL_1

PIN7 - COOL_2

PIN1 - GND

PIN2 - VFD

PIN3 - GND

PIN9 - HT_MON

PIN8 - HEAT_3

PIN7 - HEAT_2

PIN1 - HEAT_1

PIN2-24VAC

PIN3-24VAC

HIGH SPEED

HSS

SERIAL

COMMUNICATIONS

CONNECTOR

P-BUS

PERIPHERAL BUS

CONNECTOR

HB Mini Controller

5

Page 6

Technical Guide

Controller Installation & Wiring

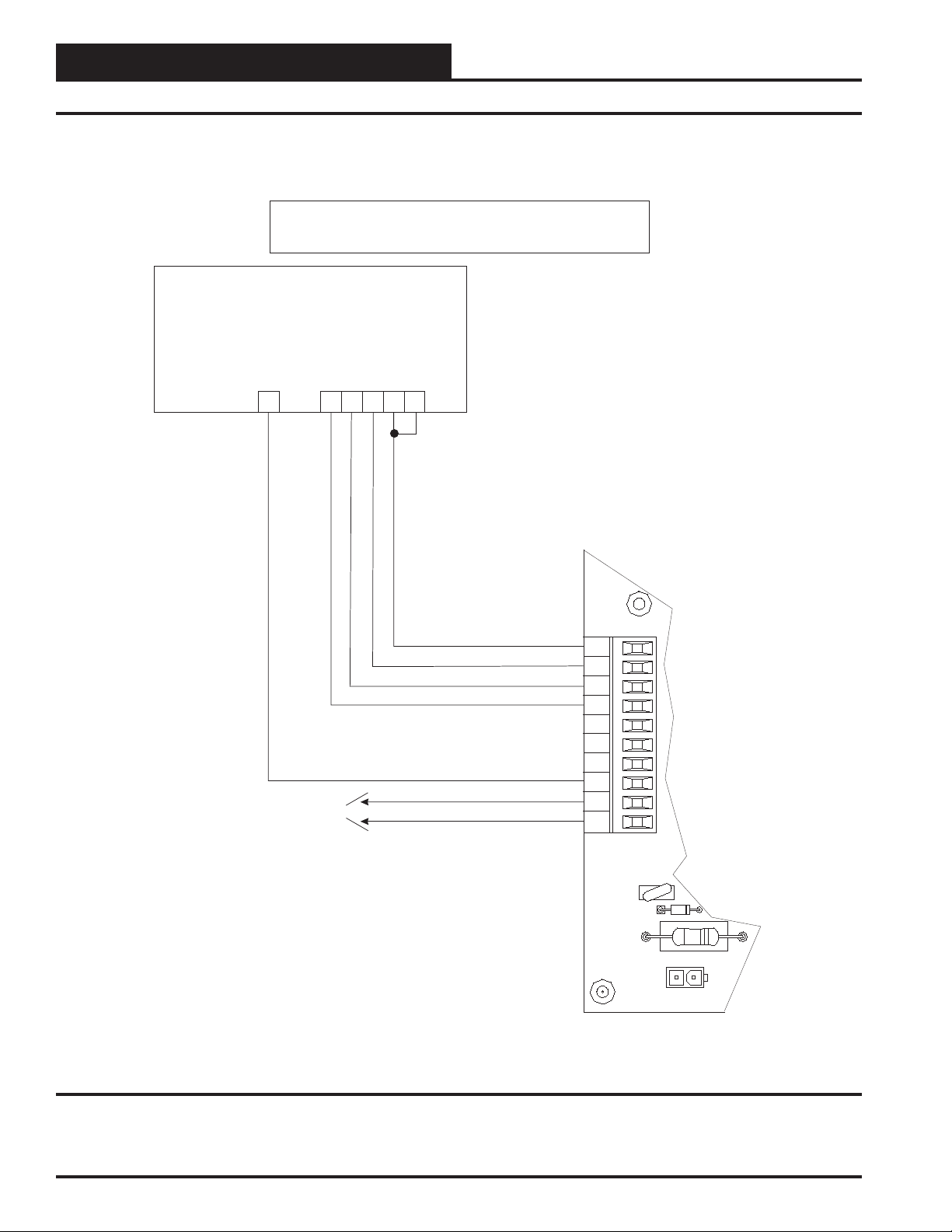

Single Stage T-stat Wiring For HB Unit

Single Stage T-stat Wiring For HB Units

With 1 Stage Cooling&1StageHeating

With 1 Stage Cooling&1StageHeating

Single-Stage Thermostat

1-Cool / 1-Heat

W1

Y1

Clogged Filter Indicator

(Outputs 24VAC)

(24VAC)

G

RC

C

RH

HB Mini Controller Terminal Block

(GND)

24VAC

GND

R

C

G

Y1

Y2

W1

W2

W3

C1

C2

TB3

V10

24VAC

P10

Figure 3: Single Stage T-stat Wiring For HB Unit With 1 Stage Cooling & 1 Stage Heating

6

HB Mini Controller

R69

GND

Page 7

Technical Guide

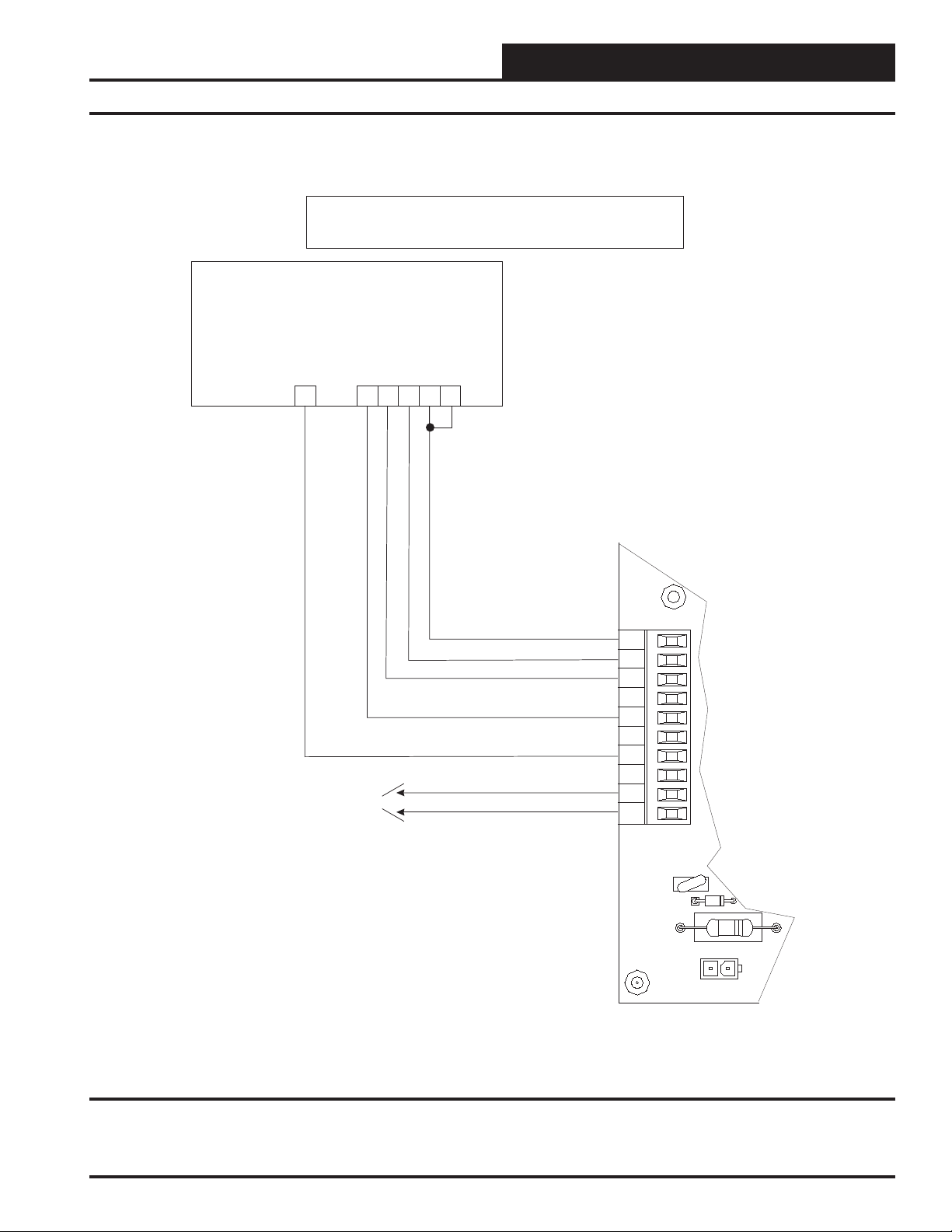

Single Stage T-stat Wiring For HB Unit

Single Stage T-stat Wiring For HB Units

With 1 Stage Cooling&1StageHeating

With 2 Stage Cooling&2StageHeating

Single-Stage Thermostat

1-Cool / 1-Heat

W1

Y1

Clogged Filter Indicator

(Outputs 24VAC)

(24VAC)

G

C

RC

RH

24VAC

GND

HB Mini Controller Terminal Block

(GND)

R

C

G

Y1

Y2

W1

W2

W3

C1

C2

TB3

V10

24VAC

P10

Figure 4: Single Stage T-stat Wiring For HB Units With 2 Stage Cooling & 2 Stage Heating

HB Mini Controller

R69

GND

7

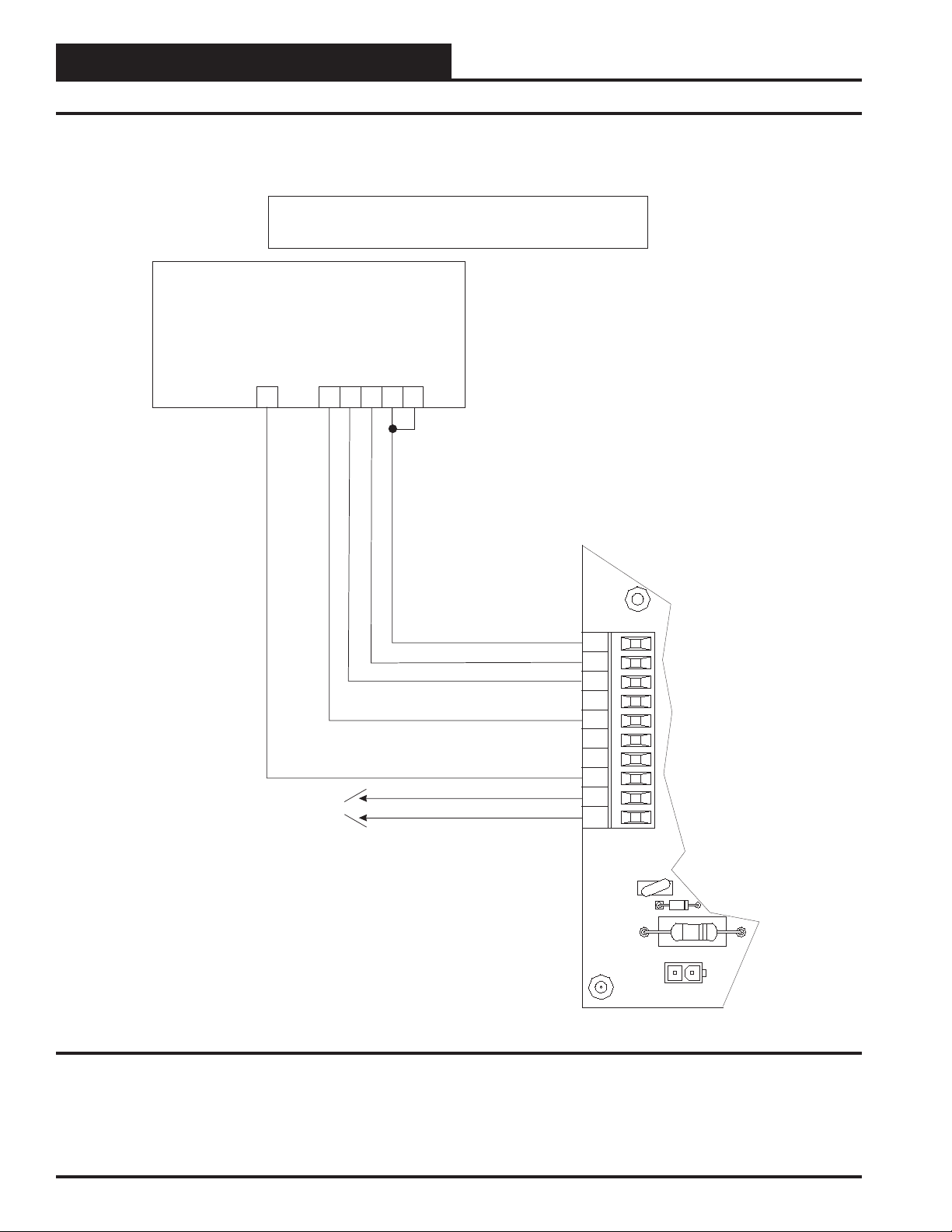

Page 8

Technical Guide

Controller Installation & Wiring

Single Stage T-stat Wiring For HB Unit

Single Stage T-stat Wiring For HB Units

With 1 Stage Cooling&1StageHeating

With 2 Stage Cooling&3StageHeating

Single-Stage Thermostat

1-Cool / 1-Heat

W1

Y1

Clogged Filter Indicator

(Outputs 24VAC)

(24VAC)

G

C

RC

RH

24VAC

GND

HB Mini Controller Terminal Block

(GND)

R

C

G

Y1

Y2

W1

W2

W3

C1

C2

TB3

V10

24VAC

P10

Figure 5: Single Stage T-stat Wiring For HB Units With 2 Stage Cooling & 3 Stage Heating

8

HB Mini Controller

R69

GND

Page 9

Technical Guide

Single Stage T-stat Wiring For HB Unit

Multi-Stage T-stat Wiring For HB Units

With 1 Stage Cooling&1StageHeating

With 2 Stage Cooling&2StageHeating

Multi-Stage Thermostat

2-Cool / 2-Heat

W2

W1

Y1

Y2

Clogged Filter Indicator

(Outputs 24VAC)

(24VAC)

G

C

RC

RH

HB Mini Controller Terminal Block

(GND)

24VAC

GND

R

C

G

Y1

Y2

W1

W2

W3

C1

C2

TB3

V10

24VAC

P10

Figure 6: Multi Stage T-stat Wiring For HB Units With 2 Stage Cooling & 2 Stage Heating

HB Mini Controller

R69

GND

9

Page 10

Technical Guide

Controller Installation & Wiring

Single Stage T-stat Wiring For HB Unit

Multi-Stage T-stat Wiring For HB Units

With 1 Stage Cooling&1StageHeating

With 2 Stage Cooling&3StageHeating

Multi-Stage Thermostat

2-Cool / 3-Heat

W3

W2

W1

Y1

Y2

Clogged Filter Indicator

(Outputs 24VAC)

(24VAC)

G

C

RC

RH

24VAC

GND

HB Mini Controller Terminal Block

(GND)

R

C

G

Y1

Y2

W1

W2

W3

C1

C2

TB3

V10

24VAC

P10

Figure 7: Multi Stage T-stat Wiring For HB Units With 2 Stage Cooling & 3 Stage Heating

10

HB Mini Controller

R69

GND

Page 11

Programming With The HB Service Tool

Technical Guide

Entering Passcodes

The HB Service Tool is used to program setpoints and view the status

of the HB Mini Controller. It is connected to the HB Mini Controller by

means of a modular cable. The cable is connected between the HB

Service Tool and the HB Mini Controller board. The HB Service Tool

doesn’t require batteries or a separate power source as all power to

operate the HB Service Tool is provided through this cable. The HB

Mini Controller must be powered in order for the HB Service Tool to

function.

Device Address

064

When the HB Service T ool is initially powered up, the program version

and the current time and date will be displayed. After the initial power

up, this screen only appears when the HB power is removed and then

reapplied. Press ENTER and the HB Service T ool will check all current

parameters. When it has finished this checking procedure, press ENTER and the main HB programming screen will be displayed. If you

want to change setpoints you will need to enter a passcode at this time.

If you only want to view status, a passcode is not required and you can

proceed to view status directly by pressing the ENTER key.

The passcode entry screen uses a four digit alpha passcode. Position the

cursor under the first letter field. To select the desired letter, use the

ADJUST ARROWS. The UP arrow increases through the alphabet and

the DOWN arrow decreases. When the desired letter appears, press the

RIGHT ARROW key to advance to the next letter field. Once all four

letter fields spell the desired passcode, press the ENTER key.

Available passcodes are:

“OPER” = The Operator is at level 1 for Status and

Setpoints

“CONT” = The Contractor is at level 2 for Status, Setpoints

and Force Modes

Again, if no passcode is entered, the default level is 0 and only allows

viewing of the status screens.

General Procedures

When the HB Service Tool is initially powered up, this screen will be

displayed. Press ENTER to proceed to the next screen.

Version: X.XX

Date: XX/XX/XX

Enter your passcode as described in the previous section and proceed

by pressing the MENU key. The following screen will be displayed.

Device Address:

064

Line #2 displays the default address for the HB Mini Controller. Press

the ENTER key. The following screen will be displayed.

If you want to change the Passcode, hold down on the UP and DOWN

SELECT ARROWS simultaneously and the following screen will be

displayed.

Enter Code

AAAA

HB Mini Controller

Device Name

HBMini

Line #2 displays the controller name or program name. Press the ENTER key to advance.

Module Selection Screens

After pressing ENTER in the previous step, the first available programming module screen appears. All of the HB Mini Controller S tatus and

Setpoint Screens are grouped in specific modules designated by a specific function name.

Main Status

Fan Status

Using the select arrows, scroll to select the desired module on line #1

and press the ENTER key. The other available module screens are listed

below in order that they would appear as you scroll down.

11

Page 12

Technical Guide

Programming With The HB Service Tool

OAT Cool Lockout

Cooling Module

Heating Module

OAT Cool Lockout

NO

Alarms

HVAC Test

Factory Options

Factory Options should not be accessed without contacting AAON® or

WattMaster.

Warning: The Factory Options settings should only be accessed

when authorized by AAON

Support personnel. Serious damage to the controller

and/or HVAC unit could result from improper use of

these settings.

®

or W attMaster Technical

HB Mini Controller Status & Setpoints

The Status and Setpoint screens for the various modules are accessed

by selecting a specific module and pressing the ENTER key.

Main Status Screens

The Main Status Screen is accessed by selecting the Main Status Module and pressing the ENTER key. This screen, as its name indicates,

allows the user to view the Main Status screens for the HB Mini Controller. After the ENTER key is pressed, the following screen will be

displayed.

HVAC Mode

HVAC Mode

Idle

Line #2 displays “YES” if the Outdoor Air Temperature is below the

Cooling Lockout Temperature Setpoint.

OAT Temperature

OAT

XXX F

Line #2 displays the current Outdoor Air Temperature.

Alarms

Alarms

NO

Line #2 displays “YES” if an alarm is active. To identify the active

alarm(s), press the ESC key, select the Alarm Module and scroll through

the available alarms using the up and down SELECT arrow keys.

Program Date

Program Date

XX/XX/XX

Line #2 displays the Month/Day/Year that the HB Mini Controller

software was created.

Program Time

Program Time

XX:XX:XX

Line #2 displays one of the following HVAC Modes:

• Idle • Venting

• Cooling • Fault

• Heating

Press the down SELECT arrow key or up SELECT arrow key to move

forward or backward through the Main Status screens as desired.

OAT Heat Lockout

OAT Heat Lockout

NO

Line #2 displays “YES” if the Outdoor Air Temperature is above the

Heating Lockout Temperature Setpoint.

12

Line #2 displays the time, in 24-hour (military) format that the HB

Mini Controller software was created .

Program Version

Program Version

X.XX

Line #2 displays the HB Mini Controller software version number.

.

HB Mini Controller

Page 13

Technical Guide

Reset Counts

Reset Count

XXXX

Line #2 displays the total number of times the HB Mini Controller has

been reset or has had its power cycled.

Fan Module Status Screens

The Fan Module Status Screens are accessed by navigating to the Fan

Module and pressing the ENTER key.

Fan Terminal Active

G-Active

NO

Line #2 displays “YES” if there is a 24 VAC signal connected to the

“G” Fan terminal on the HB Mini Controller.

High Speed Fan Relay

High Fan Relay

OFF

Cooling Stage 1 Energized

Y1-Active

NO

Line #2 displays “YES” if there is a 24 VAC signal on HB Mini Controller terminal “Y1”.

Cooling Stage 2 Energized

Y2-Active

NO

Line #2 displays “YES” if there is a 24 VAC signal on HB Mini Controller terminal “Y2”.

Fan Status

Fan Status

Fan Off

Line #2 displays the current Supply Fan Status. If the Supply Fan is

on, line #2 displays either “Fan Low Speed” or “Fan High Speed”.

Line #2 displays “ON” if the High Speed Fan Relay is active.

Low Speed Fan Relay

Low Fan Relay

OFF

Line #2 displays “ON” if the Low Speed Fan Relay is active.

Cooling Module Status Screens

The Cooling Module Status Screens are accessed by navigating to the

Cooling Module screen and pressing the ENTER key. The following

screen will then appear.

Status

Setpoints

Select “Status” by pressing the ENTER key. Press the up or down SELECT arrow key to move forward or backward through the Cooling

Module Status screens.

Cooling Relay #1

Cool 1 Relay

OFF

Line #2 displays “ON” if Cooling Relay #1 is active.

Cooling Relay #2

Cool 2 Relay

OFF

Line #2 displays “ON” if Cooling Relay #2 is active.

Low Pressure Switch

LPS

OPEN

Line #2 displays the current status of the Low Pressure Switch. It will

only display “CLOSED” when Cooling Relay #1 relay is active and

the Low Pressure Switch is operating correctly.

HB Mini Controller

13

Page 14

Technical Guide

Programming With The HB Service Tool

High Pressure Switch

HPS

OPEN

Line #2 displays the current status of the High Pressure Switch. It

will only display “CLOSED” when Cooling Relay #1 relay is active

and the High Pressure Switch is operating correctly.

Cooling Module Setpoint Screens

The Cooling Module Setpoints Screens are accessed by navigating to

the Cooling Module screen and then pressing the ENTER key. The following screen will then appear.

Status

Setpoints

Press the down SELECT arrow key until “Setpoints” is on the top line

of the screen and then press the ENTER key. Press the down SELECT

arrow key or up SELECT arrow key to move forward or backward

through the Cooling Module Setpoint screens.

Please see the Appendix section in the back of this manual for Tables

listing the minimum, maximum and default setpoints for all of the

setpoint screens.

Cooling Stages Quantity

Cool Stages

X

Cooling Minimum On Time

Cool Min On

XXX Sec

Adjust the desired Cooling Minimum On Time and then press the ENTER key.

Cooling Stage Up Delay

Cool Stage Up

XXX Sec

Adjust the desired Cooling Stage Up Delay time and then press the

ENTER key.

Cooling Stage Down Delay

Cool Stage Down

XXX Sec

Adjust the desired Cooling Stage Down Delay time and then press the

ENTER key.

Low Pressure Switch Delay

LPS Delay

XXX Sec

Adjust the quantity of Cooling Stages or Steps of Cooling and then

press the ENTER key.

Outdoor Air Temperature Cooling Lockout

OAT Cool Lockout

XXX F

Adjust the Outdoor Air Temperature Cooling Lockout and then press

the ENTER key.

Cooling Minimum Off Time

Cool Min Off

XXX Sec

Adjust the desired Cooling Minimum Off Time and then press the

ENTER key.

The Low Pressure Switch Delay time is a factory setting and should not

be changed unless authorized to do so by W attMaster or AAON® T echnical Support.

Low Pressure Switch Safety Delay

LPS Safety

XX Sec

The Low Pressure Switch Safety Delay time is a factory setting and

should not be changed unless authorized to do so by WattMaster or

AAON® Technical Support.

LPS Maximum Trips

LPS Max trips

XX

The Low Pressure Switch Max Trips is a factory setting and should not

be changed unless authorized to do so by W attMaster or AAON® T echnical Support.

14

HB Mini Controller

Page 15

Technical Guide

Cooling Fan Off Delay

Cool Fan Off Dly

XXX Sec

The Cooling Fan Off Delay is a factory setting and should not be

changed unless authorized to do so by WattMaster or AAON

cal Support.

®

Techni-

Auto Stage Up Time

Auto Stage Up

XXX Sec

The Auto Stage Up Time can be adjusted on this screen when you are

using a single-stage thermostat with a multi-stage HB unit.

Heating Module Status Screens

The Heating Module Status Screens are accessed by navigating to the

Heating Module screen and pressing the ENTER key. The following

screen will then appear.

Heating Stage 3 Energized

W3-Active

NO

Line #2 displays “YES” if there is a 24 VAC signal on HB Mini Controller terminal “W3”.

Fan Status

Fan Status

Fan Off

Line #2 displays the current Supply Fan Status. If the Supply Fan is

on, line #2 displays either “Fan Low Speed” or “Fan High Speed”.

Heating Relay #1

Heat 1 Relay

OFF

Line #2 displays “ON” if Heating Relay #1 is active.

Status

Setpoints

Select “Status” by pressing the ENTER key. Press the up or down SELECT arrow key to move forward or backward through the Heating

Module Status screens.

Heating Stage 1 Energized

W1-Active

NO

Line #2 displays “YES” if there is a 24 VAC signal on HB Mini Controller terminal “W1”.

Heating Stage 2 Energized

W2-Active

NO

Line #2 displays “YES” if there is a 24 VAC signal on HB Mini Controller terminal “W2”.

Heating Relay #2

Heat 2 Relay

OFF

Line #2 displays “ON” if Heating Relay #2 is active.

Heating Relay #3

Heat 3 Relay

OFF

Line #2 displays “ON” if Heating Relay #3 is active.

Heat Safety Monitor

HSM

CLOSED

Line #2 displays “OPEN” anytime the Heat Safety Monitor is open.

HB Mini Controller

15

Page 16

Technical Guide

Programming With The HB Service Tool

Heating Module Setpoint Screens

The Heating Module Setpoints Screens are accessed by navigating to

the Heating Module and then pressing the ENTER key. The following

screen will then appear.

Status

Setpoints

Press the down SELECT arrow key until “Setpoints” is on the top line

of the screen and then press the ENTER key. Press the down SELECT

arrow key or up SELECT arrow key to move forward or backward

through the Heating Module Setpoint screens.

Please see the Appendix section in the back of this manual for Tables

listing the minimum, maximum and default setpoints for all of the

setpoint screens.

Heating Stages Quantity

Heat Stages

X

Adjust the quantity of Heating Stages and then press the ENTER key.

Outdoor Air Temperature Heating Lockout

OAT Heat Lockout

XXX F

Heating Stage Up Delay

Heat Stage Up

XXX Sec

Adjust the desired Heating Stage Up Delay time and then press the

ENTER key.

Heating Stage Down Delay

Heat Stage Down

XXX Sec

Adjust the desired Heating Stage Down Delay time and then press the

ENTER key.

Heat Safety Monitor Maximum Trips

HSM Max Trips

X

The Heating Safety Maximum Trips is a factory setting and should not

be changed unless authorized to do so by W attMaster or AAON

nical Support.

®

Tech-

Heating Fan Off Delay

Heat Fan Off Dly

XXX Sec

Adjust the Outdoor Air Temperature Heating Lockout and then press

the ENTER key.

Heating Minimum Off Time

Heat Min Off

XXX Sec

Adjust the desired Heating Minimum Off Time and then press the

ENTER key.

Heating Minimum On Time

Heat Min On

XXX Sec

Adjust the desired Heating Minimum On Time and then press the ENTER key.

The Heating Fan Off Delay is a factory setting and should not be changed

unless authorized to do so by WattMaster or AAON® Technical Support.

Auto Stage Up Time

Auto Stage Up

XXX Sec

The Auto Stage Up Time can be adjusted on this screen when you are

using a single-stage thermostat with a multi-stage HB unit.

Alarm Module Status Screens

The Alarm Module Status Screens are accessed by navigating to the

Alarm Module and pressing the ENTER key. Setpoints are not available for the Alarm Module. After pressing ENTER the following screen

will appear.

16

HB Mini Controller

Page 17

Technical Guide

HSM Lockout

HSM Lockout

NO

Line #2 displays “YES” when the Heat Safety Monitor has tripped more

than the HSM Max Trips setpoint.

HPS Fault

HPS Fault

NO

Line #2 displays “YES” when the High Pressure Switch is open and

a Cooling Relay is active.

LPS Lockout

LPS Lockout

NO

Line #2 displays “YES” when the Low Pressure Switch has tripped

more than the LPS Max Trips setpoint.

Bad OAT Sensor

Clogged Filter

Clogged Filter

NO

Line #2 displays “YES” if there is a 24 VAC signal on the Clogged

Filter Input.

HVAC Test Module Screens

The HV AC Test Module screens are accessed by navigating to the HV AC

Test Module screen and pressing the ENTER key. After pressing ENTER the following screen will then appear.

Force Time Limit

Force Time Limit

XXX Min

Adjust the desired time needed for forcing the HB Mini Controller

into an HVAC Test Mode and then press the ENTER key.

Force Relays

Force Relays

NO

Bad OAT

NO

Line #2 displays “YES” when the Outdoor Air Temperature Sensor is

bad or missing.

OAT Cooling Lockout

OAT Cool Lockout

NO

Line #2 displays “YES” if the Outdoor Air Temperature is below the

Cooling Lockout Temperature setpoint.

OAT Heating Lockout

OAT Heat Lockout

NO

Line #2 displays “YES” if the Outdoor Air Temperature is above the

Heating Lockout Temperature setpoint.

Select “YES” to enable Relay Force Mode and then press the ENTER

key.

High Speed Fan Relay Force

HSpd Fan Relay

OFF

Select “YES” to activate the High Speed Supply Fan Relay and then

press the ENTER key.

Low Speed Fan Relay Force

LSpd Fan Relay

OFF

Select “YES” to activate the Low Speed Supply Fan Relay and then

press the ENTER key.

HB Mini Controller

17

Page 18

Technical Guide

Programming With The HB Service Tool

Cooling Relay #1 Force

Cool 1 Relay

OFF

Select “YES” to activate Cooling Relay #1 and then press the ENTER

key.

Cooling Relay #2 Force

Cool 2 Relay

OFF

Select “YES” to activate Cooling Relay #2 and then press the ENTER

key.

Heating Relay #1 Force

Heat 1 Relay

OFF

Select “YES” to activate Heating Relay #1 and then press the ENTER

key.

Heating Relay #2 Force

Heat 2 Relay

OFF

Select “YES” to activate Heating Relay #2 and then press the ENTER

key.

Heating Relay #3 Force

Heat 3 Relay

OFF

Select “YES” to activate Heating Relay #3 and then press the ENTER

key.

18

HB Mini Controller

Page 19

Troubleshooting

Technical Guide

Using LEDs To Verify Operation

The HB Mini Controller is equipped with LEDs that can be used as

very powerful troubleshooting tools. The HB Mini Controller circuit

board has three different colored LEDs. See Figure 8 for the various

LED locations. The Red LED is used to indicate fault conditions. The

Y ellow LED indicates the mode of operation the HB Mini Controller is

currently operating in. The Green LED indicates the power and communications status of the HB Mini Controller.

MHGRV

RESET

ECONO

POS

RAB

LD1 - Red LED

LD2 - Yellow LED

LD3 - Green LED

GND

TB2

LD1

LD2

LD3

TB1

SAT

GND

HB Mini Controller Fault Condition Operation

If the Red LED indicates you have a Bad Outdoor Air Temperature

Sensor, heating mode will operate but Cooling Mode will be disabled

until the sensor problem is fixed.

Yellow LED

LED Blinks Mode Indication Description

1 Vent Mo de (Fan O nly)

2 Heating Mode

3 Coo ling M o de

Table 2: Yellow LED Blink Codes

Green LED

LED Blinks Power/Communications Description

1 Power Indi cator (No Communications)

2 HSS Communications

Table 3: Green LED Blink Codes

HB Controller Board

Figure 8: HB Board LED Locations

One LED blink is defined as a 1 second LED on period immediately

followed by a 1 second LED off period. After each series of blinks is

completed the LED will power off for 3 seconds and then repeat the

series of blinks. The various blink codes and their meanings are defined

in the tables that follow.

Red LED

LED Blinks Fault Condition Description

1 Hea t Safety Loc k o u t

2 High Pressure Fault

3 Low Pressure L ock out

5 Bad Outdoor Air Tem perature Sensor

7 Clog ged Filter Sw itch

Notes:

1.) W h e n n o f a u lt e xists the red LED will b e o f f .

2.) Heat Safety Lockout (1 blink) is the highest priority. Clogged

Filter S witch (7 blinks) is the lowest priority.

Table 1: Red LED Blink Codes

HB Mini Controller

19

Page 20

Technical Guide

Appendix

The HB Mini Controller has many setpoints that are user adjustable.

This adjustability allows the installer complete control of all major unit

operating characteristics during the setup and commissioning phase of

the HB unit installation. It also allows a service technician the ability to

change setpoints to monitor and record unit operation to determine if

the unit is functioning as specified. The tables that follow show the

available setpoints for each classification or control group provided on

the HB Mini Controller.

Temperature Control Setpoints

Description Min. Default Max.

Cooling Lockout

Temperature

Heating Lockout

Temperature

32° F 40° F 80° F

40° F 80° F 120° F

Cooling Control Setpoints

Description Min. Default Max.

Coolin g Stages 1 2 2

Minimum Off Time 180 Sec 180 Sec 900 Sec

Minimum On Time 300 Sec 300 Sec 900 Sec

Staging Up Delay Interval 180 Sec 180 Sec 900 Sec

Staging Down Delay Interval 60 Sec 60 Sec 900 Sec

Low Pressure Delay Period 5 Sec 30 Sec 60 Sec

Low Pressure Safety 5 Sec 5 Sec 30 Sec

Low Pressure Max. Trip Point 1 3 5

Fan Off Delay Period 1 Sec 45 Sec 120 Sec

Auto Staging Up Delay 180 Sec 600 Sec 900 Sec

Table 4: Cooling Control Setpoints

Heating Control Setpoints

Description Min. Default Max.

Heating Stages 1 3 3

Minimum Off Time 60 Sec 60 Sec 900 Sec

Minimum On Time 120 Sec 120 Sec 900 Sec

Staging Up Delay Interval 180 Sec 180 Sec 900 Sec

Staging Down Delay Interval 60 Sec 60 Sec 900 Sec

Heat Safety Maximum Count 1 3 5

Fan Off Delay Period 1 Sec 120 Sec 180 Sec

Auto Stage Up Delay 180 Sec 600 Sec 900 Sec

Table 6: Temperature Control Setpoints

Miscellaneous Control Setpoints

Description Min. Default Max.

Force Mode Timer 1 Min 60 Min 240 Min

Table 7: Miscellaneous Control Setpoints

Table 5: Heating Control Setpoints

20

HB Mini Controller

Page 21

Technical Guide

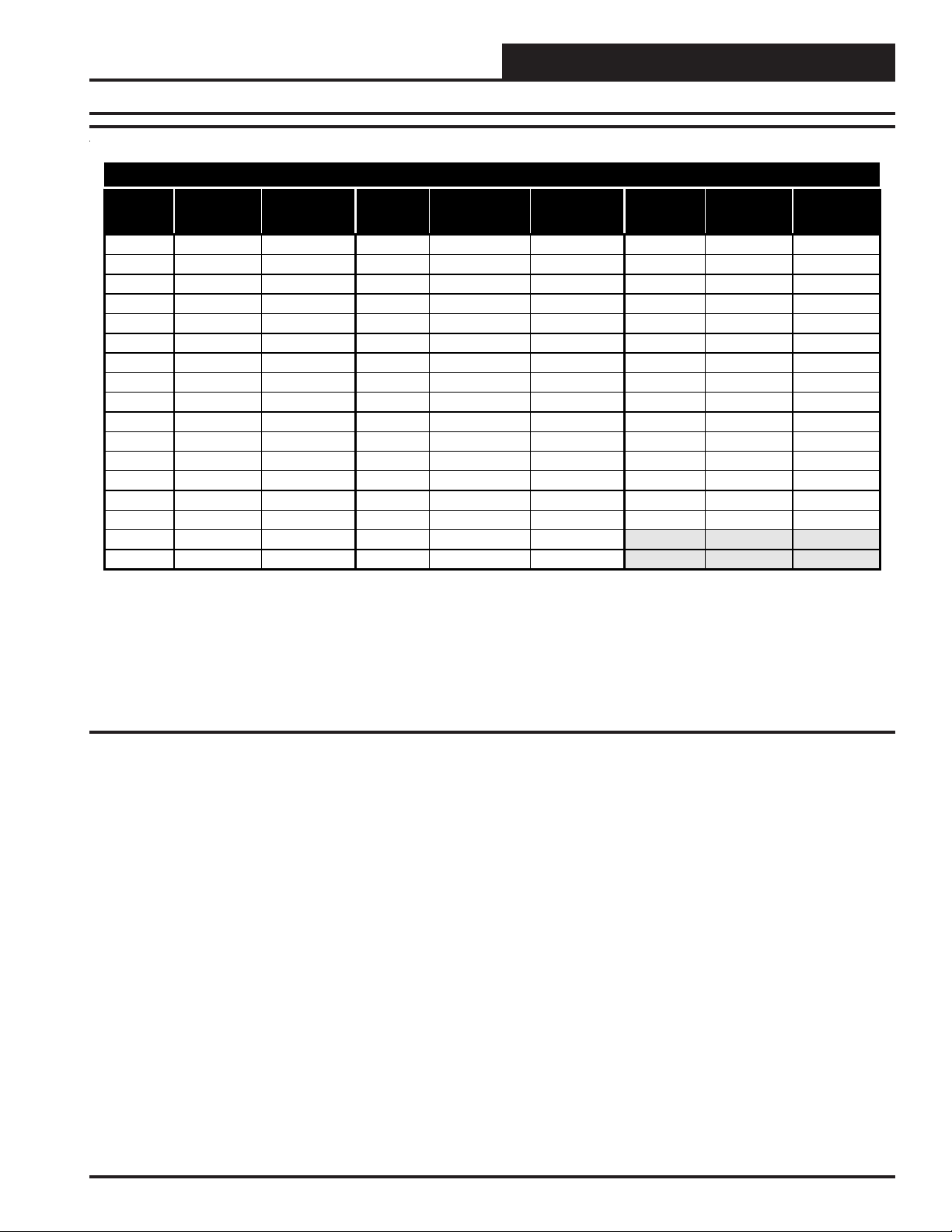

Temperature – Resistance – Voltage For Type III 10 K Ohm Thermistor Sensors

Temp

(ºF)

-10 93333 2.98 60 14681 1.96 86 8153 1.48

-5 80531 2.94 62 14014 1.93 88 7805 1.45

10 52500 2.77 68 12191 1.81 100 6047 1.24

15 45902 2.71 69 11906 1.79 105 5453 1.16

20 40147 2.64 70 11652 1.78 110 4923 1.09

25 35165 2.57 71 11379 1.76 115 4449 1.02

30 30805 2.49 72 11136 1.74 120 4030 0.95

35 27140 2.41 73 10878 1.72 125 3656 0.88

40 23874 2.33 74 10625 1.70 130 3317 0.82

45 21094 2.24 75 10398 1.68 135 3015 0.76

50 18655 2.15 76 10158 1.66 140 2743 0.71

52 17799 2.11 78 9711 1.63 145 2502 0.66

54 16956 2.08 80 9302 1.59 150 2288 0.61

56 16164 2.04 82 8893 1.55

58 15385 2.00 84 8514 1.52

Resistance

(Ohms)

0 69822 2.89 64 13382 1.89 90 7472 1.41

5 60552 2.83 66 12758 1.85 95 6716 1.33

Voltage @

Input (VDC)

Temp

(ºF)

Resistance

(Ohms)

Voltage @

Input (VDC)

Temp

(ºF)

Resistance

(Ohms)

Voltage @

Input (VDC)

Thermistor Sensor Testing Instructions

1.) Use the resistance column to check the thermistor sensor while disconnected from the controllers (not powered).

2.) Use the voltage column to check sensors while connected to powered controllers. Read voltage with meter set on DC volts. Place

the “-”(minus) lead on GND terminal and the “+”(plus) lead on the sensor input terminal being investigated.

If the voltage is above 3.3 VDC, then the sensor or wiring is “open.” If the voltage is less than 0.05 VDC, the sensor or wiring is shorted.

Table 8: Temperature Sensor - Voltage & Resistance for Type III Sensors

HB Mini Controller

21

Page 22

Notes:

Technical Guide

22

HB Mini Controller

Page 23

Technical Guide

HB Mini Controller

23

Page 24

AAON, Inc.

Form: AA-HBM-TGD-01A Printed in the USA November 2005

All rights reserved Copyright 2005

WattMaster Controls Inc. • 8500 NW River Park Drive • Parkville, Mo. • 64152

Phone (816) 505-1100 www.wattmaster.com Fax (816) 505-1101

2425 So. Yukon Ave • Tulsa, OK 74107-2728

Ph: (918) 583-2266 • Fax: (918) 583-6094

AAON® Part No. R38860

Loading...

Loading...