Page 1

HB Controller

Technical Guide

Page 2

Table of Contents

Controller Overview ......................................................................................................................................... 3

General ........................................................................................................................................................................................3

Inputs ...........................................................................................................................................................................................3

Outputs ........................................................................................................................................................................................3

Controller Sequence of Operation .................................................................................................................. 4

Fan Mode .....................................................................................................................................................................................4

Heating Mode ..............................................................................................................................................................................4

Cooling Mode ..............................................................................................................................................................................4

Economizer Cooling ...................................................................................................................................................................4

General Economizer Operation.............................................................................................................................................4

Economizer Operation with ECS Control ............................................................................................................................. 4

Mechanical Cooling Staging with ECS Control .....................................................................................................................4

Economizer IAQ Control ...........................................................................................................................................................4

Economizer Dehumidifi cation ...................................................................................................................................................4

1-or 2-Stage Cooling Units with Adjustable Two-Speed or Two-Speed Supply Fan Control ................................................4

Dehumidifi cation Mode (No Reheat) .........................................................................................................................................5

Dehumidifi cation Mode with Hot-Gas Reheat ..........................................................................................................................5

1-Stage Cooling with Adjustable Two-Speed or Two-Speed Supply Fan Control ................................................................. 5

2-Stage Cooling with Adjustable Two-Speed or Two-Speed Supply Fan Control ................................................................ 5

Lockout Modes ...........................................................................................................................................................................5

SAT Lockout Modes ...................................................................................................................................................................6

Exhaust Fan Control .................................................................................................................................................................. 6

HB Processor Board .................................................................................................................................................................. 6

Controller Installation & Wiring ...................................................................................................................... 7

Programming with the HB Service Tool ........................................................................................................ 14

Optional MHGRV Module Settings ................................................................................................................. 34

Troubleshooting ............................................................................................................................................. 36

Appendix ........................................................................................................................................................ 37

Index .............................................................................................................................................................. 42

Space Temperature Control Sequence ................................................................................................................................. 6

Controller Mounting ...................................................................................................................................................................7

Important Wiring Considerations .............................................................................................................................................7

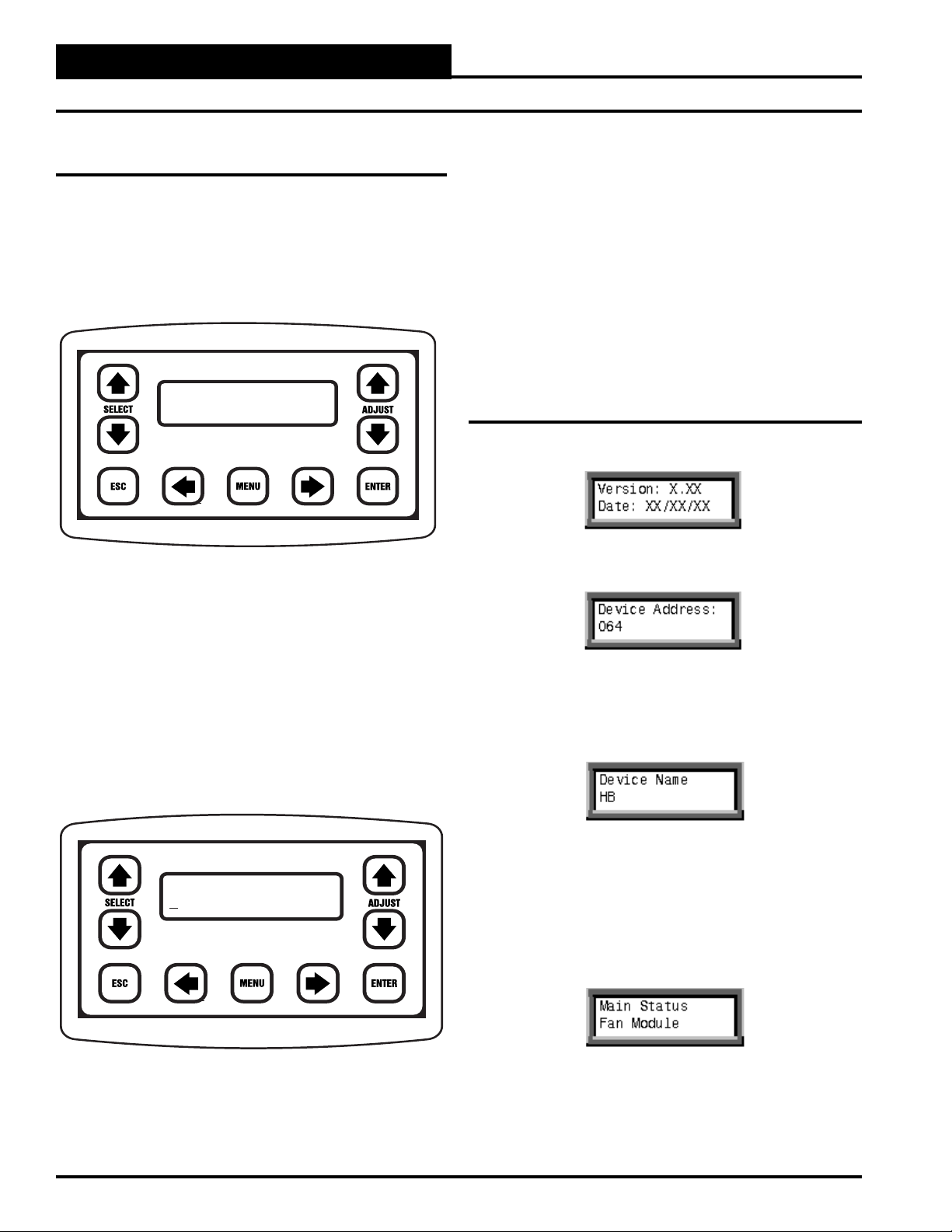

Entering Passcodes .................................................................................................................................................................14

General Procedures ................................................................................................................................................................. 14

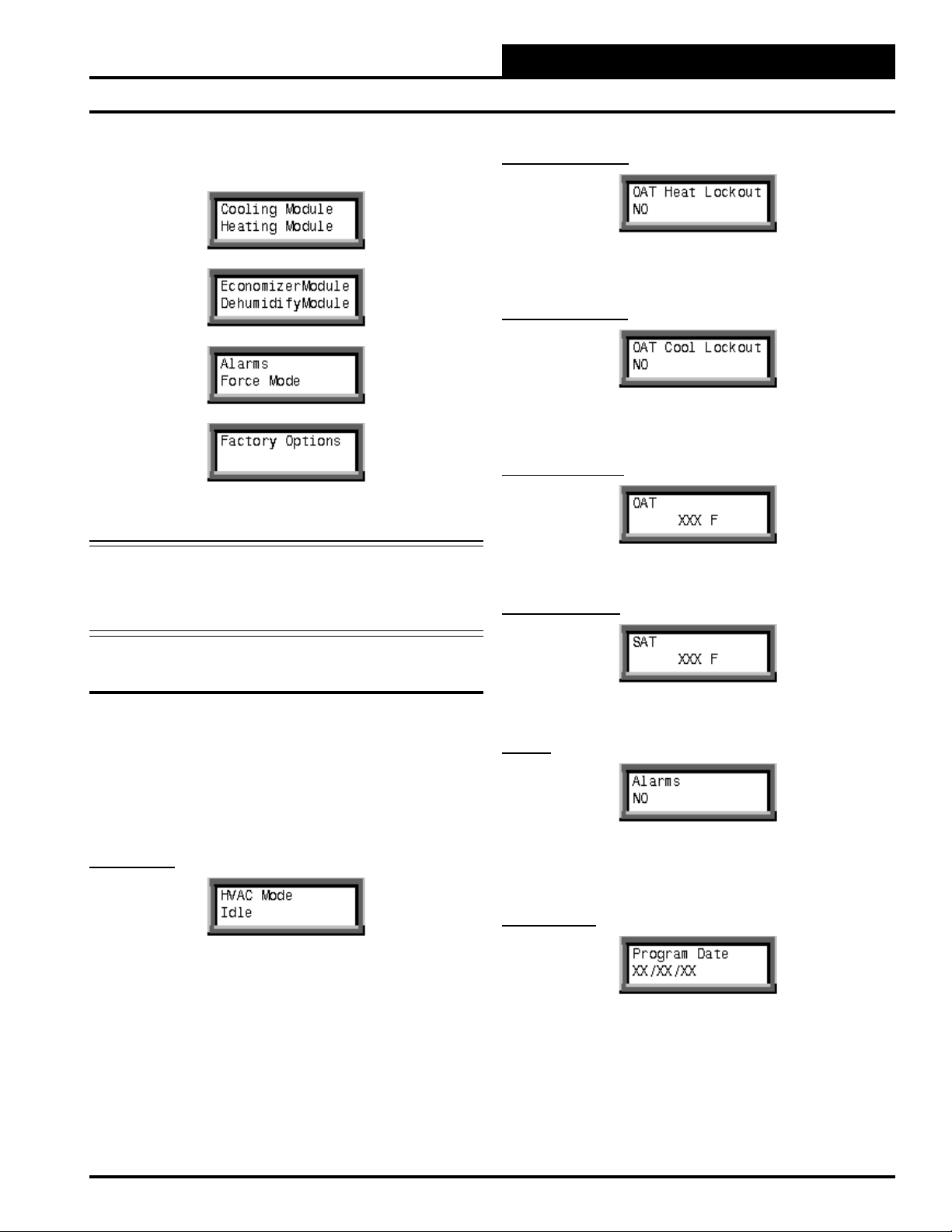

Module Selection Screens ..................................................................................................................................................14

HB Controller Status & Setpoints ..........................................................................................................................................15

Main Status Screens ...........................................................................................................................................................15

Fan Module Status Screens ................................................................................................................................................16

Fan Module Setpoint Screens .............................................................................................................................................16

Cooling Module Status Screens ..........................................................................................................................................17

Cooling Module Setpoint Screens .......................................................................................................................................18

Heating Module Status Screens..........................................................................................................................................19

Heating Module Setpoint Screens.......................................................................................................................................20

Economizer Module Status Screens ................................................................................................................................... 21

Economizer Module Setpoint Screens ................................................................................................................................ 22

Dehumidify Module Status Screens .................................................................................................................................... 23

Alarm Module Status Screens.............................................................................................................................................24

Force Mode Module Screens .............................................................................................................................................. 25

Force Mode Module Setpoint Screens ................................................................................................................................26

Factory Options Module Screens ................................................................................................

........................................27

HB Processor Board ................................................................................................................................................................ 28

HB Processor Board Status Screens .................................................................................................................................. 28

HB Processor Setpoint Screens..........................................................................................................................................29

HB Processor Week Schedule Module Screens .................................................................................................................30

HB Processor Real Time Clock Module Screens ................................................................................................................ 31

Hot Gas Reheat Controller ......................................................................................................................................................32

Hot Gas Reheat Status Screens ......................................................................................................................................... 32

Supply Air Temperature ...........................................................................................................................................................34

Supply Air Temperature Reset Limit ...................................................................................................................................... 34

Using LEDs To Verify Operation ............................................................................................................................................. 36

HB Controller Fault Condition Operation.............................................................................................................................36

WattMaster Controls, Inc.

8500 NW River Park Drive · Parkville , MO 64152

Toll Free Phone: 866-918-1100

PH: (816) 505-1100 · FAX: (816) 505-1101 · E-mail: mail@wattmaster.com

Visit our web site at www.wattmaster.com

Form: AA-HB-TGD-01E Copyright 2009 WattMaster Controls, Inc.

®

AAON

is a registered trademark of AAON, Inc., Tulsa, OK.

WattMaster Controls, Inc. assumes no responsibility for errors, or omissions.

This document is subject to change without notice.

Page 3

Overview

Controller Overview

General

The HB Controller is designed to work with a normal 24 VAC Thermostat

and Dehumidistat. Single or Multi-stage Thermostats can be used. When

a Single-Stage Thermostat is used, an auto-staging feature is built-in for

Multi-stage HB units. Fan speed can be adjusted for both high and low

speeds by way of an interface when the HB unit is equipped with an

adjustable speed controller. Dehumidifi cation is optimized by use of a

Return Air Bypass damper. Modulating Hot-Gas Reheat can be used to

reheat the Supply Air during Dehumidifi cation.

A CO2 sensor can be connected through the wiring harness when IAQ

control is desired. Also, two damper positions are available when using

Two-Speed Supply Fans, thus providing enhanced IAQ control.

The HB Controller also monitors equipment safeties, logs information,

and locks out the equipment in the event of multiple failures. All sensors are needed in order to provide all modes of operation. However, to

prevent a potential freeze condition, Heating Mode will still operate if

all sensors have failed or are missing.

Terminal block style connections are provided for fi eld wiring of the

Thermostat, Dehumidistat, and Supply Air Temperature Sensor wires.

All other inputs and outputs are connected via a wiring harness on the

HB unit. A list of all available inputs and outputs follows.

Inputs

G, Y1, Y2, W1, W2, W3

RH: Dehumidistat

SAT: Supply Air Temperature Sensor

MHGRV Reset: Modulating Hot-Gas Reheat Signal (0-10VDC)

RAB: Return Air Bypass Damper Actuator (by others)

ECS: (Enthalpy Changeover Switch)

Econo Pos: Economizer Control (by others)

Carbon Dioxide Sensor

Outdoor Air Temperature Sensor

Liquid Line Temperature Sensor (currently not used)

Heat Safety Monitor (monitors main and auxiliary limit thermostats)

High-Pressure Switch

Low-Pressure Switch

Clogged Filter Switch

Outputs

Supply Fan High-Speed Relay

Supply Fan Low-Speed Relay

Cool-1 Relay

Cool-2 Relay

Heat-1 Relay

Heat-2 Relay

Heat-3 Relay

Condenser Fan Relay

AUX: Currently used for an exhaust fan relay

Modulating Hot-Gas Reheat Signal (from HGR controller)

Adjustable Two-Speed Fan Signal (0-10VDC)

Return Air Bypass Damper Actuator (0-10VDC)

Economizer Damper Actuator (2-10VDC)

Modulating Hot-Gas Reheat Reset Signal (0-10 VDC)

A1, A2: Economizer 24 VAC Power Supply Jumper Terminals

C1, C2: Clogged Filter Switch 24 VAC Output Terminals

PBS

P11

HEATSECTION

PROGRAM

SOCKET

P

V3

V2

6.10"

V1

6.50

SW1

C1

ECONO SECTION

RAB

ECONO

P1

POS

P3

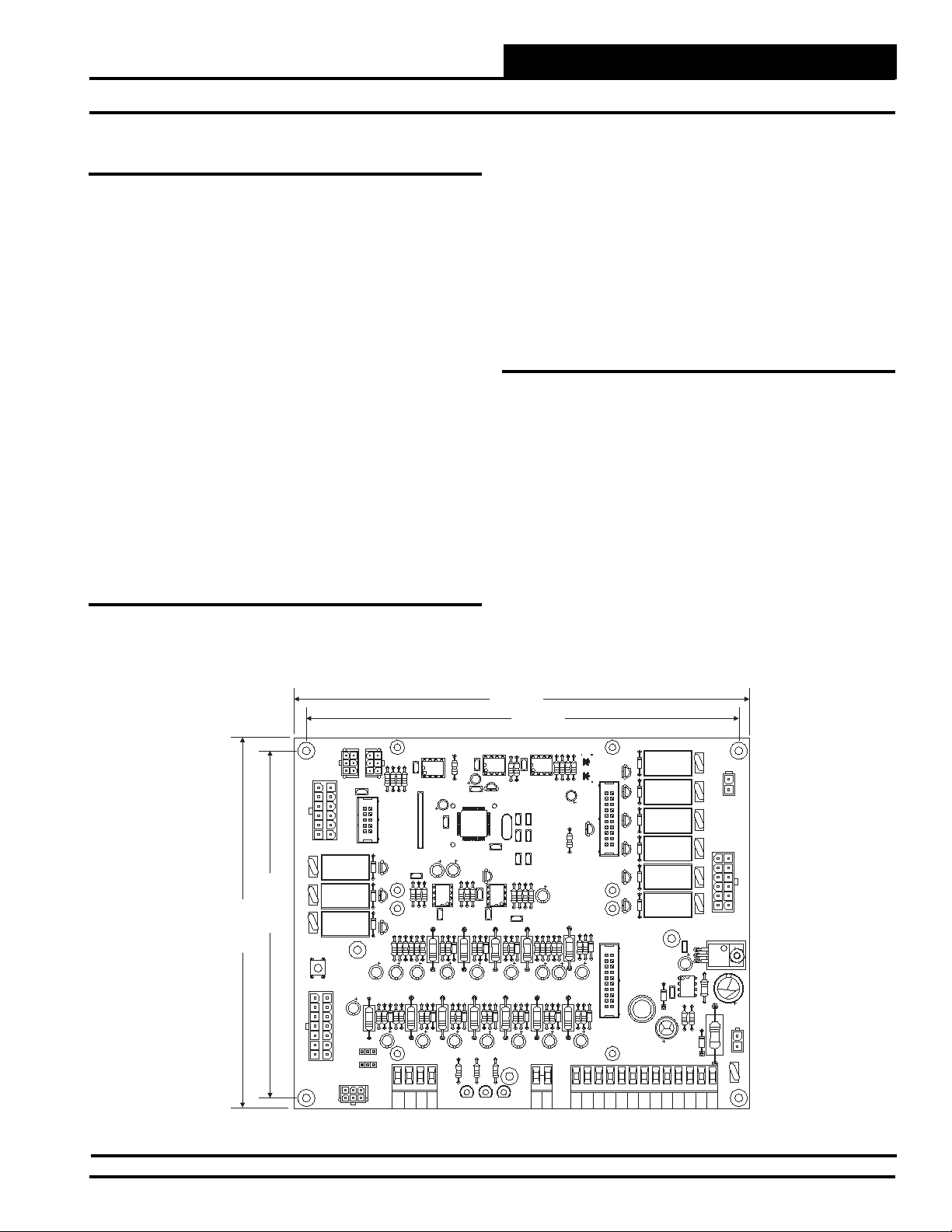

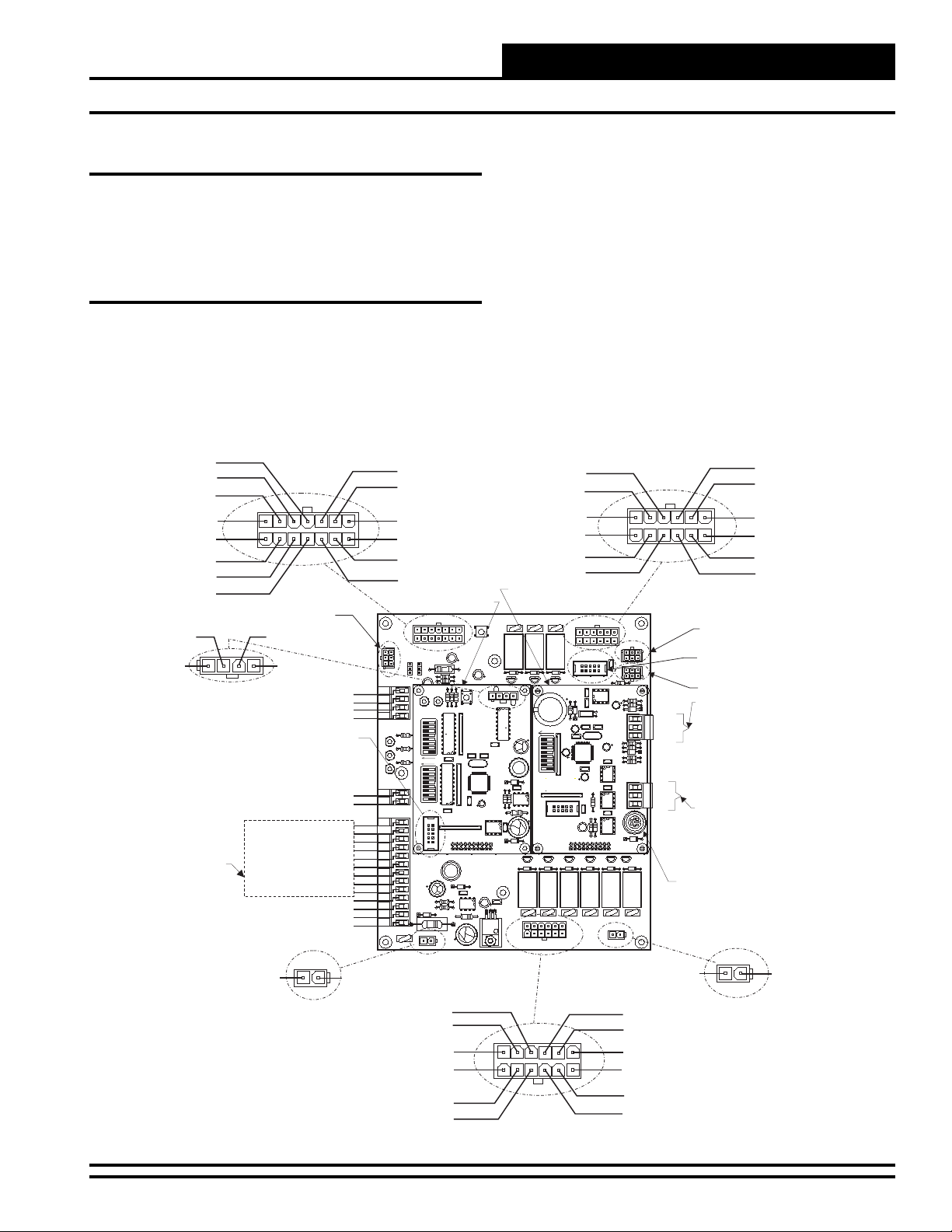

Figure 1: HB Controller Dimensions

8.00"

7.60"

HSS

R71

R11

R13

R8

P8

C5

C37

K4

D1

D21

D20

K2

C2

R1

D1

C4

JO2

JO1

INT

EXT

HSS

1

P6

RN1

7

7

C36

R21

R1

R16

8

R15

R18

R12

R7

R5

R10

C6

C3

R14

R17

R2

R3

D5

R6

R

C7

RAB

MHGRV

RESET

ECONO

POS

C20

R3

C3

C17

C38

C13

4

C43

C11

C8

R22

C10

R20

D6

GND

10

R31

R33

R2

2

C35

C

C16

R30

D7

R23

R25

D

R32

R36

C14

R24

R24

R35

R37

R28

D8

R26

R38

C12

C15

R40

R34

R27

TB2

LD2LD1

8

R74

R75

R72

6

R61

R58

5

C24

X1

C23

C41

R46

R70

3

C34

R41

R4

R42

R44

D11

C18

R43

R45

R47

D10

C1

LD3

R73

C46

C42

C44

C45

R48

C22

D12

TB1

TTL

C40

VR1

R4

R50

C21

R60

R63

R51

R53

R56

R57

D13

C28

C26

R52

R5

R62

R55

D14

R54

C27

C25

R

GND

SAT

D1

1

P7

D3

3

D2

AXCP

2

D18

6

D17

5

D4

4

R65

D16

R64

D15

GND

K5

C32

REV 4

YS101 2

7

D22

HB VB NIT BOARD

MADE IN THE SA

MOD HGR

P5

P5

RH

G

Y1

C2

L1

C30

Y2

W1

W2

W3

P2

V4

V8

V7

V6

V

V5

C31

MC34064A

36

R67

R66

A1

A2

AX

SERIAL #

SECTION

COOLING

P4

I

0

VR2

R68

C33

R6

GND

D23

P10

POWER

24VAC

V10

TB3

C2

C1

HB Controller Technical Guide

3

Page 4

Sequence of Operations

Controller Sequence of Operations

Fan Mode

The HB Controller supports 2 different Supply Fan confi gurations. It

can be confi gured for Adjustable Two-Speed Fan or Two-Speed Fan. On

a call for “G,” the Supply Fan runs at Low Speed. Minimum on and off

times are maintained in the event of a short cycled call for “G.”

Heating Mode

On a call for “W1,” the Supply Fan runs at High Speed (maintained

during the Heating mode), and Heat Stage 1 is energized. On a call for

“W2,” Heat Stage 2 is energized after the Stage-Up delay. If “W2” is

called without “W1,” Heat Stage 1 is energized, and then Heat Stage 2

is energized after the Auto Stage-Up Delay period. On a call for “W3,”

Heat Stage 3 is energized after the Stage-Up delay. If “W3” is called

without “W1” or “W2,” Heat Stages 1, 2, and 3 will energize based on

Auto Stage-Up Delays.

Cooling Mode

If the HB Controller is confi gured for 1 stage of Cooling, on a call for

“Y1,” the Supply Fan runs at High speed, and Cool Stage 1 will energize.

If the HB Controller is confi gured for 2 stages of Cooling, on a call for

“Y1,” the Supply Fan runs at Low Speed, and Cool Stage 1 is energized.

On a call for “Y2,” the Supply Fan runs at High Speed, and Cool Stage

2 is energized after the Stage-Up Delay. If “Y2” is called without “Y1,”

Cool Stage 1 is energized, and then Cool Stage 2 is energized after the

Auto Stage-Up Delay.

Economizer Cooling

General Economizer Operation

If the Outdoor Air Temperature is below the Economizer Enable Setpoint

and there is a call on “Y1,” the compressors will be locked out, and the

Economizer will modulate to achieve a 55° F Supply Air Temperature.

If the HB Controller is confi gured for 1 stage of Cooling, on a call for

“Y1,” the Supply Fan will run at High Speed. If the HB Controller is

confi gured for 2 stages of Cooling, on a call for “Y1,” the Supply Fan

will run at low speed. When “Y2” is called, the Supply Fan will go to

high speed.

Economizer Operation with ECS Control

If the Enthalpy Changeover Switch (ECS) is closed and the outdoor air

temperature is below the ECS, OAT Enable setpoint (default 65° F),

the economizer will modulate and attempt to achieve 55° F supply air

temperature. If the outdoor air temperature is above 55° F, the economizer will generally open to 100%. Mechanical cooling can be used

to supplement the economizer if the outdoor air temperature is above

the ECS OAT Enable setpoint and the economizer signal is at 100%.

Once mechanical cooling is activated to supplement the economizer, the

economizer will remain at 100% until the cooling call is satisfi ed.

Mechanical Cooling Staging with ECS Control

If the HB Controller is confi gured for 1 stage of Cooling, on a call for

“Y1,” the Supply Fan will run at High Speed. Cool Stage 1 will activate

after the Cooling Auto Stage-Up Delay. If the HB Controller is confi gured for 2 stages of Cooling, on a call for “Y1,” the Supply Fan will

run at Low Speed. Cool Stage 1 will activate after either the Cooling

Auto Stage-Up Delay Expires or a call for “Y2” is made. When “Y2”

is called, Cool Stage 2 will activate after the Cooling Auto Stage-Up

Delay. After Cool Stage 2 is activated, the Supply Fan will switch to

High-Speed operation.

Economizer IAQ Control

The economizer is also used for CO2 control. If the CO2 level is above

the Minimum CO2 PPM setpoint, the Economizer Minimum Position will

be reset proportionally between the Minimum CO2 PPM and Maximum

CO2 PPM setpoints. When the CO2 level is above the Maximum CO2

PPM setpoint, the Economizer will open as far as the Maximum Damper

Adjustment Position setpoint setting. There are two Minimum and two

Maximum Economizer Damper Positions depending on the Supply Fan

speed. These are the Maximum Damper Position with Low-Speed Fan,

the Minimum Damper Position with Low-Speed Fan, the Maximum

Damper Position with High-Speed Fan, and the Minimum Damper Position with High-Speed Fan. The air balancing contractor should determine

these settings in order to maintain the proper amount of fresh air being

supplied to the building.

Economizer Dehumidifi cation

1-or 2-Stage Cooling Units with Adjustable

Two-Speed or Two-Speed Supply Fan Control

If the Outdoor Air Temperature is below the Economizer Enable Setpoint

and there is a call for Dehumidifi cation on “RH,” the compressors will

be locked out, and the Economizer will modulate to achieve 55° F Supply Air Temperature. The Supply Fan will run at Low Speed, and the

Return Air Bypass will be closed.

For 1 stage Cooling units, on a call for “Y1,” the HB Controller will

enter the Cooling Mode, and the Supply Fan will run at High Speed. The

Cooling Mode will be maintained until “Y1” is satisfi ed. As long as there

is still a call for “RH,” the Dehumidifi cation Mode will resume.

For 2 stage Cooling Units, “Y1” is ignored during this mode to extend

Dehumidifi cation. On a call for “Y2,” the HB Controller will enter the

Cooling mode, and the Supply Fan will run at High Speed. The Cooling

Mode will be maintained until both “Y2” and “Y1” are satisfi ed. As long

as there is still a call for “RH,” the Dehumidifi cation Mode will resume,

and the Supply Fan will run at Low Speed.

If the HB Controller is confi gured for 1 stage of Heating, on a call for

“W1,” the mode changes to Heating. The Economizer will close to its

Minimum Position, Heat Stage 1 will energize, and the Supply Fan will

run at High Speed.

If the HB Controller is confi gured for 2 or 3 stages of Heating, on a call

for “W1,” the Economizer will be locked at its current position, attempting to deliver 55° F Supply Air to the heating section. Heat Stage 1 is

energized, and the Supply Fan will run on High speed. On a call for “W2,”

the HB Controller will enter the Heating Mode. The Economizer will

move to its Minimum Position, and Heat Stage 2 will energize after the

Stage-Up Delay. The Heating Mode will be maintained until both “W2”

and “W1” are satisfi ed. W3 is also available for 3 Stage Electric Heating

Units. As long as there is still a call for “RH,” the Dehumidifi cation Mode

will resume, and the Supply Fan will run at Low Speed.

4

HB Controller Technical Guide

Page 5

Sequence of Operations

Controller Sequence of Operations

Dehumidifi cation Mode (No Reheat)

Note: If the HB Controller is confi gured for 1 stage of Cooling,

regardless of the Supply Fan confi guration, the Dehumidifi cation call on “RH” is ignored during this mode.

On a call for “RH,” Cooling Stage 1 is energized and the Supply Fan

runs at Low Speed. The Return Air Bypass Damper will open to 100%.

“Y1” is ignored during this mode. On a call for “Y2,” the HB Controller

will enter the Cooling Mode, and the Supply Fan will run at High Speed.

The Cooling Mode will be maintained until both “Y2” and “Y1” are

satisfi ed. As long as there is still a call for “RH,” the Dehumidifi cation

Mode will resume, and the Supply Fan will run at Low Speed.

If the HB Controller is confi gured for 1 stage of Heating, on a call for

“W1,” the mode changes to Heating. Cool Stage 1 will de-energize, the

Return Air Bypass will close, Heat Stage 1 will energize, and the Supply

Fan will run at High Speed.

If the HB Controller is confi gured for 2 or 3 stages of Heating, a “W1”

call will be delayed to extend Dehumidifi cation. On a call for “W2,”

the HB Controller will enter the Heating Mode. Cool Stage 1 will deenergize, the Return Air Bypass will close, Heat Stage 1 will energize,

and the Supply Fan will run at High Speed. Heat Stage 2 will energize

after the Auto Stage-Up Delay. The Heating Mode will be maintained

until both “W2” and “W1” are satisfi ed. W3 is also available for 3Stage Electric Heating Units. As long as there is still a call for “RH,”

the Dehumidifi cation Mode will resume, and the Supply Fan will run

at Low Speed.

2-Stage Cooling with Adjustable Two-Speed or

Two-Speed Supply Fan Control

On a call for “RH,” Cool Stage 1 is energized, and the Supply Fan runs

at low speed. The Return Air Bypass is opened to 100%. The hot-gas

reheat will then modulate the valves to achieve the Supply Air setpoint

DIP switch setting. On a call for “Y1,” the Supply Air setpoint on the

reheat controller is lowered 10° F, and the Return Air Bypass will close.

On a call for “Y2,” the HB Controller will enter the Cooling Mode. The

Supply Fan will switch to high speed, and Cool Stage 2 is energized. The

modulating hot-gas reheat valves will move to the full Cooling position.

The Cooling mode will be maintained until both “Y2” and “Y1” are

satisfi ed. As long as there is still a call for “RH,” the dehumidifi cation

mode will resume.

If the HB Controller is confi gured for 1 stage of heating, on a call for

“W1,” the mode changes to Heating, and the Supply Fan will run at High

Speed. Cool Stage 1 will de-energize, the Return Air Bypass will close,

Heat Stage 1 will energize, and the Supply Fan will run at High Speed.

If the HB Controller is confi gured for 2 or 3 stages of Heating, on a call

for “W1,” the Supply Air Setpoint on the Reheat Controller is raised

10° F, and Cool Stage 1 continues to run. On a call for “W2,” the HB

Controller will enter the Heating Mode. Cool Stage 1 will de-energize,

the Return Air Bypass will close, Heat Stage 1 will energize, and the

Supply Fan will run at High Speed. Heat Stage 2 will energize after the

Auto Stage-Up Delay. The Heating Mode will be maintained until both

“W2” and “W1” are satisfi ed. W3 is also available for 3 Stage Electric

Heating Units. As long as there is still a call for “RH,” the Dehumidifi cation Mode will resume, and the Supply Fan will run at Low Speed.

Lockout Modes

Dehumidifi cation Mode with Hot-Gas

Reheat

1-Stage Cooling with Adjustable Two-Speed

or Two-Speed Supply Fan Control

On a call for “RH,” Cool Stage 1 is energized, and the Supply Fan

runs at High Speed. The Return Air Bypass is opened to 100%. The

Hot Gas Reheat will then modulate the valves to achieve the Supply

Air Setpoint DIP Switch setting. On a call for “Y1,” the HB Controller

enters the Cooling Mode. The Return Air Bypass will close, and the

Hot Gas Reheat will modulate to full Cooling. The Cooling Mode will

be maintained until “Y1” is satisfi ed. As long as there is still a call for

“RH,” the Dehumidifi cation Mode will resume.

If the HB Controller is confi gured for 1 stage of Heating, on a call for

“W1,” the mode changes to Heating, and the Supply Fan will run at

High Speed. Cool Stage 1 will de-energize, the Return Air Bypass will

close, Heat Stage 1 will energize, and the Supply Fan will run at High

Speed. If the HB Controller is confi gured for 2 or 3 Stages of Heating,

on a call for “W1,” the Supply Air Setpoint on the Reheat Controller

is raised 10° F, and Cool Stage 1 continues to run. On a call for “W2,”

the HB Controller will enter the Heating Mode. Cool Stage 1 will deenergize, the Return Air Bypass will close, Heat Stage 1 will energize,

and the Supply Fan will run at High Speed. Heat Stage 2 will energize

after the Auto Stage-Up Delay. The Heating Mode will be maintained

until both “W2” and “W1” are satisfi ed. W3 is also available for 3Stage Electric Heating Units. As long as there is still a call for “RH,”

the Dehumidifi cation Mode will resume.

Heating Mode is locked out if the HSM (Heat Safety Monitor) trips 3

times during a call for Heating. To reset the lockout condition, either

remove the call for Heating or cycle power to the HB Controller. Heating Mode is also locked out if the Outdoor Air Temperature is above the

OAT Heat Lockout setpoint temperature.

Cooling Mode is locked out if the LPS (Low Pressure Switch) trips 3

times during a call for Cooling or Dehumidifi cation. To reset the lockout

condition, either remove the call for Cooling or Dehumidifi cation or

cycle power to the HB Controller. Cooling Mode is also locked out if

the Outdoor Air Temperature is below the OAT Cool Lockout setpoint

temperature or if the OAT Sensor is bad or missing.

Economizer and Reheat during Dehumidifi cation modes are locked out

if the SAT sensor is missing.

Note: The Cooling OAT Lockout must be set less than the

Economizer Enable.

HB Controller Technical Guide

5

Page 6

Sequence of Operations

Controller Sequence of Operations

SAT Lockout Modes

Note: The SAT Lockout Modes only apply if a Supply Air

Temperature Sensor is installed on the HB unit.

SAT High Temperature Limit Cut Off Mode

During the Heating Mode, if the Supply Air Temperature rises above

the Supply Air High Temperature Limit Cut Off (150° F), the Heating

will stage off, but the main Supply Fan will remain on in Low-Speed

operation. If this occurs, the Supply Air Temperature must fall below

80° F in order for the Heating to stage back on. If this condition occurs 2 times consecutively during a Heating call, the HB Controller

will lockout in Supply Air High Temperature Limit Cut Off. To restore

normal operation, either remove the call for Heating or cycle power to

the HB Controller.

SAT Low Temperature Limit Cut Off Mode

During the Heating Mode, if the Supply Air Temperature falls below

the Supply Air Low Temperature Limit Cut Off (40° F), the Outdoor

Air Damper will close. If the Supply Air Temperature is still too cold

and remains there for 15 minutes, the Heating and the Supply Fan will

be turned off and locked out. This condition can only happen once, and

then the HB Controller will lockout in Supply Air Low Temperature

Limit Cut Off. To restore normal operation, either remove the call for

Heating or cycle power to the HB Controller.

Exhaust Fan Control

The Exhaust Fan is energized via the Auxiliary Relay. The Exhaust Fan

has two Economizer Position Activation points based on the Low- and

High-Speed Supply Fan condition. The air balancing contractor should

determine these settings for proper Building Pressure Control.

HB Processor Board

When the HB Controller has the optional HB Processor board installed,

a Space Temperature Sensor can be connected to it for HVAC Mode

Control. When the Space Temperature Sensor is used, the Push-Button

Override and Slide Adjust options are also available. Occupied and

Unoccupied Modes are available through week scheduling, force schedule, and a broadcast schedule. The HB Processor board also provides

communication with other HB controllers. Up to 60 other controllers

can be connected together via the RS-485 loop.

Space Temperature Control Sequence

When the Space Temperature Sensor is confi gured for control, Cooling

and Heating setpoints are used to activate the HVAC Modes of operation.

An HVAC Mode Deadband setpoint is used to determine the temperature

at which the Cooling and Heating Modes are activated above or below the

setpoints. Once in the Cooling Mode, the Space Temperature must drop

below the Cooling setpoint minus the deadband to enter the Vent Mode.

The same is true for the Heating mode; the Space Temperature must rise

above the Heating setpoint plus the deadband to enter the Vent Mode.

An additional Cooling Stage is activated for each 1° F rise of the Space

Temperature above the Cooling Setpoint up to the maximum number of

Cooling Stages available. In like manner, an additional Heating Stage is

activated for each 1° F drop of the Space Temperature below the Heating

Setpoint up to the maximum number of Heating Stages available.

When the Space Temperature rises above the Cooling setpoint plus the

deadband, the HB Controller enters the Cooling Mode, and Cooling Stage

1 is activated. Cooling Stage 2 is activated if the Space Temperature rises

by another 1° F above the Cooling setpoint. Cooling Stage 2 deactivates

when the Space Temperature drops below the Cooling setpoint. Cooling Stage 1 deactivates when the Space Temperature drops below the

Cooling setpoint minus the deadband.

When the Space Temperature drops below the Heating setpoint minus

the deadband, the HB Controller enters the Heating Mode, and Heating

Stage 1 is activated. Heating Stage 2 is activated if the Space Temperature

drops by 1° F. Heating Stage 3 is activated if the Space Temperature

drops by another 1° F below the Heating setpoint. Heating Stage 3 and

Heating Stage 2 both deactivate when the Space Temperature rises

above the Heating setpoint. Heating Stage 1 deactivates when the Space

Temperature rises above the Heating setpoint plus the deadband.

The Slide Adjust feature on the Space Temperature Sensors that are

equipped with this option allows the user to change the Heating and

Cooling setpoints up or down by the Slide Adjust setpoint value. If 3°

F is entered as the Slide Adjust setpoint, when the slider is all the way

up, the Heating and Cooling setpoints will be raised by 3° F. When the

slider is all the way down, the Heating and Cooling setpoints will be

lowered by 3° F. The Override Button feature on Space Temperature

sensors that are equipped with this option allows the user to force the

HB Controller into the Occupied Mode. The time the controller is in

Occupied Mode is determined by the Override Time Setpoint. Once

this time is expired, the HB Controller will follow its normal schedule.

A momentary push of the Override Button will activate the Override.

Once in the Override Mode, pushing down and holding the Override

Button for 5 seconds will deactivate the Override Mode.

6

HB Controller Technical Guide

Page 7

Installation & Wiring

Controller Installation & Wiring

Controller Mounting

It is important to mount the controller in a location that is free from

extreme high or low temperatures, moisture, dust, and dirt. Be careful

not to damage the electronic components when mounting the controller.

The HB controller mounts in the HB unit control panel using the 4 plastic

standoffs located on the HB control enclosure mounting base.

Important Wiring Considerations

Please carefully read and apply the following information when wiring

the HB controller.

1. All 24 VAC wiring must be connected so that all ground

wires remain common. Failure to follow this procedure

can result in damage to the controller and connected

devices.

PIN11 - 24 VAC

PIN12 - RAB

PIN13 - CO2

PIN14 - GND

PIN7-24VAC

PIN6 - GND

PIN5 - OAT

PIN4-24VAC

PIN2 - WH PIN3 - RD

PIN1 - BK

HGR VALVE

(SAT) SUPPLY AIR TEMPERATURE SENSOR INPUT

(GND) SUPPLY AIR TEMPERATURE SENSOR INPUT

SEE THERMOSTAT

AND DEHUMIDISTAT

WIRING DIAGRAMS

FOR COMPLETE

WIRING DETAILS

(A1) ECONOMIZER 24 VAC JUMPER

(C1) CLOGGED FILTER SWITCH 24 VAC OUTPUT

(C2) CLOGGED FILTER SWITCH 24 VAC OUTPUT

(A2) ECONOMIZER 24 VAC JUMPER

PIN1-24VAC

ECONO SECTION

P1

HSS CONNECTOR

PIN4 - GN

MHGRV RESET

ECONO POSITION

RETURN AIR BYPASS

GND

PROGRAMMING SOCKET

(R) FROM THERMOSTAT

(C) FROM THERMOSTAT

(RH) FROM DEHUMIDISTAT

(G) FROM THERMOSTAT

(Y1) FROM THERMOSTAT

(Y2) FROM THERMOSTAT

(W1) FROM THERMOSTAT

(W2) FROM THERMOSTAT

(W3) FROM THERMOSTAT

POWER

P10

MHGRV

RESET

ECONO

POS

RAB

GND

LD2LD1

LD3

SAT

GND

R

C

GND

RH

G

Y1

Y2

W1

W2

W3

A1

A2

C1

C2

PIN2 - GND

PIN2 - F-SIGNAL

PIN10 - GND

PIN9 - ECONO POS

PIN8 - CFS

PIN1 - ECONO-24VAC

PIN2 - GND

PIN3 - ECS

HB - MHGR BOARD

ECONOSECTION

P1

P3

ECONO

POS

RAB

EXT

HSS

INT

JO2

JO1

C4

LED2

LED1

R2

R3

C7

SETPOINT

1

TB2

2

C12

U2

4

R27

8

OFF

16

32

R34

64

128

C15

R40

C3

ADD

1

2

4

C19

8

TB1

OFF

16

32

64

C25

128

RESET

C1

LIMIT

PROGRAM

SOCEKT

P1

C27

P5

P5

L1

C30

C29

R66

R67

D23

TB3

V10

R69

POWER

24VAC

GND

C33

P10

PIN3 - GND

PIN1 - GND

PIN7 - COOL-2

PIN8 - COOL-1

PIN9 - LPS

D1

R2

R3

D5

R6

R9

R1

R17

R20

D6

R26

R28

D8

R37

R38

D10

R45

R47

D12

R54

R55

D14

R62

R64

RN3

D15

MOD HGR

C1

R1

C3

R14

R24

R24

HBMHGR

YS101988

RN2

R35

X1

R43

RN1

R52

C26

R59

HB/VBUNIT BOARD

MADEIN THE USA

R68

C6

SERIAL#

C10

REV1

C14

C9 C8

C18

C22

U4

C2

C28

D22

U7

9936

MC34064A

2. All wiring is to be in accordance with local and national

electrical codes and specifi cations.

3. Minimum wire size for 24 VAC thermostat wiring should

be 22 gauge.

4. Minimum wire size for all sensors should be 24 gauge.

5. Be sure that all wiring connections are properly inserted

and tightened into the terminal blocks. Do not allow wire

strands to stick out and touch adjoining terminals which

could potentially cause a short circuit.

6. Be sure all modular wiring harness connectors are seated

fi rmly in their respective modular connectors on the HB

circuit board.

PIN10 - 24 VAC

PIN11 - 24 VAC

PIN12 - GND

PIN6 - HEAT-1

PIN5-24VAC

PIN4 - GND

HB - PROCESSOR BOARD

SW1

V1P9V2

K2

C2

D20

D21

Q9

Q9

Q8

R5

VALVE

HGR

R7

R10

MADEIN THE USA

R12

R16

R15

R19

R18

R21

U5

R22

R23

C9

R25

D7

C12

1

R30

2

R32

4

C4

R36

C35

8

C16

D9

16

L1

32

R41

R42

C34

R44

SW1

D11

R49

D2

R6

C11

R51

RN1

R53

C21

R5

9936

D13

MC34064A

R56

C7

R57

P4

R4

R60

U7

YS101992

REV4

C32

0I

VR2

HBAUXILIARY

R63

PROCESSORBOARD

R65

YS102002

C5

D16

REV2

C10

D1

P2

Q5

Q4

D4

K5

C31

V5

P4

P4

COOLING SECTION

HEAT SECTION

PIN9 - HSM

PIN8 - HEAT-3

PIN7 - HEAT-2

P9

PIN1 - FAN STATUS

PIN2-24VAC

PIN3-24VAC

HEATSECTION

V3

P11

P6

X2

C38

C12

C3

D2Q3D3

P-BUS

P8

HSS

C37

R71

R8

U2

R11

R13

C11

R6

C5

R7

D3

U1

TB1

TMP

ADJ

C17

GND

R39

C39

R8

C20

R9

D4

R3

U6

R2

U5

R58

R61

COMM

C46

R

C2

485DRV

U8

SH

T

R75

R74

C5

R73

HSSDRV

R72

C40

TTL

P3

P2

P7

D1

Q1

D1

PROGRAM

SOCKET

K4

D19

Q7

Q7

C36

C7

SC1

R1

D2

C8

RN1

CLOCK

C8

C9

C10

C14

U2

C13

C11

ADDR

11.059Mhz

C6

R29

C13

SERIAL#

X1

U4

Q10

C43

U1

RN2

EEPROM

C1

X1

C41

C23

C24

C15

U3

C44

C42

U4

C45

R4

C4

R4

U5

LD1

VR1

REC

AUX CPU

Q6

Q2

D18

D17

R31

R33

U3

R70

R46

R48

R50

P-BUS CONNECTOR

PROGRAMMING SOCKET

HSS CONNECTOR

OPTIONAL SPACE

TEMPERATURE SENSOR

TMP

INPUT TERMINALS

ADJ

"ADJ" TERMINAL IS ONLY

GND

USED WITH SENSORS

EQUIPPED WITH THE SLIDE

ADJUST OPTION. CONNECT

"ADJ" TERMINAL ON BOARD TO

"AUX" TERMINAL ON SENSOR

R

SH

T

RS-485 COMM TERMINALS

USED TO CONNECT TO

COMMLINK OR OTHER

CONTROLLERS ON THE

LOCAL COMMUNICATION LOOP

AS REQUIRED

MINI-DIN CONNECTOR

V6V9V7

V8P2V4

SERIAL#

COOLING

SECTION

AUX

PIN1 - E-FAN

P2

PIN2 - GND

AUX

PIN4 - LLT

PIN5 - GND

PIN6 - C-FAN

PIN12 - H-FAN

PIN11 - L-FAN

PIN10 - HPS

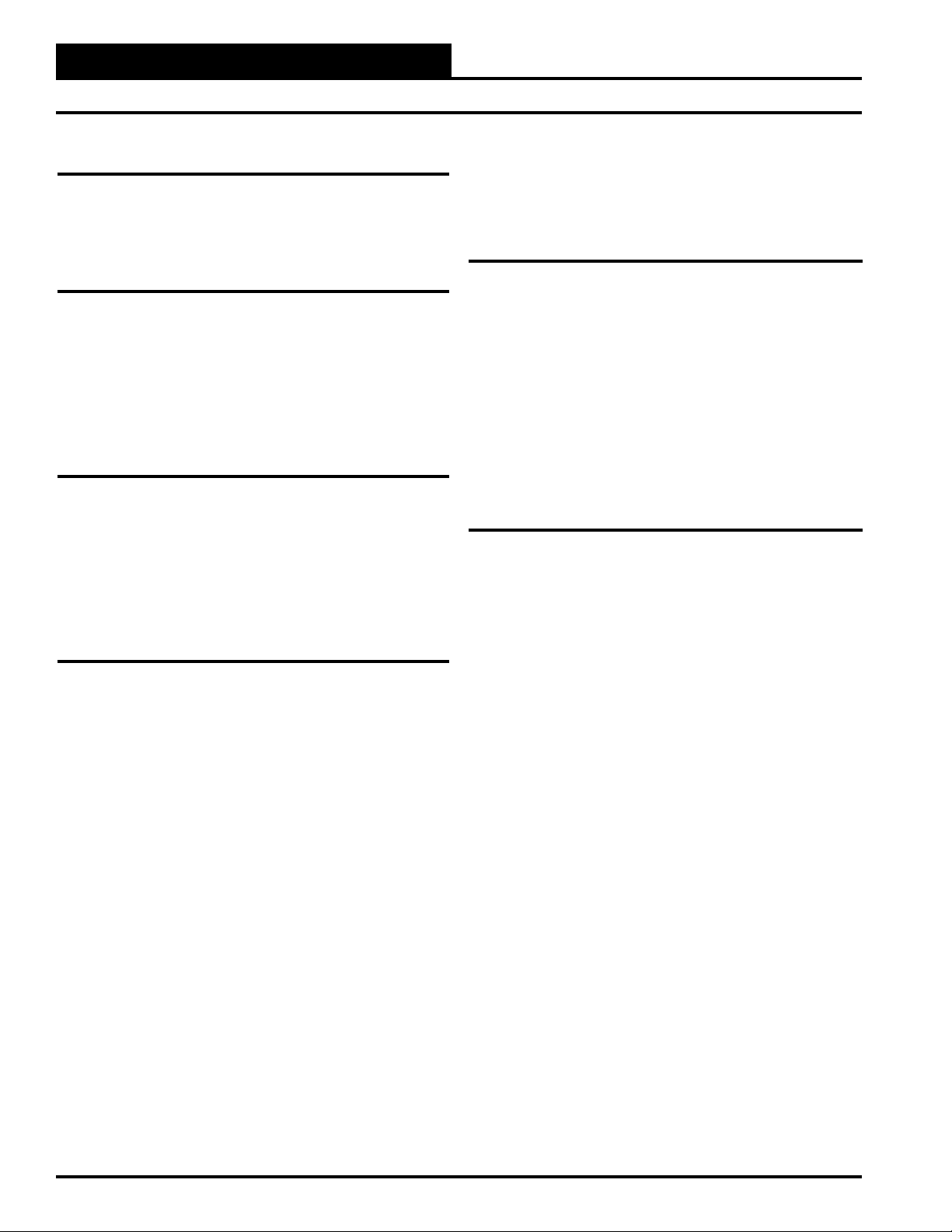

Figure 2: HB Controller Wiring (Shown with Optional MHGRV & HB Processor Boards Installed)

HB Controller Technical Guide

7

Page 8

Installation & Wiring

Controller Installation & Wiring

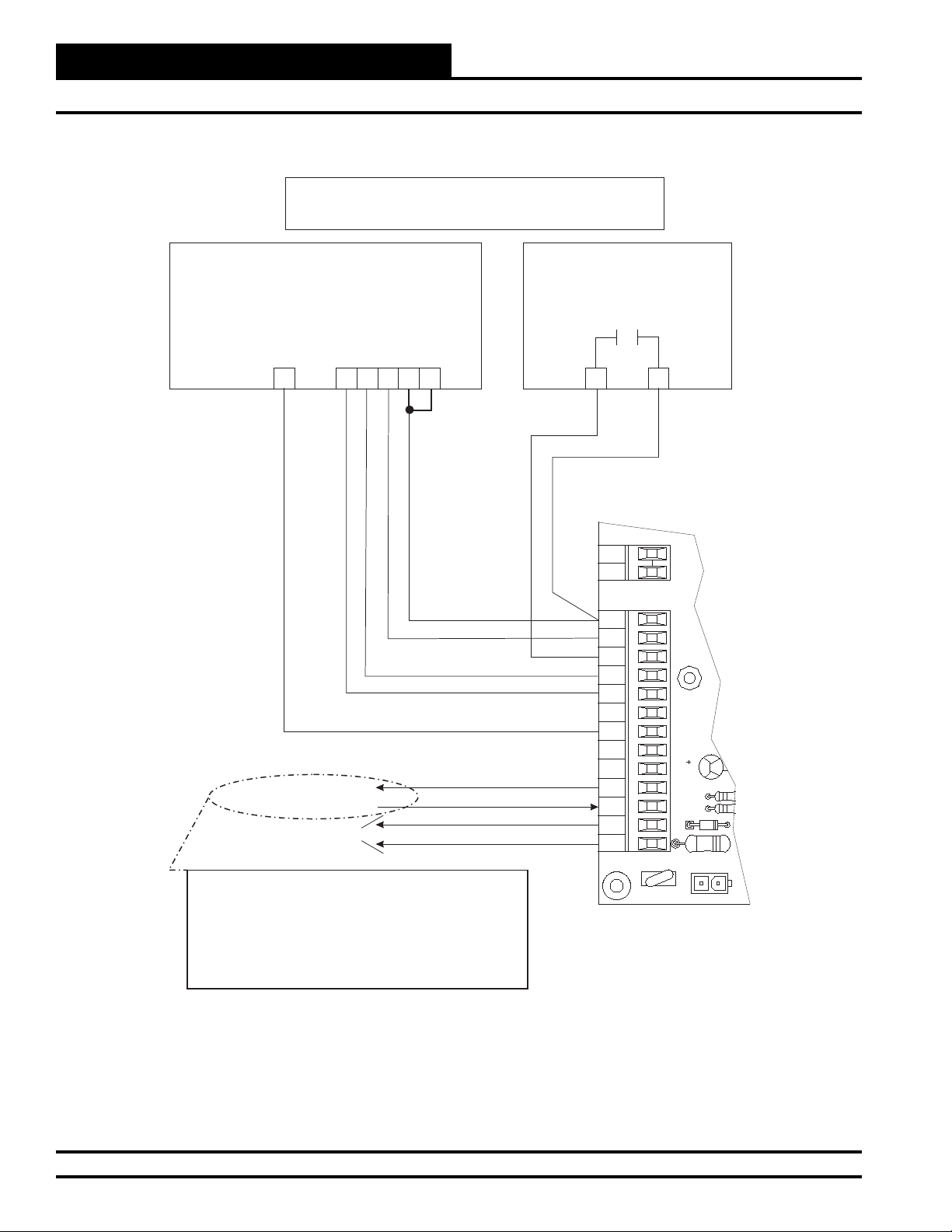

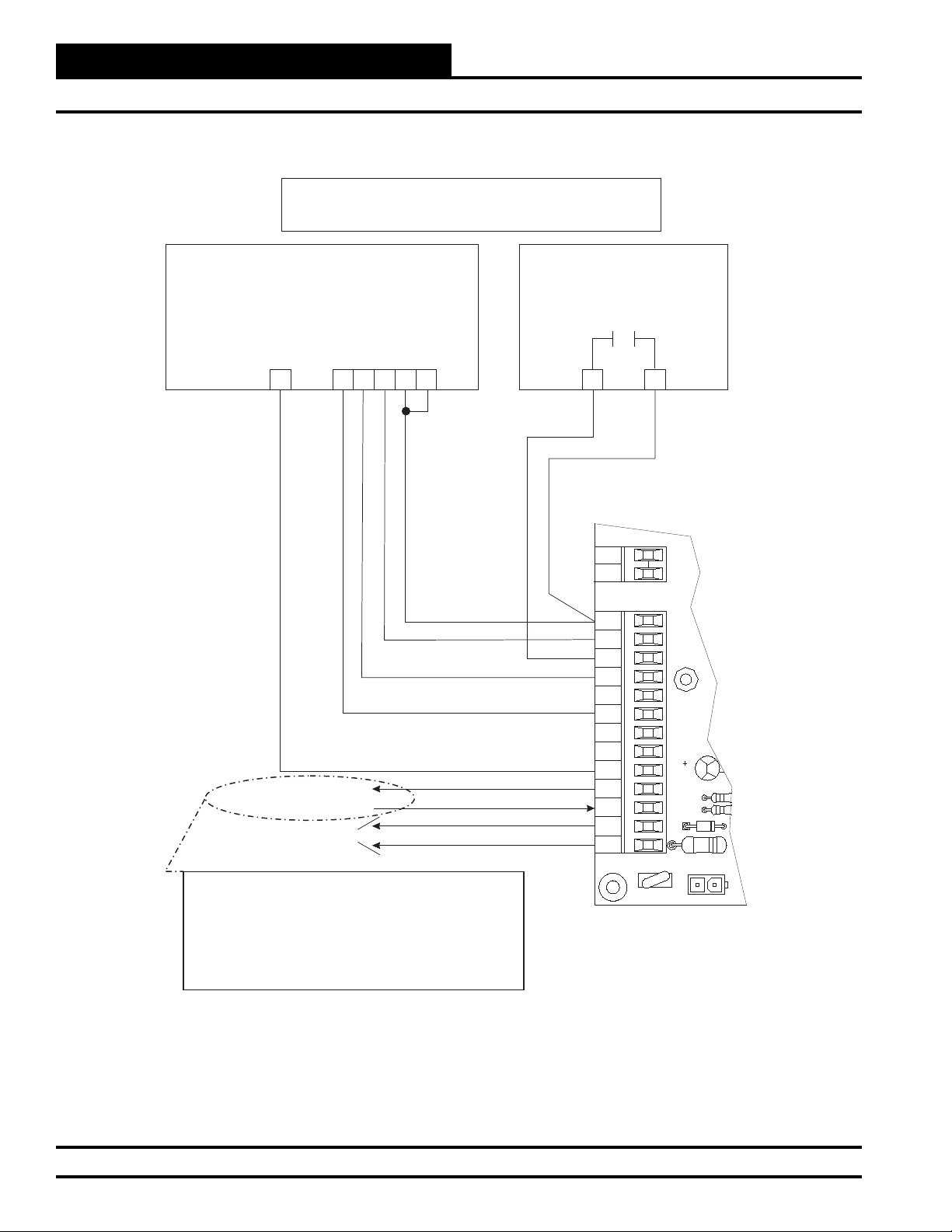

Single Stage T-stat Wiring For HB Unit

Single Stage T-stat Wiring For HB Units

With 1 Stage Cooling&1StageHeating

With 1 Stage Cooling&1StageHeating

Zone

Zone

Single-Stage Thermostat

(24VAC)

1-Cool / 1-Heat

RC

G

Y1

C

W1

RH

24VAC Power Supply

24VAC to Economizer

Clogged Filter Indicator

(Outputs 24VAC)

24VAC

GND

Note:

The economizer will not have 24VAC to the actuator

without installing a jumper wire between A1 and A2.

If a device needs to disable the economizer, install a

normally closed contact between A1 and A2.

If a device needs to enable the economizer, install a

normally open contact between A1 and A2.

Dehumidistat (24VAC)

Normally Open

DH

DH

HB Controller Terminal Block

TB1

SAT

GND

R

(GND)

C

RH

G

Y1

Y2

W1

W2

W3

A1

A2

C1

C2

TB3

R66

R67

V10

C30

POWER

P10

Figure 3: Single-Stage T-Stat Wiring for HB Unit with 1-Stage Cooling & 1-Stage Heating

8

HB Controller Technical Guide

Page 9

Installation & Wiring

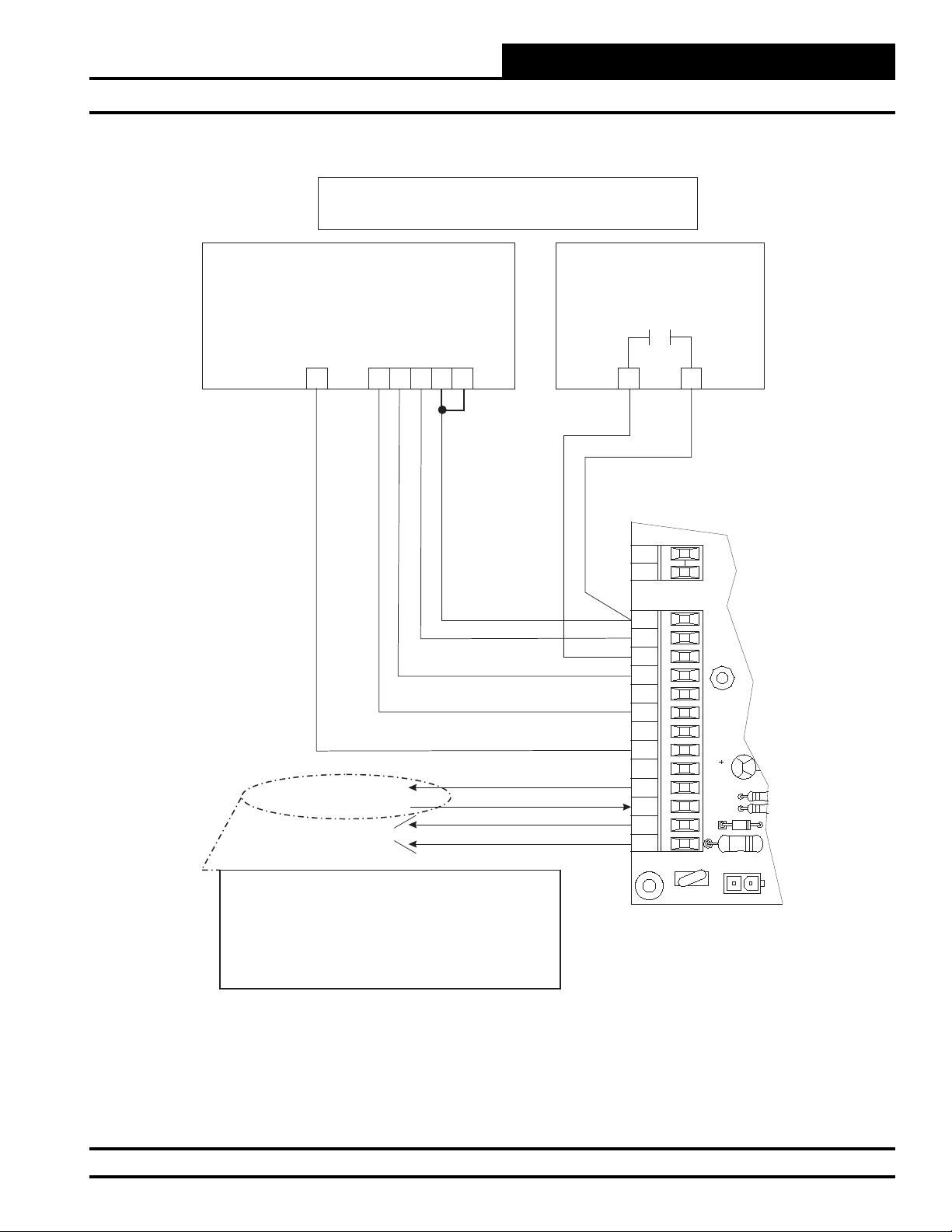

Controller Installation & Wiring

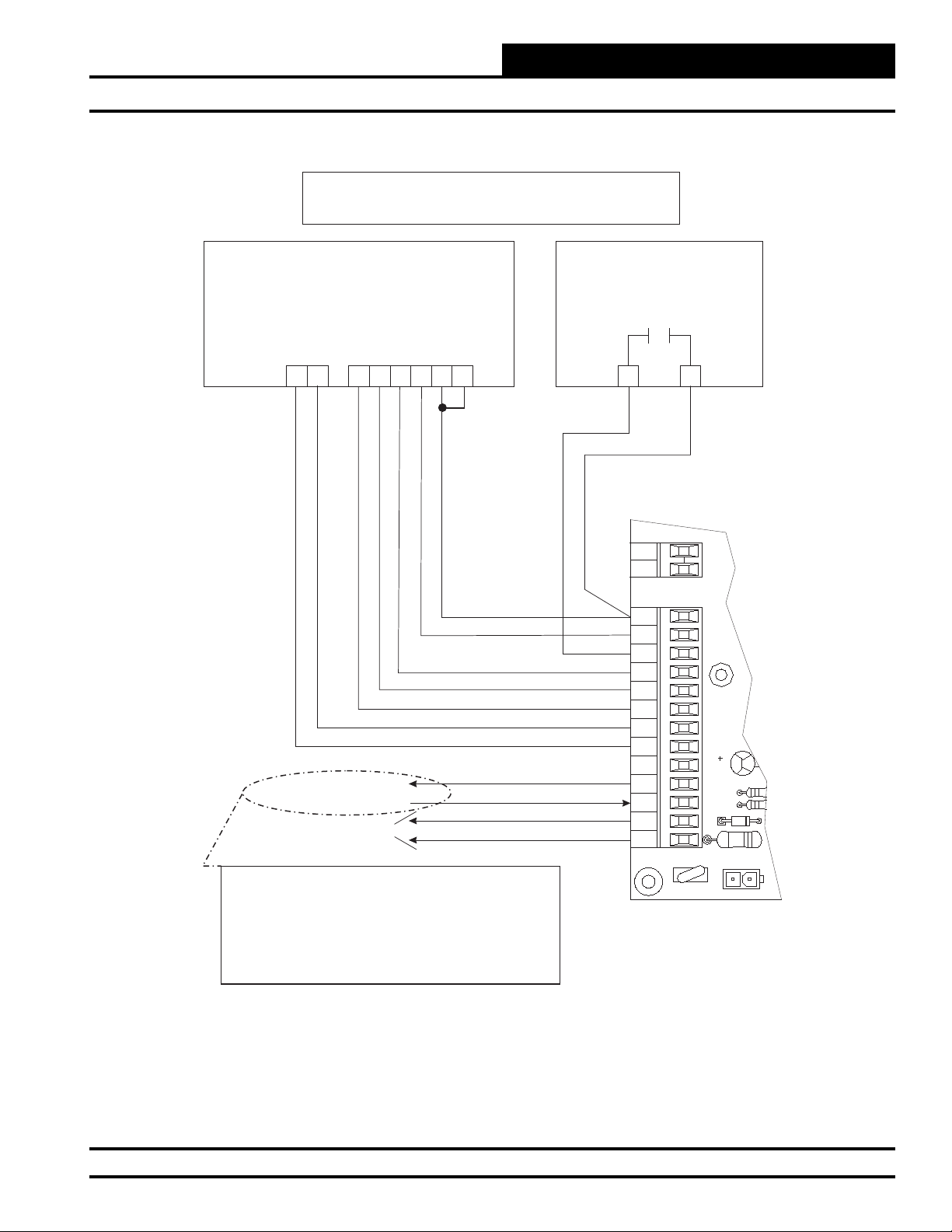

Single Stage T-stat Wiring For HB Units

With 2 Stage Cooling&2StageHeating

Single-Stage Thermostat

(24VAC)

1-Cool / 1-Heat

RC

G

Y1

C

W1

RH

24VAC Power Supply

24VAC to Economizer

Clogged Filter Indicator

(Outputs 24VAC)

24VAC

GND

Note:

The economizer will not have 24VAC to the actuator

without installing a jumper wire between A1 and A2.

If a device needs to disable the economizer, install a

normally closed contact between A1 and A2.

If a device needs to enable the economizer, install a

normally open contact between A1 and A2.

Dehumidistat (24VAC)

Normally Open

DH

DH

HB Controller Terminal Block

TB1

SAT

GND

R

(GND)

C

RH

G

Y1

Y2

W1

W2

W3

A1

A2

C1

C2

TB3

R66

R67

V10

C30

POWER

P10

Figure 4: Single-Stage T-Stat Wiring for HB Units with 2-Stage Cooling & 2-Stage Heating

HB Controller Technical Guide

9

Page 10

Installation & Wiring

Controller Installation & Wiring

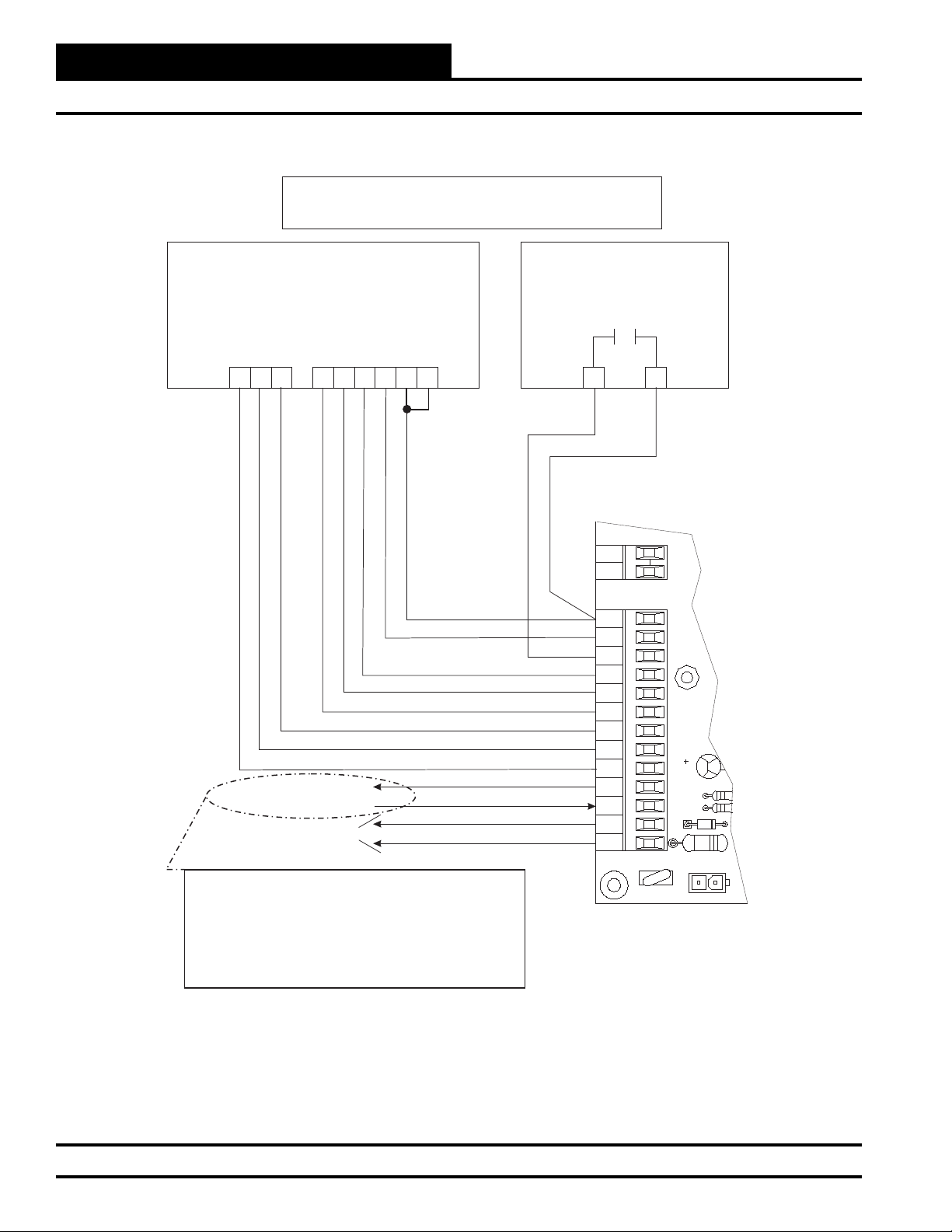

Single Stage T-stat Wiring For HB Units

With 2 Stage Cooling&3StageHeating

Zone

Zone

Single-Stage Thermostat

(24VAC)

1-Cool / 1-Heat

RC

G

Y1

C

W1

RH

24VAC Power Supply

24VAC to Economizer

Clogged Filter Indicator

(Outputs 24VAC)

24VAC

GND

Note:

The economizer will not have 24VAC to the actuator

without installing a jumper wire between A1 and A2.

If a device needs to disable the economizer, install a

normally closed contact between A1 and A2.

If a device needs to enable the economizer, install a

normally open contact between A1 and A2.

Dehumidistat (24VAC)

Normally Open

DH

DH

HB Controller Terminal Block

TB1

SAT

GND

R

(GND)

C

RH

G

Y1

Y2

W1

W2

W3

A1

A2

C1

C2

TB3

V10

R66

R67

C30

POWER

P10

Figure 5: Single-Stage T-Stat Wiring for HB Units with 2-Stage Cooling & 3-Stage Heating

10

HB Controller Technical Guide

Page 11

Installation & Wiring

Controller Installation & Wiring

Multi-Stage T-stat Wiring For HB Units

With 2 Stage Cooling&2StageHeating

Multi-Stage Thermostat

(24VAC)

2-Cool / 2-Heat

RC

W2

W1

G

Y1

C

Y2

RH

24VAC Power Supply

24VAC to Economizer

Clogged Filter Indicator

(Outputs 24VAC)

24VAC

GND

Note:

The economizer will not have 24VAC to the actuator

without installing a jumper wire between A1 and A2.

If a device needs to disable the economizer, install a

normally closed contact between A1 and A2.

If a device needs to enable the economizer, install a

normally open contact between A1 and A2.

Dehumidistat (24VAC)

Normally Open

DH

DH

HB Controller Terminal Block

TB1

SAT

GND

R

(GND)

C

RH

G

Y1

Y2

W1

W2

W3

A1

A2

C1

C2

TB3

V10

R66

R67

C30

POWER

P10

Figure 6: Multi-Stage T-Stat Wiring for HB Units with 2-Stage Cooling & 2-Stage Heating

HB Controller Technical Guide

11

Page 12

Installation & Wiring

Controller Installation & Wiring

Multi-Stage T-stat Wiring For HB Units

With 2 Stage Cooling&3StageHeating

Zone

Zone

Multi-Stage Thermostat

(24VAC)

2-Cool / 3-Heat

W3

W2

W1

Y1

Y2

RC

G

C

RH

24VAC Power Supply

24VAC to Economizer

Clogged Filter Indicator

(Outputs 24VAC)

24VAC

GND

Note:

The economizer will not have 24VAC to the actuator

without installing a jumper wire between A1 and A2.

If a device needs to disable the economizer, install a

normally closed contact between A1 and A2.

If a device needs to enable the economizer, install a

normally open contact between A1 and A2.

Dehumidistat (24VAC)

Normally Open

DH

DH

HB Controller Terminal Block

TB1

SAT

GND

R

(GND)

C

RH

G

Y1

Y2

W1

W2

W3

A1

A2

C1

C2

TB3

R66

R67

V10

C30

POWER

P10

Figure 7: Multi-Stage T-Stat Wiring for HB Units with 2-Stage Cooling & 3-Stage Heating

12

HB Controller Technical Guide

Page 13

Installation & Wiring

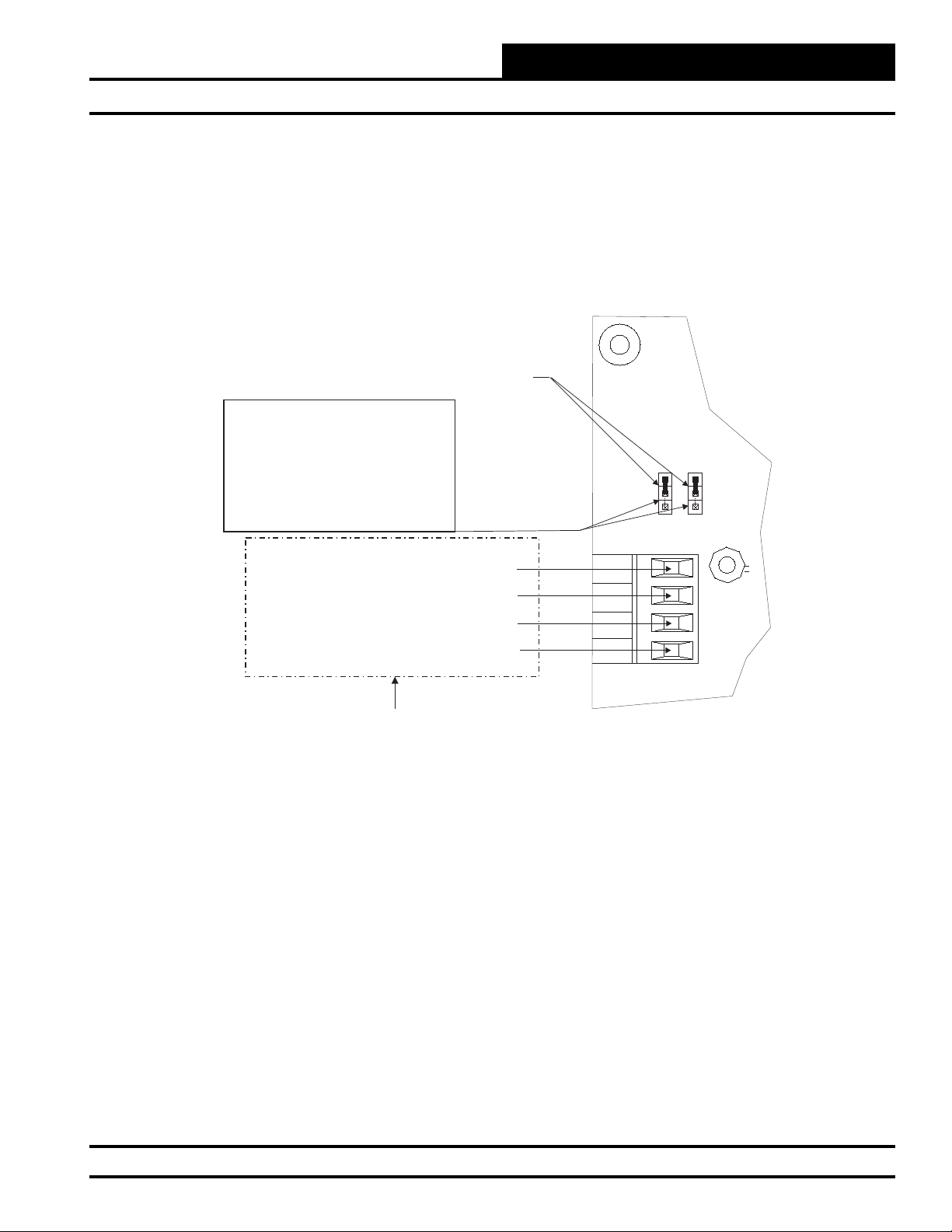

Optional Jumper

Locations

For External Control

Controller Installation & Wiring

Note:

The factory jumpers are located on

the bottom two pins for each 3-pin

header. For field control of either the

Economizer and/or the Return Air

Bypass, move their respective

jumpers to the “External” position on

the jumper pins as shown.

0-10VDC Input Signal for

Modulating Hot-Gas Reheat

2-10VDC Economizer Signal

0-10VDC Return Air Bypass Signal

Common Ground for External Signals

External Control Inputs

MHGRV

RESET

ECONO

POS

RAB

GND

POS

ECONO

JO1

TB2

POS

JO2

RAB

EXTERNAL

INTERNAL

C7

Figure 8: Field Wiring & Jumper Settings for Mod Hot Gas Reheat, Economizer, and Return Air Bypass

HB Controller Technical Guide

13

Page 14

Programming

Programming with the HB Service Tool

Zone

Zone

Entering Passcodes

The HB Service Tool is used to program setpoints and view the status

of the HB controller. It is connected to the HB controller by means of

a modular cable. The cable is connected between the HB Service Tool

and the HB controller board. The HB Service Tool doesn’t require batteries or a separate power source, because all power to operate the HB

Service Tool is provided through this cable. The HB controller must be

powered in order for the HB Service Tool to function.

Device Address

064

When the HB Service Tool is initially powered up, the program version

and the current time and date will be displayed. After the initial power

up, this screen only appears when the HB power is removed and then

reapplied. Press ENTER, and the HB Service Tool will check all current

parameters. When it has fi nished this checking procedure, press ENTER,

and the main HB programming screen will be displayed. If you want

to change setpoints, you will need to enter a passcode at this time. If

you only want to view status, a passcode is not required, and you can

proceed to view status directly by pressing the ENTER key.

If you want to change the Passcode, hold down on the UP and DOWN

SELECT ARROWS simultaneously and the following screen will be

displayed.

the DOWN arrow decreases. When the desired letter appears, press the

RIGHT ARROW key to advance to the next letter fi eld. Once all four

letter fi elds spell the desired passcode, press the ENTER key.

Available passcodes are:

● “OPER” = The Operator is at level 1 for Status and

Setpoints

● “CONT” = The Contractor is at level 2 for Status, Setpoints

and Force Modes

Again, if no passcode is entered, the default level is 0 and only allows

viewing of the status screens.

General Procedures

When the HB Service Tool is initially powered up, this screen will be

displayed. Press ENTER to proceed to the next screen.

Enter your passcode as described in the previous section and proceed by

pressing the MENU key. The following screen will be displayed:

Line #2 displays the default address for the HB Controller. If equipped

with a MHGRV Controller, adjust the address to 065 in a similar fashion

as you did when you entered your passcode. Once you have the desired

address on the screen, press the ENTER key. The following screen will

be displayed:

Enter Code

AAAA

The passcode entry screen uses a four-digit alpha passcode. Position

the cursor under the fi rst letter fi eld. To select the desired letter, use the

ADJUST ARROWS. The UP arrow increases through the alphabet and

14

Line #2 displays the controller name or program name. Press the ENTER

key to advance.

Module Selection Screens

After pressing ENTER in the previous step, the fi rst available programming module screen appears. All of the HB controller Status and Setpoint Screens are grouped in specifi c modules designated by a specifi c

function name.

Using the select arrows, scroll to select the desired module on line #1

and press the ENTER key.

HB Controller Technical Guide

Page 15

Programming

Programming with the HB Service Tool

The other available module screens are listed below in the order that

they would appear as you scroll down.

Factory Options should not be accessed without contacting AAON®

or WattMaster.

Warning: The Factory Options settings should only be ap-

plied when authorized by AAON® or WattMaster

Technical Support personnel. Serious damage to the

controller and/or HVAC unit could result from im proper use of the Factory settings.

OAT Heat Lockout

Line #2 displays “YES” if the Outdoor Air Temperature is above the

Heating Lockout Temperature Setpoint.

OAT Cool Lockout

Line #2 displays “YES” if the Outdoor Air Temperature is below the

Cooling Lockout Temperature Setpoint.

OAT Temperature

Line #2 displays the current Outdoor Air Temperature.

SAT Temperature

HB Controller Status & Setpoints

The Status and Setpoint screens for the various modules are accessed by

selecting a specifi c module and pressing the ENTER key.

Main Status Screens

The Main Status Screen is accessed by selecting the Main Status Module

and pressing the ENTER key. This screen, as its name indicates, allows

you to view the Main Status screens for the HB controller. After the

ENTER key is pressed, the following screen will be displayed:

HVAC Mode

Line #2 displays one of the following HVAC Modes:

• Idle • Venting

• Cooling • Econo Cooling

• Heating • Dehumidify

• Econo Dehumidify • Fault

• Force

Press the down SELECT arrow key or up SELECT arrow key to move

forward or backward through the Main Status screens.

Line #2 displays the current Supply Air Temperature.

Alarms

Line #2 displays “YES” if an alarm is active. To identify the active

alarm(s), press the ESC key, select the Alarm Module, and scroll through

the available alarms using the up and down SELECT arrow keys.

Program Date

Line #2 displays the Month/Day/Year that the HB Controller software

was created.

HB Controller Technical Guide

15

Page 16

Programming

Programming with the HB Service Tool

Zone

Zone

Program Time

Line #2 displays the time, in 24-hour (military) format, that the HB

Controller software was created.

Program Version

Line #2 displays the HB Controller software version number.

Reset Counts

Line #2 displays the total number of times the HB Controller has been

reset or has had its power cycled.

Fan Status

Line #2 displays the current Supply Fan Status. If the Supply Fan is on,

line #2 displays either “Fan Low Speed” or “Fan High Speed.” Line #2

displays “ON” if the High Speed Fan Relay is active.

Supply Fan Analog Output Signal

Line #2 displays the current Supply Fan Analog Output Signal in DC

Volts.

Fan Module Setpoint Screens

The Fan Module Setpoint Screens are accessed by navigating to the

Fan Module and then pressing the ENTER key. The following screen

will then appear:

Fan Module Status Screens

The Fan Module Status Screens are accessed by navigating to the Fan

Module and pressing the ENTER key. The following screen will then

appear:

Select “Status” by pressing the ENTER key. Press the up and down

SELECT arrow keys to move forward and backward through the Fan

Module Status screens.

Fan Terminal Active

Line #2 displays “YES” if there is a 24 VAC signal connected to the

“G” Fan terminal on the HB controller.

Press the down SELECT arrow key until “Setpoints” is on the top line

of the screen and then press the ENTER key. Press the up and down

SELECT arrow keys to move forward and backward through the Fan

Setpoint screens.

Please see the Appendix section in the back of this manual for Tables

listing the minimum, maximum, and default setpoints for all of the

setpoint screens.

Supply Fan Confi guration

Select the appropriate Supply Fan Confi guration by using the up and

down ADJUST arrow keys and then pressing the ENTER key. Available

options are Two-Speed or Adj. Two-Speed.

16

HB Controller Technical Guide

Page 17

Programming

Programming with the HB Service Tool

Adjustable Two-Speed Supply Fan Low-Speed Signal

Description Min. Default Max.

Low Speed Fan Signal 1.0 VDC 3.0 VDC 10.0 VDC

Adjust the desired Low-Speed Output Signal for Adjustable Two-Speed

Fan confi gurations by pressing the up or down ADJUST arrow key until

the desired value is displayed and then pressing the ENTER key. Settings are in DC Volts.

Adjustable Two-Speed Supply Fan High Speed Signal

Description Min. Default Max.

High Speed Fan Signal 1.0 VDC 10.0 VDC 10.0 VDC

Adjust the desired High-Speed Output Signal for Adjustable Two-Speed

Fan confi gurations by pressing the up or down ADJUST arrow key until

the desired value is displayed and then pressing the ENTER key. Settings are in DC Volts.

Fan Status

Line #2 displays the current Supply Fan Status. If the Supply Fan is on,

line #2 displays either “Fan Low Speed” or “Fan High Speed.”

Fan Signal

Line #2 displays the current Supply Fan Analog Output Signal in DC

Volts.

Cooling Relay #1

Line #2 displays “ON” if Cooling Relay #1 is active.

Cooling Relay #2

Cooling Module Status Screens

The Cooling Module Status Screens are accessed by navigating to the

Cooling Module screen ad pressing the ENTER key. The following

screen will then appear:

Select “Status” by pressing the ENTER key. Press the up and down

SELECT arrow keys to move forward and backward through the Cooling Module Status screens.

Cooling Stage 1 Energized

Line #2 displays “YES” if there is a 24 VAC signal on HB Controller

terminal “Y1.”

Cooling Stage 2 Energized

Line #2 displays “ON” if Cooling Relay #2 is active.

Liquid Line Temperature

Line #2 displays the current Liquid Line Temperature.

Condenser Fan Relay

Line #2 displays “ON” if the Condenser Fan Relay is active.

Low Pressure Switch

Line #2 displays “YES” if there is a 24 VAC signal on HB Controller

terminal “Y2.”

HB Controller Technical Guide

Line #2 displays the current status of the Low Pressure Switch. It will

only display “CLOSED” when Cooling Relay #1 is active and the Low

Pressure Switch is operating correctly.

17

Page 18

Programming

Programming with the HB Service Tool

Zone

Zone

High Pressure Switch

Line #2 displays the current status of the High Pressure Switch. It will

only display “CLOSED” when Cooling Relay #1 relay is active and the

High Pressure Switch is operating correctly.

Cooling Module Setpoint Screens

The Cooling Module Setpoint Screens are accessed by navigating to

the Cooling Module screen and then pressing the ENTER key. The

following screen will then appear:

Press the down SELECT arrow key until “Setpoints” is on the top line

of the screen and then press the ENTER key. Press the up and down

SELECT arrow keys to move forward and backward through the Cooling Module Setpoint screens.

Cooling Stages Quantity

Low Supply Air Temperature Cutoff

Description Min. Default Max.

Supply Air Low Temperature

Limit Cut Off

Adjust the Low Supply Air Temperature Cutoff and then press the

ENTER key. The value must be below the Economizer Oat Enable.

32ºF 40ºF 80ºF

Cooling Minimum Off Time

Description Min. Default Max.

Minimum Off Time 180 Sec 180 Sec 900 Sec

Adjust the desired Cooling Minimum Off Time and then press the

ENTER key.

Cooling Minimum On Time

Description Min. Default Max.

Cooling Stages 1 2 2

Adjust the quantity of Cooling Stages or Steps of Cooling and then

press the ENTER key.

Condenser Fan Control

Select “YES” for Condenser Fan Control if you are using a Liquid Line

Temperature Sensor and then press the ENTER key.

Outdoor Air Temperature Cooling Lockout

Description Min. Default Max.

Cooling Lockout Temperature 32ºF 40ºF 80ºF

Adjust the Outdoor Air Temperature Cooling Lockout and then press

the ENTER key.

Adjust the desired Cooling Minimum On Time and then press the

ENTER key.

Description Min. Default Max.

Minimum On Time 300 Sec 300 Sec 900 Sec

Cooling Stage-Up Delay

Description Min. Default Max.

Staging Up Delay Interval 180 Sec 180 Sec 900 Sec

Adjust the desired Cooling Stage-Up Delay time and then press the

ENTER key.

Cooling Stage Down Delay

Description Min. Default Max.

Staging Down Delay Interval 60 Sec 60 Sec 900 Sec

Adjust the desired Cooling Stage-Down Delay time and then press the

ENTER key.

18

HB Controller Technical Guide

Page 19

Programming

Programming with the HB Service Tool

Low Pressure Switch Delay

Description Min. Default Max.

Low Pressure Delay Period 5 Sec 30 Sec 60 Sec

The Low Pressure Switch Delay time is a factory setting and should

not be changed unless authorized to do so by WattMaster or AAON

Technical Support.

Low Pressure Switch Safety Delay

Description Min. Default Max.

Low Pressure Safety 5 Sec 5 Sec 30 Sec

The Low Pressure Switch Safety Delay time is a factory setting and

should not be changed unless authorized to do so by WattMaster or

AAON® Technical Support.

LPS Maximum Trips

Condenser Fan Deactivation Temperature

The Condenser Fan Deactivation Temperature is a factory setting and

should not be changed unless authorized to do so by WattMaster or

AAON® Technical Support.

®

Auto Stage-Up Time

Description Min. Default Max.

Auto Staging Up Delay 180 Sec 600 Sec 900 Sec

The Auto Stage-Up Time can be adjusted on this screen when you are

using a single-stage thermostat with a multi-stage HB unit.

Heating Module Status Screens

The Heating Module Status Screens are accessed by navigating to the

Heating Module screen and pressing the ENTER key. The following

screen will then appear:

Description Min. Default Max.

Low Pressure Max. Trip Point 1 3 5

The Low Pressure Switch Max Trips is a factory setting and should

not be changed unless authorized to do so by WattMaster or AAON®

Technical Support.

Cooling Fan Off Delay

Description Min. Default Max.

Fan Off Delay Period 1 Sec 45 Sec 120 Sec

The Cooling Fan Off Delay is a factory setting and should not be

changed unless authorized to do so by WattMaster or AAON® Technical Support.

Condenser Fan Activation Temperature

Select “Status” by pressing the ENTER key. Press the up and down

SELECT arrow keys to move forward and backward through the Heating Module Status screens.

Heating Stage 1 Energized

Line #2 displays “YES” if there is a 24 VAC signal on HB Controller

terminal “W1.”

Heating Stage 2 Energized

Line #2 displays “YES” if there is a 24 VAC signal on HB Controller

terminal “W2.”

The Condenser Fan Activation Temperature is a factory setting and

should not be changed unless authorized to do so by WattMaster or

AAON® Technical Support.

HB Controller Technical Guide

19

Page 20

Programming

Programming with the HB Service Tool

Zone

Zone

Heating Stage 3 Energized

Line #2 displays “YES” if there is a 24 VAC signal on HB Controller

terminal “W3.”

Fan Status

Line 2 displays the current Supply Fan Status. If the Supply Fan is on,

line #2 displays either “Fan Low Speed” or “Fan High Speed.”

Fan Signal

Line #2 displays the current Supply Fan Analog Output Signal in DC

Volts.

Heating Module Setpoint Screens

The Heating Module Setpoint Screens are accessed by navigating to

the Heating Module and then pressing the ENTER key. The following

screen will then appear:

Press the down SELECT arrow key until “Setpoints” is on the top line

of the screen and then press the ENTER key. Press the up and down

SELECT arrow keys to move forward and backward through the Heating Module Setpoint screens.

Heating Stages Quantity

Description Min. Default Max.

Heating Stages 1 3 3

Adjust the quantity of Heating Stages and then press the ENTER key.

Outdoor Air Temperature Heating Lockout

Heating Relay #1

Line #2 displays “ON” if Heating Relay #1 is active.

Heating Relay #2

Line #2 displays “ON” if Heating Relay #2 is active.

Heating Relay #3

Line #2 displays “ON” if Heating Relay #3 is active.

Heat Safety Monitor

Line #2 displays “OPEN” anytime the Heat Safety Monitor is open.

Description Min. Default Max.

Heating Lockout Temperature 40ºF 80ºF 120ºF

Adjust the Outdoor Air Temperature Heating Lockout and then press

the ENTER key.

Low Supply Air Temperature Cutoff

Description Min. Default Max.

Supply Air Low Temperature

Limit Cut Off

Adjust the Low Supply Air Temperature Cutoff and then press the

ENTER key.

32ºF 40ºF 80ºF

High Supply Air Temperature Cutoff

Description Min. Default Max.

Supply Air High Temperature

Limit Cut Off

Adjust the High Supply Air Temperature Cutoff and then press the

ENTER key.

120ºF 150ºF 170ºF

20

HB Controller Technical Guide

Page 21

Programming

Programming with the HB Service Tool

Heating Minimum Off Time

Description Min. Default Max.

Minimum Off Time 60 Sec 60 Sec 900 Sec

Adjust the desired Heating Minimum Off Time and then press the

ENTER key.

Heating Minimum On Time

Description Min. Default Max.

Minimum On Time 120 Sec 120 Sec 900 Sec

Adjust the desired Heating Minimum On Time and then press the

ENTER key.

Heating Stage-Up Delay

Description Min. Default Max.

Staging Up Delay Interval 180 Sec 180 Sec 900 Sec

Heating Fan Off Delay

Description Min. Default Max.

Fan Off Delay Period 1 Sec 120 Sec 180 Sec

The Heating Fan Off Delay is a factory setting and should not be

changed unless authorized to do so by WattMaster or AAON® Technical Support.

Auto Stage-Up Time

Description Min. Default Max.

Auto Staging Up Delay 180 Sec 600 Sec 900 Sec

The Auto Stage-Up Time can be adjusted on this screen when you are

using a single-stage thermostat with a multi-stage HB unit.

Economizer Module Status Screens

The Economizer Module Status Screens are accessed by navigating to

the Economizer Module and pressing the ENTER key. The following

screen will then appear:

Adjust the desired Heating Stage-Up Delay time and then press the

ENTER key.

Heating Stage Down Delay

Description Min. Default Max.

Staging Down Delay Interval 60 Sec 60 Sec 900 Sec

Adjust the desired Heating Stage Down Delay time and then press the

ENTER key.

Heat Safety Monitor Maximum Trips

Description Min. Default Max.

Heat Safety Maximum Count 1 3 5

The Heating Safety Maximum Trips is a factory setting and should

not be changed unless authorized to do so by WattMaster or AAON

Technical Support.

Select “Status” by pressing the ENTER key. Press the up and down

SELECT arrow keys to move forward and backward through the

Economizer Module Status screens.

Economizer Current Position

Line #2 displays the current Economizer Position as a percent open

value.

Supply Air Temperature

Line #2 displays the current Supply Air Temperature.

®

HB Controller Technical Guide

21

Page 22

Programming

Programming with the HB Service Tool

Zone

Zone

Outdoor Air Temperature

Line #2 displays the current Outdoor Air Temperature.

Fan Status

Line #2 displays the current Supply Fan status. If the Supply Fan is on,

line #2 displays either “Fan Low Speed” or “Fan High Speed.”

Fan Signal

Line #2 displays the current Supply Fan Analog Output Signal in DC

Volts.

Exhaust Fan Relay

Economizer Module Setpoint Screens

The Economizer Module Setpoint Screens are accessed by navigating

to the Economizer Module and then pressing the ENTER key. The following screen will then appear:

Press the down SELECT arrow key until “Setpoints” is on the top line

of the screen and then press the ENTER key. Press the up and down

SELECT arrow keys to move forward and backward through the Economizer Module Setpoint screens.

Economizer Confi guration

Description Min. Default Max.

Outdoor Air Enable Temp 33ºF 55ºF 65ºF

Select either “Has Economizer” or “No Economizer” and then press the

ENTER key. The value must be greater than the OAT Lockout.

.

Outdoor Air Temperature Enable

Line #2 displays “ON” when the Exhaust Fan Relay is active.

Carbon Dioxide Level

Line #2 displays the Current Carbon Dioxide levels, given in parts per

million.

Economizer Change Over Switch

Line #2 displays “CLOSED” if there is a 24 VAC signal on the Economizer Changeover Switch input. This signal is provided by an Enthalpy

controller to enable the economizer for free Cooling.

Description Min. Default Max.

Outdoor Air Enable Temp 33ºF 55ºF 65ºF

Adjust the Outdoor Air Temperature to enable Economizer Free Cooling

and then press the ENTER key.

OAT Changeover to Mechanical Cooling

Description Min. Default Max.

ECS OAT Enable Temp 55ºF 65ºF 75ºF

Adjust the Outdoor Air Temperature that will allow supplemental Mechanical Cooling during ECS Economizer operation and then press the

ENTER key.

CO2 Minimum Position with Low-Speed Fan

Description Min. Default Max.

Min. with Low-Speed Fan 0% 10% 100%

Adjust the Economizer Minimum Position during Low-Speed Supply

Fan operation when CO

and then press the ENTER key.

levels are below the Minimum CO2 setpoint

2

22

HB Controller Technical Guide

Page 23

Programming

Programming with the HB Service Tool

CO2 Minimum Position with High-Speed Fan

Description Min. Default Max.

Min. with High-Speed Fan 0% 5% 100%

Adjust the Economizer Minimum Position during High-Speed Supply

Fan operation when CO2 levels are below the Minimum CO2 setpoint

and then press the ENTER key.

CO2 Maximum Position with Low Speed Fan

Description Min. Default Max.

Max. with Low-Speed Fan 0% 50% 100%

Adjust the Economizer Maximum Position during Low-Speed Supply

Fan operation when CO2 levels are above the Maximum CO2 setpoint

and then press the ENTER key.

CO Maximum Position with High-Speed Fan

Description Min. Default Max.

Max. with High Speed Fan 0% 30% 100%

Adjust the Economizer Maximum Position during High-Speed Supply

Fan operation when CO2 levels are above the Maximum CO2 setpoint

and then press the ENTER key.

CO2 Level Economizer Opens Above Minimum

Description Min. Default Max.

Min. CO

2

Adjust the Minimum CO2 Level that will allow the Economizer to

Modulate above its minimum position and then press the ENTER key.

0 PPM 900 PPM 2000 PPM

CO2 Level Economizer Opens to Economizer Maximum

Description Min. Default Max.

Max. CO

Adjust the Maximum CO2 Level that will allow the Economizer to Modulate open to its maximum position and then press the ENTER key.

2

0 PPM 1100 PPM 2000 PPM

Dehumidify Module Status Screens

The Dehumidify Module Status Screens are accessed by navigating to

the Dehumidify Module and pressing the ENTER key. Setpoints are

not available for the Dehumidify Module. After pressing ENTER, the

following screen will appear:

RH Terminal Active

Exhaust Fan On with Low-Speed Fan

Description Min. Default Max.

Low-Speed Supply Fan 0% 50% 100%

Adjust the Economizer Position during Low-Speed Supply Fan operation

that will activate the Exhaust Fan and then press the ENTER key.

Exhaust Fan On with High-Speed Fan

Description Min. Default Max.

High-Speed Supply Fan 0% 30% 100%

Adjust the Economizer Position during High-Speed Supply Fan operation

that will activate the Exhaust Fan and then press the ENTER key.

HB Controller Technical Guide

Line #2 displays “YES” if there is a 24 VAC signal on the “RH”

terminal.

Fan Status

Line #2 displays the current Supply Fan Status. If the Supply Fan is on,

Line #2 displays either “Fan Low Speed” or “Fan High Speed.”

Fan Signal

Line #2 displays the current Supply Fan Analog Output Signal in DC

Volts.

23

Page 24

Programming

Programming with the HB Service Tool

Zone

Zone

RAB Position

Line #2 displays the current Return Air Bypass damper position.

Cooling Relay #1

Line #2 displays “ON” if Cooling Relay #1 is active.

Cooling Relay #2

Line #2 displays “ON” if Cooling Relay #2 is active.

OAT Temperature

Condenser Fan Relay

Line #2 displays “ON” if the Condenser Fan Relay is active.

Alarm Module Status Screens

The Alarm Module Status Screens are accessed by navigating to the

Alarm Module and pressing the ENTER key. Setpoints are not available

for the Alarm Module. After pressing ENTER, the following screen

will appear:

HSM Lockout

Line #2 displays “YES” when the Heat Safety Monitor has tripped more

than the HSM Max Trips setpoint.

HPS Fault

Line #2 displays the current Outdoor Air Temperature.

Economizer Current Position

Line #2 displays the current Economizer Position as a percent

open value.

Supply Air Temperature

Line #2 displays the current Supply Air Temperature.

Liquid Line Temperature

Line #2 displays the current Liquid Line Temperature.

Line #2 displays “YES” when the High Pressure Switch is open and a

Cooling Relay is active.

LPS Lockout

Line #2 displays “YES” when the Low Pressure Switch has tripped

more than the LPS Max Trips setpoint.

B a d O A T S e n s o r

Line #2 displays “YES” when the Outdoor Air Temperature Sensor is

bad or missing.

B a d S A T S e n s o r

Line #2 displays “YES” when the Supply Air Temperature Sensor is

bad or missing.

24

HB Controller Technical Guide

Page 25

Programming

Programming with the HB Service Tool

Bad LLT

Line #2 displays “YES” when Condenser Fan Control is confi gured and

the Liquid Line Temperature Sensor is bad or missing.

High SAT Cutoff

Line #2 displays “YES” when the HB Controller is locked out in High

Supply Air Temperature Cutoff.

Low SAT Cutoff

Line #2 displays “YES” when the HB Controller is locked out in Low

Supply Air Temperature Cutoff.

OAT Cooling Lockout

Force Mode Module Screens

The Force Mode Module screens are accessed by navigating to the

Force Mode Module screen and pressing the ENTER key. After pressing

ENTER, the following screen will appear:

Press the down SELECT arrow key until “Force” is on the top line

of the screen and then press the ENTER key. Press the up and down

SELECT arrow keys to move forward and backward through the Force

Mode Module screens.

Force Time Limit

Description Min. Default Max.

Force Mode Timer 1 Min 60 Min 240 Min

Adjust the desired time needed for forcing the HB Controller into the

Force Module Mode and then press the ENTER key.

Force Mode

Line #2 displays “YES” if the Outdoor Air Temperature is below the