Page 1

Component Speaker

MODEL

CO552

CO652

OWNER'S MANUAL

Page 2

TABLE OF CONTENTS

English ........................................................................ 1

Français

Español ...............................................................13

Deutsch ...............................................................17

Italiano ...............................................................21

Português .............................................................25

Introduction.................................................................... 1

Practice Safe Sound™ ............................................................ 1

What’s in the Box ...............................................................2

Installing Process ................................................................ 2

Tools of the Trade............................................................... 2

Finding Speaker Mounting Locations ............................................... 2

Door Mounting .................................................................3

Rear Deck Mounting............................................................. 3

Installing the Mid/Woofers........................................................ 4

Installing the Tweeter............................................................ 5

Installing the Crossover .......................................................... 6

Wiring Diagram................................................................. 7

Specifications................................................................... 8

Features .......................................................................8

Warranty .............................................................. back cover

................................................................9

INTRODUCTION

Thank you for your purchase of the OrionTM Cobalt Component Loudspeaker system. These

speakers represent a combination of incredible performance and value. The OrionTM stamped

steel frame components feature treated paper cones and metalized PEI (Polyetherimide)

tweeters. Capable of maintaining their balance and clarity at exceptionally high output levels,

they are the perfect complement to the Orion woofers. The crossovers feature tweeter level

adjustment. The components are available in standard 5-1/4" and 6-1/2" sizes to fit most

applications.

TM

We at Orion

What we can't give you in this manual is personal installation or technical experience. If you

have questions concerning the use or application of this product, please refer to the nearest

Authorized ORION

800-876-0800. As we are always finding new ways to improve our product, the features and

specifications are subject to change without notice.

strive to give you all the latest up to date information about this product.

TM

Dealer for assistance or call the OrionTM technical support hotline at 1-

PRACTICE SAFE SOUND™

Continuous exposure to sound pressure levels over 100dB may cause permanent hearing loss.

High powered automotive sound systems can generate sound pressure levels in excess of 130dB.

When playing your system at high levels, please use hearing protection and prevent long term

exposure.

© 2009 directed electronics—all rights reserved 1

Page 3

Model Number: _____________________________

Serial Number: _____________________________

Date of Purchase: _____________________________

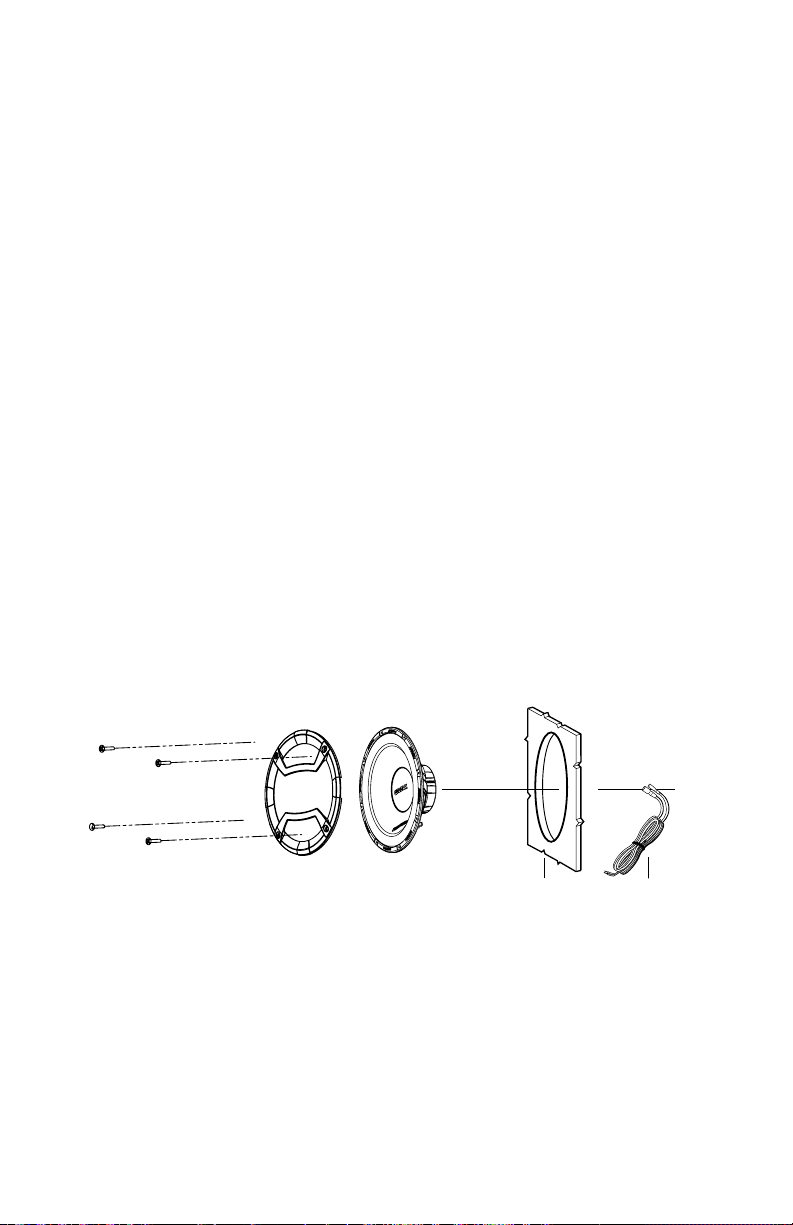

WHAT’S IN THE BOX

Included in this box are all the necessary mounting hardware and cables for your basic

installation. Listed below is a detailed list of the components included in this system package.

Quantity Description

1 Installation and Operation Manual

2 OrionTM Tweeter Elements

2 Surface mount hardware

2 Flush mount hardware

2 Orion

2 Passive crossovers with cables

1 Mounting template

2 Grills

Mounting screws

TM

mid/woofer speakers

INSTALLING PROCESS

The performance of the OrionTM Component Loudspeaker is directly proportional to the

quality of installation. Care taken during the installation process will be rewarded with years

of satisfying performance. If you are unsure about your installation capabilities, please refer

to your local Authorized Orion

professionals dedicated to extracting the maximum performance out of your OrionTM system.

If you decide to install this speaker system yourself, please read the entire installation section

before starting your installation.

TM

Dealer for technical assistance. OrionTM dealers are trained

TOOLS OF THE TRADE

Listed are the majority of the tools required to perform the installation. Having the proper tools

will make the installation much easier. It is very difficult when you get half way through the

installation and discover that you require a specific tool to get yourself through a particular part

of the installation. Some of these tools are necessities. Some make the job much easier.

o Marking Pen o Electric Drill

o 1/4" Drill Bit o Phillips Screwdriver

o 1/8" Drill Bit o Volt/Ohm Meter (Optional)

o 3/8" Drill Bit o Needle Nose Pliers

o Hole Saw Arbor o Assorted Tin Snips

o Wire Crimpers o Wire Strippers

o 4-3/4" Hole Saw (5-1/4" mid/woofer install.)

o 5-5/8" Hole Saw (6-1/2" mid/woofer install.)

o 1-7/8"Hole Saw (for flush mount tweeter installation.)

FINDING SPEAKER MOUNTING LOCATIONS

Choosing the correct speaker locations will have the greatest effect on the sound quality of the

system. Different considerations are needed when choosing the locations that best suit your

2 © 2009 directed electronics—all rights reserved

Page 4

needs. The locations must be large enough for the speakers to fit. Care is needed to ensure that

Inside

of Door

Speaker

cut out

Coaxial

Driver

Dampening Mat

Speaker installed

with no gaps

or air leaks

Dampening on

top of outer

door skin

Door

Panel

Grille

Screws

Inside

of Door

Speaker

cut out

Speaker installed

with no gaps

or air leaks

Dampening on

top of outer

door skin

Door

Panel

Rear/Trunk

of Car

Rear Seat

the location you have chosen will not affect any of the mechanical or electrical operations of

the vehicle.

Determining the best location for the speakers will depend on your cosmetic needs and your

vehicle's interior. If minimal intrusion in your vehicle is desired, factory speaker locations may

be the ticket for you. Placing the speaker in the factory location can often give very desirable

results.

DOOR MOUNTING

When checking for possible speaker locations in the doors, check the operation of the window

and all assemblies. There is also a stabilizer stop bar in between the door and the door jamb.

This bar prevents the door from opening too far. Many shade tree installers overlook this and

check for clearance only when the door is fully open.

Figure 1

Figura 1

Abbildung 1

REAR DECK MOUNTING

In rear deck installations, check the operation of the trunk suspension springs or tension bars.

These tension bars move in the opening and closing of the trunk. You cannot be too cautious

during this part of the installation, In addition, do not locate the speakers too close to the back

of the rear deck. Installing the far screws will only be possible with the removal of the rear

window.

Figure 2

Figura 2

Abbildung 2

© 2009 directed electronics—all rights reserved 3

Page 5

INSTALLING THE MID/WOOFERS

Flush Mount

Tweeter

Assembly

Tweeter

Cup

Pressure

Ring

Tweeter

Wire

Flush Mount

Trim Ring

Wiring

Harness

Panel

Wiring

Harness

Panel

Step 1: Determine where the speakers will be mounted. Make sure there is a flat area large

enough for the speakers to fit properly. An uneven mounting surface can damage the

driver.

Step 2: Check to make sure the space you have chosen for the speakers will not interfere with

the operation of the vehicle.

Step 3: Using the supplied template guide, mark the mounting hole and mounting screw hole

locations with a pen for each speaker.

Step 4: Cut the holes for the speaker. When using correctly sized factory locations, this step

can be passed. A hole can be cut either with a pair of metal tin snips, an air or jig saw,

or with a hole saw corresponding to the size of the midrange listed below.

o 4-3/4" Hole Saw (5-1/4" woofer installation)

o 5-5/8" Hole Saw (6-1/2" woofer installation)

WARNING: Check for clearance of window mechanisms and electrical wires BEFORE you drill.

Step 5: Run the speaker wire to the speakers. Make sure to keep wires away from sharp metal

or other edges. When passing through metal, use a protective grommet.

Step 6: Pre-drill mounting screw holes using a 1/8" drill bit.

WARNING: Check for clearance of window mechanisms and electrical wires BEFORE you drill.

Step 7: Pull the wire through the speaker opening and connect to the speaker. Be sure to

observe proper mid/woofer polarity during this process.

Step 8: Mount the speaker- Place the speaker and the grille in the installation hole. Align the

mounting screw holes and drive in the four mounting screws.

Figure 3

Figura 3

Abbildung 3

4 © 2009 directed electronics—all rights reserved

Page 6

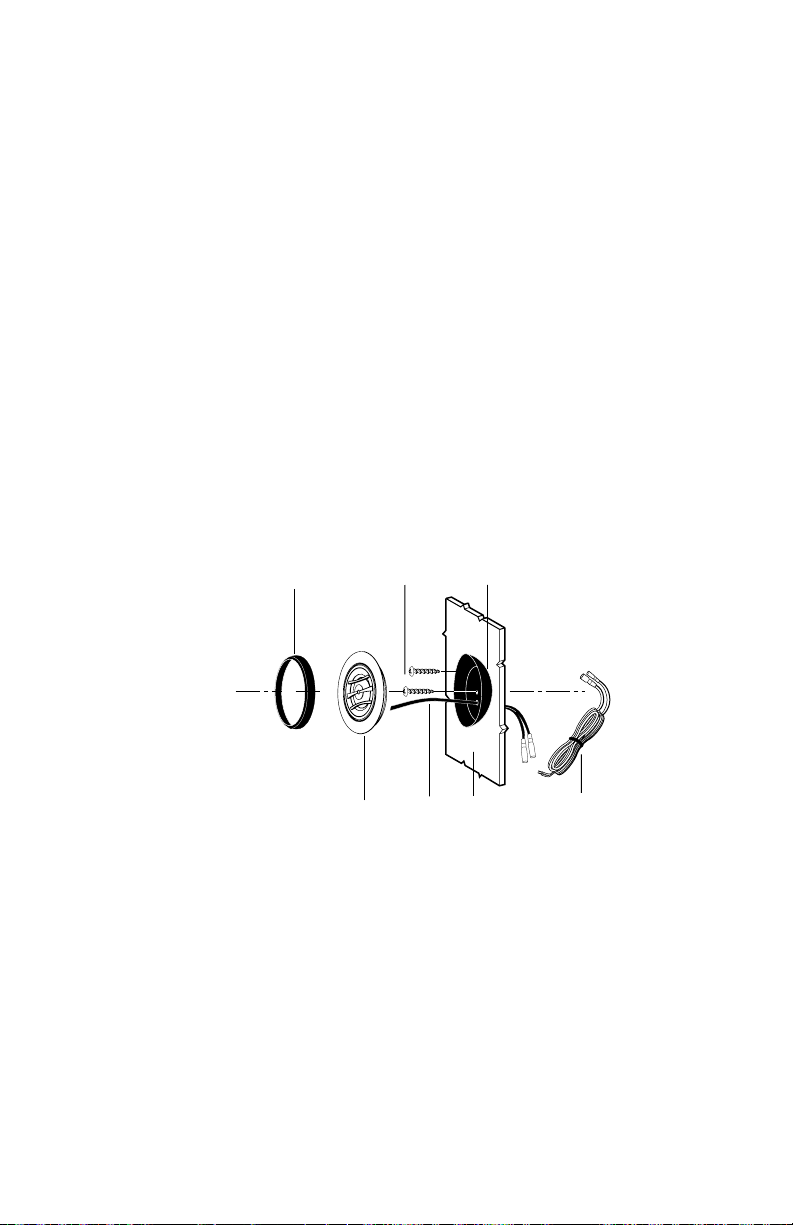

INSTALLING THE TWEETER

Surface

Mount

Trim Ring

Mounting

Screws

Surface Mount Housing

Tweeter

Tweeter

Wire

Panel

Wiring

Harness

SURFACE MOUNTING

Step 1: Determine the tweeter mounting location, then route the wires from the crossover to

Step 2: Place the provided template or tweeter cup against the panel and mark the two holes

Step 3: Drill the smaller holes using a 1/8" drill bit. These are the mounting screw holes.

WARNING: Check for clearance of window mechanisms and electrical wires BEFORE you drill.

Step 4: Drill the larger off-center hole using a 3/8" drill bit, insert a grommet and route the

Step 5: After removing the surface mount tweeter assembly trim ring, route the tweeter wires

Step 6: Insert the excess speaker wire into the hole and position the housing so the housing

Step 7: Attach the housing using the supplied screws of the correct length for a solid mount.

Step 8: Insert the tweeter into the housing and attach the surface mount trim ring.

the tweeter location.

at the rear of the housing.

speaker wire from the crossover through the grommet.

through the larger hole in the housing and connect to the speaker wires from the

crossover. (See Figure 4.)

will not pinch the wires after final mounting.

Figure 4

Figura 4

Abbildung 4

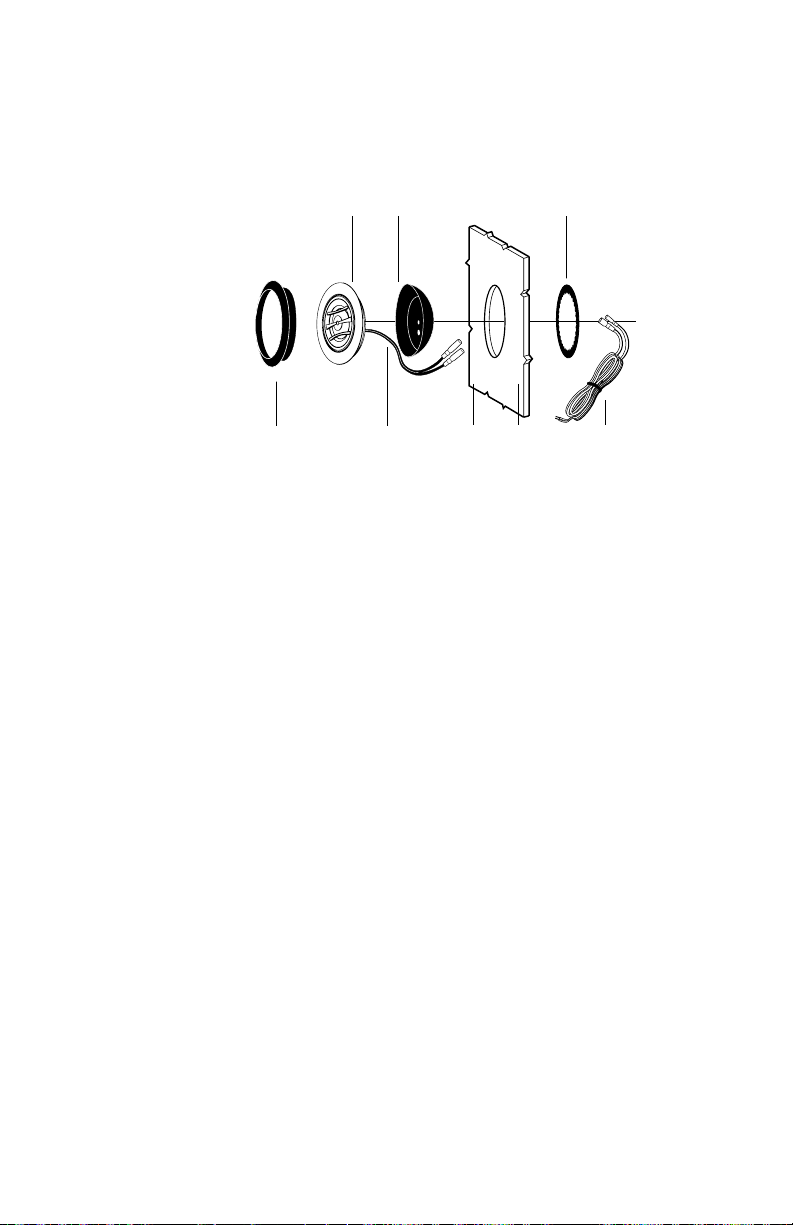

FULL FLUSH MOUNTING

Step 1:. Determine where the tweeter will be mounted. Make sure there is a flat area large

Step 2: Using the back half of the tweeter housing, mark with a pen the hole needed for the

Step 3: Be sure the hole is large enough for the tweeter housing, but not so large that the

Step 4: Cut the hole for the tweeter. When using factory locations, this step can be skipped.

WARNING: Check for clearance of window mechanisms and electrical wires BEFORE you drill.

© 2009 directed electronics—all rights reserved 5

enough for the tweeter and no obstructions behind the area.

tweeter.

flange will not cover the hole..

A hole can be cut either with a pair of metal tin snips or a 1-7/8" hole saw for hard

materials.

Page 7

Step 5: Install tweeter in flush mount housing.

Flush Mount

Tweeter

Assembly

Tweeter

Cup

Pressure

Ring

Tweeter

Wire

Flush Mount

Trim Ring

Wiring

Harness

Panel

Step 6: Connect the speaker wires observing the correct polarity.

Step 7: Install tweeter and housing in the hole cut for mounting, so that the trim ring is flat

Step 8: Use the supplied pressure ring to secure the housing to the surface.

with the front of the surface.

Figure 5

Figura 5

Abbildung 5

INSTALLING THE CROSSOVER

Step 1: Find a location for the crossover away from any factory or after market electrical wires.

Step 2: Mount the crossover using the supplied wire ties.

Step 3: Connect the wires. Make sure the speaker wires for the midrange go to the mid/

It is recommended to mount the passive crossover close to the amplifier.

woofer output and the tweeter to the tweeter output. Be sure to observe the correct

polarity. Changing the polarity of the tweeter may be necessary for optimum sound

quality.

6 © 2009 directed electronics—all rights reserved

Page 8

WIRING DIAGRAM

To woofer

To tweeter

To Amplifier

Note: The tweeter positive is the wire marked with the stripe.

Note: Le câble positif du haut-parleur d'aigus est rayé.

Nota. El positivo del tweeter es el cable que tiene la franja.

Hinweis: Der positive Hochtönerdraht ist mit dem Streifen markiert.

Nota: il filo positivo del tweeter è contrassegnato da una striscia.

Nota: O cabo positivo do tweeter está marcado com a listra.

OutputInput

+

_

+

_

+

_

Figure 6

Figura 6

Abbildung 6

© 2009 directed electronics—all rights reserved 7

Page 9

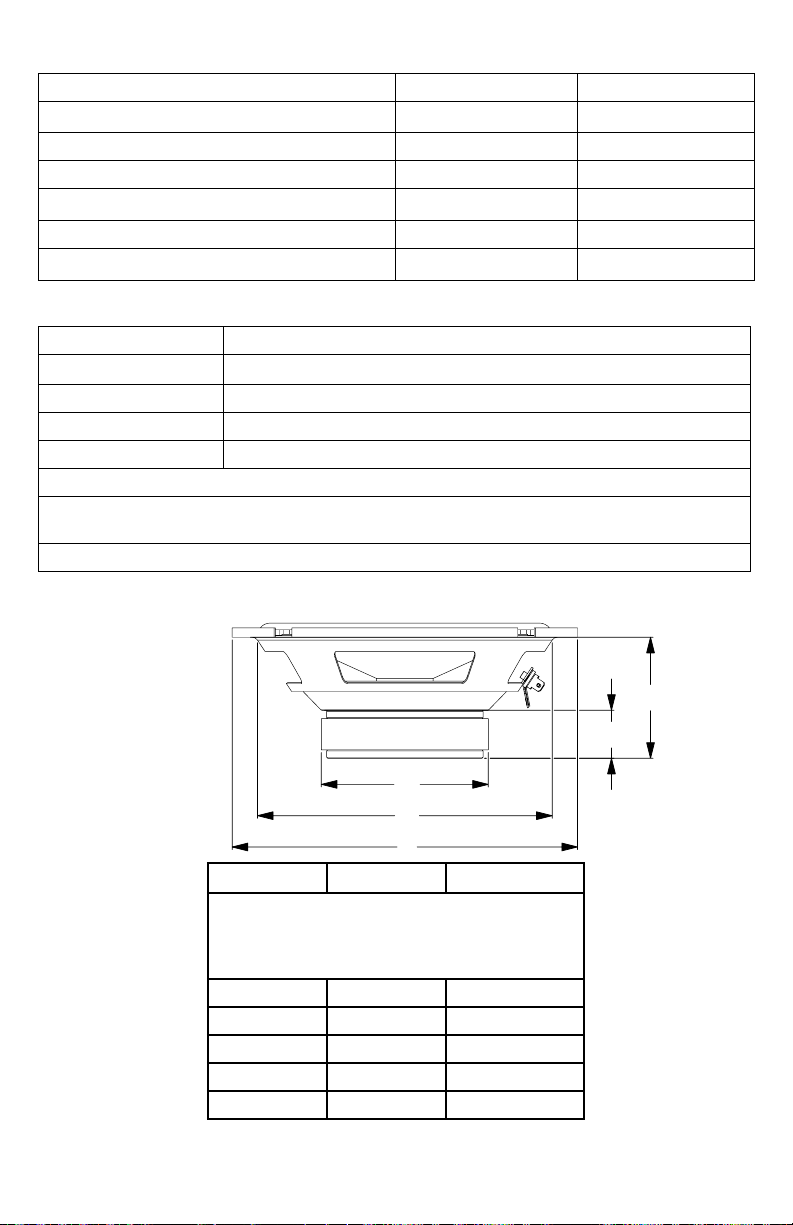

SPECIFICATIONS

E

D

A

B

C

Model/Part number CO552 CO652

Nominal Impedance

Power Continuous/Maximum 40 /100 w 50 /120 w

Frequency Response 120 -20kHz 60 - 20kHz

Sensitivity 87dB 85dB

Mounting Depth 1.97"/50mm 2.36"/60mm

Mounting Diameter 4.72"/120mm 5.63"/143mm

4 ohm

4 ohm

FEATURES

Cone moisture and UV resistant paper cone

Surround NBR (Nitrile butadiene rubber)

Voice Coil 2 layer copper clad aluminum wire on a Kapton former

Tweeter metalized PEI (Polyetherimide) - Ferrofluid

Spider single interlaced Conex

Stamped steel baskets with Euro mounting configurations

Two way systems have custom crossover with 6 dB high pass, 6 dB low pass and tweeter

protection

Swivel tweeter

NOTE: All Specifications are subject to change without notice.

Figure 7

Figura 7

Abbildung 7

CO552 CO652

Dimensions inches/mm, Dimensions pouces/mm,

Dimensiones plg./mm, Abmessungen Zoll/mm,

Dimensioni pollici/millimetri, Dimensões

polegadas/mm

A 1.97/50 2.36/60

B 0.71/18 0.91/23

C 2.76/70 3.15/80

D 4.72/120 5.63/143

E 5.12/130 6.50/165

8 © 2009 directed electronics—all rights reserved

Page 10

FRANÇAIS

OÙ MONTER LES HAUT-PARLEURS

Le choix du bon emplacement des haut-parleurs aura un effet majeur sur la qualité du son du

système. Plusieurs choses doivent être prises en considération pour faire le meilleur choix. Les

emplacements doivent être assez grands pour accueillir les haut-parleurs. Faites attention que

l'emplacement choisi n'affecte en aucune façon le fonctionnement mécanique et électrique du

véhicule.

Le meilleur emplacement pour les haut-parleurs dépend de vos goûts et de l'aménagement

intérieur du véhicule. Si vous voulez une installation aussi discrète que possible, les emplacements

prévus par le fabricant sont sans doute le meilleur choix. Cela donnera souvent d'excellents

résultats.

MONTAGE SUR UNE PORTIÈRE

Quand vous recherchez une location possible pour installer vos haut-parleurs dans les portières,

vérifiez le fonctionnement de la fenêtre et de tous les mécanismes. Vérifiez aussi la barre

stabilisatrice entre la portière et son montant. Elle empêche la portière de s'ouvrir trop grand.

Beaucoup d'installateurs inexpérimentés négligent ce détail et ne vérifient l'espace libre que

quand la porte est grand ouverte (figure 1).

MONTAGE DANS LE COFFRE

Pour une installation dans le coffre, vérifiez le fonctionnement des ressorts de suspension ou

barres de tension du coffre. Ces barres se déplacent durant l'ouverture et la fermeture du coffre.

On n'est jamais trop prudent durant cette partie de l'installation. De plus, ne placez pas les hautparleurs trop près de l'arrière du coffre. L'installation des vis les plus écartées n'est possible que

si on retire la vitre arrière (figure 2).

INSTALLATION DES HAUT-PARLEURS MÉDIAUX ET DE

GRAVES

Étape 1: Décidez où fixer les haut-parleurs et assurez-vous qu'il y ait une surface plane suffisante

Étape 2: Assurez-vous que l'emplacement choisi pour les haut-parleurs n'interfère pas avec le

Étape 3: Au moyen du gabarit de montage fourni et d'un crayon, marquez l'emplacement des

Étape 4: Découpez les trous pour le haut-parleur. Si vous utilisez les emplacements prévus par le

© 2009 directed electronics—all rights reserved 9

pour bien les fixer. Une surface de montage inégale peut endommager le moteur.

fonctionnement du véhicule.

trous de montage et des vis de montage pour chaque haut-parleur.

fabricant et qu'ils sont de la bonne dimension, cette étape peut être sautée. Utilisez

soit une paire de cisailles à tôles, une scie pneumatique ou sauteuse, ou une scie-cloche

de la taille correspondant à celle ci-dessous.

o Scie-cloche 4-3/4" (installation d'un haut-parleur de graves de 5-1/4")

o Scie-cloche 5-5/8" (installation d'un haut-parleur de graves de 6-1/2")

Page 11

ATTENTION: Vérifiez l'espace libre du mécanisme et des fils électriques des fenêtres AVANT de

percer.

Étape 5: Amenez les câbles à leurs haut-parleurs. Assurez-vous de les garder loin de tout bord

Étape 6: Pré-percez les trous de vis de montage avec une mèche 1/8".

ATTENTION: Vérifiez l'espace libre du mécanisme et des fils électriques des fenêtres AVANT de

percer.

Étape 7: Faites passer le câble par l'ouverture du haut-parleur et raccordez-le. Assurez-vous de

Étape 8: Montez le haut-parleur — Placez-le avec sa grille dans le trou d'installation. Alignez les

métallique ou autre aiguisé. Pour passer à travers le métal, utilisez une rondelle

isolante.

respecter la polarité du haut-parleur médial et de graves.

trous des vis de montage et vissez les quatre vis.

INSTALLATION DU HAUT-PARLEUR D'AIGUS

MONTAGE EN SURFACE

Étape 1: Décidez où fixer le haut-parleur d'aigus, puis amenez-y les câbles du répartiteur.

Étape 2: Placez le gabarit fourni ou le cône du haut-parleur d'aigus sur le panneau et marquez

Étape 3: Percez les petits trous avec une mèche 1/8". Ce sont les trous de montage.

ATTENTION: Vérifiez l'espace libre du mécanisme et des fils électriques des fenêtres AVANT de

percer.

Étape 4: Percez le grand trou excentré (mèche de 3/8"), insérez une rondelle isolante et faites-y

Étape 5: Ôtez la garniture de montage en surface, passez les câbles du haut-parleur d'aigus

Étape 6: Insérez le câble de haut-parleur en trop dans le trou et placez le logement afin qu'il ne

Étape 7: Pour un montage solide, utilisez les vis fournies de la bonne longueur pour attacher le

Étape 8: Insérez le haut-parleur d'aigus dans le logement et attachez la garniture.

les deux trous à l'arrière du logement.

passer le câble du haut-parleur vers le répartiteur.

par le grand trou du logement et raccordez aux câbles de haut-parleur du répartiteur

(figure 4.)

pince pas les câbles après le montage final.

logement.

MONTAGE ENCASTRÉ

Étape 1: Décidez où fixer le haut-parleur d'aigus et assurez-vous qu'il y ait une surface plane

Étape 2: Marquez le trou de montage nécessaire à l'aide d'un crayon et de la moitié arrière du

Étape 3: Assurez-vous que le trou est assez grand pour le logement du haut-parleur, mais pas trop

Étape 4: Coupez le trou du haut-parleur (inutile si vous utilisez les emplacements prévus par

ATTENTION: Vérifiez l'espace libre du mécanisme et des fils électriques des fenêtres AVANT de

percer.

Étape 5: Installez le haut-parleur dans le logement encastré.

Étape 6: Raccordez les câbles du haut-parleur en respectant la polarité.

10 © 2009 directed electronics—all rights reserved

suffisante pour bien le fixer, sans obstructions à l'arrière de la surface.

logement du haut-parleur.

grand pour être couvert par la flasque.

le fabricant). Utilisez des cisailles à tôles ou une scie-cloche 1-7/8" pour les matériaux

durs.

Page 12

Étape 7: Installez le haut-parleur et le logement dans le trou découpé pour le montage, afin que

Étape 8: Utilisez l'anneau de pression inclus pour fixer le logement à la surface.

la garniture soit au niveau de l'avant de la surface.

INSTALLATION DU RÉPARTITEUR

Étape 1: Décidez où fixer le répartiteur, loin de tout fil électrique, d'origine ou installé après

Étape 2: Montez le répartiteur avec les fils d'attache métalliques.

Étape 3: Raccordez les câbles. Assurez-vous que les câbles du haut-parleur médial vont à la sortie

NOTE: Diagramme de référence aux pages 4 - 7 (figure 3, 4, 5, 6)

coup. Le répartiteur passif devrait être monté à proximité de l'amplificateur.

médial/graves et ceux du haut-parleur d'aigus à la sortie des aigus. Assurez-vous de

respecter la polarité. Changer celle du haut-parleur d'aigus peut être requis pour une

qualité sonore optimale.

SPÉCIFICATIONS

Modèle/ Numéro de pièce CO552 CO652

Impédance nominale

Puissance continue/maximum 40 /100 w 50 /120 w

Réponse de fréquence 120 -20kHz 60 - 20kHz

Sensitivité 87dB 85dB

Profondeur de montage (pouces/mm) 1.97"/50mm 2.36"/60mm

Diamètre de montage (pouces/mm) 4.72"/120mm 5.63"/143mm

4 ohm

4 ohm

CARACTÉRISTIQUES

Cône Papier résistant à l'humidité et aux ultraviolets

Boîtier Nitrile

Bobine acoustique Fil d'aluminium recouvert de 2 couches de cuivre sur manchon

Haut-parleur d'aigus Polyétérimide métallisé - ferrofluide

Anneau de centrage Conex simple entrelacé

Paniers en acier matricé avec configuration de montage européen

Systèmes bidirectionnels avec répartiteur personnalisé: passe-haut 6 dB, passe-bas 6 dB et

protection du haut-parleur d'aigus

Haut-parleur d'aigus orientable

Kapton

NOTE: Toutes spécifications sujettes à changement sans préavis.

© 2009 directed electronics—all rights reserved 11

Page 13

Page 14

ESPAÑOL

UBICACIONES DE MONTAJE DE LOS ALTAVOCES

Escoger la ubicación correcta de los altavoces tendrá el mayor efecto en la calidad del sonido

del sistema. Es necesario que usted tenga en cuenta varias consideraciones cuando escoja el

lugar que mejor se adapte a sus necesidades. Los lugares escogidos deben ser lo suficientemente

grandes como para que quepan los altavoces. Es necesario que en la ubicación escogida no se

afecte ninguna operación mecánica o eléctrica del vehículo.

Determinar la mejor ubicación de los altavoces depende de sus necesidades cosméticas y del

interior del vehículo. Si desea interferir lo menos posible con el vehículo, las ubicaciones de

altavoz de fábrica son ideales. Colocar el altavoz en la ubicación de fábrica puede a menudo dar

muy buenos resultados.

MONTAJE EN LA PUERTA

Cuando esté buscando posibles ubicaciones de altavoz en las puertas, verifique el funcionamiento

de las ventanas y de todos los mecanismos de las puertas. También hay una barra de tope

estabilizadora entre la puerta y la jamba de la puerta. Esta barra evita que la puerta se abra

demasiado. Muchos instaladores informales olvidan esto y verifican que haya espacio sólo

cuando la puerta está completamente abierta (figura 1).

MONTAJE EN LA REPISA TRASERA

En las instalaciones en repisa trasera, verifique el funcionamiento de los resortes de suspensión o

barras de tensión de la tapa del maletero. Estas barras de tensión se mueven cuando se abre o se

cierra el maletero. Ser precavido nunca está de más durante esta parte de la instalación. Además,

no ubique los altavoces demasiado cerca del fondo de la repisa trasera. Montar los tornillos del

fondo será posible solamente quitando la ventana trasera (figura 2).

INSTALACIÓN DE LOS ALTAVOCES DE FRECUENCIAS MEDIAS

Y BAJAS

Paso 1: Determine el lugar en que va a montar los altavoces. Debe haber una superficie plana

Paso 2: Verifique que, en el lugar escogido, el altavoz no interfiera con el funcionamiento del

Paso 3: Con la plantilla guía suministrada y un lápiz, marque el agujero de montaje del altavoz

Paso 4: Haga los agujeros para los altavoces. Cuando instale los altavoces en ubicaciones de

© 2009 directed electronics—all rights reserved 13

suficientemente grande como para que los altavoces encajen correctamente. Las

superficies de montaje irregulares pueden dañar el excitador.

vehículo.

y los agujeros de los tornillos de montaje de los altavoces.

fábrica, este paso se puede omitir. El agujero se puede hacer con unas tijeras para cortar

metal, una sierra caladora o una sierra circular que corresponda al tamaño del altavoz

de frecuencias medias que se indica abajo.

Page 15

* Sierra circular de 4 3/4 plg. (woofer de 5 1/4 plg.)

* Sierra circular de 5 5/8 plg. (woofer de 6 1/2 plg.)

ADVERTENCIA: Verifique que haya espacio para los mecanismos de ventana y los cables

eléctricos ANTES de taladrar.

Paso 5: Encamine el cable de altavoz hasta los altavoces. Mantenga los cables de altavoz lejos

Paso 6: Haga de antemano los agujeros de montaje con una broca perforadora de 1/8 de plg.

ADVERTENCIA: Verifique que haya espacio para los mecanismos de ventana y los cables eléctricos

ANTES de taladrar.

Paso 7: Jale el cable a través de la abertura del altavoz y conéctelo al altavoz. Mantenga

Paso 8: Monte el altavoz. Coloque el altavoz y la rejilla en el agujero de instalación. Alinee los

de los bordes afilados de metal u otro material. Cuando pase los cables a través de

metal, ponga en el agujero una arandela de goma protectora.

la polaridad correcta de los altavoces de frecuencias medias y bajas durante este

proceso.

agujeros de los tornillos de montaje y atornille los cuatro tornillos de montaje.

INSTALACIÓN DEL TWEETER

MONTAJE EN SUPERFICIE

Paso 1: Determine la ubicación de montaje del tweeter y luego encamine los cables

Paso 2: Ponga la plantilla suministrada o la copa del tweeter contra el panel y marque los dos

Paso 3: Haga los agujeros pequeños con una broca de 1/8 plg. Estos son los agujeros de los

ADVERTENCIA: Verifique que haya espacio para los mecanismos de ventana y los cables eléctricos

ANTES de taladrar.

Paso 4: Haga el agujero grande excéntrico con una broca perforadora de 3/8 plg., inserte una

Paso 5. Después de quitar el anillo de guarnición de la unidad de tweeter para montaje en

Paso 6. Inserte el exceso de cable de altavoz en el agujero y ponga en posición el alojamiento

Paso 7. Fije el alojamiento con los tornillos suministrados de la longitud correcta para lograr un

Paso 8. Inserte el tweeter en el alojamiento y fije el anillo de guarnición de montaje en

provenientes del crossover hasta la ubicación del tweeter.

agujeros en la parte de atrás del alojamiento.

tornillos de montaje.

arandela de goma y encamine el cable de altavoz proveniente del crossover a través de

la arandela de goma.

superficie, encamine los cables del tweeter a través del agujero grande que hay en el

alojamiento y conecte los cables de altavoz provenientes del crossover (vea la Figura

4).

de manera que no vaya a aplastar los cables después del montaje final.

montaje sólido.

superficie.

MONTAJE AL RAS

Paso 1. Determine dónde va a montar el tweeter. Debe haber una superficie plana lo

Paso 2. Con la parte de atrás del alojamiento del tweeter y un lápiz, marque el agujero

Paso 3. El agujero debe ser lo suficientemente grande como para que quepa el alojamiento del

14 © 2009 directed electronics—all rights reserved

suficientemente grande como para que quepa el tweeter y no debe haber obstrucciones

detrás.

necesario para el tweeter.

tweeter, pero no tanto que el reborde no cubra el agujero.

Page 16

Paso 4. Haga el agujero para el tweeter. Cuando instale el tweeter en ubicaciones de fábrica,

ADVERTENCIA: Verifique que haya espacio para los mecanismos de ventana y los cables eléctricos

ANTES de taladrar.

Paso 5. Instale el tweeter en el alojamiento de montaje al ras.

Paso 6. Conecte los cables de altavoz con la polaridad correcta.

Paso 7. Instale el tweeter y el alojamiento en el agujero de montaje de manera que el anillo de

Paso 8. Con el anillo de presión suministrado, asegure el alojamiento contra la superficie.

este paso se puede omitir. Se puede hacer el agujero con unas tijeras de metal o una

sierra circular de 1 7/8 plg. para materiales duros.

guarnición quede de plano contra la superficie exterior.

INSTALACIÓN DEL CROSSOVER

Paso 1. Escoja una ubicación lejos de cables eléctricos de posventa o de fábrica para el

Paso 2. Monte el crossover con las amarras de cable suministradas.

Paso 3. Conecte los cables. Asegúrese de que los cables para el altavoz de frecuencias medias

Consulte el diagrama de las páginas 4 - 7 (figura 3, 4, 5, 6).

crossover. Se recomienda montar el crossover pasivo cerca del amplificador.

vayan a la salida de frecuencias medias y bajas y los del tweeter a la salida de tweeter.

Mantenga la polaridad correcta. Puede ser necesario cambiar la polaridad del tweeter

para lograr una calidad de sonido óptima.

ESPECIFICACIONES

Modelo/Número de pieza CO552 CO652

Impedancia nominal

Potencia continua/máxima 40 /100 w 50 /120 w

Respuesta de frecuencias 120 -20kHz 60 - 20kHz

Sensibilidad 87dB 85dB

Profundidad de montaje (plg/mm) 1.97"/50mm 2.36"/60mm

Diámetro de montaje (plg/mm) 4.72"/120mm 5.63"/143mm

4 ohm

4 ohm

CARACTERÍSTICAS

Cono cono de papel resistente a la humedad y los rayos ultravioleta

Envolvente Goma de Butadieno de Nitrilo (Nitrile Butadiene Rubber, NBR)

Bobina de voz Cable de cobre de 2 capas blindado de aluminio en un formador

Tweeter Polieterimida (Polyetherimide, PEI) metalizada. Ferrofluido

Araña Conex entrelazado de una pieza

Canastas de acero troquelado con configuraciones de montaje Euro

Los sistemas de dos canales tienen crossover a la medida con pasaaltas de 6 dB, pasabajas de

6 dB y protección de tweeter

Tweeter oscilante

Kapton

NOTA: Todas las especificaciones están sujetas a cambios sin aviso previo.

© 2009 directed electronics—all rights reserved 15

Page 17

Page 18

DEUTSCH

SO PLATZIEREN SIE DIE LAUTSPRECHER

Die Wahl der korrekten Lautsprecherposition hat große Auswirkungen auf die Soundqualität

des Systems. Bei der Wahl der Lautsprecherposition, die Ihren Ansprüchen am besten entspricht,

sind mehrere Faktoren zu beachten. Es muss an der Stelle genügend Platz für den Lautsprecher

vorhanden sein. Sie müssen sicherstellen, dass die gewählte Stelle die mechanischen oder

elektrischen Funktionen des Fahrzeugs nicht beeinträchtigt.

Die Wahl der geeigneten Einbaustelle hängt sowohl von ästhetischen Faktoren als auch vom

Innenraum Ihres Fahrzeugs ab. Wenn Sie das Fahrzeug nur minimal verändern wollen, sind die

werksseitigen Einbaustellen am besten. Der Einbau an diesen Stellen kann oft zu sehr guten

Ergebnissen führen.

TÜREINBAU

Wenn Sie mögliche Lautsprechereinbaustellen in den Türen suchen, müssen Sie die Funktionen

der Fenster und aller Baugruppen beachten. Zwischen der Tür und der Türschwelle befindet

sich eine Stabilisator-Anschlagleiste. Diese Leiste verhindert, dass die Tür sich zu weit öffnet.

Viele Amateur-Einbauer übersehen das und prüfen nur den Freiraum bei voll geöffneter Tür

(abbildung 1).

EINBAU IM KOFFERRAUM

Beim Einbau im Kofferraum ist auf die Funktionsfähigkeit der Kofferraumfedern oder Zugstäbe

zu achten. Diese Zugstäbe bewegen sich beim Öffnen und Schließen des Kofferraums. Seien Sie

bei diesem Teil der Installation besonders vorsichtig und platzieren Sie die Lautsprecher auch

nicht zu nahe an der Kofferraumhinterkante. Der Einbau der hinteren Schrauben ist erst nach

Ausbau des Rückfensters möglich (abbildung 2).

EINBAU DER MITTEL-/TIEFTÖNER

1. Schritt: Legen Sie fest, wo die Lautsprecher eingebaut werden. Vergewissern Sie sich, dass eine

2. Schritt: Stellen Sie sicher, dass die gewählte Stelle den Betrieb des Fahrzeugs auf keine Weise

3. Schritt: Verwenden Sie die beiliegende Schablone und markieren Sie das Einbauloch und die

4. Schritt: Schneiden Sie das jeweilige Loch für den Lautsprecher aus. Bei Verwendung der

© 2009 directed electronics—all rights reserved 17

für den fachgemäßen Einbau ausreichende ebene Fläche vorhanden ist. Eine unebene

Oberfläche kann den Treiber beschädigen.

behindert.

Positionen der Befestigungsschrauben für jeden Lautsprecher mit einem Stift.

werksseitigen Einbaustellen (die schon die richtige Größe haben) kann dieser Schritt

übersprungen werden. Man kann das Loch entweder mit einer Blechschere, einer

Pressluftsäge oder einer Stichsäge ausschneiden, je nach Größe des unten aufgelisteten

Mitteltöners.

* 4,75 Zoll Lochsäge (5,25 Zoll Tieftönerinstallation)

* 5,625 Zoll Lochsäge (6,5 Zoll Tieftönerinstallation)

Page 19

WARNUNG: Prüfen Sie VOR dem Bohren, dass Sie keine Fenstermechanismen oder Stromkabel

anbohren.

5. Schritt: Verlegen Sie die Lautsprecherkabel zu den Lautsprechern. Dabei müssen Sie die Kabel

6. Schritt: Bohren Sie die Befestigungsschraubenlöcher mit einem 1/8-Zoll-Bohrer vor.

WARNUNG: Prüfen Sie VOR dem Bohren, dass Sie keine Fenstermechanismen oder Stromkabel

anbohren.

7. Schritt: Ziehen Sie das Kabel durch die Lautsprecheröffnung und schließen Sie es an den

8. Schritt: Bauen Sie den Lautsprecher ein. Platzieren Sie hierzu den Lautsprecher und den Grill

von scharfen Metallkanten oder anderen Kanten entfernt halten. Bei der Verlegung

durch Metall ist eine Schutztülle zu verwenden.

Lautsprecher an. Beachten Sie dabei, dass die Mitteltöner/Tieftöner richtig gepolt

sind.

in der Einbauöffnung. Richten Sie die Befestigungsschraubenlöcher aus und ziehen Sie

die vier Befestigungsschrauben an.

EINBAU DES HOCHTÖNERS

OBERFLÄCHENEINBAU

1. Schritt: Legen Sie den Einbauort des Hochtöners fest und verlegen Sie dann die Kabel von der

2. Schritt: Legen Sie die beiliegende Schablone oder den Hochtönerbecher auf die Verkleidung

3. Schritt: Bohren Sie die kleineren Löcher mit einem 1/8-Zoll-Bohrer. Das sind die

WARNUNG: Prüfen Sie VOR dem Bohren, dass Sie keine Fenstermechanismen oder Stromkabel

anbohren.

4. Schritt: Bohren Sie das größere Loch neben der Mitte mit einem 3/8-Zoll-Bohrer, stecken

5. Schritt: Nachdem Sie die Blende der Hochtöner-Oberflächeneinbaugruppe entfernt haben,

6. Schritt: Führen Sie das nicht benötigte Lautsprecherkabel in das Loch ein und platzieren Sie das

7. Schritt: Bringen Sie das Gehäuse mit den beiliegenden Schrauben der richtigen Länge an, um

8. Schritt: Führen Sie den Hochtöner in das Gehäuse ein und bringen Sie die Blende für den

Crossover-Einheit zum Einbauort.

und markieren Sie die zwei Löcher an der Rückseite des Gehäuses.

Befestigungsschraubenlöcher.

Sie eine Schutztülle ein und verlegen Sie das von der Crossover-Einheit kommende

Lautsprecherkabel durch die Schutztülle.

führen Sie die Hochtönerkabel durch das größere Loch im Gehäuse und schließen

Sie sie an die von der Crossover-Einheit kommenden Lautsprecherkabel an. (Siehe

Abbildung 4.)

Gehäuse so, dass es nach dem Endeinbau das Kabel nicht einklemmt.

eine sichere Befestigung zu gewährleisten.

Oberflächeneinbau an.

BÜNDIGER EINBAU

1. Schritt: Legen Sie die Einbaustelle für den Hochtöner fest. Vergewissern Sie sich, dass eine für

2. Schritt: Verwenden Sie die Rückseite des Hochtönergehäuses, um das Loch für den Hochtöner

3. Schritt: Vergewissern Sie sich, dass das Loch für das Hochtönergehäuse groß genug ist, aber

4. Schritt: Schneiden Sie das Loch für den Hochtöner aus. Bei Verwendung der werksseitigen

18 © 2009 directed electronics—all rights reserved

den Einbau des Hochtöners ausreichende ebene Fläche vorhanden ist und dass sich

dahinter keine Hindernisse befinden.

mit einem Stift zu markieren.

nicht so groß, dass der Flansch das Loch nicht mehr abdeckt.

Einbaustellen kann dieser Schritt übersprungen werden. Sie können das Loch

entweder mit einer Blechschere oder einer 1-7/8-Zoll-Lochsäge für harte Oberflächen

Page 20

WARNUNG: Prüfen Sie VOR dem Bohren, dass Sie keine Fenstermechanismen oder Stromkabel

anbohren.

5. Schritt: Installieren Sie den Hochtöner im bündig eingebauten Gehäuse.

6. Schritt: Schließen Sie die Lautsprecherkabel an, wobei Sie auf die korrekte Polung achten

7. Schritt: Installieren Sie den Hochtöner und das Gehäuse im Einbauloch, wobei die Blende

8. Schritt: Verwenden Sie den beiliegenden Druckring, um das Gehäuse an der Oberfläche zu

ausschneiden.

müssen.

bündig mit der Oberfläche sein muss.

befestigen.

INSTALLATION DER CROSSOVER-EINHEIT

1. Schritt: Suchen Sie eine von werksseitig oder später verlegten Stromkabeln entfernte

2. Schritt: Befestigen Sie die Crossover-Einheit mit den beiliegenden Drahtbefestigungen.

3. Schritt: Schließen Sie die Kabel an. Vergewissern Sie sich, dass die Lautsprecherkabel für

Siehe Diagramm auf Seite 4 - 7 (Abbildung 3, 4, 5, 6).

Einbaustelle für die Crossover-Einheit. Die passive Crossover-Einheit sollte nahe am

Verstärker installiert werden.

den Mittelbereich an den Mittel-/Tieftönerausgang und die für den Hochtöner an

den Hochtönerausgang angeschlossen werden. Achten Sie dabei auf die korrekte

Polung. Um die optimale Klangqualität zu erreichen, ist eventuell eine Änderung der

Hochtönerpolung nötig.

DATEN

Modell/Teilenummer CO552 CO652

Nennimpedanz

Dauerleistung/Spitzenleistung 40 /100 w 50 /120 w

Frequenzgang 120 -20kHz 60 - 20kHz

Empfindlichkeit 87dB 85dB

Einbautiefe 50mm 60mm

Einbaudurchmesser 120mm 143mm

4 ohm

4 ohm

EIGENSCHAFTEN

Membran Feuchtigkeits- und UV-beständige Papiermembran

Sicke NBR (Nitrilgummi)

Schwingspule Zweischichtiger, kupferbeschichteter Aluminiumdraht auf Kapton-

Hochtöner Metallisiertes PEI (Polyetherimid) - Ferrofluid

Zentriermembran Conex, einfach verknüpft

Körbe aus Stahlblech mit Euro-Befestigungskonfiguration

Zweiwegsysteme haben spezielle Crossover-Einheiten mit 6 dB Hochpass, 6 dB Tiefpass und

Hochtönerschutz.

Schwenkbarer Hochtöner

Träger

HINWEIS: Alle Daten können ohne vorherige Ankündigung geändert werden

© 2009 directed electronics—all rights reserved 19

Page 21

Page 22

ITALIANO

INDIVIDUAZIONE DELLA POSIZIONE DI MONTAGGIO DEGLI

ALTOPARLANTI

La scelta della posizione degli altoparlanti ha la massima influenza sulla qualità del suono

dell'impianto. Nella scelta delle posizioni di montaggio che soddisfano meglio le proprie

esigenze, occorre considerare diversi fattori. Le posizioni devono offrire uno spazio sufficiente per

l'altoparlante. Accertarsi con cura che la posizione scelta non interferisca con il funzionamento

dei componenti meccanici o elettrici del veicolo.

La scelta della posizione migliore per gli altoparlanti dipende dalle esigenze estetiche del

proprietario e dalla configurazione dell'interno del veicolo. Se si desidera che il montaggio

interferisca il meno possibile con il veicolo, la cosa migliore è avvalersi delle sedi di montaggio

predisposte in fabbrica. Collocando l'altoparlante nella sede predisposta in fabbrica spesso si

ottengono risultati estremamente desiderabili.

MONTAGGIO SULLE PORTIERE

Quando si valutano le possibili posizioni di montaggio sulle portiere, controllare il funzionamento

dei finestrini e di tutti i componenti. Tra portiera e relativo montante c'è anche una barra

stabilizzatrice di arresto. La barra evita un'apertura eccessiva della portiera. Molti installatori

improvvisati trascurano questo fatto e controllano la distanza dalla barra solo quando la portiera

è completamente aperta (figura 1).

MONTAGGIO NEL PIANO PORTAOGGETTI POSTERIORE

In caso di montaggio nel piano portaoggetti posteriore, controllare il funzionamento delle molle

di sospensione o dei tiranti dello sportello del vano bagagli. Questi tiranti si muovono quando

si apre e chiude lo sportello. Prestare la massima attenzione durante questa fase del montaggio.

Inoltre, non collocare gli altoparlanti troppo vicini alla parte posteriore del piano portaoggetti.

In questo caso, sarà possibile inserire le viti esterne solo smontando il lunotto posteriore (figura

2).

INSTALLAZIONE DEI MIDRANGE/WOOFER

Fase 1: stabilire dove montare gli altoparlanti. Accertarsi che ci sia una superficie piana

Fase 2: accertarsi che lo spazio scelto per gli altoparlanti non interferisca con il funzionamento

Fase 3: usando come guida la dima appositamente fornita, segnare con una penna il contorno

Fase 4: praticare i fori per l'altoparlante. Quando si usano le sedi di montaggio della misura

© 2009 directed electronics—all rights reserved 21

abbastanza grande per montare correttamente gli altoparlanti. Una superficie di

montaggio irregolare può danneggiare il driver.

del veicolo.

del foro di installazione e la posizione dei fori per le viti di montaggio di ogni

altoparlante.

corretta predisposte in fabbrica, è possibile tralasciare queste operazioni. Eseguire il

foro con un paio di forbici da lattoniere, una sega pneumatica, un seghetto da traforo

Page 23

o una sega a tazza della misura dell'altoparlante indicata di seguito.

o sega a tazza da 4-3/4" (per installare un woofer da 5-1/4")

o sega a tazza da 5-5/8" (per installare un woofer da 6-1/2")

ATTENZIONE: controllare la distanza dai meccanismi e dai fili elettrici dei finestrini PRIMA di

eseguire i fori.

Fase 5: passare il filo fino all'altoparlante. Accertarsi di tenere i fili lontani da bordi od oggetti

Fase 6: eseguire i fori per le viti di montaggio usando una punta per trapano da 3,2 mm

ATTENZIONE: controllare la distanza dai meccanismi e dai fili elettrici dei finestrini PRIMA di

eseguire i fori.

Fase 7: tirare il filo attraverso l'apertura nell'altoparlante e collegarlo all'altoparlante stesso.

Fase 8: montare l'altoparlante - Collocare altoparlante e griglia nel foro di installazione.

di metallo taglienti. Quando si passano i fili in un foro in un oggetto metallico, usare

un anello di protezione.

(1/8").

Accertarsi di rispettare la polarità del midrange/woofer durante questo processo.

Allineare i fori per le viti di montaggio e inserire le quattro viti.

INSTALLAZIONE DEL TWEETER

MONTAGGIO A SUPERFICIE

Fase 1: stabilire la posizione di montaggio del tweeter, quindi passare i fili dal crossover al

Fase 2: collocare la dima fornita o il cestello del tweeter sul pannello e segnare i punti dei due

Fase 3: eseguire i fori più piccoli con una punta per trapano da 3,2 mm (1/8"). Sono i fori per

ATTENZIONE: controllare la distanza dai meccanismi e dai fili elettrici dei finestrini PRIMA di

eseguire i fori.

Fase 4: eseguire il foro centrale più grande usando una punta per trapano da 9,5 mm (3/8");

punto di montaggio del tweeter.

fori sulla parte posteriore del supporto.

le viti di montaggio.

inserire un anello e passare al suo interno il filo dell'altoparlante proveniente dal

crossover.

Fase 5: dopo aver smontato l'anello di finitura del montaggio a superficie del tweeter, passare

Fase 6: inserire nel foro il filo in eccesso e posizionare il supporto in modo che questo non

Fase 7: fissare il supporto usando le viti fornite della lunghezza corretta per un montaggio

Fase 8: inserire il tweeter nel supporto e fissare l'anello di finitura del montaggio a superficie.

MONTAGGIO A FILO

Fase 1: stabilire dove montare il tweeter. Accertarsi che ci sia una superficie piana abbastanza

Fase 2: usando la metà posteriore del supporto del tweeter, segnare con una penna il contorno

Fase 3: accertarsi che il foro sia grande abbastanza per il supporto del tweeter, ma non al

22 © 2009 directed electronics—all rights reserved

i fili del tweeter attraverso il foro più grande nel supporto e collegare i fili provenienti

dal crossover (vedere la figura 4).

schiacci i fili dopo il montaggio finale.

saldo.

Anello di finitura del montaggio a superficie.

grande per il tweeter e che non ci siano ostacoli dietro di essa.

del foro per il tweeter.

punto che la flangia non riesca a coprire il foro stesso.

Page 24

Fase 4: praticare il foro per il tweeter. Quando si inserisce l'altoparlante nelle sedi predisposte

ATTENZIONE: controllare la distanza dai meccanismi e dai fili elettrici dei finestrini PRIMA di

eseguire i fori..

Fase 5: installare il tweeter montandolo a filo sul supporto.

Fase 6: collegare i fili all'altoparlante rispettando la polarità corretta.

Fase 7: installare tweeter e supporto nel foro praticato per il montaggio in modo che l'anello

Fase 8: usare l'anello di arresto per fissare il supporto alla superficie.

in fabbrica, è possibile tralasciare queste operazioni. Eseguire il foro con un paio di

forbici da lattoniere o con una sega a tazza da 47,6 mm (1-7/8") per materiali duri.

di finitura sia a filo con la superficie esterna.

INSTALLAZIONE DEL CROSSOVER

Fase 1: trovare una posizione per il crossover lontano dai fili elettrici montati in fabbrica o

Fase 2: montare il crossover usando le fascette fermacavi appositamente fornite.

Fase 3: collegare i fili. Accertarsi che i fili del midrange vadano all'uscita per il midrange/

Vedere lo schema a pagina 4 - 7 (figura 3, 4, 5, 6).

successivamente. Si consiglia di montare il crossover passivo vicino all'amplificatore.

woofer quelli del tweeter all'uscita per il tweeter. Accertarsi di rispettare la polarità

corretta. Potrebbe essere necessario cambiare la polarità del tweeter per ottenere una

qualità ottimale del suono.

DATI TECNICI

Modello/Codice CO552 CO652

Impedenza nominale

Assorbimento continuo/massimo 40 /100 w 50 /120 w

Risposta in frequenza 120 -20kHz 60 - 20kHz

Sensibilità 87dB 85dB

Profondità di fissaggio 1.97"/50mm 2.36"/60mm

Diametro di fissaggio 4.72"/120mm 5.63"/143mm

4 ohm

4 ohm

CARATTERISTICHE

Cono Cono in carta resistente all'umidità e ai raggi ultravioletti

Surround NBR (gomma nitrile butadiene)

Bobina mobile Doppio strato di filo di alluminio rivestito di rame su un supporto in

Tweeter PEI (Polieterimide) metallizzato- Ferrofluido

Centratore Conex intrecciato

Telai in acciaio stampato con configurazioni di montaggio europee

Gli impianti a due vie hanno un crossover su misura con filtro passa alto da 6 dB, filtro passa

basso da 6 dB e protezione del tweeter

Tweeter girevole

Kapton

NOTA: tutti i dati tecnici possono essere modificati senza preavviso.

© 2009 directed electronics—all rights reserved 23

Page 25

Page 26

PORTUGUÊS

DETERMINAÇÃO DOS LOCAIS PARA INSTALAÇÃO DOS

ALTOS-FALANTES

A seleção dos locais corretos para instalação dos alto-falantes é o fator que mais influenciará a

qualidade do som produzido pelo sistema. É necessário considerar vários aspectos ao escolher

os locais mais adequados às suas necessidades. Os locais de instalação devem ser grandes o

suficiente para acomodar os alto-falantes e é necessário cuidado para assegurar que os locais

escolhidos não afetem nenhuma das funções mecânicas ou elétricas do veículo.

A determinação dos melhores locais para a instalação dos alto-falantes dependerá de suas

necessidades estéticas e do interior do veículo. Para minimizar a intrusão dos alto-falantes

na aparência interna do veículo, as posições predefinidas pela fábrica podem ser a solução

mais adequada. Colocar os alto-falantes nas posições definidas pela fábrica pode muitas vezes

produzir resultados muito satisfatórios.

INSTALAÇÃO NAS PORTAS

Ao verificar os possíveis locais de instalação dos alto-falantes nas portas, estude como

funcionam os vidros e todos os componentes das portas. Existe também uma barra de limitação

estabilizadora entre a porta e o batente. Ela evita que a porta se abra demasiadamente. Muitos

instaladores amadores ignoram esse detalhe e verificam apenas se existe espaço quando a porta

está totalmente aberta (figura 1).

INSTALAÇÃO NO PAINEL TRASEIRO

Nas instalações no painel traseiro, verifique como as molas de suspensão ou barras de tensão da

tampa do porta-malas funcionam. Essas barras de tensão se movimentam quando o porta-malas

é aberto e fechado. Muito cuidado é pouco durante essa parte da instalação. Além disso, não

posicione os alto-falantes muito próximos da parte de trás do painel traseiro, pois só será possível

apertar os parafusos mais afastados se o vidro traseiro for removido (figura 2).

INSTALAÇÃO DOS WOOFERS (ALTO-FALANTES PARA

PRODUÇÃO DE GRAVES MÉDIOS)

Etapa 1: Determine onde os alto-falantes serão instalados. Certifique-se de que seja uma área

Etapa 2: Certifique-se de que o espaço selecionado para a instalação dos alto-falantes não

Etapa 3: Usando o modelo de referência fornecido, marque com uma caneta o orifício de

Etapa 4: Corte os orifícios para instalação dos alto-falantes. Esta etapa pode ser ignorada para

© 2009 directed electronics—all rights reserved 25

plana e grande o suficiente para encaixar bem os alto-falantes. Uma superfície de

instalação desigual pode danificar o alto-falante.

interferirá com o funcionamento do veículo.

instalação e as posições dos parafusos de instalação de cada alto-falante.

instalação nos locais designados pela fábrica de tamanhos corretos. Um orifício pode

Page 27

ser cortado com uma tesoura para metal fina, uma serra tico-tico ou a ar, ou uma serra

copo correspondente ao tamanho do alto-falante de graves médios descrito abaixo.

•Serracopode120mm(4-3/4")parainstalaçãodowooferde133mm(5-14”)

•Serracopode143mm(5-5/8")parainstalaçãodowooferde165mm(6-1/2")

ATENÇÃO: Verifique se há espaço suficiente até os mecanismos e fios elétricos de operação do

vidro da janela ANTES de perfurar.

Etapa 5: Passe o cabo para caixa acústica até os alto-falantes. Mantenha os cabos afastados de

Etapa6:Perfureosorifíciosdeinstalaçãodosparafusosusandoumabrocade3,2mm(1/8”).

ATENÇÃO: Verifique se há espaço suficiente até os mecanismos e fios elétricos de operação do

Etapa 7: Puxe o cabo através da abertura do alto-falante e conecte-o ao alto-falante. Observe a

Etapa 8: Instale o alto-falante. Coloque o alto-falante e a grade no orifício de instalação. Alinhe

superfícies de metal ou outras bordas afiadas. Use um olhal de proteção ao passar o

cabo através de metal.

vidro da janela ANTES de perfurar.

polaridade correta do woofer durante este processo.

os orifícios dos parafusos de instalação e coloque e aperte os quatro parafusos.

INSTALAÇÃO DO TWEETER

INSTALAÇÃO NA SUPERFÍCIE

Etapa 1: Determine a localização de instalação do tweeter e passe os cabos do crossover até o

Etapa 2: Posicione o modelo fornecido ou a base do tweeter de encontro ao painel e marque a

Etapa3:Perfure os orifícios menores usandoumabroca de 3,2 mm (1/8”).Essesorifícios serão

ATENÇÃO: Verifique se há espaço suficiente até os mecanismos e fios elétricos de operação do

vidro da janela ANTES de perfurar.

Etapa4:Perfureoorifíciomaiordescentralizadousandoumabrocade9,5mm(3/8”),insiraum

Etapa 5: Depois de remover o anel de acabamento do conjunto de instalação em superfície do

Etapa 6: Insira o excesso de cabo para caixa acústica no orifício e posicione a carcaça de modo

Etapa 7: Fixe a carcaça usando os parafusos do tamanho correto fornecidos para proporcionar

Etapa 8: Insira o tweeter na carcaça e fixe o anel de acabamento para instalação na superfície.

local onde o tweeter será instalado.

posição dos dois orifícios localizados na parte traseira da carcaça.

usados para fixar a unidade com os parafusos.

olhal e passe o cabo para caixa acústica do crossover através do olhal.

tweeter, passe os cabos do tweeter através do orifício maior na carcaça e conecte-os aos

cabos para caixa acústica do crossover. (Ver a figura 4).

que não prense os cabos depois da instalação final.

uma instalação firme.

INSTALAÇÃO EMBUTIDA

Etapa 1: Determine onde o tweeter será instalado. O local selecionado deve ter uma área plana

Etapa 2: Usando a metade da carcaça do tweeter, marque com uma caneta o orifício necessário

Etapa 3: O orifício deve ser grande o suficiente para acomodar a carcaça do tweeter, mas não tão

Etapa 4: Corte o orifício para instalação do tweeter. Esta etapa pode ser ignorada para instalação

26 © 2009 directed electronics—all rights reserved

e grande o suficiente para acomodar o tweeter, sem nenhuma obstrução atrás.

para instalá-lo.

grande que o flange não cobrirá o orifício.

nos locais designados pela fábrica. Um orifício pode ser cortado com uma tesoura para

Page 28

metalouumaserracopode476mm(1-7/8”)paramateriaisduros.

ATENÇÃO: Verifique se há espaço suficiente até os mecanismos e fios elétricos de operação do

vidro da janela ANTES de perfurar.

Etapa 5: Instale o tweeter na carcaça para instalação embutida.

Etapa 6: Conecte os cabos para caixa acústica observando a polaridade correta.

Etapa 7: Instale o tweeter e a carcaça no orifício cortado para a instalação de modo que o anel

Etapa 8: Use o anel de pressão fornecido para prender a carcaça à superfície.

de acabamento fique alinhado com a superfície frontal.

INSTALAÇÃO DO CROSSOVER

Etapa 1: Encontre um local para a instalação do crossover afastado de todos os fios elétricos

Etapa 2: Instale o crossover usando as braçadeiras de metal fornecidas.

Etapa 3: Conecte os cabos. Certifique-se de que os cabos para caixa acústica do woofer sejam

Consulte o diagrama nas páginas 4 - 7 (figura 3, 4, 5, 6).

ESPECIFICAÇÕES

Modelo/Número do produto CO552 CO652

Impedância nominal

Potência contínua/máxima 40 /100 w 50 /120 w

Resposta de freqüência 120 -20kHz 60 - 20kHz

Sensibilidade 87dB 85dB

Profundidade de instalação (polegadas/mm) 1.97"/50mm 2.36"/60mm

Diâmetro de instalação (polegadas/mm) 4.72"/120mm 5.63"/143mm

instalados pela fábrica ou terceiros. Recomenda-se que o crossover passivo seja

instalado próximo do amplificador.

conectados à saída do woofer e o do tweeter à saída do tweeter. Certifique-se de que

a polaridade esteja correta. Pode ser necessário mudar a polaridade do tweeter para

maximizar a qualidade do som.

4 ohm

4 ohm

CARACTERÍSTICAS

Cone Cone de papel resistente à umidade e à radiação ultravioleta

Surround Borracha nitrílica (NBR)

Bobina móvel Fio de alumínio revestido de cobre de duas camadas em um copo

Tweeter Polieterimida (PEI) metalizada - Ferrofluido

Aranha Conex entrelaçado simples

Carcaças de aço estampado com configurações de instalação européias

Sistemas bidirecionais com crossover personalizado com passa-alta de 6 dB, passa-baixa de 6

dB e proteção de tweeter

Tweeter pivotante

Kapton

NOTA: Todas as especificações estão sujeitas a alterações sem aviso prévio.

© 2009 directed electronics—all rights reserved 27

Page 29

Page 30

WARRANTY

LIMITED ONE-YEAR CONSUMER WARRANTY/*LIMITED TWO-YEAR CONSUMER WARRANTY FOR AUTHORIZED

DIRECTED DEALER PURCHASE & INSTALLATION

Directed Electronics (herein “Directed”) promises to the original purchaser of the subwoofer or amplifier, as

applicable (herein “Unit” or “Product”), to repair or replace with a new or refurbished Unit (at Directed’s

sole and absolute discretion) should the Unit prove to be defective in workmanship or material under normal

use, for a period of *two-years from the date of purchase from the authorized Directed dealer PROVIDED

the Unit was purchased and installed by an authorized Directed dealer. During this *two-year period, there

will be no charge for the repair or replacement PROVIDED the Unit is returned to Directed (DO NOT RETURN

THE ENTIRE ENCLOSURE. PLEASE RETURN THE WARRANTIED UNIT ONLY.), shipping prepaid, along with the

required proof of installation, the bill of sale or other dated proof of purchase, and the consumer’s contact

information. If the Unit is installed by anyone other than an authorized Directed dealer, the warranty period

will be one-year from the date of purchase. This warranty is non-transferable and does not apply to any Unit

that has been modified or used in a manner contrary to its intended purpose, and does not cover damage to

the Unit caused by installation or removal of the Unit. During this one-year period, there will be no charge

for the repair or replacement PROVIDED the Unit is returned to Directed, shipping pre-paid, along with

the bill of sale or other dated proof of purchase and the consumer’s contact information. This warranty is

void if the product has been damaged by accident or unreasonable use, neglect, improper service or other

causes not arising out of defects in materials or construction. This warranty does not cover the elimination

of externally generated static or noise, or the correction of antenna problems or weak reception, damage to

speakers, accessories, electrical systems, cosmetic damage or damage due to negligence, misuse, failure to

follow operating instructions, accidental spills or customer applied cleaners, damage due to environmental

causes such as floods, airborne fallout, chemicals, salt, hail, lightning or extreme temperatures, damage due

to accidents, road hazards, fire, theft, loss or vandalism, damage due to improper connection to equipment

of another manufacturer, modification of existing equipment, or Product which has been opened or tampered for any reason. Units which are found to be damaged by abuse resulting in thermally damaged voice

coils are not covered by this warranty but may be replaced at the absolute and sole discretion of Directed.

Unit must be returned to Directed (DO NOT RETURN THE ENTIRE ENCLOSURE. THE UNIT ENCLOSURE IS COVERED BY A SEPARATE 90-DAY LIMITED CONSUMER WARRANTY. PLEASE ONLY RETURN THE WARRANTIED

UNIT UNLESS A WARRANTY CLAIM IS BEING MADE FOR THE ENCLOSURE.), postage pre-paid, with bill of sale

or other dated proof of purchase bearing the following information: consumer’s name, telephone number,

and address, authorized dealer’s name and address, and product description. Unit must be returned to the

following address: ATTN: WARRANTY DEPARTMENT, Directed Electronics , 1 Viper Way, Vista, CA 92081. Note:

This warranty does not cover labor costs for the removal and/or reinstallation of the Unit. IN ORDER FOR

THE TWO-YEAR WARRANTY TO BE VALID, YOUR UNIT MUST BE SHIPPED WITH PROOF OF INSTALLATION BY

AN AUTHORIZED DIRECTED DEALER. ALL UNITS RECEIVED BY DIRECTED FOR WARRANTY REPAIR WITHOUT

PROOF OF DIRECTED DEALER INSTALLATION AND PURCHASE WILL BE COVERED BY THE LIMITED 1 YEAR

WARRANTY.

BY PURCHASING THIS PRODUCT, ALL WARRANTIES INCLUDING BUT NOT LIMITED TO EXPRESS WARRANTY,

IMPLIED WARRANTY, WARRANTY OF MERCHANTABILITY, FITNESS FOR PARTICULAR PURPOSE, AND WARRANTY OF NON-INFRINGEMENT OF INTELLECTUAL PROPERTY ARE EXPRESSLY EXCLUDED TO THE MAXIMUM

EXTENT ALLOWED BY LAW, AND DIRECTED NEITHER ASSUMES NOR AUTHORIZES ANY PERSON TO ASSUME

FOR IT ANY LIABILITY IN CONNECTION WITH THE SALE OF THE PRODUCT. DIRECTED HAS ABSOLUTELY NO

LIABILITY FOR ANY AND ALL ACTS OF THIRD PARTIES INCLUDING ITS AUTHORIZED DEALERS OR INSTALLERS.

IN NO EVENT WILL DIRECTED BE LIABLE FOR ANY INCIDENTAL, SPECIAL OR CONSEQUENTIAL DAMAGES (INCLUDING LOSS OF PROFITS). BY PURCHASING THIS PRODUCT, THE CONSUMER AGREES AND CONSENTS THAT

ALL DISPUTES BETWEEN THE CONSUMER AND DIRECTED SHALL BE RESOLVED IN ACCORDANCE WITH CALIFORNIA LAWS IN SAN DIEGO COUNTY, CALIFORNIA. This warranty is only valid for sale of Product within the

United States of America. Product sold outside of the United States of America is sold “AS-IS,” and shall have

NO WARRANTY, express or implied. Some states do not allow limitation on how long an implied warranty

lasts. In such states, the limitation or exclusions of this Limited Warranty may not apply. Some states do not

allow the exclusion or limitation of incidental or consequential damages. In such states, the exclusion or limitation of this Limited Warranty may not apply to you. This Limited Warranty gives you specific legal rights,

and you may have other rights which vary from state to state. 920-0033 04-07

For more information on Orion products please visit www.orioncaraudio.com

Directed Electronics is committed to delivering

Directed Electronics is an

ISO 9001 registered company.

© 2009 Directed Electronics. All rights reser ved GCO552 2009-03

world class quality products and services

that excite and delight our customers.

Vista, CA 92081

WWW.DIRECTED.COM

Loading...

Loading...