Page 1

BUSH BTV17 GOODMANS GTV371VCR

CONTENTS

SERVICING NOTICES ON CHECKING.....................................................................................

HOW TO ORDER PARTS ..........................................................................................................

CONTENTS .................................................................................................................................

GENERAL SPECIFICATIONS....................................................................................................

DISASSEMBLY INSTRUCTIONS

1. REMOVAL OF MECHANICAL PARTS AND P. C. BOARDS............................................

2. REMOVAL OF DECK PARTS............................................................................................

3. REMOVAL OF ANODE CAP..............................................................................................

KEY TO ABBREVIATIONS ........................................................................................................

SERVICE MODE LIST ................................................................................................................

PREVENTIVE CHECKS AND SERVICE INTERVALS..............................................................

NOTE FOR THE REPLACING OF MEMORY IC .......................................................................

SERVICING FIXTURES AND TOOLS .......................................................................................

MECHANICAL ADJUSTMENTS ................................................................................................

ELECTRICAL ADJUSTMENTS..................................................................................................

BLOCK DIAGRAMS

TV ............................................................................................................................................

Y/C/AUDIO/HEAD AMP/21PIN/IN/OUT ..................................................................................

MICON/POWER/OPERATION/DECK.....................................................................................

T' TEXT ....................................................................................................................................

PRINTED CIRCUIT BOARDS

MAIN/CRT................................................................................................................................

OPERATION/DECK.................................................................................................................

SYSCON..................................................................................................................................

SCHEMATIC DIAGRAMS

Y/C/AUDIO/HEAD AMP ..........................................................................................................

MICON .....................................................................................................................................

POWER ...................................................................................................................................

21PIN/IN/OUT..........................................................................................................................

CHROMA/IF.............................................................................................................................

SOUND AMP ...........................................................................................................................

T' TEXT ....................................................................................................................................

TV POWER..............................................................................................................................

DEFLECTION ..........................................................................................................................

CRT..........................................................................................................................................

OPERATION............................................................................................................................

DECK .......................................................................................................................................

INTERCONNECTION DIAGRAM ...............................................................................................

WAVEFORMS .............................................................................................................................

MECHANICAL EXPLODED VIEWS...........................................................................................

CHASSIS EXPLODED VIEWS ...................................................................................................

MECHANICAL REPLACEMENT PARTS LIST .........................................................................

CHASSIS REPLACEMENT PARTS LIST..................................................................................

ELECTRICAL REPLACEMENT PARTS LIST...........................................................................

A1-1

A1-1

A2-1

A3-1~A3-6

B1-1, B1-2

B2-1~B2-5

B3-1, B3-2

C1-1, C1-2

C2-1

C3-1, C3-2

C4-1

C5-1, C5-2

D1-1~D1-4

D2-1~D2-6

E-1, E-2

E-3, E-4

E-5, E-6

E-7, E-8

F-1, F-2

F-3, F-4

F-5~F-8

G-1, G-2

G-3, G-4

G-5, G-6

G-7, G-8

G-9, G-10

G-11, G-12

G-13, G-14

G-15, G-16

G-17, G-18

G-19, G-20

G-21, G-22

G-23, G-24

G-25, G-26

H-1~H-3

I-1, I-2

I-3, I-4

J1-1

J2-1

J3-1~J3-3

A2-1

Page 2

DISASSEMBLY INSTRUCTIONS

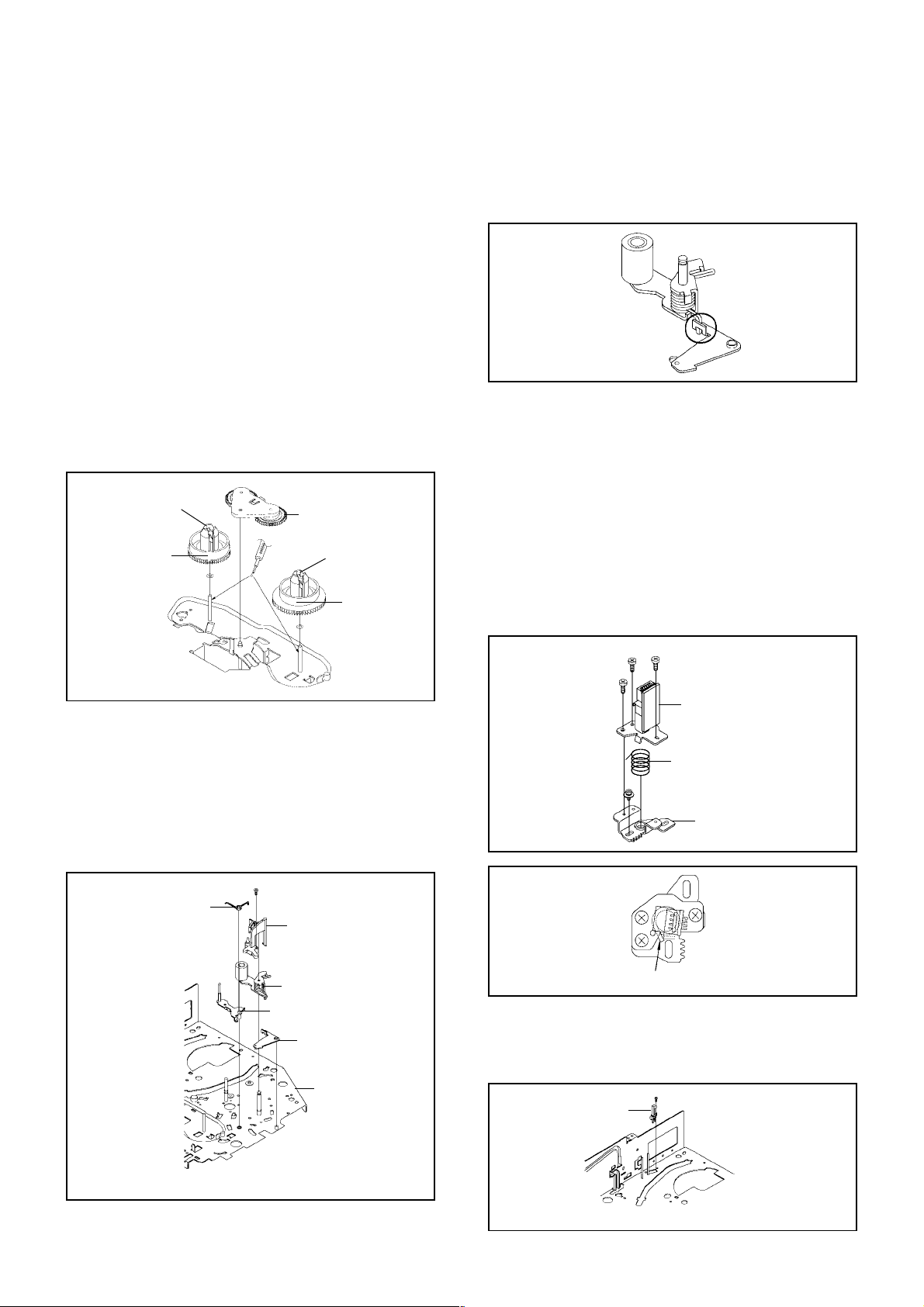

REMOVAL OF MECHANICAL PARTS

1.

AND P.C. BOARDS

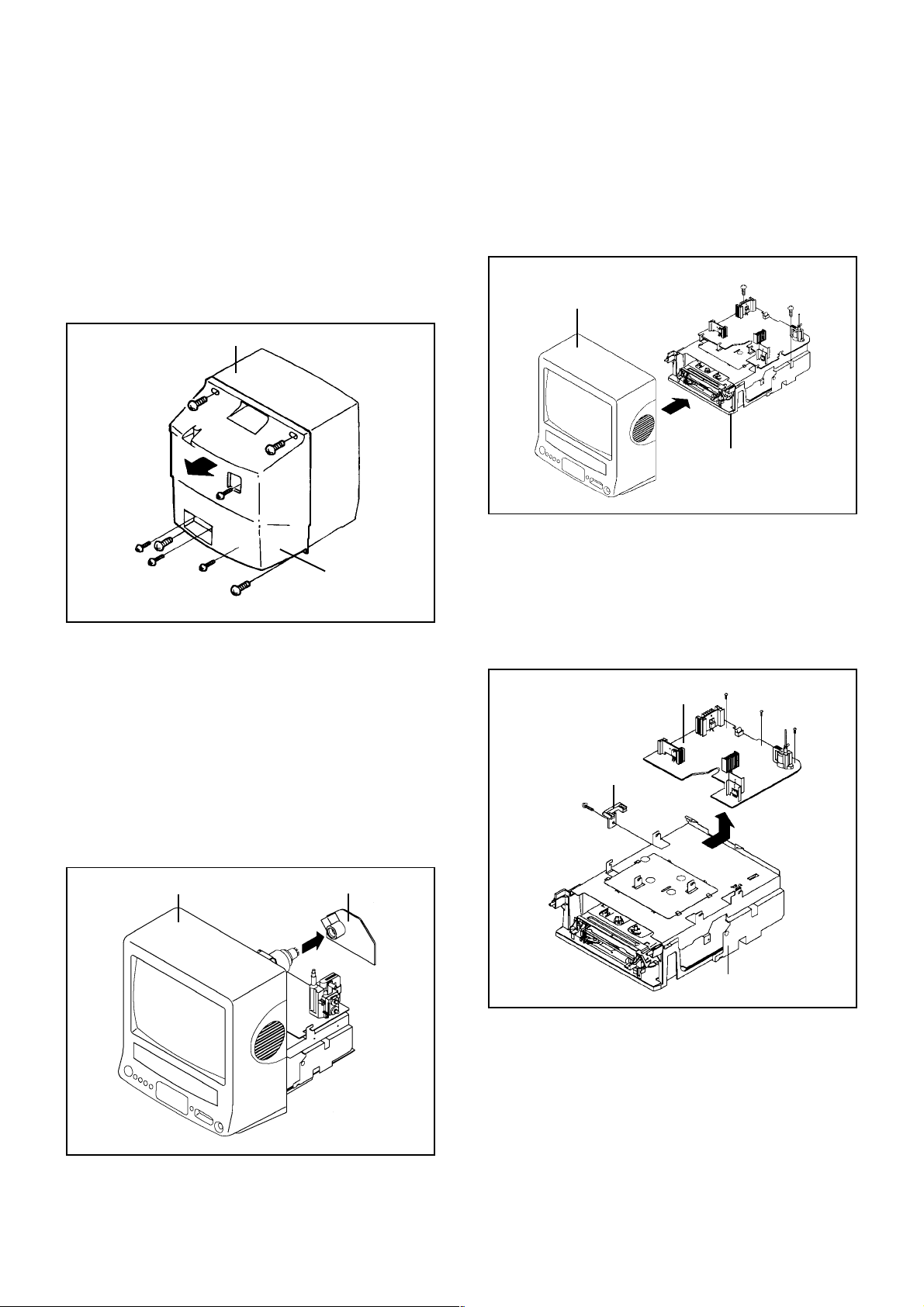

1-1: BACK CABINET (Refer to Fig. 1-1)

1.

Remove the 4 screws 1.

2.

Remove the 2 screws 2.

3.

Remove the 2 screws 3 which are used for holding the

Back Cabinet.

4.

Remove the AC cord from the AC cord hook 4.

5.

Remove the Back Cabinet in the direction of arrow.

Front Cabinet

1

1

2

3

1-2: CRT PCB (Refer to Fig. 1-2)

CAUTION: BEFORE REMOVING THE ANODE CAP,

1.

Remove the Anode Cap.

(Refer to REMOVAL OF ANODE CAP)

2.

Disconnect the following connectors:

(CP801 and CP850).

3.

Remove the CRT PCB in the direction of arrow.

1

3

2

1

4

Back Cabinet

Fig. 1-1

DISCHARGE ELECTRICITY BECAUSE IT

CONTAINS HIGH VOLTAGE.

BEFORE ATTEMPTING TO REMOVE OR

REPAIR ANY PCB, UNPLUG THE POWER

CORD FROM THE AC SOURCE.

1-3: TV/VCR BLOCK (Refer to Fig. 1-3)

1.

Remove the 2 screws 1.

2.

Disconnect the following connectors:

(CP351, CP757, CP302, CP403 and CP401).

3.

Unlock the support 2.

4.

Remove the TV/VCR Block in the direction of arrow.

1

Front Cabinet

UP TO

RELEASE

TV/VCR Block

1-4: MAIN PCB (Refer to Fig. 1-4)

1.

Remove the screw 1.

2.

Remove the Main PCB Holder.

3.

Remove the 3 screws 2.

4.

Disconnect the following connectors:

(CP810, CP820, CP404, CP501 and CP601).

5.

Remove the Main PCB in the direction of arrow.

Main PCB

Main PCB Holder

1

2

2

1

2

Fig. 1-3

2

Front Cabinet

CRT PCB

VCR Block

Fig. 1-4

Fig. 1-2

B1-1

Page 3

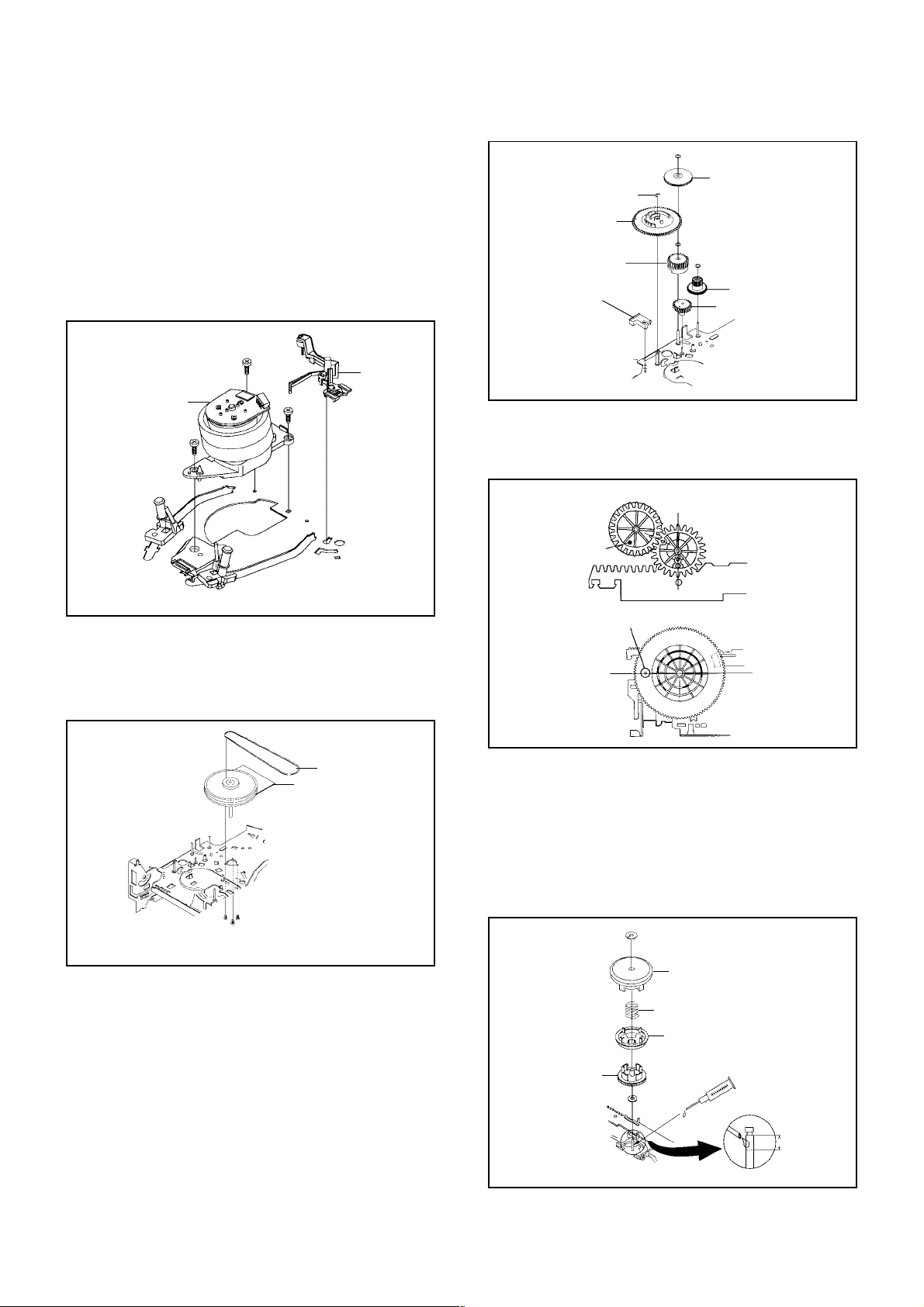

DISASSEMBLY INSTRUCTIONS

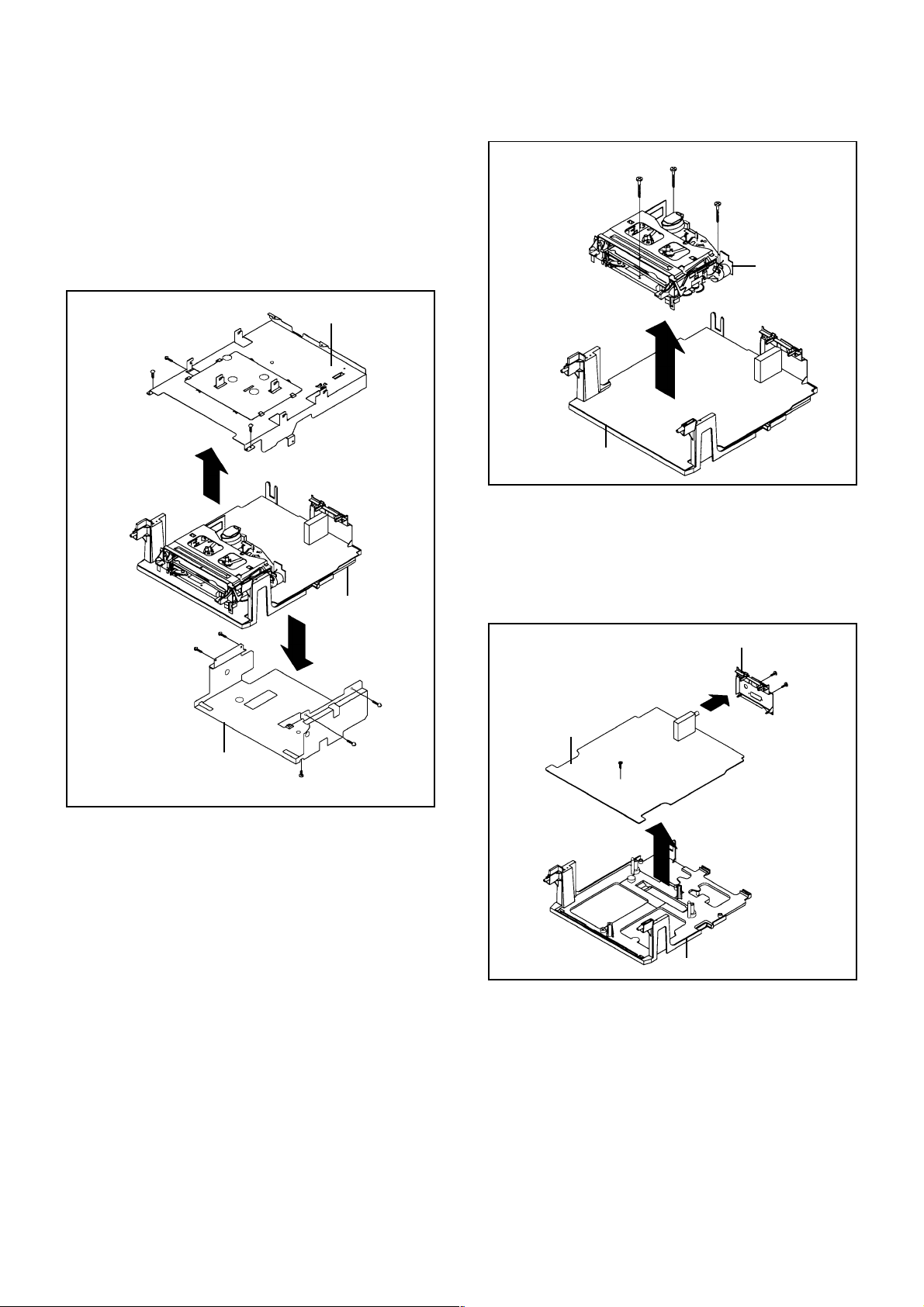

1-5:

DECK SHIELD PLATE AND BOTTOM SHIELD

PLATE (Refer to Fig. 1-5)

1.

Remove the 2 screws 1.

2.

Remove the 4 screws 2.

3.

Remove the screw 3.

4.

Remove the Deck Shield Plate in the direction of arrow (A).

5.

Remove the screw 4.

6.

Remove the Bottom Shield Plate in the direction of arrow (B).

Deck Shield Plate

3

1

1

(A)

VCR Block

2

2

Shield Plate Bottom

(B)

2

2

4

Fig. 1-5

1

1

1

Deck Chassis

Syscon PCB

Fig. 1-6

1-7: JACK PLATE AND SYSCON PCB (Refer to Fig. 1-7)

1.

Remove the screw 1.

2.

Remove the Syscon PCB in the direction of arrow (A).

3.

Remove the 2 screws 2.

4.

Unlock the 2 supports 3.

5.

Remove the Jack Plate in the direction of arrow (B).

Jack Plate

2

2

(B)

3

Syscon PCB

1

3

1-6: DECK CHASSIS (Refer to Fig. 1-6)

Remove the 3 screws 1.

1.

Disconnect the following connectors:

2.

(CP1001, CD1002, CP1004, CP1005, CP1006, CP4001,

CP4004 and CP4005).

Remove the Deck Chassis in the direction of arrow.

3.

B1-2

(A)

Deck Holder

Fig. 1-7

Page 4

DISASSEMBLY INSTRUCTIONS

2. REMOVAL OF DECK PARTS

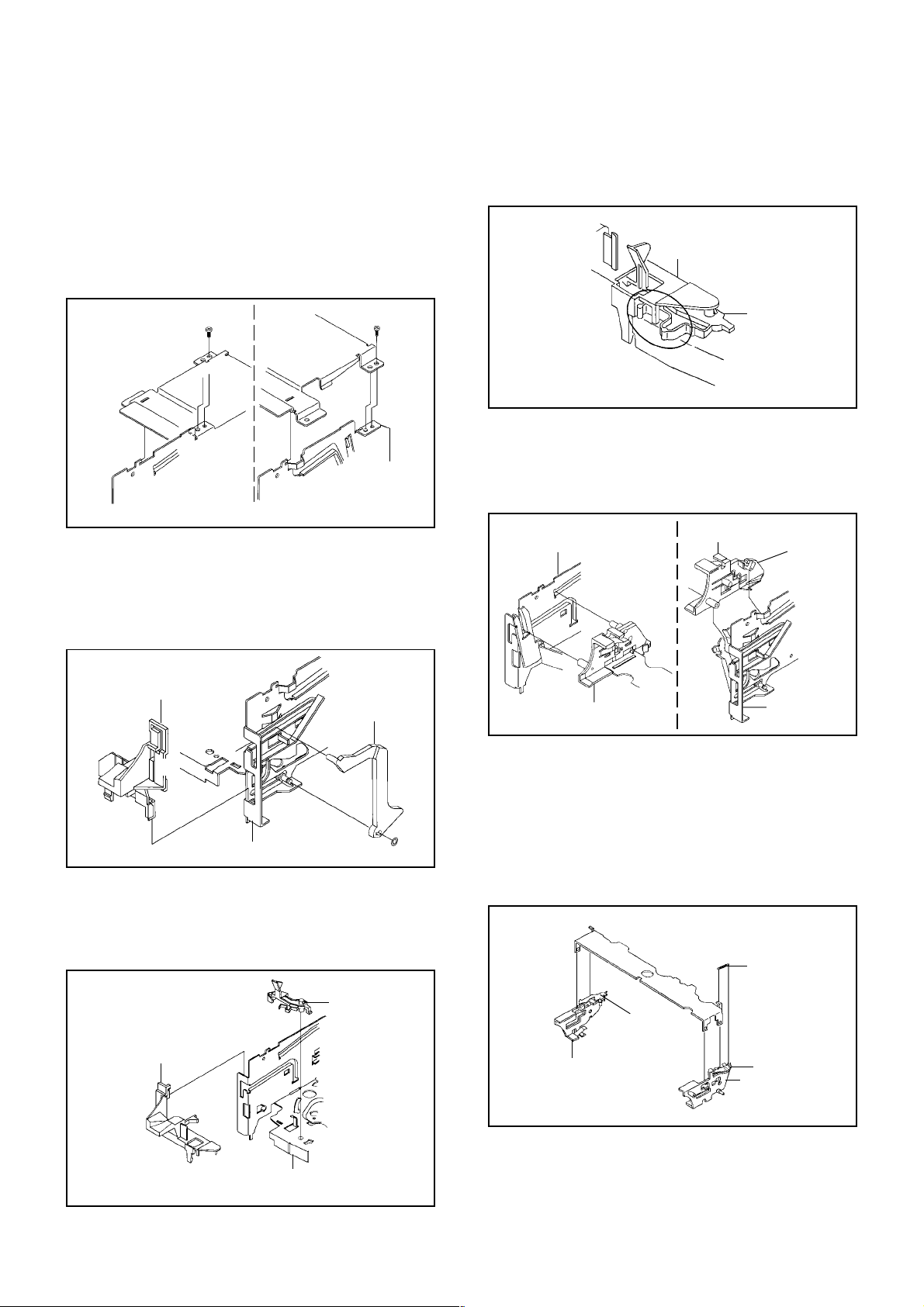

2-1: TOP BRACKET (Refer to Fig. 2-1)

Remove the 2 screws 1.

1.

Slide the 2 supports 2 and remove the Top Bracket.

2.

NOTE

When you install the Top Bracket, install the screw (1)

first, then install the screw (2).

(2)

1

Top Bracket

2

Main Chassis

• Screw Torque: 5 ± 0.5kgf•cm

Top Bracket

2

Main Chassis

2-2: FLAP LEVER/TAPE GUIDE R (Refer to Fig. 2-2)

Move the Cassette Holder Ass'y to the back side.

1.

Remove the Polyslider Washer 1.

2.

Remove the Flap Lever.

3.

Unlock the 3 supports 2 and remove the Tape Guide R.

4.

(1)

1

Fig. 2-1

NOTE

When you install the Tape Guide L, install as shown in the

circle of Fig. 2-3-B. (Refer to Fig. 2-3-B)

Tape Guide L

REC Lever

• The REC Lever is not installed on the Video Cassette Player.

Fig. 2-3-B

2-4: CASSETTE HOLDER ASS'Y (Refer to Fig. 2-4)

Move the Cassette Holder Ass'y to the front side.

1.

Push the Locker R to remove the Cassette Side R.

2.

Remove the Cassette Side L.

3.

Main Chassis

Cassette Side R

Locker R

Tape Guide R

Flap Lever

2

2

2

Main Chassis

Fig. 2-2

2-3: TAPE GUIDE L (Refer to Fig. 2-3-A)

Move the Cassette Holder Ass'y to the back side.

1.

Unlock the 2 supports 1 and remove the Tape Guide L.

2.

Remove the REC Lever. (Recorder only)

3.

REC Lever

Tape Guide L

1

Cassette Side L

Main Chassis

Fig. 2-4

2-5: CASSETTE SIDE L/R (Refer to Fig. 2-5)

Remove the Locker Spring.

1.

Unlock the 4 supports 1 and then remove the Cassette

2.

1

Side L/R.

NOTE

When you install the Cassette Side L/R, be sure to move

the Locker L/R after installing.

1

1

Locker Spring

Locker R

Cassette Side R

1

1

Locker L

Cassette Side L

Fig. 2-5

1

Main Chassis

• The REC Lever is not installed on the Video Cassette Player.

Fig. 2-3-A

B2-1

Page 5

DISASSEMBLY INSTRUCTIONS

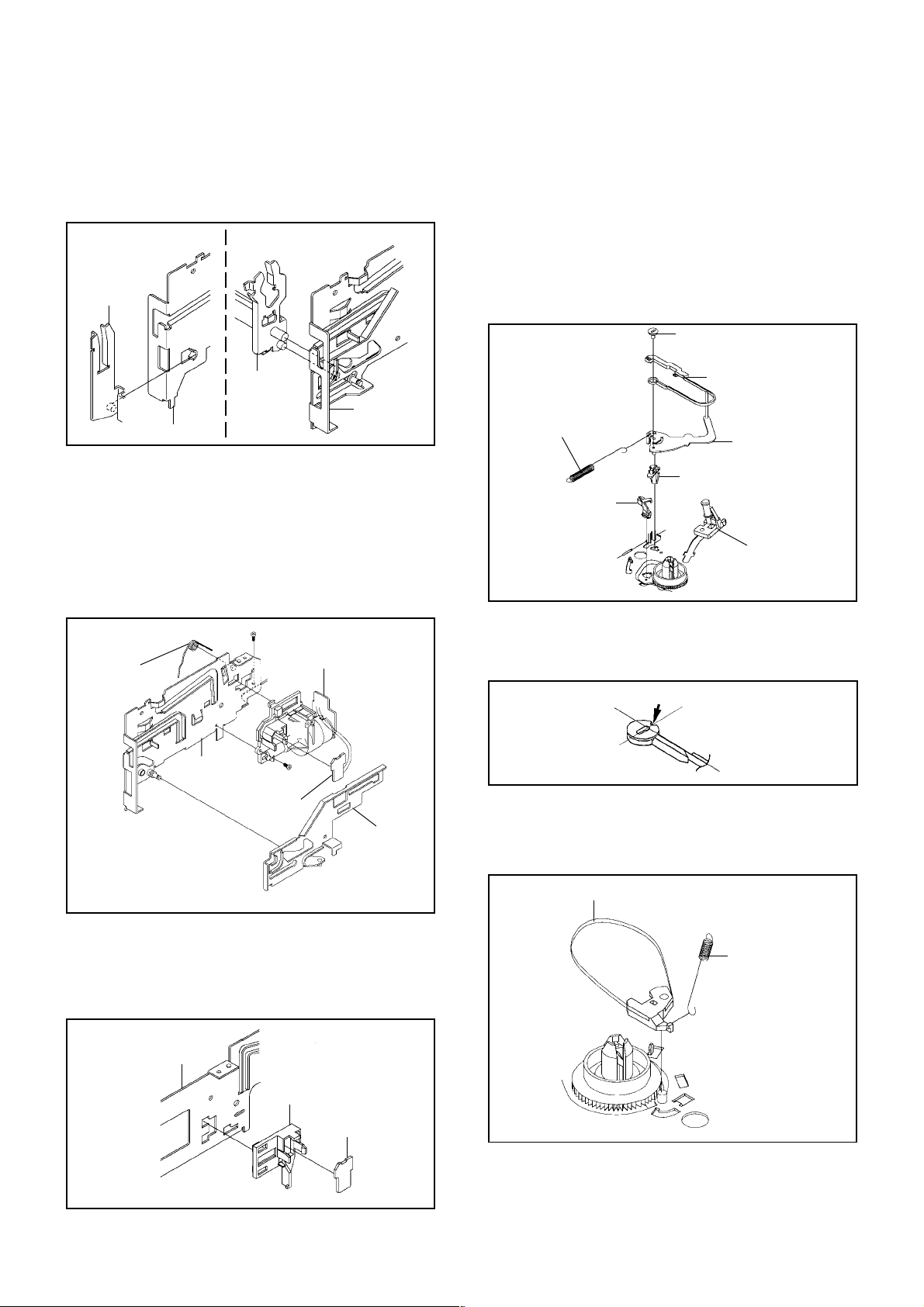

2-6: LINK ASS'Y (Refer to Fig. 2-6)

Set the Link Ass'y to the Eject position.

1.

Remove the (A) side of the Link Ass'y first, then remove

2.

the (B) side.

Link Ass'y

(A)

Main Chassis

(B)

Link Ass'y

Main Chassis

Fig. 2-6

2-7: LOADING MOTOR ASS'Y (Refer to Fig. 2-7)

Remove the Link Lever.

1.

Remove the Dumper Spring.

2.

Remove the 2 screws 1.

3.

Unlock the support 2 and remove the Loading Motor

4.

Ass'y.

Unlock the 2 supports 3 and remove the Deck PCB

5.

(BOT).

1

Dumper Spring

Loading Motor Ass'y

2

2-9: TENSION ASS'Y (Refer to Fig. 2-9-A)

Move the Inclined S Ass'y to the back side.

1.

Unlock the support 1 and remove the S Reel Stopper.

2.

Remove the Tension Spring.

3.

Unlock the support 2 and remove the Tension Arm

4.

Ass'y.

Remove the Tension Adjust.

5.

Unlock the 2 supports 3 and remove the Tension Band

6.

Ass'y.

Unlock the support 4 and remove the Tension Holder.

7.

Tension Adjust

3

3

Tension Spring

2

4

S Reel Stopper

1

Tension Band Ass'y

Tension Arm Ass'y

Tension Holder

Inclined S Ass'y

Fig. 2-9-A

NOTE

When you install the Tension Adjust, install as shown in

Fig. 2-9-B. (Refer to Fig. 2-9-B)

Adjust the direction of the Marker to inside.

3

Main Chassis

• Screw Torque: 5 ± 0.5kgf•cm

1

Deck PCB

(BOT)

Link Lever

2-8: SENSOR COVER L (Refer to Fig. 2-8)

Unlock the support 1 and remove the Sensor Cover L.

1.

Unlock the 2 supports 2 and remove the Deck PCB

2.

(EOT).

Main Chassis

Sensor Cover L

Deck PCB

(EOT)

1

2

2

Fig. 2-8

Fig. 2-7

2-10: T BRAKE ASS'Y (Refer to Fig. 2-10)

Remove the T Brake Spring.

1.

Remove the T Brake Ass'y.

2.

T Brake Ass'y

T Brake Spring

Fig. 2-9-B

Fig. 2-10

B2-2

Page 6

DISASSEMBLY INSTRUCTIONS

2-11: S REEL/T REEL ASS'Y (Refer to Fig. 2-11)

Remove the Idler Ass'y.

1.

Remove the S Reel and T Reel Ass'y.

2.

Remove the 2 Polyslider Washers 1.

3.

NOTE

Take care not to damage the gears of the S Reel, T

1.

Reel Ass'y and Idler Ass'y.

The Polyslider Washer may be remained on the back of

2.

the reel.

Take care not to damage the shaft.

3.

Do not touch the section "A" of S Reel and T Reel Ass'y.

4.

(Use gloves.) (Refer to Fig. 2-11) Do not adhere the

stains on it.

When you install the reel, clean the shaft and oil it

5.

(KYODO OIL Slidas #150). (If you do not oil, noise may

be heard in FF/REW mode.)

After installing the reel, adjust the height of the reel.

6.

(Refer to MECHANICAL ADJUSTMENT)

S Reel

(A)

1

Idler Ass'y

T Reel Ass'y

(A)

1

Fig. 2-11

NOTE

Do not touch the Pinch Roller. (Use gloves.)

1.

When you install the Pinch Roller Ass'y, install as

2.

shown in the circle. (Refer to Fig. 2-12-B)

Fig. 2-12-B

2-13: A/C HEAD (Refer to Fig. 2-13-A)

Remove the screw 1.

1.

Remove the A/C Head Base.

2.

Remove the 3 screws 2.

3.

Remove the A/C Head and A/C Head Spring.

4.

NOTE

Do not touch the A/C Head. (Use gloves.)

1.

When you install the A/C Head Spring, install as shown

2.

in Fig. 2-13-B. (Refer to Fig. 2-13-B)

When you install the A/C Head, tighten the screw (1)

3.

first, then tighten the screw (2), finally tighten the screw

(3).

(3)

(1)

2

2

(2)

2

A/C Head

2-12: PINCH ROLLER ASS'Y/P5 ARM ASS'Y

(Refer to Fig. 2-12-A)

Remove the P5 Spring.

1.

Remove the screw 1.

2.

Unlock the 2 supports 2 and remove the Cassette

3.

Opener.

Remove the Pinch Roller Ass'y, Pinch Roller Lever and

4.

P5 Arm Ass'y.

1

P5 Spring

2

Cassette Opener

2

Pinch Roller Ass'y

P5 Arm Ass'y

Pinch Roller Lever

Main Chassis

A/C Head Spring

1

A/C Head Base

Fig. 2-13-A

Spring Position

Fig. 2-13-B

2-14: FE HEAD (RECORDER ONLY) (Refer to Fig. 2-14)

Remove the screw 1.

1.

Remove the FE Head.

2.

FE Head

1

• Screw Torque: 5 ± 0.5kgf•cm

Fig. 2-12-A

B2-3

• The FE Head is not installed on the Video Cassette Player.

Fig. 2-14

Page 7

DISASSEMBLY INSTRUCTIONS

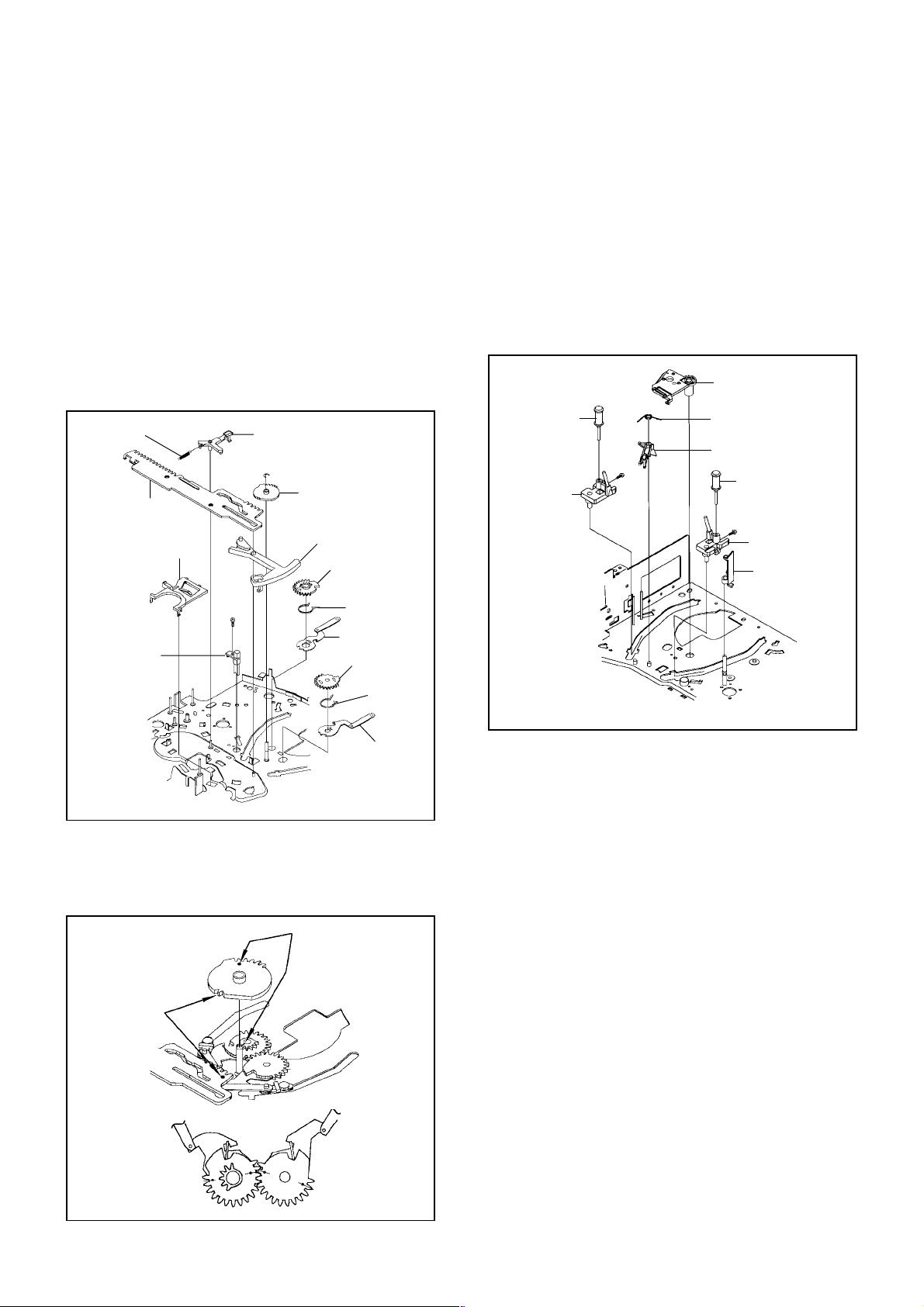

2-15: AHC ASS'Y/CYLINDER UNIT ASS'Y

(Refer to Fig. 2-15)

Unlock the support 1 and remove the AHC Ass'y.

1.

Remove the 3 screws 2.

2.

Remove the Cylinder Unit Ass'y.

3.

NOTE

When you install the Cylinder Unit Ass'y, tighten the

screws from (1) to (3) in order while pulling the Ass'y

toward the left front direction.

2

Cylinder Unit Ass'y

2

(2)

(3)

2

(1)

AHC Ass'y

1

1

Middle Gear

E-Ring

Main Cam

2

Pinch Roller Cam

Link Lever Spacer

3

Joint Gear

P5 Cam

Fig. 2-17-A

NOTE

When you install the Pinch Roller Cam, P5 Cam and Main

Cam, align each marker. (Refer to Fig. 2-17-B)

Pinch Roller Cam

Check the hole of Main

Chassis can be seen.

P5 Cam

• Screw Torque: 5 ± 0.5kgf•cm

Fig. 2-15

2-16: CAPSTAN DD UNIT (Refer to Fig. 2-16)

Remove the Capstan Belt.

1.

Remove the 3 screws 1.

2.

Remove the Capstan DD Unit.

3.

Capstan Belt

Capstan DD Unit

1

1

1

• Screw Torque: 5 ± 0.5kgf•cm

Fig. 2-16

2-17: MIDDLE GEAR/MAIN CAM (Refer to Fig. 2-17-A)

Remove the Polyslider Washer 1, then remove the

1.

Middle Gear.

Remove the E-Ring, then remove the Main Cam, Link

2.

Lever Spacer and P5 Cam.

Remove the Polyslider Washer 2, then remove the

3.

Pinch Roller Cam.

Remove the Polyslider Washer 3, then remove the

4.

Joint Gear.

Main Cam

Marker

Fig. 2-17-B

2-18: CLUTCH ASS'Y (Refer to Fig. 2-18)

Remove the Polyslider Washer 1.

1.

Remove the Clutch Ass'y, Ring Spring, Ring Clutch,

2.

Gear Clutch and Polyslider Washer 2.

NOTE

When you install the Clutch Ass'y, oil the shaft (KYODO

OIL Slidas #150).

1

Clutch Ass'y

Ring Spring

Ring Clutch

Gear Clutch

2

App. 5mm

B2-4

Fig. 2-18

Page 8

DISASSEMBLY INSTRUCTIONS

2-19: LOADING GEAR S/T ASS'Y (Refer to Fig. 2-19-A)

Remove the E-Ring 1 and remove the Main Loading

1.

Gear.

Remove the Capstan Brake Spring.

2.

Slide the Main Rod and remove the Capstan Brake

3.

Arm Ass'y.

Remove the Main Rod.

4.

Remove the Tension Lever.

5.

Unlock the 2 supports 2 and remove the Clutch Lever.

6.

Remove the screw 3.

7.

Remove the LED Reflector.

8.

Remove the Loading Arm S Ass'y and Loading Arm T

9.

Ass'y.

Remove the Loading Gear S and Loading Gear T.

10.

Remove the Loading Gear Spring.

11.

Capstan Brake Spring

Main Rod

Clutch Lever

Capstan Brake Arm Ass'y

1

Main Loading Gear

Tension Lever

Loading Gear T

2-20: INCLINED S/T ASS'Y (Refer to Fig. 2-20)

Unlock the support 1 and remove the P4 Cover.

1.

Remove the S-S Brake Spring.

2.

Unlock the support 2 and remove the Loading Gear

3.

Holder.

Remove the S-S Brake Arm.

4.

Remove the Inclined S.

5.

Remove the Inclined T.

6.

Remove the 2 screws 3, then remove the Guide Roller.

7.

NOTE

Do not touch the roller of Guide Roller.

Loading Gear Holder

Guide Roller

Inclined S

3

2

S-S Brake Spring

S-S Brake Arm

Guide Roller

3

Inclined T

1

P4 Cover

2

LED Reflector

3

2

Loading Gear

Spring

Loading Arm T Ass'y

Loading Gear S

Loading Gear

Spring

Loading Arm S Ass'y

Fig. 2-19-A

NOTE

When you install the Loading Arm S Ass'y, Loading Arm T

Ass'y and Main Loading Gear, align each marker. (Refer

to Fig. 2-19-B)

Marker

Main Loading Gear

Marker

• Screw Torque: 0.7 ± 0.2kgf•cm

Fig. 2-20

Loading Arm T Ass'y

Loading Arm S Ass'y

Fig. 2-19-B

B2-5

Page 9

DISASSEMBLY INSTRUCTIONS

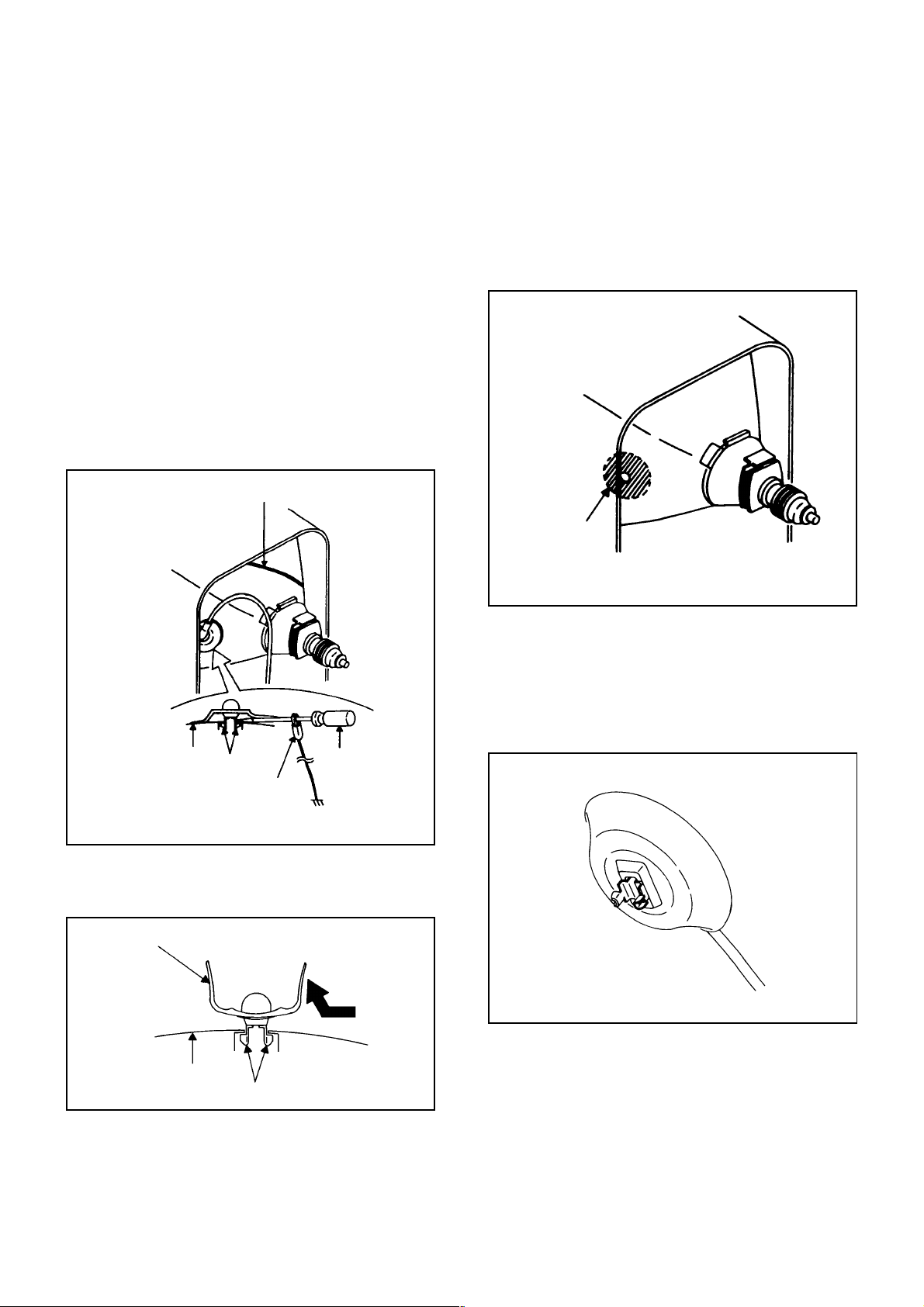

3. REMOVAL OF ANODE CAP

Read the following NOTED items before starting work.

After turning the power off there might still be a potential

*

voltage that is very dangerous. When removing the

Anode Cap, make sure to discharge the Anode Cap's

potential voltage.

Do not use pliers to loosen or tighten the Anode Cap

*

terminal, this may cause the spring to be damaged.

REMOVAL

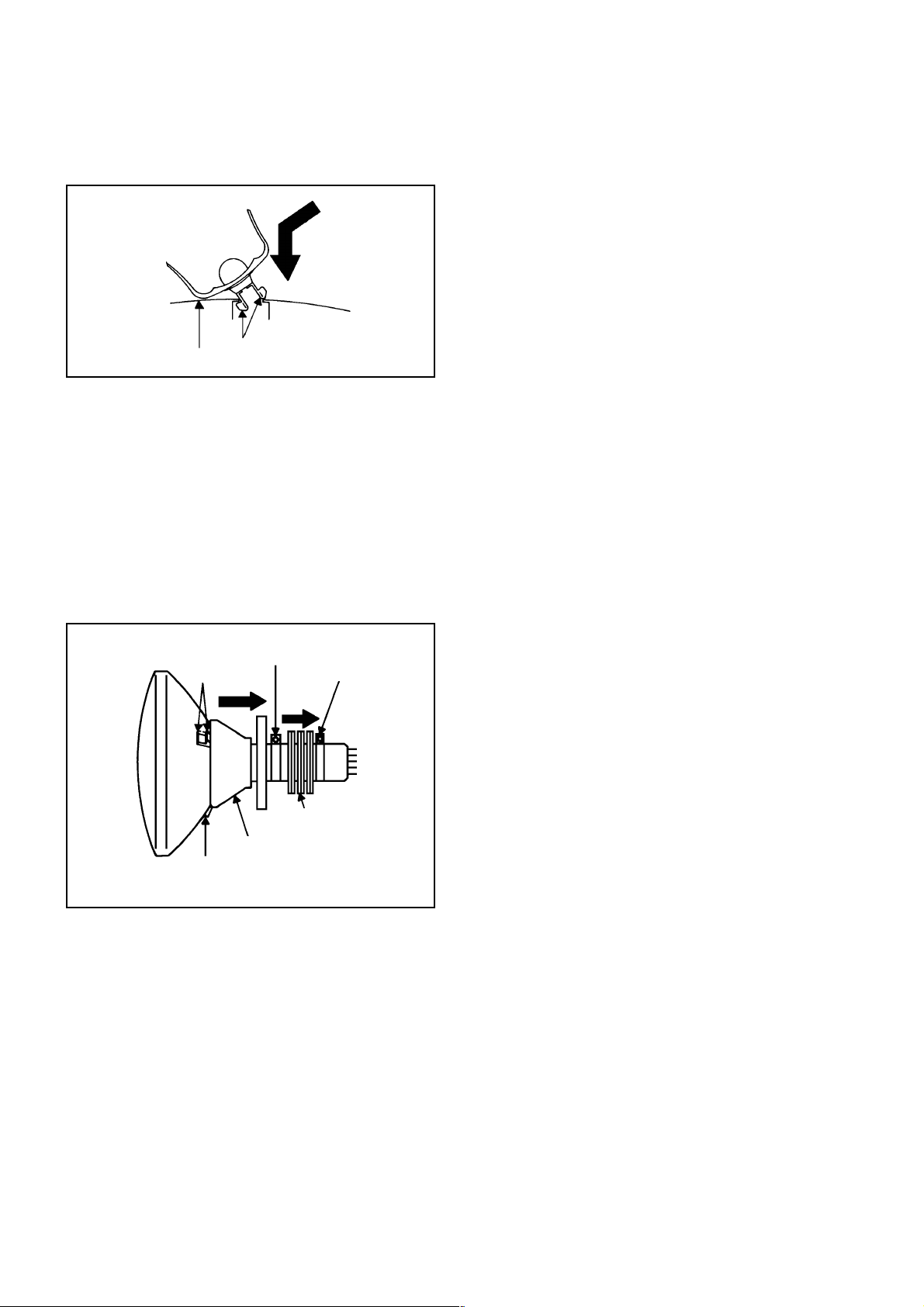

1. Follow the steps as follows to discharge the Anode Cap.

(Refer to Fig. 3-1.)

Connect one end of an Alligator Clip to the metal part of a

flat-blade screwdriver and the other end to ground.

While holding the plastic part of the insulated Screwdriver,

touch the support of the Anode with the tip of the

Screwdriver.

A cracking noise will be heard as the voltage is discharged.

GND on the CRT

3. After one side is removed, pull in the opposite direction to

remove the other.

NOTE

Take care not to damage the Rubber Cap.

INSTALLATION

1. Clean the spot where the cap was located with a small

amount of alcohol. (Refer to Fig. 3-3.)

Location of Anode Cap

CRT

Support

Alligator Clip

Screwdriver

GND on the CRT

Fig. 3-1

Flip up the sides of the Rubber Cap in the direction of the

2.

arrow and remove one side of the support.

(Refer to Fig. 3-2.)

Rubber Cap

Fig. 3-3

NOTE

Confirm that there is no dirt, dust, etc. at the spot where

the cap was located.

2.3.Arrange the wire of the Anode Cap and make sure the

wire is not twisted.

Turn over the Rubber Cap. (Refer to Fig. 3-4.)

Fig. 3-4

CRT

Support

Fig. 3-2

B3-1

Page 10

DISASSEMBLY INSTRUCTIONS

4. Insert one end of the Anode Support into the anode button,

then the other as shown in Fig. 3-5.

Support

CRT

5.6.Confirm that the Support is securely connected.

Put on the Rubber Cap without moving any parts.

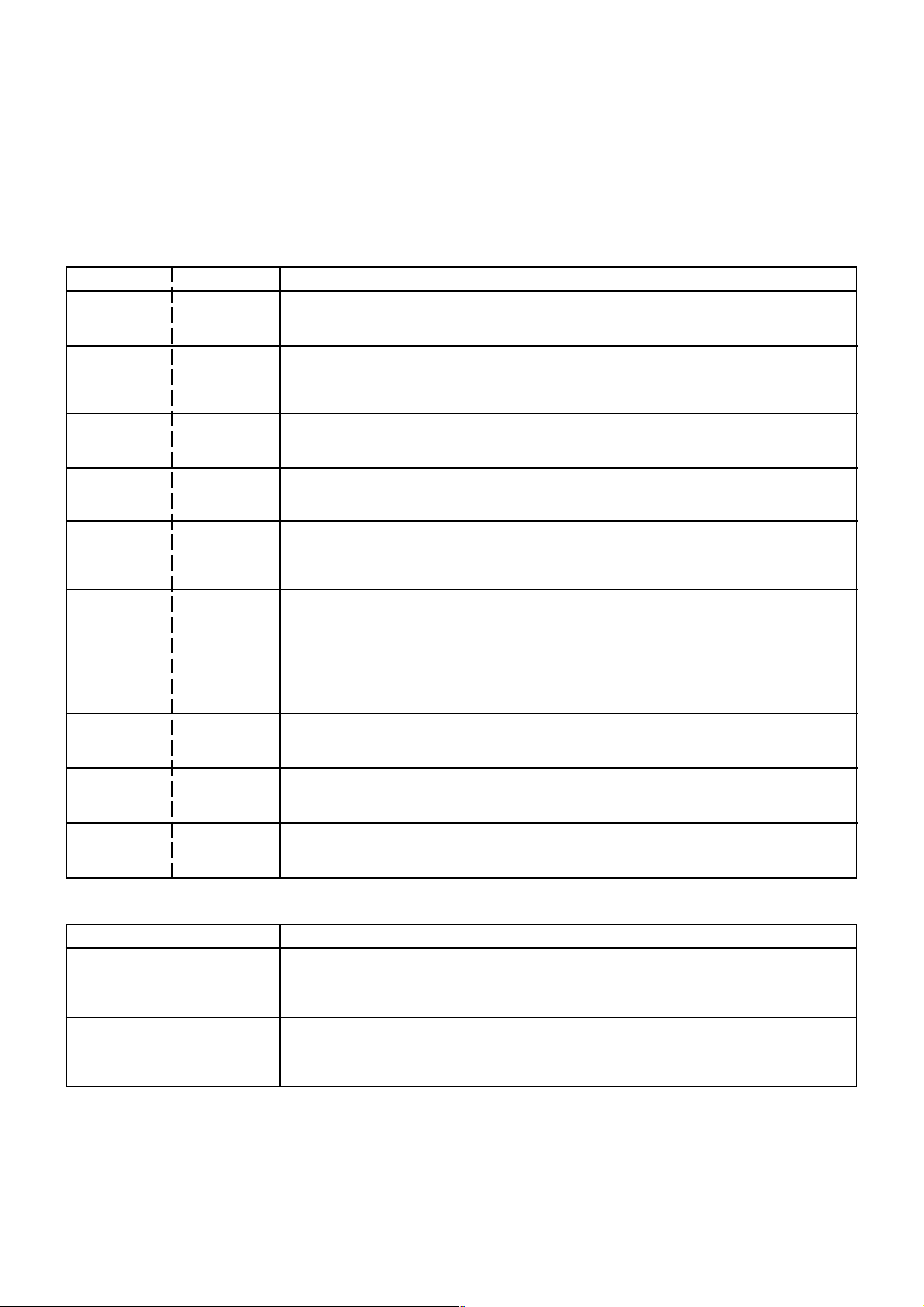

4. REMOVAL OF DEFLECTION YOKE

(Refer to Fig. 4-1)

1.

Loosen the screw 1.

2.

Remove the Convergence • Purity Magnet in the

direction of arrow (A).

3.

Loosen the screw 2.

4.

Remove the 3 Wedges.

5.

Remove the Deflection Yoke in the direction of arrow

(B).

Fig. 3-5

2

Wedge

Wedge

INSTALLATION

Install new Deflection Yoke in reverse steps of REMOVAL.

NOTE

After adjusting the purity and the convergence, fix the

screw 2 and lock the wedges.

(B)

Deflection Yoke

1

(A)

Convergence •

Purity Magnet

Fig. 4-1

B3-2

Page 11

A

A/C

ACC

AE

AFC

AFT

AFT DET

AGC

AMP

ANT

A.PB

APC

ASS'Y

AT

AUTO

A/V

B

BGP

BOT

BPF

BRAKE SOL

BUFF

B/W

C

C

CASE

CAP

CARR

CH

CLK

CLOCK (SY-SE)

COMB

CONV

CPM

CTL

CYL

CYL-M

CYL SENS

D

DATA (SY-CE)

dB

DC

DD Unit

DEMOD

DET

DEV

E

E

EF

EMPH

ENC

ENV

EOT

EQ

EXT

F

F

FBC

FE

FF

FG

FL SW

FM

FSC

FWD

G

GEN

GND

H

H.P.F

KEY TO ABBREVIATIONS

:

Audio/Control

:

Automatic Color Control

:

Audio Erase

:

Automatic Frequency Control

:

Automatic Fine Tuning

:

Automatic Fine Tuning Detect

:

Automatic Gain Control

:

Amplifier

:

Antenna

:

Audio Playback

:

Automatic Phase Control

:

Assembly

:

All Time

:

Automatic

:

Audio/Video

:

Burst Gate Pulse

:

Beginning of Tape

:

Bandpass Filter

:

Brake Solenoid

:

Buffer

:

Black and White

:

Capacitance, Collector

:

Cassette

:

Capstan

:

Carrier

:

Channel

:

Clock

:

Clock (Syscon to Servo)

:

Combination, Comb Filter

:

Converter

:

Capstan Motor

:

Control

:

Cylinder

:

Cylinder-Motor

:

Cylinder-Sensor

:

Data (Syscon to Servo)

:

Decibel

:

Direct Current

:

Direct Drive Motor Unit

:

Demodulator

:

Detector

:

Deviation

:

Emitter

:

Emitter Follower

:

Emphasis

:

Encoder

:

Envelope

:

End of Tape

:

Equalizer

:

External

:

Fuse

:

Feed Back Clamp

:

Full Erase

:

Fast Forward, Flipflop

:

Frequency Generator

:

Front Loading Switch

:

Frequency Modulation

:

Frequency Sub Carrier

:

Forward

:

Generator

:

Ground

:

High Pass Filter

H.SW

Hz

I

IC

IF

IND

INV

K

KIL

L

L

LED

LIMIT AMP

LM, LDM

LP

L.P.F

LUMI.

M

M

MAX

MINI

MIX

MM

MOD

MPX

MS SW

N

NC

NR

O

OSC

OPE

P

PB

PB CTL

PB-C

PB-Y

PCB

P. CON

PD

PG

P-P

R

R

REC

REC-C

REC-Y

REEL BRK

REEL S

REF

REG

REW

REV, RVS

RF

RMC

RY

S

S. CLK

S. COM

S. DATA

SEG

SEL

SENS

SER

SI

SIF

SO

SOL

SP

STB

SW

:

Head Switch

:

Hertz

:

Integrated Circuit

:

Intermediate Frequency

:

Indicator

:

Inverter

:

Killer

:

Left

:

Light Emitting Diode

:

Limiter Amplifier

:

Loading Motor

:

Long Play

:

Low Pass Filter

:

Luminance

:

Motor

:

Maximum

:

Minimum

:

Mixer, mixing

:

Monostable Multivibrator

:

Modulator, Modulation

:

Multiplexer, Multiplex

:

Mecha State Switch

:

Non Connection

:

Noise Reduction

:

Oscillator

:

Operation

:

Playback

:

Playback Control

:

Playback-Chrominance

:

Playback-Luminance

:

Printed Circuit Board

:

Power Control

:

Phase Detector

:

Pulse Generator

:

Peak-to Peak

:

Right

:

Recording

:

Recording-Chrominance

:

Recording-Luminance

:

Reel Brake

:

Reel Sensor

:

Reference

:

Regulated, Regulator

:

Rewind

:

Reverse

:

Radio Frequency

:

Remote Control

:

Relay

:

Serial Clock

:

Sensor Common

:

Serial Data

:

Segment

:

Select, Selector

:

Sensor

:

Search Mode

:

Serial Input

:

Sound Intermediate Frequency

:

Serial Output

:

Solenoid

:

Standard Play

:

Serial Strobe

:

Switch

C1-1

Page 12

S

SYNC

SYNC SEP

T

TR

TRAC

TRICK PB

TP

U

UNREG

V

V

VCO

VIF

VP

V.PB

VR

V.REC

VSF

VSR

VSS

V-SYNC

VT

X

X'TAL

Y

Y/C

KEY TO ABBREVIATIONS

:

Synchronization

:

Sync Separator, Separation

:

Transistor

:

Tracking

:

Trick Playback

:

Test Point

:

Unregulated

:

Volt

:

Voltage Controlled Oscillator

:

Video Intermediate Frequency

:

Vertical Pulse, Voltage Display

:

Video Playback

:

Variable Resistor

:

Video Recording

:

Visual Search Fast Forward

:

Visual Search Rewind

:

Voltage Super Source

:

Vertical-Synchronization

:

Voltage Tuning

:

Crystal

:

Luminance/Chrominance

C1-2

Page 13

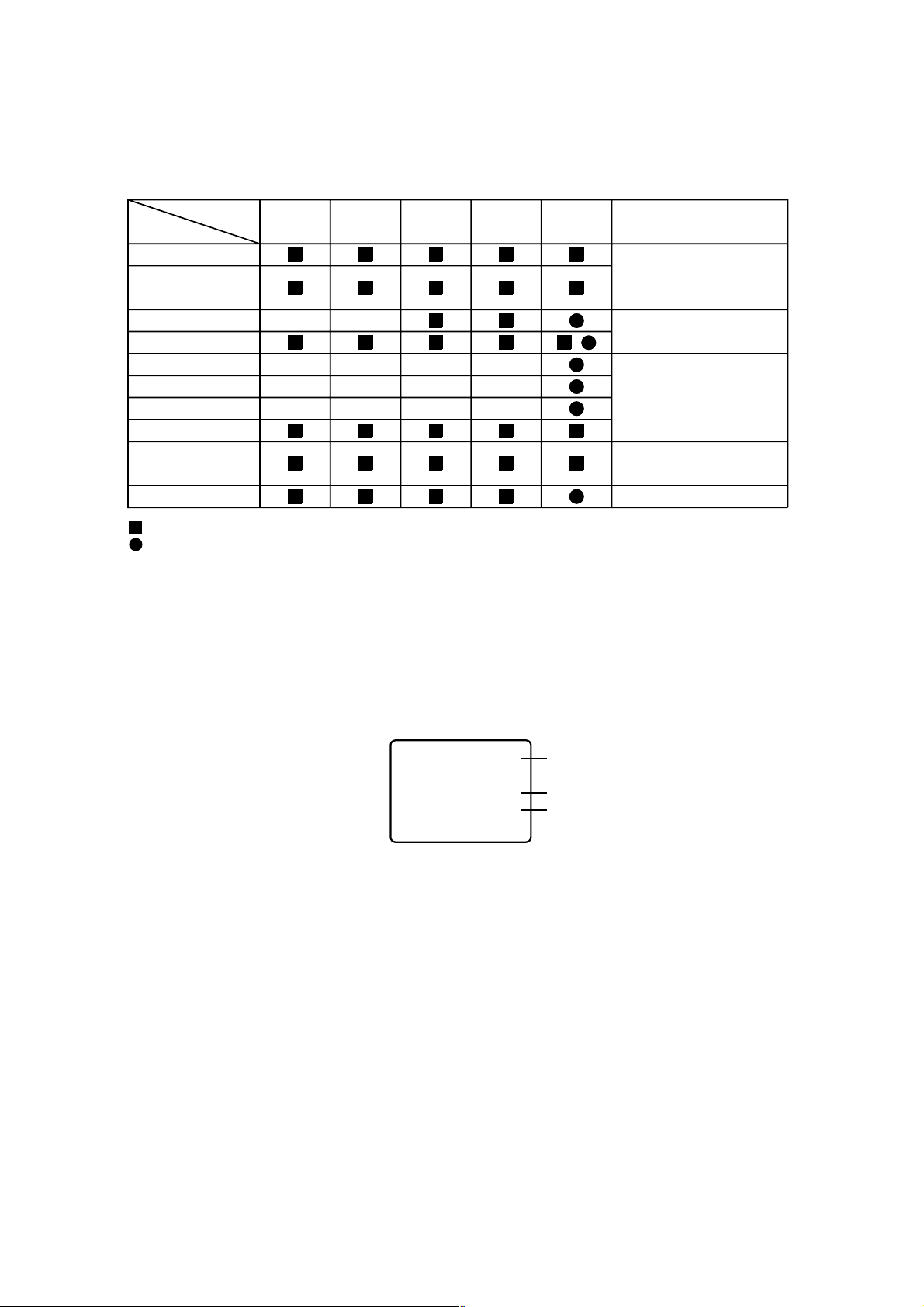

SERVICE MODE LIST

This unit provided with the following SERVICE MODES so you can repair, examine and adjust easily.

To enter SERVICE MODE, unplug AC cord till lost actual clock time. Then press and hold Vol (-) button of main unit and

remocon key simultaneously.

The both pressing of set key and remote control key will not be possible if clock has been set. To reset clock, either unplug

AC cord and allow at least 30 minutes before Power On or alternatively, discharge backup capacitor.

Set Key Remocon Key Operations

VOL. (-) MIN 1

VOL. (-) MIN 2

VOL. (-) MIN

VOL. (-) MIN 4

VOL. (-) MIN 5

VOL. (-) MIN 6

VOL. (-) MIN 7

Initialization of the factory.

NOTE: Do not use this for the normal servicing.

Horizontal position adjustment of OSD.

NOTE: Also can be adjusted by using the Adjustment MENU.

Refer to the "ELECTRICAL ADJUSTMENT" (OSD HORIZONTAL).

3

Adjust the PG SHIFTER automatically.

Refer to the "ELECTRICAL ADJUSTMENT" (PG SHIFTER).

Adjust the PG SHIFTER manually.

Refer to the "ELECTRICAL ADJUSTMENT" (PG SHIFTER).

Adjusting of the Tracking to the center position.

NOTE: Also can be adjusted by pressing the ATR button for more than 2 seconds

during PLAY.

POWER ON total hours and PLAY/REC total hours are displayed on the screen.

Refer to the "PREVENTIVE CHECKS AND SERVICE INTERVALS" (CONFIRMATION

OF USING HOURS).

Can be checked of the INITIAL DATA of MEMORY IC.

Refer to the "NOTE FOR THE REPLACING OF MEMORY IC".

Releasing of PROTECTION PASSWORD.

VOL. (-) MIN 8

VOL. (-) MIN 9

Method Operations

Press the ATR button on the

remote control for more than

2 seconds during PLAY.

Make the short circuit between

the test point of SERVICE and

the GND.

Writing of EEPROM initial data.

NOTE: Do not use this for the normal servicing.

Display of the Adjustment MENU on the screen.

Refer to the "ELECTRICAL ADJUSTMENT" (On-Screen Display Adjustment).

Adjusting of the Tracking to the center position.

Refer to the "MECHANICAL ADJUSTMENT" (GUIDE ROLLER) and "ELECTRICAL

ADJUSTMENT" (PG SHIFTER).

The EOT/BOT/Reel sensor do not work at this moment.

Refer to the "PREPARATION FOR SERVICING"

C2-1

Page 14

PREVENTIVE CHECKS AND SERVICE INTERVALS

The following standard table depends on environmental conditions and usage. Unless maintenance is properly

carried out, the following service intervals may be quite shortened as harmful effects may be had on other parts.

Also, long term storage or misuse may cause transformation and aging of rubber parts.

Time

Parts Name

Audio Control Head

Full Erase Head

(Recorder only)

Capstan Belt

Pinch Roller

Capstan DD Unit

Loading Motor

Tension Band

Capstan Shaft

Tape Running

Guide Post

Cylinder Unit

: Clean

: Replace

500

hours

1,000

hours

1,500

hours

2,000

hours

3,000

hours

Notes

Clean those parts in

contact with the tape.

Clean the rubber, and parts

which the rubber touches.

Replace when rolling

becomes abnormal.

Clean the Head

CONFIRMATION OF USING HOURS

POWER ON total hours and PLAY/REC total hours can be checked on the screen.

Total hours are displayed in 16 system of notation.

NOTE: The confirmation of using hours will not be possible if clock has been set. To reset clock, either unplug

AC cord and allow at least 30 minutes before Power On or alternatively, discharge backup capacitor.

1.

Set the VOLUME to minimum.

2.

Press both VOL. DOWN button on the set and the Channel button (6) on the remote control simultaneously.

3.

After the confirmation of using hours, turn off the power.

INIT 00 83

POWER ON

PLAY/REC

(16 x 16 x 16 x thousands digit value) + (16 x 16 x hundreds digit value) + (16 x tens digit value) + (ones digit value)

0010

0003

Initial setting content of MEMORY IC.

POWER ON total hours.

PLAY/REC total hours.

C3-1

Page 15

PREVENTIVE CHECKS AND SERVICE INTERVALS

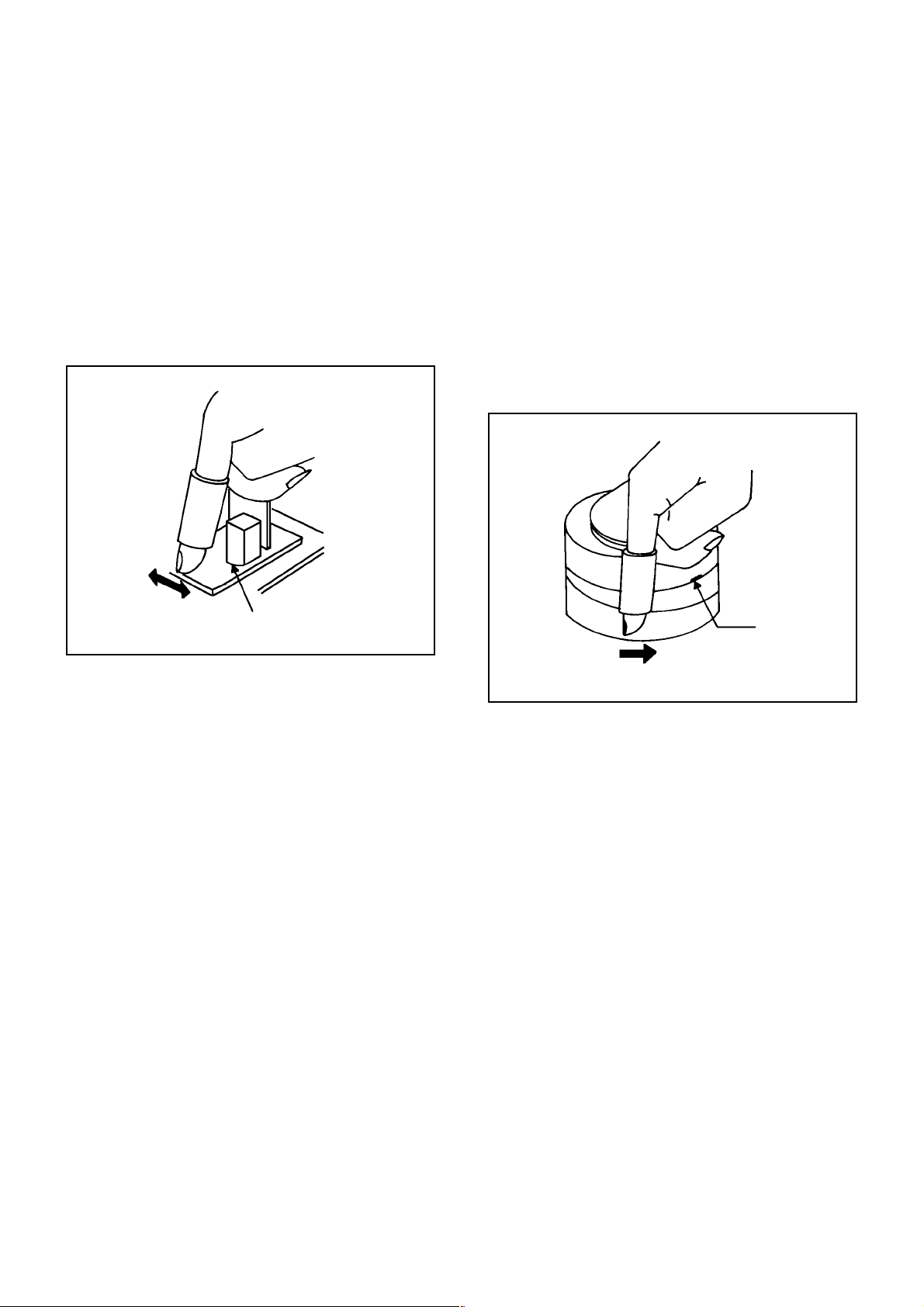

CLEANING

NOTE

After cleaning the heads with isopropyl alcohol, do not

run a tape until the heads dry completely. If the heads

are not completely dry and alcohol gets on the tape,

damage may occur.

1. AUDIO CONTROL HEAD

Wrap a piece of chamois around your finger. Dip it in

isopropyl alcohol and clean the audio control head by

wiping it horizontally. Clean the full erase head in the

same manner. (Refer to the figure below.)

2. TAPE RUNNING SYSTEM

When cleaning the tape transport system, use the

gauze moistened with isopropyl alcohol.

3. CYLINDER

Wrap a piece of chamois around your finger. Dip it in

isopropyl alcohol. Hold it to the cylinder head softly.

Turn the cylinder head counterclockwise to clean it (in

the direction of the arrow). (Refer to the figure below.)

NOTE

Do not exert force against the cylinder head. Do not move

the chamois upward or downward on the head.

Use the chamois one by one.

Audio Control Head

Cylinder Head

C3-2

Page 16

NOTE FOR THE REPLACING OF MEMORY IC

If a service repair is undertaken where it has been required to change the MEMORY IC, the following steps should be taken to

ensure correct data settings while making reference to TABLE 1.

NOTE:

Initial Data setting will not be possible if clock has been set. To reset clock, either unplug AC cord and allow

at least 30 minutes before Power On or alternatively, discharge backup capacitor. No need the setting for after INI 3F.

ADDRESS DATA

00 10

01 1E

02 04

03 6A

04 00

05 00

06 00

07 2F

08 40

09 60

0A 02

0B 08

ADDRESS DATA

0C

0D

0E

0F

10

11

12

13

14

15

16

17

00

B3

35

66

FA

40

80

40

00

6A

00

35

ADDRESS DATA

18 A3

19 89

1A 35

1B 5F

1C 05

1D F0

1E 35

1F F2

20 00

21 00

22 00

23 00

ADDRESS DATA

24 00

25 5F

26 01

27 F1

28 01

29 F0

2A 0E

2B 00

2C 01

2D 01

2E 06

2F 01

ADDRESS

30 04

31 00

32 00

33 18

34 00

35 00

36 00

37 00

38 00

39 00

3A 00

3B 00

Table 1

Enter DATA SET mode by setting VOLUME to minimum.

1.

While holding down VOLUME button on front cabinet, press key 6 on remote control simultaneously.

2.

ADDRESS and DATA should appear as FIG 1.

ADDRESS DATA

INIT 00 83

DATA ADDRESS DATA

3C 6C

3D 2B

3E

3F

21

15

POWER ON

PLAY/REC

0010

0003

Fig. 1

ADDRESS is now selected and should "blink". Using the SET + or - keys on the remote, step through the

3.

ADDRESS until required ADDRESS to be changed is reached.

Press ENTER to select DATA. When DATA is selected, it will "blink".

4.

Again, step through the DATA using SET + or - until required DATA value has been selected.

5.

Pressing ENTER will take you back to ADDRESS for further selection if necessary.

6.

Repeat steps 3 to 6 until all data has been checked.

7.

When satisfied correct DATA has been entered, turn POWER off (return to STANDBY MODE) to finish DATA input.

8.

The unit will now have the correct DATA for the new MEMORY IC.

C4-1

Page 17

SERVICING FIXTURES AND TOOLS

(For 2 head 1 speed model,

4 head model)

VHS Alignment Tape

JG001E

JG001F

JG001R

JG001U

(VP S-LI6 )

(VP S-CO1 )

(VP S-LI6 H)

(VP S-X6 )

3

1

3

1

3

1

3

1

Screwdriver

JG154 Cable

(For 2 head 2 speed model)

VHS Alignment Tape

JG001C

JG001D

JG001V

(VP S-LI6 )

(VP S-CO1 )

(VP S-X6 )

3

2

3

2

3

2

JG162D Cable (11 Pins)

JG162Y Cable (5 Pins)

JG002B

JG002E

JG002F

JG024AJG022 Master PlaneJG153 X Value Adjustment

TentelometerJG162C Cable (10 Pins)

Adapter

Dial Torque Gauge

(10~90gf•cm)

(60~600gf•cm)

Reel Disk Height

Adjustment Jig

JG005 Post Adjustment

Screwdriver

Part No. SV-TG0-030-000

(small)

JG100A Torque Tape

(VHT-063)

Part No. Remarks

JG001E

JG001F

Monoscope, 6KHz (For 2 head 1 speed model, 4 head model)

Color Bar, 1KHz (For 2 head 1 speed model, 4 head model)

JG001R Hi-Fi Audio (For Hi-Fi model)

JG001U X Value Adjustment (For 2 head 1 speed model, 4 head model)

JG001C

JG001D

Monoscope, 6KHz (For 2 head 2 speed model)

Color Bar, 1KHz (For 2 head 2 speed model)

JG001V X Value Adjustment (For 2 head 2 speed model)

JG002B

JG002E

JG002F

JG005

JG153

VSR Torque, Brake Torque (S Reel/T Reel Ass'y)

Brake Torque (T Reel Ass'y)

VSR Torque, Brake Torque (S Reel)

Guide Roller Adjustment

X Value Adjustment

JG022/JG024A Reel Disk Height Adjustment

JG100A

JG154

JG162C/JG162D

JG162Y

Playback Torque, Back Tension Torque During Playback

Used to connect the test point of SERVICE and GROUND

Used to connect the Syscon PCB and Main PCB

Used to connect the Syscon PCB and CRT PCB

C5-1

Page 18

PREPARA TION FOR SER VICING

How to use the Servicing Fixture

1.

Unplug the connector CP351, CP757, CP302 and CP403, then remove the TV/VCR Block from the set.

2.

Unplug the connector CP810, CP820 and CP850, then remove the Main PCB from the VCR Block.

3.

Connect as shown in the below figure using the Service Fixture.

• Connect the Syscon PCB to the Main PCB with the cable JG162C and JG162D.

• Connect the Syscon PCB to the CRT PCB with the cable JG162Y.

4.

Remove the Operation PCB from the set, then connect it with the Syscon PCB.

If necessary, connect CP351 (Front A/V Jack Input Terminal)

5.

Short circuit between TP1001 and Ground with the cable JG154.

(Refer to MAJOR COMPONENTS LOCATION GUIDE)

The EOT, BOT and Reel Sensor do not work at this moment.

6.

At that time, the STOP/EJECT button is available to insert and eject the Cassette Tape.

Front Cabinet

Syscon PCB

CD850

CRT PCB

CP850

Main PCB

JG162Y

CP820

CP810

JG162D

JG162C

CD820

CD810

To Ground

JG154

TP1001

Operation PCB

CD351

C5-2

CP757

CD757

Page 19

MECHANICAL ADJUSTMENTS

1. CONFIRMATION AND ADJUSTMENT

Read the following NOTES before starting work.

••Place an object which weighs between 450g~500g on

the Cassette Tape to keep it steady when you want to

make the tape run without the Cassette Holder. (Do not

place an object which weighs over 500g.)

When you activate the deck without the Cassette

Holder, short circuit between TP1001 and TP1002. (Refer

to ELECTRICAL ADJUSTMENT PARTS LOCATION

GUIDE) In this condition the BOT/EOT/Reel Sensor will

not function.

CONFIRMATION AND ADJUSTMENT OF REEL

1-1:

DISK HEIGHT

1.

Turn on the power and set to the STOP mode.

2.

Set the master plane (JG022) and reel disk height

adjustment jig (JG024A) on the mechanism framework,

taking care not to scratch the drum, as shown in Fig. 1-

1-A.

3.

Confirm that "A" of the reel disk is lower than "B" of the

reel disk height adjustment jig (JG024A) , and is higher

than "C". If it is not enough height, adjust to 10(+0.2, -0)

mm with the height adjustment washer.

4.

Adjust the other reel in the same way.

Master Plane (JG022)

1-2: CONFIRMATION AND ADJUSTMENT OF TENSION

POST POSITION

1.

Set to the PLAY mode.

2.

Adjust the Tension Adjust until the edge of the Tension

Arm is positioning within 0.5mm range from the

standard line center of Main Chassis.

After this adjustment, confirm that the cut position is

located in "A" area as shown in Fig. 1-2-B. If it is

located in "B" area, adjust again.

3.

While turning the S Reel clockwise, confirm that the

edge of the Tension Arm is located in the position

described above.

Standard line of Main Chassis

Tension Arm

0.5mm (Adjusting range)

Standard line center of Main Chassis

Tension Adjust

Fig. 1-2-A

Master Plane (JG022)

10(+0.2, -0)mm

Reel Disk Height Adjustment Jig

(JG024A)

Reel Disk

Height Adjustment

Washer

2.6x4.7xT0.13

2.6X4.7xT0.25

Reel Disk Height

Adjustment Jig

(JG024A)

(B)

(A)

Fig. 1-1-A

(C)

Fig. 1-1-B

(A)

Cut Position

(B)

Tension Adjust

Fig. 1-2-B

1-3: CONFIRMATION OF PLAYBACK TORQUE AND

BACK TENSION TORQUE DURING PLAYBACK

Load a video tape (E-180) recorded in standard speed

1.

mode. Set the unit to the PLAY mode.

Install the tentelometer as shown in Fig. 1-3. Confirm that

2.

the meter indicates 20 ± 2gf in the beginning of playback.

• USING A CASSETTE TYPE TORQUE TAPE (JG100A)

1.

After confirmation and adjustment of Tension Post

position (Refer to item 1-2), load the cassette type

torque tape (JG100A) and set to the PLAY mode.

2.

Confirm that the right meter of the torque tape indicates

60~100gf•cm during playback in SP mode.

3.

Confirm that the left meter of the torque tape indicates

25~40gf•cm during playback in SP mode.

Tentelometer

Video Tape

D1-1

P1 Post

Guide Roller

Fig. 1-3

Page 20

MECHANICAL ADJUSTMENTS

1-4: CONFIRMATION OF VSR TORQUE

Operate within 4~5 seconds after the reel disk begins to

1.

turn.

Install the Torque Gauge (JG002F) and Adapter (JG002B)

2.

on the S Reel. Set to the Rewind mode. (Refer to Fig.1-4)

Then, confirm that it indicates 120~180gf•cm.

3.

NOTE

Install the Torque Gauge on the reel disk firmly. Press the

REW button to turn the reel disk.

1-5: CONFIRMATION OF REEL BRAKE TORQUE

(S Reel Brake) (Refer to Fig. 1-4)

Set to the STOP mode.

1.

Move the Idler Ass'y from the S Reel.

2.

Install the Torque Gauge (JG002F) and Adapter

3.

(JG002B) on the S Reel. Turn the Torque Gauge

(JG002F) clockwise.

Then, confirm that it indicates 70~100gf•cm.

4.

(T Reel Brake) (Refer to Fig. 1-4)

Set to the STOP mode.

1.

Move the Idler Ass'y from the T Reel Ass'y.

2.

Install the Torque Gauge (JG002E) and Adapter

3.

(JG002B) on the T reel. Turn the Torque Gauge

(JG002E) counterclockwise.

Then, confirm that it indicates 35~60gf•cm.

4.

Torque Gauge/Adapter

(JG002F/JG002B)

2. CONFIRMATION AND ADJUSTMENT

OF TAPE RUNNING MECHANISM

Tape Running Mechanism is adjusted precisely at the

factory. Adjustment is not necessary as usual. When you

replace the parts of the tape running mechanism because

of long term usage or failure, the confirmation and

adjustment are necessary.

2-1: GUIDE ROLLER

Playback the VHS Alignment Tape (JG001C or JG001E).

1.

(Refer to SERVICING FIXTURE AND TOOLS)

Connect CH-1 of the oscilloscope to TP4002 (Envelope)

2.

and CH-2 to TP4001 (SW Pulse).

Press and hold the TRACKING-AUTO button on the

3.

remote control more than 2 seconds to set tracking to

center.

Trigger with SW Pulse and observe the envelope. (Refer

4.

to Fig. 2-1-A)

When observing the envelope, adjust the Adjusting Driver

5.

(JG005) slightly until the envelope will be flat.

Even if you press the Tracking Button, adjust so that

flatness is not moved so much.

Adjust so that the A : B ratio is better than 3 : 2 as shown

6.

in Fig. 2-1-B, even if you press the Tracking Button to

move the envelope (The envelope waveform will begin to

decrease when you press the Tracking Button).

Adjust the PG shifter during playback.

7.

(Refer to the ELECTRICAL ADJUSTMENTS)

NOTE

After adjustment, confirm and adjust A/C head.

(Refer to item 2-2)

Torque Gauge/Adapter

(JG002E/JG002B)

S Reel

T Reel Ass'y

Fig. 1-4

NOTE

If the torque is out of the range, replace the following

parts.

Check item

1-4

1-5

Replacement Part

Idler Ass'y/Clutch Ass'y

T Brake Spring/Tension Spring

Envelope

CH-3

Audio

Max

CH-1

Envelope

(TP4002)

CH-1

CH-2

Track

Track

CH-2

SW Pulse (TP4001)

(1)

(2)

Entrance Exit

A

B

Fig. 2-1-A

Max

D1-2

A : B = 3 : 2

Fig. 2-1-B

Page 21

MECHANICAL ADJUSTMENTS

CONFIRMATION AND ADJUSTMENT OF AUDIO/

CONTROL HEAD

When the Tape Running Mechanism does not work well,

adjust the following items.

1.

Playback the VHS Alignment Tape (JG001C or JG001E).

(Refer to SERVICING FIXTURE AND TOOLS)

2.

Confirm that the reflected picture of stamp mark is

appeared on the tape prior to P4 Post as shown in Fig. 2-

2-A.

a)

When the reflected picture is distorted, turn the screw

1 clockwise until the distortion is disappeared.

b)

When the reflected picture is not distorted, turn the

screw 1 counterclockwise until little distortion is

appeared, then adjust the a).

3.

Turn the screw 2 to set the audio level to maximum.

4.

Confirm that the bottom of the Audio/ Control Head and

the bottom of the tape is shown in Fig. 2-2-C.

c)

When the height is not correct, turn the screw 3 to

adjust the height. Then, adjust the 1~3 again.

Audio/Control Head

Reflected picture of

Stamp Mark

P4 Post

Audio/Control Head

3

Stamp Mark

1

Fig. 2-2-A

2-3:2-2:

TAPE RUNNING ADJUSTMENT

(X VALUE ADJUSTMENT)

Confirm and adjust the height of the Reel Disk.

1.

(Refer to item 1-1)

Confirm and adjust the position of the Tension Post.

2.

(Refer to item 1-2)

Adjust the Guide Roller. (Refer to item 2-1)

3.

Confirm and adjust the Audio/Control Head.

4.

(Refer to item 2-2)

Connect CH-1 of the oscilloscope to TP4002, CH-2 to

5.

TP4001 and CH-3 to HOT side of Audio Out Jack.

Playback the VHS Alignment Tape (JG001U or JG001V).

6.

(Refer to SERVICING FIXTURE AND TOOLS)

Press and hold the TRACKING-AUTO button on the

7.

remote control more than 2 seconds to set tracking to

center.

Set the X Value adjustment driver (JG153) to the 4 of

8.

Fig. 2-2-B. Adjust X value so that the envelope waveform

output becomes maximum. Check if the relation between

Audio and Envelope waveform becomes (1) or (2) of Fig.

2-1-A.

2-4: CONFIRM HI-FI AUDIO (Hi-Fi model only)

Connect CH-1 of the oscilloscope to TP4002, CH-2 to

1.

TP4001 and CH-3 to the Hi-Fi Audio Out Jack.

Playback the VHS Alignment Tape (JG001R).

2.

(Refer to SERVICING FIXTURE AND TOOLS)

Press and hold the TRACKING-AUTO button on the

3.

remote control more than 2 seconds to set tracking to

center.

Press the Tracking Up button and count number of steps

4.

which the audio output is changed from Hi-Fi (10KHz) to

MONO (6KHz).

Press the Tracking Down button and count number of

5.

steps which the audio output is changed from Hi-Fi

(10KHz) to MONO (6KHz).

Confirm that the difference between these counted steps

6.

number in the above items are within 2 steps. If the

difference are more than 3 steps, do Tape Running

Adjustment again. (Refer to item 2-3)

2

Audio/Control Head

Tape

4

Fig. 2-2-B

0.25±0.05mm

Fig. 2-2-C

D1-3

Page 22

MECHANICAL ADJUSTMENTS

3. MECHANISM ADJUSTMENT PARTS LOCATION GUIDE

4

3

2

5

6

7

1

8

11

1. Tension Adjust

2. Tension Arm

3. Guide Roller

4. P1 Post

5. Audio/Control Head

6. X value adjustment driver hole

1012

10.

11.

12.

9

7.

P4 Post

8.

T Brake Spring

9.

T Reel Ass'y

Idler Ass'y

S-S Brake Spring

S Reel

D1-4

Page 23

ELECTRICAL ADJUSTMENTS

1. ADJUSTMENT PROCEDURE

Read and perform these adjustments when repairing the

circuits or replacing electrical parts or PCB assemblies.

CAUTION

When replacing IC's or transistors, use only specified

silicon grease (YG6260M).

(To prevent the damage to IC's and transistors.)

On-Screen Display Adjustment

1.2.Unplug the AC plug for more than 30 minutes to set the

clock to the non-setting state. Then, set the volume level

to minimum.

Press the VOL. DOWN button on the set and the channel

button (9) on the remote control simultaneously to display

adjustment mode on the screen as shown in Fig. 1-1.

NOTE

Use the channel buttons (1-8) on the remote control to

select the options shown in Fig. 1-1.

Press the channel button (0) on the remote control to

end the adjustments.

1. H/V

2. AKB

3. COLOR TEMP

4. PICTURE

5. OTHERS

6. TEST PATTERN

7. STEREO/SAP

8. (VOL TEST) 0. END

Fig. 1-1

CH-2

6.5H

CH-1

Fig. 2-1-A

CH-2

CH-1

6.5H

Fig. 2-1-B

2-2: RF AGC DELAY

1.

Receive the monoscope pattern.

2.

Connect the digital voltmeter between the pin 5 of

CP603 and the pin 1 (GND) of CP603.

3.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (5) on the remote control.

The Fig. 2-2 appears on the display.

4.

Press the channel button (1) on the remote control to

select "RF AGC DELAY".

5.

Press the VOL. UP/DOWN button on the remote control

until the digital voltmeter is 2.50 ± 0.05V (80dB).

2. BASIC ADJUSTMENTS

(VCR SECTION)

2-1: PG SHIFTER

1.

Connect CH-1 on the oscilloscope to TP4001 and CH-2

to TP4501.

2.

Playback the alignment tape. (JG001C)

3.

Press and hold the Tracking-Auto button on the remote

control more than 2 seconds to set tracking to center.

4.

Press the VOL. DOWN button on the set and the

channel button (3) on the remote control simultaneously

until the indicator REC disappears. If the indicator REC

disappears, adjustment is completed.

(If the above adjustments doesn't work well:)

5.

Press the VOL. DOWN button on the set and the

channel button (3) on the remote control simultaneously

until the indicator REC disappears.

6.

When the REC indicator is blinking, press both VOL.

DOWN button on the set and the channel button (4) on

the remote control simultaneously and adjust the

Tracking +/- button until the arising to the down of Head

Switching Pulse becomes 6.5 ± 0.5H.

(Refer to Fig. 2-1-A, B)

7.

Press the Tracking Auto button.

1. RF AGC DELAY

2. VIDEO LEVEL

3. FM LEVEL

4. OSD H

5. CUT OFF

6.

7.

8. 0. RETURN

Fig. 2-2

2-3: VCO FREERUN

1.

Connect the oscillator to pin 11 of TU601.

2.

Connect the digital voltmeter to pin 47 of IC601.

3.

Adjust the L608 until the digital voltmeter is 3.6 ± 0.05V.

(TV SECTION)

2-4: CONSTANT VOLTAGE (AC)

1.

Using the remote control, set the brightness and

contrast to normal position.

2.

Connect the digital voltmeter to TP401.

3.

Set condition is AV MODE without signal.

4.

Adjust the VR502 until the DC voltage is DC 130 ± 0.5V.

2-5: CONSTANT VOLTAGE (DC)

1.

Using the remote control, set the brightness and

contrast to normal position.

2.

Connect the digital voltmeter to TP401.

3.

Set condition is AV MODE without signal.

4.

Adjust the VR501 until the DC voltage is DC 130 ± 0.5V.

D2-1

Page 24

ELECTRICAL ADJUSTMENTS

2-6: CUT OFF

1.

Place the set with Aging Test for more than 15 minutes.

2.

Set condition is AV MODE without signal.

3.

Using the remote control, set the brightness and

contrast to normal position.

4.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (5) on the remote control.

The Fig. 2-2 appears on the display.

5.

Press the channel button (5) on the remote control to

select "CUT OFF".

6.

Adjust the Screen Volume until a dim raster is obtained.

2-7: FOCUS

1.

Receive the monoscope pattern.

2.

Using the remote control, set the brightness and

contrast to normal position.

3.

Turn the Focus Volume fully counterclockwise once.

4.

Adjust the Focus Volume until picture is distinct.

2-8: WHITE BALANCE

NOTE:

1.

2.

3.

4.

5.

6.

7.

8.

9.

Adjust after performing CUT OFF adjustments.

Place the set with Aging Test for more than 15 minutes.

Receive the white 100% signal from the Pattern

Generator.

Using the remote control, set the brightness and contrast

to normal position.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (2) on the remote control to

select "AKB". The Fig. 2-3 appears on the display.

Press the channel button (2) on the remote control to

select the "R.BIAS".

Using the SET +/- keys on the remote control, adjust the

R.BIAS.

Press the CH. UP/DOWN button on the remote control to

select the "G.BIAS", "B.BIAS", "R.DRIVE" or "B.DRIVE".

Using the SET +/- keys on the remote control, adjust the

G.BIAS, B.BIAS, R.DRIVE or B.DRIVE.

Perform the above adjustment 7 and 8 until the white

color is looked like a white.

1. AKB AUTO

2. R. BIAS

3. G. BIAS

4. B. BIAS

5. R. DRIVE

6. G. DRIVE

7. B. DRIVE

8. AGC AUTO 0. RETURN

Fig. 2-3

2-9: SUB BRIGHTNESS

1.

Receive the monoscope pattern. (RF Input)

2.

Using the remote control, set the brightness and

contrast to normal position.

3.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (4) on the remote control.

The Fig. 2-4 appears on the display.

4.

Press the channel button (1) on the remote control to

select "BRIGHT".

5.

Press the VOL. UP/DOWN button on the remote control

until the white 25% is starting to be visible.

6.

Receive the monoscope pattern. (Audio Video Input)

7.

Press the AV button on the remote control to set to the

AV mode. Then perform the above adjustments 2~5.

1. BRIGHT

2. CONTRAST

3. COLOR

4. TINT

5. SHARPNESS

6. OSD CONT

7.

8. 0. RETURN

2-10: SUB COLOR

1.

Receive the color bar pattern. (RF Input)

2.

Connect the synchro scope to TP801.

3.

Using the remote control, set the brightness, contrast

and color to normal position.

4.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (4) on the remote control.

The Fig. 2-4 appears on the display.

5.

Press the channel button (3) on the remote control to

select "COLOR".

6.

Adjust the VOLTS RANGE VARIABLE knob of the

oscilloscope until the range between white 100% and 0%

is set to 4 divisions on the screen of the oscilloscope.

7.

Press the VOL. UP/DOWN button on the remote control

until the red level is set to the 4 divisions.

(Refer to Fig. 2-5)

8.

Receive the rainbow pattern. (Audio Video Input)

9.

Press the AV button on the remote control to set to the

AV mode. Then perform the above adjustments 2~7.

Fig. 2-4

0%

D2-2

100%

100%

Fig. 2-5

Page 25

ELECTRICAL ADJUSTMENTS

2-11: HORIZONTAL PHASE

1.

Receive the monoscope pattern.

2.

Using the remote control, set the brightness and

contrast to normal position.

3.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (1) on the remote control.

The Fig. 2-6 appears on the display.

4.

Press the channel button (1) on the remote control to

select "H. PHASE".

5.

Press the VOL. UP/DOWN button on the remote control

until the SHIFT quantity of the OVER SCAN on right and

left becomes minimum.

1. H. PHASE

2. H. BLK

3. V. SIZE

4. V. POSI

5. V. LIN

6. V. SC

7. V. COMP

8. (H FREQ) 0. RETURN

2-12: VERTICAL SIZE

1.

Receive the monoscope pattern.

2.

Using the remote control, set the brightness and

contrast to normal position.

3.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (1) on the remote control.

The Fig. 2-6 appears on the display.

4.

Press the channel button (3) on the remote control to

select "V. SIZE".

5.

Press the VOL. UP/DOWN button on the remote control

until the horizontal over scan is equal to the vertical over

scan.

2-13: VERTICAL LINEARITY

1.

Receive the monoscope pattern.

2.

Using the remote control, set the brightness and

contrast to normal position.

3.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (1) on the remote control.

The Fig. 2-6 appears on the display.

4.

Press the channel button (5) on the remote control to

select "V. LIN".

5.

Press the VOL. UP/DOWN button on the remote control

until the SHIFT quantity of the OVER SCAN on upside

and downside becomes minimum.

Fig. 2-6

2-15: OSD HORIZONTAL

1.

Receive monoscope pattern.

2.

Using the remote control, set the brightness and

contrast to normal position.

3.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (5) on the remote control.

The Fig. 2-2 appears on the display.

4.

Press the channel button (4) on the remote control to

select "OSD H".

5.

Press the VOL. UP/DOWN button on the remote control

until the difference of A and B becomes minimum.

(Refer to Fig. 2-7)

[ TV ]

OSD H

AB

2-16: VERTICAL LINEARITY 60 (AV)

1.

Receive the monoscope pattern (Audio Video Input).

2.

Using the remote control, set the brightness and

contrast to normal position.

3.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (1) on the remote control.

The Fig. 2-6 appears on the display.

4.

Press the channel button (5) on the remote control to

select "V. LIN".

5.

Press the VOL. UP/DOWN button on the remote control

until the horizontal line of the colour bar comes to

approximate center of the CRT.

Fig. 2-7

2-14: VERTICAL POSITION

1.

Receive the monoscope pattern.

2.

Using the remote control, set the brightness and

contrast to normal position.

3.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (1) on the remote control.

The Fig. 2-6 appears on the display.

4.

Press the channel button (4) on the remote control to

select "V. POSI".

5.

Press the VOL. UP/DOWN button on the remote control

until the horizontal line of the monoscope comes to

approximate center of the CRT.

D2-3

Page 26

ELECTRICAL ADJUSTMENTS

3. ELECTRICAL ADJUSTMENT PARTS LOCATION GUIDE

(VCR SECTION)

TP1001

TP4002

TP4001

L608

TP4501

IC601

J4501

TU601

CP603

SYSCON PCB

D2-4

Page 27

(TV SECTION)

ELECTRICAL ADJUSTMENTS

CRT PCB

FOCUS VOLUME

SCREEN VOLUME

MAIN PCB

D2-5

Page 28

ELECTRICAL ADJUSTMENTS

4. PURITY AND CONVERGENCE

ADJUSTMENTS

NOTE

1.

Turn the unit on and let it warm up for at least 30

minutes before performing the following adjustments.

2.

Place the CRT surface facing east or west to reduce the

terrestrial magnetism.

3.

Turn ON the unit and demagnetize with a Degauss Coil.

4-1: STATIC CONVERGENCE (ROUGH ADJUSTMENT)

1.

Tighten the screw for the magnet. Refer to the adjusted

CRT for the position. (Refer to Fig. 4-1)

If the deflection yoke and magnet are in one body,

untighten the screw for the body.

2.

Receive the green raster pattern from the color bar

generator.

3.

Slide the deflection yoke until it touches the funnel side

of the CRT.

4.

Adjust center of screen to green, with red and blue on

the sides, using the pair of purity magnets.

5.

Switch the color bar generator from the green raster

pattern to the crosshatch pattern.

6.

Combine red and blue of the 3 color crosshatch

pattern on the center of the screen by adjusting the pair

of 4 pole magnets.

7.

Combine red/blue (magenta) and green by adjusting the

pair of 6 pole magnets.

8.

Adjust the crosshatch pattern to change to white by

repeating steps 6 and 7.

4-2: PURITY

NOTE

Adjust after performing adjustments in section 4-1.

1.

Receive the green raster pattern from color bar

generator.

2.

Adjust the pair of purity magnets to center the color on

the screen.

Adjust the pair of purity magnets so the color at the

ends are equally wide.

3.

Move the deflection yoke backward (to neck side)

slowly, and stop it at the position when the whole screen

is green.

4.

Confirm red and blue color.

5.

Adjust the slant of the deflection yoke while watching

the screen, then tighten the fixing screw.

DEFLECTION YOKE

DEFLECTION YOKE SCREW

MAGNET SCREW

4-3: STATIC CONVERGENCE

NOTE

Adjust after performing adjustments in section 4-2.

1.

Receive the crosshatch pattern from the color bar

generator.

2.

Combine red and blue of the 3 color crosshatch

pattern on the center of the screen by adjusting the pair

of 4 pole magnets.

3.

Combine red/blue (magenta) and green by adjusting the

pair of 6 pole magnets.

4-4: DYNAMIC CONVERGENCE

NOTE

Adjust after performing adjustments in section 4-3.

1.2.Adjust the differences around the screen by moving the

deflection yoke upward/downward and right/left.

(Refer to Fig. 4-2-a)

Insert three wedges between the deflection yoke and

CRT funnel to fix the deflection yoke.

(Refer to Fig. 4-2-b)

R G B

R

G

B

UPWARD/DOWNWARD

SLANT

Fig. 4-2-a

WEDGE

WEDGE POSITION

Fig. 4-2-b

R

G

B

RIGHT/LEFT SLANT

WEDGE

WEDGE

R G B

6 POLE MAGNETS

4 POLE MAGNETS

PURITY MAGNETS

Fig. 4-1

D2-6

Page 29

Page 30

Page 31

Page 32

PRINTED CIRCUIT BOARDS

SYSCON/CRT/POWER SW. (CHIP MOUNTED PARTS)

SOLDER SIDE

C4215

W817

C4230

R4221

R4222

R4223

W805

R4210

Q4210

R420

R636

C640

R4228

R4206

W807

C664

Q4205

C4202

Q4202

R647

R4030

R4205

R4225

W804

R4208

R4220

Q4207

R4239

C4205

R656

C413

C604

C609

R645

R678

C655

R609

R634

C639

R640

R637

R638

R607

C618

0

C634

C607

R641

R662

R624

R618

R643

R608

C644

W862

C612

C647

C675

C605

R648

C654

R679

R639

W905

C646

R616

C614

W837

C615

R642

C601

R646

W836

R604

Q608

C621

C677

W066

C643

C656

W802

Q602

R619

C670

R626

R649

R610

W065

W812

R657

C658

R611

R603

R625

C659

C619

R612

W067

C660

R630

C620

R613

R658

C623

R628

W801

R622

R621

R629

W893

Q403

Q601

Q611

W889

C4101

R665

C4002

R4003

R4001

R4067

Q4018

R4053

R4054

Q4007

C4023

C4102

C4033

C4025

R4017

C4032

R4038

R4052

R4055

C4004

R4008

R4015

R4069

C4107

C4016

R4014

C4026

C4037

R4063

C4019

W318

C4014

C4028

C4098

W911

R4016

R308

C4027

C4097

C4043

R4027

Q351

C4010

C4020

1

R4032

C4035

C4018

W309

C361

R353

R4022

C4070

R4023

R361

C4038

81

IC4001

C4047

C359

R359

R352

C4044

C4048

31

C362

C4042

R4065

R4026

51

C4068

C4046

C4123

C4054

C4059

C4061

R4034

C4083

R1070

C4089

C4076

C4064

Q4006

C4067

R4050

C4075

C4115

Q1007

C4063

C4099

R4042

C4080

C4072

R4075

Q4015

C4086

R1015

W871

C4116

R4077

C4082

R1011

C1006

R4074

C4121

C4122

R1058

Q1002

W222

R1024

R1010

Q1010

W230

C805

R816

R1006

R813

C811

R1078

R811

W839

C1069

C809

C810

C821

C822

R1035

R812

R1080

R814

R815

C4203

C4217

W825

R403

W890

R4020

R1071

R4057

R4005

R4004

C4006

W109

R4011

C4053

R4013

C4007

R4031

C4013

R4002

C1009

C4206

C4005

R426

C4062

R4012

Q4003

R4058

R4056

C4060

R1008

C1007

R4033

C4052

R4073

C4056

R4051

R1029

C4100

C1062

C4058

W196

R4035

R1069

C1012

C1022

C1001

R1090

C1015

C1074

C1063

R1057

Q1004

C1028

C1004

R1053

R1039

C1026

C1082

C1073

W869

C1092

85

R1009

C1020

C1033

C1023

R1033

C1025

C1024

R1012

C1031

R1054

C1081

W868

R1064

C1008

C1002

C1060

57

IC1006

1

C1067

R1067

C1010

R1007

C1019

R4209

R355

R1020

R1017

C1018

R1027

R1022

W828

Q4203

29

R1030

C1078

R1026

C1038R1021

C1035

W853

C1040

C1027

R1003

R1094

C1043

W858

R1028

R1056

C1052

R1059

R1050

R1083

C1050

R1087

C1056

Q1015

R1013

R1063

Q1016

IC1003

C1017

C1044

R1062

C1055

R1044R1045

R1096

C1030

R1032

C1072

C1071

R1051

R1049

C1014

R1031

F-5

F-6

Page 33

ABC D E F GH

Y/C/AUDIO/HEAD AMP SCHEMATIC DIAGRAM

8

7

FROM/TO CYL/MOTOR

4

3

2

6

1

5

CP4004 TMC-T02X-E1

2

1

CD4005

1.25X6X138XC

4

FROM/TO A/C HEAD

CP4005 IMSA-9604S-06Z14

1

2

3

4

5

6

3

2

(SYSCON PCB)

FROM/TO POWER

P.CON+5V_A

CP4001_1

TOC-C04X-B1

SP-CH1 (R)

SP COM

SP-CH2 (L)

TO F/E HEAD

FE HEAD(GND)

FE HEAD(HOT)

AE HEAD(+)

AE HEAD(-)

CTLCTL+

AUDIO REC

AUDIO PB

P.CON+9V

NC

GND

B4001

W5RH3.5X5X1.0

1

C4107

0.022 B

L4008

1mH

C4108

CTLCTL+

47010V YK

Y/C_A

P.CON+5V_A

MESECAM_M

VCR_A_MUTE

C4033

0.0018

R4052

R4053

1.2K

R4020

VD

10M

V.REC_ST_H

NC

B

Q4007

2SC2412K

6.3

560K

R4038

390K

NORMAL AUDIO

REC ST SW

R4056

2.2K

TP4002

V.ENV

AMP

1.4

2.0

C4101

0.1 B

R4001

1.5K

C4002

0.056 B

15.6KHZ TRAP

L4001

2623003

4

NC

R4069

BUFFER

Q4018

2SC2412K

1.5

C4102

Q4001

KTC3203_Y

0

R4055

R4054

NC

10M

0.0047 B

330K

123

6

R4063

R4067

H.SW

ENV_DET

2

R4065

1K

2.250V KA

C4040

C4042

C4046

C4044

560

0.039 B

R4026

0.47 B

27K

680

1B

C4035

0.01 B

C4038

R4022

0.068 B

C4048

C4050

0.022 B

4.750V KA

C4054

3P CH

L4011

3.7

1.0

4.7

0

560

390

R4002

3.3

C4004

0.01 B

4.6 4.9

4.9

R4003

Q4002

KTC3203_Y

C4005

330

100uH 0305

3

4

OSC

R4004

10K

C4006

0.0047 B

0.01 B

L4004

R4057

39K +-1%

C4001

336.3V KA

C4007

R4005

NC

H.SW

TP4001

C4032

0.01 B

150

L4003

P.CON+5V_A

10

D4001

SB10-03A3

R4017

820P CH

47K +-1%

1

6

2

5

34

L4005

1626008

100uH 9A06B

C4010

0.001 B

C4018 0.033 B

C4014 0.1 B

C4019 0.01 B

C4020 0.01 B

C4027 0.01 B

C4028 0.01 B

C4015 476.3V KA

C4016 0.1 B

C4025

R4008

1K

2206.3V YK

C4017

C4023

W911

C4013

220P CH

R4011

2.2K +-1%

0.022100V MKT

C4009

Y/C/AUDIO/CCD/HEAD AMP

IC4001

HA118217F

NC

2.5

818283848586878889

1.2

C4024

2.6

1.5

3.350V KA

ENV

DET

0

HA GND

2.2

2.2

2.1

2.2

4.8

HA VCC

90919293949596979899

0

C4097

0

0.01 B

0

C4098

0

0.01 B

0.5

1B

4.8

AVCC

0

4.8

2.5

10uH

MUTE

2.5

100

110

270K

R4014

L4025

R4015

10K

L4024

C4026 0.01 B

0.1 B

R4016

C4031

V.REC ST SW

Q4003

KRA103SRTK

R4012

4.8

4.8

0

R4058

4.7K

27K

R4013

4.7K

P.CON+5V_A

V.REC_ST_H

W941

LIMITTER

KILLER

DET OUT

SW32

SW33

SW34

SW35

SW36

SW37

SW38

SW39

10uH

L4026

180

4.750V KA

C4036

R4021

18K +-1%

PB SW

Q4004

KTC3198

KTC3198

HPF

DET

0.7

0.7

PB SW

Q4005

COMP

SP2

10uH

C4037

1016V KA

HEAD SW1

HEAD SW2

+

-

-

SP1

+

EP2

-

-

EP1

SW1EP ON

REC EQ

C4039

680P CH

0

0

DET

DET

SP2

SP1

CH2

+

CH1

EP2

CH2

EP1

MESECAM

+

SW40

A.GND

4

4.750V KA

0

0

SW30

SW31

CH1

PRE

AMP

SP ON

5

TANC

VCA

FROM

DET

+

BAND

GAP

C4041

R4023

10K

SW29

SP

EP

SW2

P

R

VCA

SW3

REC ON

4.750V KA

5

R4027

TUNER_A_YC

X4001

REC

MUTE

P SW7

R

3

2

C4043 1 B

27K

4.433619MHz

ME

SECAM

DET

SW28

L SECAM

L SECAM

629

TRAP

SW4

SW6

1

NC

C4047

NC

C GND

RECPB/REC

SEP

P

1M HPF

7M HPF

LAG LERD

LPF

FM MOD

FO/DEV

ADJ

S-DET

YVCC

1016V KA

2FSCVCO

REC

APC

PHASE SW

SW20

P

R

HPF

SW19COMP

MIX

LEVEL

ADJ

S

DL

SQPB

R4032

C4052 150P CH

R4033 1.5K

C4053

DO

ACC

SQPB

MAIN

EMPH

CARRIER

OFFSET

W.C/DC

6.8K

C4100 27P CH

R4051 10K

0.1 B

PB

APC

C4056

476.3V KA

CR DET 2FSCX TAL VCO/OSD

DISCRI AFC

DOWN1/2 1/2

CONV.

2FL VCO

4PHASE GEN

2M LPF

SW27

LPF

+

AGCFMEQ

DET

SW5

11 12 13 14 15 16 17 18 192 20 21 22 23 24 25 26 27 28 293 30

9

226.3V KA

C4049

1B

C4051

R4030 6.8K

R4031

4.7K

C4055

L4009

100uH 9A06B

REAR_A_IN_L

P.CON+5V_A

C4123

C4057

12uH

R4034

FH SYNC

COLOR

KILLER

ID DET

CTL TRAP

HPF

FHTRAP

B.EC.K