Page 1

Installation and Operating Manual

Enhanced Model 2xx

Software v3.x

Magnetostrictive

Level Transmitter

SIL 2

Page 2

Read this Manual Before Installing

his manual provides information on the Jupiter

T

®

agne-

m

tostrictive transmitter. It is important that all instructions

are read carefully and followed in sequence. Detailed

instructions are included in the Installation section of this

manual.

Conventions Used in this Manual

Certain conventions are used in this manual to convey

specific types of information. General technical material,

support data, and safety information are presented in

narrative form. The following styles are used for notes,

cautions, and warnings.

Notice of Trademark, Copyright, and Limitations

rion & Orion logotype, Magnetrol & Magnetrol

O

logotype, and Jupiter are registered trademarks of

Magnetrol International.

Copyright © 2010 Magnetrol International.

All rights reserved.

Performance specifications are effective with date of issue

and are subject to change without notice. Magnetrol

reserves the right to make changes to the product

described in this manual at any time without notice.

Magnetrol makes no warranty with respect to the accuracy

of the information in this manual.

NOTES

Notes contain information that augments or clarifies

an operating step. Notes do not normally contain

actions. They follow the procedural steps to which

they refer.

Cautions

Cautions alert the technician to special conditions that

could injure personnel, damage equipment, or reduce

a component’s mechanical integrity. Cautions are also

used to alert the technician to unsafe practices or the

need for special protective equipment or specific

materials. In this manual, a caution box indicates a

potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

WARNINGS

Warnings identify potentially dangerous situations or

serious hazards. In this manual, a warning indicates an

imminently hazardous situation which, if not avoided,

could result in serious injury or death.

Safety Messages

Follow all standard industry procedures for servicing electrical equipment when working with or around high

voltage. Always shut off the power supply before touching any components.

WARNING! Explosion hazard. Do not connect or dis-

connect equipment unless power has been switched off or

the area is known to be non-hazardous.

Low Voltage Directive

For use in Installation Category II, Pollution Degree 2. If

equipment is used in a manner not specified by the manufacturer, protection provided by the equipment may be

impaired.

Warranty

All Magnetrol/Orion electronic level and flow controls

are warranted free of defects in materials or workmanship

for one full year from the date of original factory shipment.

If returned within the warranty period; and, upon factory

inspection of the control, the cause of the claim is

determined to be covered under the warranty; then,

Magnetrol/Orion will repair or replace the control at no

cost to the purchaser (or owner) other than transportation.

Specific to the Jupiter line of products; warranty will be

void should the electronics housing or threaded fittings be

rotated. Rotating the electronics enclosure could cause

damage to the sensor cables.

Magnetrol/Orion shall not be liable for misapplication,

labor claims, direct or consequential damage or expense

arising from the installation or use of equipment. There

are no other warranties expressed or implied, except special written warranties covering some Magnetrol/Orion

products.

Quality Assurance

The quality assurance system in place at Magnetrol guarantees the highest level of quality throughout the company. Magnetrol is committed to providing full customer

satisfaction both in quality products and quality service.

Magnetrol’s quality assurance system is

registered to ISO 9001 affirming its

commitment to known international

quality standards providing the

strongest assurance of product/service

quality available.

46-648 Jupiter Magnetostrictive Transmitters

Page 3

Enhanced Jupiter®Magnetostrictive Transmitter

Table of Contents

1.0 Installation .....................................................................4

1.1 Unpacking ................................................................4

1.2 Electrostatic Discharge (ESD) Handling Procedure...4

1.3 Before You Begin.......................................................5

1.3.1 Site Preparation..............................................5

1.3.2 Equipment and Tools .....................................5

1.3.3 Operational Considerations............................6

1.3.4 Configuration Information.............................6

1.4 Mounting..................................................................6

1.4.1 External..........................................................6

1.4.2 Internal, Direct Insertion................................7

1.5 Wiring ......................................................................8

1.6 Configuring the Transmitter......................................9

1.6.1 Operating Parameters.....................................9

1.6.2 Transmitter Display and Keypad ....................9

1.6.3 Password Protection .......................................9

1.6.4 Menu: Step-By-Step Procedure.....................10

1.6.4.1 Measurement Type: Level Only.............11

1.6.4.2 Measurement Type: Interface Only .......13

1.6.4.3 Measurement Type: Interface & Level ...15

1.6.4.4 Measurement Type: Level & Interface ...17

1.7 Configuration Using HART®..................................19

1.7.1 Connections .................................................19

1.7.2 HART Display Menu...................................19

1.7.3 HART Revision Table ..................................19

1.7.4 HART Menu................................................20

UNDATION

1.8 FO

1.8.1 Description ...................................................21

1.8.2 Benefits .........................................................22

1.8.3 Device Descriptions ......................................22

1.8.4 Intrinsically Safe............................................23

2.0 Reference Information..................................................24

2.1 Description .............................................................24

2.2 Theory of Operation...............................................24

2.3 Troubleshooting ......................................................25

2.3.1 Troubleshooting ...........................................25

2.3.2 Status Messages ............................................26

2.3.3 Troubleshooting Flowcharts..........................27

2.4 Agency ....................................................................30

2.4.1 Agency Drawing...........................................30

2.4.2 Agency Specifications (Explosion Proof) ......32

2.4.3 Agency Specifications (ATEX)......................32

2.5 Maintenance ...........................................................32

2.5.1 Keep Control Clean .....................................32

2.6 Replacement Parts...................................................33

2.6.1 Parts Identification .......................................33

2.7 Specifications ..........................................................34

2.7.1 Performance .................................................34

2.7.2 Functional....................................................35

2.7.3 Physical ........................................................35

Glossary .........................................................................37

Configuration Data Sheet .............................................39

Fieldbus®Digital Communications ...21

46-648 Jupiter Magnetostrictive Transmitters

Page 4

1.0 Installation

aution: If equipment is used in a manner not specified by manu-

C

facturer, protection provided by equipment may be

impaired

This section provides detailed procedures for properly

installing, wiring, configuring and, if needed, troubleshooting the Jupiter magnetostrictive level transmitter.

In most cases externally mounted units will be shipped

from the factory attached to the Orion Instruments

magnetic level indicator.

1.1 Unpacking

Caution: Do not rotate the Jupiter electronics enclosure or any

threaded fittings. Rotating the electronics enclosure will

void warranty and could cause damage to sensor cables.

Unpack the instrument carefully. Inspect all units for

damage. Report any concealed damage to carrier within

24 hours. Check the contents against the packing slip and

purchase order. Check and record the serial number for

future reference when ordering parts.

Caution: Do not discard the shipping container until all parts are

accounted for and inspected.

1.2 Electrostatic Discharge (ESD) Handling Procedure

Magnetrol/Orion’s electronic instruments are manufactured to the highest quality standards. These instruments

use electronic components that may be damaged by static

electricity present in most work environments.

The following steps are recommended to reduce the risk of

component failure due to electrostatic discharge.

• Ship and store circuit boards in anti-static bags. If an antistatic bag is not available, wrap the board in aluminum

foil. Do not place boards on foam packing materials.

• Use a grounding wrist strap when installing and removing

circuit boards. A grounded workstation is recommended.

• Handle circuit boards only by the edges. Do not touch

components or connector pins.

• Make sure that all electrical connections are completely

made and none are partial or floating. Ground all equipment to a good, earth ground.

4

46-648 Jupiter Magnetostrictive Transmitters

Page 5

1.3 Before You Begin

Caution: This instrument is intended for use in Installation

ategory II, Pollution Degree 2 locations.

C

1.3.1 Site Preparation

Each Jupiter magnetostrictive transmitter is built to match

the specifications required within the defined model

option number. Wiring terminations will need to be made

and the configuration will need to be accomplished.

Ensure that the power to be supplied to the instrument is

the same voltage (24 VDC) as ordered with the instrument, and that the wiring between the power supply and

the Jupiter transmitter is correct for the type of installation. See Specifications, Section 2.7.

NOTE: Applying incorrect voltage will damage the unit.

When installing the Jupiter transmitter in a general

purpose or hazardous area, all local, state, and federal

regulations and guidelines must be observed. See Wiring,

Section 1.5.

1.3.2 Equipment and Tools

For installation of a new Jupiter with magnetic level indicator set, refer to Orion Instruments instruction manual

46-638.

To attach a Jupiter transmitter to an existing MLI or direct

insertion model, you may need the following tools:

5

⁄16" Nut-Driver (for tightening the mounting clamps).

•

• Screwdriver and assorted hand tools for making conduit

and electrical connections.

• Tape measure or ruler if configuring via Set 4 mA and

Set 20 mA display screens.

• Digital multimeter or DVM to troubleshoot supply

voltage problems.

46-648 Jupiter Magnetostrictive Transmitters

5

Page 6

1.3.3 Operational Considerations

Exterior ambient temperature of the service should not

exceed the design specifications of the electronics (-40° to

+175° F (-40° to +80° C)). The operating temperature

limits of the LCD are -5° to +160° F (-20° to +70° C).

Temperatures below -5° F will cause the display to temporarily white out, and temperatures above +160° F will

cause the display to go temporarily black. It will recover

without damage when the operating temperature range

returns. A sunshade should be used if electronics are

mounted in direct sunlight.

Maximum process temperature for direct insertion

transmitters is +500° F (+260° C). Externally mounted

transmitters can be used with process temperatures up

to +850° F (+455° C) if the MLI is equipped with an

insulation blanket from the factory.

1.3.4 Configuration Information

Some key information is needed to configure the Jupiter

transmitter. Complete the following operating parameters

table before beginning configuration.

Display Question Answer

Units What units of measurement will be

used? (inches or centimeters) _____________

Probe What probe length is listed on the

Length model information? _____________

Set What is the 0% reference point for the

4.0 mA 4.0 mA value? _____________

Set What is the 100% reference point for

20.0 mA the 20.0 mA value? _____________

1.4 Mounting

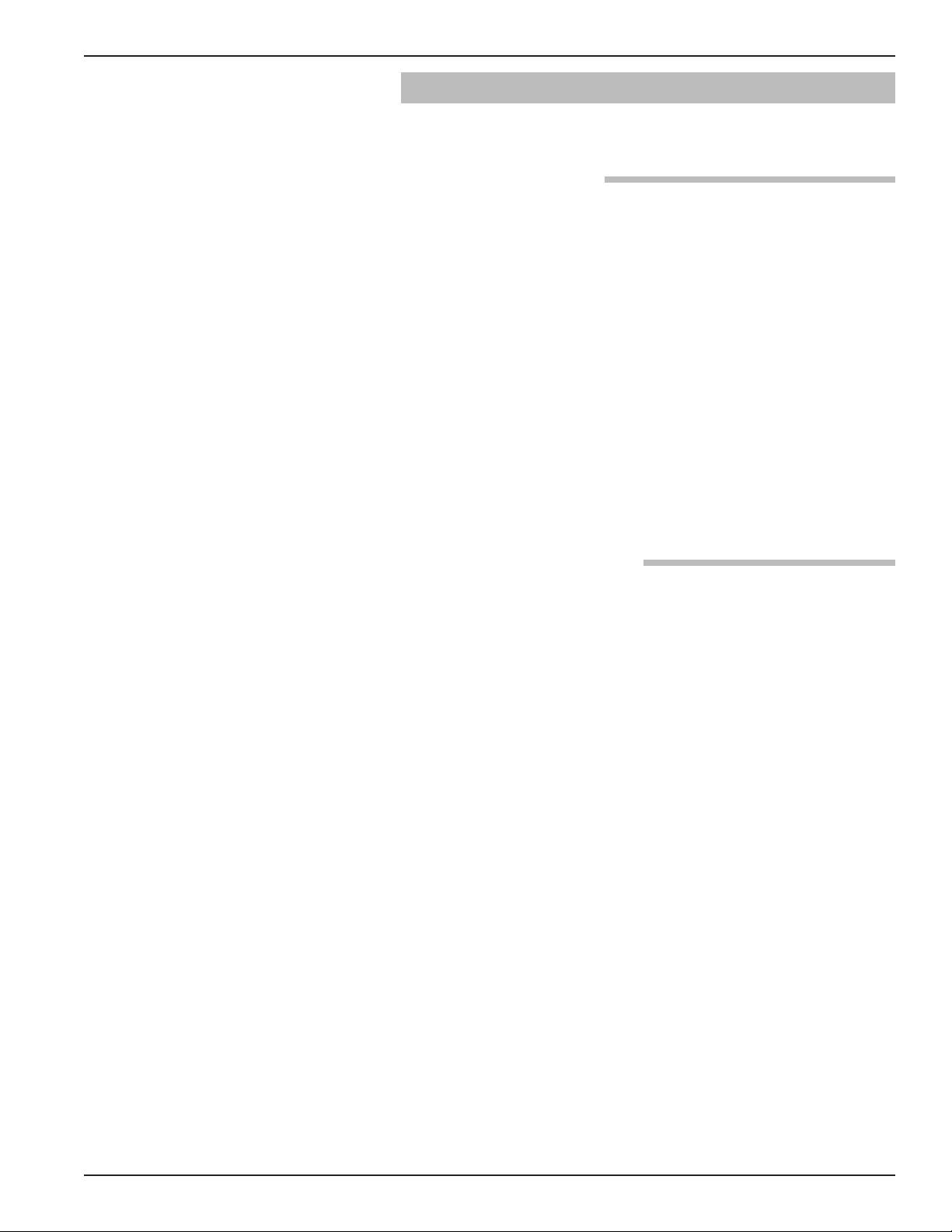

1.4.1 External

Caution: Do not rotate the Jupiter electronics enclosure or any

threaded fittings. Rotating the electronics enclosure will

void warranty and could cause damage to sensor cables.

If ordered from the factory with the MLI, the transmitter

will be attached to the gauge and configured for the measuring range specified at the time of order placement. If

not, use the following directions:

1. Place the Jupiter transmitter and mounting clamps in a

convenient location.

2. Position the Jupiter transmitter on the side of the MLI

where it will be attached. Mark the location and the exact

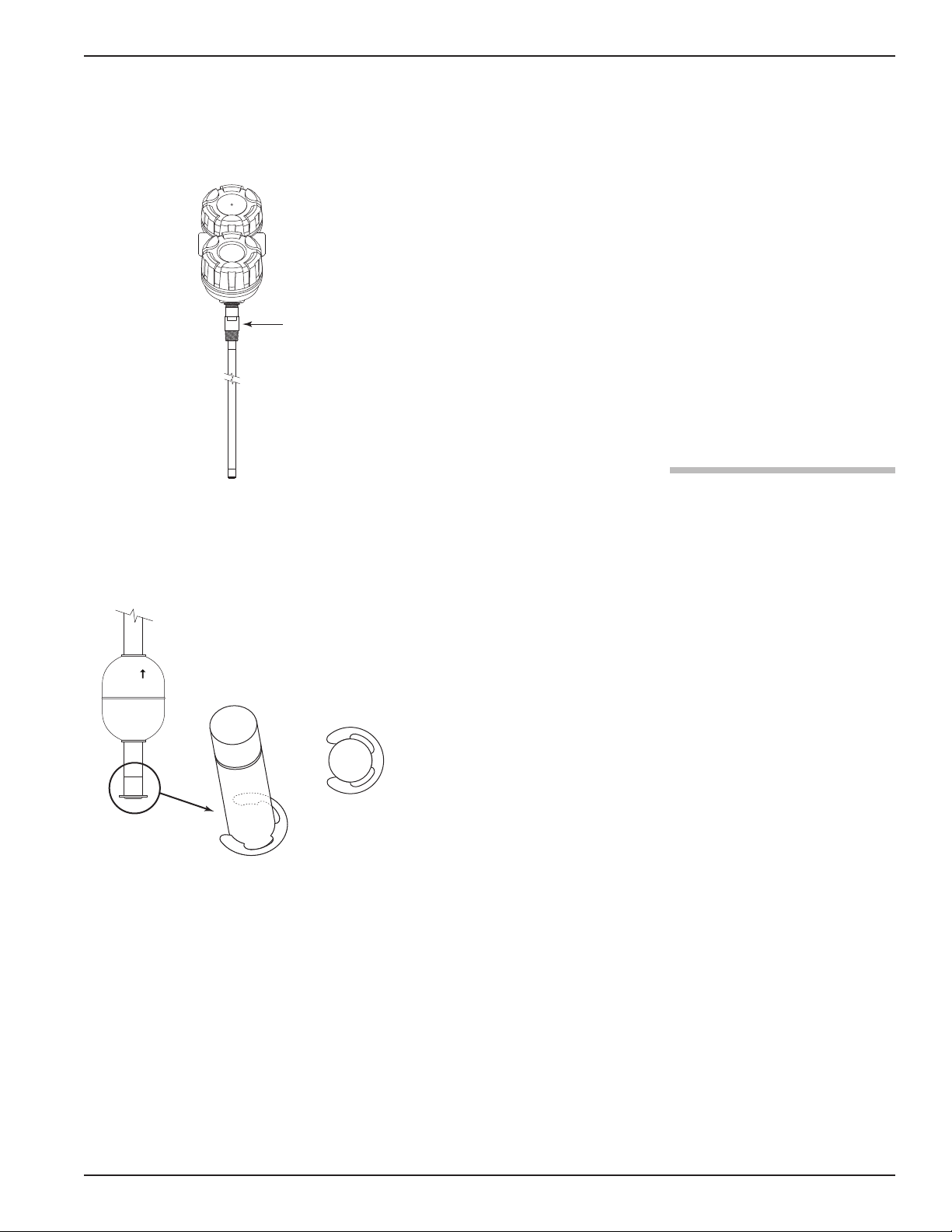

Figure 1

Mounting External Jupiter

6

area where the clamps will be attached to hold the Jupiter

in place.

46-648 Jupiter Magnetostrictive Transmitters

Page 7

3. Attach the lower clamp and tighten so that it remains in

Bottom view

Up

Upper Clamp

place, but loose enough so that there is still room to place

the guide tab from the Jupiter between the inside of the

clamp and the outer diameter of the MLI chamber. See

Figure 1.

4. The upper clamp will need to be open to a large enough

diameter to be able to mount to the MLI as well as the

probe. The upper clamp should be positioned just above

3

⁄4" NPT threads. See Figure 2.

the

5. Mount the Jupiter guide pin in the lower clamp and tighten.

If necessary, use strapping tape to temporarily hold in

place on the MLI. See Figure 1.

6. Position the upper clamp to attach the unit to the MLI

and tighten. See Figure 1.

7. Discard any tape temporarily holding the Jupiter to the

MLI.

1.4.2 Internal, Direct Insertion

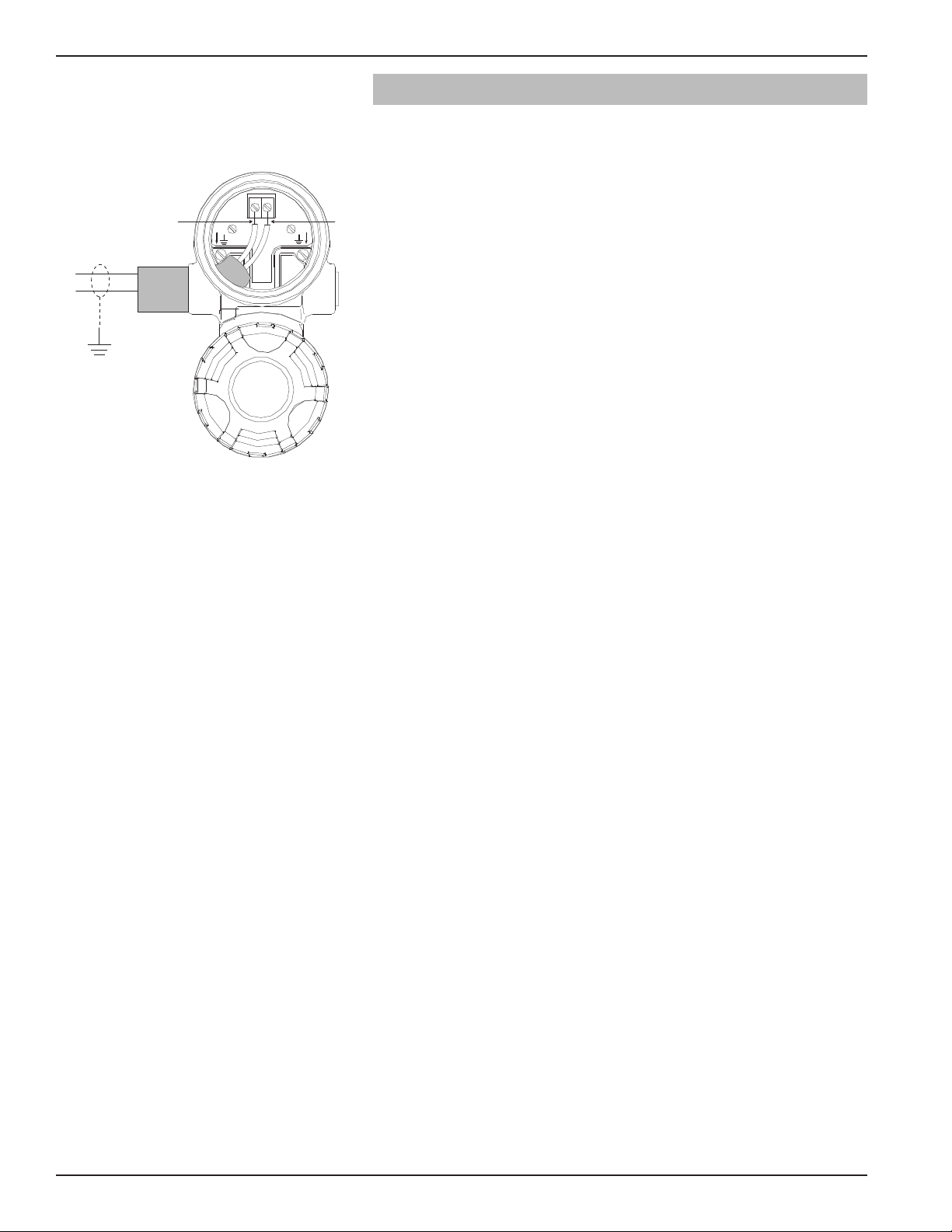

Figure 2

Figure 3

Float Attachment Detail

Use caution when handling probes to ensure probe is not

bent during installation. A bend in the probe may prevent

float from traveling freely up and down the probe.

Caution: Do not rotate the Jupiter electronics enclosure or any

threaded fittings. Rotating the electronics enclosure will

void warranty and could cause damage to sensor cables.

NOTE: Direct Insertion models may be calibrated prior to installation

by positioning the float at the desired 4 mA & 20 mA points.

See Section 1.6 for calibration details.

1. Verify float will pass through vessel opening, if not, it will

be necessary to attach the float after the probe is installed.

2. Carefully insert probe into vessel and thread or bolt to the

mating connection as appropriate.

3. The float is held on the probe by a C-clip inserted into a

groove machined into the tip of the probe. The float is

attached or removed by removing and reinserting the

C-clip. See figure 3. To ensure proper float orientation, the

float is marked “Up ”.

©

46-648 Jupiter Magnetostrictive Transmitters

7

Page 8

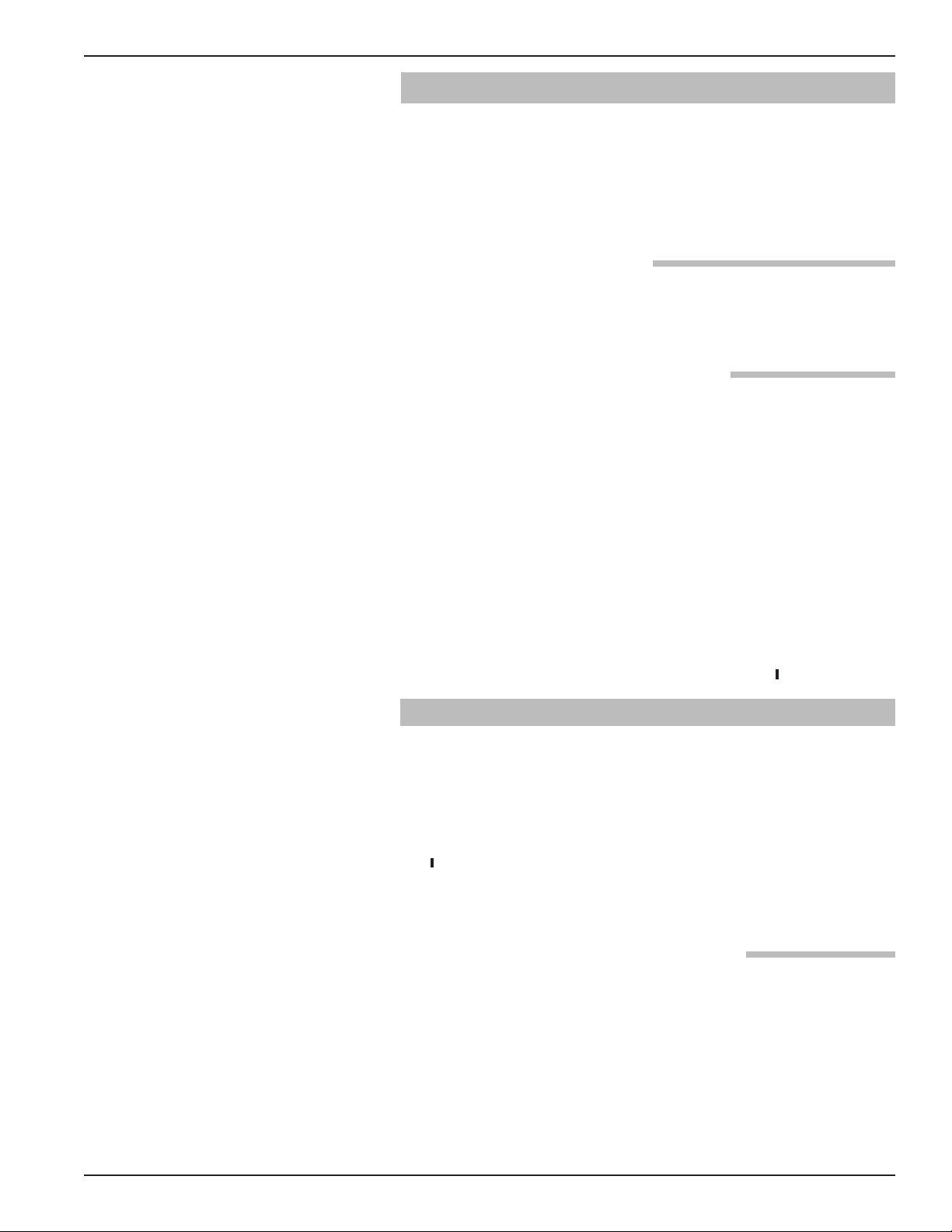

1.5 Wiring

Red (+)

Black (-)

(

+)

(

-)

Caution: The HART version Jupiter transmitter operates at 12–28

DC. The Fieldbus version operates at the 9–32 VDC.

V

Higher voltages will damage the transmitter.

Wiring between the power supply and the Jupiter

transmitter should be made using 18–22 AWG shielded

twisted pair instrument cable. The transmitter enclosure

consists of two compartments. The upper compartment is

used to terminate the field wires (wiring termination compartment), and the lower is the electronics compartment.

The Jupiter is offered for use in Class I, Div 1 areas (flammable gasses may be present). Follow the instructions

below to complete wiring of the instrument.

WARNING! Explosion hazard. Do not disconnect equipment unless

power has been switched off or the area is known to be

non-hazardous.

Figure 4

Wiring Diagram

An explosion proof (XP) installation potentially has flammable vapors or media present. Covers on instruments in

these areas must remain on and tight while power is

applied to the instrument.

Equipment installed in an area classified as Class I, Div 2,

reflects that flammable or explosive vapors may be present.

To install intrinsically safe wiring, make sure the IS barrier

is properly installed in the safe area or suitably installed in

a hazardous area (refer to local plant or facility procedures). Complete the wiring from the barrier to the Jupiter

transmitter. See Agency Specifications– Intrinsically Safe

Installations, Section 2.4.1.

1. Make sure power is off in any junction box which will be

exposed to the atmosphere, unless the area has already

been sniffed and approved free of flammable vapors.

2. The top cover (field wiring compartment) of the Jupiter

transmitter may be removed. Place the cover in a location

where dirt will not get on the threads.

3. Connect shield to an earth ground at the power supply.

4. Connect positive supply wire to the (+) terminal and the

negative supply wire to the (-) terminal.

5. Tighten and check connections, then replace cover.

6. An explosion proof seal is not required unless specifically

noted by the local code.

Note: All local, state and federal regulations and electrical codes

must be adhered to during and after installation.

7. Power may be applied to the instrument when the installation is complete and has been checked by the instrument

engineer or safety officer.

8

46-648 Jupiter Magnetostrictive Transmitters

Page 9

1.6 Configuring the Transmitter

The Jupiter transmitter comes configured from the factory

with regard to probe, float type, and orientation.

Information on configuring the transmitter using a HART

communicator is given in Configuration Using HART,

Section 1.7.

1.6.1 Operating Parameters

Some key information is needed to calibrate the Jupiter

transmitter. Complete the configuration information table.

See Configuration Information, Section 1.3.4.

1.6.2 Transmitter Display and Keypad

The Jupiter transmitter has a liquid-crystal display (LCD)

capable of showing two lines of 8 characters each.

Transmitter measurements and configuration menu screens

are shown on the LCD.

The transmitter default display is the measurement screen.

It cycles every 5 seconds to display STATUS, LEVEL,

%OUTPUT, and LOOP information. The transmitter

defaults to this display after 5 minutes if no keystrokes

are sensed.

The keypad has three arrows used to scroll through the

displays and to calibrate the transmitter – the Up and

Down Arrow ( ) keys and the Enter ( ) key.

Arrows Display Mode Configuration Mode

Up and Down Moves forward and backward Increases or decreases the

Á

Enter Enters the configuration mode Accepts a value and returns

Á

1.6.3 Password Protection (Default = 0)

Function in Function in

Á

in the configuration program value displayed or moves to

from one display to another. another choice.

(noted by an exclamation point to the display mode.

as the last character in the top

display line).

Á

Á

Á

Note: Hold arrow key for

rapid scrolling.

The Jupiter transmitter is password protected to restrict

access to certain portions of the menu structure that affect

the operation of the system. When the proper password is

entered, an exclamation point (!) appears as the last character of the first line of the display. The password can be

changed to any numerical value up to 255. The password

is required whenever configuration values are changed.

46-648 Jupiter Magnetostrictive Transmitters

9

Page 10

The default password installed in the transmitter at the

factory is 0 (password disabled). The last step in the configuration menu provides the option to enter a new password. If 0 is entered as a password, the transmitter is no

longer password protected and any value in the menu can

be altered (except diagnostic values) without entering a

confirming password.

NOTE: If the password is not known, the menu item New Password

displays an encrypted value representing the present password. Call the factory with this encrypted value to determine

the actual password.

1.6.4 Menu: Step-By-Step Procedure

The following table provides a complete explanation of

the software menus displayed by the Jupiter transmitter.

Use this table as a step-by-step guide to configure the

transmitter.

The first column presents the menus shown on the transmitter display. The displays are in the order they would

appear if the arrow keys were used to scroll through the

menu. The numbers are not shown on the display. They

are provided as a reference.

The second column provides the actions to take when

configuring the transmitter. Additional information or an

explanation of an action is given in the third column.

Models with one float:

Level only calibration — proceed to Section 1.6.4.1

Interface only calibration — proceed to Section 1.6.4.2

Models with two floats:

Interface and level calibration — proceed to

Section 1.6.4.3

• The loop output will follow the interface layer.

• Upper liquid level is for display only.

Level and interface calibration — proceed to

Section 1.6.4.4

• The loop output will follow overall liquid level.

• Interface level is for display only.

NOTE: Float 1 is the float nearest to the transmitter head, Float 2 is

the second (i.e., for top-mounted units, Float 1 is the top level

float and Float 2 is the interface layer float; for bottom-mounted models, Float 1 is the interface float, Float 2 is the top level

float).

10

46-648 Jupiter Magnetostrictive Transmitters

Page 11

1.6.4.1 Measurement Type: Level Only

Display Action Comment

Status

1

2

Level

% Output

Loop

Level

xxx.xx

Transmitter Display Transmitter default display. Status, Level, % Output, and Loop

Transmitter Display Level measurement in centimeters or inches

values cycle every 8 seconds.

3

4

5

6

7

8

9

10

11

12

13

14

15

16

% Output

xx.xx%

Loop

xx.xx mA

MeasType

Units

Probe Ln

xxx.xxlu

Set 4mA

xxx.xxlu

Set 20mA

xxx.xxlu

Lvl Ofst

xxx.xxlu

Damping

xx.x s

Fault

22mA

Poll Adr

xx

Trim 4

xxxx

Trim 20

xxxx

Loop Tst

Transmitter Display Level as a percentage of loop current span

ransmitter Display Loop current output (mA)

T

Select type of measurement Choose Lvl Only

Select units of length Choose cm or in

Enter exact length of probe 6–420 inches (15.24–1066.8 cm)

Enter the PV value for 4 mA

Enter 4 mA point in level units

point

Enter the PV value for 20 mA

Enter 20 mA point in level units

point

Enter the level offset value Changes zero level as referenced from probe tip

Enter damping filter time 0–1 second in 0.1 increments

1–25 seconds in 1.0 increments

Select loop current under

3.6 mA, 22 mA or Hold

fault condition

Enter HART polling address

0–15

number

Adjust 4 mA point Attach a meter to the output. If the output does not equal 4 mA,

adjust the value of the display until the meter reads 4 mA

Adjust 20 mA point Attach a meter to the output. If the output does not equal 20 mA,

adjust the value of the display until the meter reads 20 mA

Enter a mA value Set mA output to a value between 3.6 and 22.0 mA

17

DeadBand

xx.x

Factory Setting Diagnostic, factory setting

Enter mounting type MLI Top (external probe; transmitter top mounted)

18

19

20

21

22

23

46-648 Jupiter Magnetostrictive Transmitters

Snsr Mnt

Trim Lvl

xx.xx

F1 Cnts

New Pass

Xxx

Language

(select)

Jupiter HT

Ver 3.0A

Enter value to adjust Level

reading

Display only For factory diagnostic use

Enter new password Use up and down keys to select desired value (0–255)

Select from English or

Spanish

Display only Product firmware version

MLI Bot (external probe; transmitter bottom mounted)

Dir Near (NPT, BSP, and 600# or less flanged probe)

Dir Ext (flanged probes 900# class and over)

-20.00 inches ≤ Trim Lvl ≤ 20.00 inches

Changes display language

11

Page 12

1.6.4.1 Measurement Type: Level Only (cont.)

Display Action Comment

4

2

25

(current status)

26

DispFact

(select)

History

Run Time

Select Yes to display factory

parameter menus

Enter to view history of

exceptions

Display only Elapsed time since power on; reset to zero with History Reset

Diagnostic Display

27

28

29

30

31

32

33

34

35

36

History

Reset

Conv Fct

xxxxxx

Scl Ofst

F1Thresh

F1 Polar

Senstvty

Drv Ampl

ElecTemp

xxx C

Max Temp

xxx c

Min Temp

xxx C

Press Enter and select yes to

lear history

c

Factory parameter Do not adjust

Factory parameter Do not adjust

Factory parameter Do not adjust

Factory parameter Do not adjust

Factory parameter Do not adjust

Factory parameter Do not adjust

Diagnostic Display Present temperature in electronics compartment (degrees C)

Diagnostic Display Maximum electronics temperature recorded (degrees C)

Diagnostic Display Minimum electronics temperature recorded (degrees C)

12

46-648 Jupiter Magnetostrictive Transmitters

Page 13

1.6.4.2 Measurement Type: Interface Only

Display Action Comment

Status

1

2

IfcLvl

% Output

Loop

IfcLevel

xxx.xx

Transmitter Display Transmitter default display. Status, Interface Level, % Output, and

Transmitter Display Interface level measurement in centimeters or inches

Loop values cycle every 8 seconds.

3

4

5

6

7

8

9

10

11

12

13

14

15

16

% Output

xx.xx%

Loop

xx.xx mA

MeasType

Units

Probe Ln

xxx.x

Set 4mA

xxx.xxlu

Set 20mA

xxx.xxlu

Lvl Ofst

xxx.xxlu

Damping

xx.x s

Fault

22mA

Poll Adr

xx

Trim 4

xxxx

Trim 20

xxxx

Loop Tst

Transmitter Display Interface level as a percentage of loop current span

ransmitter Display Loop current output (mA)

T

Select type of measurement Choose Ifc Only

Select units of length Choose cm or in

Enter exact length of probe 6–420 inches (15.24–1066.8 cm)

Enter the PV value for 4 mA

Enter 4 mA point in level units

point

Enter the PV value for 20 mA

Enter 20 mA point in level units

point

Enter the level offset value Changes zero level as referenced from probe tip

Enter damping filter time 0–1 second in 0.1 increments

1–25 seconds in 1.0 increments

Select loop current under

3.6 mA, 22 mA or Hold

fault condition

Enter HART polling address

0–15

number

Adjust 4 mA point Attach a meter to the output. If the output does not equal 4 mA,

adjust the value of the display until the meter reads 4 mA

Adjust 20 mA point Attach a meter to the output. If the output does not equal 20 mA,

adjust the value of the display until the meter reads 20 mA

Enter a mA value Set mA output to a value between 3.6 and 22.0 mA

17

DeadBand

xx.x

Factory Setting Diagnostic, factory setting

Enter mounting type MLI Top (external probe; transmitter top mounted)

18

19

20

21

22

23

46-648 Jupiter Magnetostrictive Transmitters

Snsr Mnt

Trim Ifc

xx.xx

F1 Cnts

New Pass

Xxx

Language

(select)

Jupiter HT

Ver 3.0A

Enter value to adjust Interface

reading

Display only For factory diagnostic use

Enter new password Use up and down keys to select desired value (0–255)

Select from English or

Spanish

Display only Product software version

MLI Bot (external probe; transmitter bottom mounted)

Dir Near (NPT, BSP, and 600# or less flanged probe)

Dir Ext (flanged probes 900# class and over)

-20.00 inches ≤ Lvl Trim ≤ 20.00 inches

Changes display language

13

Page 14

1.6.4.2 Measurement Type: Interface Only (cont.)

Display Action Comment

4

2

25

(current status)

26

DispFact

(select)

History

Run Time

Select Yes to display factory

parameter menus

Enter to view history of

Diagnostic Display

exceptions

Display only Elapsed time since power on; reset to zero with history reset

27

28

29

30

31

32

33

34

35

36

History

Reset

Conv Fct

xxxxxx

Scl Ofst

F1Thresh

F1 Polar

Senstvty

Drv Ampl

ElecTemp

xxx C

Max Temp

xxx c

Min Temp

xxx C

Press Enter and select yes to

lear history

c

Factory parameter Do not adjust

Factory parameter Do not adjust

Factory parameter Do not adjust

Factory parameter Do not adjust

Factory parameter Do not adjust

Factory parameter Do not adjust

Diagnostic Display Present temperature in electronics compartment (degrees C)

Diagnostic Display Maximum electronics temperature recorded (degrees C)

Diagnostic Display Minimum electronics temperature recorded (degrees C)

14

46-648 Jupiter Magnetostrictive Transmitters

Page 15

1.6.4.3 Measurement Type: Interface & Level

Display Action Comment

Status

1

2

IfcLvl

% Output

Loop

IfcLevel

xxx.xx

Transmitter Display Transmitter default display. Status, Interface Level, % Output,

Transmitter Display Interface level measurement in centimeters or inches

and Loop values cycle every 8 seconds.

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

% Output

xx.xx%

Loop

xx.xx mA

Level

MeasType

Units

Probe Ln

xxx.x

Set 4mA

xxx.xxlu

Set 20mA

xxx.xxlu

Lvl Ofst

xxx.xxlu

Damping

xx.x s

Fault

22mA

Poll Adr

xx

Trim 4

xxxx

Trim 20

xxxx

Loop Tst

Transmitter Display Interface level as a percentage of loop current span

Transmitter Display Loop current output (mA)

Transmitter Display Displays top liquid level

Select type of measurement Choose Ifc&Lvl

Select units of length Choose cm or in

Enter exact length of probe 6–420 inches (15.24–1066.8 cm)

Enter the PV value for 4 mA

Enter 4 mA point in level units

point

Enter the PV value for 20 mA

Enter 20 mA point in level units

point

Enter the level offset value Changes zero level as referenced from probe tip

Enter damping filter time 0–1 second in 0.1 increments

1–25 seconds in 1.0 increments

Select loop current under

3.6 mA, 22 mA or Hold

fault condition

Enter HART polling address

0–15

number

Adjust 4 mA point Attach a meter to the output. If the output does not equal 4 mA,

adjust the value of the display until the meter reads 20 mA

Adjust 20 mA point Attach a meter to the output. If the output does not equal 4 mA,

adjust the value of the display until the meter reads 20 mA

Enter a mA value Set mA output to a value between 3.6 and 22.0 mA

18

DeadBand

xx.x

Factory Setting Diagnostic, factory setting

Enter mounting type MLI Top (external probe; transmitter top mounted)

19

20

21

22

23

46-648 Jupiter Magnetostrictive Transmitters

Snsr Mnt

Trim Lvl

xx.xx

Trim Ifc

xx.xx

F1 Cnts

F2 Cnts

Enter value to adjust Level

reading

Enter value to adjust Interface

reading

Display only For factory diagnostic use

Display only For factory diagnostic use

MLI Bot (external probe; transmitter bottom mounted)

Dir Near (NPT, BSP, and 600# or less flanged probe)

Dir Ext (flanged probes 900# class and over)

-20.00 inches ≤ Trim Lvl ≤ 20.00 inches

-20.00 inches ≤ Trim Ifc ≤ 20.00 inches

15

Page 16

1.6.4.3 Measurement Type: Interface & Level (cont.)

Display Action Comment

24

New Pass

Xxx

Enter new password Use up and down keys to select desired value (0–255)

25

26

27

28

29

30

31

32

33

34

35

36

Language

(select)

Jupiter HT

Ver 3.0A

DispFact

(select)

History

(current status)

Run Time

History

Reset

Conv Fct

xxxxxx

Scl Ofst

F1Thresh

F1 Polar

F2Thresh

F2 Polar

Select from English or

Changes display language

Spanish

isplay only

D

roduct software version

P

Select Yes to display factory

parameter menus

Enter to view history of

Diagnostic Display

exceptions

Display only Elapsed time since power on; reset to zero with History Reset

Press Enter and select yes to

clear history

Factory parameter Do not adjust

Factory parameter Do not adjust

Factory parameter Do not adjust

Factory parameter Do not adjust

Factory parameter Do not adjust

Factory parameter Do not adjust

37

38

39

40

41

42

Senstvty

Drv Ampl

Min Sep

ElecTemp

xxx C

Max Temp

xxx c

Min Temp

xxx C

Factory parameter Do not adjust

Factory parameter Do not adjust

Factory parameter Do not adjust

Diagnostic Display Present temperature in electronics compartment (degrees C)

Diagnostic Display Maximum electronics temperature recorded (degrees C)

Diagnostic Display Minimum electronics temperature recorded (degrees C)

16

46-648 Jupiter Magnetostrictive Transmitters

Page 17

1.6.4.4 Measurement Type: Level & Interface

Display Action Comment

Status

1

2

Level

% Output

Loop

Level

xxx.xx

Transmitter Display Transmitter default display. Status, Level, % Output, and Loop

Transmitter Display Level measurement in centimeters or inches

values cycle every 8 seconds.

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

% Output

xx.xx%

Loop

xx.xx mA

IfcLevel

MeasType

Units

Probe Ln

xxx.x

Set 4mA

xxx.xxlu

Set 20mA

xxx.xxlu

Lvl Ofst

xxx.xxlu

Damping

xx.x s

Fault

22mA

Poll Adr

xx

Trim 4

xxxx

Trim 20

xxxx

Loop Tst

Transmitter Display Level as a percentage of loop current span

Transmitter Display Loop current output (mA)

Transmitter Display Displays interface level

Select type of measurement Choose Lvl&Ifc

Select units of length Choose cm or in

Enter exact length of probe 6–420 inches (15.24–1066.8 cm)

Enter the PV value for 4 mA

Enter 4 mA point in level units

point

Enter the PV value for 20 mA

Enter 20 mA point in level units

point

Enter the level offset value Changes zero level as referenced from probe tip

Enter damping filter time 0–1 second in 0.1 increments

1–25 seconds in 1.0 increments

Select loop current under

3.6 mA, 22 mA or Hold

fault condition

Enter HART polling address

0–15

number

Adjust 4 mA point Attach a meter to the output. If the output does not equal 4 mA,

adjust the value of the display until the meter reads 4 mA

Adjust 20 mA point Attach a meter to the output. If the output does not equal 20 mA,

adjust the value of the display until the meter reads 20 mA

Enter a mA value Set mA output to a value between 3.6 and 22.0 mA

18

DeadBand

xx.x

Factory Setting Diagnostic, factory setting

Enter mounting type MLI Top (external probe; transmitter top mounted)

19

20

21

22

23

46-648 Jupiter Magnetostrictive Transmitters

Snsr Mnt

Trim Lvl

xx.xx

Trim Ifc

xx.xx

F1 Cnts

F2 Cnts

Enter value to adjust Level

reading

Enter value to adjust Interface

reading

Display only For factory diagnostic use

Display only For factory diagnostic use

MLI Bot (external probe; transmitter bottom mounted)

Dir Near (NPT, BSP, and 600# or less flanged probe)

Dir Ext (flanged probes 900# class and over)

-20.00 inches ≤ Trim Lvl ≤ 20.00 inches

-20.00 inches ≤ Trim Ifc ≤ 20.00 inches

17

Page 18

1.6.4.4 Measurement Type: Level & Interface (cont.)

Display Action Comment

24

New Pass

Xxx

Enter new password Use up and down keys to select desired value (0–255)

25

26

27

28

29

30

31

32

33

34

35

36

Language

(select)

Jupiter HT

Ver 3.0A

DispFact

(select)

History

(current status)

Run Time

History Reset

Conv Fct

xxxxxx

Scl Ofst

F1Thresh

F1 Polar

F2Thresh

F2 Polar

Select from English or

Changes display language

Spanish

isplay only

D

roduct software version

P

Select Yes to display factory

parameter menus

Enter to view history of

Diagnostic Display

exceptions

Display only Elapsed time since power on; reset to zero with History Reset

Press Enter and select yes to

clear history

Factory parameter Do not adjust

Factory parameter Do not adjust

Factory parameter Do not adjust

Factory parameter Do not adjust

Factory parameter Do not adjust

Factory parameter Do not adjust

37

38

39

40

41

42

Senstvty

Drv Ampl

Min Sep

ElecTemp

xxx C

Max Temp

xxx c

Min Temp

xxx C

Factory parameter Do not adjust

Factory parameter Do not adjust

Factory parameter Do not adjust

Diagnostic Display Present temperature in electronics compartment (degrees C)

Diagnostic Display Maximum electronics temperature recorded (degrees C)

Diagnostic Display Minimum electronics temperature recorded (degrees C)

18

46-648 Jupiter Magnetostrictive Transmitters

Page 19

1.7 Configuration Using HART

+

+

-

-

Junction

R

L

> 250 Ω

Control

Room

Display

Power

Supply

Current

Meter

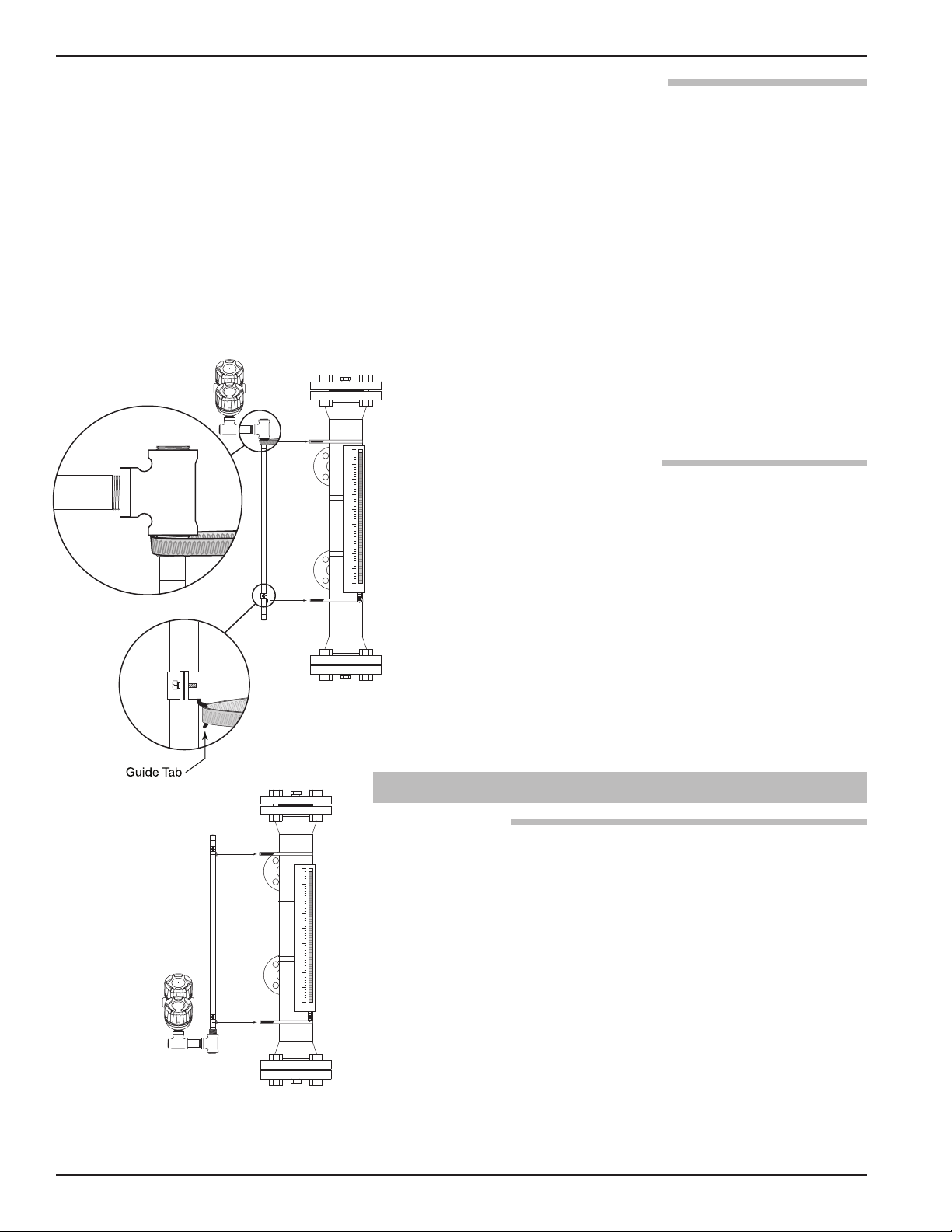

A HART (Highway Addressable Remote Transducer)

remote unit, such as a HART 375 handheld communicator,

can be used to provide a communication link to the

Jupiter transmitter. When connected to the control loop,

the same system measurement readings shown on the

transmitter are shown on the communicator. In addition,

the communicator can be used to configure the transmitter.

The HART communicator may need to be updated to

include the Jupiter software (Device Descriptors). Contact

your local HART Service Center for additional information.

Device manufacturer listed as Magnetrol International.

1.7.1 Connections

A HART communicator can be operated from a remote

location by connecting to a remote junction or by connecting directly to the terminal block in the electronics

housing of the Jupiter transmitter.

HART uses the Bell 202 frequency shift key technique of

high-frequency digital signals. It operates on the 4–20 mA

loop and requires a minimum of 250 Ω load resistance. A

typical connection between a communicator and the

Jupiter transmitter is illustrated.

1.7.2 HART Display Menu

A typical HART communicator display is an 8-line by

21-character LCD. Usually the bottom line of each menu

is reserved for software-defined function keys (F1–F4). For

detailed operating information, refer to the instruction

Figure 5

manual provided with the HART communicator.

The Jupiter transmitter online menu tree is shown in the

following illustration. Open the menu by pressing the

alphanumeric key 1, Device Setup, to display the secondlevel menu.

1.7.3 HART Revision Table

HART Version HCF Release Date Compatible with Jupiter

Software

Dev V2, DD V1 July 2003 Version 2.0A through 2.0B

Dev V3, DD V2 July 2006 Version 3.0A and later

46-648 Jupiter Magnetostrictive Transmitters

19

Page 20

1

Calibration

2

Basic Setup

3 Advanced Setup

4 Diagnostics

5 Review

1

Device Setup

2 Level

1

Level

2

IfcLvl

5

Device Variables

3

% Range

4

Loop

1 Tag

2 Descriptor

3

Date

4 Message

5

Poll Address

6 Final asmbly num

1 4 mA

2 20 mA

3 Other

4 End

1 Faults

2 Warnings

1 View History

2 Reset History

1 Loop Test

2 Present Status

3 Status History

4 Float1 Counts

5 Float2 Counts

6 Elec Temperature

1 Model

2 Manufacturer

3 Orion S/N

4 Firmware Version

5 Coprocessor Version

6 Tag

7 Descriptor

8 Date

9 Message

10 Poll Address

11 Final asmbly num

12 Device ID

13 Measurement Type

14 Level Units

15 Probe Length

16 4mA Set Point

17 20mA Set Point

18 Level Offset

19 Damping

20 System Fault State

21 Deadband

31 Float1 Threshold

32 Float1 Polarity

22 Sensor Mount

23 Trim Level

33 Float2 Threshold

34 Float2 Polarity

35 Sensitivity

36 Drive Amplitude

37 Min Separation

24 Trim Ifc Level

25 SV is

26 Date/Time/Initials

27 4 mA Trim Value

28 20 mA Trim Value

29 Conversion Factor

30 Scale Offset

38 Universal rev

39 Fld dev rev

40 Software rev

41 Num req preams

1 Trim Loop Current

2 Enter Password

3 Factory Settings

4 Max Temperature

5 Min Temperature

7 New User Password

6

Reset Temperatures

1 M

easurement Type

2 Level Units

4 4 mA Set Point

5 20 mA Set Point

6

Level Offset

7

Damping

8

System Fault State

9 Deadband

1

0 Sensor Mount

1

1 Trim Level

12 Trim Ifc Level

1

3 SV is

1

4 Date/Time/Initials

3 Probe Length

1 Orion S/N

2 Device ID

4 Scale Offset

5 Float1 Threshold

6 Float1 Polarity

7 Float2 Threshold

8 Float2 Polarity

9 Sensitivity

10 Drive Amplitude

11 Min Seperation

12 Factory Param 1

13 Factory Param 2

3 Conversion Factor

1.7.4 HART Menu (Jupiter 2.0)

20

46-648 Jupiter Magnetostrictive Transmitters

Page 21

1.8 FOUNDATION Fieldbus Digital Communications

Control Room

Power Supply

Terminator

6234 feet (1900 meters) maximum

PC

Terminator

Power

Conditioner

1.8.1 Description

FOUNDATION Fieldbus™is a digital communications system

that serially interconnects devices in the field. A Fieldbus

system is similar to a Distributed Control System (DCS)

with two exceptions:

• Although a Fieldbus system can use the same physical

wiring as an existing 4–20 mA device, Fieldbus devices are

not connected point-to-point, but rather are multidropped

on a single pair of wires (referred to as a segment).

• Fieldbus is a system that allows the user to distribute

control across a network. Fieldbus devices are smart and

actually maintain control over the system.

Unlike 4–20 mA analog installations in which the two

wires carry a single variable (the varying 4–20 mA current),

a digital communications scheme such as Fieldbus considers

the two wires as a network. The network can carry many

process variables as well as other information. The Jupiter

transmitter is a F

OUNDATION Fieldbus

™

registered device

that communicates with the H1 Foundation Fieldbus protocol operating at 31.25 kbits/sec. The H1 physical layer is

an approved IEC 61158 standard. The illustration below

shows a typical Fieldbus installation.

An IEC61158 shielded twisted pair wire segment can be as

long as 6234 feet (1900 meters) without a repeater. Up to

4 repeaters per segment can be used to extend the distance.

The maximum number of devices allowed on a Fieldbus

segment is 32 although this depends on the current draw

of the devices on any given segment.

46-648 Jupiter Magnetostrictive Transmitters

Typical Fieldbus Installation

21

Page 22

Details regarding cable specifications, grounding, termination,

and other network information can be found in IEC 61158

or at www.fieldbus.org.

1.8.2 Benefits

The benefits of Fieldbus can be found throughout all phases

of an installation:

1. Design/Installation: Connecting multiple devices to a single

pair of wires means less wire and fewer I/O equipment.

Initial Engineering costs are also reduced because the

Fieldbus Foundation requires interoperability, defined as

“the ability to operate multiple devices in the same system,

regardless of manufacturer, without a loss of functionality.”

All Foundation Fieldbus devices must be tested for

interoperability by the Fieldbus Foundation. Orion Jupiter

device registration information can be found listed under

Magnetrol International at www.fieldbus.org.

2. Operation: With control now taking place within the

devices in the field, better loop performance and control are

the result. A Fieldbus system allows for multiple variables to

be brought back from each device to the control room for

additional trending and reporting.

3. Maintenance: The self-diagnostics residing in the smart

field devices minimizes the need to send maintenance

personnel to the field.

1.8.3 Device Descriptions

The function of a Fieldbus device is determined by the

arrangement of a system of blocks defined by the Fieldbus

Foundation. The types of blocks used in a typical User

Application are described as follows:

Resource Block describes the characteristics of the Fieldbus

device such as the device name, manufacturer, and serial

number.

Transducer Blocks contain information such as calibration

data and sensor type. They are used to connect the sensor to

the input function blocks.

Function Blocks are built into the Fieldbus devices as needed

to provide the desired control system behavior. The input

and output parameters of function blocks can be linked

over the Fieldbus. There can be numerous function blocks

in a single User Application.

22

46-648 Jupiter Magnetostrictive Transmitters

Page 23

An important requirement of Fieldbus devices is the interoperability concept mentioned above. Device Description

(DD) technology is used to achieve this interoperability.

The DD provides extended descriptions for each object and

provides pertinent information needed by the host system.

DDs are similar to the drivers that your personal computer

(PC) uses to operate peripheral devices connected to it. Any

Fieldbus host system can operate with a device if it has the

proper DDs for that device.

The most recent DD and Common File Format (CFF) files

can be found on Magnetrol’s web site at magnetrol.com or

fieldbus.org.

1.8.4 Intrinsically Safe

H1 supports Intrinsic Safety (IS) applications with bus

powered devices. To accomplish this, an IS barrier is placed

between the power supply in the safe area and the device in

the hazardous area.

H1 also supports the Fieldbus Intrinsically Safe Concept

(FISCO) model which allows more field devices in a network.

The FISCO model considers the capacitance and inductance

of the wiring to be distributed along its entire length. The

stored energy during a fault will be less and more devices

are permitted on a pair of wires. Instead of the conservative

entity model, which only allows about 90 mA of current, the

FISCO model allows a maximum of 112 mA for Class II C

installations and 319 mA for Class II B installations.

FISCO certifying agencies have limited the maximum

trunk length to 1000 meters and spur length to 30 meters

because the FISCO model does not rely on standardized

ignition curves.

The Orion Jupiter is available with an entity IS, FISCO IS,

and explosion proof approvals.

46-648 Jupiter Magnetostrictive Transmitters

23

Page 24

2.0 Reference Information

MADEINU

SA

This section presents an overview of the operation of the

Jupiter magnetostrictive transmitter, information on troubleshooting common problems, listing of agency

approvals, lists of replacement and recommended spare

parts, and detailed functional, performance and physical

specifications for the instrument.

2.1 Description

The Jupiter is a two-wire, 24 VDC level transmitter based

on the concept of magnetostrictive level measurement

technology.

The Jupiter electronics are housed in an ergonomic housing of two tandem compartments angled at a 45° angle for

ease of wiring and calibration. The electronics compartment is permanently attached to the probe assembly via an

explosion-proof seal.

2.2 Theory of Operation

Magnetostrictive level sensors are based on "time-of-flight"

technology.

Permanent magnets contained within a float device tracks

the process liquid as it changes level. The Jupiter probe is

fixed within close proximity to this magnetic field. A short

current pulse is then applied to a specially designed wire

alloy contained within the probe. The interaction of the

current pulse and magnetic field cause distortion in a small

section of the wire alloy. This in turn creates a vibratory

disturbance which begins to travel through the wire at a

very constant rate of speed. The disturbance is later detected

via a sensing device at the top of the probe and sent to the

electronics unit where it is filtered and amplified.

Extremely accurate level measurement can thus be

obtained precisely measuring the elapsed time between the

current pulse (start), and the returned pulse (stop). The

Jupiter electronics module processes these signals, and then

performs various mathematical operations in order to provide the user with an analog and/or digital representation

of the liquid level.

24

46-648 Jupiter Magnetostrictive Transmitters

Page 25

2.3 Troubleshooting

The Jupiter transmitter is designed and manufactured for years of trouble free operation over a wide

range of conditions. Common transmitter problems are discussed in terms of their symptoms and

recommended corrective actions.

Caution: Do not rotate the Jupiter electronics enclosure or any threaded fittings.

Rotating the electronics enclosure will void warranty and could cause

damage to sensor cables.

2.3.1 Troubleshooting

Problem Solution

Transmitter does not track level (External Mount) Remove transmitter from piping column and test with

re-alignment magnet. Run magnet from bottom to top of

probe. Check zero and span calibration. If no change in

output, consult the factory.

(Direct Insertion) Float stuck, Probe bent (Chamber)

Float inside the level gauge is moving slow Ensure that the magnetic level indicator is plumb.

or not at all.

The process fluid being measured may be too viscous and

heat tracing may be required to make the material more fluid.

The specific gravity of the process fluid and float weight may

need to be reverified.

The liquid being measured may contain magnetic particles

collecting on the magnetic section of the float causing drag.

If this happens magnetic trap assemblies can be purchased

from the factory.

Visual inspection of the float may be required to see if the float

has collapsed.

LEVEL, % OUTPUT, and LOOP values are Basic configuration data is questionable. Reconfigure probe

all inaccurate. length and offset. Ensure the level is accurate. Reconfigure

loop values.

LEVEL, % OUTPUT, and LOOP values fluctuate. Turbulence, increase damping factor until readings stabilize.

Level reading on display is correct, but loop Set poll address to zero

value is stuck at 4 mA.

46-648 Jupiter Magnetostrictive Transmitters

25

Page 26

.3.2 Status Messages

2

Display Message Action Comment

OK None Normal operating mode

Initial None Shown at power-up during

self check

TrimReqd Factory set Loop values are defaults, Consult Factory

loop output may be in accurate

Cal Reqd Factory set default calibration parameters Consult Factory

are in use, level reading may be inaccurate

Lo Temp Present temperature in electronics Transmitter may need to be moved

compartment is below -40° F (-40° C) to ensure temperature is within

specification

Hi Temp Present temperature in electronics Transmitter may need to be moved

compartment is above +176° F (+80° C) to ensure temperature is within

specification

Float 2 No level signal detected from float 2 Make sure 2 floats are being used,

Fail are not damaged, and within

measuring range

Float 1 No level signal detected from float 1 Make sure float is not damaged

Fail and within measurement range

No Signal No signal detected from any float Make sure float is not damaged

and within measurement range

LoopFail Loop current differs from expected value Consult Factory

Snsr Brd Measurement board not responding Consult Factory

DfltParm Internal non-volatile parameters have been Consult Factory

reset to default values

26

46-648 Jupiter Magnetostrictive Transmitters

Page 27

U

nit Equipped

with Display?

Check Voltage at

Terminal Board

No Voltage?

Check Power

Supply and Wiring

Negative

Voltage?

Reverse Wiring

Consult Factory

Check Loop

Current at terminal

Board

Loop Current

Above 23 mA?

Remove Electronic

Module

Loop Current

Above 1 mA?

Replace Terminal

Board

Replace Electronic

Module

Y

es

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

No

Display has

Text?

No

Reseat Boards.

Check Power

Supply and Wiring

Loop

Resistance

Wrong?

Correct Loop

Resistance

Start

Good

Display

No

Active

HART

Yes

Failure to Operate

with Correct Loop

Inputs

No

Faint Display?

Yes

Yes

No

Some problems could be

temporarily solved by power

c

ycling the unit. Please call

factory if this problem persists.

Display

Working?

No

Yes

No

RetestYes

HART

Communications

OK?

Voltage Above

36 Volts?

Voltage

< 12V

2 1

3

.3.3 Troubleshooting Flowchart

2

46-648 Jupiter Magnetostrictive Transmitters

27

Page 28

Check Loop

Current at Terminal

Board

Loop Current

Above 23 mA?

Remove Electronic

Module

Loop Current

Above 1 mA?

Replace Terminal

Board

Replace Electronic

Module

Yes Yes

No

No

F

ailure to Operate

with Correct Loop

Inputs

Display

Working?

Yes

No

Retest Unit

Good

Display

Key Board

Responds?

Replace Electronic

Module

No

Check Loop

Current at Wiring

Board

Loop Current

22 - 4.0 mA?

Adjust 4 and 20 mA

Unit has

HART?

HART

Working?

Yes

Yes No

Yes

No

Address

Correct?

Correct Address

Replace Electronic

Module

No

Yes

Unit with Display

Communicates

No Yes

Reseat Boards

Display

Working?

Retest

No

Yes

1

2

4

Display

W

orking?

Yes

Retest Unit

28

continued on next page ¯

46-648 Jupiter Magnetostrictive Transmitters

Page 29

U

nit with Display

Communicates

E

rror

D

isplayed?

N

o Level Signal

Error Codes

N

o

N

o

Y

es

R

eload all

P

arameters

Yes

Yes Yes

Corrupt Display

Text?

Replace Electronic

Module

No

Y

es

Replace Electronic

Module

Same Error

Message?

Retest No

Yes

Out of Calib

Analog Loop

Correct?

Trim 4-20 mA

No

Yes

No

Call Factory

Display Reading

Correctly?

4

Yes

No

U

nit with Display

C

ommunicates

3

Check probe

length

Float is not

detected

Consult Factory

Check Offset

and

4-20 mA

Set Points

46-648 Jupiter Magnetostrictive Transmitters

29

Page 30

2.4 Agency Drawing/Specifications

2.4.1 Agency Drawing

30

46-648 Jupiter Magnetostrictive Transmitters

Page 31

2.4.1 Agency Drawing

46-648 Jupiter Magnetostrictive Transmitters

31

Page 32

2.4.2 Agency Specifications – Explosion Proof Installation

Factory Sealed:

This product has been approved by Factory Mutual Research

FM) and Canadian Standards Association (CSA) as a Factory

(

Sealed device.

NOTE: Factory Sealed: No Explosion Proof conduit fitting (EY seal) is

required within 18" of the transmitter. However, an Explosion

Proof conduit fitting (EY seal) is required between the hazardous and safe areas.

Caution: Grounding (+) will cause faulty operation, but will not

cause permanent damage.

Caution: Do not rotate the Jupiter electronics enclosure or any

threaded fittings. Rotating the electronics enclosure will

void warranty and could cause damage to sensor cables.

2.4.3 Agency specifications ATEX Intrinsically safe

Entity parameters 4–20 mA:

Ui 28.4 Ii = 94 mA Pi = 0.67@ Ci = 2.2 nF Li = 3µH

Entity parameters Fieldbus Fisco:

Ui = 17.5V Ii=380mA Pi = 5.32W Ci = 0.705 nF Li = 3µH

2.5 Maintenance

2.5.1 Keep Control Clean

Periodic inspections are a necessary means to keep your

level control in good working order. This control is a safety

device to protect the valuable equipment it serves.

If the process liquid is clean (no solids or deposits), the

MLI should require minimum maintenance. If the process

liquid is dirty (solids and deposits), it is recommended the

external cage be isolated from the process and flushed periodically. For complete cleaning, drain the unit, remove the

bottom flange and float, inspect cage and float for buildup and clean if required.

32

46-648 Jupiter Magnetostrictive Transmitters

Page 33

➀

➁

➂

➂

➃

➄

2.6 Replacement Parts

2.6.1 Parts Identification

Item Description Part Number

Electronic module

isplay and HART 031-2839-001

D

Display & FOUNDATION fieldbus

Terminal board

HART 030-9151-001

FOUNDATION fieldbus

O-ring (Viton

Aluminum housing cover without glass 004-9193-002

Aluminum housing cover with glass 036-4410-003

®

) 012-2201-237

™

™

031-2840-001

030-9151-004

46-648 Jupiter Magnetostrictive Transmitters

Replacement Parts Diagram

33

Page 34

2.7 Specifications

2.7.1 Performance

Accuracy ±0.015"

Repeatability ±0.005% of full span or 0.005" (0.127 mm) (whichever is greater)

inearity 0.020% of full span or 0.031" (0.794 mm) (whichever is greater)

L

Maximum level rate of change 6 inches per second (models with HART)

Response time 0.1 second

Warm-up <5 second

Upper dead zone None

Lower dead zone <2" (5 cm), SIL 2: <5" (13 cm)

Ambient temperature range Transmitter: -40° to +175° F (-40° to +80° C)

LCD: -10° to +160° F (-20° to +70° C)

Process temperature External Mount: -40° to +248° F (-40° to +120° C)

-320° to +850° F (-195° to +455° C) (with factory insulated MLI)

Direct Insertion: -40° to +200° F (-40° to +95° C)

-40° to +500° F (-40° to +260° C) (high temperature probe)

Humidity 0 to 99% non-condensing

Electromagnetic compliance EN 61326

Environmental protection compliance EN 60654-1

Drop protection compliance EN 50178

Surge Protection Compliance EN 61326 (1000 V)

Maximum Pressure (Direct Insertion) 1700 psig @ +100° F (117 bar @ +38° C)

(limited to the pressure rating of the selected flange or float)

34

46-648 Jupiter Magnetostrictive Transmitters

Page 35

2.7.2 Functional

Measured variables Continuous liquid level

nput power (at terminals) 12-28 VDC

I

Signal output 4–20 mA

4–20 mA with HART 5.0

NAMUR NE 43 compliant with 3.8 to 21.5 mA useable range

Loop resistance 620 maximum ohms @ 24 VDC—refer to chart below

Power consumption 0.7 watt, refer to chart below

Damping 0 to 25 seconds

Error signal 3.6 or 22 mA, field selectable

User interface 3-button keypad, HART communicator, AMS software, PACTware

UNDATION

or FO

Display 2-line × 8-character LCD in inches or cm, mA, and % of level

Resolution Analog: 0.01 mA

Digital: 0.01 units

Span 6 to 400 inches (999 cm)

SIL 2 Safe Failure Fraction (SFF) 90.7%

(consult factory for SIL safety manual)

Fieldbus

™

See Bulletin 46-649 for

F

OUNDATION Fieldbus output

1200

20.5 mA

24 VDC

Ω

1000

800

620

600

400

200

0

0 10 20 30 40 VDC

11

Power Consumption

2.7.3 Physical

Enclosure type Dual compartment

Enclosure material Sand cast aluminum grade 356 HT or 316 stainless steel

Enclosure finish Baked on polymer powder coat

Enclosure rating NEMA 4X7/9, IP 66

Sensor material 316 stainless steel

Sensor length 6 to 400 inches (15 to 999 centimeters)

46-648 Jupiter Magnetostrictive Transmitters

35

Page 36

MADEINUSA

M

ADEINUSA

M

ADEI

N

USA

M

A

D

EI

N

USA

M

ADEI

N

U

S

A

MADEIN

US

A

1

1

(

279)

8

(203)

11.5

(292)

1

2.5

(

318)

11

(279)

8

(203)

11.5

(292)

12.5

(318)

1

1.5

(

292)

8.00

(203)

Flanged or

NPT Connection

nches (mm)

I

Direct Insertion

Top Mount Top Mount Offset Top Mount Offset

High Temperature Bend

36

Bottom Mount Offset Bottom Mount Offset

High Temperature Bend

Gemini – Bottom Mount Offset

and Secondary Transmitter

46-648 Jupiter Magnetostrictive Transmitters

Page 37

Glossary

Accuracy The maximum positive and negative % devia-

ion from the actual value over the total span.

t

ANSI American National Standards Institute.

CSA Canadian Standards Association Canadian, third

party agency that qualifies the safety of electrical equipment.

Damping The mathematical averaging of a meter and/or

output signal to stabilize the effects of a noisy process due

to surface turbulence.

Default Values The main position of the menu structure

that displays the primary measurement values of LEVEL,

% OUTPUT, and LOOP. The transmitter returns to this

position after 5 minutes of inactivity.

DVM/DMM Digital Volt Meter/Digital Multimeter.

Electromagnetic Energy The radiation that travels

through space as electric and magnetic fields varying with

position and time. Examples in increasing frequency:

radio waves, microwave, infrared light, visible light, ultraviolet light, x-rays, gamma waves, and cosmic waves.

EM See Electromagnetic Energy.

EMI Electromagnetic Interference Electrical noise caused

by electromagnetic fields that may affect electrical circuits,

particularly low-power electronic devices.

EN European Normal Committee guidelines in EC

countries that take precedence over local, country guidelines.

Ergonomic A mechanism that considers human capability in its design or function.

Explosion-Proof Enclosure An enclosure designed to

withstand an explosion of gas or vapor within it and prevent the explosion from spreading outside the enclosure.

Fault A defect or failure in a circuit. The current (mA)

value unit defaults to 3.6, 22, or Hold when a diagnostic

condition occurs.

Feedthrough A small, connecting cavity between the

main housing compartments, carrying the cable that supplies the operating energy to the measurement circuitry

and returns the output value proportional to level. This

cavity is potted to maintain the environmental isolation

between the two compartments.

FM Factory Mutual American, third party agency that

qualifies the safety of electrical equipment.

FSK Frequency Shift Keying.

Ground An electrical connection to the Earth’s poten-

tial that is used as a reference for the system and electrical

safety.

Grounded A state where no electrical potential exists

between the ground (green) connection on the transmitter

and the Earth or system ground.

ART Highway Addressable Remote Transducer.

H

Protocol that uses the Bell 202 frequency shift keying

(FSK) method to superimpose low level frequencies

(1200/2000 Hz) on top of the standard 4–20 mA loop

to provide digital communication.

HART ID See Poll Address.

Hazardous Area An area where flammable gases or

vapors are or may be present in the air in quantities sufficient to produce explosive or ignitable mixtures.

IEC International Electrotechnical Commission

Organization that sets international standards for electrical devices.

Increased Safety Designs and procedures that minimize

sparks, arcs, and excessive temperatures in hazardous

areas. Defined by the IEC as Zone 1 environments (Ex e).

Interface: Electrical A boundary between two related,

electronic circuits.

Interface: Process A boundary between two or more

immiscible liquids.

Intrinsic Safety A design or installation approach that

limits the amount of energy that enters a hazardous area

to eliminate the potential of creating an ignition source.

Level The present reading of the height of material in a

vessel.

Linearity The worst case error calculated as a deviation

from a perfect straight line drawn between two calibration

points.

Loop The present reading of the 4–20 mA current output.

Low Voltage Directive A European Community

requirement for electrical safety and related issues of

devices using 50-1000 VDC or 75-1500 VAC.

Magnetic Level Indicator a magnetically coupled,

liquid level indicator which isolates the process in

a sealed non-magnetic piping column. Contrasting

colored flags provide indication of level.

Magnetostrictive Utilizing the Wiedemann effect to create a mechanical torsion or twist in a ferromagnetic wire

which occurs as a result of the interaction between an

electrical pulse on the wire and a magnetic field from the

float.

Measured Value The typical level measurement values

used to track the level of a process: Level, % Output, and

Loop.

Media The liquid material being measured by the level

transmitter.

Multidrop The ability to install, wire, or communicate

with multiple devices over one cable. Each device is given

a unique address and ID.

46-648 Jupiter Magnetostrictive Transmitters

37

Page 38

Nonhazardous Area An area where no volatile mixtures

of vapors/gas and oxygen will be found at any time. Also

called General Purpose Area.

Non-incendive Equipment and wiring which in its normal operating condition is incapable of igniting a specific

hazardous atmosphere or hazardous dust layer.

Offset The distance from the bottom of the tank to the

bottom of the probe.

Password A numerical value between 0 and 255 that

protects stored configuration data from unauthorized

manipulation.

Percent (%) Output The present reading as a fraction of

the 16mA scale (4–20mA).

Poll Address A number between 1 and 15 which sets an

address or location of a device in a multi-drop loop.

Probe A waveguide that propagates an electromagnetic

pulse from the top of the tank into the process fluid.

Probe Length Exact measurement from the bottom of

the process thread connection to the very bottom of the

probe.

Range A value related to probe length (factory setting).

Repeatability The maximum error between two or more

output readings of the same point.

RFI Radio Frequency Interference Electrical noise that

can have an adverse affect on electrical circuits, particularly low-power devices.

Span The difference between the upper and lower limits

of the range.

Specific Gravity (SG) The ratio of the density of a material to the density of water at the same conditions.

Tst Loop Test Loop Built-in system capability to

test/calibrate a loop (or separate loop device) by driving

the transmitter output to a particular value.

Trim 4/Trim 20 Built-in system capability to fine tune

the 4 mA and 20 mA points so the transmitter output

corresponds exactly to user’s meter, DCS input, etc.

Two Wire An electrical instrument design that uses one

set of wires to provide both the supply power and process

measurement signal. The process measurement is achieved

by varying the current of the loop. Also called Loop

Powered.

Units The engineering units used to measure level in the

system. The choices are in (inches) and cm (centimeters).

38

46-648 Jupiter Magnetostrictive Transmitters

Page 39

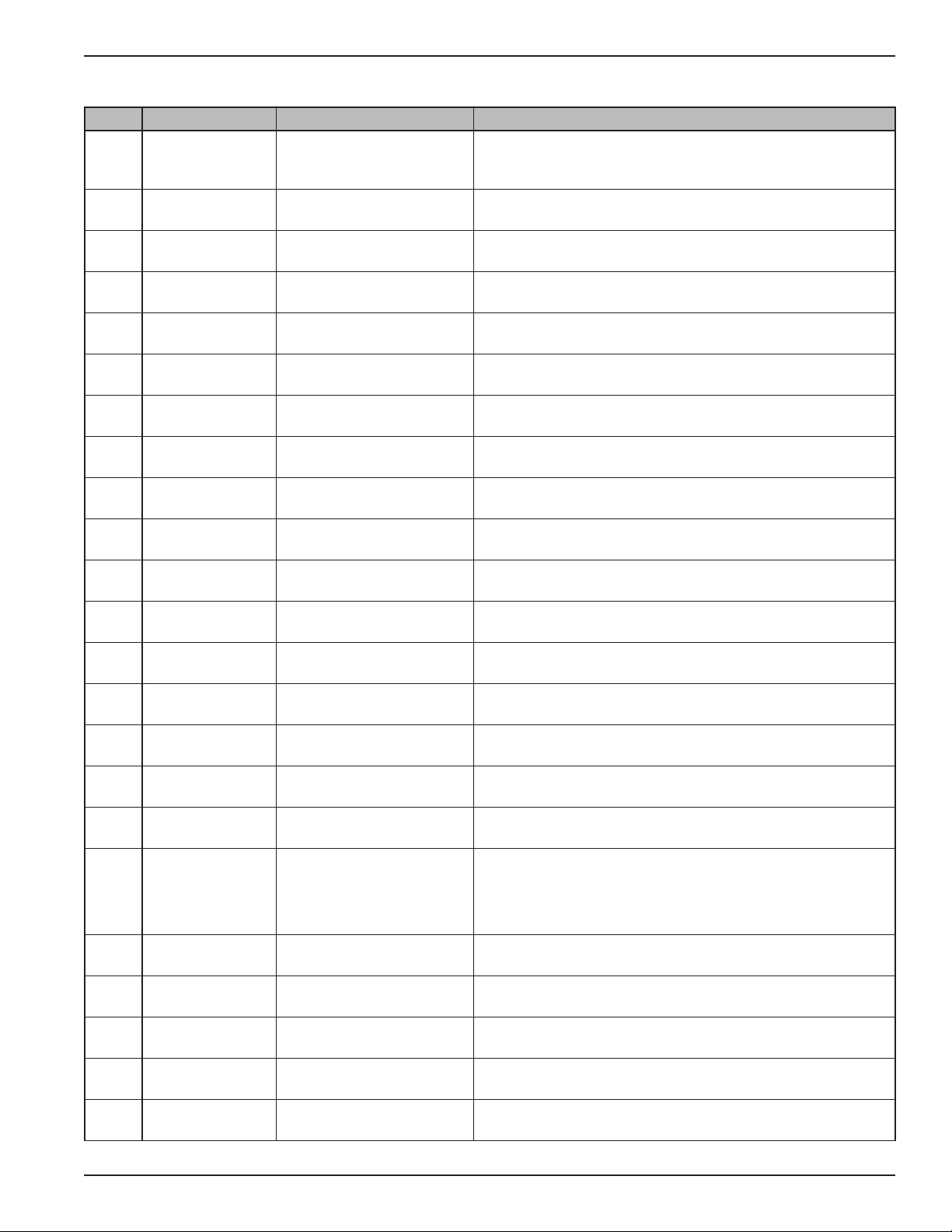

®

Jupiter Magnetostrictive

Transmitter

Configuration Data Sheet

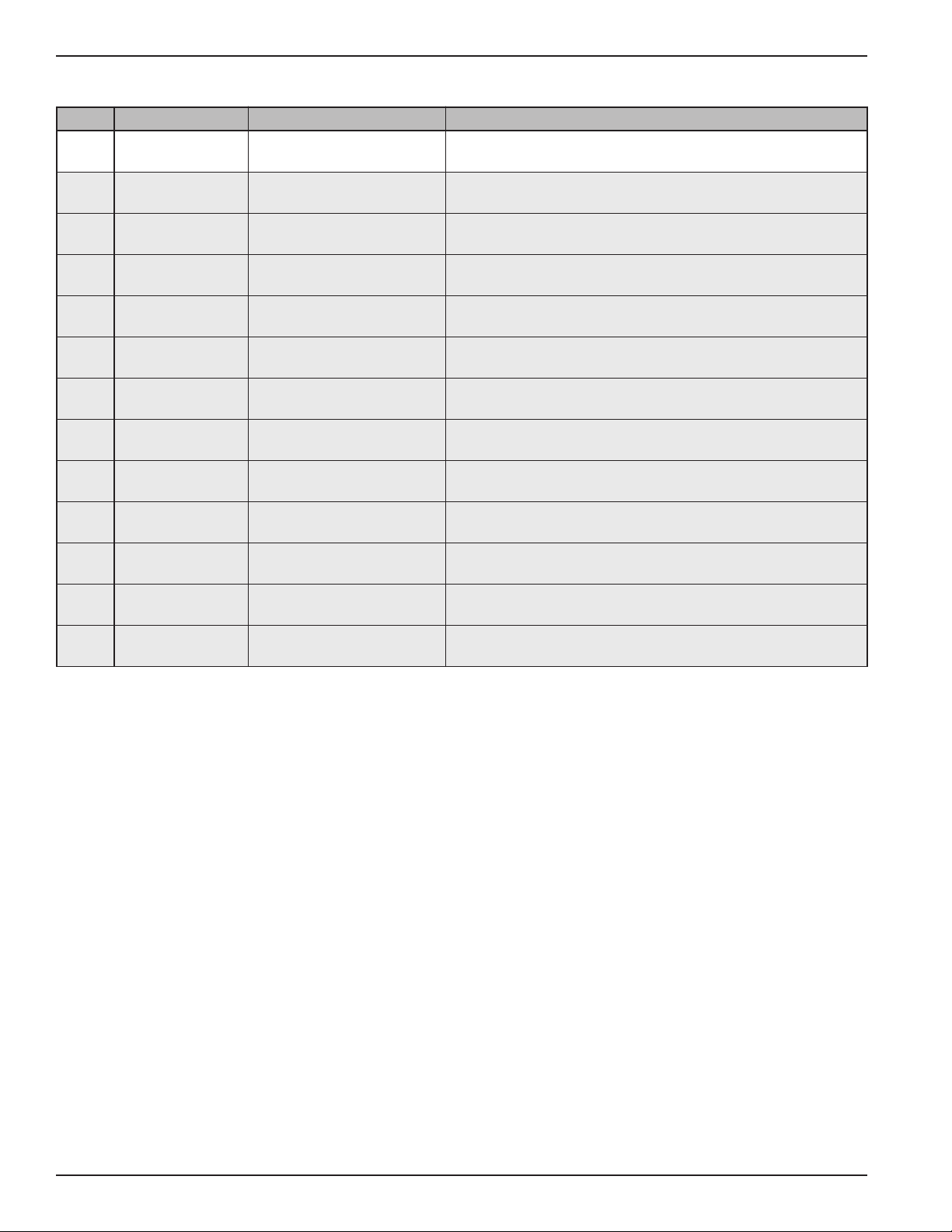

Copy blank page and store calibration data for future reference and troubleshooting.

Item Value Value Value

Vessel Name

Vessel #

Media & Dielectric

Tag #

Serial # TROUBLESHOOTING

Measurement Type Correct Value Incorrect Value

Units

Probe Length

4 mA Point

20 mA Point

Level Offset

Damping

Fault Choice

HART Poll Address

Trim 4 mA

Trim 20 mA

Loop Test

Deadband

Sensor Mount

Trim Level

Trim Interface

Conversion Factor

Scale Offset

Float 1 Threshold

Float 1 Polarity

Float 2 Threshold

Float 2 Polarity

Sensitivity

Drive Amplitude

Minimum Separation

# of Counts

Software Version

New Password

Name Date/Time

46-648 Jupiter Magnetostrictive Transmitters

39

Page 40

ASSURED QUALITY & SERVICE COST LESS

5300 B elmont Road • Downers Gro ve, Il linois 60515-4499 • 630-969-4000 • Fax 630-969-9489 • www.magne trol.co m

145 Ja rdin Dr ive, U nits 1 & 2 • Conco rd, Ont ario C anada L4K 1X 7 • 90 5-738- 9600 • Fax 9 05-738 -1306

Heiken sstraa t 6 • B 9240 Zele, Belgium • 052 45.11.11 • Fax 0 52 45. 09.93

Regent Busin ess Ct r., Jubilee Rd. • Burge ss Hil l, Sus sex RH 15 9TL U.K. • 0144 4-8713 13 • F ax 014 44-871 317

6646 C omplex Drive • Baton Rouge, Louisiana 70809 • 22 5-906- 2343 • Fax 225-906-2344 • www.ori oninst rument s.com

Copyright © 2010 Magnetrol International, Incorporated. All rights reserved. Printed in the USA.

Service Policy

Owners of Magnetrol/Orion Instruments controls may

request the return of a or any part of an instrument for

complete rebuilding or replacement. They will be rebuilt

or replaced promptly. Instruments returned under our

service policy must be returned by prepaid transportation.

Magnetrol/Orion will repair or replace the control at no

cost to the purchaser (or owner) other than transportation

if:

1. Returned within the warranty period; and

2. The factory inspection finds the cause of the claim

to be covered under the warranty.

If the trouble is the result of conditions beyond our control; or, is NOT covered by the warranty, there will be

charges for labor and the parts required to rebuild or

replace the equipment.

In some cases it may be expedient to ship replacement

parts; or, in extreme cases a complete new instrument, to

replace the original equipment before it is returned. If

this is desired, notify the factory of both the model and

serial numbers of the instrument to be replaced. In such

cases, credit for the materials returned will be determined

on the basis of the applicability of our warranty.

Return Material Procedure