Page 1

INSTRUCTION MANUAL

Orion SkyQuest™ XTi

IntelliScope Dobsonian

Telescopes

#10026 XT6i, #10018 XT8i, #10019 XT10i, #10020 XT12i

Providing Exceptional Consumer Optical Products Since 1975

Customer Support (800)-676-1343

E-mail: support@telescope.com

Corporate Offices (831)-763-7000

89 Hangar Way, Watsonville, CA 95076

OrionTelescopes.com

IN 226 Rev. J 09/12

Page 2

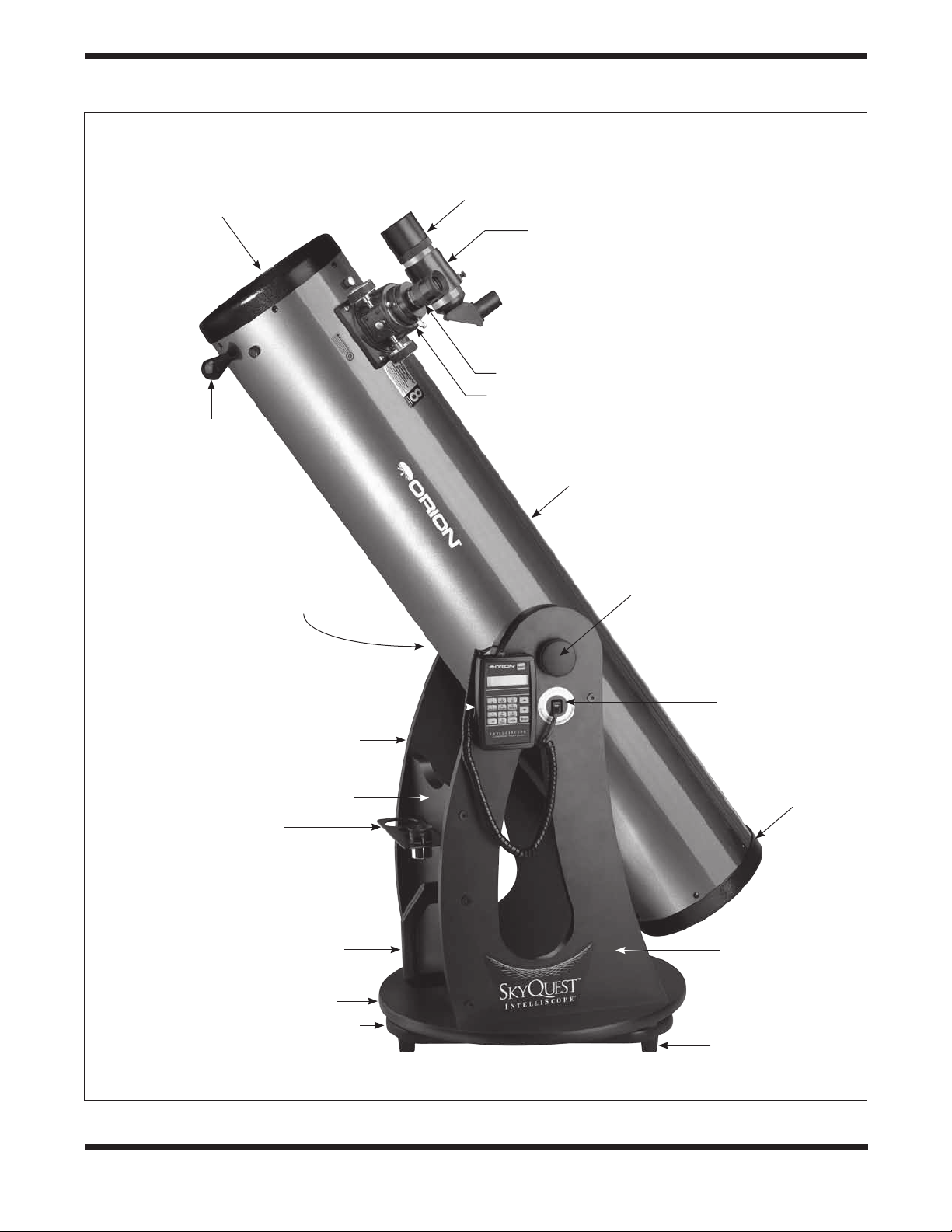

Secondary mirror holder

with 4-vane spider

(not visible)

Navigation

knob

Retaining knob

(opposite side)

Finder

scope

Finder scope

bracket

Eyepiece

Focuser

Optical tube

Altitude

tensioning

knob

Computerized

Object Locator

Right side panel

Front brace

Eyepiece

rack

Handle

Top baseplate

Ground baseplate

IntelliScope

Controller Port

modular jack

Primary

mirror cell

Left side panel

Foot (3)

Figure 1. The SkyQuest XT8 IntelliScope

2

Page 3

Congratulations on your purchase of an Orion SkyQuest XTi IntelliScope Dobsonian. It is a high-performance astronomical instrument designed to provide dazzling views of celestial objects and unprecedented ease of use. With the addition of the optional IntelliScope Computerized Object Locator (Controller),

you gain the ability to locate and view thousands of celestial objects with the push of a button. Searching

for faint objects – so often a source of frustration for telescope users – is a thing of the past, as the IntelliScope’s high-resolution digital encoders find them for you in seconds. It’s so easy!

Your SkyQuest IntelliScope will provide years of stargazing enjoyment, thanks to its large-aperture, precision optics; its innovative, user-friendly design; its complement of outstanding features and accessories;

and most of all, its easy object locating technology. We hope you enjoy your journey through the universe!

Please read these instructions thoroughly before beginning assembly and subsequent use of the telescope.

Table of Contents

1. Unpacking ....................................3

2. Assembly .....................................4

3. Using Your Telescope ...........................11

4. Alignment (Collimation) of the Optical System .......15

5. Astronomical Observing ........................17

6. IntelliScope Computerized Object Location ..........20

7. Care and Maintenance .........................21

8. Specifications .................................22

1. Unpacking

The telescope is packed in two boxes (three for the XT12i),

one containing the optical tube assembly and accessories,

the other containing the unassembled Dobsonian base (the

third box for the XT12i includes the mirror and cell). Be careful unpacking the boxes. We recommend keeping the original

shipping containers. In the event that the telescope needs to

be shipped to another location, or returned to Orion for warranty repair, having the proper shipping containers will help

ensure that your telescope will survive the journey intact.

Make sure all the parts in the Parts List are present. Be sure

to check boxes carefully, as some parts are small. If anything

appears to be missing or broken, immediately call Orion Customer Support (800-676-1343) or email:

sales@telescope.com for assistance.

WARNING: Never look directly at the Sun

through your telescope or its finder scope—

even for an instant—without a professionally

made solar filter that completely covers the

front of the instrument, or permanent eye

damage could result. Young children should use

this telescope only with adult supervision.

Parts List

Box #1: Optical Tube Assembly and Accessories

Qty Description

1 Optical tube assembly

1 Dust cover

1 25mm Sirius Plössl eyepiece, 1.25"

1 10mm Sirius Plössl eyepiece, 1.25"

1 9x50 Right-angle correct-image finder scope (6x30

for the XT6i) with bracket

1 Collimation cap

1 4-Hole eyepiece rack (3-hole for XT6i)

2 Eyepiece rack mounting screws

2 Tensioning/Retaining knobs

1 Tensioning knob nylon washer (white)

1 Tensioning knob metal washer

1 Handle

2 Handle mounting hex-head screws

2 Handle mounting screw washers

1 Crescent wrench

1 Azimuth encoder board

1 Encoder connector board

1 Azimuth encoder disk

Box #2: Dobsonian Base

Qty Description

1 Left panel

1 Right panel

1 Front brace

1 Top baseplate

1 Ground baseplate

12 Base assembly wood screws (length 2", black)

2 Hex keys (4mm, 2mm)

3

Page 4

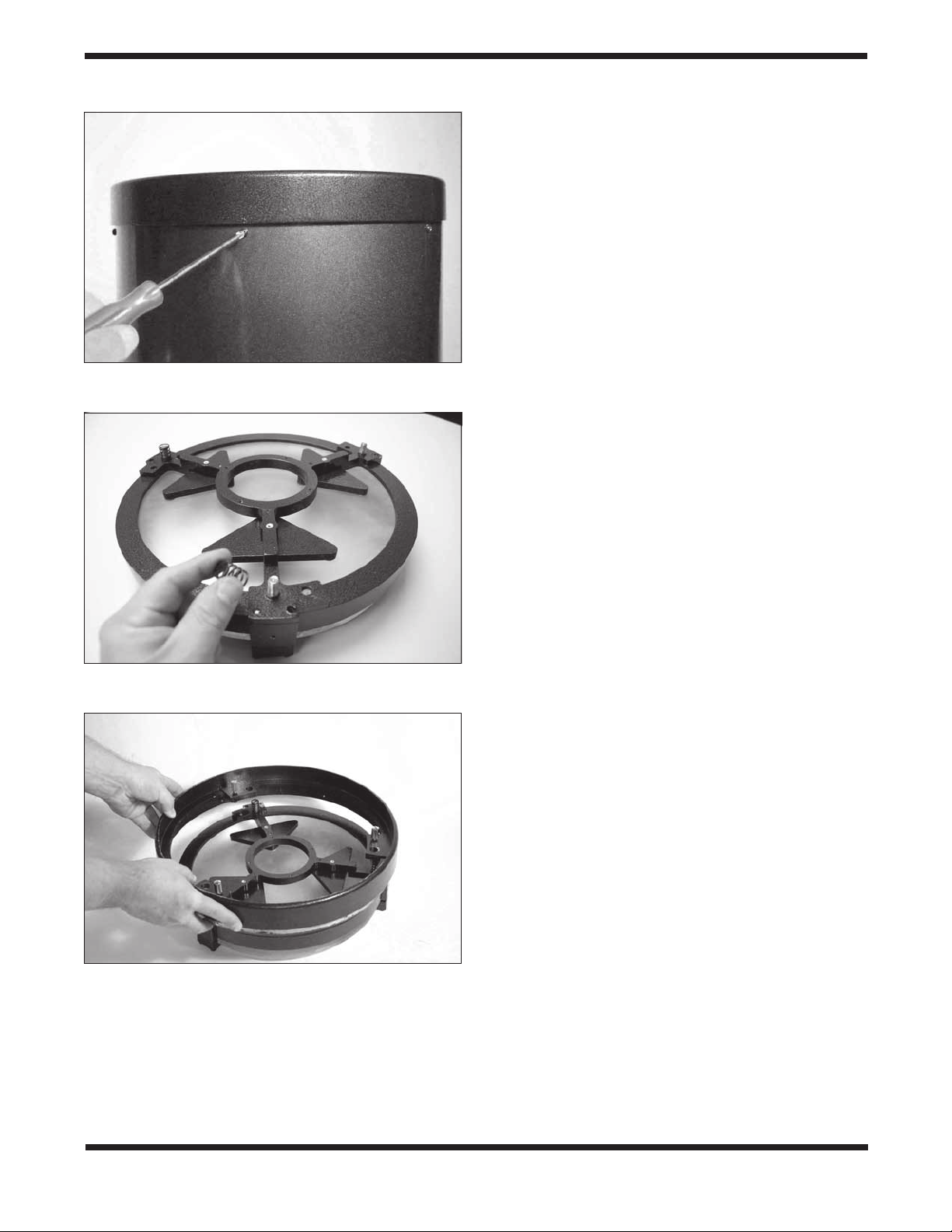

Figure 1.2.

that connect it to the tube.

To remove the rear end ring, unthread the screws

3 Plastic feet

3 Feet attachment wood screws (length 1")

5 Encoder board mounting wood screws

1 Brass bushing

1 Azimuth axis hex-head screw (length 2.25")

2 Fender washers (diameter 1")

1 Hex lock nut

4 Altitude bearing cylinders

4 Altitude bearing cylinder screws (length 1.5", black)

1 Vertical stop knob

1 Small thin Azimuth Encoder board washer

3 Vertical stop knob washers

Box #3 (XT12i only): Primary mirror and cell

Qty Description

1 Primary mirror

1 Mirror cell

3 Collimation knobs

3 Nylon washers

3 Springs

Figure 1.3. Place the three springs on the exposed threaded

shafts of the mirror cell.

Figure 1.4. Lower the rear end ring onto the mirror cell so that

the threaded shafts pass through the end ring, and the end ring

rests on the springs.

2. Assembly

Now that you have unpacked the boxes and familiarized yourself with all the parts in front of you, it’s time to begin assembly.

The optics of the XT6i, XT8i, and XT10i are already installed

inside the tube, so most of the required assembly concerns

the Dobsonian base. Skip to “Assembly of the Dobsonian

Base.” For the XT12i, the primary mirror is shipped in a separate box and will have to be installed in the optical tube. If

you purchased the XT12i, start with the next paragraph for

instructions on how to install the mirror into the tube.

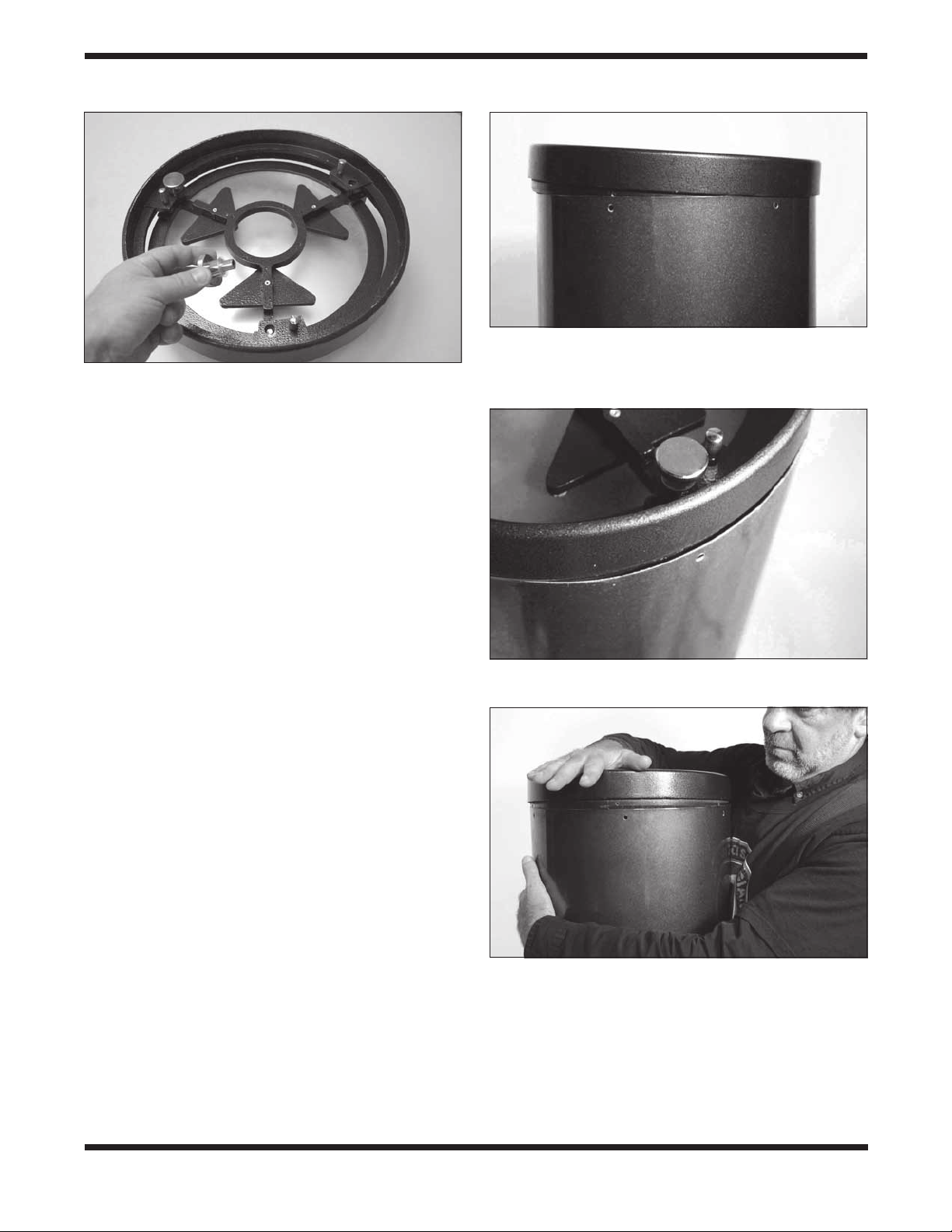

Assembly of the Optical Tube (XT12i only)

In order to prevent damage to the primary mirror in shipment,

it is shipped in its cell separately from the optical tube. To

install the mirror cell into the optical tube, the rear end ring

attached to the optical tube must first be removed. This is

done by unthreading and removing the Phillips-head screws

that connect the end ring to the tube (Figure 1.2), and then

pulling the end ring off of the tube.

Warning: Once the rear end ring is removed from the tube,

the raw edge of the tube itself will be exposed. Be careful

not to cut or otherwise hurt yourself on the tube’s edge.

Also be careful not to pinch your fingers when attaching

the assembled mirror cell onto the tube.

4

Page 5

Figure 1.5. Thread the collimation thumbnuts, with nylon

washers attached, through the rear end ring and onto the

threaded shafts. Make sure the thumbnuts have at least three full

turns of engagement on the shafts.

Next, assemble the rear end ring to the mirror cell. Find a

clean, flat surface, and turn the mirror cell over so that the

mirror is facing downwards. Place the three springs onto the

three exposed threaded shafts (Figure 1.3). Lower the end

ring onto the mirror cell so the threaded shafts pass through

it, and the end ring rests on the springs (Figure 1.4). Add

a nylon washer to each collimation knob and thread the collimation knobs through the end ring and onto the threaded

shafts (Figure 1.5). Make sure the knobs have at least three

full turns of engagement on the shafts. The mirror cell is now

ready to be installed into the tube.

Assembling the SkyQuest XT12i IntelliScope mirror cell to the

tube can be a bit tricky. This is because the large diameter

and thin aluminum of the tube will cause the tube to become

somewhat out of round once the rear end ring is removed.

To assemble the mirror cell to the tube, stand the tube up

vertically so that the raw edge of the tube is facing upward.

Line up the threaded holes in the edge of the mirror cell end

ring with the holes in the end of the tube. Then, lower the

mirror cell onto the tube so that one side of the end ring is

fully seated onto the tube (Figure 1.6). Now, look along the

perimeter of the tube, and you will notice a bulge in the tube

that prevents the mirror cell from fully seating on the tube

(Figure 1.7). Position your body so that your chest is pressing

against this bulge, and hug the telescope with your left hand

so that the tube becomes round. With your right hand, gently

tap down the side of the mirror cell that needs to be seated,

and the entire mirror cell should seat onto the tube (Figure

1.8). Then replace the Phillips-head screws that connect the

rear end ring to the tube.

Figure 1.6. Lower the assembled mirror cell onto the tube so

one side of the end ring is seated on the tube edge. The threaded

attachment holes in the end ring should also be lined up with the

through holes in the end of the tube.

Figure 1.7. Locate the area of tube that is bulging out and

preventing the mirror cell from fully seating.

Figure 1.8.

bulge, and a gentle tap should fully seat the mirror cell onto the

tube.

Hug the tube so that your chest pushes against the

5

Page 6

C

N

B

Spacer

washer

L

K

M

D

E

F

G

J

A

H

I

Figure 2.

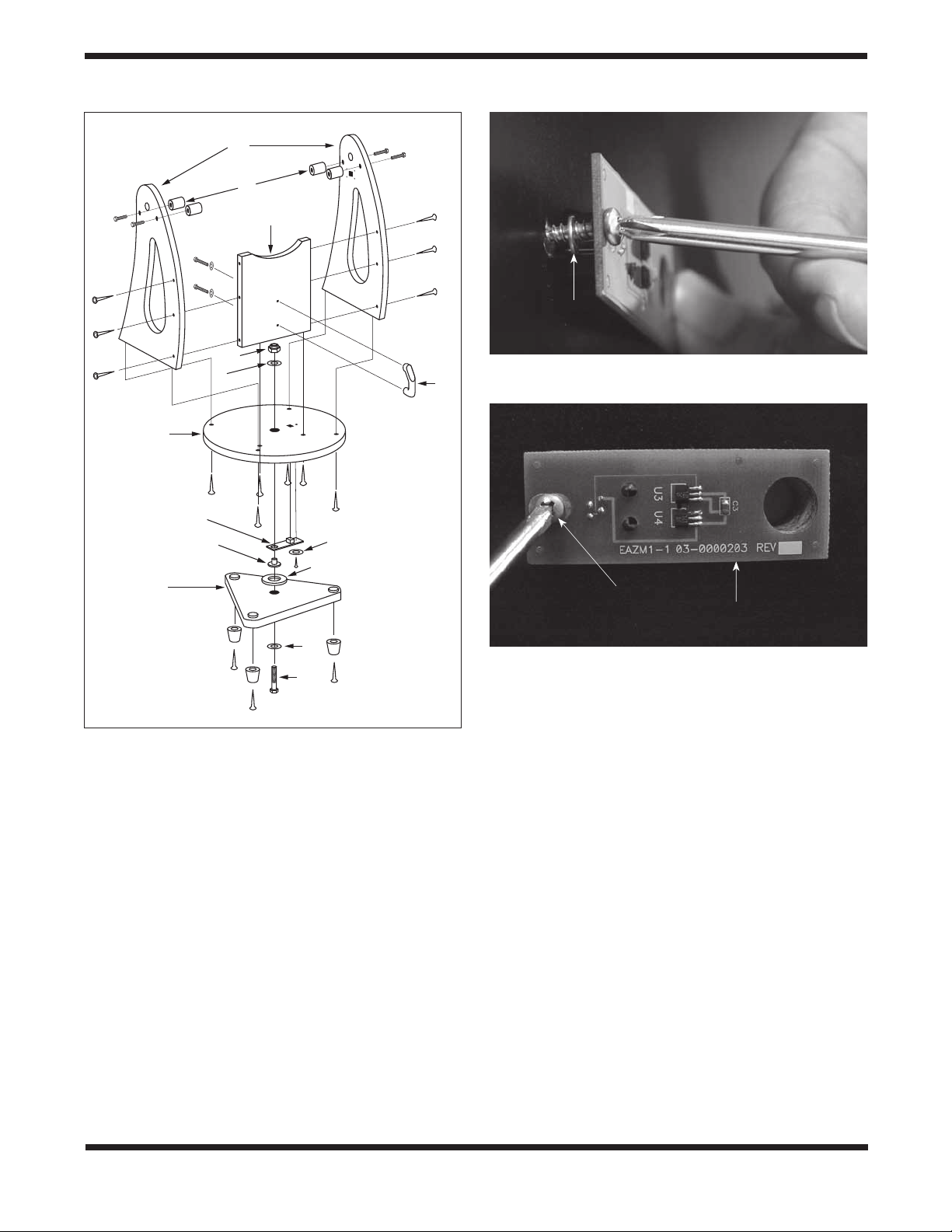

Assembly of the Dobsonian Base

Refer to Figure 2 during base assembly. The base need only

be assembled once, unless you disassemble it for long-term

storage. The assembly process takes about 45 minutes and

requires, in addition to the supplied tools, a Phillips screwdriver, and two adjustable crescent wrenches. You can substitute a 7/16" crescent wrench for one of the adjustable crescent wrenches, or use a pair of pliers.

When tightening screws, tighten them until firm, but be careful

not to strip the holes by over-tightening. If you use an electric

screwdriver, do final tightening with a standard screwdriver to

avoid stripping.

1. With a Phillips screwdriver, screw the plastic feet into the

underside of the ground baseplate (A) using the self-tapping wood screws provided. Insert the screws through the

feet and thread them into the predrilled starter holes.

2. Loosely attach the front brace (B) to the two side panels

(C) with six of the base assembly screws in the predrilled

holes. Use the 4mm hex wrench to tighten the screws. The

Exploded view of the XTi IntelliScope Dobsonian base.

Figure 3a. The spacer washer goes between the azimuth

encoder board and the top baseplate of the Dobsonian base.

Encoder board

mounting screw

Figure 3b. Installing the azimuth encoder board. Line up the large

hole in the encoder board with the central hole in the top baseplate.

side panels should be oriented so the SkyQuest IntelliScope labels are facing outward. The front brace should be

oriented so the threaded insert is facing the interior of the

base. Do not completely tighten the screws yet.

3. Connect the two side panels (C) with the front brace

attached to the top baseplate (D) with the remaining six

base assembly screws in the predrilled holes. The side of

the baseplate with the pilot hole near the square-shaped

cutout should be facing downwards. Tighten all six screws

firmly.

4. Tighten the six side screws installed earlier.

5. Attach the azimuth encoder board (E) to the underside of

the top baseplate (D). Insert the encoder board mounting

screw through the circuit board and install the small spacer

washer (G) over the screw (Figure 3a). Insert the modular

jack on the encoder board into the square-shaped hole

in the baseplate and align the encoder board so that the

small slotted hole in the board lines up with the predrilled

starter hole, and the large hole lines up with the central

hole in the baseplate. Thread the encoder board mounting

screw into the predrilled starter hole with a Phillips screwdriver and tighten until just tight (Figure 3b).

Azimuth encoder board

6

Page 7

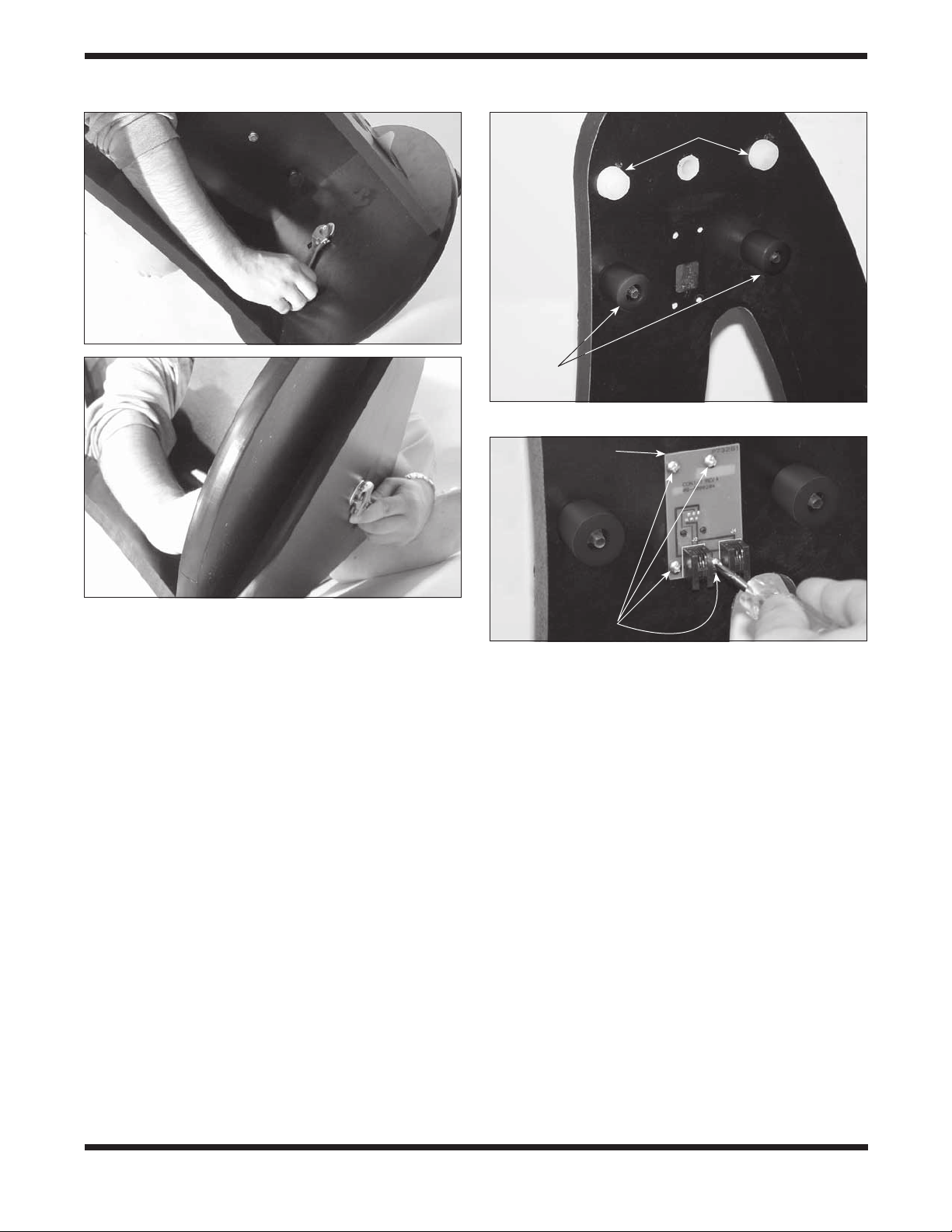

a.

b.

Correct Tension pads

Bearing

cylinders

Figure 5. Attaching the bearing cylinders.

Encoder

connector

board

Figure 4. To connect the baseplates, tilt them only slightly, as

shown. Do not place them on their side. (a) Use one wrench to hold

the hex nut steady (b) while turning the other end of the azimuth

axis screw.

6. Place a fender washer (H) onto the azimuth axis screw (I).

Then push the screw up through the hole in the ground

baseplate (A).Then slide the encoder disk (J), flat side

down, onto the azimuth axis screw.

7. Place the brass bushing (F) onto the azimuth axis screw

(I) so that the wide end of the bushing is closest to the

encoder disk (J). Seat the bushing onto the encoder disk

so that the registration feature on the bushing goes into

the hole in the encoder disk. You may need to move the

encoder disk around on the azimuth axis screw a bit for

the bushing to seat properly.

8. Carefully position the top baseplate (D) over the ground

baseplate (A) and lower it so the brass bushing (F) goes

into in the center hole of the top baseplate. Place the

remaining fender washer (K) onto the shaft of the azimuth

axis screw, then thread the hex lock nut (L) onto the end of

the azimuth axis screw and tighten it finger tight, for now.

9. To tighten the azimuth axis screw (I) and hex lock nut

(L), tilt the assembled Dobsonian base at a slight angle

to lift the ground baseplate off the ground. Now, with one

wrench (or pliers) hold the head of the azimuth axis screw

still while turning the hex lock nut with the other wrench.

Figure 4 shows this being done. Tighten the hex lock nut

just until the top fender washer is no longer moving freely,

Screws

Figure 6.

Attaching the encoder connector board.

then tighten the hex nut a quarter turn beyond that. This

ensures proper spacing between the encoder disk and the

azimuth encoder board.

10. Attach the handle (M) to the front brace (B) with the two

handle mounting hex-head screws. Place one washer on

each screw, then press the handle against the front brace

(the end of the handle bearing the Orion logo should be

up). Then thread the screws from the inside of the base

into the handle until tight using the supplied crescent

wrench.

11. Line up one of the altitude bearing cylinders (N) with the

inside of one of the four bearing cylinder holes on the side

panels. Push a bearing cylinder screw through the side

panel and thread the bearing cylinder onto it (Figure 5).

The beveled end of the cylinder should be farthest from

the side panel. You can tighten the cylinder by hand or, if

needed, with the supplied 4mm hex key. Repeat for the

remaining three bearing cylinders.

12. Attach the encoder connector board to the side panel. Place

the board against the side panel so that the modular jack fits

into the square-shaped hole and thread four encoder board

mounting screws through the connector board and into the

predrilled holes in the side panel until tight (Figure 6).

7

Page 8

Next, you’ll need to install the altitude encoder board assembly. To do so, please refer to the separate instruction manual

for the IntelliScope Computerized Object Locator.

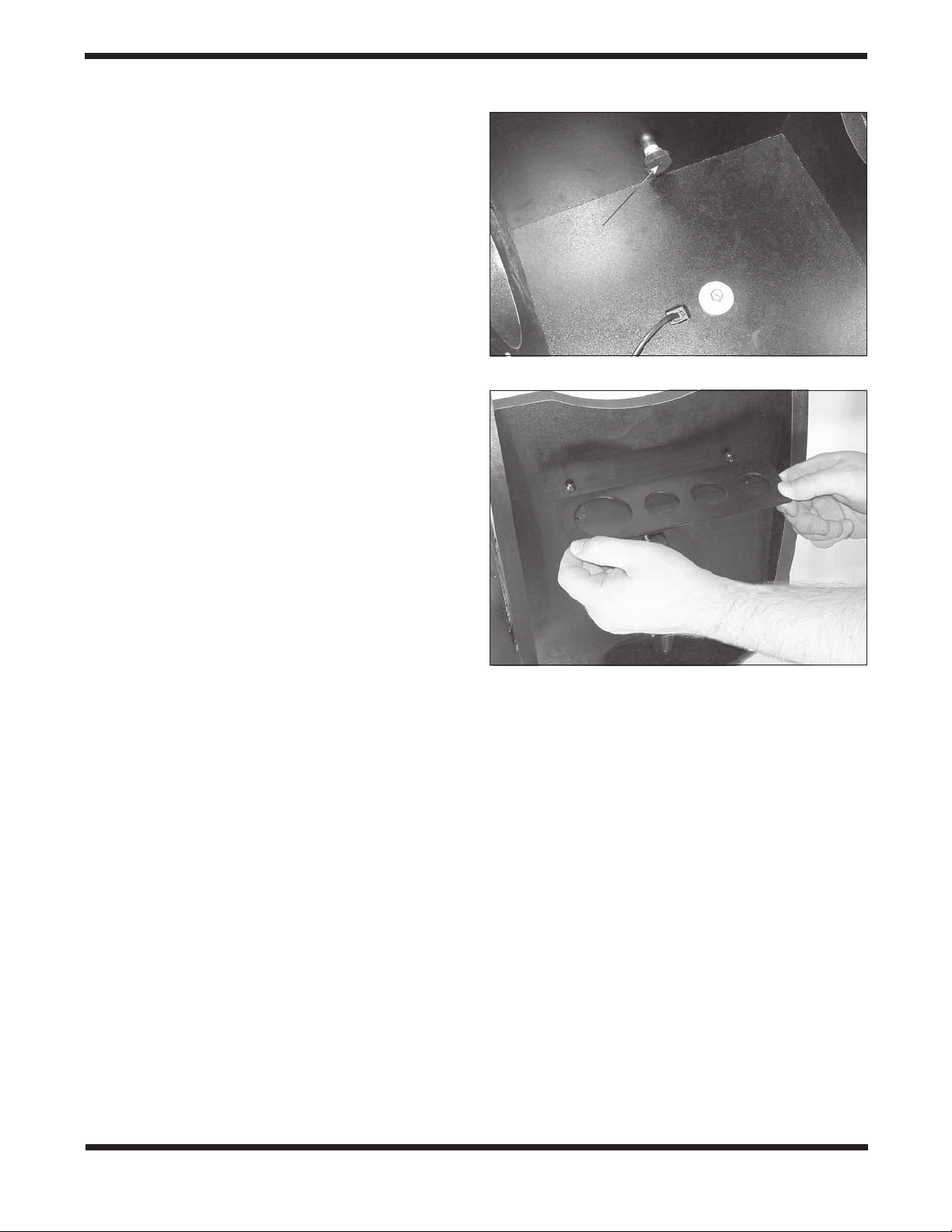

Installing the Vertical Stop

Place three flat washers onto the shaft of the vertical stop

screw. Thread the vertical stop into the threaded insert on the

inside of the front panel until just tight (Figure 7). The position

of the vertical stop is adjustable by adding or removing washers. This is important when using the IntelliScope Computerized Object Locator, since the optical tube must be exactly

vertical before commencing with the two-star alignment procedure (described later). For precise adjustment of the vertical stop, see the manual for the Computerized Object Locator.

Installing the Eyepiece Rack

The aluminum eyepiece rack is a standard accessory on SkyQuest IntelliScope Dobsonians. It holds three 1.25" eyepieces

and one 2" eyepiece (three 1.25" eyepieces on the XT6i) in a

convenient place on the base, within easy reach while you’re

observing. An optional 1.25" barlow lens also can be held in

the rack. A few inches down from the top of the front brace

panel you will notice two predrilled starter holes, about 6"

apart. Thread the black wood screws into the starter holes

with a Phillips screwdriver. Then you can “keyhole” the eyepiece rack onto the wood screws and continue tightening the

screws (Figure 8). If you want to be able to remove the rack-

later without using a screwdriver, do not tighten the screws

too tightly. Be certain that the screws are loose enough that

you can lift the rack and remove it from the screws through

the larger opening of the keyhole. If you want to have the

rack permanently attached, tighten the screws. You may find

it easier to carry the base by the handle if the eyepiece rack

is removed.

Placing the Optical Tube on the Dobsonian Base

Lift the optical tube and gently place it into the Dobsonian

base so that the altitude bearings on either side of the tube

rest on the bearing cylinders. Orient the optical tube as shown

in Figure 9. Make certain that the optical tube does not get

hung up on the vertical bumper stop or the CorrecTension

pads as you put it in place. Be careful when placing the tube

on the bearings, since if it is inserted at the wrong angle the

hub can strike the encoder connector board and potentially

damage it. Once on the bearing cylinders, the tube should

pivot freely up and down with gentle hand pressure. Note that

the tube will not yet be properly balanced, since the eyepiece

and finder scope are not in place, and the CorrecTension system has not been installed.

Installing the CorrecTension Friction

Optimization System

An exciting feature of the SkyQuest IntelliScope Dobsonians is

the redesigned CorrecTension (XT) system. Because of their

Vertical Stop

Figure 7. The vertical stop

Figure 8. Using the two supplied wood screws, install the

aluminum eyepiece rack in the predrilled holes near the top of the

front panel.

relatively light weight, smaller Dobsonians (under 16") have

always been plagued by insufficient friction on the altitude

bearing surfaces. As a result, such telescopes move up and

down much too freely. This causes problems when the observer tries to accurately center and track an object for viewing,

especially at higher powers. Also, the telescope becomes very

sensitive to balance, requiring additional equipment such as

counterweight systems or springs to compensate.

SkyQuest IntelliScope Dobsonians employ a simple yet effective remedy for the friction problem that obviates the need for

such cumbersome countermeasures. CorrecTension Friction

Optimization utilizes a simple “disc brake” to apply the correct

level of tension to the altitude bearings. With the XT system,

you can change eyepieces or add a barlow lens without having to tediously adjust the telescope’s balance as you would

with other Dobsonians. The altitude friction can be made equal

to the azimuth friction, ensuring optimal navigation motion.

8

Page 9

Altitude

bearings

Bearing

cylinders

Figure 10. The tensioning knob, with the metal and nylon

washers, goes on the left side of the base, just above the

IntelliScope port. The tensioning knob should be tightened until the

CorrecTension pads just touch the telescope’s altitude bearing.

Figure 9. Lift the optical tube and place it into the Dobsonian

base so that the altitude bearings rest on the bearing cylinders.

Orient the optical tube as shown. Do not bump the encoder

connector board or vertical stop when installing the optical tube.

To install the XT system, follow these steps while referring to

Figures 10 and 11:

1. Select one of the retaining/tensioning knobs and slide the

metal washer onto the shaft, followed by the white nylon

washer (you will need to thread this washer onto the shaft).

This knob will now be known as the tensioning knob. Push

the shaft of the tensioning knob through the hole in the

left side panel (the one that has the IntellisScope port)

(Figure 10). Thread the knob into the altitude bearing until

Figure 11.

is inserted though the aluminum shaft of the altitude encoder

assembly.

The retaining knob on the right side of the base

the CorrecTension pads on the interior surface of the side

panel just touch the altitude bearing on the optical tube.

2. Thread the other retaining/tensioning knob, which we’ll

now refer to as just the retaining knob, through the altitude

encoder’s aluminum shaft and thread it into the optical tube’s

right side bearing (Figure 11). Make sure this knob is fully

tightened.

Note: Only the left side panel has a white nylon bushing

in the hole for the tensioning knob. The right side panel

does not require this bushing.

9

Page 10

alignment

EyepieceNylon

Objective

lens cell

Finder

scope

thumbscrew

(2)

bracket

Correct-Image

Focusing

lock ring

prism housing

Tensioner

Figure 12a. The 9x50 right-angle correct-image finder scope

and bracket (6x30 for the XT6i).

Knurled thumbscrew

2" eyepiece adapter

Figure 13a.

XT10i, and XT12i.

The 2" Crayford focuser of the SkyQuest XT8i,

Focusing tension

adjustment set screws

1.25" eyepiece adapter

Focus knobs

Focus lock

thumbscrew

Focusing tension

adjustment set screw

Focus knobs

Focus lock

thumbscrew

Finder scope bracket

Dovetail holder

Figure 12b. Inserting the finder scope into its dovetail holder.

The CorrecTension system is now installed. If you wish to

remove the optical tube from the base, you will first need to

unthread and remove both the knobs. Once the optical tube

is removed from the base, thread the knobs back into the

altitude bearings so you do not lose them.

Installing the Finder Scope

SkyQuest IntelliScope Dobsonians come with a high-quality,

large-aperture 9x50 (6x30 for the XT6) right-angle correctimage (RACI) achromatic crosshair finder scope (Figure 12a)

as standard equipment. This greatly aids in finding objects to

view in the night sky.

The finder scope arrives pre-installed in its bracket, but must

be placed into the dovetail holder on the telescope tube. Insert

the base of the finder scope into the dovetail holder located

adjacent to the focuser (Figure 12b). Lock the bracket into

position by tightening the knurled thumbscrew on the dovetail

holder.

Figure 13b. The 1.25" rack-and-pinion focuser of the SkyQuest

XT6i.

Inserting an Eyepiece

The final step in the assembly process is to insert an eyepiece into the telescope’s focuser. First, take the cover cap off

the focuser drawtube.

For the XT8i, XT10i, and XT12i: Loosen the thumbscrew

on the 1.25" eyepiece adapter (Figure 13a). Do not loosen

the two thumbscrews on the 2" eyepiece adapter. Insert the

supplied 25mm Sirius Plössl eyepiece, then secure it by

retightening the thumbscrew on the 1.25" eyepiece adapter.

The other eyepiece can be placed in the eyepiece rack until

it is needed.

For the XT6i: Loosen the two thumbscrews on the eyepiece

holder and insert the 25mm Sirius Plössl eyepiece. Then

secure it in place with the thumbscrews (Figure 13b). The

other eyepiece can be placed in the eyepiece rack until it is

needed.

The basic assembly of your SkyQuest IntelliScope Dobsonian

is now complete. It should appear as shown in Figure 1. The

10

Page 11

Altitude

Azimuth

Figure 14. The SkyQuest IntelliScope has two axes of motion;

altitude (up/down) and azimuth (left/right).

dust cap on the front of the telescope tube should always

remain in place when the telescope is not in use. It is also

a good idea to store eyepieces in an eyepiece case and to

replace the cover caps on the focuser and finder scope when

the telescope is idle.

3. Using Your Telescope

One of the great benefits of the SkyQuest XTi IntelliScope

Dobsonian is its ability to point to more than 14,000 celestial objects via the IntelliScope Computerized Object Locator (Controller). This functionality will greatly enhance your

observing experience by enabling you to quickly and precisely

locate even very faint objects. For more about IntelliScope

Controller functionality, see Section 6.

Before using your IntelliScope for the first time at night, we

recommend getting a feel for its basic functions during daylight hours. Find a spot outdoors where you have a clear view

of some object or landmark that is at least 1/4-mile away.

It is not critical that the base be exactly level, but it should

be placed on somewhat flat ground or pavement to ensure

smooth movement of the telescope.

Remember, never point the telescope at or near the Sun without using a proper solar filter over the front aperture!

Altitude and Azimuth Motion

The SkyQuest’s Dobsonian base permits smooth motion of

the telescope along two axes: altitude (up/down) and azimuth

(left/right) (Figure 14). For altitude motion, the altitude bear-

ings on the telescope tube glide on pairs of bearing cylinders

made from ultra-high molecular weight (UHMW) polyethylene.

For azimuth motion, the top baseplate moves on three PTFE/

UHMW bearing pads affixed to the ground baseplate.

Figure 15. Adjust the tensioning knob until the altitude balance

is just right. The telescope should move easily in altitude without

drifting when you let go.

To move the telescope, simply take hold of the navigation

knob near the front opening of the scope and gently move the

tube up or down and left or right as desired. Both motions can

be made simultaneously and in a continuous manner for easy

aiming. When the telescope is pointed high in altitude, rotating the tube in azimuth can cause the base to “tip” because

of the reduced leverage. In this case it is helpful to place your

other hand on the base or the optical tube to help “guide” it.

Setting the Altitude Tension Level

The telescope should move smoothly with just gentle hand

pressure. While azimuth friction is not adjustable, the altitude

friction can be adjusted to the desired level by turning the

altitude tensioning knob (Figure 10). Note that the altitude

tensioning knob is the one just above the IntelliScope Controller Port. The knob on the opposite (right) side of the base

is merely a retaining knob; it does not affect altitude tension.

Adjustable tension is a feature of the IntelliScopes’ exclusive springless CorrecTension Friction Optimization system.

CorrecTension adds just the right amount of friction to keep

the telescope tube in proper balance, even when other accessories are added on, such as a barlow lens or a heavier eyepiece.

A good way to set the altitude tension is to point the telescope at

about a 45° angle with the eyepiece and finder scope removed.

Loosen the altitude tension knob until the front of the optical

tube starts to drift upward. As it does so, tighten the tension

knob just enough to make the tube stop drifting (Figure 15).

When the eyepiece and finder scope are replaced, the motion

should be ideal – not too stiff, not too loose.

You will want to be able to “track” the motion of celestial

objects while viewing them by making small movements of

the telescope without experiencing jerking (too much tension)

or overshooting of the desired position (too little tension).

11

Page 12

Focusing the Telescope

With the 25mm Sirius Plössl eyepiece in the focuser and

secured with the thumbscrew(s), move the telescope so the

front (open) end is pointing in the general direction of an

object at least 1/4-mile away. Now, with your fingers, slowly

rotate one of the focusing knobs until the object comes into

sharp focus. Go a little bit beyond sharp focus until the image

just starts to blur again, then reverse the rotation of the knob,

just to make sure you’ve hit the exact focus point.

If you have trouble focusing, rotate the focusing knob so the

drawtube is in as far as it will go. Now look through the eyepiece

while slowly rotating the focusing knob in the opposite direction.

You should soon see the point at which focus is reached.

For XT8i, XT10i and XT12i models, the focus lock thumb

screw on the bottom of the focuser body (Figure 13a) will

lock the focuser drawtube in place once the telescope is properly focused. The XT6i’s focus lock thumb screw is located

on the top of the focuser body (Figure 13b). Before focusing,

remember to first loosen the focus lock thumb screw. Do not

loosen the thumb screw too much as there must be some tension to keep the drawtube secure within the focuser.

If you find the drawtube tension when focusing is either too

tight (focus knob is difficult to turn) or too loose (image shifts

when focusing or drawtube moves inward by itself), the tension can be adjusted for optimal performance. On the XT8i,

XT10i, and XT12i, the focusing tension adjustment set screw

is a 3mm socket head set screw located below the focus lock

thumb screw (Figure 13a). A 3mm hex key is required for

adjustment of focus tension. On the XT6i, the focusing tension adjustment set screws are the two small set screws

located on either side of the focus lock thumb screw (Figure

13b). A 1.5mm hex key is required to adjust the focus tension

on the XT6i. Due to the rack-and-pinion focuser design on the

XT6, tension adjustment should not normally be needed as it

has been pre-adjusted at the factory.

Viewing with Eyeglasses

If you wear eyeglasses, you may be able to keep them on

while you observe, if your eyepieces have enough eye relief

to allow you to see the whole field of view. You can try this by

looking through the eyepiece first with your glasses on and

then with them off, and see if the glasses restrict the view

to only a portion of the full field. If they do, you can easily

observe with your glasses off by just refocusing the telescope

the needed amount. If you suffer from severe astigmatism,

however, you may find images noticeably sharper with your

glasses on.

Aligning the Finder Scope

The finder scope must be aligned accurately with the telescope for proper use. To align it, first aim the main telescope

in the general direction of an object at least 1/4-mile away,

e.g., the top of a telephone pole, a chimney, etc. Position that

object in the center of the telescope’s eyepiece.

The finder scope uses a spring-loaded bracket that makes

alignment of the finderscope very easy. As you turn either

Naked-eye view

View through telescope

Figure 16. The view through a reflector telescope is upside

down. This is true for the SkyQuest XT IntelliScope.

of the thumbscrews, the spring in the bracket’s tensioning

pin moves in and out to keep the finder scope secure in the

bracket.

Note: The image in the main telescope will appear

upside-down (rotated 180°). This is normal for reflector

telescopes (see Figure 16).

Now look through the finder scope. Ideally, the object should

be within the field of view. If not, then coarse adjustments to

the alignment thumbscrews will be needed. Once the image

is in the finder scope’s field of view, you will now use the alignment thumbscrews to center the object on the intersection of

the crosshairs. By loosening one alignment thumbscrew, you

change the line of sight of the finder scope. Continue making

adjustments to the alignment thumbscrews until the image

in both the finder scope and the telescope’s eyepiece are

exactly centered.

Check the alignment by moving the telescope to another

object and fixing the finder scope’s crosshairs on the exact

point you want to look at. Then look through the telescope’s

eyepiece to see if that point is centered in the field of view. If

it is, the job is done. If not, make the necessary adjustments

until the two images match up.

The finder scope alignment should be checked before every

observing session. This can easily be done at night, before

viewing through the telescope. Choose any bright star or

planet, center the object in the telescope eyepiece, and then

adjust the finder scope’s alignment thumb screws until the

star or planet is also centered on the finder’s crosshairs. The

finder scope is an invaluable tool for locating objects in the

night sky; its usage for this purpose will be discussed later.

Focusing the Finder Scope

The finder scope with your SkyQuest IntelliScope has adjustable focus. If the images in the finder appear somewhat out

12

Page 13

of focus, you will need to refocus the finder scope for your

vision. Loosen the lock ring located behind the objective lens

cell on the body of the finder scope (see Figure 12a) by turning it counterclockwise. Back the lock ring off by a few turns,

for now. Focus the finder scope on a distant object by threading the objective lens cell in or out on the finder scope body.

Precise focusing will be achieved by focusing the finder scope

on a bright star. Once the image appears sharp, retighten the

lock ring behind the objective lens cell. The finder scope’s

focus should not need to be adjusted again.

Aiming/Pointing the Telescope

With the finder scope aligned, the telescope can be quickly

and accurately pointed at anything you wish to observe. The

finder scope has a much wider field of view than the telescope’s eyepiece, and therefore it is much easier to find and

center an object in the finder scope. Then, if the finder scope

is accurately aligned, the object will also be centered in the

telescope’s field of view.

Start by once again moving the telescope until it is pointed

in the general direction of the object you want to see. Some

observers find it convenient to sight along the tube to do this.

Now, look in the finder scope. If your general aim is accurate, the object should appear somewhere in the field of view.

Make small adjustments to the telescope’s position until the

object is centered on the finder’s crosshairs. Now, look in the

telescope’s eyepiece and enjoy the view!

Of course, with the Computerized Object Locator, the finder

scope is really only needed for assisting with the initial twostar alignment. Once the telescope is aligned, objects targeted with the Object Locator should fall within the filed of view of

the 25mm eyepiece – without any help from the finder scope!

Magnification

Now that the object you want to view is centered in the 25mm

eyepiece, you may want to increase the magnification to get a

closer view. Loosen the thumbscrew(s) on the focuser drawtube and remove the eyepiece. Place it in the eyepiece rack,

if you wish. Insert the 10mm eyepiece in the focuser then

tighten the thumbscrew(s). If you were careful not to bump

the telescope, the object should still be visible in the field of

view. Notice that the object being viewed is now larger, but

somewhat dimmer.

Magnification, or power, is determined by the focal length of

the telescope and the focal length of the eyepiece. Therefore,

by using eyepieces of different focal lengths, the resultant

magnification can be varied.

Magnification is calculated as follows:

Magnification=

For example, the SkyQuest XT8i has a focal length of

1200mm. So, the magnification with the supplied 25mm eyepiece is:

Telescope Focal Length (mm)

Eyepiece Focal Length (mm)

1200 mm

25 mm

= 48x

The magnification provided by the 10mm eyepiece is:

1200 mm

10 mm

The maximum attainable magnification for a telescope is

directly related to how much light its optics can collect. A telescope with more light-collecting area, or aperture, can yield

higher magnifications than a smaller-aperture telescope. The

maximum practical magnification for any telescope, regardless of optical design, is about 60x per inch of aperture. This

translates to about 360x for the SkyQuest XT6i, 480x for the

XT8i, 600x for the XT10i, and 720x for the XT12i. Of course,

such magnifications will only yield reasonable images if atmospheric conditions are favorable.

Keep in mind that as magnification is increased, the brightness of the object being viewed will decrease; this is an inherent principle of the physics of optics and cannot be avoided.

If magnification is doubled, an image appears four times dimmer. If magnification is tripled, image brightness is reduced by

a factor of nine!

Use of 2-Inch Eyepieces

(XT8i, XT10i, and XT12i only)

All SkyQuest XTi IntelliScopes are designed to accept eyepieces with a barrel diameter of 1.25". The XT8i, XT10i, and

XT12i have 2" focusers that accept both 1.25" and optional 2"

eyepieces. At low magnifications, 2" eyepieces can provide

a wider field of view than standard 1.25" eyepieces. A wider

field can be desirable for viewing extended deep-sky objects

that are too large to fit within a narrower field of view.

To use 2" eyepieces, simply loosen the two large thumbscrews

on the 2" adapter that are just in front of the thumbscrew that

holds the provided 1.25" adapter in place (Figure 13a). Once

these thumbscrews are loosened the adapter comes off,

exposing the 2" diameter focuser drawtube. Now, insert your

2" eyepiece into the drawtube and secure with the two thumbscrews loosened previously, and you’re ready to observe.

Tube Balance

SkyQuest IntelliScope Dobsonians are designed to balance

with standard supplied accessories, such as an eyepiece

and a finder scope. But what if you want to use a larger finder

scope or a heavier eyepiece? Traditional Dobsonian designs

require the user to compensate by adding weight to the opposite end of the telescope tube. Such counterweighting systems

can be expensive and unwieldy. The CorrecTension system of

the SkyQuest IntelliScope Dobsonians, however, solves the

finicky balance problem. The brake pads press against the

altitude bearings on the optical tube and increase the friction.

With CorrecTension, the added weight of front-end loads will

not adversely affect the balance of the telescope. Simply tighten the tensioning knob to balance any extra load.

Carrying the Telescope

Transporting the IntelliScope is easy to do. The tube uncouples from the base and each component can be carried

separately. The base has a handle for easy carrying. With the

= 120x

13

Page 14

a.

b. c.

Figure 17.

Picking up and carrying the SkyQuest IntelliScope as a single unit (with tube held captive on the base) requires some caution.

(a) First, position the tube vertically. Then grasp the handle on the base with one hand while supporting the tube with the other. This ensures

that the tube will not swing down and impact the ground (b) With knees bent, slowly lift the base while supporting the tube. (c) As you lift,

continue to support the tube with one hand to keep it parallel with the ground. Make sure you are comfortable with the weight of the whole

assembly before attempting the carry it!

retaining and tensioning knobs of the CorrecTension(XT) system holding the optical tube captive on the base, the entire

telescope can be carried as one unit. (This is not practical

for the XT10i and XT12i due to the hefty weight and size.)

This requires some caution, however. If the telescope is lifted

improperly, the tube could swing down and hit the ground.

First, point the optical tube straight up (vertical). Remove any

eyepieces from the telescope and eyepiece rack, and place

them in an eyepiece case. Grasp the handle on the front of

the base with one hand while supporting the telescope tube

vertically with the other (Figure 17). Now, lift the telescope by

the handle. Once the telescope is in the horizontal position,

you can carry the entire unit with one hand while supporting

the optical tube with the other hand.

If you wish to carry the optical tube and base separately,

simply remove the retaining and tensioning knobs. Then, lift

the tube off the base, then rethread the knobs back into the

bearings so that you do not lose them. Be careful, however,

that the knobs don’t get bent when transporting the telescope

tube. Do not use the navigation knob as a carry handle! It is

not designed to support the weight of the telescope tube and

could break off or damage the tube.

Figure 18. The quick collimation cap, which features a reflective

inner surface, helps in centering reflections of the optics in the

focuser during the collimation process.

Note: The IntelliScope may be too heavy for some users

to lift and carry as one unit. Do not strain yourself! If the

load seems too heavy, carry the base and tube separately

or get help.

14

Page 15

Reflective surface of

collimation

cap

b.

Center

ring on

primary mirror

c.

a.

Figure 19. Collimating the optics. (a) When the mirrors are properly aligned, the view down the focuser drawtube should

look like this. (b) With the collimation cap in place, if the optics are out of alignment, the view might look something like this.

(c) Here, the secondary mirror is centered under the focuser, but it needs to be adjusted (tilted) so that the entire primary

mirror is visible. (d) The secondary mirror is correctly aligned, but the primary mirror still needs adjustment. When the primary

mirror is correctly aligned, the “dot” will be centered, as in (e).

When putting the IntelliScope into a vehicle, common sense

prevails. It is especially important that the optical tube does

not get knocked around; this can cause the optics to become

misaligned, and could dent the tube. We recommend transporting and storing the tube assembly in an optional padded

case for proper protection.

4. Alignment (Collimation)

of the Optical System

To get the sharpest images, your telescope’s optical system

must be in precise alignment. The process of aligning the

primary and secondary mirrors with each other and with the

mechanical axis of the telescope is called collimation.

Your telescope’s optical system was collimated at the factory

and will probably not need any further adjustment. But rough

handling during shipment can knock the optics out of alignment, in which case you will need to recollimate the system.

Collimation is relatively easy to do and can be done in daylight. It is a good idea to check the collimation of your telescope before each observing session and make any necessary adjustments.

To check collimation, remove the eyepiece and look down the

focuser drawtube. You should see the secondary mirror cen-

d.

tered in the drawtube, as well as the reflection of the primary

mirror centered in the secondary mirror, and the reflection of

the secondary mirror (and your eye) centered in the reflection

of the primary mirror, as depicted in Figure 18a. If anything

is off-center, as in Figure 18b, proceed with the following collimation procedure.

The Collimation Cap and Mirror Center Mark

Your SkyQuest XTi IntelliScope comes with a quick collimation cap (Figure 18). This is a simple cap that fits on the focuser drawtube like a dust cap, but has a hole in the center

and a reflective inner surface. The cap helps center your eye

so that collimation is easier to perform. Figures 19b through

19e assume you have the collimation cap in place.

As an additional aid in collimation, the primary mirror of every

SkyQuest XTi IntelliScope has a tiny adhesive ring marking

its exact center. This center ring will not affect the images you

see when observing with the telescope in any way (since it

lies directly in the shadow of the secondary mirror), but will

greatly facilitate accurate collimation when using the supplied

collimation cap or other, more sophisticated collimation devices such as the Orion LaserMate Deluxe laser collimator. The

center ring should never be removed from the primary mirror!

e.

15

Page 16

Preparing the Telescope for Collimation

Once you get the hang of collimation, you will be able to do

it quickly even in the dark. When trying it for the first time or

two, though, it is best to collimate in daylight, preferably in a

brightly lit room and with the telescope aimed at a white wall.

It is recommended that the telescope tube be oriented horizontally. This will prevent any parts from the secondary mirror

from falling down onto the primary mirror and causing damage,

should something come loose when you are making adjustments. Place a sheet of white paper inside the optical tube

directly opposite the focuser. This will provide a bright “background” when viewing into the focuser. When properly set up

for collimation, your telescope should resemble Figure 20.

Aligning the Secondary Mirror

With the collimation cap in place, look through the hole in the

cap at the secondary (diagonal) mirror. Ignore the reflections

for the time being. The secondary mirror itself should be centered in the focuser drawtube, in the direction parallel to the

length of the telescope. If it isn’t, as in Figure 19b, it must be

adjusted. This adjustment will rarely, if ever need to be done.

Using the included 2mm hex key, loosen the three small

alignment set screws in the center hub of the 4-vaned spider several turns. Now keep the mirror’s holder stationary (be

careful not to touch the surface of the mirrors), while turning

the center screw with a Phillips head screwdriver (see Figure

21). Turning the screw clockwise will move the secondary mirror toward the front opening of the optical tube, while turning

the screw counter-clockwise will move the secondary mirror

toward the primary mirror.

Note: When making these adjustments, be careful not to

stress the spider vanes or they may bend.

Figure 20.

The SkyQuest

XTi IntelliScope

properly set up

for collimation.

Note the white

paper placed

across from the

focuser, and

the level angle

of the optical

tube. Ideally, the

telescope should

be pointing at a

white wall.

When the secondary mirror is centered in the focuser drawtube, rotate the secondary mirror holder until the reflection of

the primary mirror is as centered in the secondary mirror as

possible. It may not be perfectly centered, but that is OK. Now

tighten the three small alignment screws equally to secure the

secondary mirror in that position.

If the entire primary mirror reflection is not visible in the secondary mirror, as in Figure 19c, you will need to adjust the tilt

of the secondary mirror. This is done by alternately loosening one of the three alignment hex screws while tightening

the other two, as depicted in Figure 22. Do not make excessive turns of these hex screws or force them past their normal

travel. A simple 1/2 turn of the screw can dramatically change

the tilt of the mirror. The goal is to center the primary mirror reflection in the secondary mirror, as in Figure 19d. Don’t

worry that the reflection of the secondary mirror (the smallest

circle, with the collimation cap “dot” in the center) is off-center.

You will fix that in the next step.

Adjusting the Primary Mirror

The final adjustment is made to the primary mirror. It will need

adjustment if, as in Figure 19d, the secondary mirror is centered under the focuser and the reflection of the primary mirror is centered in the secondary mirror, but the small reflection

Figure 21. To center the secondary mirror under the focuser, hold

the mirror holder in place with one hand while adjusting the center

bolt with a Phillips screwdriver. Do not touch the mirror’s surface!

Figure 22. Adjust the tilt of the secondary mirror by loosening or

tightening the three alignment set screws with the 2mm hex key.

16

Page 17

Figure 23.

Out of collimation Collimated

mirror in place must first be loosened before any adjustments can

be made. Then the tilt of the primary mirror can be adjusted by

turning one or more of the three larger thumbscrews.

The three small thumbscrews that lock the primary

Figure 24. A star test will determine if a telescope’s optics are

properly collimated. An unfocused view of a bright star through

the eyepiece should appear as illustrated on the right if the optics

are perfectly collimated. If the circle is unsymmetrical, as in the

illustration on the left, the scope needs collimation.

of the secondary mirror (with the “dot” of the collimation cap)

is off-center.

The tilt of the primary mirror is adjusted with three springloaded collimation thumbscrews on the back end of the optical tube (bottom of the primary mirror cell); these are the

larger thumbscrews. The three smaller thumbscrews lock the

mirror’s position in place. These thumbscrews must be loosened before any collimation adjustments can be made to the

primary mirror.

To start, turn the smaller thumbscrews counterclockwise a

few turns each (Figure 23). Use a screwdriver in the slots, if

necessary.

Now, try tightening or loosening one of the larger collimation

thumbscrews with your fingers. Look into the focuser and see

if the secondary mirror reflection has moved closer to the center of the primary. You can tell this easily with the collimation

cap and mirror center mark by simply watching to see if the

“dot” of the collimation cap is moving closer or further away

from the “ring” on the center of the primary mirror. If turning

that one thumbscrew does not seem to be bringing you closer

to collimation, try using one of the other collimation thumbscrews. It will take some trial and error using all three thumbscrews to adjust the telescope properly. Over time you will

get the feel for which collimation screws to turn to move the

image in a given direction.

When you have the dot centered as much as is possible in the

ring, your primary mirror is collimated. The view through the

collimation cap should resemble Figure 19e. Now be sure to

re-tighten the locking thumbscrews to lock the primary mirror

in that position.

A simple star test will tell you whether the optics are accurately collimated.

Star-Testing the Telescope

When it is dark, point the telescope at a bright star high in

the sky and center it in the eyepiece’s field of view. Slowly

defocus the image with the focusing knob. If the telescope is

correctly collimated, the expanding disk should be a perfect

circle (Figure 24). If the image is unsymmetrical, the scope

is out of collimation. The dark shadow cast by the secondary mirror should appear in the very center of the out-of-focus

circle, like the hole in a doughnut. If the “hole” appears offcenter, the telescope is out of collimation.

If you try the star test and the bright star you have selected

is not accurately centered in the eyepiece, then the optics will

always appear out of collimation, even though they may be perfectly aligned. It is critical to keep the star centered, so over

time you will need to make slight corrections to the telescope’s

position in order to account for the sky’s apparent motion.

5. Astronomical Observing

SkyQuest IntelliScope Dobsonians provide prodigious capability for observing the many wonders of the heavens, from

the major planets to deep-space nebulas and galaxies. In this

section we give you some observing tips and briefly summarize what you can expect to see.

A. Selecting an Observing Site

Since most astronomical objects are faint, observing them

from dark skies will give you the best views. While some

objects, such as the planets and Moon, are bright enough

to see clearly even from light-polluted city skies, for nebulas,

galaxies, and most star clusters, the less ambient light there

is to reduce contrast, the better.

When it isn’t possible or convenient to get out of town to a

pitch-dark observing location, try to set up in a spot that is

removed from street and building lights and that has a clear

view of a large portion of the sky. For observing faint deepsky objects, choose a Moonless night. Use of a light-pollution

filter can mitigate the effects of background sky brightness,

enhancing the view of faint objects.

17

Page 18

B. Seeing and Transparency

1.9

1.9

1.7

4.9

2.4

3.4

2.5

2.4

Atmospheric conditions play a huge part in quality of viewing. Light from stars and other celestial objects must travel

through miles of Earth’s atmosphere to reach our eyes. The

air in the atmosphere will refract and bend the light. Atmospheric turbulence will worsen the effects of refraction, which

can cause the image you see in your telescope to be unstable. The steadiness of the atmosphere is called “seeing.”

In conditions of good “seeing,” star twinkling is minimal and

objects appear steady in the eyepiece. Seeing is best overhead, worst at the horizon. Also, seeing generally gets better later in the evening as much of the heat absorbed by the

Earth during the day has radiated off into space. In conditions of bad seeing, stars will twinkle and objects will appear

unsteady and blurry in the telescope.

“Transparency” is the clarity of the atmosphere, which can

be adversely affected by the presence of moisture, smoke,

and dust. All tend to scatter light, which reduces an object’s

brightness. Good transparency is desirable for astronomical

observing, especially for viewing faint objects.

One good measure of transparency is by how many stars you

can see with your unaided eyes. If you cannot see stars of

magnitude 3.5 or dimmer then transparency is poor. Magnitude is a measure of how bright a star is. The brighter a star,

the lower its magnitude. A good star to remember for this is

Megrez (magnitude 3.4), which is the star in the Big Dipper

that connects the handle to the “dipper.” If you cannot see

Megrez, then you have fog, haze, clouds, smog, light pollution or other conditions that are hindering your viewing (see

Figure 25).

C. Cooling the Telescope

All optical instruments need time to reach “thermal equilibrium” to achieve maximum stability of the lenses and mirrors, which is essential for peak performance. Images will be

unstable if the optics are not in equilibrium with the outdoor

temperature. When moved from a warm indoor location outside to cooler air (or vice-versa), a telescope needs time to

cool to the outdoor temperature. The bigger the instrument

and the larger the temperature change, the more time will be

needed.

Allow at least 30 minutes for your SkyQuest IntelliScope to

equilibrate. If the temperature difference between indoors and

outdoors is more than 40°, allow an hour or more. In the winter, storing the telescope outdoors in a shed or garage greatly

reduces the amount of time needed for the optics to stabilize.

It also is a good idea to keep the scope covered until the Sun

sets so the tube does not heat greatly above the temperature

of the outside air.

SkyQuest XT8i, XT10i and XT12i models are designed to

accept an optional Orion Cooling Accelerator Fan. When

attached to the rear cell of the telescope, the fan hastens the

equilibration of the primary mirror to ambient temperature.

D. Let Your Eyes Dark-Adapt

Do not expect to go from a lighted house into the darkness

of the outdoors at night and immediately see faint nebulas,

Figure 25. Megrez connects the Big Dipper’s handle to its “pan”.

It is a good guide to judging the “seeing” conditions. If you cannot

see Megrez (a 3.4-magnitude star) then seeing is poor.

galaxies, and star clusters — or even very many stars, for

that matter. Your eyes take about 30 minutes to reach perhaps 80% of their full dark-adapted sensitivity. Many observers notice improvements after several hours of total darkness.

As your eyes become dark-adapted, more stars will glimmer

into view and you will be able to see fainter details in objects

you view in your telescope. Exposing your eyes to very bright

daylight for extended periods of time can adversely affect your

night vision for days. So give yourself at least a little while to

get used to the dark before you begin observing.

To see what you are doing in the darkness, use a red-filtered

flashlight rather than a white light. Red light does not spoil

your eyes’ dark adaptation like white light does. A flashlight

with a red LED light is ideal, or you can cover the front of a

regular incandescent flashlight with red cellophane or paper.

Dim light is preferable to bright light. Beware, too, that nearby

porch and streetlights and automobile headlights will spoil

your night vision.

Eyepiece Selection

By using eyepieces of different focal lengths, it is possible

to attain many different magnifications with your telescope.

The telescope comes with two high-quality Sirius Plössl eyepieces: a 25mm focal length, and a 10mm focal length, which

provides higher magnification. Other eyepieces can be used

to achieve higher or lower powers. It is quite common for an

observer to own five or more eyepieces to access a wide

range of magnifications. This allows the observer to choose

the best eyepiece to use depending on the object being

viewed and the sky conditions. At least to begin with, the two

supplied eyepieces will suffice nicely.

Whatever you choose to view, always start by inserting your

lowest-power (longest focal length) eyepiece to locate and

center the object. Low magnification yields a wide field of

view, which shows a larger area of sky in the eyepiece. This

makes acquiring and centering an object much easier. If you

try to find and center objects with high power (narrow field of

view), it’s like trying to find a needle in a haystack!

Once you’ve centered the object in the eyepiece, you can

switch to higher magnification (shorter focal length eyepiece),

18

Page 19

if you wish. This is especially recommended for small and

bright objects like planets and double stars. The Moon also

takes higher magnifications well.

Deep-sky objects, however, typically look better at medium

or low magnifications. This is because many of them are

quite faint, yet have some extent (apparent width). Deep-sky

objects will often disappear at higher magnifications, since

greater magnification inherently yields dimmer images. This is

not the case for all deep-sky objects, however. Many galaxies

are quite small, yet have high surface brightness, so higher

power may show more detail.

The best rule of thumb with eyepiece selection is to start with

a low power, wide field, and then work your way up in magnification. If the object looks better, try an even higher magnification. If the object looks worse, then back off the magnification

a little by using a lower power eyepiece.

A. The Moon

With is rocky and cratered surface, the Moon is one of the

most interesting and easy subjects to view with your scope.

The best time to view it is during its partial phases when

shadows fall on the craters and canyon walls to give them

definition. While the full moon may look like a tempting target,

it is not optimal for viewing! The light is too bright and surface

definition is low.

Even at partial phases the Moon is very bright. Use of an

optional Moon filter to helps to dim the glare. It simply threads

onto the bottom of the eyepiece. You’ll find the Moon filter

improves viewing comfort, and helps bring out the subtle features of the lunar surface.

B. The Sun

You can change your nighttime telescope into a daytime Sun

viewer by installing an optional full-aperture solar filter over

the front opening of the telescope. The primary attraction is

sunspots, which change shape, appearance, and location

daily. Sunspots are directly related to magnetic activity in the

Sun. Many observers like to make drawings of sunspots to

monitor how the Sun is changing from day to day.

Important Note: Do not look at the Sun with any optical

instrument without a professionally made solar filter, or

permanent eye damage could result. Also, be sure to cover

the finder scope, or better yet, remove it altogether.

C. The Planets

The planets don’t stay put like the stars, so to find them you

should refer to the monthly star chart and In the Sky column

on the Orion website (www.telescope.com), or to charts

published monthly in Astronomy, Sky & Telescope, or other

astronomy magazines. Venus, Mars, Jupiter, and Saturn are

the brightest objects in the sky after the Sun and the Moon.

Your SkyQuest IntelliScope is capable of showing you these

planets in great detail. Other planets may be visible but will

likely appear starlike. Because planets are quite small in

apparent size, optional higher power eyepieces and/or a barlow lens are recommended for detailed observations. Not all

the planets are generally visible at any one time.

JUPITER The largest planet, Jupiter, is a great subject for

observation. You can see the disk of the giant planet and

watch the ever-changing positions of its four largest moons:

Io, Callisto, Europa, and Ganymede. Higher power eyepieces

should bring out the cloud bands on the planet’s disk and the

Great Red Spot.

SATURN The ringed planet is a breathtaking sight. The tilt

angle of the rings varies over a period of many years; sometimes they are seen edge-on, while at other times they are

broadside and look like giant “ears” on each side of Saturn’s

disk. A steady atmosphere (good seeing) is necessary for a

good view. Look closely and you should see the Cassini division, a thin, dark gap in the rings. You should also see one

or more of Saturn’s moons, which look like faint stars. The

brightest is the moon Titan.

VENUS At its brightest, Venus is the most luminous object in

the sky, excluding the Sun and the Moon. It is so bright that

sometimes it is visible to the naked eye during full daylight!

Ironically, Venus appears as a thin crescent, not a full disk,

when at its peak brightness. Because it is so close to the Sun,

it never wanders too far from the morning or evening horizon.

No surface markings can be seen on Venus, which is always

shrouded in dense clouds.

MARS The Red Planet makes a close approach to Earth

every two years. Observing Mars is most favorable at these

times. You should see salmon-colored disk with some distinct

dark patches, and you may be able to spot a whitish polar ice

cap. To see surface detail on Mars, you will need a high power

eyepiece and very steady air!

D. The Stars

Stars will appear as tiny points of light. Even powerful telescopes cannot magnify stars to appear as anything more than

pinpoints. You can, however, enjoy the different colors of the

stars and locate many pretty double and multiple stars. The

famous “Double-Double” in the constellation Lyra and the gorgeous two-color double star Albireo in Cygnus are favorites.

Defocusing a star slightly can help bring out its color.

E. Deep-Sky Objects

Under dark skies, you can observe a wealth of fascinating

deep-sky objects; that is, objects that reside outside of our

solar system. These include gaseous nebulas, open and globular star clusters, and a variety of different types of galaxies.

The large apertures of SkyQuest IntelliScope Dobsonians are

particularly well suited to gathering light, which is critical for

observing these usually faint celestial entities. For deep-sky

observing it is important that you find an observing site well

away from light pollution. Take plenty of time to let your eyes

adjust to the darkness. As you become more experienced and

your observing skills get sharper, you will be able to ferret out

more and more subtle details and structure from these fascinating objects.

Beginners are often surprised to discover that the deep-sky

objects they see through the eyepiece of a telescope are

mostly grayish, not colorful like those you see in long-exposure photographs. The reason is that our eyes are not sensi-

19

Page 20

tive to color in faint light. Still, there is something very special

about seeing an astronomical object in real time, with your

own eyes — “live,” if not in living color.

Note About Astrophotography

SkyQuest IntelliScope Dobsonians are designed for visual,

not photographic use. Their mounts are not equatorial-type

designs and are not motor driven, so they are not suitable for

long-exposure astrophotography. Also, the telescopes’ optics

have been optimized for visual, rather than photographic, use.

With that in mind, however, it is possible to do some simple

astrophotography with a SkyQuest IntelliScope. With the use

of afocal photography techniques (where the camera is simply put right up to the eyepiece to take a picture) and digital

cameras, it is possible to take pictures of bright objects. Certain photographic aids, such as the Orion SteadyPix afocal

adapter, can help in taking photos by the afocal, or eyepiece

projection, method.

6. IntelliScope

Computerized Object

Location

Perhaps the most exciting feature of the SkyQuest XT IntelliScope is the IntelliScope Computerized Object Locator

(controller). When plugged into the IntelliScope port on the

telescope’s base, the IntelliScope controller enables the user

to point the telescope quickly and effortlessly to more than

14,000 celestial objects with the push of a button. After a simple two-star alignment procedure, you just select an object

to view from the intuitive keypad, then read the guide arrows

on the controller’s illuminated liquid crystal display and move

the telescope in the corresponding direction. In seconds the

object will be waiting in the telescope’s field of view, ready to

observe. It’s that simple!

The controller provides a whole new level of convenience and

capability, as you’re able to locate and view more objects in

an evening than you ever could before.

The IntelliScope controller works by communicating electronically with a pair of high-resolution, 9,216-step digital encoders that allow highly precise positioning of the telescope to

coordinates programmed into the IntelliScope controller’s

database for each object. Since the telescope is not dependent on motors for movement, you can move the telescope to

your target much more quickly (and quietly!) than motorized

telescopes can — and without guzzling all those batteries in

the process.

The IntelliScope database includes:

• 7,840 objects from the Revised New General Catalog

• 5,386 objects from the Index Catalog

• 110 objects from the Messier Catalog

• 837 selected stars (mostly double, multiple, and

variable stars)

• 8 planets

• 99 user-programmable objects

With the user-friendly IntelliScope controller, there are many

ways to locate an object. If you know its catalog number

(NGC or Messier number, for instance), you can enter it using

the illuminated keypad buttons. Or you can press one of the

object-category buttons (Cluster, Nebula, Galaxy, etc.) to

access a list of objects by type. For a tour of the best objects

visible in a given month, you just press the Tour button. Another great feature of the IntelliScope is the ability to identify an

“unknown” object in the field of view — just press the ID button. You can even add up to 99 objects of your own choosing

to the IntelliScope controller’s database.

The backlit, two-line liquid crystal display on the controller

shows you the object’s catalog number, its common name if it

has one, the constellation in which it resides, its right ascension and declination coordinates, the object type, magnitude,

angular size, as well as a brief description in scrolling text.

The two guide arrows and associated “navigation numbers”

tell you in what direction to move the telescope to pinpoint

an object’s location. As the telescope approaches the object’s

location, the numbers get progressively smaller. When the

navigation numbers reach 0, the telescope will be pointed

right at the object! You just look into the eyepiece and enjoy

the view!

The features, functionality, and alignment procedure of

the IntelliScope Computerized Object Locator are covered in detail in the separate instruction manual for that

component.

20

Page 21

7. Care and Maintenance

If you give your telescope reasonable care, it will last a lifetime. Store it in a clean, dry, dust-free place, safe from rapid

changes in temperature and humidity. Do not store the telescope outdoors, although storage in a garage or shed is OK.

Small components like eyepieces and other accessories

should be kept in a protective box or storage case. Keep the

cloth dust cover on the front of the telescope when not in use.

Your SkyQuest XTi IntelliScope requires very little mechanical maintenance. The optical tube is steel and has a smooth

painted finish that is fairly scratch-resistant. If a scratch does

appear on the tube, it will not harm the telescope. Smudges

on the tube or base can be wiped off with a soft cloth and a

household cleaner.

Cleaning Eyepiece Lenses

Any quality optical lens cleaning tissue and optical lens cleaning fluid specifically designed for multi-coated optics can be

used to clean the exposed lenses of your eyepieces or finder scope. Never use regular glass cleaner or cleaning fluid

designed for eyeglasses. Before cleaning with fluid and tissue,

however, blow any loose particles off the lens with a blower

bulb or compressed air. Then apply some cleaning fluid to a

tissue, never directly on the optics. Wipe the lens gently in

a circular motion, then remove any excess fluid with a fresh

lens tissue. Oily fingerprints and smudges may be removed

using this method. Use caution; rubbing too hard may scratch

the lens. On larger lenses, clean only a small area at a time,

using a fresh lens tissue on each area. Never reuse tissues.

Cleaning Mirrors

You should not have to clean the telescope’s mirrors very

often; normally once every few years or so. Covering the telescope with the dust cover when it is not in use will prevent

dust from accumulating on the mirrors. Improper cleaning can

scratch mirror coatings, so the fewer times you have to clean

the mirrors, the better. Small specks of dust or flecks of paint

have virtually no adverse effect on the visual performance of

the telescope.

The large primary mirror and the elliptical secondary mirror of

your telescope are front-surface aluminized and over-coated

with hard silicon dioxide, which prevents the aluminum from

oxidizing. These coatings normally last through many years of

use before requiring re-coating (which is easily done).

To clean the secondary mirror, you will need to remove it

from the telescope. Before doing so, orient the telescope tube

horizontally so that nothing accidentally falls down and hits

the primary mirror. Hold the secondary mirror holder stationary while loosening the center Phillips-head screw. Handle

the mirror by its holder; do not touch the mirror surface itself.

Once the mirror (still in its holder) is removed from the tube,

follow the same procedure described below for cleaning the

primary mirror. You do not need to remove the secondary mirror from its holder when cleaning.

To clean the primary mirror, you must carefully remove the

mirror cell from the telescope. To do this, remove the screws

on the side of the tube near the primary mirror. You do not

need to remove the collimation screws on the bottom of the

mirror cell. Remove the mirror cell from the tube. You will

notice the primary mirror is held down with three (or four,

depending on the model) clips fastened by two screws each.

Loosen the screws and remove the clips.

You may now remove the mirror from the mirror cell. Do not

touch the surface of the mirror with your fingers; lift it carefully

by the edge. Set the mirror, aluminized face up, on a clean,

soft towel. Fill a clean sink free of abrasive cleanser with roomtemperature water, a few drops of liquid dishwashing detergent, and if possible a capful of rubbing alcohol. Submerge

the mirror (aluminized face up) in the water and let it soak for

a few minutes (or hours if it’s a very dirty mirror). Wipe the mirror under water with clean cotton balls, using extremely light

pressure and stroking in a straight line across the mirror. Use

one ball for each wipe across the mirror. Then rinse the mirror

under a stream of lukewarm water. Any particles on the surface can be swabbed gently with a series of cotton balls, each

used just one time. Dry the mirror in a stream of air (a “blower

bulb” works great), or remove any stray drops of water with

the corner of a paper towel. Water will run off a clean surface.

Cover the mirror surface with a tissue, and leave the mirror in

a warm area until it is completely dry before reassembling the

telescope.

21

Page 22

8. Specifications

SkyQuest XT6i IntelliScope

Primary mirror: 150mm diameter, parabolic, center marked

Primary mirror material: Low thermal expansion optical glass

Mirror coatings: Enhanced-reflectivity (94%) aluminum, SiO

overcoat

Secondary mirror minor axis: 34.5mm

Focal length: 1200mm

Focal ratio: f/8.0

Focuser: Rack-and-pinion, accepts 1.25" eyepieces

Altitude bearing diameter: 5.75"

Optical tube material: Rolled steel

Azimuth pad material: PTFE/UHMW

Altitude bearing material: UHMW polyethylene

Eyepieces: 25mm & 10mm Sirius Plössl, multi-coated, 1.25"

Eyepiece magnification: 48x and 120x

Finder scope: 6x30mm, right-angle correct-image, 7° field of

view

Eyepiece rack: Holds three 1.25" eyepieces

Optical tube weight: 13.5 lbs.

Base weight: 20.9 lbs.

Tube length: 45.5"

Tube outer diameter: 7.25"

SkyQuest XT8i IntelliScope

Primary mirror: 203mm diameter, parabolic, center marked