Page 1

Operating Instructions for

Rhino

Duct Leakage Tester

(Metric)

© Copyright 2015 ORIFLOW LLC

Page 2

Table of Contents

Introduction

Introduction ……………………………………….…….. 2

Safety Precautions

Safety Precautions ………………………………….…. 2

Prior to Testing

System Preparation …………………….………………. 3

Power Requirements …………………………………... 3

Extension Cord Requirements ………………………... 4

Flex-Duct Length ………………………………………... 4

Determining Maximum Allowable Leakage ….……... 4

Determining Which Orifice Plate to Use ……………... 5 - 7

Duct Leakage Test Setup and Procedure

Install Orifice Plate and Upper Tube Section………… 8 - 9

Connect Flexible Duct to Orifice Tube ……………….. 10

Connect Flexible Duct to Duct System ………………. 10

System Test Pressure Connection …………………… 11

Duct Leakage Test Setup (SUPPLY) ………………… 12

Duct Leakage Test Setup (RETURN/EXHAUST) ...….. 13

Inlet Transition Required for Return/Exhaust Testing . 14

Zeroing Pressure Gauges ……………………………… 15

Avoiding Over-Pressurization ………………………… 16

Obtaining System Test Pressure ……………………… 16 - 17

Determining Leakage Rate……………………………… 17 - 19

Troubleshooting

Zero reading on “DUCT SYSTEM” gauge ………….... 19

Zero reading on “ORIFICE PLATE” gauge …………….. 20

Can’t obtain system test pressure ……………………… 21

“ORIFICE PLATE” gauge reading maxed out………...... 21

© Copyright 2018 ORIFLOW LLC Rev: 03-2018

1

Page 3

Introduction

These operating instructions are for ORIFLOW model RHINO air leakage tester.

Take pride in knowing that you have purchased the best air leakage tester on the

market. It is no secret that Oriflow manufactures the highest quality testers, and has

unparalleled customer service and technical support.

The orifice plates available for your duct leakage tester are constructed from lasercut 3.2 mm stainless steel and do not require recalibration for 10 years. Note the

authority having jurisdiction may override this requirement, and if so, Oriflow has very

reasonable rates for calibrating orifice plates manufactured by Oriflow.

Safety Precautions

Before operating your tester, read the following safety precautions:

DO NOT operate the tester in the rain,

DO NOT operate the tester while it is near or in water,

DO NOT operate the tester with a damaged electrical cord or plug,

DO NOT remove the inlet safety screen,

DO NOT touch the blower wheel when the unit is plugged in,

DO NOT look into the discharge end of the tester when the unit is plugged in,

DO NOT use the tester as a ladder or step stool,

DO NOT allow children near the tester,

DO use an extension cord of the proper gauge (see Table 2),

DO use the proper voltage and line frequency listed on the motor nameplate,

DO lock the caster when the tester is positioned horizontally,

DO use the tester on level ground,

DO secure the tester when transporting it,

DO wear proper hearing protection, safety glasses and work gloves,

DO seek assistance when lifting the tester (e.g., loading onto truck, going up

or down stairs).

© Copyright 2018 ORIFLOW LLC Rev: 03-2018

2

Page 4

Prior to Testing

System Preparation

Cap off all ends of system using clear plastic and duct tape or sheetmetal duct end

caps. Make sure you test the part of the duct system that leakage testing is required.

Usually, this is from the system fan up to, but not including, the VAV boxes (terminal

units). Refer to the engineer's specifications and all applicable codes and test

standards.

Power Requirements

Do you have an adequate power supply for your tester (see Table 1)?

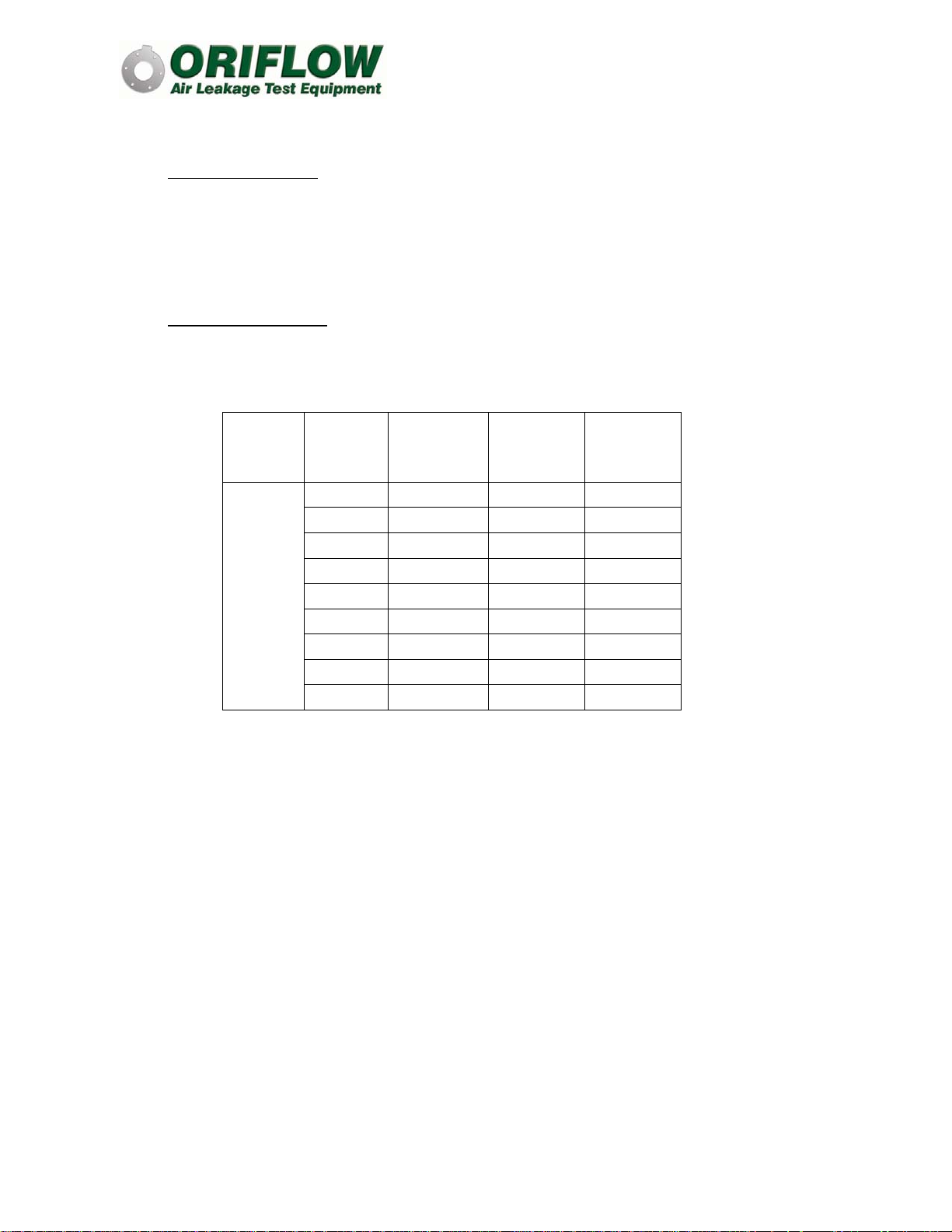

Table 1 – Tester Amp Draw

Tester

Model

Rhino

Flow

Voltage

208 Slide Gate 3 13

208 VFD 3 14

230 VFD 1 21

230 Slide Gate 3 12

230 VFD 3 13

380 Slide Gate 3 7

380 VFD 3 8

460 Slide Gate 3 6

460 VFD 3 7

Control

Option

Phase

Full Load

Amps

© Copyright 2018 ORIFLOW LLC Rev: 03-2018

3

Page 5

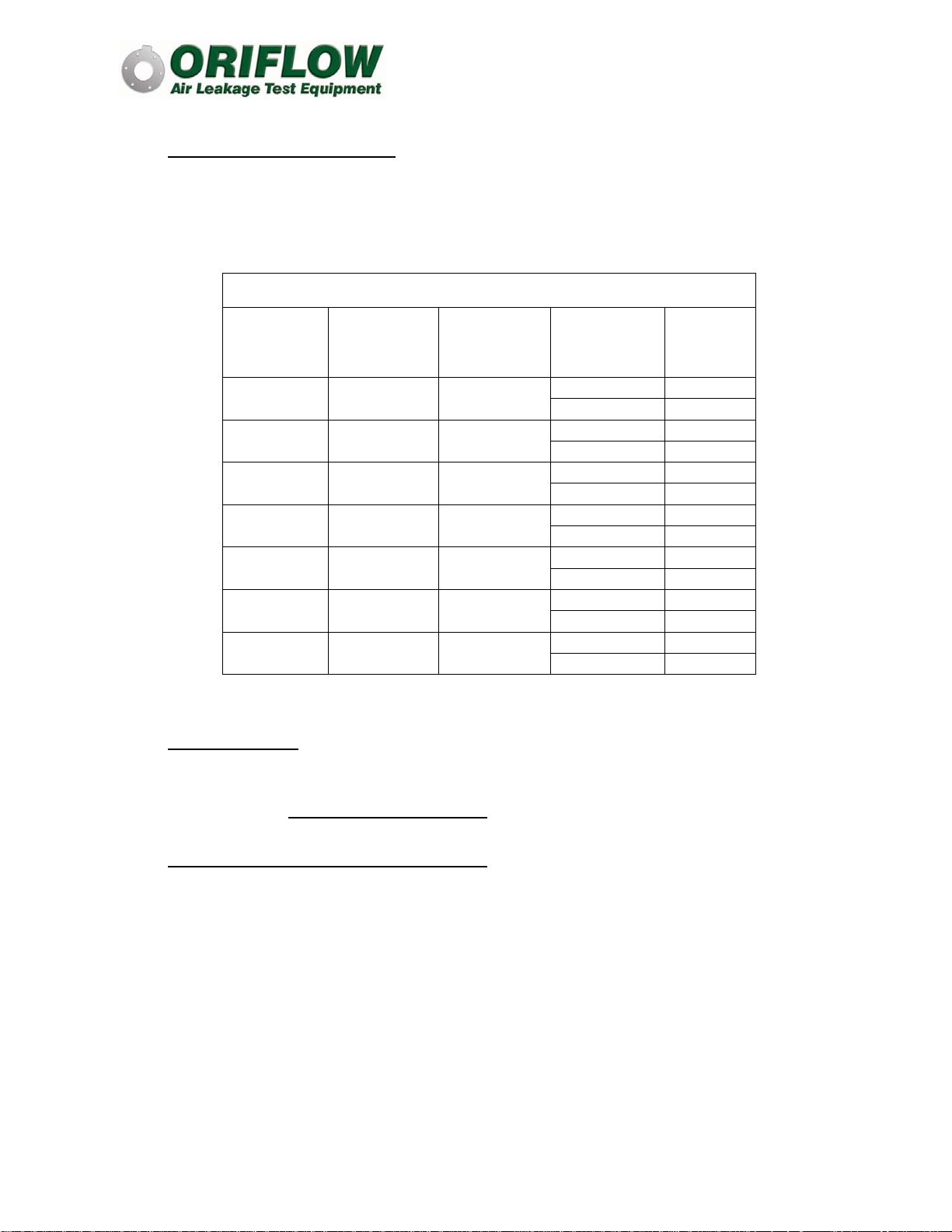

Extension Cord Requirements

If you need an extension cord, is it the proper gauge? See Table 2 below for

extension cord requirements.

Table 2 – Required Extension Cord Wire Gauge

Rhino Model

Flow

Control

Option

VFD 230 1

Slide Gate 230 3

VFD 230 3

Slide Gate 380 3

VFD 380 3

Slide Gate 460 3

VFD 460 3

Flex-Duct Length

Voltage Phase

Cord Length

Extension

(meters)

3 to 15 10

15 to 30 10

3 to 15 14

15 to 30 14

3 to 15 14

15 to 30 14

3 to 15 14

15 to 30 14

3 to 15 14

15 to 30 14

3 to 15 14

15 to 30 14

3 to 15 14

15 to 30 14

Gauge

Wire

Make sure you have enough flexible-duct with your tester for the job. Each tester

includes 3.8 m, which is enough for most applications. Extra lengths of flexible-duct

are available at www.oriflow.com/products.

Determining Maximum Allowable Leakage

To determine the maximum allowable leakage for the project, use ORIFLOW’s free

online programs to make these calculations (www.oriflow.com/programs).

Calculations are done for either of the two typical specifications: percentage of

system flow, or leakage class. If the specification uses leakage class, you will need

to calculate the total duct system surface area. Oriflow has a free Adobe form

available to our customers that will calculate duct surface area given the duct shape,

dimensions and length.

© Copyright 2018 ORIFLOW LLC Rev: 03-2018

4

Page 6

Determining Which Orifice Plate to Use

After determining the allowable leakage at the system test pressure, refer to the

following tables for the capacities of each orifice plate available for the RHINO model

tester. Make sure you have an orifice plate that can measure the maximum allowable

leakage. The proper plate is the one where the maximum allowable leakage falls

between the minimum and maximum leakage at the system static pressure. For

example, if you are testing a system at 2500 Pa pressure and the maximum

allowable leakage is 283 L/s, you will need a 125 mm orifice plate since the 125 mm

plate can be used for up to 380 L/s of leakage (see Table 7).

It is a good idea to have the next larger orifice plate size since it is common for duct

systems to leak more than the maximum allowable. Smaller diameter plates are use

when leakage is relatively low.

Table 3 – Tester Capacities using the 25 mm Orifice Plate

System Static

Pressure

(Pa)

Minimum

Leakage*

(L/s)

Maximum

Leakage

(L/s)

500 4 21

1000 4 19

1500 4 18

2000 4 17

2500 4 14

3000 4 12

3500 4 9

4000 4 6

© Copyright 2018 ORIFLOW LLC Rev: 03-2018

5

Page 7

Determining Which Orifice Plate to Use (continued)

Table 4 – Tester Capacities using the 50 mm Orifice Plate

System Static

Pressure

(Pa)

500 17 87

1000 17 78

1500 17 73

2000 17 66

2500 17 57

3000 17 47

3500 17 35

4000 17 26

Table 5 – Tester Capacities using the 75 mm Orifice Plate

System Static

Pressure

(Pa)

Minimum

Leakage*

(L/s)

Minimum

Leakage*

(L/s)

Maximum

Leakage

(L/s)

Maximum

Leakage

(L/s)

500 40 195

1000 40 180

1500 40 165

2000 40 145

2500 40 130

3000 40 105

3500 40 80

4000 40 60

Table 6 – Tester Capacities using the 100 mm Orifice Plate

System Static

Pressure

(Pa)

Minimum

Leakage*

(L/s)

Maximum

Leakage

(L/s)

500 75 370

1000 75 340

1500 75 310

2000 75 280

2500 75 245

3000 75 195

3500 75 155

4000 75 105

© Copyright 2018 ORIFLOW LLC Rev: 03-2018

6

Page 8

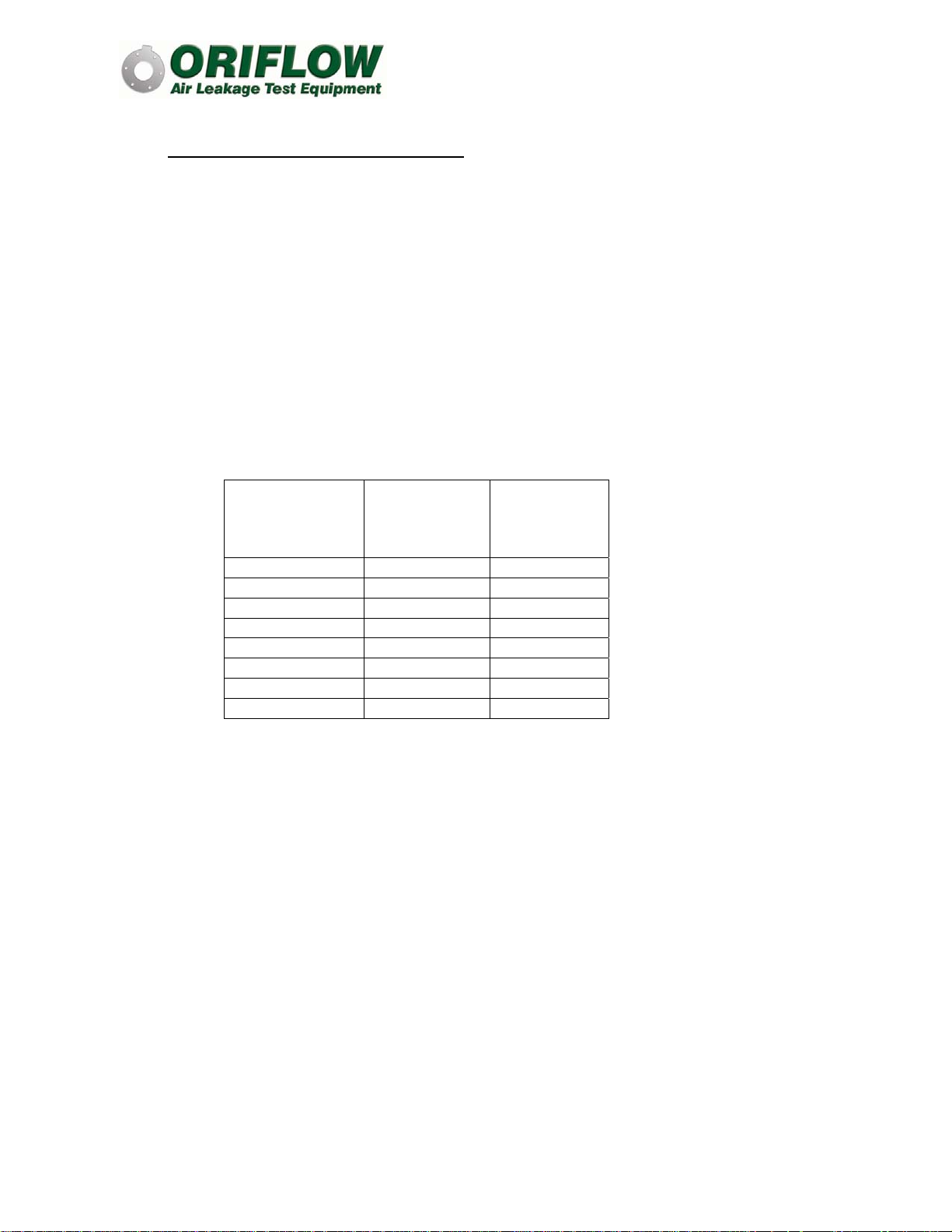

Determining Which Orifice Plate to Use (continued)

Table 7 – Tester Capacities using the 125 mm Orifice Plate

System Static

Pressure

(Pa)

500 125 560

1000 125 520

1500 125 480

2000 125 430

2500 125 380

3000 125 310

3500 125 240

4000 125 175

Table 8 – Tester Capacities using the 159 mm Orifice Plate

System Static

Pressure

(Pa)

Minimum

Leakage*

(L/s)

Minimum

Leakage*

(L/s)

Maximum

Leakage

(L/s)

Maximum

Leakage

(L/s)

500 215 730

1000 215 670

1500 215 630

2000 215 560

2500 215 510

3000 215 425

3500 215 310

4000 215 230

© Copyright 2018 ORIFLOW LLC Rev: 03-2018

7

Page 9

Install Orifice Plate and Upper Tube Section

The orifice plate that was determined from the previous section should now be

installed with the serial number facing upwards, so the corresponding calibration

certificate may be referenced after installation. Refer to Figures 1 through 4.

Figure 1 – Install Orifice Plate and then Rotate Clockwise

Figure 2 – Rotate Orifice Plate Clockwise until it Locks in Place

© Copyright 2018 ORIFLOW LLC Rev: 03-2018

8

Page 10

Install Orifice Plate and Upper Tube Section (continued)

After the orifice plate is locked in place, place the upper tube section over the

bolt/wing nut set, rotate clockwise, and tighten wing nuts (Figures 3 and 4).

Figure 3 – Install Upper Tube Section and Rotate Clockwise

Figure 4 – Tighten Wing Nuts after Rotation

© Copyright 2018 ORIFLOW LLC Rev: 03-2018

9

Page 11

Connect Flexible Duct to Orifice Tube

See the figures below for securing one end of the flexible duct to the orifice tube.

Note that the worm-gear clamp should be slid over the flex-duct before connecting it

to the orifice tube. Slide the flexible duct so that it overlaps the orifice tube 25 to 50

mm, and tighten clamp using a 8 mm nut driver.

Figure 5 – Installing Flex-Duct on Tube Figure 6 – Tightening Clamp

Connect Flex-Duct to Duct System

Find a convenient location in the duct system where the tester has easy access.

Make sure that the connection where you connect the flexible duct is a sturdy, sealed

tight connection. You don’t want to create a leaky connection where the tester is

supplying air into the system.

Figure 7 – Connection to Duct System

© Copyright 2018 ORIFLOW LLC Rev: 03-2018

10

Page 12

System Test Pressure Connection

So that you can monitor the system static pressure, you need to drill a hole at least 1

meter away from the flex-duct connection. Drill a 8 mm diameter hole and insert the

pressure tubing from the “DUCT SYSTEM” gauge so that 150 to 300 mm of tubing is

inside the duct system. Using putty or duct tape, seal the connection. If your

pressure tubing has a plastic static pressure tap at the end of the pressure tubing,

insert the tap in the hole and seal it to the duct wall using duct tape. See Figure 8

below.

Figure 8 - Static Pressure Tubing Connection

See Figure 9 showing the test setup for SUPPLY system testing. Refer to Figure 10

for the test setup required to measure air leakage of a RETURN/EXHAUST system.

Note you will need an inlet transition to attach to the blower inlet when performing a

return/exhaust test. The dimensions of the transition required depends on whether

you have a Rhino model with an inlet slide gate or VFD for flow control. See Figure

11 and 12 for inlet transition dimensions required.

DUCT SYSTEM pressure tubing

inserted into duct system

© Copyright 2018 ORIFLOW LLC Rev: 03-2018

11

Page 13

Figure 9 – Duct Leakage Test Setup for a SUPPLY System

Tap into existing

outlet if possible

Cap and seal

all outlets

1. Drill 9.5 mm hole

2. Insert tubing 150 to 300 mm

3. Seal penetration with putty

© Copyright 2018 ORIFLOW LLC Rev: 03-2018

12

Page 14

Figure 10 – Duct Leakage Test Setup for a RETURN/EXHAUST System

© Copyright 2018 ORIFLOW LLC Rev: 03-2018

13

Page 15

Figure 11 - Inlet Transition Required for Rhino with Inlet Slide Gate

Figure 12 - Inlet Transition Required for Rhino with VFD Speed Controller

© Copyright 2018 ORIFLOW LLC Rev: 03-2018

14

Page 16

Zeroing Pressure Gauges

Before you run the tester, make sure both gauges have been zeroed.

Zeroing Analog Gauges

Using a very small screwdriver, turn the zero-adjustment screw on the gauge

until the needle is aligned with the zero reading. Turning the screw clockwise

increases the pressure reading; turning it counterclockwise, decreases the

reading. See Figure 13.

Figure 13 – Zeroing Analog Gauges

(zero BOTH gauges before testing)

Zeroing Digital Gauges

Use the following steps to zero each digital gauge:

1. Press MENU button once.

2. Press

3. Press

4. Press

5. Press

6. Press MENU button two times to get back to the pressure reading.

7. Pressure should be reading zero or within +/- 5 Pa If not, repeat

steps.

© Copyright 2018 ORIFLOW LLC Rev: 03-2018

▼ arrow button until Adu shows on screen.

E button once to go into auto-zero mode

E button again and AUTO will be blinking on screen

E button a third time to complete the zeroing process.

15

Page 17

Avoid Over-Pressurization

Prior to starting the blower, shut the inlet slide gate on models without the speed

controller option. For models with the VFD speed controller, rotate the speed control

knob completely counter-clockwise.

Figure 14 – Avoid Over-Pressurizing by Minimizing Air Delivery upon Startup

Obtaining System Test Pressure

Turn the blower on and slowly open the inlet slide gate for models without the

speed control option. If your tester has the VFD speed controller, rotate speed

control knob slowly clockwise to obtain system test pressure.

Figure 15 – Obtaining System Test Pressure

© Copyright 2018 ORIFLOW LLC Rev: 03-2018

16

Page 18

Obtaining System Test Pressure (continued)

Regardless of tester model used, pay attention to the “DUCT SYSTEM” gauge while

increasing airflow. When you have reached the required system static pressure,

tighten the set-screw on the inlet damper (or STOP rotating speed control knob).

Figure 16 – Duct System Gauge Reading (analog on left, digital on right)

Determining the Leakage Rate

Now that you have obtained the system test pressure, note the pressure reading of

the ORIFICE PLATE gauge (Figure 17). Refer to your calibration certificate to

determine the leakage rate that corresponds to the gauge reading. An example of a

calibration certificate is shown in Figure 18; it is for informational purposes only and

used in the example shown on the next page. Always refer to the calibration

certificate(s) that came with your calibrated orifice plate(s).

Figure 17 –ORIFICE PLATE Gauge Reading (analog on left, digital on right)

© Copyright 2018 ORIFLOW LLC Rev: 03-2018

17

Page 19

Determining the Leakage Rate (continued)

SAMPLE CALIBRATION CERTIFICATE

USE YOUR CERTIFICATE

203.2 mm

Figure 18 – Example Calibration Certificate. Use the calibration certificate that came with your orifice

plate

Example (refer to Figures 17 and 18)

For an ORIFICE PLATE gauge reading of 725 Pa (Figure 16), the leakage

rate is approximately 194 L/s using the calibration certificate shown in

Figure 18 (see arrow).

For an exact value, use the equation that comes with every calibration

certificate. For the ORIFICE PLATE gauge reading shown in Figure 17:

Leakage = 7.206 x

© Copyright 2018 ORIFLOW LLC Rev: 03-2018

18

Page 20

Determining the Leakage Rate (continued)

where the value of “7.206” is a constant and will be specific to the orifice

plate used (every plate has its own value; yours will be different).

Using a calculator, take the square root of the gauge reading first, and then

multiply by the constant for your orifice plate (for this example, the constant

is "7.206"). The exact leakage is 7.206 x (square root of 725) = 194.0 L/s.

Oriflow has FREE Adobe forms available that will calculate the leakage, leakage

factor, allowable leakage, Pass/Fail criteria and duct surface area among other

variables (www.oriflow.com/freeform).

Troubleshooting

Zero reading on “DUCT SYSTEM” gauge

If the gauge reading is zero, refer to the table below to fix this problem. Perform

troubleshooting steps in the order shown in the Table 9 below.

Table 9 –Troubleshooting steps when “DUCT SYSTEM” gauge is zero

Step Scenario What to do

1

2

3

4

Inlet damper was left shut,

cutting off air to the system.

Pressure tubing connected

to gauge incorrectly

Plugged fitting or

malfunctioning gauge.

System is leaking

too much air.

Open inlet damper slowly.

Look at the P1 and P2 stickers that are located on the

orifice tube and gauges. Make sure tubing from P1 tap

matches the P1 tap on the “ORIFICE PLATE” gauge.

Gently blow through other end of pressure tubing from

“DUCT SYSTEM” gauge, and watch needle increase

pressure reading.

Check for these other sources of leakage:

Rectangular duct joints (check and seal corners),

Fire or smoke dampers,

Duct joints (pay particular attention to flex-duct

joints if they are part of the leak test),

VAV boxes (pay particular attention to parallel box

back draft dampers),

Built-up air handlers,

Plenums,

Uncured duct sealant blow-thru (follow

manufacturer instructions for cure time),

Improperly sealed or un-sealed joints,

Hot water coils and electric heaters,

Open duct end that was supposed to be

sealed/capped-off for the leak test.

© Copyright 2018 ORIFLOW LLC Rev: 03-2018

19

Page 21

Zero reading on “ORIFICE PLATE” gauge

If the gauge reading is zero, refer to the table below to fix this problem. Perform

troubleshooting steps in the order shown in Table 10 below.

Table 10 –Troubleshooting steps when “ORIFICE PLATE” gauge is zero

Step Scenario What to do

1

2 Plugged pressure taps.

3

4

4

5 Malfunctioning gauge.

6 Not sure

Inlet damper was left shut,

cutting off air to the system.

Orifice plate too large for

application.

System is leaking very little

air.

Pressure tubing connected

incorrectly.

Open inlet damper slowly.

Remove pressure tubing from “ORIFICE PLATE” gauge,

and blow through each end to make sure the pressure taps

on the orifice tube are clear.

If you are using a 100 mm ID orifice plate, and the system

is leaking 20 L/s, you probably won’t even notice the gauge

needle moving. This can happen to other orifice plates too.

You need to use an orifice plate with a smaller bore

diameter so that a small amount of airflow/leakage will

result in a bigger pressure drop.

You’ll know if this is true if the fan inlet is almost shut. Not

likely unless system is small. Solution is to use a smaller

ID plate.

Look at the P1 and P2 stickers that are located on the

orifice tube and gauges. Make sure they match.

Remove the clear pressure tubing from the lower pressure

tap on the orifice tube and blow through the end of the

tubing. The needle should move in response. If not, the

gauge is faulty.

The best way to make sure that your tester is working

properly is to disconnect the flex duct from the system and

turn the blower on, and slowly open the inlet damper. If you

feel a lot of air coming out of the tube end, you should see

a pressure reading on the gauge “ORIFICE PLATE”.

© Copyright 2018 ORIFLOW LLC Rev: 03-2018

20

Page 22

Can’t obtain system test pressure

This happens when the system is leaking too much air. Make sure all outlets are

sealed. Check corners of rectangular duct for excessive leakage. Inspect all duct

and fitting joints for leakage. Make sure you seal all suspect joints and allow to cure

24 to 48 hours. Always refer to duct sealant manufacturer’s instructions.

Check for these other sources of leakage:

Rectangular duct joints (check and seal corners),

Fire or smoke dampers,

Duct joints (pay particular attention to flex-duct joints if they are part of the

leak test),

VAV boxes (pay particular attention to parallel box back draft dampers),

Built-up air handlers,

Plenums,

Uncured duct sealant blow-thru (follow manufacturer instructions for cure

time),

Improperly sealed or un-sealed joints,

Hot water coils and electric heaters,

Open duct end that was supposed to be sealed/capped-off for the leak test.

A non-toxic smoke machine is an excellent tool for locating significant sources of

leakage. Call ORIFLOW at 727-400-4881 or online at www.oriflow.com for more

information.

“ORIFICE PLATE” gauge reading maxed out

Scenario 1: The system is leaking too much air. Make sure all outlets are

sealed. Check corners of rectangular duct for excessive leakage. Inspect all

duct and fitting joints for leakage. Make sure you seal all suspect joints and

allow curing time of 24 to 48 hours. Always refer to duct sealant

manufacturer’s instructions.

Scenario 2: The orifice plate bore could be too small, causing a high

pressure drop at low to moderate flows. You need an orifice plate with a

larger bore.

ORIFLOW LLC

www.oriflow.com

2125 Range Rd., Suite B

Clearwater, Florida 33765

727-400-4881 (phone) 8am to 5pm PST

877-420-7091 (fax)

sales@oriflow.com

engineering@oriflow.com

© Copyright 2018 ORIFLOW LLC Rev: 03-2018

21

Loading...

Loading...