Oriental motor PK264-E2.0B, PK266-E2.0A, PK264M-E2.0A, PK264M-E2.08, PK266M-E2.0A Operating Manual

...Page 1

1

HP-4169-2

Introduction

Before using the driver

Only qualified personnel should work with the product.

Use the product correctly after thoroughly reading the section “Safety

precautions.”

The product described in this manual has been designed and

manufactured for use in general industrial machinery, and must not be

used for any other purpose. For the power supply use a DC power

supply with reinforced insulation on its primary and secondary sides.

Oriental Motor Co., Ltd. is not responsible for any damage caused

through failure to observe this warning.

OPERATING MANUAL

Microstep Driver for 2-Phase

Stepping Motor

Thank you for purchasing an Oriental Motor product.

This Operating Manual describes product handling procedures and

safety precautions.

• Please read it thoroughly to ensure safe operation.

• Always keep the manual where it is readily available.

Caution

• Do not use the driver beyond its specification, or injury or damage

to equipment may result.

• Do not touch the driver’s heat sink during operation or immediately

after stopping. The surface is hot and may cause a burn.

• Keep the area around the driver free of combustible materials in

order to prevent fire or a burn.

• To prevent the risk of damage to equipment, leave nothing around

the driver that would obstruct ventilation.

• Use a motor and driver only in the specified combination. An

incorrect combination may cause a fire.

• To avoid injury, remain alert during operation so that the motor can

be stopped immediately in an emergency.

• Before supplying power to the driver, turn all input signals to the

driver to “OFF”. Otherwise, the motor may start suddenly and

cause injury or damage to equipment.

• When an abnormality is noted, stop the operation immediately, or

fire or injury may occur.

• When disposing of the driver, treat it as industrial waste.

Precaution

Checking the product

Upon opening the package, verify that the items listed below are

included.

Report any missing or damaged items to the branch or sales office

from which you purchased the product.

• Driver 1 unit

• Operating manual 1 copy

Overview of the product

This is a 2-phase microstep driver for use with a 2-phase stepping

motors. The use of a microstep drive, which electrically divides the

basic step angle of a 2-phase motor, offers reduced vibration and

noise in the low-speed range compared with the levels in full-step

mode.

• Do not turn the C.OFF (All windings off) input to “ON” while the

motor is operating. The motor will stop and lose its holding ability,

which may result in injury or damage to the equipment.

• Do not disassemble or modify the driver. This may cause injury.

Refer all such internal inspections and repairs to the branch or sales

office from which you purchased the product.

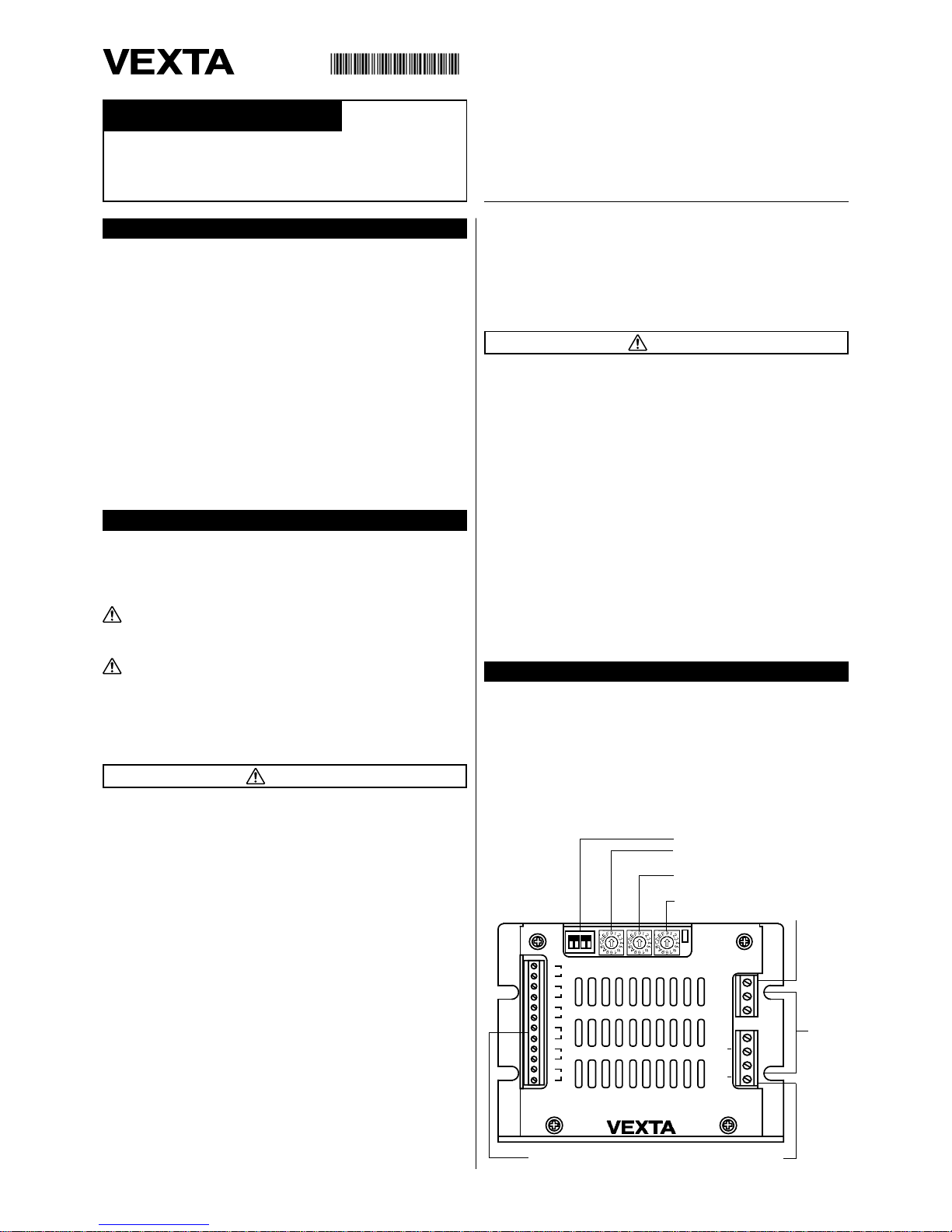

Names of parts

DC+

GND

A

A

B

B

FG

FUNCTION

STOP

POWER

1

4

RUN RES.

+

‑

STEP

+

‑

DIR.

+

‑

C.OFF

+

‑

RESET

+

‑

+

‑

ERR.

TIM.

2−PHASE DRIVER

D2D2043−S

2

3

Function selector switch (FUNCTION)

Motor standstill current

adjustment switch (STOP)

Motor running current

adjustment switch (RUN)

Step resolution switch (RES.)

I/O terminal block (TB1) Motor terminal block (TB3)

Mounting

cutouts

Power terminal block (TB2)

Safety precautions

The precautions described below are intended to prevent danger or

injury to the user and other personnel through safe, correct use of the

product. Use the product only after carefully reading and fully

understanding these instructions.

Warning

• Do not use the product in explosive or corrosive environments, in

the presence of flammable gases, locations subjected to splashing

water, or near combustibles.

• Assign qualified personnel the task of installing, wiring, operating/

controlling, inspecting and troubleshooting the product. Failure to

do so may result in fire or injury.

• Install the driver in an enclosure in order to prevent injury.

• Keep the driver’s input-power voltage within the specified range to

avoid fire.

• For the driver’s power supply, use a DC power supply with

reinforced insulation on its primary and secondary sides. Failure to

do so may result in electric shock.

• Connect the cables securely according to the wiring diagram in

order to prevent fire.

• Do not forcibly bend, pull or pinch the power cable or motor lead

wire. Doing so may result in fire.

• Turn off the driver power in the event of a power failure, or the motor

may suddenly start when the power is restored and may cause

injury or damage to equipment.

• If this product is used in an vertical application, be sure to provide a

measure for the position retention of moving parts. The motor loses

its holding torque when the power is turned off. Failure to provide

such a measure may cause the moving parts to fall, resulting in

injury or damage to the equipment.

Handling the product without observing the

instructions that accompany a “Warning” symbol may

result in serious injury or death.

Handling the product without observing the

instructions that accompany a “Caution” symbol may

result in injury or property damage.

Caution

Warning

Note

The items under this heading contain important

handling instructions that the user should observe to

ensure safe use of the product.

Page 2

2

Driver

Connection

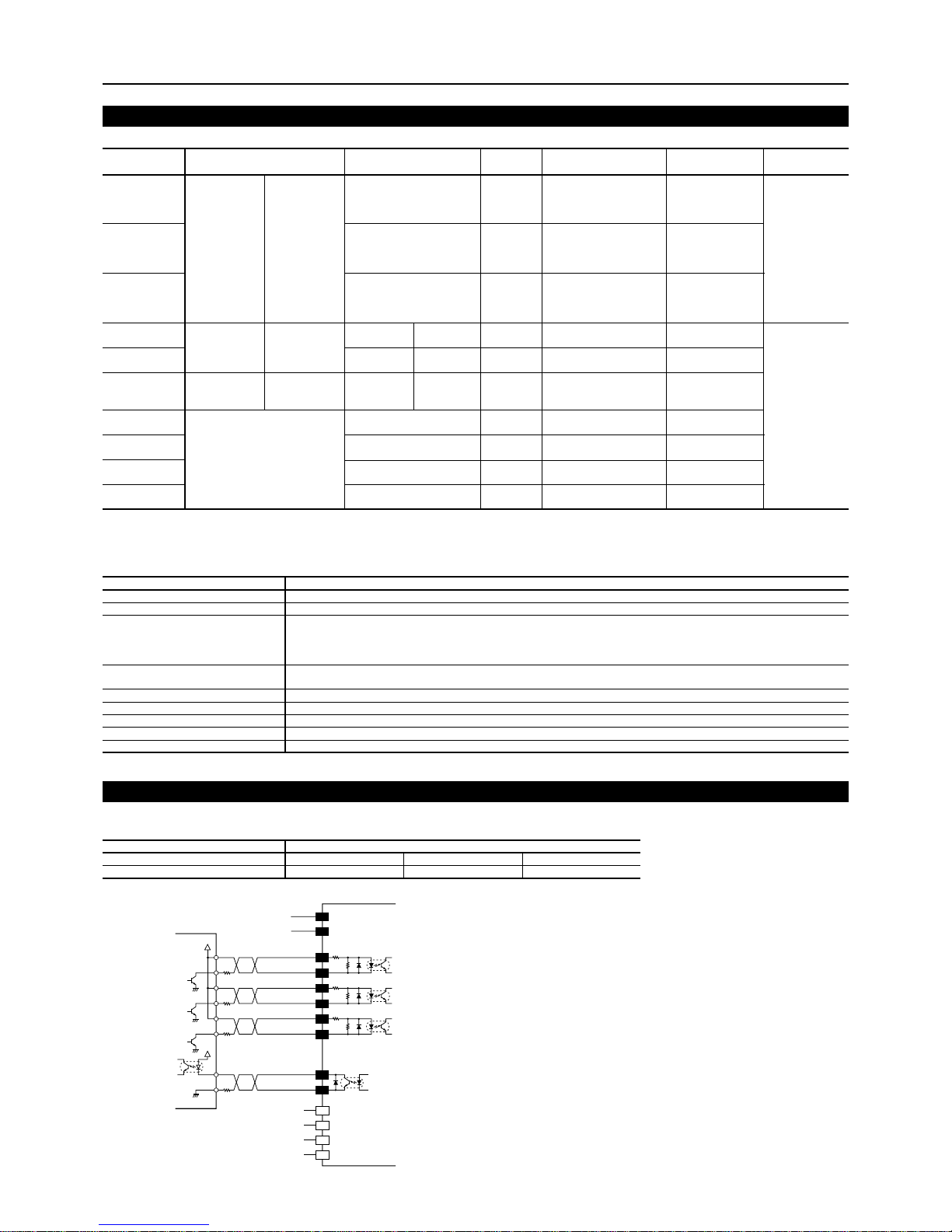

Power source connection

The power-supply input voltage is 24VDC

-

40VDC±10%. Use a power source that can supply the following current capacity.

Applicable lead wire diameter: AWG26 ~ 16 (0.14 ~ 1.5mm2)

Note

• Make the input-signal voltage 5VDC minimum and 24VDC maximum. When

the input-signal voltage is 5VDC, external resistor R1 is not necessary. If the

input-signal voltage is greater than 5VDC, connect external resistor R1, to

restrict the input current as follows:

PLS: 7mA ~ 14mA

DIR./C.OFF: 10mA ~ 14mA

• Use an output-signal voltage of 5VDC minimum and 30VDC maximum, and

use output-signal current of 5mA max. If the output-signal current is greater

than 5mA, connect external resistor R2, to restrict the current to no more than

5mA.

TB3

1

2

3

4

+5V

330Ω

R

1

R

1

R

1

R

2

330Ω

330Ω

24VDC

-

40VDC

GND

TB2

TB1

1

2

+5V

Controller

STEP input

DIR. input

C.OFF input

TI M. output

1

3

5

7

2

4

6

8

+

-

+

+

-

+

-

1kΩ

1kΩ

1kΩ

8 lead wire type

1: Black/Orange

2: Green/Yellow

3: Red/Brown

4: Blue/White

Motor lead wire

4 lead wire type

1: Black

2: Green

3: Red

4: Blue

D2D2043-S

24VDC-40VDC±10% 5.3A

Microstep

Photocoupler input 5VDC, 14mA maximum, Input resistance 330Ω

Signal voltage Photocoupler ON: +4.2 ~ +6.0V

Photocoupler OFF: 0 ~ +0.7V

PLS, DIR, C.OFF, RESET

Photocoupler Open-collector output

Excitation monitor, Error: 30VDC maximum, 5mA maximum

Automatic current cutback, Overcurrent protection, Voltage-drop protection, Regenerative protection, Overheat protection

500

Natural ventilation

8.8 (0.25)

+32°F ~ +104°F (0°C ~ +40°C)

Driver model

Power input voltage

Excitation mode

Input signal

Output signal

Function

Maximum response pulse rate kHz

Driver cooling method

Mass oz (kg)

Ambient temperature range

• The input-power current supplied to the driver represents the maximum input value (which varies with pulse speed).

Example of connection

∗1 S: Bipolar series P: Bipolar parallel

∗2 Specifications for the PK26M

• Set the current motor standstill so that it will be a maximum of 50% of the motor’s running current.

Motor model

PK264-E2.0A

PK264M-E2.0A

PK264-E2.0B

PK264M-E2.0B

PK266-E2.0A

PK266M-E2.0A

PK266-E2.0B

PK266M-E2.0B

PK268-E2.0A

PK268M-E2.0A

PK268-E2.0B

PK268M-E2.0B

PK296-F4.5A

PK296-F4.5B

PK299-F4.5A

PK299-F4.5B

PK2913-F4.0A

PK2913-F4.0B

PV264-D2.8AA

PV264-D2.8BA

PV266-D2.8AA

PV266-D2.8BA

PV267-D2.8AA

PV267-D2.8BA

PV269-D2.8AA

PV269-D2.8BA

Rated current ∗1 A/phase

Motor running current adjustment

Maximum holding torque ∗1

oz-in (N·m)

75 (0.55)

170 (1.25)

270 (1.9)

150 (1.06)

248 (1.75)

312 (2.2)

440 (3.1)

Voltage ∗1

VDC

S: 4.0

P: 2.0

S: 5.1

P: 2.6

S: 6.4

P: 3.2

S: 2.8

P: 1.4

S: 3.9

P: 1.9

S: 5.3

P: 2.6

2.1

2.8

3.4

4.2

Resistance per phase ∗1

Ω/phase

S: 2.8

P: 0.7

S: 3.6

P: 0.9

S: 4.5

P: 1.13

S: 0.96

P: 0.24

S: 1.32

P: 0.33

S: 1.94

P: 0.49

0.73

1

1.2

1.49

Rotor inertia

oz-in

2

(kg·m2)

0.657 (120 × 10

-7

)

1.65 (300× 10

-7

)

2.63 (480× 10

-7

)

7.66 (1400 × 10

-7

)

14.8 (2700 × 10

-7

)

21.9 (4000 × 10

-7

)

1.54 (280 × 10

-7

)

2.47 (450 × 10

-7

)

3.12 (570 × 10

-7

)

4.93 (900 × 10

-7

)

Basic step angle

deg

1.8 [0.9] ∗2

1.8

2.8

Switch 2: ON

RUN: 4

P: 2.8

Switch 2: ON

RUN: 4

P: 4.38

Switch 2: ON

RUN: F

P: 4.38

Switch 2: ON

RUN: F

S: 1.4

Switch 2: OFF

RUN: A

S: 3.1

Switch 2: ON

RUN: 6

S: 2.8

Switch 2: ON

RUN: 4

S: 420 (3.0)

S: 850 (6.0)

S: 1320 (9.3)

P: 290 (2.1)

P: 600 (4.2)

P: 900 (6.4)

Main specifications

Motor (specifications of applicable motor)

Driver model

Motor type

Power-supply current capacity

PK26 type

2.7A minimum

D2D2043-S

PV26 type

3.2A minimum

PK29 type

5.3A minimum

Page 3

3

Connector configuration

Description

Frame GND

Power input

A phase output

A phase output

B phase output

B phase output

Pulse (CW pulse) input

Rotation direction (CCW pulse) input

ON: CW OFF: CCW

All windings off input

The excitation sequence is not reset.

Reset input

All windings off Excitation sequence reset, Error output reset

Excitation timing output

It is turned on when the excitation state indicates the excitation

home position.

Error output

In the following cases, it is turned on.

• When overcurrent protection function is active

• When voltage-drop protection function is active (18VDC maximum)

• When the regeneration protection function is active

Regenerative voltage: 56VDC minimum/Internal temperature of

driver: 75°C minimum

Terminal block

POWER

MOTOR

I/O

Terminal block No.

TB2

TB3

TB1

Pin No.

1

2

3

1

2

3

4

1

2

3

4

5

6

7

8

9

10

11

12

Input/output

Input

Output

Input

Output

Signal

FG

DC+

GND

A

A

B

B

STEP+

STEP

-

DIR.+

DIR.

C.OFF+

C.OFF

RESET+

RESET

-

TIM.+

TIM.

-

ERR+

ERR

-

Timing chart

∗1 When switching the power back again, wait at least 5sec.

∗2 When switching the C.OFF input to “ON,” the motor excitation ends and the holding-torque is removed.

∗3 The duration here may vary, depending on the motor’s size, running speed and the load’s moment of inertia.

The section indicates that the photocoupler diode is emitting light.

All windings off

1ms min.

1µs min.

100ms

min.

100ms min.

2-pulse input

*

2

*

3

CW

CW input

C.OFF input

CCW input

ON

OFF

ON

OFF

ON

OFF

Power input

CCW

Motor

*

1

1µs min.

All windings off

1ms min.

1-pulse input

*

2

100ms min.

100ms

min.

*

3

CW CW

0s min.

CCW

CW

STEP input

C.OFF input

DIR input

ON

OFF

ON

OFF

ON

OFF

Power input

CCW

Motor

*

1

Function selector switch description

Function

Motor standstill current selector

Motor running current selector

Pulse-input mode selector

All windings off

Switch: ON

2.26 ~ 4.38A/phase

2.26 ~ 4.38A/phase

1-pulse input mode

L level: excitation OFF

Switch: OFF

0 ~ 2.12A/phase

0 ~ 2.12A/phase

2-pulse input mode

H level: excitation OFF

Factory setting

OFF

OFF

ON

OFF

Switch No.

1

2

3

4

Page 4

4

Pulse waveform diagram

ON

OFF

STEP input

5µs

min.

5µs

min.

2µs

max.

2µs

max.

90%

10%

• When pulses are input, the motor rotates one step as the pulses

start (pulse fall).

• The voltage of the pulse signal is ON: +4.5 to +5.5V, OFF: 0 to

+0.7V. Input-pulse signals should have a pulse width exceeding

1µsec, pulse rise/fall below 1µsec, and a pulse duty of less than

50%.

Driving motor current

The D2D2043-S can drive motors with a rated current of up to

4.38A/phase. However, we recommend you follow the drive

conditions below in view of the rating of internal heat generation

(which affects product life).

(Running current)2 × X + (Standstill current)2 × (1 - X) < 7.5

X: Motor’s operating duty relative to operation time

Example) If the motor is used at an operating duty of 100% or

standstill current of 100%, the running current will be

2.12A/phase or less.

Setting

Step resolution

Use this function when you want to reduce vibration and noise, or to

change the motor speed or feed rate without changing the input pulse

speed.

Factory setting

Step resolution switch: 0

Motor current

Set the motor current in accordance with the motor’s rated current.

Factory setting

Motor running current adjustment switch: 0

Function selector switch

Switch 1: OFF

Switch 2: OFF

ORIENTAL MOTOR U.S.A. CORP.

Technical Support Line Tel:(800)468-3982

Available from 7:30 AM to 5:00 PM, P.S.T.

E-mail: techsupport@orientalmotor.com

www.orientalmotor.com

ORIENTAL MOTOR CO., LTD.

Headquarters Tokyo, Japan

Tel:(03)3835-0684 Fax:(03)3835-1890

• Please contact your nearest ORIENTAL MOTOR office for further information.

Printed on Recycled Paper

Setting value

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

Nos. of division

1

2

4

5

8

10

16

20

25

32

40

50

64

80

100

128

Step angle

1.8°

0.9°

0.45°

0.36°

0.225°

0.18°

0.1125°

0.09°

0.072°

0.05625°

0.045°

0.036°

0.028125°

0.0225°

0.018°

0.0140625°

• Set the current motor standstill so that it will be maximum 50% of

the motor’s running current.

Motor current setting (representative values)

Output current

setting

Motor current

adjustment switch

Setting

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

Switch 1:

OFF

0

0.14

0.28

0.42

0.57

0.71

0.85

0.99

1.13

1.27

1.41

1.56

1.70

1.84

1.98

2.12

Switch 1:

ON

2.26

2.40

2.55

2.69

2.83

2.97

3.11

3.25

3.39

3.54

3.68

3.82

3.96

4.10

4.24

4.38

Switch 2:

OFF

0

0.14

0.28

0.42

0.57

0.71

0.85

0.99

1.13

1.27

1.41

1.56

1.70

1.84

1.98

2.12

Switch 2:

ON

2.26

2.40

2.55

2.69

2.83

2.97

3.11

3.25

3.39

3.54

3.68

3.82

3.96

4.10

4.24

4.38

Function selector switch

Motor standstill

current value

A/phase

Motor running

current value

A/phase

=

Loading...

Loading...