Page 1

HF-3027-3

© Copyright ORIENTAL MOTOR CO.,LTD. 1999

Thank you for purchasing ORIENTAL MOTOR products.

Please read this operating manual thoroughly before

installing and operating the fan, and always keep the

manual where it is readily accessible.

1. Precautions

1.1 Precautions for Installation

●Do not use in a place where there is flammable gas and/or corrosive gas.

●Fans for use only in equipment of protection class Ⅰ.

Lüfter zur Verwendung in Geräten der Schutzklasse Ⅰ.

●Connect the ground wire to the ground terminal inside the terminal box.

Das Erdungskabel wird an dem als Erde gekennzeichneten Pol im Anschluβkasten angeklemmt.

●When installing the fan into your equipment, ensure that the motor lead wires are fixed and do not move.

In addition, do not apply any pressure to these lead wires.

●Installation must be performed by a qualified installer.

1.2 Precautions for Operation

●Always turn off power to thermally protected fan before conducting checks or performing work on the fan.

These types of fans will restart automatically when fan temperature falls below a certain level.

●The enclosure temperature of this fan can exceed 70℃ (depending on operation conditions).

In case fan is accessible during operation, please attach the following warning label so that it is clearly visible. Warning label

●Do not touch the fan blades when the fan is in operation.

The use of the optional fingerguard is recommended to ensure protection.

Wegen der Verletzungsgefahr dürfen die Lüfterflügel bei Ventilatorbetrieb nicht berührt werden.

Der Gebrauch des als Sonderzubehör erhältlichen Fingerschutzes ist empfehlenswert, um erhöhte Sicherheit zu gewährleisten.

<Table of Contents>

1. Precautions

...........................................Page 1 4. Installation...........................................Page 2

2. Checking the Package Contents

...........Page 1 5. Noise Protection..................................Page 4

3. Connection

............................................Page 2 6. Overheat Protection............................Page 4

2. Checking the Package Contents

2.1 Checking the contents

Please make sure that the package contains all of the items listed below.

Contact your nearest ORIENTAL MOTOR office if any of these items are not included or are defective.

・Fan............................................................................................1 piece

・Variable resistor (with adjustment knob and dial plate).............1 set

・Operating manual (this manual)................................................1 piece

2.2 Checking the model name

This manual covers the products specified below.

Please make sure that the model, voltage, current as you ordered by the nameplate.

MRS18V2-B, MRS18V2-D

Fans are recognized by UL and certified by DEMKO.

・ Standards UL507, UL1917, CAN/CSA C22.2 No.113, EN60950

・ Installation Conditions for EN standards Installation categoryⅡ, Pollution degree 2, ClassⅠequipment

1

Varioflow Fans MRS18V2 type

OPERATING MANUAL

C

Page 2

2

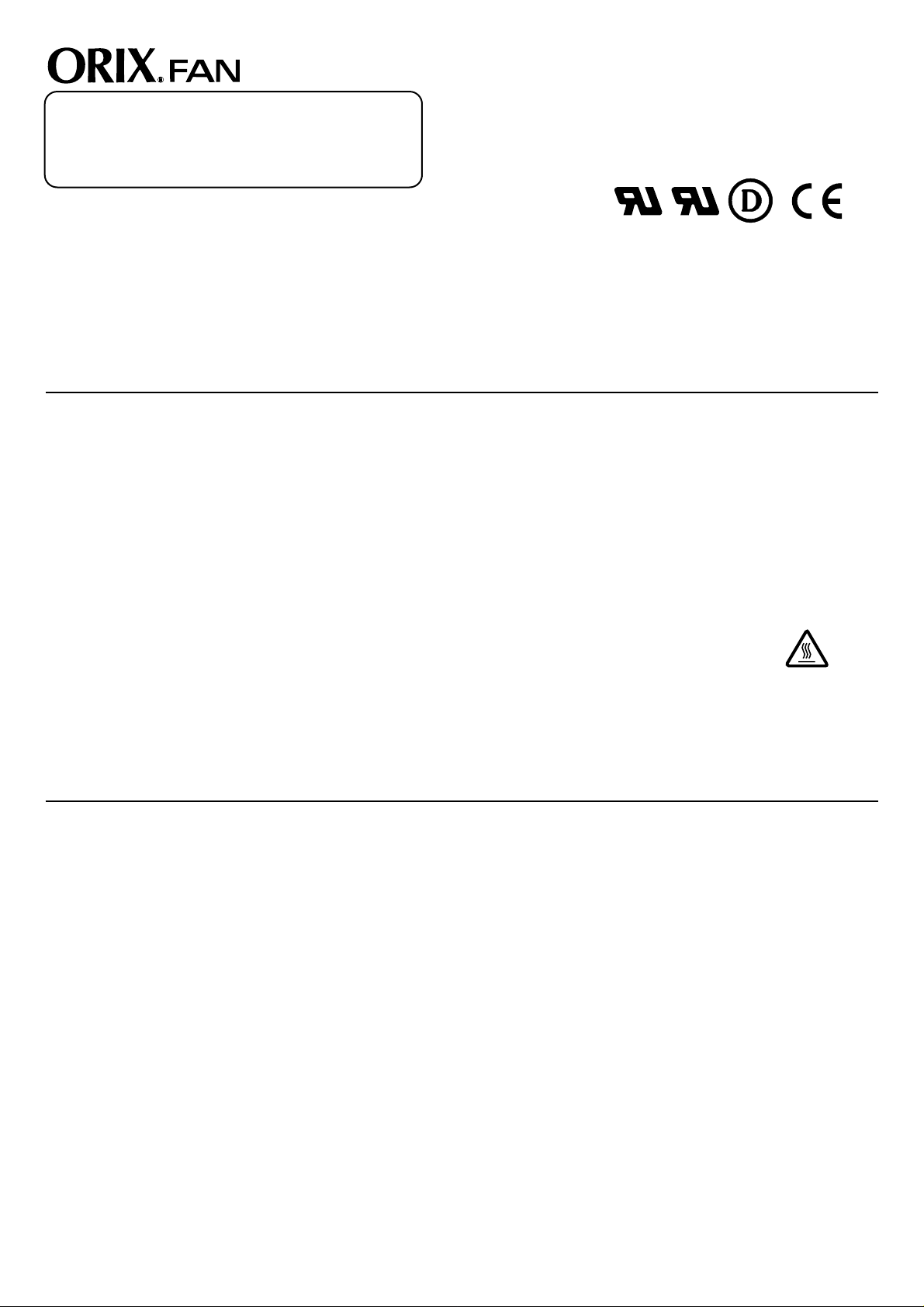

3. Connection

3.1 Connecting Diagrams

■ Using a variable resistor

①~③ indicate terminal numbers for variable resistors.

Turn the knob right to increase air flow-static pressure.

Variable resistor : 200kΩ 1/4W

with a linear resistance vs. angle curve

■ Using a fixed resistor

Fixed resistors that use relays or the like can also be switched.

R1+R2+R3=200kΩ (max.) 1/4W (min.)

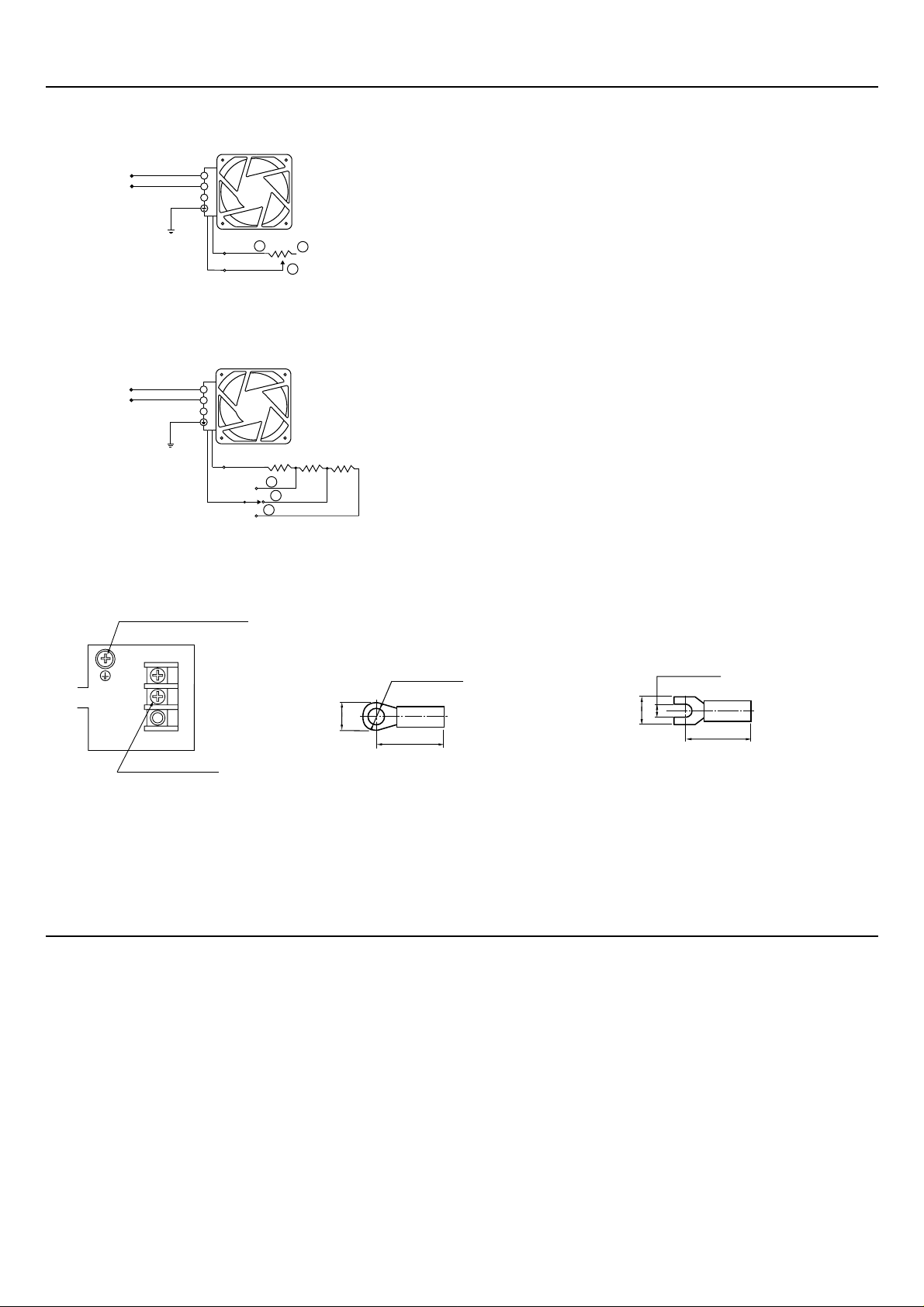

3.2 Inside the terminal box

The recommended tightening torque for the terminal screws is 1.4N・m (14kgcm).

Recommended lead diameter

Power supply: AWG20 (0.5mm

2

), Ground: AWG18 (0.75mm2) min.

<Crimp style terminals that can be used>

●Round terminal type with insulation ●U-shaped terminal type with insulation

V1.25-4 AV1.25YS4A

(JAPAN SOLDERLESS TERMINAL MFG. CO., LTD.) (JAPAN SOLDERLESS TERMINAL MFG. CO., LTD.)

or other equivalent product or other equivalent product

4. Installation

Install the fan in locations that meet the following conditions.

・Indoors (the product is designed and manufactured to be mounted in a machine.)

・Ambient temperature −10℃(14°F)〜+60℃(140°F) (Non-freezing)

・Ambient humidity 0〜85% (Non-condensing)

・No explosive, flammable, and/or corrosive gas.

・No exposure to direct sunlight.

・No splashing of water, or exposure to dust or debris.

・No oil or grease, organic solvents, acid or alkaline chemicals.

・No continuous vibration or excessive shock.

・Insert a noise filter when there is a big noise source.

・Installation categoryⅡ, Pollution degree 2, ClassⅠequipment (EN standard).

Line

Ground

Blue

Lead for connecting

variable resistor

Line

1

2

Blue V.R.

1

2

3

1

2

Ground

Blue

Blue

Lead for connecting

variable resistor

Ground terminal (green)

M4×8

123

1

2

3

Terminal screws

2-M4×12

V.R.

R3

R2

R1

1

2

3

φ

4.3mm (min.)

8mm(max.)

9mm(min.)

4.3mm(min.)

8mm(max.)

9mm(min.)

Page 3

4.2 Soldering the Variable Resistor Terminals

Do the following to solder leads into place on the variable resistor terminals.

①Pass the leads through the terminal hole and wrap around two to three times.

②Solder the lead wire to the terminal.

③Cover the soldered area with a heat shrink tube.

4.3 Installing the Variable Resistor

①Insert the Variable resistor into the Mounting panel (insulation material) as shown in the figure below.

②Put on the scale plate and inner clip washer and fasten with the Nut. (Tightening torque: 0.45N・m [4.5kgcm] max.)

③Mount the Knob and fix it in place with the Stop screw M4. (Tightening torque: 0.4N・m [4kgcm] max.)

Note: Do not run a series of fans off a single Variable resistor. Circuit damage may result.

Example of Variable Resistor Installation

3

4.1 Mounting the fan

To mount the fan, drill holes in the machinery in which it will be installed referring to Panel-Cut-Out (see General Catalog)

and then fasten the fan with screws (these must be furnished by the user).

Use screws of M5 to install the fan.

The recommended tightening torque for mounting is 1.2N

・m (12 kgcm).

The direction of airflow is indicated by the AIRFLOW mark on the side of the fan frame.

The arrow points in the direction of the outlet. The rotation arrow indicates the direction of rotation.

Variable resistor unit

Soldered terminal

Lead wire

Heat shrink tube

Lead wire

Solder (wrap lead around

two to three times)

Enlargement of Circular Area

Variable resistor

Insulation sheet

20

Mounting panel

60

50

70

40

30

10

80

90

100

0

Scale plate

Crown washer

Nut

Knob

7.5±0.4

Stop screw

φ3

φ10

Panel Cut-Out drawing

Page 4

6. Overheat Protection

To prevent burning out the windings as a result of overheating, MRS18V2 type fans have been designed with a protector

explained below.

Thermal protector ; Automatic return type

Operating temperature of thermal protectors

Open : 120℃±5℃(248°F±9°F)

Close : 77℃±15℃(170°F±27°F)

4

5. Noise Protection

5.1 Protection from noise coming in from the power line

The MRS18V2 type do not have filters against power line noise.

When fans are used in noisy environments caused by high-output control and switching, the fan rpm will become unreliable.

Common causes of noise include high-output motors, solenoids, high-frequency power supplies and electric welders.

Commercial LC filters are very effective against external noise.

For a noise filter, we recommend the ORIENTAL MOTOR ZCB2203-11S (sold separately)

5.2 Preventing noise from being discharged externally from the power line

The MRS18V2 type use triacs for phase control, which can cause noise that affects other equipment.

A commercial LC filter is an effective way of reducing that noise.

●Characteristics, specifications and dimensions are subject to change without notice.

●Please contact your nearest ORIENTAL MOTOR office for further information.

ORIENTAL MOTOR CO.,LTD.

Headquarters

Tel:(03)3835-0684 Fax:(03)3835-1890

ORIENTAL MOTOR (EUROPA) GmbH

Headquarters and Düsseldorf Office

Tel:02131-95280 Fax:02131-952899

Munich Office

Tel:08131-59880 Fax:08131-598888

Hamburg Office

Tel:04076-910443 Fax:04076-910445

ORIENTAL MOTOR (UK) LTD.

Tel:01252-519809 Fax:01252-547086

ORIENTAL MOTOR (FRANCE) SARL

Tel:01 47 86 97 50 Fax:01 47 82 45 16

ORIENTAL MOTOR ITALIA s.r.l

Tel:02-3390541 Fax:02-33910033

ORIENTAL MOTOR U.S.A. CORP.

Los Angeles Office Tel:(310)784-8200 Fax:(310)325-1076

San Jose Office Tel:(408)358-6900 Fax:(408)358-8200

Chicago Office Tel:(847)240-2649 Fax:(847)240-2753

Cincinnati Office Tel:(513)563-2722 Fax:(513)956-3183

Austin Office Tel:(512)918-9438 Fax:(512)335-5983

New York Office Tel:(973)359-1100 Fax:(973)359-1090

Boston Office Tel:(781)848-2426 Fax:(781)848-2617

Atlanta Office Tel:(770)716-2800 Fax:(770)719-8515

Canada Office Tel:(905)502-5333 Fax:(905)502-5444

Technical Support Line:(800)468-3982

Available from 8:30 AM to 8:00 PM, Eastern Time

Using a variable resistor

Fan(MRS18V2)

Variable resistor

2

1

3

E

4

Noise filter

2

1

Circuit

breaker

SW1

Line

Using a variable resistor

Fan(MRS18V2)

Variable resistor

1

Noise filter

Circuit

breaker

SW1

4

E

Line

2

1

2

3

Loading...

Loading...