Page 1

HM-60190-7

Closed Loop Stepping Motor and Driver Package

AR Series

DC power input Built-in Controller Type

USER MANUAL

Thank you for purchasing an Oriental Motor product.

This Operating Manual describes product handling procedures and safety precautions.

•Please read it thoroughly to ensure safe operation.

•Always keep the manual where it is readily available.

Page 2

1 Introduction

1 Introduction ................................................... 8

2 Operating Manuals for the AR Series .......... 9

3 Overview of the product ............................. 10

4 System conguration .................................. 12

5 Safety precautions ...................................... 13

6 Precautions for use ..................................... 16

7 General specications ................................ 18

8 CE Marking ................................................... 19

9 Preparation .................................................. 20

9.1 Checkingtheproduct................................... 20

9.2 Howtoidentifytheproductmodel............... 20

9.3 Combinationsofmotorsanddrivers............ 21

9.4 Namesandfunctionsofparts...................... 22

2 Installationand

connection

1 Installation ................................................... 26

1.1 Locationforinstallation................................ 26

1.2 Installingthemotor...................................... 26

1.3 Installingaload............................................ 27

1.4 Permissibleradialloadand

permissibleaxialload.................................. 28

1.5 Installingthedriver...................................... 29

1.6 Installingthebattery.................................... 30

1.7 Installingandwiringincompliancewith

EMCDirective.............................................. 30

2 Connection ................................................... 32

2.1 Connectionexample

(electromagneticbrakemotor)..................... 32

2.2 Groundingthemotoranddriver................... 36

2.3 Connectingthedatasetter.......................... 36

2.4 ConnectingtheRS-485communication

cable............................................................ 37

2.5 Connectingandchargingthebattery........... 38

3 Explanation of I/O signals .......................... 39

3.1 AssignmentofdirectI/O.............................. 39

Assignmenttotheinputterminals.....................39

Changingthelogiclevelsettingofinput

signals...............................................................40

Assignmenttotheoutputterminals...................41

3.2 AssignmentofnetworkI/O.......................... 43

Assignmentofinputsignals...............................43

Assignmenttotheoutputterminals...................45

3.3 Inputsignals................................................ 47

3.4 Outputsignals.............................................. 52

3.5 Sensorinput................................................ 56

3.6 Generalsignals(R0toR15)........................ 57

3 Operationtypeandsetting

1 Adjustment and setting .............................. 60

1.1 Resolution.................................................... 60

1.2 Operatingcurrent......................................... 61

1.3 Standstillcurrent.......................................... 61

1.4 Acceleration/decelerationrateand

acceleration/decelerationtime..................... 61

1.5 Smoothdrive............................................... 62

1.6 Speedlter.................................................. 62

1.7 Movingaveragelter................................... 63

1.8 Speederrorgain.......................................... 63

1.9 Controlmode............................................... 63

1.10 Positionloopgain,speedloopgain,

speedloopintegraltimeconstant................ 64

1.11 Absolute-positionbackupsystem................ 64

2 Operation ..................................................... 65

2.1 Positioningoperation................................... 66

Operationdata...................................................66

Startingmethodofpositioningoperation...........67

Operationfunction;Single-motion.....................71

Operationfunction;Linked-motionoperation.....72

Operationfunction;Linked-motionoperation2...73

Operationfunction;Push-motionoperation.......75

2.2 Return-to-homeoperation........................... 79

Additionalfunction.............................................79

Parametersrelatedtoreturn-to-home

operation............................................................80

Operationsequence..........................................81

Positionpreset...................................................86

2.3 Continuousoperation.................................. 86

Operationdata...................................................86

Startingmethodofcontinuousoperation...........87

Variablespeedoperation...................................89

2.4 Otheroperation............................................ 91

JOGoperation...................................................91

Testoperation....................................................92

Automaticreturnoperation................................92

Stopoperation...................................................93

Positioncoordinatemanagement......................93

Wrapfunction....................................................94

3 Operation data ............................................. 96

4 Parameter ..................................................... 97

4.1 Parameterlist.............................................. 97

4.2 I/Oparameter.............................................. 98

4.3 Motorparameter.......................................... 99

4.4 Operationparameter................................. 100

4.5 Return-to-homeparameter........................ 100

4.6 Alarm/warningparameter.......................... 101

4.7 Coordinationparameter............................. 101

4.8 Commonparameter................................... 101

4.9 I/Ofunctionparameter............................... 102

4.10 I/Ofunction[RS-485]parameter............... 103

4.11 Communicationparameter........................ 104

−2−

Page 3

4 MethodofcontrolviaI/O

1 Guidance .................................................... 106

2 Operation data ........................................... 108

3 Parameter ................................................... 109

3.1 Parameterlist............................................ 109

3.2 I/Oparameter............................................ 110

3.3 Motorparameter........................................ 110

3.4 Operationparameter..................................111

3.5 Return-to-homeparameter.........................111

3.6 Alarm/warningparameter.......................... 112

3.7 Coordinationparameter............................. 112

3.8 Commonparameter................................... 112

3.9 Communicationparameter........................ 112

3.10 I/Ofunctionparameter............................... 113

3.11 I/Ofunction[RS-485]parameter................ 114

4 Timing charts ............................................. 115

5 Methodofcontrolvia

ModbusRTU(RS-485

communication)

1 Guidance .................................................... 128

2 Communication specications ................ 130

3 Setting the switches .................................. 131

4 Setting the RS-485 communication ......... 133

5 Communication mode and

communication timing .............................. 134

5.1 Communicationmode................................ 134

5.2 Communicationtiming............................... 134

6 Message ..................................................... 135

6.1 Query......................................................... 135

6.2 Response.................................................. 137

7 Function code ............................................ 139

7.1 Readingfromaholdingregister(s)............ 139

7.2 Writingtoaholdingregister....................... 140

7.3 Diagnosis................................................... 141

7.4 Writingtomultipleholdingregisters........... 142

8 Register address list ................................. 143

8.1 Operationcommands................................ 143

8.2 Maintenancecommands........................... 144

8.3 Monitorcommands.................................... 145

8.4 ParameterR/Wcommands....................... 148

Operationdata.................................................148

Userparameters..............................................149

9 Group send ................................................ 158

10 Detection of communication errors ........ 160

10.1 Communicationerrors.............................. 160

10.2 Alarmsandwarnings................................ 160

11 Timing charts ............................................ 161

6 Methodofcontrolvia

industrialnetwork

1 Method of control via CC-Link

communication .......................................... 164

1.1 Guidance................................................... 164

1.2 Settingtheswitches................................... 167

1.3 Remoteregisterlist.................................... 168

1.4 AssignmentforremoteI/Oof6axes

connectionmode....................................... 168

AssignmentlistofremoteI/O..........................168

Input/outputofremoteI/O................................169

DetailsofremoteI/Oassignment....................170

1.5 AssignmentforremoteI/Oof12axes

connectionmode....................................... 171

AssignmentlistofremoteI/O..........................171

Input/outputofremoteI/O................................172

DetailsofremoteI/Oassignment....................174

2 Method of control via MECHATROLINK

communication .......................................... 176

2.1 Guidance................................................... 176

2.2 Settingtheswitches................................... 179

2.3 I/Oeldmapforthe

2.4 I/Oeldmapforthe

2.5 Communicationformat.............................. 182

RemoteI/Oinput.............................................182

RemoteI/Ooutput...........................................182

Remoteregisterinput......................................182

Remoteregisteroutput....................................183

3 Details of remote I/O ................................. 184

3.1 Inputsignalstothedriver.......................... 184

3.2 Outputsignalsfromthedriver................... 185

4 Command code list ................................... 186

4.1 Groupfunction........................................... 186

4.2 Maintenancecommand............................. 187

4.3 Monitorcommand...................................... 188

4.4 Operationdata........................................... 189

4.5 Userparameters........................................ 190

I/Oparameter..................................................190

Motorparameter..............................................191

Operationparameter.......................................191

Return-to-homeparameter..............................192

Alarm/warningparameter................................192

Coordinationparameter...................................192

Commonparameter.........................................193

I/Ofunctionparameter.....................................193

I/Ofunction[RS-485]parameter......................194

Communicationparameter..............................195

NETC01-M2

NETC01-M3

............. 180

............. 181

−3−

Page 4

7 Inspection,

troubleshootingand

remedialactions

1 Inspection .................................................. 198

2 Alarms and warnings ................................ 199

2.1 Alarms....................................................... 199

Alarmreset......................................................199

Alarmrecords..................................................199

Alarmlist..........................................................200

2.2 Warnings................................................... 204

Warningrecords..............................................204

Warninglist......................................................204

2.3 Communicationerrors............................... 205

Communicationerrorrecords..........................205

Communicationerrorlist..................................205

3 Troubleshooting and remedial actions ... 206

8 Appendix

1 Accessories (sold separately) .................. 208

Motorcable......................................................208

Datasetter.......................................................210

Communicationcableforthedatasetting

software...........................................................210

RS-485communicationcable..........................210

Batteryset.......................................................210

−4−

Page 5

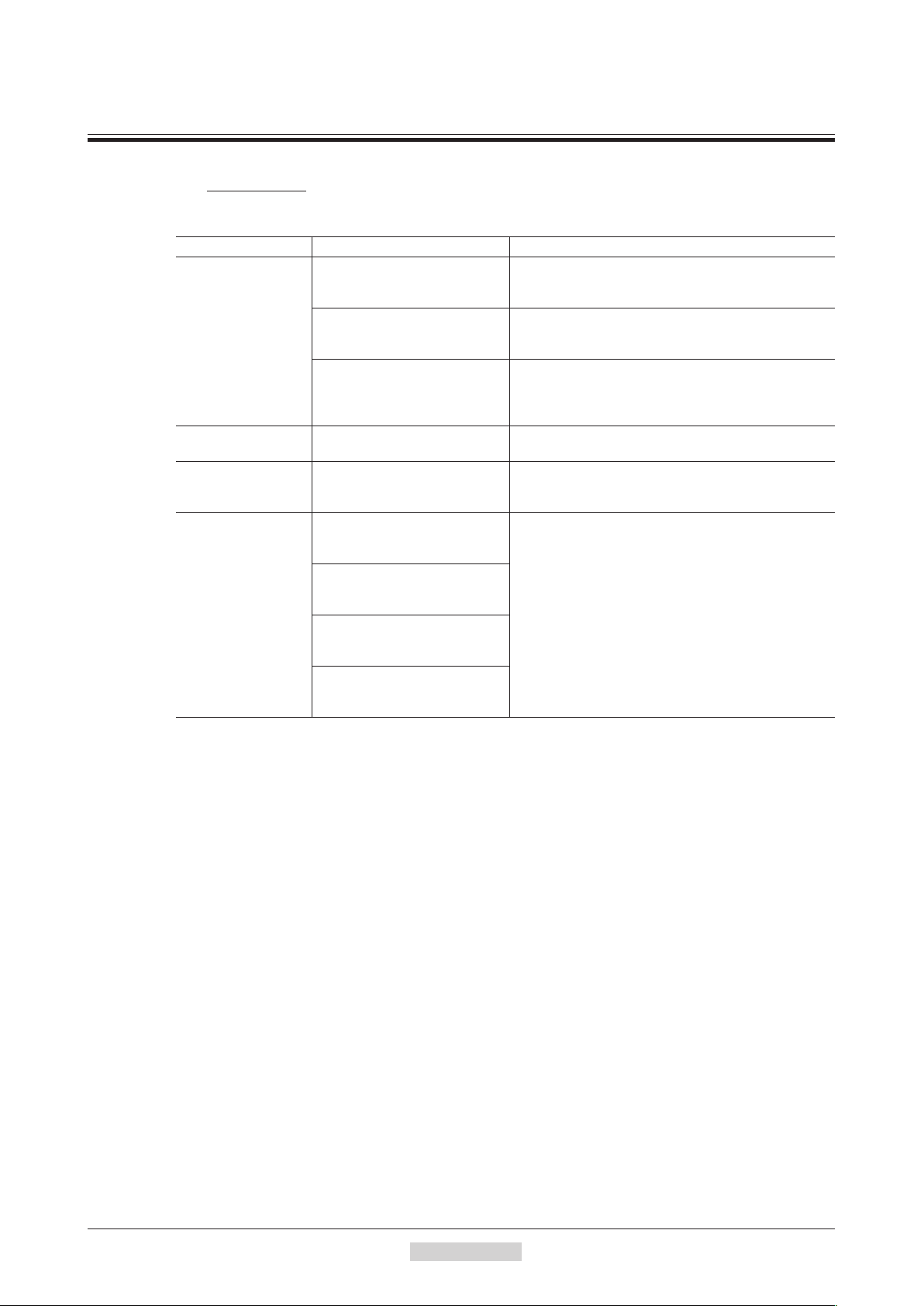

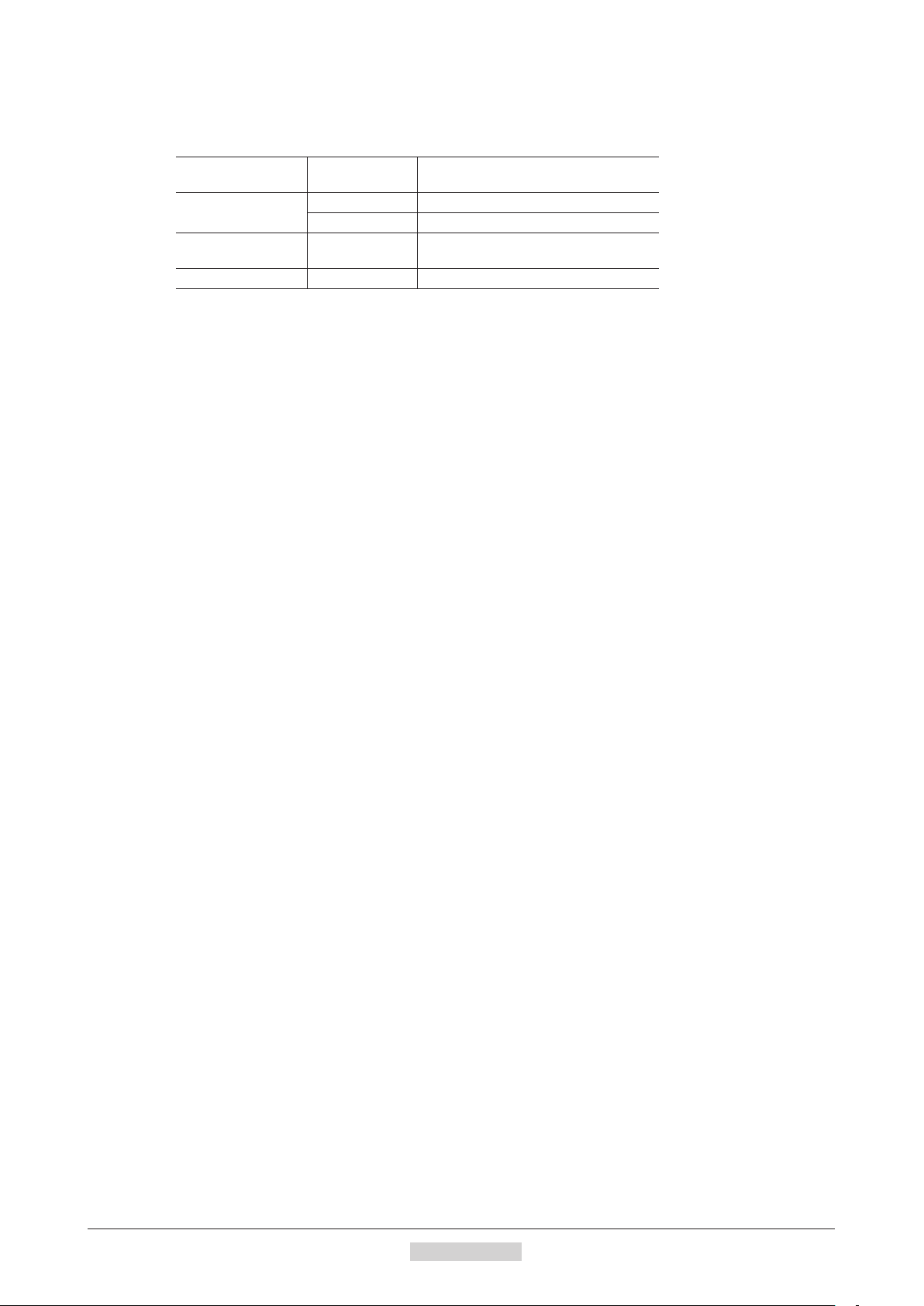

Specication Change of Driver

MEXE02 Version 3.00 or later MEXE02 older than Version 3.00

Driver after the specification change Driver before the specification change

Some specifications have been changed in this product. There are differences in data setting range, etc. between the

product after the change and before the change. For the driver before the specification change, contact your nearest

Oriental Motor sales office.

This manual describes contents of the driver which is after the specification change.

When using the driver which is before the specification change, take note of the following points.

1.Somesettingitemshavebeenchanged

Push current

Before the specification change

0 to 500 (1=0.1%) 0 to 1000 (1=0.1%)

NET-IN input function

The following input signals can be assigned in the product after the specification change.

•24: ALM-RST

•25: P-PRESET

•26: P-CLR

After the specification change

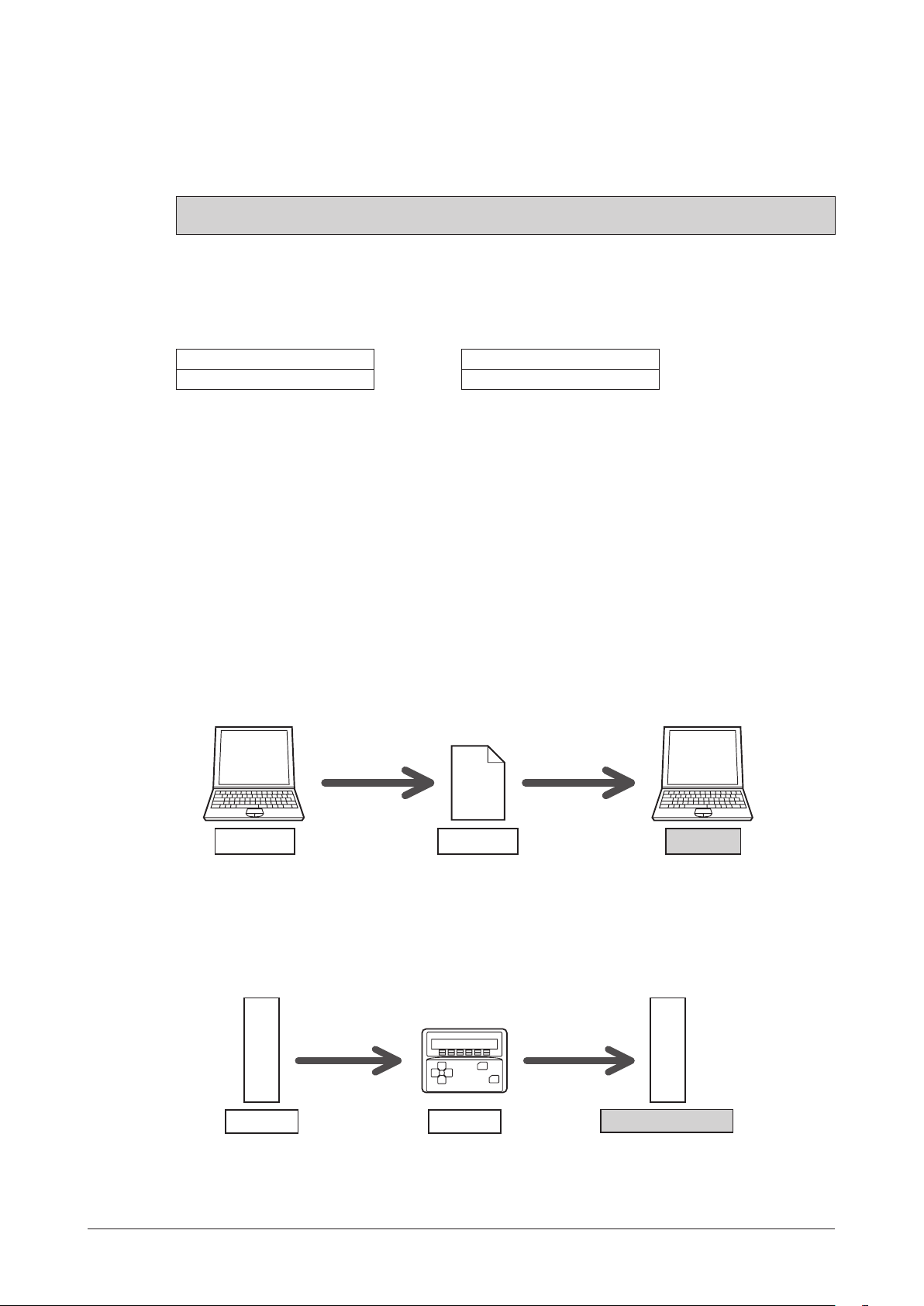

Pay attention to the data update

•When the data is set using the

MEXE02

If the

is older version than 3.00, the value after the specification change can not be set.

MEXE02

, use the

•When the following data passing is performed, the most recent value will not be effective

1) When the

using the older

If the data is opened by the older

2) When the

MEXE02

Latest value Latest value

OPX-2A

data which has set the value after the specification change is opened

MEXE02

than the Version 3.00

MEXE02

Saves the data Opens the data

than the Version 3.00, the data will be changed to the initial value.

Data file

data which has set the value after the specification change is downloaded

to the driver that is before the specification change

The value which is after the specification change will not be updated to the driver which is before the specification

change, and the value presently set is kept.

MEXE02

which software version is 3.00 or later

Initial value

OPX-2A

Uploads the data Downloads the data

Latest valueLatest value

Value before the change

−5−

Page 6

2.Theupperlimitofthealarmoutputhasbeenchanged

The maximum speed for push-motion operation has been changed. If push-motion operation is started after setting

higher speed than 30 r/min in the driver which is before the specification change, an operation data error alarm will

generate.

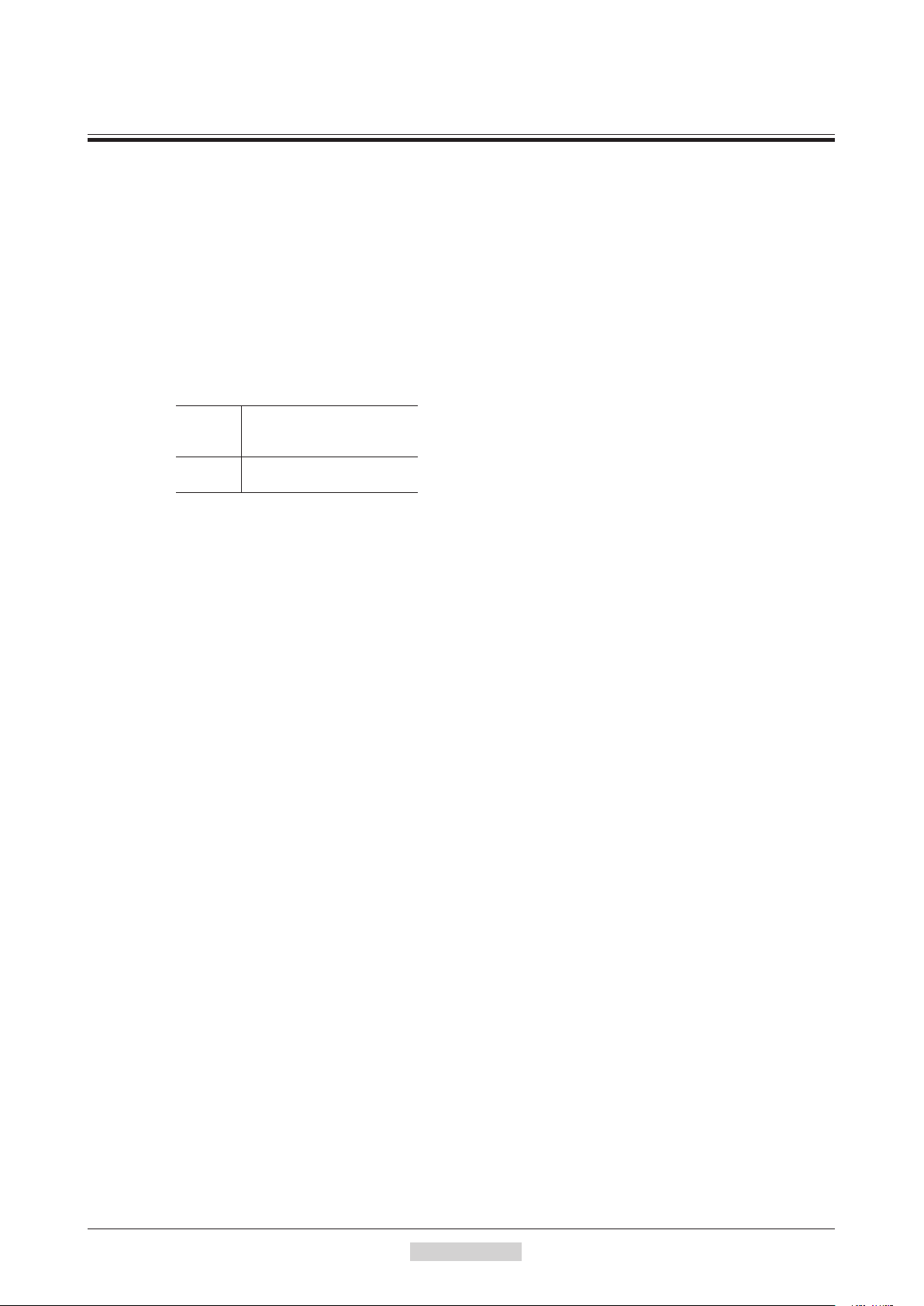

•Maximum speed for push-motion operation

Before the specification change

30 r/min 500 r/min

After the specification change

−6−

Page 7

1 Introduction

This part explains the composition of the operating manuals, the product overview, specifications and safety

standards as well as the name and function of each part and others.

Table of contents

1 Introduction ........................................ 8

2 Operating Manuals for the

AR Series ............................................. 9

3 Overview of the product .................. 10

4 System conguration ....................... 12

5 Safety precautions ........................... 13

6 Precautions for use .......................... 16

7 General specications ..................... 18

8 CE Marking ........................................ 19

9 Preparation ....................................... 20

9.1 Checking the product ............................20

9.2 How to identify the product model .........20

9.3 Combinations of motors and drivers .....21

9.4 Names and functions of parts .........

......2

2

Page 8

Introduction

1 Introduction

Before use

Only qualified personnel should work with the product.

Use the product correctly after thoroughly reading the section "5 Safety precautions" on p.13.

The product described in this manual has been designed and manufactured for use in general industrial equipment.

Do not use for any other purpose. Oriental Motor Co., Ltd. is not responsible for any damage caused through failure

to observe this warn

Hazardous substances

The products do not contain the substances exceeding the restriction values of RoHS Directive (2011/65/EU).

Notation rules

The following term is used in explanation of this manual.

Term Description

Master controller

ing.

This is a generic name for a programmable controller, master module,

pulse generator and so on.

−8−

1Introduction

Page 9

Operating Manuals for the AR Series

2 Operating Manuals for the AR Series

Operating manuals for the AR Series FLEX DC power input built-in controller type are listed below.

The "USER MANUAL" does not come with the product. For details, contact your nearest Oriental Motor sales office

or download from Oriental Motor website download page.

After reading these manuals, keep them in a convenient place so that you can reference them at any time.

Applicable product Type of operating manual Description of operating manual

Motor

OPERATING MANUAL

(Supplied with motor)

AR

Series FLEX

DC power input

Built-in controller type

Data setting software

MEXE02

Data setter

Network converter

OPX-2A

Driver

OPERATING MANUAL

(Supplied with driver)

USER MANUAL (this document)

OPERATING MANUAL

OPERATING MANUAL

CC-Link compatible

NETC01-CC

USER MANUAL

MECHATROLINK-Ⅱ compatible

NETC01-M2

USER MANUAL

MECHATROLINK-Ⅲ compatible

NETC01-M3

USER MANUAL

EtherCAT compatible

NETC01-ECT

OPERATING MANUAL

With regard to the information required to be certified under the UL Standard, refer to the "APPENDIX UL Standards

for AR Series DC power input type" (the paper is supplied with the product).

This manual explains the functions as well as the

installation method and others for the motor.

This manual explains the functions as well as the

installation method and others for t

This manual explains the functions, installation/

connection method and data setting method as well

as the operating method and others for the motor and

driver.

This manual explains how to set data using the

accessory

This manual explains the functions and installation/

connection method as well as data setting method and

o

thers for the accessory

This manual explains the functions and installation/

connection method as well as the operating method

for the network converter.

MEXE02

.

OPX-2A

ver.

he dri

(sold separately).

1Introduction

−9−

Page 10

Overview of the product

3 Overview of the product

This product is a motor and driver package product consisting of a high-efficiency stepping motor equipped with a

rotor position detection sensor, and a driver with built-in controller function.

This product can be controlled via I/O, Modbus RTU (RS-485 communication) or industrial network communication

using the network converter.

The operation data and parameters can be set using the accessory

485 communication.

Main features

•Introducing closed loop control

The AR Series can continue its operation even upon encountering quick acceleration or an abrupt change in load.

Monitoring the speed and amount of rotation while the motor is running, the AR Series performs the closed-loop

control under overload and similar conditions to continue its operation at the peak torque.

hree operating patterns

•T

You can perform positioning operation, return-to-home operation and continuous operation.

Up to 64 operation data points can be set, and multi-point positioning is also possible.

•Compatible with Modbus RTU (RS-485 communication)

You can set operation data and parameters or issue operation start/stop commands from the master controller.

Up to 31 drivers can be connected to one master.

OPX-2A

(sold separately) or

MEXE02

or via RS-

,

•Absolute-position backup system

When connecting an accessory battery set

backup system. Positions will be retained in the event of a power outage or after turning off the driver power.

BAT01B

(sold separately), this product can be used in the absolute-position

•Automatic control of the electromagnetic brake

This driver controls the electromagnetic brake automatically. The control signal input or the troublesome ladder logic

design can be saved.

•Energy-saving

Motor and driver losses have been substantially reduced to achieve low heat generation and save energy.

Since the motor and driver generate much less heat, they can now be operated for longer hours at high speed, which

was not possible with conventional motors/drivers.

•Alarm and warning functions

The driver provides alarms that are designed to protect the driver from overheating, poor connection, error in

operation, etc. (protective functions), as well as warnings that are output before the corresponding alarms generate

(warning functions).

Accessories

The operation data and parameters can be set using the accessory

485 communication. Provide the

OPX-2A

MEXE02

or

as necessary.

OPX-2A

(sold separately) or

MEXE02

, or via RS-

Related products

The AR Series FLEX DC power input built-in controller type can be used via various network when connecting to a

network converter.

−10−

Network converter Supported network

NETC01-CC

NETC01-M2

NETC01-M3

NETC01-ECT

CC-Link communication

MECHATROLINK-Ⅱ communication

MECHATROLINK-Ⅲ communication

EtherCAT communication

1Introduction

Page 11

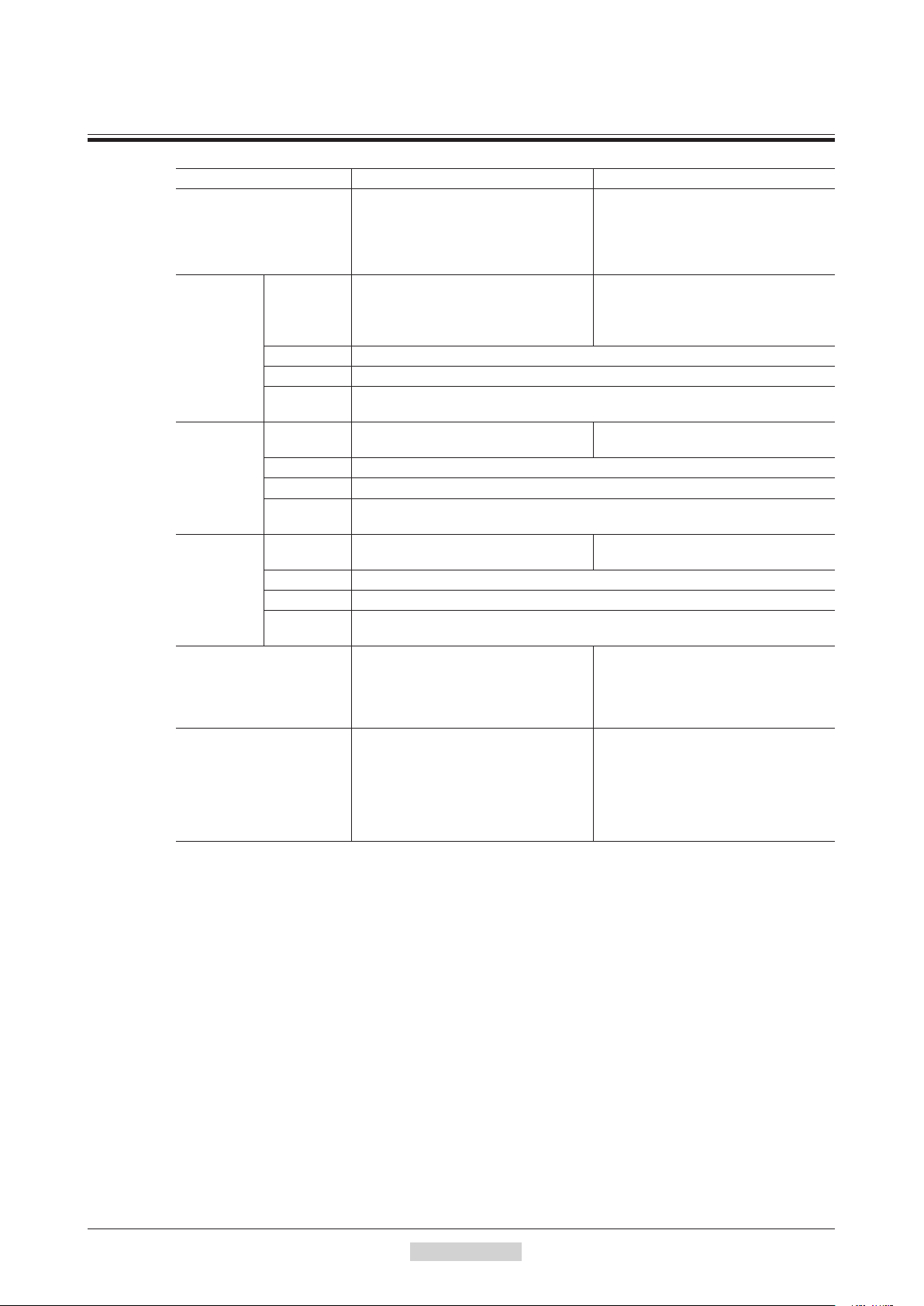

Function list

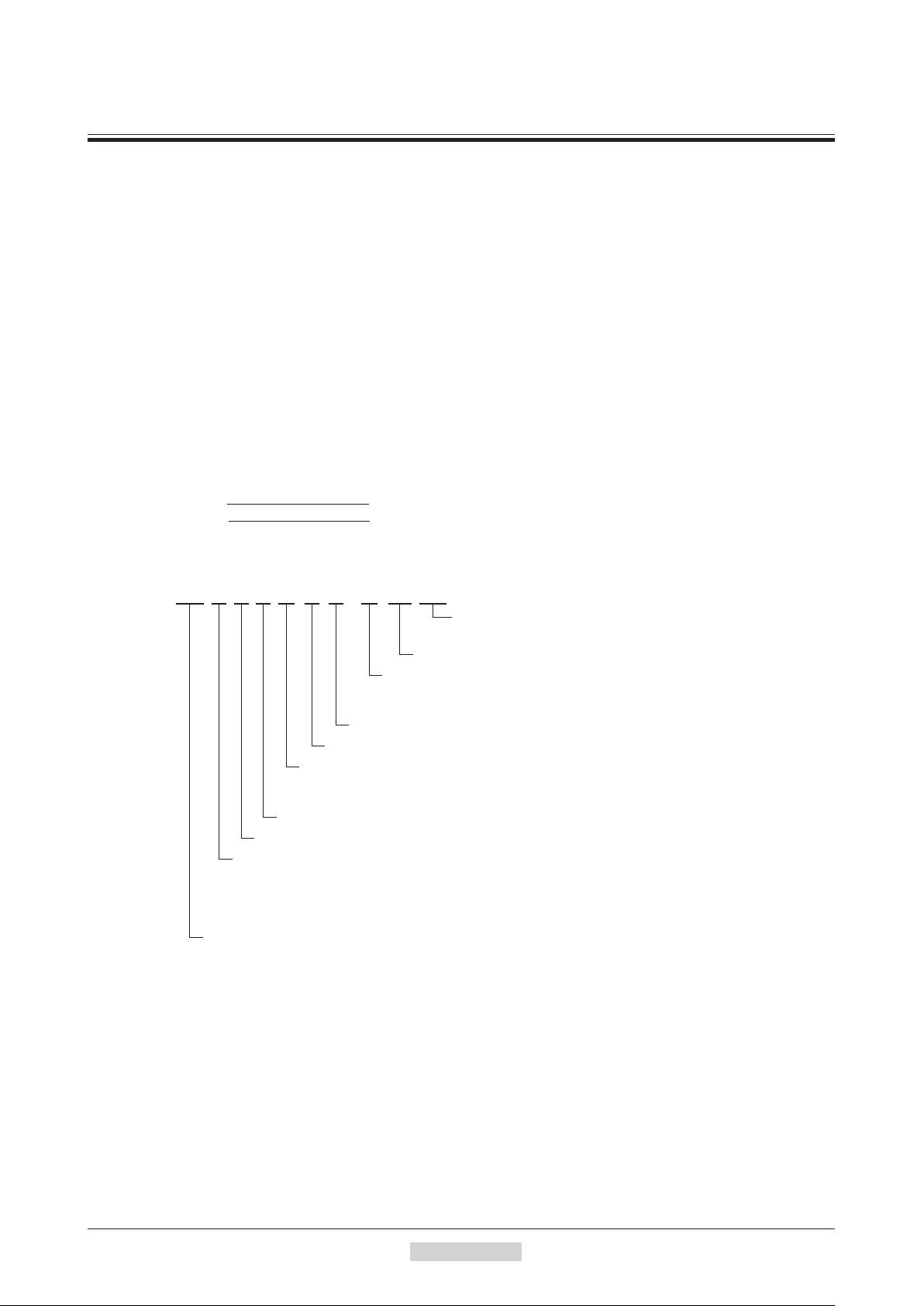

Main functions

Overview of the product

Return-to-home operation

[Setting by parameters]

Motor operation

[Setting by operation data

and parameters]

Other operations

[Setting by parameters]

Support functions

• 2-sensor mode

• 3-sensor mode

• Push-mode

• Data setting mode (Position preset)

• Positioning operation

Operation function

Single-motion operation

Linked-motion operation

Linked-motion operation 2

Push-motion

• Continuous operation

• JOG operation

• Automatic return operation

Starting method

Data number selecting operation

+

Direct positioning operation

Sequential positioning operation

[Setting by parameters]

External interface

Data setter

RS-485 communication

• Protective function

Alarm detection

Warning detection

• I/O function

Input function selection

Output function selection

Input logic level setting

• Coordination setting

Resolution (Electronic gear)

Wrap function

Motor rotation direction

• Monitor function

• Operation data setting

• Parameter setting

• Operation start

• Operation data setting

• Parameter setting

• Return-to-home function

Home position offset

External sensor signal detection

• Stop operation

STOP input action

Hardware overtravel

Software overtravel

• Motor function setting

Operating current

Standstill current

Speed filter

Moving average filter

• Data storing

• Download/Upload

• Data initialization

• Test function

Test operation

Teaching

I/O test

• Monitor function

• Maintenance function

1Introduction

−11−

Page 12

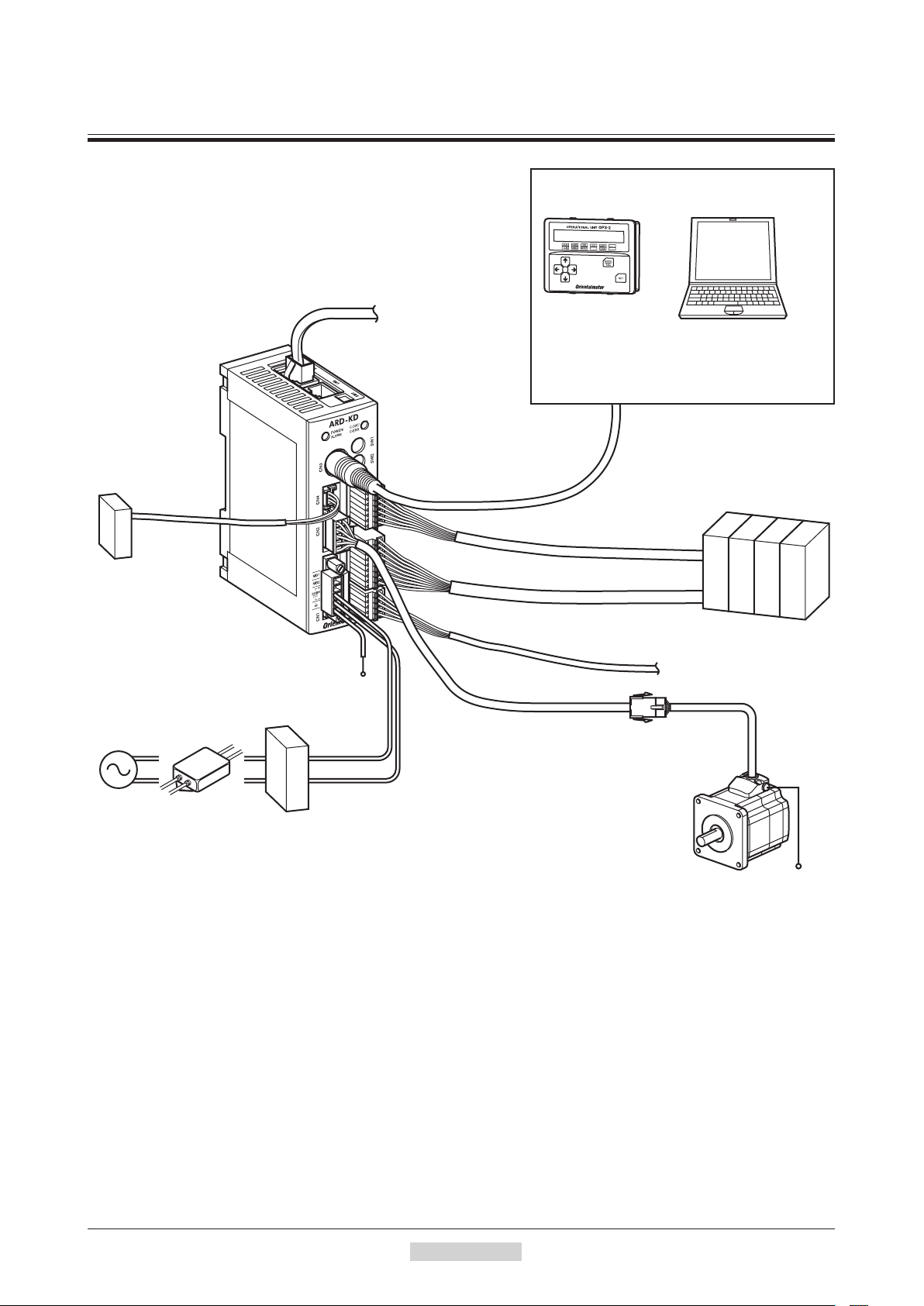

System configuration

4 System conguration

Connect to

CN4

Battery

This battery is an accessory

BAT01B (sold separately).

Connect this battery if you

want to operate the driver

in the absolute system.

AC power

supply

Noise filter

Use a noise filter to

eliminate noise.

It has the effect of

reducing noise generated

from the power supply

and driver.

Connect to CN6 or CN7

FG

24 VDC

or

48 VDC

GND

Connect to CN1

DC power

supply

Master controller

Connect when controlling

the system via RS-485

communication.

Connect to CN3

Output signals: Connect to CN9

Input signals: Connect to CN8

Connect to CN2

Cable for motor

This cable is used to connect

the motor and driver.

OPX-2A

(sold separately)

Connect to CN5

PC in which the MEXE02

has been installed

Or

The PC must be supplied by the

customer. Use the communication

cable for the data setting software

CC05IF-USB when connecting

the PC and driver.

Master controller

Sensor

Motor

PE

−12−

1Introduction

Page 13

5 Safety precautions

The precautions described below are intended to prevent danger or injury to the user and other personnel through safe,

correct use of the product. Use the product only after carefully reading and fully understanding these instructions.

Handling the product without observing the instructions that accompany a "Warning"

symbol may result in serious injury or death.

Handling the product without observing the instructions that accompany a “Caution”

symbol may result in injury or property damage.

The items under this heading contain important handling instructions that the user should

observe to ensure safe use of the product.

General

•Do not use the product in explosive or corrosive environments, in the presence of flammable gases, locations

subjected to splashing water, or near combustibles. Doing so may result in fire or injury.

•Assign qualified personnel the task of installing, wiring, operating/controlling, inspecting and troubleshooting the

product. Failure to do so may result in fire, injury or damage to equipment.

ke measures to keep the moving parts in position for vertical operations such as elevator applications. The motor

Ta

•

loses holding torque when the power is shut off, allowing the moving parts to fall and possibly cause injury or

damage to equipment.

•The brake mechanism of an electromagnetic brake motor is used to keep the moving part and motor in position. Do

not use it as a deceleration/safety b

•When the driver generates an alarm (any of the driver's protective functions is triggered), take measures to hold

the moving part in place since the motor stops and loses its holding torque. Failure to do so may result in injury or

damage to equipment.

•When the driver generates an alarm (any of the driver's protective functions is t

then clear the protection function. Continuing the operation without removing the cause of the problem may cause

malfunction of the motor and driver, leading to injury or damage to equipment.

rake

. Doing so may result in injury or damage to the equipment.

Safety precautions

riggered), first remove

the cause and

Installation

•Install the motor and driver in the enclosure in order to prevent injury.

Connection

•Keep the driver's input power voltage within the specified range. Failure to do so may result in fire.

•For the driver’s power supply, use a DC power supply with reinforced insulation on its primary and secondary

sides. Failure to do so may result in electric shock.

•Connect the cables securely according to the wiring diagram. Failure to do so may result in fire.

•Do not forcibly bend, pull or pinch the cable. Doing so may cause fire.

•Turn off the power to both the PC and

electric shock.

drive

r before connecting your PC to the driver. Failure to do so may cause

Operation

•Turn off the driver power in the event of a power failure. Or the motor may suddenly start when the power is

restored and may cause injury or damage to equipment.

•Do not turn the FREE input to ON while the motor is operating. The motor will stop and lose its holding power.

Doing so may result in

injury or damage to equipment.

Repair, disassembly and modification

•Do not disassemble or modify the motor and driver. Doing so may cause injury. Refer all such internal inspections

and repairs to the branch or sales office from which you purchased the product.

1Introduction

−13−

Page 14

Safety precautions

General

Transportation

Installation

Connection

•Do not use the motor and driver beyond its specifications. Doing so may result in injury or damage to equipment.

•Keep your fingers and objects out of the openings in the motor and driver. Failure to do so may result in fire or

injury.

•Do not touch the motor and driver during operation or immediately after stopping. The surface is hot and may

cause a skin burn(s).

BA

•Do not use other batterie

injury or damage to equipment.

•Do not carry the motor by holding the motor output shaft or motor cable. Doing so may cause injury.

•Provide a cover over the rotating parts (output shaft) of the motor. Failure to do so may result in injury.

•Do not leave anything around the motor and driver that wo

to equipment.

•The power supply connector (CN1), data edit connector (CN3) and RS-485 communication connector (CN6/

CN7) of the driver are not electrically insulated. When grounding the positive terminal of the power supply, do not

connect any equipment (PC, etc.) whose negative terminal is grounded. Doing so may cause the drive

equipment to short, damaging both.

•When connecting, check the silk screen of the driver and pay attention to the polarity of the power supply. Reversepolarity connection may cause damage to the driver. The power-supply circuit and the RS-485 communication

circuit are not insulated. Reverse-polarity connection may cause damage to the driver.

s than the accessory dedicated battery

T01B

(sold separately). Doing so may result in

uld obstruct ventilation. Doing so may result in damage

r and these

Operation

•Use a motor and driver only in the specified combination. An incorrect combination may cause a fire.

•Do not touch the rotating part (output shaft) during operation. Doing so may cause injury.

•Provide an emergency stop device or emergency stop circuit external to the equipment so that the entire equipment

will operate safely in the event of a system failure or malfunction. Failure to do so may result in injury.

•For the power s

and secondary sides. Failure to do so may result in electric shock.

•Before supplying power to the driver, turn all input signals to the driver OFF. Otherwise, the motor may start

suddenly at power ON and cause injury or damage to equipment.

•Before moving the motor directly with the hands, confirm t

result in injury.

•Immediately when trouble has occurred, stop running and turn off the driver power. Failure to do so may result in

fire or injury.

upply to the electromagnetic brake

, use a DC power supply with reinforced insulation on its primary

hat the FREE input turns ON. Fa

ilure to do so may

Maintenance and inspection

•To prevent the risk of electric shock, do not touch the terminals while performing the insulation resistance test or

dielectric strength test.

Disposal

•To dispose of the motor and driver, disassemble it into parts and components as much as possible and dispose of

individual parts/components as industrial waste.

−14−

1Introduction

Page 15

Safety precautions

Handling the battery

Be sure to observe the following instructions when using the accessory battery (sold separately). Handling the battery

without observing the instructions may cause the liquid leakage, heat generation and explosion, etc., which may result

in injury or damage to equipment.

•Do not heat the battery or throw it into a fire.

•Never short-circuit the battery or connect the positive and negative terminals in reverse.

•When carrying/storing the battery, do not place it together with metal necklaces, hairpins, coins, keys or other

conductive objects. When storing the battery, store it away from direct sunlight in a place not subject to high

temperature or high humidity.

•D

o not disassemble or modify the battery.

•D

o not apply solder directly to the battery.

•Use a dedicated driver to charge the battery.

•The battery has a vent structure for the release of internal gas. Do not apply a strong force to the battery, since it

may cause this structure to deform.

•When installing the battery into the machine, never place it inside a sealed structure. The battery sometimes

g

enerates gas, which, if trapped, may cause a burst or an explosion due to ignition.

•The battery contains an alkali solution. If the alkali solution comes in contact with the skin or clothes, flush the area

thoroughly with clean water. If the alkali solution gets into the eyes, do not rub. Flush the eyes thoroughly with

clean water and seek immediate medical attention.

•Do not use the battery if

•D

o not immerse the battery in water or seawater, nor allow it to become wet. Doing so may cause the battery to

generate heat or rust.

•Do not scratch the battery and battery cable. A scratched battery easily causes shorting, resulting in leakage, heat

generation or bursting.

•The battery is connected to the primary circuit, so d

•Do not forcibly bend, pull or pinch the cable. Also, do not bend and flex the cable repeatedly.

•Do not make a continuous vibration or excessive impact.

Note

•Always charge the battery connecting to the driver before use. Refer to p.38 for charging method.

•Nickel-metal-hydride cell is used in this battery. Disposal of the used batteries is

subject to each country's regulations on environmental control. Contact your nearest

Oriental Motor office if you have any questions.

there is leakage, discoloration, deformation or another abnormality.

o not touch the battery while the pow

er is on.

1Introduction

−15−

Page 16

Precautions for use

6 Precautions for use

This section covers limitations and requirements the user should consider when using the product.

•Always use the cable (supplied or accessory) to connect the motor and driver.

Be sure to use the cable (supplied or accessory) to connect the motor and driver.

In the following condition, an appropriate accessory cable must be purchased separately. Refer to p.208 for details.

•If a flexible cable is to be used.

•I

f a cable of 3 m (9.8 ft.) or longer is to be used.

•If a motor and driver package without a cable was purchased.

•Perform the insulation resistance test or dielectric strength test separately on the motor and the

driver.

Performing the insulation resistance test or dielectric strength test with the motor and driver connected may result in

damage to the product.

•Do not apply a radial load and axial load in excess of the specified permissible limit

Operating the motor under an excessive radial load or axial load may damage the motor bearings (ball bearings). Be

sure to operate the motor within the specified permissible limit of radial load and axial load. Refer to p.28 for details.

•Use the motor in conditions where its surface temperature will not exceed 100 °C (212 °F).

The driver has an overheat protection function, but the motor has no such feature. The motor surface temperature may

exceed 100 °C (212 °F) under certain conditions (ambient temperature, operating speed, duty cycle, etc.). To prevent

the motor bearings (ball bearings) from reaching its usable life quickly, use the motor in conditions where the surface

temperature will not exceed 100 °C (212 °F).

Use the gea

prevent deterioration of grease and parts in the gear case.

If the motor is to be operated continuously, install the motor in a location where heat dissipation capacity equivalent

to a level achieved with a heat sink [made of aluminum, 250×250×6 mm (9.84×9.84×0.24 in.)] is ensured.

red type motor in a condition where the gear case temperature does not ex

ceed 70 °C (158 °F), in order to

•Holding torque at standstill

The motor holding torque is reduced by the current cutback function of the driver at motor standstill. When selecting

a motor for your application, consider the fact that the holding torque will be reduced at motor standstill.

•Do not use the electromagnetic brake to reduce speed or as a safety brake.

Do not use the electromagnetic brake as a means to decelerate and stop the motor. The brake hub of the

electromagnetic brake will wear significantly and the braking force will drop.

Since the power off activated type electromagnetic brake is equipped, it helps maintain the position of the load when

the power is cut off, but this brake cannot securely hold the load in place. Accordingly, do not use the electromagnetic

brake as a safety brake.

To use the electromagnetic brake to ho

ld the load in place, do so after the motor has stopped.

•Double shaft type motor

Do not apply load torque, radial load or axial load to the output shaft on the opposite side of the motor output shaft.

•Preventing electrical noise

See "1.7 Installing and wiring in compliance with EMC Directive" on p.30 for measures with regard to noise.

•Peak torque of geared type motor

Always operate the geared type motor under a load not exceeding the peak torque. If the load exceeds the peak torque,

the gear will be damaged.

•Grease of geared type motor

On rare occasions, a small amount of grease may ooze out from the geared type motor. If there is concern over

possible environmental damage resulting from the leakage of grease, check for grease stains during regular

inspections. Alternatively, install an oil pan or other dev

leakage may lead to problems in the customer’s equipment or products.

ice to prevent leakage from causing further damage. Oil

−16−

1Introduction

Page 17

Precautions for use

•Rotation direction of the gear output shaft

The relationship between the rotation direction of the motor shaft and that of the gear output shaft changes as follows,

depending on the gear type and gear ratio.

Type of gear Gear ratio

TH

geared

PS

geared

PN

geared

Harmonic geared All gear ratios Opposite direction

3.6, 7.2, 10 Same direction

20, 30 Opposite direction

All gear ratios Same direction

(relative to the motor rotation direction)

Rotation direction

•Do not perform push-motion operation with geared types.

Doing so may cause damage to the motor or gear part.

•Saving data to the non-volatile memory

Do not turn off the power supply while writing the data to the non-volatile memory and 5 seconds after the

completion of writing the data. Doing so may abort writing the data and cause a EEPROM error alarm to generate.

The non-volatile memory can be rewritten approximately 100,000 times.

•Motor excitation at power ON

The motor is excited when the power is on. If the motor is required to be in non-excitation status when turning on the

power, assign the C-ON input to the direct I/O or network I/O.

•Overvoltage alarm by regeneration energy

The overvoltage alarm will generate depending on the operating condition. When an alarm is generated, review the

operating conditions.

•Note on connecting a power supply whose positive terminal is grounded

The power supply connector (CN1), data edit connector (CN3) and RS-485 communication connector (CN6/CN7)

of the driver are not electrically insulated. When grounding the positive terminal of the power supply, do not connect

any equipment (PC, etc.) whose negative terminal is grounded. Doing so may cause the driver and these equipment to

short, damaging both. Use the

OPX-2A

to set data, etc.

1Introduction

−17−

Page 18

General specifications

7 General specications

Motor Driver

IP65 (Excluding the motor mounting

surface and connectors)

Degree of protection

Ambient

temperature

Operation

environment

Storage

environment

Shipping

en

vironment

Insulation resistance

Dielectric strength

*1 When installing a motor to a heat sink of a capacity at least equivalent to an aluminum plate [100×100 mm

(3.94×3.94 in.), thickness 6 mm (0.24 in.)].

*2 0.5 kVAC for the

Humidity 85% or less

A

ltitude Up to 1000 m (3300 ft.) above sea level

Surrounding

atmosphere

Ambient

temperature

Humidity 85% or less (non-condensing)

Altitude Up to 3000 m (10000 ft.) above sea level

Surrounding

atmosphere

mbient

A

temperature

Humidity 85% or less (non-condensing)

Altitude Up to 3000 m (10000 ft.) above sea level

Surrounding

atmosphere

ARM14, ARM15, ARM24

IP20 (Double shaft type, models

including "S" in the motor identification

of motor name.)

−

10 to +50 °C (+14 to +122 °F)

(non-freezing)

Harmonic geared type: 0 to +40 °C

(+32 to +104 °F) (non-freezing)

No corrosive gas, dust, water or oil

−

20 to +60 °C (−4 to +140 °F)

(non-freezing)

No corrosive gas, dust, water or oil

−

20 to +60 °C (−4 to +140 °F)

(non-freezing)

No corrosive gas, dust, water or oil

100 MΩ or more when 500 VDC megger

is applied between the following places:

· Case - Motor windings and sensor

windings

·

Case - Electromagnetic brake windings

Sufficient to withstand 1.0 kVAC at

50 Hz or 60 Hz applied between the

following places for 1 minute:

· Case - Motor windings and sensor

windings

· Case - Electromagnetic brake

windings"

1

∗

(non-condensing)

ARM26

and

types

IP10

0 to +50 °C (+32 to +122 °F)

(non-freezing)

1

∗

−

25 to +70 °C (−13 to +158 °F)

(non-freezing)

−

25 to +70 °C (−13 to +158 °F)

(non-freezing)

100 MΩ or more when 500 VDC megger

is applied between the following places:

· FG terminal - Power supply terminal

2

∗

Sufficient to withstand 500 VAC at

50 Hz o

r 60 Hz applied betwe

following places for 1 minute:

· FG terminal - Power supply terminal

en the

−18−

1Introduction

Page 19

8 CE Marking

Low Voltage Directives

Because the input power supply voltage of this product is 24 VDC/48 VDC, it is not subject to the Low Voltage

Directive but install and connect this product as follows.

This product is designed and manufactured to be installed within another device. Install the product in an enclosure.

For the driver power supply, use a DC power supply with reinforced insulation on its primary and secondary sid

EMC Directive

This product has received EMC compliance under the conditions specified in "Example of motor and driver

installation and wiring" on p.31. Since the compliance of the final machinery with the EMC Directive will depend on

such factors as the configuration, wiring, layout and risk involved in the control-system equipment and electrical

parts, it therefore must be verified through EMC measures by th

Applicable Standards

EMI

EMS

EN 61000-6-4

EN 61800-3

EN 55011 group 1 class A

EN 61000-6-2

EN 61800-3

CE Marking

es.

e customer of the machinery.

1Introduction

−19−

Page 20

Preparation

AR 2 4 S A K D - H 50 - 3

9 Preparation

This chapter explains the items you should check, as well as the name and function of each part.

9.1 Checking the product

Verify that the items listed below are included. Report any missing or damaged items to the branch or sales office

from which you purchased the product.

Verify the model number of the purchased product against the number shown on the package label.

Check the model number of the motor and driver against

motor and driver combinations are shown on p.22.

•Motor .................................................1 unit

•Parallel key ........................................1 pc. (Supplied with geared types; except for the

•Cable for motor .................................1 pc. (Supplied with a motor and driver package)

•Cable for electromag

•Driver ................................................1 unit

•CN1 connector ..................................1 pc. (for power supply input terminals; 5 pins)

•CN5 connector ..................................1 pc. (for sensor signals; 5 pins)

•CN8 connector ..................................1 pc. (for inpu

N9 connector ..................................1 pc. (for output signals; 7 pins)

•C

•Motor OPERATING MANUAL .......1 copy

•Driver OPERATING MANUAL .......1 copy

netic brake

the number show

AR66TH

.......1 pc. (Supplied with an electromagnetic brake motor and driver package)

)

t signals; 9 pins)

n on the nameplate. Model names for

AR24, AR46TH

and

9.2 How to identify the product model

Motor size 1: 20 mm (0.79 in.)

2: 28 mm (1.10 in.) [30 mm (1.18 in.) for Harmonic geared type]

4: 42 mm (1.65 in.)

6: 60 mm (2.36 in.)

9: 85 mm (3.35 in.) [90 mm (3.54 in) for geared types]

Series name AR Series

* The model name is "7" for the gear ratio "7.2" of the PS geared type.

Gear ratio

T: TH geared type㻌 H: Harmonic geared type

PS: PS geared type㻌 Blank: Standard type

N: PN geared type

Driver type D: Built-in Controller Type

Power input K: 24 VDC/48 VDC

Motor type A: Single shaft

B: Double shaft

M: With electromagnetic brake

Motor identification

Motor length

Number: Length of supplied connection cable (m)

None: Without connection cable

∗

−20−

1Introduction

Page 21

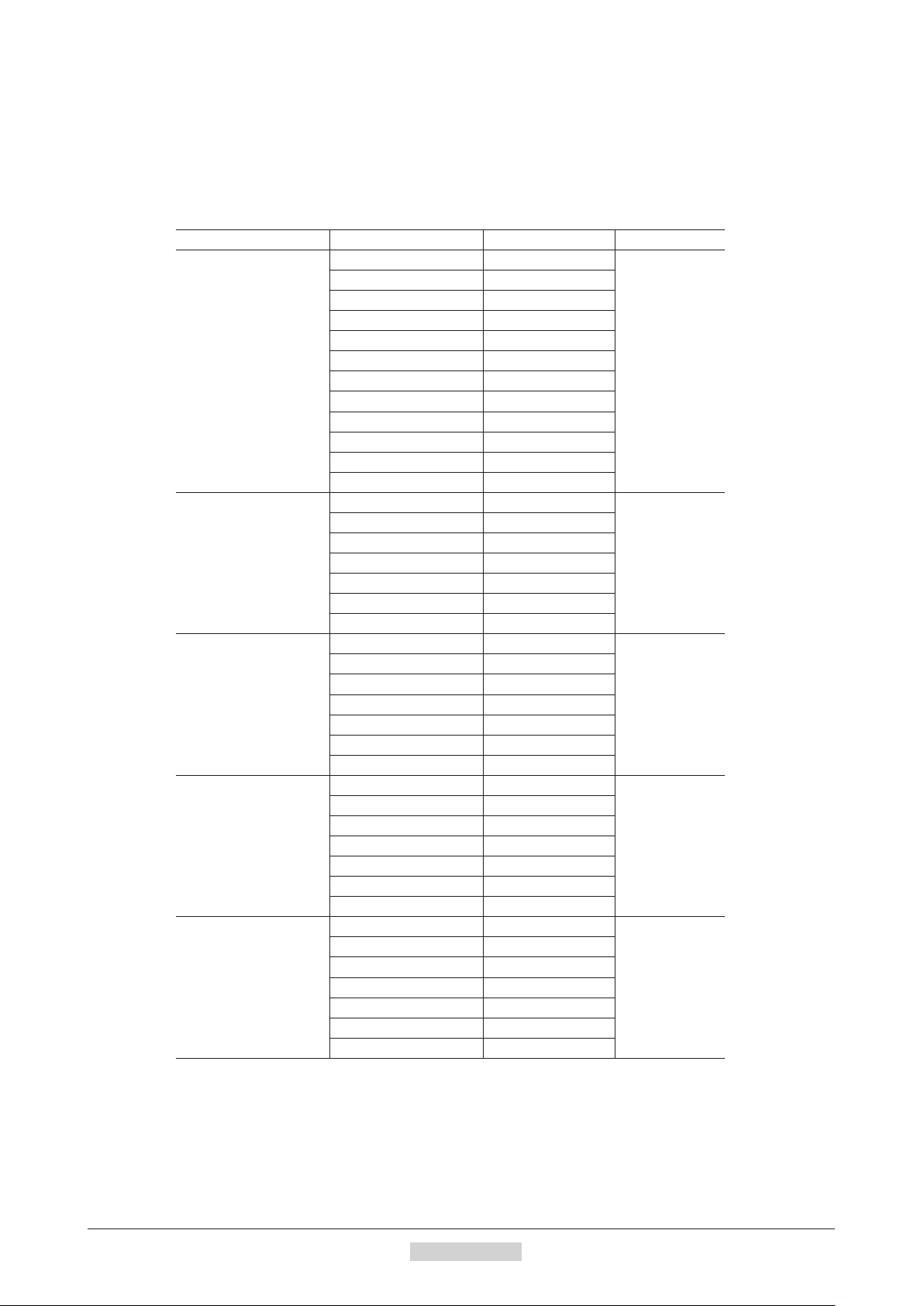

9.3 Combinations of motors and drivers

indicates A (single shaft), B (double shaft) or M (with electromagnetic brake).

••

AR14S

For

For geared type, indicates A (single shaft) or M (with electromagnetic brake).

•When a connection cable is included, in the model names indicates a number (-1, -2, -3) representing the cable

length.

in the model names indicates a number representi

••

Standard type

TH

geared type

PS

geared type

PN

geared type

Harmonic geared type

AR15S

and

, indicates A (single shaft) or B (double shaft).

ng the gear ratio.

Type Model Motor model Driver model

AR14SKD

AR15SKD

AR24SKD

AR26SKD

AR46SKD

AR46KD

AR66SKD

AR66KD

AR69SKD

AR69KD

AR98SKD

AR98KD

AR24SKD-T

AR46SKD-T

AR46KD-T

AR66SKD-T

AR66KD-T

AR98SKD-T

AR98KD-T

AR24SAKD-PS

AR46SKD-PS

AR46KD-PS

AR66SKD-PS

AR66KD-PS

AR98SKD-PS

AR98KD-PS

AR24SAKD-N

AR46SKD-N

AR46KD-N

AR66SKD-N

AR66KD-N

AR98SKD-N

AR98KD-N

AR24SKD-H

AR46SKD-H

AR46KD-H

AR66SKD-H

AR66KD-H

AR98SKD-H

AR98KD-H

ARM14SK

ARM15SK

ARM24SK

ARM26SK

ARM46SK

ARM46K

ARM66SK

ARM66K

ARM69SK

ARM69K

ARM98SK

ARM98K

ARM24SK-T

ARM46SK-T

ARM46K-T

ARM66SK-T

ARM66K-T

ARM98SK-T

ARM98K-T

ARM24SAK-PS

ARM46SK-PS

ARM46K-PS

ARM66SK-PS

ARM66K-PS

ARM98SK-PS

ARM98K-PS

ARM24SAK-N

ARM46SK-N

ARM46K-N

ARM66SK-N

ARM66K-N

ARM98SK-N

ARM98K-N

ARM24SK-H

ARM46SK-H

ARM46K-H

ARM66SK-H

ARM66K-H

ARM98SK-H

ARM98K-H

Preparation

ARD-KD

ARD-KD

ARD-KD

ARD-KD

ARD-KD

1Introduction

−21−

Page 22

Preparation

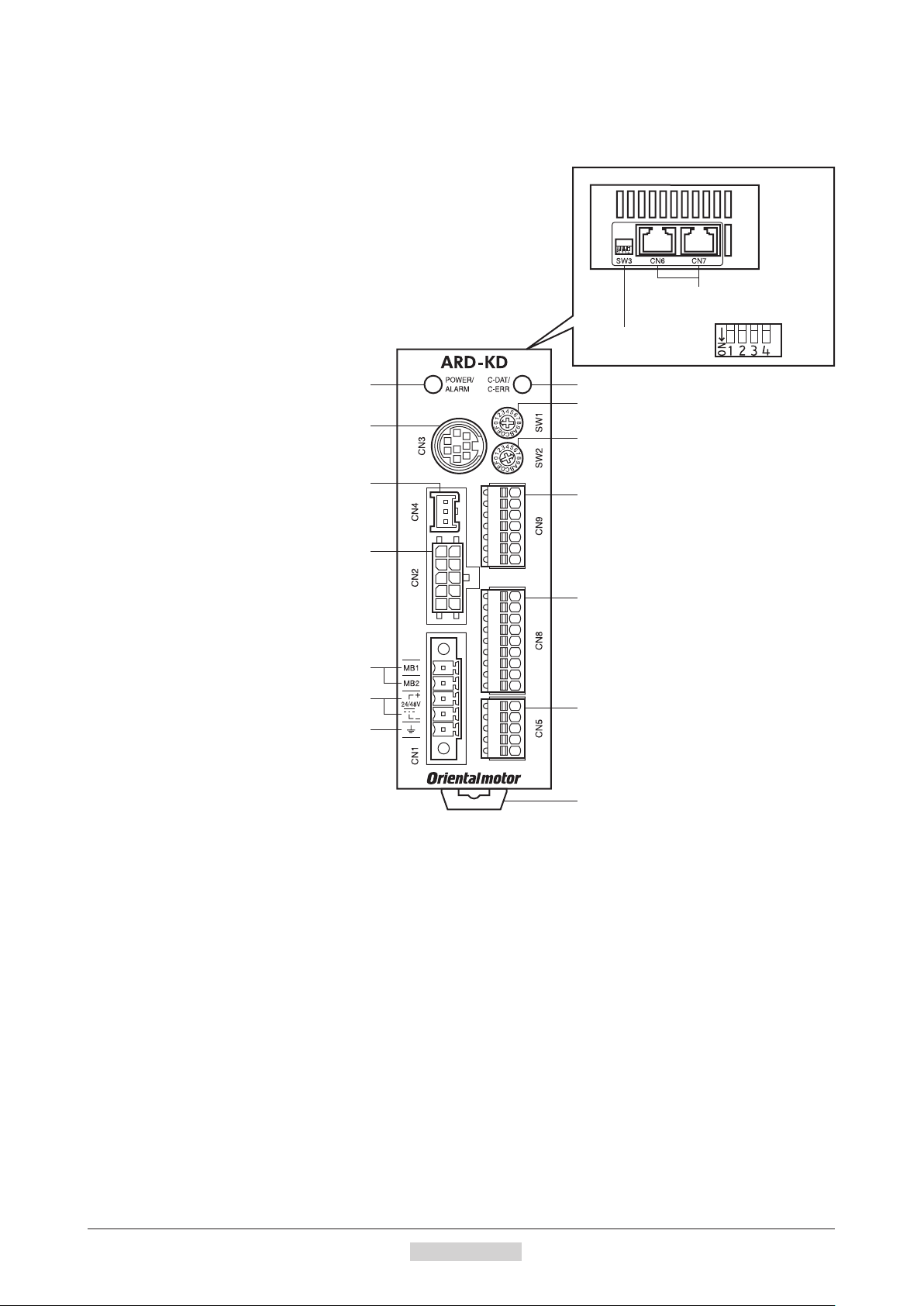

9.4 Names and functions of parts

Driver

POWER/ALARM LED C-DAT/C-ERR LED

Data edit connector (CN3)

RS-485 communication

connectors (CN6/CN7)

Function setting

switches (SW3)

Address number setting switch (SW1)

Transmission rate setting switch (SW2)

Battery connector (CN4)

Motor connector (CN2)

Electromagnetic brake terminals (CN1)

Power supply input terminals (CN1)

Frame Ground Terminal (CN1)

Output signal connector (CN9)

Input signal connector (CN8)

Sensor signal connector (CN5)

DIN lever

−22−

1Introduction

Page 23

Preparation

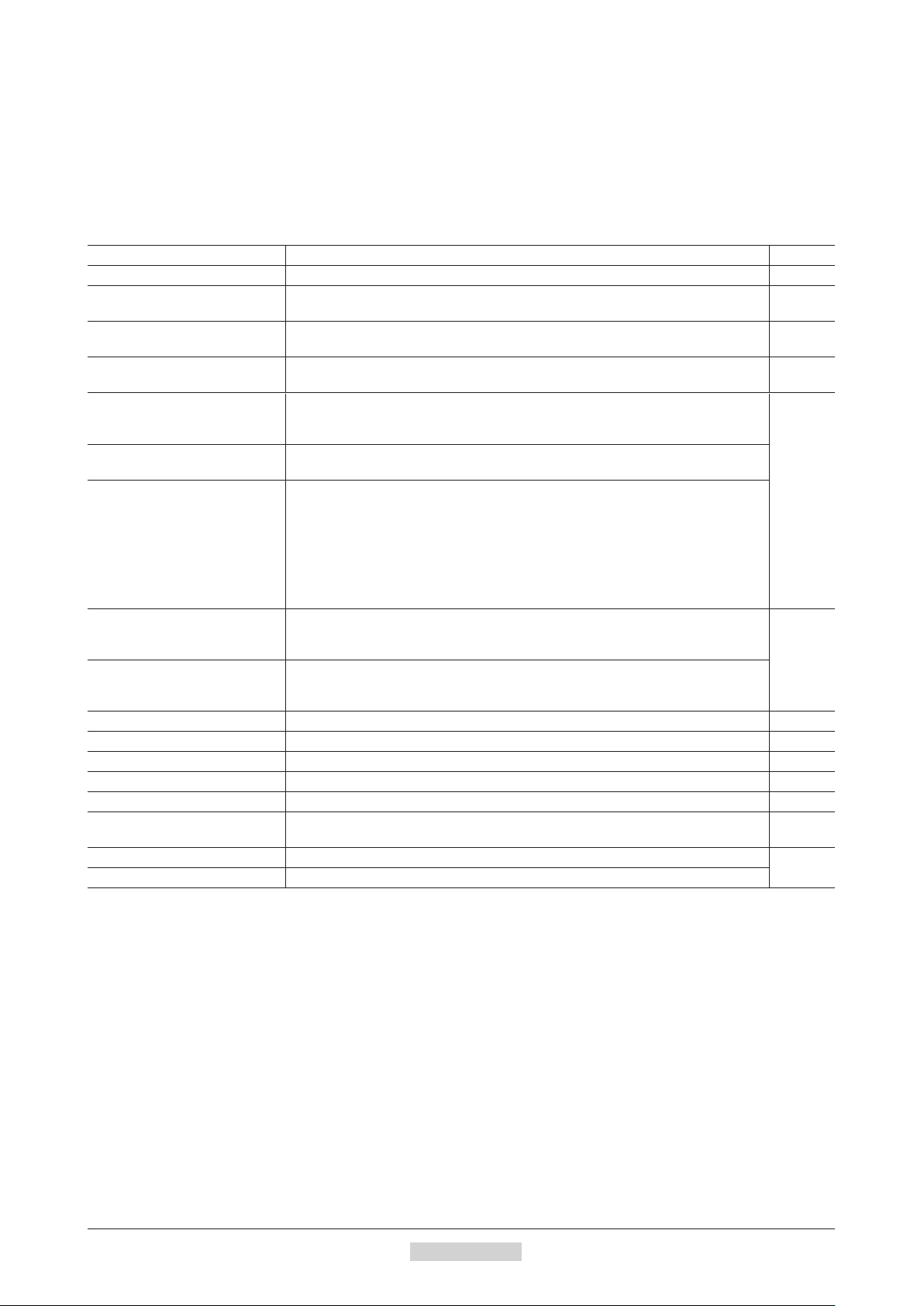

Name Description Page

POWER LED (Green) This LED is lit while the power is input.

ALARM LED (Red)

C-DAT LED (Green)

C-ERR LED (Red

)

Address number setting switch

(SW1)

Transmission rate setting switch

(SW2)

This LED will blink when an alarm generates. It is possible to check the generated

alarm by counting the number of times the LED blinks.

This LED will blink or illuminate steadily when the driver is communicating with

the master station properly via RS-485 communication.

T

his LED will illuminate when a RS-485 communication error occurs with the

master station.

Use this switch when controlling the system via RS-485 communication. Use this

switch and SW3-No.1 of the function setting switch, to set the address number

(slave address) of RS-485 communication. (Factory setting: 0)

Use this sw

itch when controlling the system via RS-485 communication. Set the

transmission rate of RS-485 communication. (Factory setting: 7)

Use this switch when controlling the system via RS-485 communication.

No.1: Using this switch and the address number setting switch (SW1), set the

address number (slave address) of RS-485 communication.

Function setting switches (SW3)

(Factory setting: OFF

N

o.2: Set the protocol of RS-485 communication. (Factory setting: OFF)

)

−

p.199

−

−

p.131

p.167

p.179

No.3: Not used.

No.4: Set the termination resistor (120 Ω) of RS-485 communication.

(Factory setting: OFF)

Electromagnetic brake terminals

(CN1-MB1/MB2)

Power supply input terminals

(CN1)

Frame Ground Terminal (CN1) Ground using a wire of AWG24 to 16 (0.2 to 1.25 mm

Connect the lead wires from the electromagnetic brake.

MB1: Electromagnetic brake − (black)

MB2: Electromagnetic brake + (white)

Connect th

r supply of the driver.

e powe

+: +24 VDC/48 VDC power supply input

−

: power supply GND

2

p.32

). p.36

Motor connector (CN2) Connect the motor cable or flexible motor cable to connect the motor. p.32

Data edit connector (CN3) Connect a PC in which the

MEXE02

Battery connector (CN4) Connect the accessory batter

has been installed, or the

y (sold separa

tely). p.38

OPX-2A

. p.36

Sensor signal connector (CN5) Connects the limit sensor. p.32

RS-485 communication

connectors (CN6/CN7)

Input signal connector (CN8) Connect the input signals cable.

Output signal connector (CN9) Connect the output signals cable.

Connect the RS-485 communication cable. p.37

p.32

1Introduction

−23−

Page 24

Preparation

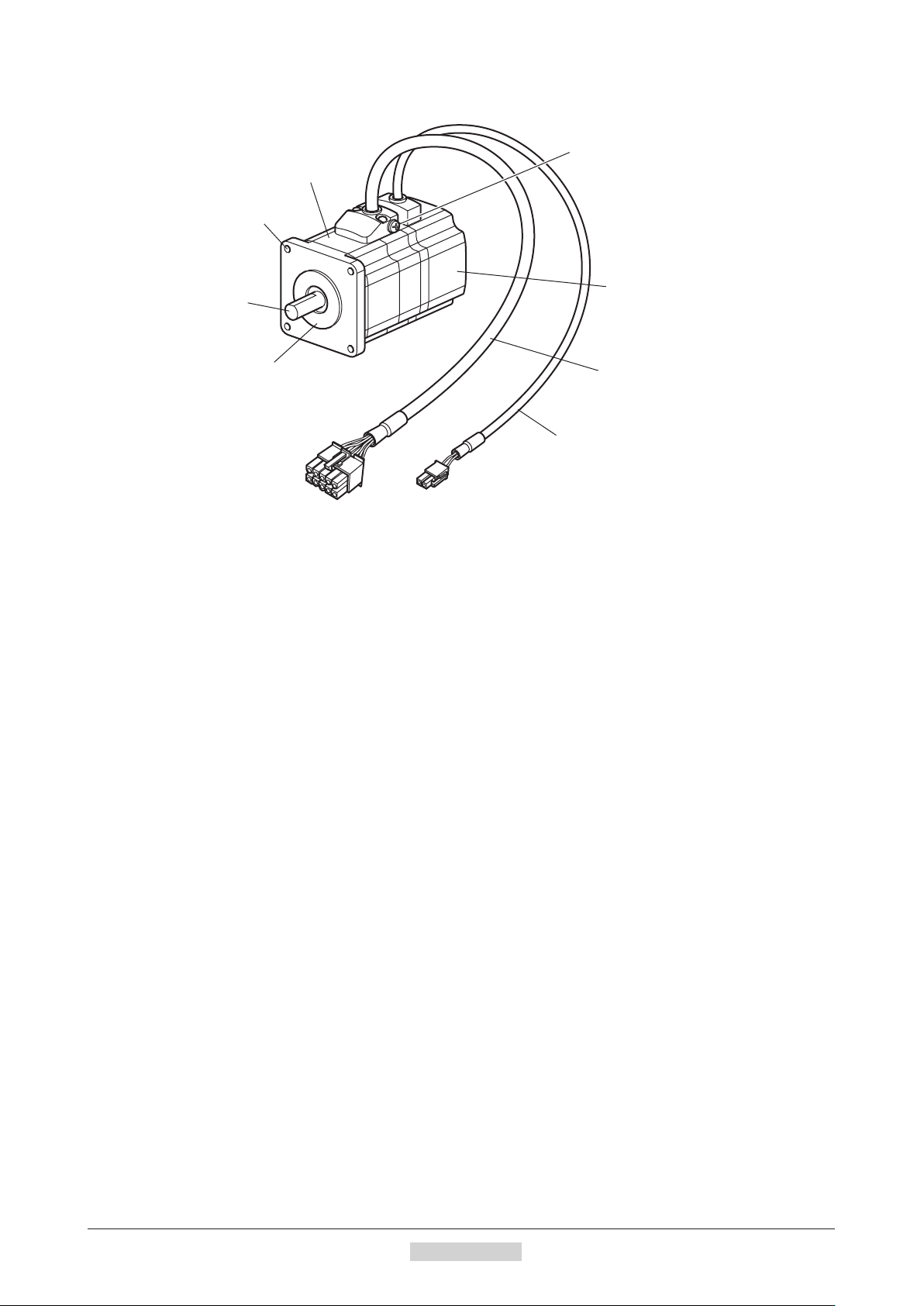

Motor (Example: ARM66SMK)

Protective Earth Terminal (M4)

Motor

Mounting holes

(4 locations)

Output shaft

Pilot

Electromagnetic brake cable

Electromagnetic brake

Motor cable

−24−

1Introduction

Page 25

2 Installation and

connection

This part explains the installation method of the product, the mounting method of a load and the connection

method as well as I/O signals.

Table of contents

1 Installation ........................................ 26

1.1 Location for installation ..........................26

1.2 Installing the motor ................................26

1.3 Installing a load .....................................27

1.4 Permissible radial load and

permissible axial load .....................

1.5 Installing the driver ................................ 29

1.6 Installing the battery .............................. 30

1.7 Installing and wiring in compliance

with EMC Directive ................................ 30

.......2

2 Connection ........................................ 32

2.1 Connection example

(electromagnetic brake motor) ..............32

2.2 Grounding the motor and driver ............36

2.3 Connecting the data setter .................... 36

2.4

C

onnecting the RS-485 communication

cable ......................................................37

2.5 Connecting and charging the battery ....38

3 Explanation of I/O signals ............... 39

3.1 Assignment of direct I/O ........................39

Assignment to the input terminals ....................39

Changing the logic level setting of input

signals ...............................................................40

Assignment to the o

8

3.2 Assignment of network I/O .................... 43

Assignment of input signals ..............................43

Assignment to the output terminals ..................45

3.3 Input signals .......................................... 47

3.4 Output signals .......................................52

3.5 Sensor input .......................................... 56

3.6 Genera

l signals (R0 to R15) .

utput terminals .

.................57

.................41

Page 26

Installation

Metal plate

1 Installation

This chapter explains the installation location and installation methods of the motor and driver, along with load

installation. The installation and wiring methods in compliance with the EMC Directive are also explained.

1.1 Location for installation

The motor and driver has been designed and manufactured to be installed within another device. Install them in a

well-ventilated location that provides easy access for inspection.

T

he location must also satisfy the following conditions:

•Inside an enclosure that is installed indoors (provide vent holes)

•Operating ambient temperature

Motor: −10 to +50 °C (+14 to +122 °F) (non-freezing)

Harmonic geared type: 0 to +40 °C (+32 to +104 °F) (non-freezing)

Driver: 0 to +50 °C (+32 to +122 °F) (non-freezing)

•Operating ambient humidity 85% or less (non-condensing)

•Area that is f

•Area not exposed to direct sun

•Area free of excessive amount of dust, iron particles or the like

•Area not subject to splashing water (rain, water droplets), oil (oil droplets) or other liquids

•Area free of excessive salt

•Area not subject to continuous vibration or excessive shocks

•Area free of excessive electromagnetic

•Area free of radioactive materials, magnetic fields or vacuum

•1000 m (3300 ft.) or lower above sea level

ree of ex

plosive atmosphere or toxic gas (such as sulfuric gas) or liquid

noise (from welders, pow

er machinery, etc.)

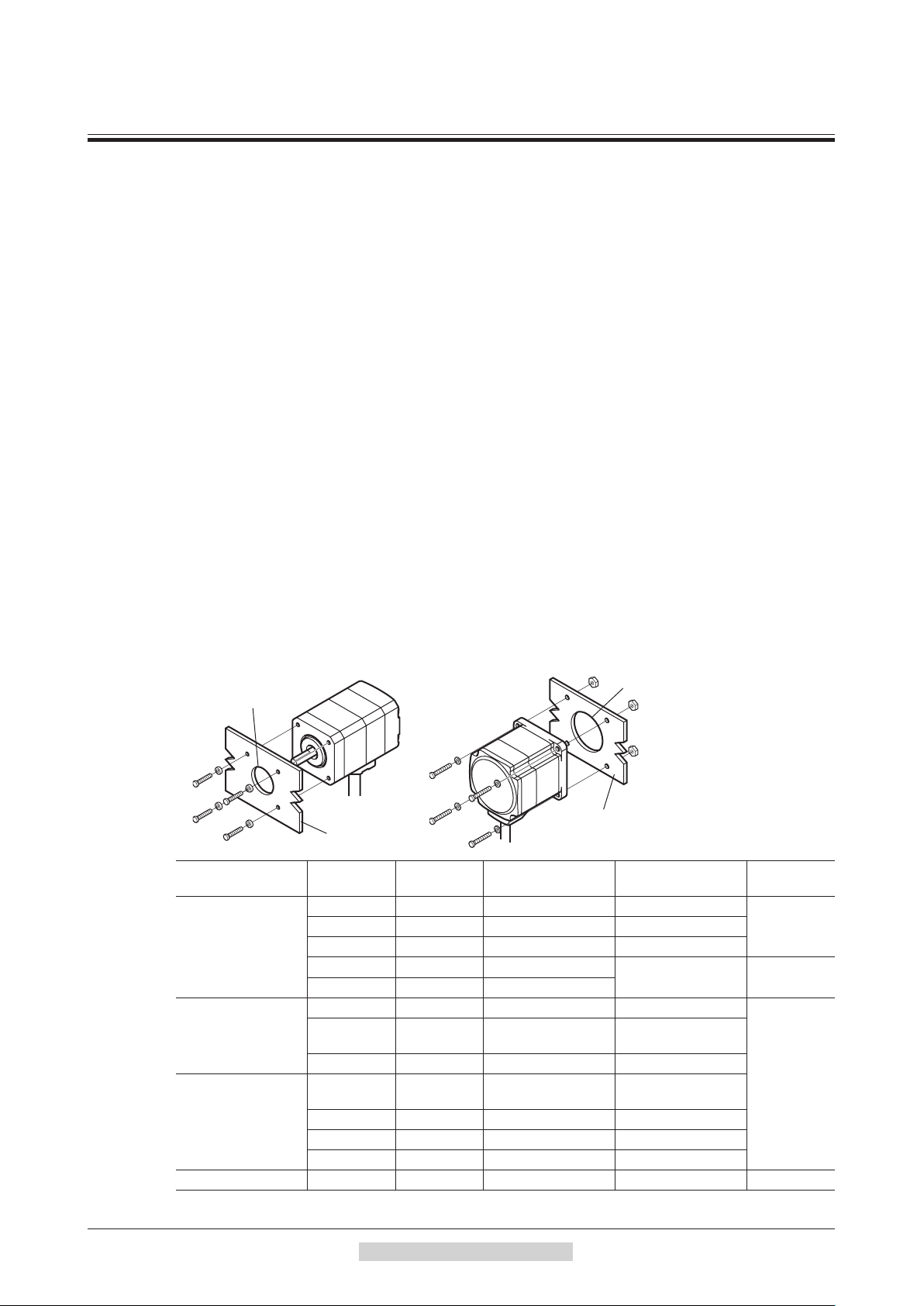

1.2 Installing the motor

The motor can be installed in any direction.

To allow for heat dissipation and prevent vibration, install the motor on a metal surface of sufficient strength.

•Installation method A

Pilot

Type

Standard

TH

geared

PS

geared

PN

geared

Harmonic geared ∗1

Harmonic geared ∗2 90 (3.54) M8 4 (560)

AR24, AR46

*3

*4

AR98

and

type only.

Frame size

[mm (in.)]

20 (0.79) M2 0.25 (35) 2.5 (0.098)

42 (1.65) M3 1 (142) 4.5 (0.177)

60 (2.36) M4 2 (280)

85 (3.35) M6 3 (420)

28 (1.10) M2.5 0.5 (71) 4 (0.157)

42 (1.65)

60 (2.36)

90 (3.54) M8 4 (560) 15 (0.591)

28

3

42 (1.65) M4 2 (280) 8 (0.315)

60 (2.36) M5 2.5 (350) 10 (0.394)

90 (3.54) M8 4 (560) 15 (0.591)

AR66

(1.10)

0 (1.18)

type only.

•Installation method B

Pilot

Metal plate

Nominal size

M4 2 (280) 8 (0.315)

M3 1 (142) 6 (0.236)

Tightening torque

[N·m (oz-in)]

Effective depth of

bolt [mm (in.)]

−

−

Installation

method

A28 (1.10) M2.5 0.5 (71) 2.5 (0.098)

B

A

B

−26−

2Installationandconnection

Page 27

1.3 Installing a load

When connecting a load to the motor, align the centers of the motor output shaft and load shaft.

Flexible couplings are available as accessories.

Note

Using a coupling

Align the centers of the motor output shaft and load shaft in a straight line.

Using a belt drive

Align the motor output shaft and load shaft in parallel with each other, and position both pulleys so that the line

connecting their centers is at a right angle to the shafts.

Using a gear drive

Align the motor output shaft and gear shaft in parallel with each other, and let the gears mesh at the center of the tooth

widths.

•When coupling the load to the motor, pay attention to the centering of the shafts, belt tension,

parallelism of the pulleys, and so on. Securely tighten the coupling and pulley set screws.

•Be careful not to damage the output shaft or bearings when installing a coupling or pulley to the

motor output shaft.

•Do not modify or machine the motor output shaft. Doing so may damage the bearings and

de

stroy

the motor.

•Do not apply strong force using hammer or other tools when removing the parallel key. Doing so

may damage the motor output shaft and bearings (ball bearings).

Installation

• Using a coupling • Using a belt drive • Using a gear drive

Using a parallel key (geared motor)

When connecting the load and gear output shaft with a key slot, secure the load using the key supplied with the gear

output shaft after machining the key slot on the load.

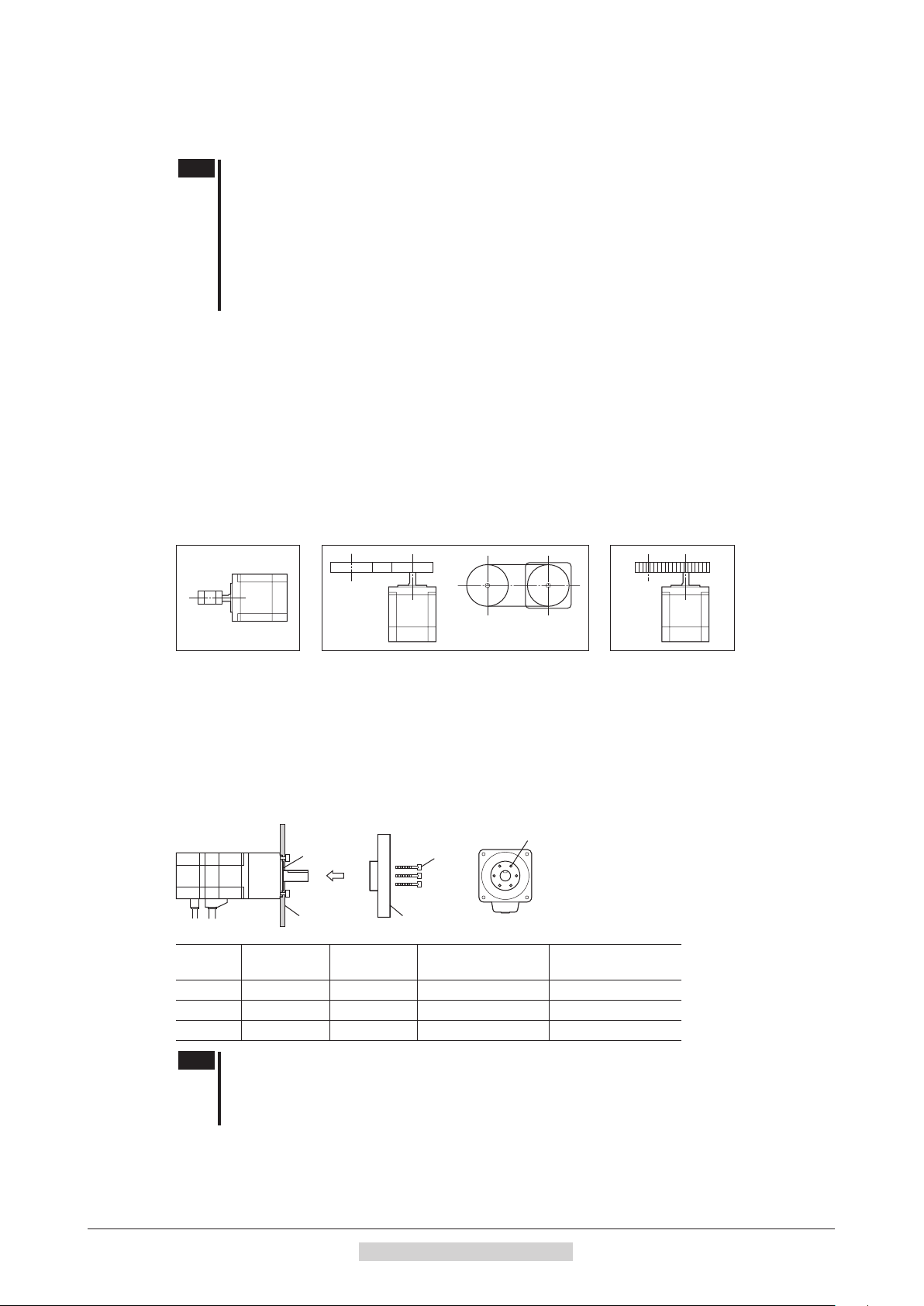

Installing on the ange surface (Harmonic geared type)

With a Harmonic geared type (excluding

holes provided on the flange surface.

Flange

Metal plate

Model Nominal size

AR24

AR46

AR66

M3 4 1.4 (198) 4 (0.157)

M3 6 1.4 (198) 5 (0.2)

M4 6 2.5 (350) 6 (0.24)

Number of

bolts

AR98

), a load can be installed directly to the gear using the load mounting

Load mounting holes

Bolts

Load

Tightening torque

[N·m (oz-in)]

Effective depth of

bolt [mm (in.)]

Note

•When installing a load on the flange surface, the load cannot be mounted using the key slot in

the output shaft.

•Design an appropriate installation layout so that the load will not contact the metal plate or bolts

used for installing the motor.

2Installationandconnection

−27−

Page 28

Installation

1.4 Permissible radial load and permissible axial load

Note

•If the radial load or axial load exceeds the specified allowable value, repeated load applications

may cause the bearing (ball bearings) or output shaft of the motor to undergo a fatigue failure.

•With a double shaft type, do not apply load torque, radial load or axial load to the output shaft on

the opposite side of the motor output shaft.

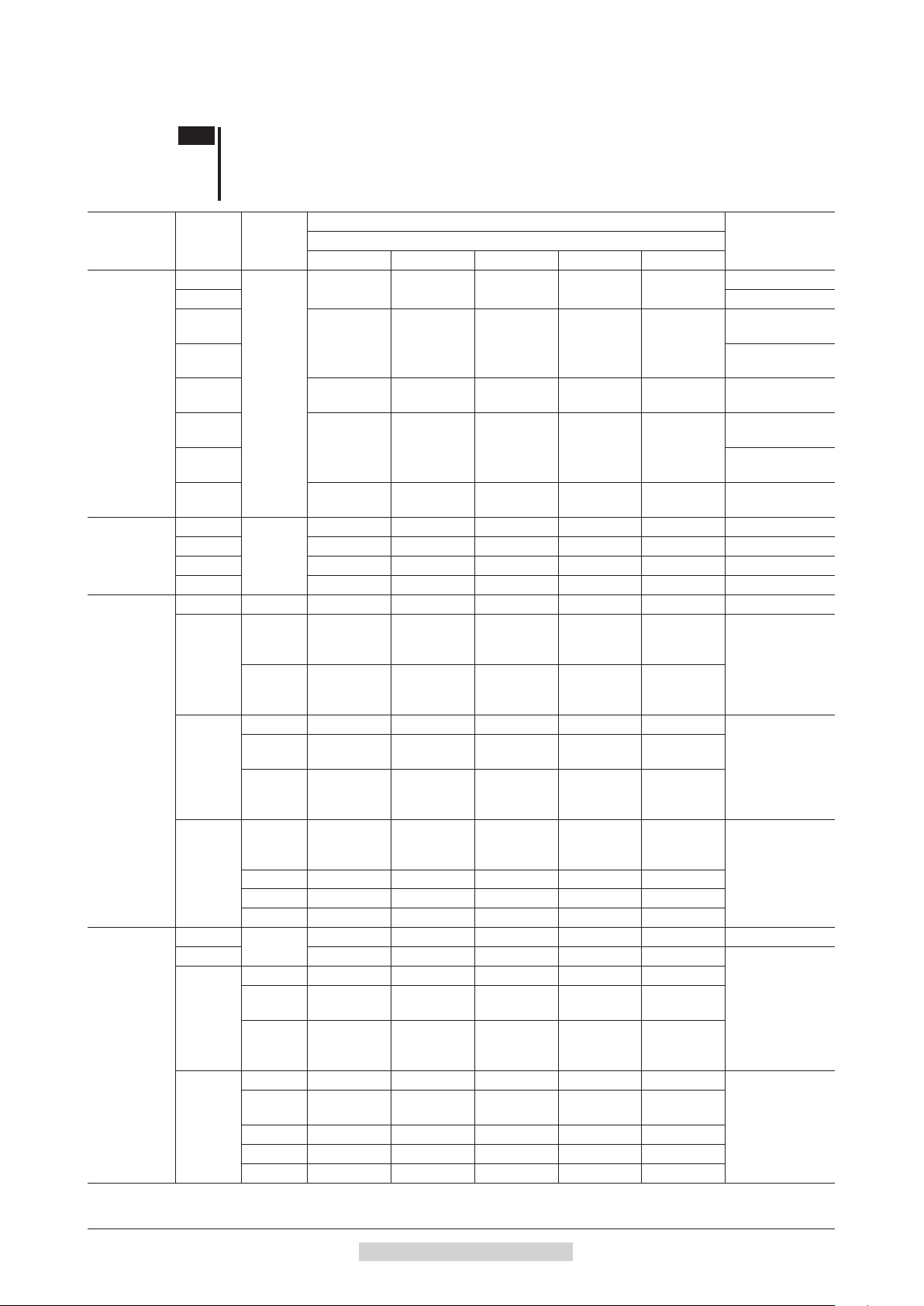

Type Model Gear ratio

AR14

AR15

AR24

AR26

Standard

TH

geared

PS

geared

PN

geared

AR46

AR66

AR69

AR98

AR24

AR46

AR66

AR98

AR24

AR46

AR66

AR98

AR24

AR46

AR66

AR98

Permissible radial load [N (lb.)]

Distance from the tip of motor output shaft [mm (in.)]

0 (0) 5 (0.2) 10 (0.39) 15 (0.59) 20 (0.79)

12 (2.7) 15 (3.3)

25 (5.6) 34 (7.6) 52 (11.7)

−

−

−

5

7.2

10

5

2

36

50

5 200 (45) 220 (49) 250 (56) 280 (63) 320 (72)

7.2

10

25

36

50

5

7.2

10

25 850 (191) 940 (210) 1050 (230) 1190 (260) 1380 (310)

36 930 (200) 1030 (230) 1150 (250) 1310 (290) 1520 (340)

50 1050 (230) 1160 (260) 1300 (290) 1480 (330)

−

5 200 (45) 220 (49) 250 (56) 280 (63) 320 (72)

7.2

10

25

36

50

5 480 (108) 520 (117) 550 (123) 580 (130) 620 (139)

7.2

10

25 850 (191) 940 (210) 1050 (230) 1110 (240) 1190 (260)

36

50 1050 (230) 1160 (260) 1300 (290) 1380 (310) 1490 (330)

35 (7.8) 44 (9.9) 58 (13) 85 (19.1)

90 (20) 100 (22) 130 (29) 180 (40) 270

260 (58) 290 (65) 340 (76) 390 (87) 480 (108)

15 (3.3) 17 (3.8) 20 (4.5) 23 (5.1)

10 (2.2) 14 (3.1) 20 (4.5) 30 (6.7)

70 (15.7) 80 (18) 100 (22) 120 (27) 150 (33) 40 (9)

220 (49) 250 (56) 300 (67) 350 (78) 400 (90) 100 (22)

45 (10.1) 60 (13.5) 80 (18) 100 (22)

73 (16.4) 84 (18.9) 100 (22) 123 (27)

109 (24) 127 (28) 150 (33) 184 (41)

250 (56) 270 (60) 300 (67) 340 (76) 390 (87)

330 (74) 360 (81) 400 (90) 450 (101) 520 (117)

480 (108) 540 (121) 600 (135) 680 (153) 790 (177)

45 (10.1) 60 (13.5) 80 (18) 100 (22)

100 (22) 120 (27) 150 (33) 190 (42)

250 (56) 270 (60) 300 (67) 340 (76) 390 (87)

330 (74) 360 (81) 400 (90) 450 (101) 520 (117)

480 (108) 540 (121) 600 (135) 680 (153) 790 (177)

930 (200) 1

030 (230) 1150 (250) 1220 (270) 1300 (290)

* The brackets < > indicate the value for the electromagnetic brake type.

− − −

− −

−

(60)

−

−

−

−

−

1710 (380)

−

−

Permissible axial

load [N (lb.)]

0.7 (0.157)

0.9 (0.2)

1.5 (0.33)

<2.1 (0.47)>

2.2 (0.49)

<2.7 (0.6)>

4.6 (1.03)

<6.1 (1.37)>

.8 (1.98)

8

<11.8 (2.6)>

13.7 (3)

<16.7 (3.7)>

18 (4)

<24 (5.4)>

10 (2.2)

15 (3.3)

20 (4.5)

0 (11.2)

5

100 (22)

300 (67)

20 (4.5)

100 (22)

300 (67)

∗

∗

∗

∗

∗

∗

−28−

2Installationandconnection

Page 29

Installation

35 mm

50 mm or more

100 mm

Type Model Gear ratio

AR24

Harmonic

geared

AR46

AR66

AR98

−

1090 (240) 1150 (250) 1230 (270) 1310 (290) 1410 (310) 1300 (290)

Permissible moment load of the Harmonic geared type

When installing an arm or table on the flange surface, calculate the moment load using the formula below if the flange

surface receives any eccentric load. The moment load should not exceed the permissible value specified in the table.

Moment load: M [N·m (oz-in)] = F × L

Model

AR24

AR46

AR66

Permissible moment load

[N·m (oz-in)]

2.9 (410)

5.6 (790)

11.6 (1640)

1.5 Installing the driver

Installation method

Mount the driver to a 35 mm (1.38 in.) width DIN rail.

When installing two or more drivers in parallel, it is possible to install them closely

in the horizontal direction.

Provide a minimum clearance of 50 mm (1.97 in.) in the vertical direction.

When installing three or more drivers closely, the heat generation of the inside drivers

become high. Install the less frequently used drivers toward the in

U

se the "overheat warning" parameter to check the inside temperature of the driver.

Note

•Install the driver in an enclosure whose pollution degree is 2

or better environment, or whose degree of protection is IP54

minimum.

•Do not install any equipment that generates a large amount of heat

or noise near the driver.

•Do not install the driver underneath the controller or other

equipment vulnerable to heat.

•If the ambient temperature of the driver exceeds 50 °C (122 °F),

improve the

ve

by using fans or creating spaces between the drivers.

•Be sure to install the driver vertically (vertical position).

Permissible radial load [N (lb.)]

Distance from the tip of motor output shaft [mm (in.)]

0 (0) 5 (0.2) 10 (0.39) 15 (0.59) 20 (0.79)

100 (22) 135 (30) 175 (39) 250 (56)

180 (40) 220 (49) 270 (60) 360 (81) 510 (114) 220 (49)

320 (72) 370 (83) 440 (99) 550 (123) 720 (162) 450 (101)

L

F

−

Permissible axial

load [N (lb.)]

140 (31)

side.

ntilation condition such as providing forced cooling

Pull down the driver's DIN lever and lock it. Hang the hook at the rear to the DIN rail, and push in the driver.

After installation, secure the both sides of the driver with the end plate.

Hook

DIN rail

DIN lever

2Installationandconnection

End plate

−29−

Page 30

Installation

•

Removing from DIN rail

Pull the DIN lever down until it locks using a flat tip screwdriver, and lift the

bottom of the driver to remove it from the rail.

Use force of about 10 to 20 N (2.2 to 4.5 lb.) to pull the DIN lever to lock it.

Excessive force may damage the DIN lever.

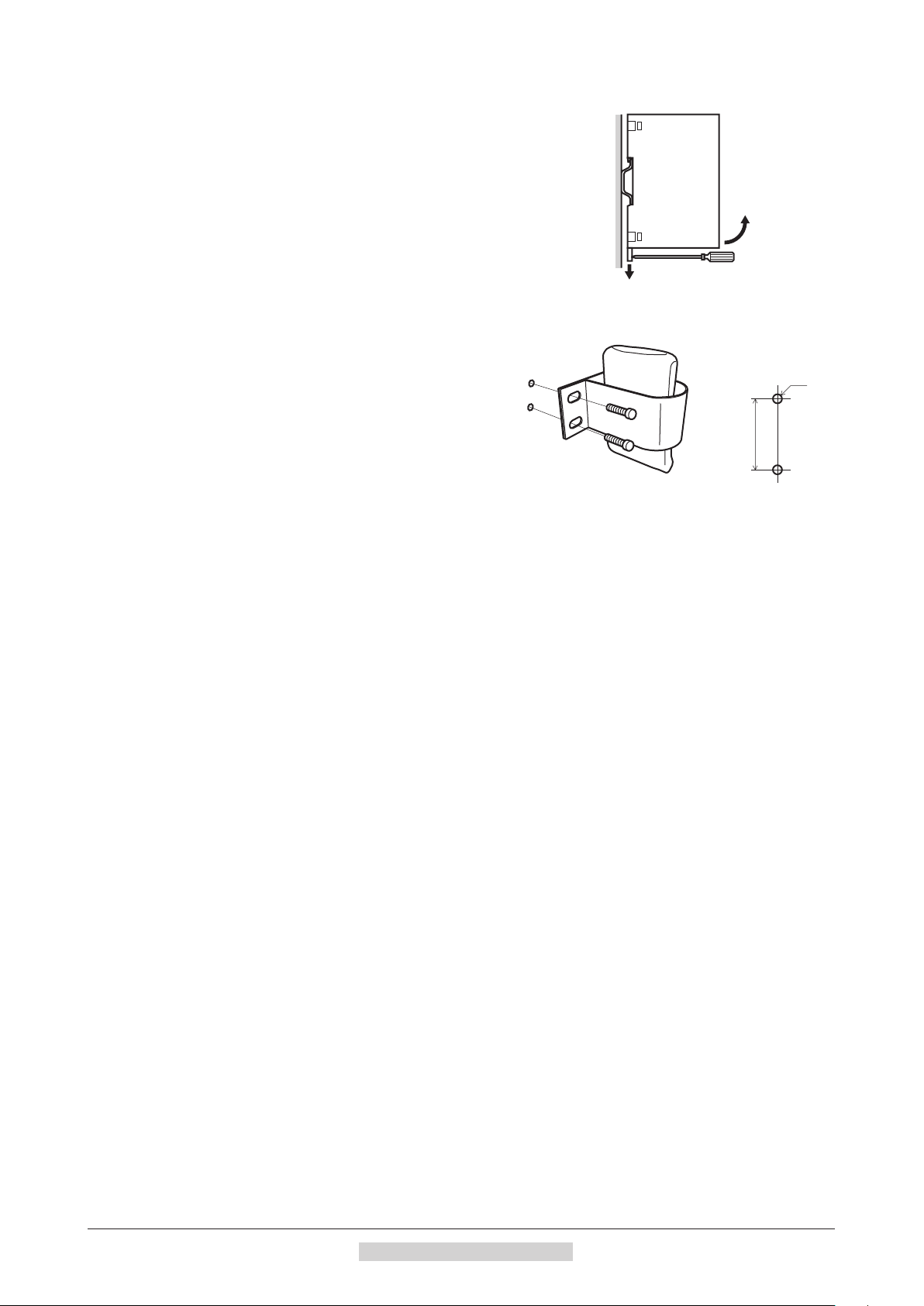

1.6 Installing the battery

A battery and battery holder are included in an accessory

battery set

Use the battery holder to secure the battery.

See p.210 for accessory.

BAT01B

(sold separately).

Battery installation

dimensions

M4

13±0.3 mm

(0.51±0.012 in.)

1.7 Installing and wiring in compliance with EMC Directive

Effective measures must be taken against the EMI that the motor and driver may give to adjacent control-system

equipment, as well as the EMS of the motor and driver itself, in order to prevent a serious functional impediment

in the machinery. The use of the following installation and wiring methods will enable the motor and driver to be

compliant with the EMC directive. Refer to "8 CE Marking" o

riental Motor conducts EMC measurements on its motors and drivers in accordance with "Example of motor and

O

driver installation and wiring" on p.31. The user is responsible for ensuring the machine's compliance with the EMC

Directive, based on the installation and wiring explained below.

Connecting the power supply

Use a DC power supply compliant with the EMC Directive.

Use a shielded cable for wiring and wire/ground the pow

Refer to "Wiring the power supply cable and I/O signal cable" for how to ground the shielded cable.

Connecting noise lter for power supply line

•Connect a noise filter in the DC power supply input to prevent the noise generated in the driver from propagating

externally through the power supply line.

•When using a power supply transformer, be sure to connect a noise filter to the AC

transformer.

•For a noise filter, use HF2010A (SOSHIN ELECTRIC CO.,LTD), FN2070-10-06 (Schaffner EMC) or equivalent

product.

•Install the noise filter as close to the AC input terminal of DC power supply as possible. Use cable clamps and other

means to secure the AC input cables (AWG18: 0.75 mm

firmly to the surface of the enclosure.

•Connect the ground terminal of the noise filter to the grounding point, using as thick and short a wire as possible.

•Do not place the AC input cable parallel with the noise filter output cable. Parallel placement will reduce noise

filter effectiveness if the enclosure's internal noise is directly coupled to the power supply cable by means of stray

capacita

nce.

n p.19 for the applicable standards.

er supply over the shortest possible distance.

input side of the power supply

2

or more) and output cables (AWG18: 0.75 mm2 or more)

−30−

How to ground

The cable used to ground the driver and noise filter must be as thick and short as possible so that no potential

difference is generated. Choose a large, thick and uniformly conductive surface for the grounding point.

•Grounding the motor

Be sure to ground the Protective Earth Terminal of the motor. Refer to p.36 for grounding method.

•Grounding the driver

Refer to p.36 for grounding method.

2Installationandconnection

Page 31

Installation

A: Cable cramp

PE

Wiring the power supply cable and I/O signal cable

Use a shielded cable for the power supply cable and I/O signal cable, and keep it as short as possible.

To ground a shielded cable, use a metal cable clamp or similar

device that will maintain contact with the entire circumference

of the cable. Attach a cable clamp as close to the end of the

Shielded cable

Cable clamp

cable as possible, and connect it as shown in the figure.

Notes about installation and wiring

•Connect the motor, driver and other peripheral control equipment directly to the grounding point so as to prevent a

potential difference from developing between grounds.

•When relays or electromagnetic switches are used together with the system, use noise filters and CR circuits to

suppress surges generated by them.

•Keep cables as short as possible without coiling and bundling extra lengths.

lace the power cables such as the motor and power supply cables as far apart [200 mm (7.87 in.)] as possible from

P

•

the signal cables. If the power cables and signal cables have to cross, cross them at a right angle. Place the AC input

cable and output cable of a noise filter separately from each other.

•When extending the distance between the motor and driver, it is recommended that an accessory m

s

eparately) should be used. The EMC measures are conducted using the Oriental Motor extension cable.

otor cable (sold

Example of motor and driver installation and wiring

RS-485 communication cable

OPX-2A

Motor

Controller

PE

Motor cable

(Shielded cable)

AC

Noise

Filter

DC power

supply

PEPE

Shielded

cable

BAT01B

A

FG

Driver

FG

Shielded

cable

A

FG

Grounded panel

Sensor

Shielded cable

Precautions about static electricity

Static electricity may cause the driver to malfunction or suffer damage. While the driver is receiving power, handle

the driver with care and do not come near or touch the driver.

Always use an insulated screwdriver to adjust the driver's switches.

Note

The driver uses parts that are sensitive to electrostatic charge. Before touching the driver, turn off

the power to prevent electrostatic charge from generating. If an electrostatic charge is impressed

on the driver, the driver may be damaged.

2Installationandconnection

−31−

Page 32

Connection

2 Connection

This chapter explains how to connect the motor, I/O signals and power supply to the driver, as well as grounding

method.

2.1 Connection example (electromagnetic brake motor)

Wiring the CN5/CN8/CN9 connector

Button of the orange color

Lead wire

Cable for motorMotor cable

Connect to CN2

∗

Insert the lead wire

while pushing the

button of the orange

color with a screwdriver.

Output signals

Connect to CN9

Electromagnetic

brake cable

DC power supply

24 VDC±5%

or 48 VDC±5%

Wiring the CN1 connector

Screwdriver

(connector screw size: M2)

Tightening torque:

0.22 to 0.25 N·m

(31 to 35 oz-in)

Lead wire

Note

•Have the connector plugged in securely. Insecure connections may cause malfunction or damage to the motor

or driver.

•When unplugging the connector, do so while pressing the latches on the connector.

•When plugging/unplugging the connector, turn off the power and wait for the POWER LED to turn off before

doing so.

•When connecting, check the silk screen of the driver and pay attention to the po

Reverse-polarity connection may cause damage to the driver. The power-supply circuit and the RS485 communication circuit are not insulated. Therefore, when controlling multiple drivers via RS-485

communication, the reverse polarity of the power supply will cause a short circuit and may result in damage to

the drivers.

•The lead wires of the "cable for electromagnetic b

polarities. If the lead wires are connected with their polarities reversed, the electromagnetic brake will not

operate properly.

•If the distance between the motor and driver is extended to 20 m (65.6 ft.) or longer, use a power supply of

24 VDC±4%.

•When installing the motor to a moving part, use an accessory flexible cable offering excellent

flexible motor cable, refer to p.208.

•Do not wire the power supply cable of the driver in the same cable duct with other power lines or motor cables.

Doing so may cause malfunction due to noise.

Cable for electromagnetic brake

Connect to CN1

+24 V (+48 V)

GND

Pay attention to the

polarity of the power

supply.

+24 VDC

GND

Input signals

Black

∗

White

FG

Screwdriver

(connector screw size: M2.5)

Tightening torque: 0.4 N·m (56 oz-in)

* Keep 30 m (98.4 ft.) or less for the wiring distance between the motor and driver.

Connect to CN8

Sensor signals

Connect to CN5

larity of the power supply.

ra

ke" have polarities, so connect them in the correct

flex

ibility. For the

−32−

2Installationandconnection

Page 33

Power supply current capacity

5

Model

AR14

AR15

AR24

AR26

AR46

AR66

AR69

AR98

Input power

supply voltage

24 VDC±5%

24 VDC±5%

48 VDC±5%

Standard type Electromagnetic brake type

0.4 A or more

0.5 A or more

1.3 A or more 1.37 A or more

1.72 A or more 1.8 A or more

3.55 A or more 3.8 A or more

3.45 A or more 3.7 A or more

2.85 A or more 3.1 A or more

Pin assignment list

•CN1

Pin No. Signal name Description