Orientalmotor FPW540A2 U, FPW425A2 U, FPW425A2 J, FPW540A2 J, FPW560A2 J Operating Manual

...Page 1

HM-9211-2

OPERATING MANUAL

FPW Series

Dust Resistant, Water Tight Motors

Thank you for purchasing an Oriental Motor product.

This Operating Manual describes product handling procedures and safety

precautions.

・Please read it thoroughly to ensure safe operation.

・Always keep the manual where it is readily available.

(Induction Motors)

Introduction

Before using the motor

Only qualified personnel should work with the product.

Use the product correctly after thoroughly reading the section “Safety

precautions”.

Should you require the inspection or repair of internal parts, contact the

Oriental Motor office where you purchased the product.

The product described in this manual has been designed and

manufactured for use in general industrial machinery, and must not be

used for any other purpose. Oriental Motor Co., Ltd. is not responsible

for any damage caused through failure to observe this warning.

Standard and CE marking

Motors are recognized by UL and certified by CQC. Recognized name

and certified name are motor model name.

Voluntary display of the CE mark conforming to the Low Voltage Directives.

Standards

UL 1004, UL 2111, CSA C22.2 No.100, CSA C22.2 No.77, IEC 60529,

IEC 60034-5, GB 12350

Standards File No.

UL File No.E64197, UL File No.166348 (Degree of protection), CQC

Applications for standard

EN 60034-1, EN 60034-5, IEC 60664-1

Installation conditions

Overvoltage category II, Pollution degree 3, Class I equipment

(For EN/IEC Standards)

When the machinary to which the motor is mounted requires

overvoltage category III specifications, connect to power supply via an

isolation transformer.

Standards for accessories

Capacitor: UL File No.E83671 (CYWT2), VDE License Nos.112847

(capacitors with a rated voltage of 250 VAC),

114747 (capacitors with a rated voltage of 450 VAC)

Capacitor cap: UL File No.E56078 (YDTU2)

Hazardous substances

RoHS (Directive 2002/95/EC 27Jan.2003) compliant

Safety precautions

The precautions described below are intended to prevent danger or

injury to the user and other personnel through safe, correct use of the

product. Use the product only after carefully reading and fully

understanding these instructions.

Note

Handling the product without observing the

instructions that accompany a “Warning” symbol may

result in serious injury or death.

Handling the product without observing the

instructions that accompany a “Caution” symbol may

result in injury or property damage.

The items under this heading contain important

handling instructions that the user should observe to

ensure safe use of the product.

Do not use the product in explosive or corrosive environments,

in the presence of flammable gases, in water, or near

combustibles. Doing so may result in fire, electric shock or

injury.

Assign qualified personnel the task of installing, wiring,

operating/controlling, inspecting and troubleshooting the

product. Failure to do so may result in fire, electric shock or

injury.

Do not transport, install the product, perform connections or

inspections when the power is on. Always turn the power off

before carrying out these operations. Failure to do so may

result in electric shock.

Turn off the power in the event the overheat protection device

(thermal protector) is triggered. Failure to do so may result in

injury or damage to equipment, since the motor will start

abruptly when the overheat protection device (thermal

protector) is automatically reset.

To prevent the risk of electric shock, use the motor for class I

equipment only.

Motore zur Verwendung in Geräten der Schutzklasse I.

When installing the motor, ground the motor using a protective

grounding wire. Failure to do so may result in electric shock.

Erden Sie den Motor bei der Installation mit einem

Schutzerdungskabel. Nichtbeachtung dieses Hinweises könnte einen

elektrischen Schlag verursachen.

If the product is used in a place where it may come in contact

with water during operation, provide an earth leakage breaker.

Failure to do so may result in electric shock.

Keep the input-power voltage within the specification to avoid

fire and electric shock.

Connect the cables securely according to the wiring diagram in

order to prevent fire and electric shock.

Do not forcibly bend, pull or pinch the cables. Doing so may

result in fire and electric shock.

Be sure to insulate the connection terminal of the capacitor.

Failure to do so may result in electric shock.

Turn off the power in the event of a power failure, or the motor

will suddenly start when the power is restored and may cause

injury or damage to equipment.

Do not touch the connection terminal of the capacitor

immediately after the power is turned off (for a period of 30

seconds). The residual voltage may cause electric shock.

Do not disassemble or modify the motor. This may cause

electric shock or injury.

Do not use the motor beyond its specifications, or electric

shock, injury or damage to equipment may result.

Do not touch the motor during operation or immediately after

stopping. The surface is hot and may cause a burn.

Do not hold the motor output shaft or motor cable. This may

cause injury.

Keep the area around the motor free of combustible materials

in order to prevent fire or a burn.

1

Page 2

To prevent the risk of damage to equipment, leave nothing

around the motor that would obstruct ventilation.

To prevent bodily injury, do not touch the rotating parts (output

shaft) of the motor during operation.

When an abnormality is noted, turn off the power immediately,

or fire, electric shock or injury may occur.

The motor’s surface temperature may exceed

70 °C, even under normal operating conditions.

If a motor is accessible during operation, post

the warning label shown in the figure in a

conspicuous position to prevent the risk of

Warning label

burns.

To dispose of the motor, disassemble it into parts and

components as much as possible and dispose of individual

parts/components as industrial waste.

Preparation

Checking the product

Upon opening the package, verify that the items listed below are

included. Report any missing or damaged items to the branch or sales

office from which you purchased the product.

• Motor .................................. 1 unit

• Capacitor............................. 1 piece (only for single-phase motors)

• Capacitor cap ...................... 1 piece (only for single-phase motors)

• Operating manual................ 1 copy

• Set of mounting bolts.......... 1 set

(Mounting screws, Nuts, Washers 4 pieces each, Key 1 piece)

Checking the model name

Check the model number against the number indicated on the product.

● 100 V/110 V/115 V type

Model Motor model Capacitor model

FPW425A2-J FPW425A2- CH80CFAUL2

FPW425A2-U FPW425A2- CH65CFAUL2

FPW540A2-J FPW540A2- CH110CFAUL2

FPW540A2-U FPW540A2- CH90CFAUL2

FPW560A2-J FPW560A2- CH180CFAUL2

FPW560A2-U FPW560A2- CH120CFAUL2

FPW690A2-J FPW690A2- CH250CFAUL2

FPW690A2-U FPW690A2- CH180CFAUL2

● 200 V/220 V/230 V type

Model Motor model Capacitor model

FPW425C2-J FPW425C2- CH20BFAUL

FPW425C2-E FPW425C2- CH15BFAUL

FPW540C2-J FPW540C2- CH30BFAUL

FPW540C2-E FPW540C2- CH23BFAUL

FPW560C2-J FPW560C2- CH40BFAUL

FPW560C2-E FPW560C2- CH30BFAUL

FPW690C2-J FPW690C2- CH60BFAUL

FPW690C2-E FPW690C2- CH45BFAUL

FPW425S2- FPW425S2- -

FPW540S2- FPW540S2- -

FPW560S2- FPW560S2- -

FPW690S2- FPW690S2- -

The gear ratio appears at the model number indicated by the box ().

Installation

Location for installation

Install the motor in a well-ventilated location that provides easy access

for inspection. The location must also satisfy the following conditions:

• Indoors

• Operating ambient temperature

−10 to +40 °C (+14 to +104 °F) (non-freezing)

−10 to +50 °C (+14 to +122 °F) for 100 V/200 V

• Area that is free from an explosive atmosphere or toxic gas (such as

sulfuric gas) or liquid

• Area not exposed to direct sun

• Area free of excessive salt

• Area not subject to continuous vibration or excessive shocks

• Area free of excessive electromagnetic noise (from welders, power

machinery, etc.)

• Area free of radioactive materials, magnetic fields or vacuum

• 1000 m or less above sea level

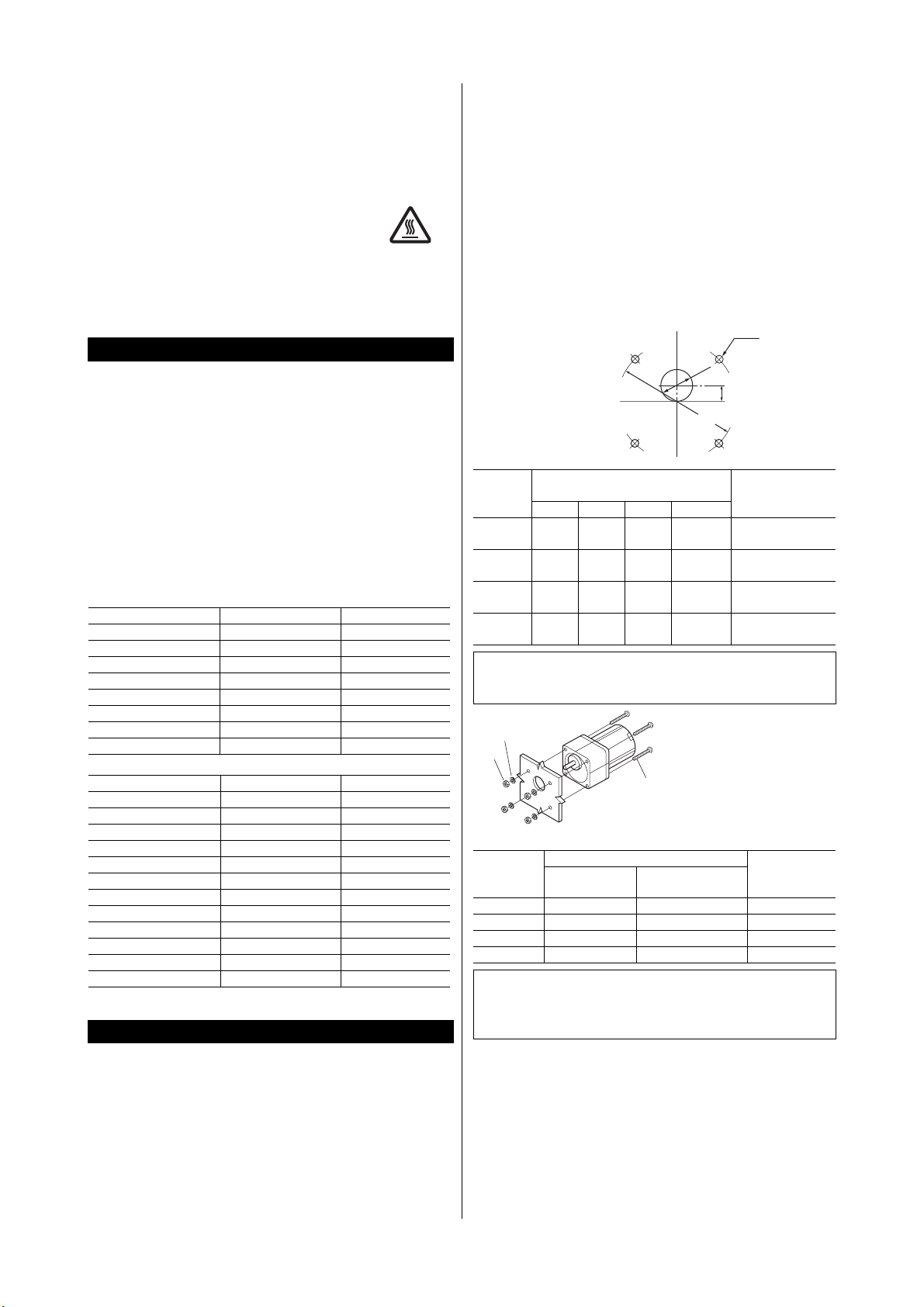

How to install the motor

Drill holes in the mounting plate and fasten the motor to the mounting

plate with screws, nuts, and washers. Be sure that no gaps are left

between the gearhead pilot section of the mounting plate.

The maximum plate thickness applicable when the supplied screws are

used is 10 mm (0.39 in.).

Installation holes

Model

FPW

425

FPW

540

FPW

560

FPW

690

Installation hole dimensions

[mm (in.)]

ØA ØB C 4-ØD

94

(3.70)

104

(4.09)

104

(4.09)

120

(4.72)

34

(1.34)

36

(1.42)

34

(1.34)

42

(1.65)

15

(0.59)

18

(0.71)

18

(0.71)

20

(0.79)

Note

ØB indicates the external dimension of the gearhead boss.

Provide a hole with a sufficient allowance.

Washers

Nuts

Motor

Mounting plate

Screws provided

with motor

Mounting screws

Model

FPW425 M5 P0.8 80 (3.15) 3.8 (33)

FPW540 M6 P1.0 90 (3.54) 6.4 (56)

FPW560 M6 P1.0 90 (3.54) 6.4 (56)

FPW690 M8 P1.25 100 (3.94) 15.5 (137)

Size of mounting screws

Thread size Length [mm (in.)]

Note

Do not disassemble the gearhead from the motor.

Be sure to use the supplied screws and tighten within the

specified torque in order to ensure proper water proof fit.

ØB

ØA

5.5

(0.22)

6.5

(0.26)

6.5

(0.26)

8.5

(0.34)

4-ØD

C

Size of key

[mm (in.)]

4×25

(0.1575×0.984)

4×25

(0.1575×0.984)

5×25

(0.1969×0.984)

6×25

(0.2362×0.984)

Tightening

torque

[N·m (lb-in.)]

2

Page 3

Attaching Load

To shaft of the gearhead has been machined to an outer diameter

tolerance of h7 and is provided with a key slot for connecting the

transmission parts. When connecting the transmission parts, ensure that

the shaft and parts have a clearance fit, and always fix the parallel key to

the output shaft with a screw to prevent the parts from rattling or

spinning.

Note

Do not use excessive force, or hammer the transmission parts

onto the gearmotor shaft as damage may occur.

Mounting the capacitor (only for single-phase motors)

Before mounting the provided capacitor, check

that the capacitor’s capacitance matches that

stated on the motor’s name plate.

Mount the capacitor securely by using M4

screws (not provided).

Ø4.3 mm

(0.169 in.)

Note

Do not let the screw fastening torque exceed 1 N·m (8.8 lb-in)

to prevent damage to the mounting foot.

Mount capacitor at least 10 cm (3.94 in.) away from the

motor. If it is located closer, the life of the capacitor will be

shortened.

Connection and operation

Insulate all the wire connections, such as the connection between the

motor and the capacitor connection.

Ground the motor using a protective grounding wire.

Note

When removing the sheath of the cable, be careful not to

damage the inside lead wire.

Insulation class of this motor is B. Make sure that the motor

case temperature does not exceed 90 °C (194 °F) during

operation of the motor. Operation exceeding case

temperature 90 °C (194 °F) may significantly deteriorate the

coils and ball bearings of the motor and shorten the motor’s

life span. Motor case temperature can be measured by fixing

a thermometer on the motor surface. It can also be

measured using thermo tape or a thermocouple.

To change rotation direction of the single-phase motor, wait

until the motor completely stops. Otherwise its direction may

not change or may take much time to change.

Single-phase motors use a capacitor and keep it connected

even after rotation of the motor has started.

Be sure not to splash water on the cable terminal, otherwise

water could seep inside the motor through the lead wire or

the fabric covering.

Fabric covering

Cable

Keep water from splashing

on this part of the cable

Lead wire

Wiring Diagram

The direction of rotation is as viewed from the side of the motor’s output

shaft. The motor rotates in a clockwise (CW) and counterclockwise

(CCW) direction.

The connection method will vary depending on the gear ratio of the

gearhead.

Motor

25 W

40 W

60 W

90 W

Singlephase

100 V

110 V

115 V

200 V

220 V

230 V

Threephase

200 V

220 V

230 V

type

<Clockwise>

L

N

Capacitor

Green/Yellow

<Counterclockwise>

L

N

Capacitor

Green/Yellow

L1(R)

L2(S)

L3(T)

Green/Yellow

The connection shown in the

figure causes the motor to

rotate clockwise.

To change the direction of

rotation, change any two

connections between R, S

and T.

3 to 18

50 to 180

3 to 9

25 to 60

3 to 9

50 to 180

White

Red

Black

PE

White

Red

Black

PE

Red

White

Black

PE

Motor

CCW

Motor

Motor

Gear ratio

25 to 36

12.5 to 18

75 to 180

12.5 to 36

<Clockwise>

CW

L

N

Capacitor

Green/Yellow

PE

<Counterclockwise>

L

N

Capacitor

Green/Yellow

CW

L1(S)

L2(R)

L3(T)

The connection shown in the

figure causes the motor to

rotate clockwise.

To change the direction of

rotation, change any two

connections between R, S

and T.

PE

Green/Yellow

PE

White

Red

Black

White

Red

Black

Red

White

Black

CW

Motor

CCW

Motor

CW

Motor

A relay box and extension cable for cable are available as an option.

Relay box TB4-0608

Extension cable CC05AC43P (4 wires, 5 m)

CC10AC43P (4 wires, 10 m)

∗ The extension cable has 4-wires; white, gray, black and green/yellow.

When using an extension cable, be sure to connect the red lead wire

of the motor to the gray wire of the cable.

Capacitor connection (only for single-phase motors)

The capacitor internal wiring as follows:

Capacitor terminals are internally electrically connection in twos; A-B and

C-D for easy connection. For

easy to install terminals use

187 series AMP FASTON

terminals (Tyco Electronics

Capacitor cap

AMP).

Use the supplied capacitor cap

to insulate the capacitor

terminal connection.

Capacitor

Note

For lead wire connection, use one lead wire for each individual

terminal.

C

D

A

B

187 series

tab

3

Page 4

r

Time rating

This motor can be operated continuously (continuous rating).

Locked rotor burnout protection

This motor is equipped with the feature listed below to prevent the

motor from burning out as a result of abnormal heating which may be

caused by misapplication.

Thermal protection

“TP” is stamped on the motor nameplate. The motor has an “auto reset”

type thermal protector built into its motor coil. When the motor reaches

a predetermined temperature, the internal thermal protector is activated

and the motor is stopped.

Always turn the power off before performing inspections.

Thermal protector activation range:

Power is turned off at 130±5 °C (266±9 °F)

Power is turned back on at 82±15 °C (180±27 °F)

Troubleshooting

When the motor cannot be operated correctly, refer to the contents

provided in this section and take appropriate action. If the problem

persists, contact your nearest office.

Phenomena Check items

The motor does

not rotate.

Motor sometimes

rotates and stops.

The motor rotates

in the direction

opposite to the

specified direction.

Motor temperature

abnormally high

[Motor case

temperature

exceeds 90 °C

(194 °F)]

• Check the power supply voltage.

• Connect the power supply and the motor

correctly.

• With a single-phase motor, connect the

supplied capacitor correctly.

• If terminal blocks or crimp terminals are used,

check them for poor connection.

• Keep the load at or below the allowable value.

• Connect the power supply and the motor

correctly.

• With a single-phase motor, connect the

supplied capacitor correctly.

• If terminal blocks or crimp terminals are used,

check them for poor connection.

• Connect correctly by referring to “Wiring

diagram.”

• With a single-phase motor, connect the

supplied capacitor correctly.

• The rotating direction of the motor output shaft

may be different from that of the gearhead

output shaft depending on the gear ratio of the

gearhead. Connect correctly by referring to

“Wiring diagram.”

• The rotating direction is indicated as viewed

from the motor output shaft. Check the

reference direction.

• Check the power supply voltage.

• With a single-phase motor, connect the

supplied capacitor correctly.

• Review the ventilation condition.

• Unauthorized reproduction or copying of all or part of this manual is

prohibited.

• Oriental Motor shall not be liable whatsoever for any problems

relating to industrial property rights arising from use of any

information, circuit, equipment or device provided or referenced in

this manual.

• Characteristics, specifications and dimensions are subject to change

without notice.

• While we make every effort to offer accurate information in the

manual, we welcome your input. Should you find unclear

descriptions, errors or omissions, please contact the nearest office.

• is a registered trademark or trademark of

Oriental Motor Co., Ltd., in Japan and other countries.

© Copyright ORIENTAL MOTOR CO., LTD. 2007

• Please contact your nearest Oriental Motor office for further information.

Technical Support Tel:(800)468-3982

A.M.

to 5:00

P.M .

8:30

A.M.

to 5:00

7:30

E-mail: techsupport@orientalmotor.com

www.orientalmotor.com

Headquarters and Düsseldorf Office Tel:0211-52067-00 Fax:0211-52067-099

Munich Office Tel:089-3181225-00 Fax:089-3181225-25

Hamburg Office Tel:040-76910443 Fax:040-76910445

, P.S.T. (M-F)

P.M .

, C.S.T. (M-F)

Tel:01256-347090 Fax:01256-347099

Tel:02-93906346 Fax:02-93906348

Tel:(6745)7344 Fax:(6745)9405

Tel:(03)22875778 Fax:(03)22875528

Tel:66-2-254-6113 Fax:66-2-254-6114

KOREA

Tel:(032)822-2042~3 Fax:(032)819-8745

Tel:01 47 86 97 50 Fax:01 47 82 45 16

Tel:(02)8228-0707 Fax:(02)8228-0708

Headquarters Tokyo, Japan

Tel:(03)3835-0684 Fax:(03)3835-1890

Printed on Recycled Pape

4

Loading...

Loading...