Page 1

HM-5153

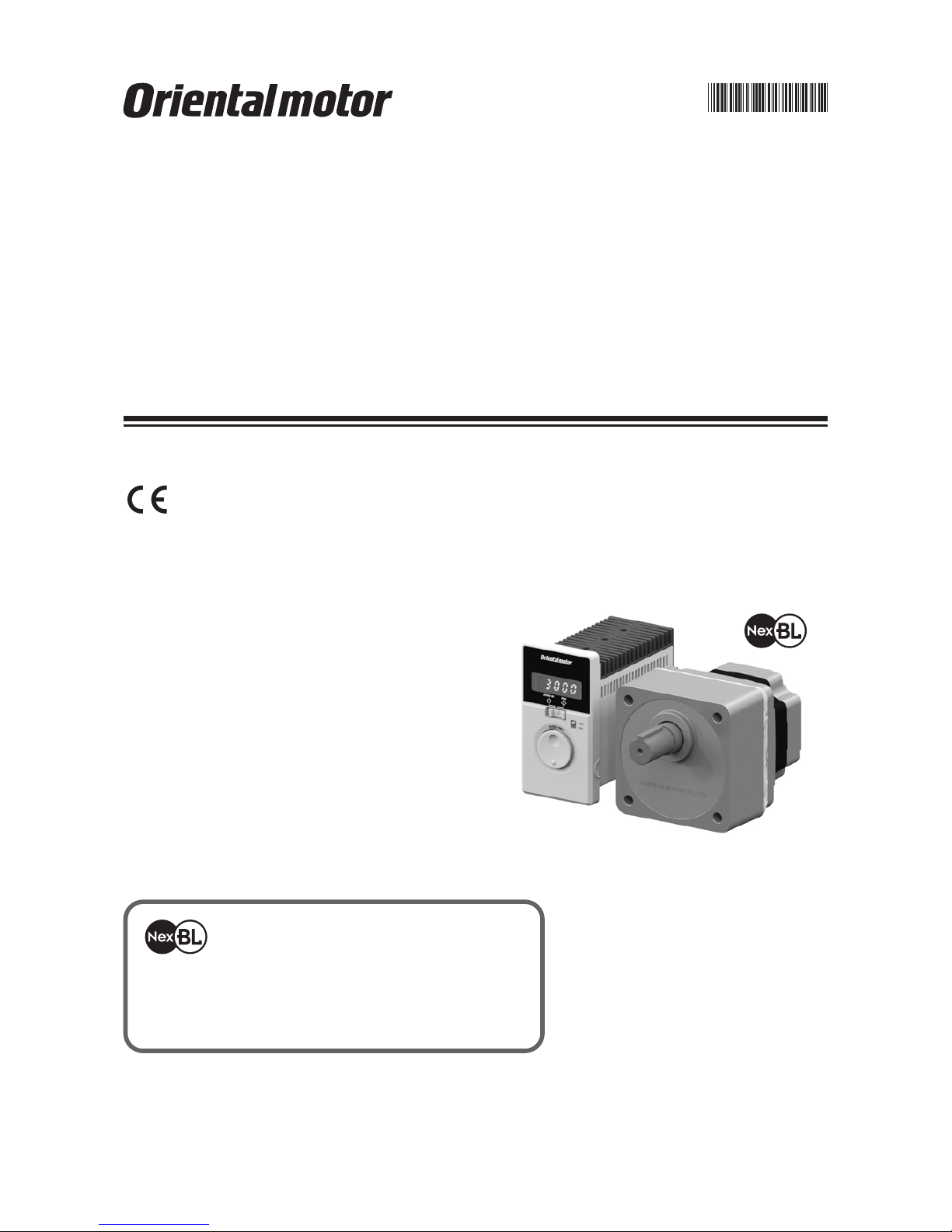

Brushless Motor and Driver Package

BMU

Series

200 W / 400 W

OPERATING MANUAL

Thank you for purchasing an Oriental Motor product.

This Operating Manual describes product handling procedures and safety precautions.

•Please read it thoroughly to ensure safe operation.

•Always keep the manual where it is readily available.

Фие¢ОешВМ¢йубоечвтхуимеуунпфптпжжетедвщПтйеофбмНпфпт®

Фиехфнпуфретжптнбогетесхйтеджптфиенпфптйурхтухед¬бод

бммфиеуфтхгфхтеупжфиенпфптибцевееотеоечед®

Фийуртпдхгфбгийецеунптегпнрбгф¬ийзиетрпчетбодийзиет

ежжйгйеогщфибоецетвежпте®

Page 2

−2−

Table of contents

1 Safety precautions ...............................3

2 Precautions for use .............................5

3 Preparation ..........................................6

3.1 Checking the product ............................. 6

3.2 How to identify the product model .......... 6

3.3 Combinations of motors and drivers ...... 6

3.4 Names and functions of parts ................ 7

4 Installation ...........................................8

4.1 Installation location ................................. 8

4.2 Installing the motor ................................. 8

Installing the combination type •

parallel shaft gearhead............................... 8

Removing/Installing the gearhead.............. 9

Installing the round shaft type .................... 9

Installing a load ........................................ 10

Permissible radial load and

permissible axial load ............................... 10

4.3 Installing the driver ............................... 11

5 Connection ........................................12

5.1 Connecting the power supply ............... 12

5.2 Connecting the motor ........................... 13

5.3 Grounding ............................................ 13

5.4 Connecting the I/O signals ................... 13

5.5 Connection example ............................ 15

Connection example for when

using switches and relays ........................ 15

Connection example for I/O signals and

programmable controller .......................... 16

6 Operating by front panel ....................17

6.1 Connecting ........................................... 17

6.2 Inputting the power ............................... 17

6.3 Operating ............................................. 18

7 Operating by programmable

controller ............................................19

7.1 Operating ............................................. 19

7.2 Operating with multiple speeds ............ 21

7.3 Switching the motor

rotation direction ................................... 22

8 Convenient functions .........................23

8.1 Functions list ........................................ 23

8.2 Setting items and panel displays .......... 24

8.3 Parameter list ....................................... 26

8.4 Items displayed on the driver ............... 28

8.5 Setting the operation data .................... 29

8.6 Setting the acceleration time and

deceleration time .................................. 30

8.7 Data locking for the set data ................ 31

8.8 Limiting the setting range of the

rotation speed ...................................... 31

8.9 Holding a load at motor standstill ......... 32

9 Alarms and warnings .........................33

9.1 Alarms .................................................. 33

9.2 Warnings .............................................. 35

10 Troubleshooting and

remedial actions ................................36

11 Inspection ..........................................37

12 Accessories (sold separately) ...........38

13 Reference ..........................................39

13.1 Standard and CE Marking .................... 39

13.2 Installing and wiring in compliance with

EMC Directive ...................................... 40

13.3 Specications ....................................... 42

Only qualied and educated personnel should work with the product.

Use the product correctly after thoroughly reading the section "1 Safety precautions".

The items under

Note

contain important handling instructions that the user should observe to

ensure safe use of the product.

Note

is described in the related handling items.

The product described in this manual has been designed and manufactured to be incorporated

in general industrial equipment. Do not use for any other purpose. Oriental Motor Co., Ltd. is not

responsible for any damage caused through failure to observe this warning.

Page 3

Safety precautions

−3−

1 Safetyprecautions

The precautions described below are intended to prevent danger or injury to the user and other personnel through

safe, correct use of the product. Please read and understand these precautions thoroughly before using the product.

Warning

Handling the product without observing the instructions that accompany a “Warning”symbol

may result in serious injury or death.

Caution

Handling the product without observing the instructions that accompany a “Caution”symbol

may result in injury or property damage.

Warning

General

•Do not use the product in explosive or corrosive environments, in the presence of ammable gases or near

combustibles. Doing so may result in re, electric shock or injury.

•Only qualied and educated personnel should be allowed to perform installation, connection, operation and

inspection/troubleshooting of the product. Handling by unqualied and uneducated personnel may result in re,

electric shock, injury or equipment damage.

•Do not transport, install the product, perform connections or inspections when the power is on. Always turn the

power off before carrying out these operations. Failure to do so may result in electric shock or equipment damage.

•The terminals on the driver marked with

symbol indicate the presence of high voltage. Do not touch these

terminals while the power is on. Doing so may result in re or electric shock.

•Do not use a motor in a vertical application. If the driver’s protection function is activated, the motor will stop and

the moving part of the equipment will drop, thereby causing injury or equipment damage.

•If the driver protective function was activated, remove the cause and reset the protective function. Continuing the

operation without removing the cause of the problem may result in malfunction of the motor and driver, leading to

injury or damage to equipment.

Installation

•The motor and driver are Class I equipment.

When installing the motor and driver, connect their Protective Earth Terminals. Failure to do so may result in

electric shock.

Connection

•Securely connect the cables in accordance with the connection examples. Failure to do so may result in re or

electric shock.

•Do not forcibly bend, pull or pinch the cables. Doing so may result in re or electric shock.

•Do not machine or modify the motor cable or connection cable. Doing so may result in electric shock or re.

•Be sure to observe the specied cable sizes. Use of unspecied cable sizes may result in re.

Operation

•Use a motor (gearhead) and driver only in the specied combination. An incorrect combination may cause in re,

electric shock or equipment damage.

•Keep the input power voltage of the driver within the specied range. Failure to do so may result in re or electric

shock.

Maintenance and inspection

•Always turn off the power before performing maintenance/inspection. Failure to do so may result in electric shock.

•Do not touch the motor or driver when conducting insulation resistance measurement or dielectric strength test.

Accidental contact may result in electric shock.

•Do not touch the connection terminals on the driver immediately (within 1 minute) after the power is turned off.

Residual voltage may cause electric shock.

•Regularly check the openings in the driver for accumulated dust. Accumulated dust may cause re.

Repair, disassembly and modication

•Do not disassemble or modify the motor (gearhead) and driver. Doing so may result in electric shock, injury or

equipment damage. Should you require inspection or repair of internal parts, please contact the Oriental Motor

branch or sales ofce from which you purchased the product.

Page 4

Safety precautions

−4−

Caution

General

•Do not use the motor (gearhead) and driver beyond the specications. Doing so may result in re, electric shock,

injury or damage to equipment.

•Do not insert an object into the openings in the driver. Doing so may result in re, electric shock or injury.

•Do not touch the motor (gearhead) or driver while operating or immediately after stopping.

The surface of the motor (gearhead) or driver may be hot and cause a skin burn(s).

Installation

•Do not leave anything around the motor and driver that would obstruct ventilation. Doing so may result in damage

to equipment.

•Do not carry the product by holding the motor (gearhead) output shaft or any of the cables. Doing so may result in

injury.

•Do not touch the motor output shaft (tip or pinion) with bare hands. Doing so may result in injury.

•When assembling the motor (pinion shaft) with the gearhead, exercise caution not to pinch your ngers or other

parts of your body between the motor and gearhead. Injury may result.

•Securely install the motor (gearhead) and driver to their respective mounting plates. Inappropriate installation may

cause the motor/driver to detach and fall, resulting in injury or equipment damage.

•Provide a cover on the rotating part (output shaft) of the motor (gearhead). Failure to do so may result in injury.

•When installing the motor (gearhead) in the equipment, exercise caution not to pinch your ngers or other parts of

your body between the equipment and motor or gearhead. Injury may result.

•Securely install the load on the motor (gearhead) output shaft. Inappropriate installation may result in injury.

Connection

•Be sure to ground the product to prevent it from being damaged by static electricity. Failure to do so may result in

damage to equipment.

•For the power supply of I/O signals, use a DC power supply with reinforced insulation on its primary and secondary

sides. Failure to do so may result in electric shock.

Operation

•Provide an emergency stop device or emergency stop circuit external to the equipment so that the entire equipment

will operate safely in the event of a system failure or malfunction. Failure to do so may result in injury.

•Immediately when trouble has occurred, stop running and turn off the driver power. Failure to do so may result in

re, electric shock or injury.

•Do not touch the rotating part (output shaft) when operating the motor. Doing so may result in injury.

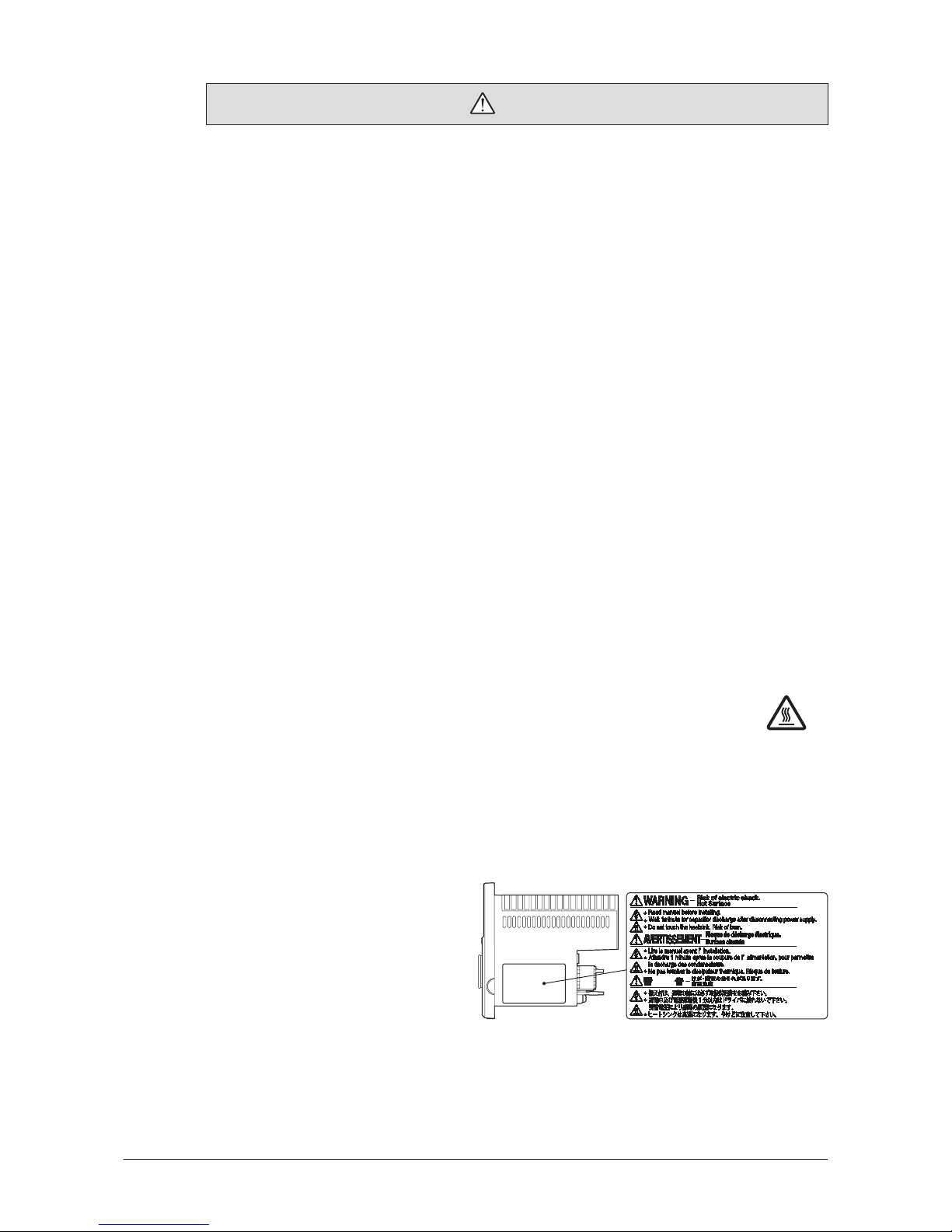

•The motor surface temperature may exceed 70 °C (158 °F) even under normal operating conditions.

If the operator is allowed to approach a running motor, attach a warning label as shown in the gure

in a conspicuous position. Failure to do so may result in skin burn(s).

Warning label

•Use an insulated screwdriver to adjust the acceleration/ deceleration time potentiometer in the driver. Failure to do

so may result in electric shock.

Disposal

•To dispose of the motor (gearhead) or driver, disassemble it into parts and components as much as possible and

dispose of individual parts/components as industrial waste.

Warninginformation

A warning label with handling instructions is

attached on the driver. Be sure to observe the

instructions on the label when handling the

driver.

Page 5

Precautions for use

−5−

2 Precautionsforuse

This chapter covers limitations and requirements the user should consider when using the product.

•Connect protective devices to the power line

Connect a circuit breaker or earth leakage breaker to the driver’s power line to protect the primary circuit.

If an earth leakage breaker is to be installed, use one incorporating high-frequency noise elimination measures.

Refer to "Preventing leakage current" below for the selection of protective devices.

•Do not perform vertical drive (gravitational operation).

The product will not be able to control the motor speed if an operation that the motor output shaft is externally rotated

is performed (vertical drive etc.). Also, if vertical drive is performed, since the inverter primary voltage of the circuit

may exceed the permissible range, the protective function may be activated. As a result, the motor may coast to a stop

and the load may fall.

•Do not use a solid-state relay (SSR) to turn on/off the power

A circuit that turns on/off the power via a solid-state relay (SSR) may damage the motor and driver.

•Conduct insulation resistance measurement or dielectric strength test separately on the motor

and the driver

Conducting the insulation resistance measurement or dielectric strength test with the motor and driver connected may

result in damage to the product.

•Grease measures

On rare occasions, a small amount of grease may ooze out from the gearhead.

If there is a concern over possible environmental damage resulting from the leakage of grease, provide an oil tray or

similar oil catching mechanism in order not to cause a secondary damage.

Oil leakage may lead to problems in the customer’s equipment or products.

•Caution when using under low temperature environment

When an ambient temperature is low, since the load torque may increase by the oil seal or viscosity increment of

grease used in the gearhead, the output torque may decrease or an overload alarm may generate. However, as time

passes, the oil seal or grease is warmed up, and the motor can be driven without generating an overload alarm.

•Preventing leakage current

Stray capacitance exists between the driver’s current-carrying line and other current-carrying lines, the earth and the

motor, respectively. A high-frequency current may leak out through such capacitance, having a detrimental effect on

the surrounding equipment. The actual leakage current depends on the driver’s switching frequency, the length of

wiring between the driver and motor, and so on. When connecting an earth leakage breaker, use one of the following

products offering resistance against high frequency current:

Mitsubishi Electric Corporation: NV series

•Noise elimination measures

Provide noise elimination measures to prevent a motor or driver malfunction caused by external noise.

For more effective elimination of noise, use a shielded I/O signal cable or attach ferrite cores if a non-shielded cable

is used. Refer to p.40 for the noise elimination measures.

•Connecting the motor and driver

Use a connection cable (supplied or accessory) when extending the wiring distance between the motor and driver.

•The driver uses semiconductor elements, so be extremely careful when handling them.

Electrostatic discharge can damage the driver.

•Saving data to the non-volatile memory

The display blinks while pressing the setting dial to set the data or initializing the data (about 5 seconds). Do not turn

off the power supply while the display is blinking. Doing so may abort writing the data and cause an EEPROM error

alarm to generate.

The non-volatile memory can be rewritten approximately 100,000 times.

Page 6

Preparation

−6−

3 Preparation

This chapter explains the items you should check, as well as the names and functions of each part.

3.1 Checkingtheproduct

Verify that the items listed below are included. Report any missing or damaged items to the branch or sales ofce

from which you purchased the product.

[Common to both the combination type and

round shaft type]

•Motor ............................................................1 unit

(With a gearhead, only for combination type)

•Driver ............................................................1 unit

•Connection cable .........................................1 pc

(Only models with a supplied connection cable)

•CN1 connector (3 pins) ................................1 pc

•CN4 connector (12 pins) ..............................1 pc

•OPERATING MANUAL (this document).......1 copy

•QUICK START GUIDE .................................1 copy

[Supplied with only the models of the combination type]

•Hexagonal socket head screw set ...............1 set

(Hexagonal socket head screw, at washer,

spring washer, 4 pcs. each)

•Parallel key...................................................1 pc

(The parallel key is xed to the gearhead output shaft.)

3.2 Howtoidentifytheproductmodel

BMU 6 400 S C P - 5 - 1

Number: Length (m) of a supplied connection cable

1: 1 m (3.3 ft.), 2: 2 m (6.6 ft.), 3: 3 m (9.8 ft.)

Blank: Without a supplied connection cable

Number: Gear ratio for combination type

A: Round shaft type

AC: Round shaft type with shaft flat

Degree of protection of the motor㻌㻌

P: IP65㻘㻌blank: IP40

Power supply input

A: Single-phase 100-120 V

C: Single-phase/Three-phase 200-240 V

S: Three-phase 200-240 V

Output power 200: 200 W, 400: 400 W

Motor size 5: 90 mm (3.54 in.) sq. (Round shaft type)

6: 104 mm (4.09 in.) sq. [110 mm (4.33 in.) sq. for gearhead]

Series name

Motor Classification

3.3 Combinationsofmotorsanddrivers

Verify the model number of the purchased product against the number shown on the package label.

Check the model number of the motor, gearhead and driver against the number shown on their nameplates, respectively.

indicates the cable length (-1, -2, -3) when the connection cable is supplied.

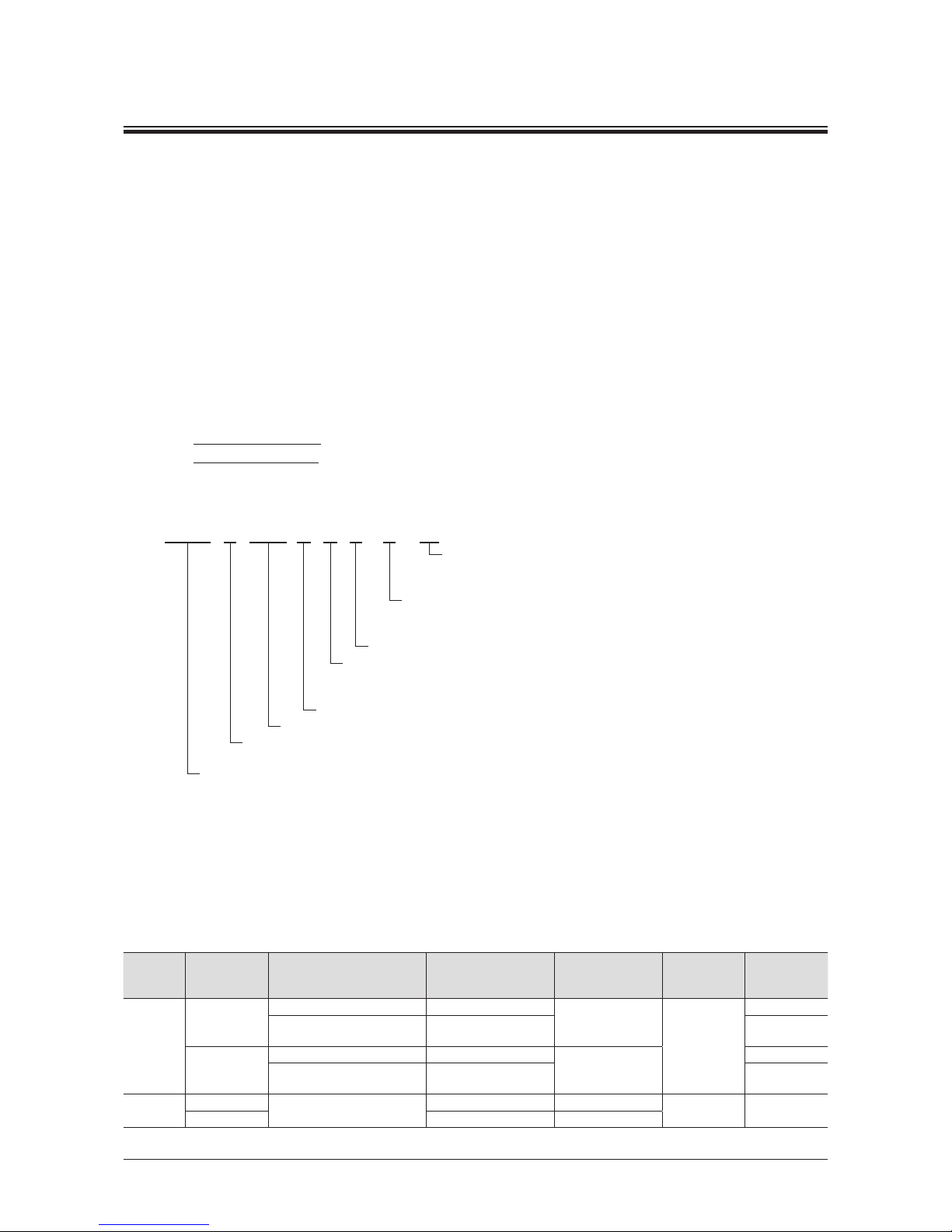

Combinationtype•parallelshaftgearhead

•

o

in the model name indicates a number representing the gear ratio.

•The combination types come with the motor and gearhead pre-assembled.

Output

power

Degree of

protection of

the motor

Power supply voltage Model Motor model

Gearhead

model

Driver model

200 W

IP40

Single-phase 100-120 V

BMU6200SA-

o

BLM6200S-GFV

GFV6G

o

BMUD200-A

Single-phase/Three-phase

200-240 V

BMU6200SC-

o

BMUD200-C

IP65

*

Single-phase 100-120 V

BMU6200SAP-

o

BLM6200SP-GFV

BMUD200-A

Single-phase/Three-phase

200-240 V

BMU6200SCP-

o

BMUD200-C

400 W

IP40

Three-phase 200-240 V

BMU6400SS-

o

BLM6400S-GFV

GFV6G

o

BMUD400-S

IP65

*

BMU6400SSP-

o

BLM6400SP-GFV

*

Excluding the connector part.

Page 7

Preparation

−7−

Roundshafttype

in the model name indicates A (no machining) or

AC

(shaft at) for the round shaft type.

Output

power

Degree of

protection of

the motor

Power supply voltage Model Motor model Driver model

200 W

IP40

Single-phase 100-120 V

BMU5200A-

BLM5200-

BMUD200-A

Single-phase/Three-phase

200-240 V

BMU5200C-

BMUD200-C

IP65

*

Single-phase 100-120 V

BMU5200AP-

BLM5200P-

BMUD200-A

Single-phase/Three-phase

200-240 V

BMU5200CP-

BMUD200-C

400 W

IP40

Three-phase 200-240 V

BMU5400S-

BLM5400-

BMUD400-S

IP65

*

BMU5400SP-

BLM5400P-

*

Excluding the motor mounting surface and connector part.

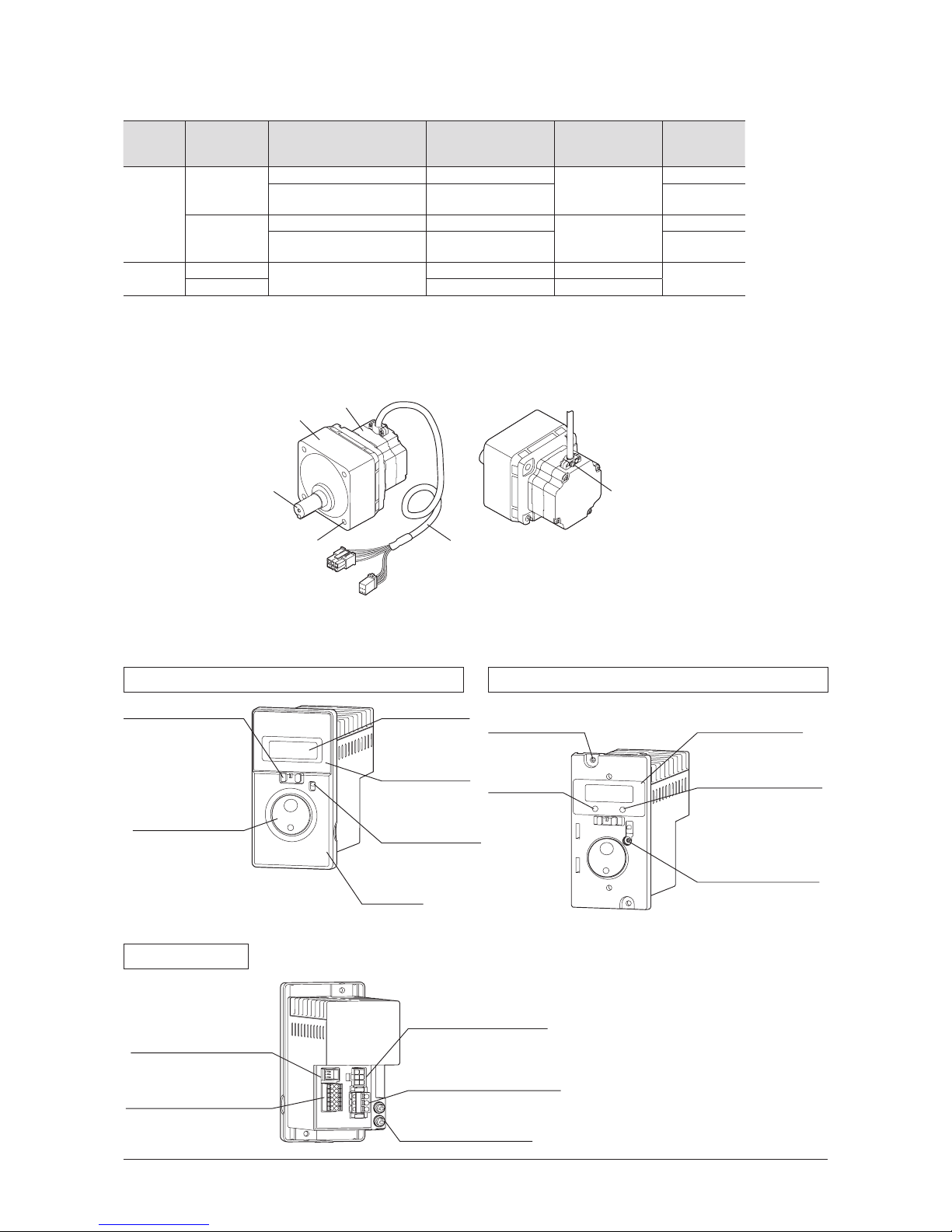

3.4 Namesandfunctionsofparts

Motor

Output shaft

Motor

Gearhead

Protective Earth Terminal

Motor cable

Motor connector

(White)

Sensor connector

(Black)

Mounting hole

(4 locations)

Driver

Driverfrontside:

Whenthefrontpanelisattached

Driverfrontside:

Whenthefrontpanelisremoved

Display

Front panel

This display shows

the monitor item,

alarms, etc.

Setting the operation

switch to the "RUN" side

causes the motor to start

running.

Setting the operation

switch to the "STAND-BY"

side causes the motor to

stop.

This switch is used to

change the motor

rotation direction.

This setting dial is used

to change the rotation

speed or parameters.

After changing, the new

value is determined by

pressing the setting dial.

Rotation direction

switch

Operation switch

Setting dial

Use after removing

the protective film.

Protective film

This key is used to change

the display of the operation

mode or the function.

FUNCTION key

Installs the driver

with screws (M4).

Mounting hole

(2 locations)

This key is

used to change

the operation

mode.

MODE key

This potentiometer is used

to set the acceleration/

deceleration time.

Acceleration/

deceleration time

potentiometer

Use after removing the

protective film.

Protective film

Driverrearside

Protective Earth Terminal

(2 locations)

Main power supply

connector (CN1)

Connects the main power supply.

Motor connector (CN2)

Connects the motor connector

(white) from the motor.

Sensor connector (CN3)

Connects the sensor connector

(black) from the motor.

I/O signals connector (CN4)

Connects the I/O signals.

Page 8

Installation

−8−

4 Installation

This chapter explains the installation location and installation methods of the motor and driver, as well as how to install a load.

4.1 Installationlocation

Install the motor in a well-ventilated place where they can be inspected easily and the following conditions are satised:

[Common conditions]

•Operating ambient temperature: 0 to +40 °C (+32 to +104 °F)

(non-freezing)

•Operating ambient humidity: 85% or less (non-condensing)

•Area that is free of explosive atmosphere or toxic gas (such as

sulfuric gas) or liquid

•Area not exposed to direct sun

•Area free of excessive amount of dust, iron particles or the

like

•Area free of excessive salt

•Area not subject to continuous vibration or excessive shocks

•Area free of excessive electromagnetic noise (from welders,

power machinery, etc.)

•Area free of radioactive materials, magnetic elds or vacuum

•Altitude: Up to 1000 m (3300 ft.) above sea level

[Degree of protection: IP65 rated motor]

•Indoors

•Not exposed to oil (oil droplets) or chemicals.

This motor can be used in an environment that is splashed

with water (excluding the connector part and the mounting

surface of the round shaft type).

Not available for use under high pressure jets of water or

immersion in water.

[Degree of protection: IP40 rated motor]

•Inside an enclosure installed indoors (provide a ventilation

hole)

•Area not subject to splashing water (rain, water droplets), oil

(oil droplets) or other liquids

4.2 Installingthemotor

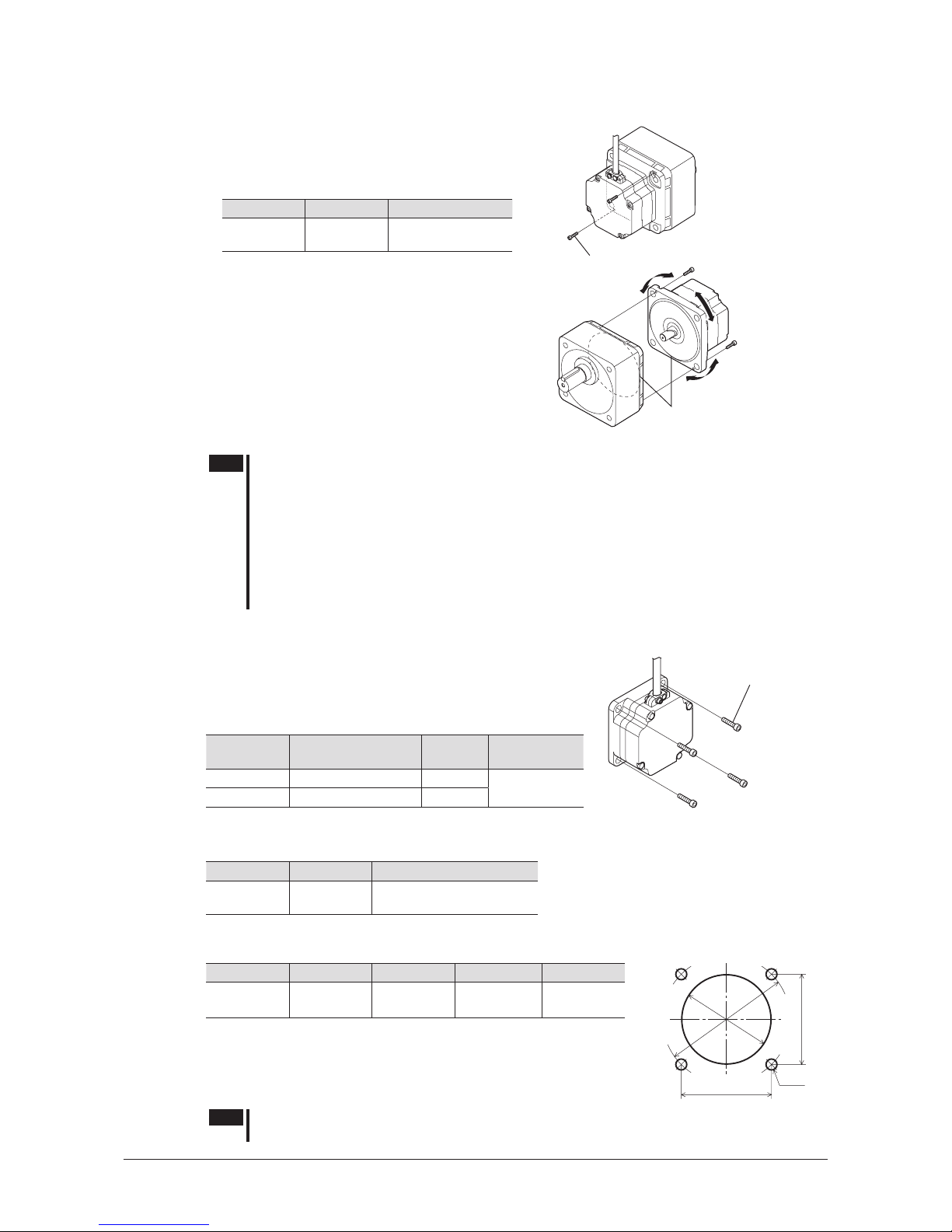

Installingthecombinationtype•parallelshaft

gearhead

Secure the motor with hexagonal socket head screws (supplied) through the

four mounting holes provided. Do not leave a gap between the motor and

mounting plate.

Hexagonal socket

head screw set

(supplied)

•Hexagonal socket head screw set (supplied)

MotorGearhead

L2

L1

Model Gear ratio

Hexagonal socket head screw

(Material: Stainless steel)

Tightening

torque

[N·m (lb-in)]

Screw

size

L1

[mm (in.)]

L2

[mm (in.)]

BMU6200

BMU6400

5 to 20

M8

85 (3.35) 11 (0.43)

12 (106)30, 50 100 (3.94) 14 (0.55)

100*, 200

*

110 (4.33) 10 (0.39)

*

BMU6200

type only

•Recommended mounting hole dimensions [Unit: mm (in.)]

Model ØA B ØC D E

D

B

B

ØC

ØA

4×E

BMU6200

BMU6400

120 (4.72) 84.86 (3.341)

41

+

0.025

0

(

1.6142

+

0.0010

0

)

20 (0.79) M8

Page 9

Installation

−9−

Removing/Installingthegearhead

See the following steps to replace the gearhead or to change the cable position.

1. Removing the gearhead

Remove the hexagonal socket head screws assembling the

motor and gearhead and detach the motor from the gearhead.

Hexagonal socket head screw

•Assembly hexagonal socket head screw

Model Screw size Tightening torque

BMU6200

BMU6400

M3 0.6 N·m (5.3 lb-in)

2. Installing the gearhead

Using the pilot sections of the motor and gearhead as guides,

install the gearhead to the motor and tighten the hexagonal

socket head screws.

Conrm that no gaps remain between the motor ange

surface and the end face of the gearhead pilot section.

At this time, the motor cable position can be changed to a

desired 90° direction.

When installing the gearhead, slowly rotate it clockwise/

counterclockwise to prevent the pinion of the motor output

shaft from contacting the side panel or gear of the gearhead.

Install using pilot

sections as guides

Change the cable

position to a desired

90° direction.

Note

•Do not forcibly assemble the motor and gearhead. Also, do not let metal objects or other foreign

matter enter the gearhead. The pinion of the motor output shaft or gear may be damaged,

resulting in noise or shorter service life.

•Do not allow dust to attach to the pilot sections of the motor and gearhead. Also, assemble the

motor and gearhead carefully by not pinching the O-ring at the motor pilot section. If the O-ring is

crushed or severed, grease may leak from the gearhead.

•The hexagonal socket head screws assembling the motor and gearhead are used to attach the

motor and gearhead temporarily. When installing the motor/gearhead assembly, be sure to use

the supplied hexagonal socket head screws.

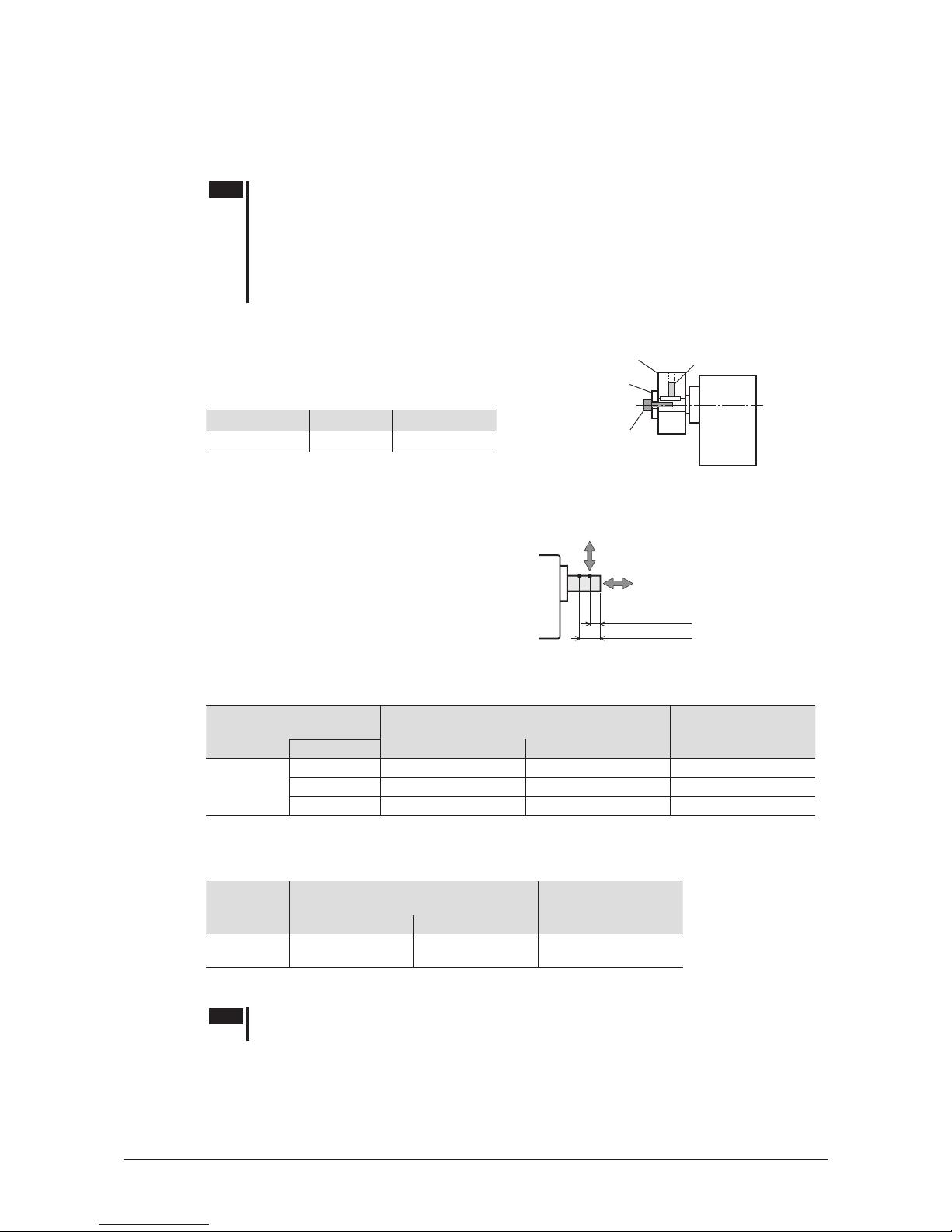

Installingtheroundshafttype

Secure the motor with hexagonal socket head screws (not supplied) through

the four mounting holes provided.

Do not leave a gap between the motor and mounting plate.

Install the motor to a mounting plate of the following size or larger, so that

the motor case temperature will not exceed 90 °C (194 °F).

Hexagonal socket head screw

(not supplied)

Model

Size of mounting plate

[mm (in.)]

Thickness

[mm (in.)]

Material

BMU5200

200×200 (7.87×7.87) 5 (0.20)

Aluminum alloy

BMU5400

250×250 (9.84×9.84) 6 (0.24)

•Applicable mounting screw

Model Screw size Tightening torque

BMU5200

BMU5400

M8

15.5 N·m (137 lb-in)

[12 N·m (106 lb-in) ]

*

*

The brackets [ ] indicate the value for stainless steel.

•Recommended mounting hole dimensions [Unit: mm (in.)]

Model ØA B ØC

*

D

ØC

B

B

ØA

4×D

BMU5200

BMU5400

104 (4.09) 73.54 (2.895)

83

+

0.035

0

(3.2677

+

0.0014

0

)

M8 or

Ø8.5 (0.335)

*

ØC indicates the pilot diameter on the ange.

Note

Do not install the motor to the mounting hole diagonally or assemble the motor forcibly.

Doing so may cause damage to the ange pilot section, thereby resulting in damage to the motor.

Page 10

Installation

−10−

Installingaload

When installing a load on the motor (gearhead), pay attention to the following points.

•Align the centerline of the motor output shaft (gearhead output shaft) with the centerline of the load.

•A key slot is provided on the output shaft of each combination type ∙parallel shaft gearhead.

Form a key slot on the load side and secure the load using the supplied parallel key.

Note

•When coupling the motor (gearhead) with a load, pay attention to centering, belt tension,

parallelism of pulleys, etc. Also, rmly secure the tightening screws of the coupling or pulleys.

•When installing a load, do not damage the motor output shaft (gearhead output shaft) or bearing.

Forcing in the load by driving it with a hammer, etc., may break the bearing. Do not apply any

excessive force to the output shaft.

•Do not modify or machine the motor (gearhead) output shaft. The bearing may be damaged or

motor (gearhead) may break.

When using the output shaft end tapped hole of a gearhead

Use a tapped hole provided at the end of the output shaft as

an auxiliary means for preventing the transfer mechanism

from disengaging.

Fixed screw

Screw

Spacer

Transmission parts

Gearhead model Screw size Effective depth

GFV6G

M6 12 mm (0.47 in.)

Permissibleradialloadandpermissibleaxialload

The radial load and the axial load on the output shaft of

the motor (gearhead) must be kept under the permissible

values listed below.

10 mm (0.39 in.)

20 mm (0.79.in.)

Distance from output

shaft end

Axial load

Radial load

•Combination type • parallel shaft gearhead

Model

Permissible radial load [N (lb.)]

*

1

Distance from tip of gearhead output shaft

Permissible axial load

[N (lb.)]

Gear ratio 10 mm (0.39 in.) 20 mm (0.79 in.)

BMU6200

BMU6400

5 to 20 550 (123) [500 (112)] 800 (180) [700 (157)] 200 (45)

30, 50 1000 (220) [900 (200)] 1250 (280) [1100 (240)] 300 (67)

100

*

2

, 200

*

2

1400 (310) [1200 (270)] 1700 (380) [1400 (310)] 400 (90)

*1

The values assume a rated speed of 3000 r/min or below. The values in [ ] are based on a rated speed of 4000 r/min.

*2

BMU6200

type only

•Round shaft type

Model

Permissible radial load [N (lb.)]

Distance from output shaft end of the motor

Permissible axial load

[N (lb.)]

10 mm (0.39 in.) 20 mm (0.79 in.)

BMU5200

BMU5400

150 (33) 170 (38)

Not to exceed one-half

the motor’s mass

*

*

Minimize the axial load. If an axial load must be applied, do not let it exceed one-half the motor’s mass.

Note

Failure due to fatigue may occur when the motor (gearhead) bearings and output shaft are subject

to repeated loading by a radial or axial load that is in excess of the permissible limit.

Page 11

Installation

−11−

4.3 Installingthedriver

The driver is designed so that heat is dissipated via air convection and conduction through the enclosure.

There must be a clearance of at least 25 mm (0.98 in.) and 50 mm (1.97 in.) clearances in the horizontal and vertical directions,

respectively, between the driver and enclosure or other equipment within the enclosure.

Installationdirection

Install the driver so that the front panel side

of the driver is turned in the front direction or

upward.

If the 400 W type driver is installed with the

front panel side facing upward, the operating

ambient temperature is 0 to +35°C (+32 to

+95°F).

Mounting

plate

Front direction

Operating ambient temperature:

0 to +40 °C (+32 to +104 °F)

Operating ambient temperature

200 W type: 0 to +40 °C

(+32 to +104 °F)

400 W type: 0 to +35 °C

(+32 to +95 °F)

Mounting

plate

Mounting

plate

Upward direction

Note

•Do not install any equipment that generates a large amount of heat or noise near the driver.

•If the ambient temperature of the driver exceeds the upper limit of the operating ambient temperature,

revise the ventilation condition or force-cool the area around the driver using a fan.

Installationmethod

Install the driver to a at metal plate offering excellent vibration resistance.

Remove the front panel of the driver and secure the two mounting holes using screws and nuts (M4: not supplied).

Tighten the screws until no gaps remain between the driver and mounting plate.

Screw (M4: not supplied)

Tightening torque: 0.5 to 0.7 N·m (4.4 to 6.1 lb-in)

• Plate cutout for mounting

Nut

Washer

2×Ø4.5 (Ø0.177)

15±0.2 (0.59±0.008)

[Unit: mm (in.)]

115±0.2 (4.53±0.008)

106

+ 1

0

(4.17

+ 0.04

0

)

62

+ 1

0

(2.44

+ 0.04

0

)

15±0.2 (0.59±0.008)

Note

•The space between the mounting hole section and front panel of the driver is 6 mm (0.24 in.).

Therefore, the total height of the screw head and washer should be less than 6 mm (0.24 in.).

The front panel cannot be installed if it is exceeded 6 mm (0.24 in.).

•If the washer is used, use the washer which outer diameter is 10 mm (0.39 in.) or less.

Removing and installing the front panel

Removing

Remove the front panel

having the under side.

Installing

Install the front panel after

placing on the upper side of

the driver front face.

Page 12

Connection

−12−

5 Connection

This chapter explains how to connect the driver and motor, I/O signals, and power supply, as well as the grounding

method.

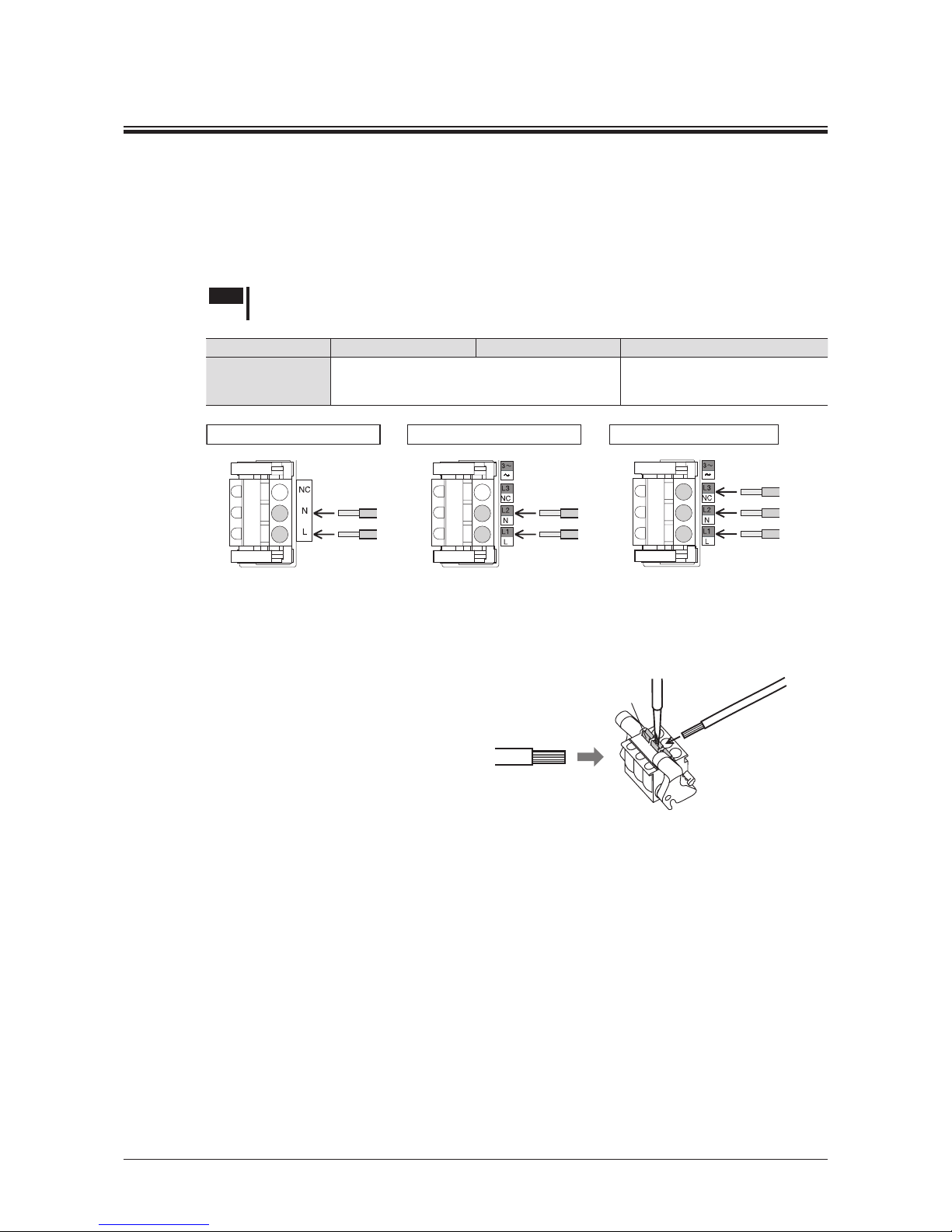

5.1 Connectingthepowersupply

The connection varies depending on the power supply voltage of the product. Connect the power supply cable to the

CN1 as shown in the gure.

The power cable is not included. It is provided as an accessory (sold separately).(p.38)

Note

Check the specication of the power supply voltage for the driver before applying a voltage.

If a voltage exceeding the rated range is applied, the driver may be damaged.

Input power supply Single-phase 100-120 V Single-phase 200-240 V Three-phase 200-240 V

Connecting method

Connect the live side to terminal L, and

the neutral side to terminal N.

Connect the R, S and T phase

lines to the L1, L2 and L3

terminals, respectively.

Three-phase 200-240 V

Single-phase 200-240 V

Single-phase 100-120 V

The 400 W type is indicated

L1, L2, and L3 only.

Connector model:

FKC2,5/3-ST-5,08-LR (PHOENIX CONTACT GmbH & Co. KG)

Connecting the lead wire

Connect to insert the lead wire to the connector.

•Applicable lead wire:

AWG18 to 14 (0.75 to 2.0 mm

2

)

•Length of the insulation cover which

can be peeled: 10 mm (0.39 in.)

•Conductive material: Use only copper wire.

Insert the lead wire

while pushing the

button of the orange

color with a screwdriver.

Button of the

orange color

Strip the

insulation cover

of the lead wire

Crimp terminals can also be used to connect.

If crimp terminals are used, select the following terminals.

Manufacturer: PHOENIX CONTACT GmbH & Co. KG

Model: AI 0,75-10 [Conductor cross-sectional area: 0.65 to 0.82 mm

2

(AWG18)]

AI 1-10 [Conductor cross-sectional area: 0.82 to 1.2 mm

2

(AWG18)]

AI 1,5-10 [Conductor cross-sectional area: 1.25 to 1.8 mm

2

(AWG16)]

AI 2,5-10 [Conductor cross-sectional area: 2.0 to 3.0 mm

2

(AWG14)]

Circuitbreaker

Be sure to connect a circuit breaker to the power line of the driver to protect the primary circuit.

Rated current of protective device: Single-phase input 10 A, three-phase input 10 A

Circuit breaker: Mitsubishi Electric Corporation NF30

Page 13

Connection

−13−

5.2 Connectingthemotor

Connect the motor connector (white) of the motor cable to the CN2, and the sensor connector (black) to the CN3 on

the driver. Check the pin assignment on p.38.

Use a connection cable (supplied or accessory) when extending the wiring distance between the motor and driver.

The connection cable can be connected up to 2 pieces. The wiring distance between the motor and driver can be

extended to a maximum of 10.5 m (34.4 ft.).

Note

Ensure that the connector plugged in securely. Insecure connections may cause malfunction or

damage to the motor or driver.

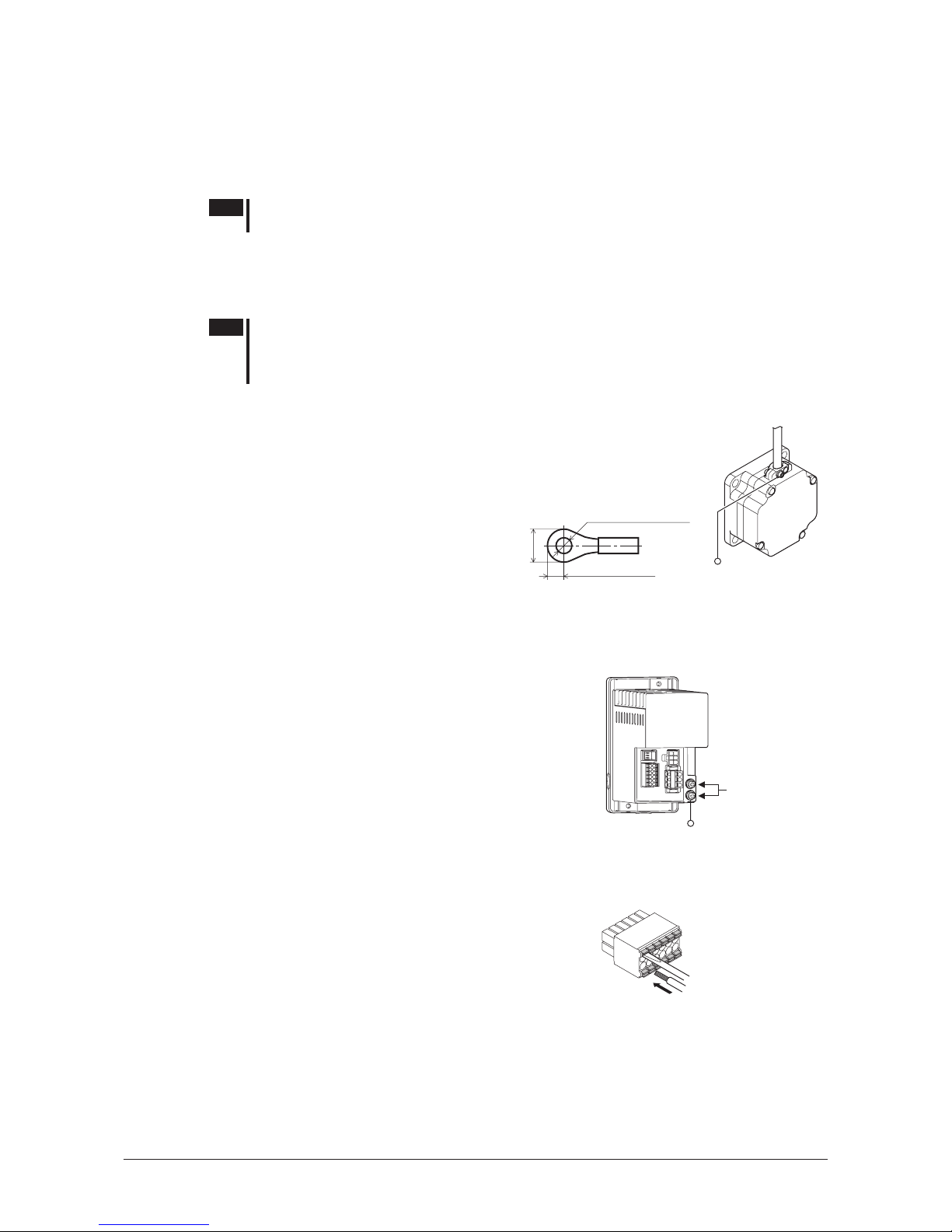

5.3 Grounding

Be sure to ground the product.

Ground the motor and driver using the Protective Earth Terminal (PE) respectively.

Note

Ground the product securely. Failure to do so may result in electric shock or damage to the

product.

The product will tend to be electried especially in a dry environment, so it may be damaged by

static electricity.

Motor

Connect the Protective Earth Terminal (PE) on the motor to the ground near the motor.

Minimize the wiring length of the ground cable.

Ground terminal

PE

•Applicable crimp terminal:

Round crimp terminal with insulation cover

•Thread size of terminal: M4

•Tightening torque: 1.2 N·m (10.6 lb-in)

•Applicable lead wire: AWG18 to 14 (0.75 to 2.0 mm

2

)

4.8 (0.19) or less

Ø4.1 (0.16) or more

[Unit: mm (in.)]

Driver

Two Protective Earth Terminals (PE) are provided on the driver. Ground either of the two Protective Earth Terminals

near the driver. You can ground either of the two Protective Earth Terminals. The terminal that is not grounded is used

as a service terminal. Use the service terminal according to your specic

need, such as connecting it to the motor in order to ground the motor.

Do not share the Protective Earth Terminal with a welder or any other

power equipment.

Ground terminal

•Applicable crimp terminal:

Round crimp terminal with insulation cover

•Thread size of terminal: M4

•Tightening torque: 1.2 N·m (10.6 lb-in)

•Applicable lead wire: AWG18 to 14 (0.75 to 2.0 mm

2

)

PE

Ground one of

these terminals.

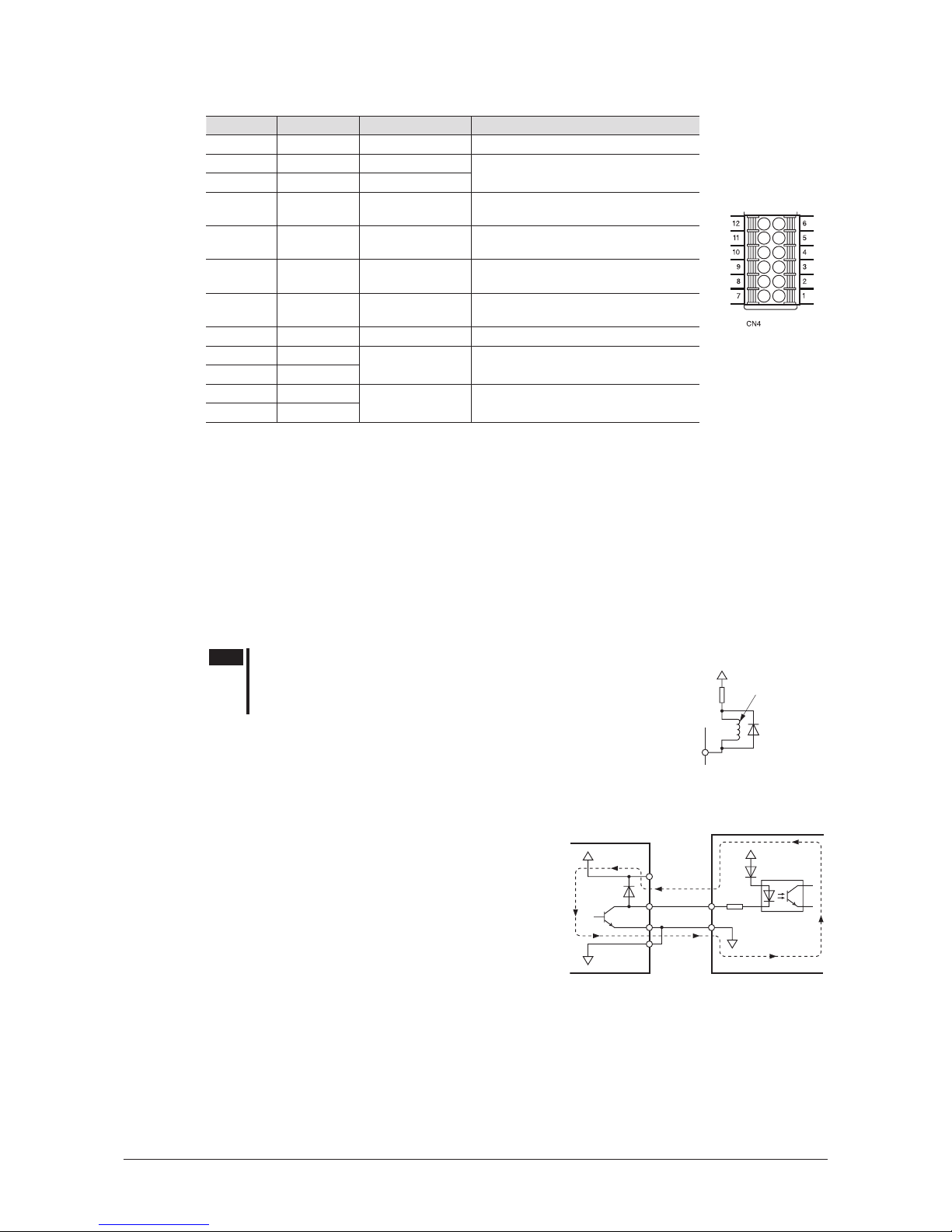

5.4 ConnectingtheI/Osignals

Connect the I/O signals to CN4 on the driver. Refer to p.16 for connection examples with a programmable controller.

Connecting the lead wire

Connect to insert the lead wire to the connector.

•Applicable lead wire: AWG24 to 18 (0.2 to 0.75 mm

2

)

•Length of the insulation cover which can be peeled: 10 mm (0.39 in.)

Crimp terminals can also be used to connect.

If crimp terminals are used, select the following terminals.

Manufacturer: PHOENIX CONTACT GmbH & Co. KG

Model: AI 0,25-10 [Conductor cross-sectional area: 0.14 to 0.34 mm

2

(AWG24)]

AI 0,34-10 [Conductor cross-sectional area: 0.14 to 0.34 mm

2

(AWG22)]

AI 0,5-10 [Conductor cross-sectional area: 0.40 to 0.65 mm

2

(AWG20)]

AI 0,75-10 [Conductor cross-sectional area: 0.65 to 0.82 mm

2

(AWG18)]

Connector model: DFMC1,5/6-ST-3,5 (PHOENIX CONTACT GmbH & Co. KG)

Page 14

Connection

−14−

CN4pinassignment

Pin No. Signal name Function

*

Description

1 IN4 [ALARM-RESET] This signal is used to reset the alarm.

2 IN3 [M1]

This signal is used to select the

operation data.

3 IN2 [M0]

4 IN1 [REV]

The motor rotates in the reverse

direction while this signal is being "ON."

5 IN0 [FWD]

The motor rotates in the forward

direction while this signal is being "ON."

6 IN-COM0 IN-COM0

Input signal common

(For external power supply)

7 IN-COM1 IN-COM1

Input signal common

(For internal power supply: 0 V)

8 N.C. N.C. Not connected.

9 OUT1-

[ALARM-OUT1]

This signal turns OFF when an alarm

generates (normally closed).

10 OUT1+

11 OUT0-

[SPEED-OUT]

30 pulses are output with each

revolution of the motor output shaft.

12 OUT0+

*

The signal in brackets [ ] is a function that is assigned at the time of shipment. The assigned functions can be changed by

setting parameters. Refer to p.27 for details.

Inputsignalcircuit

All input signals of the driver are photocoupler inputs. Use these signals by the internal power supply (+5 VDC) or

external power supply. When using the external power supply, both sink input logic and source input logic can be

used by changing the wiring.

Usable external power supply: 24 VDC −15% to +20%, 100 mA or more

Outputsignalcircuit

The driver outputs signals are photocoupler/open-collector output. The ON voltage of the output circuit is max. 1.5 V.

When driving each element using the output signal circuit, give consideration to this ON voltage.

External power supply: 4.5 to 30 VDC, 100 mA or less (For the SPEED-OUT output, supply at least 5 mA of current.)

Note

When connecting a relay (inductive load), etc., to detect

alarm outputs, use a relay with built-in ywheel diode, or

provide a y-back voltage control measure based on diode,

etc., for the inductive load.

CN4

Pin No.10, 12

Inductive load

Flywheel

diode

Usingaexternalcontrolequipmentwithabuilt-inclampdiode

If a external control equipment with a built-in clamp diode is

used, a leakage path may form and cause the motor to operate

even when the external control equipment power is off, as

long as the driver power is on. Since the power capacity of

the controller is different from that of the driver, the motor

may operate when the external control equipment and driver

powers are turned on or off simultaneously.

When powering down, turn off the driver power rst, followed

by the external control equipment power.

When powering up, turn on the external control equipment

power rst, followed by the driver power.

Driver

1 to 5

CN4

7

VCC

+5 V

0 V

0 V

External control

equipment

Page 15

Connection

−15−

5.5 Connectionexample

Connectionexampleforwhenusingswitchesandrelays

This is a connection example when the motor is operated using contact switches such as switches and relays.

(Single-phase 200-240 VAC)

Driver ground

Motor connection

Motor ground

NC

Motor connector

CN1

CN2

N

L

PE

Motor

Main circuit

Control circuit

Driver

CN4

4

7

IN-COM1 (0 V)

5

0 V

N

Circuit breaker

Shielded cable

Functional grounding

820 Ω

IN1 [REV]

IN0 [FWD]

IN2 [M0]

Sensor

connector

CN3

2

3

1

IN3 [M1]

IN4 [ALARM-RESET]

Power supply

connection

L

Refer to the next page for

connection of output signals.

+5 V

680 Ω

The I/O signal in the brackets [ ] is the assignment at the time of shipment.

Page 16

Connection

−16−

ConnectionexampleforI/Osignalsandprogrammablecontroller

This is a connection example when the motor is operated using a transistor output type programmable controller.

•Sink logic

24 VDC

CN4

4.5 to 30 VDC

100 mA or less→

IN-COM0

IN0

IN1

IN2

IN3

IN4

IN-COM1

OUT0+

OUT0

-

OUT1+

OUT1

-

100 mA or less→

0 V

5

6

4

3

2

1

6.6 kΩ

6.6 kΩ

6.6 kΩ

6.6 kΩ

6.6 kΩ

820 Ω

820 Ω

820 Ω

820 Ω

820 Ω

12

R∗

R∗

10

11

9

Programmable controller Driver

7

0 V

0 V

∗ Recommended current

In the case of 24 VDC: 680 Ω to 2.7 kΩ (2 W)

In the case of 5 VDC: 150 Ω to 560 Ω (0.5 W)

•Source logic

24 VDC

CN4

4.5 to 30 VDC

100 mA or less→

100 mA or less→

0 V

5

6

4

3

2

1

6.6 kΩ

6.6 kΩ

6.6 kΩ

6.6 kΩ

6.6 kΩ

820 Ω

820 Ω

820 Ω

820 Ω

820 Ω

12

R∗

R∗

10

11

9

Programmable controller Driver

7

0 V

0 V

IN-COM0

IN0

IN1

IN2

IN3

IN4

IN-COM1

OUT0+

OUT0

-

OUT1+

OUT1

-

∗ Recommended current

In the case of 24 VDC: 680 Ω to 2.7 kΩ (2 W)

In the case of 5 VDC: 150 Ω to 560 Ω (0.5 W)

Note

•Use a power supply of 20.4 VDC to 28.8 VDC, 100 mA or more, for connecting input signals.

•Turn ON the external power supply before turning ON the main power supply of the driver.

•For the OUT0 and OUT1, be sure to keep the current value at 100 mA or less. If the current

exceeds this value, connect the limiting resistor R.

Page 17

Operating by front panel

−17−

6 Operatingbyfrontpanel

This section explains how to operate the product with ease at the factory setting when receiving the product.

6.1 Connecting

Motor connector of the motor: White

䊻Connect the connector to the CN2

Sensor connector of the motor: Black

䊻Connect the connector to the CN3

PE

PE

Power supply

Connect the connector

to the CN1

Connecting the power supply

Example: Three-phase 200-240 V

Strip the insulation

cover of the lead wire

Insert the lead wire

while pushing the

button of the orange

color with a screwdriver.

Button of the

orange color

Connecting to the CN1

Connect the AC power supply to the CN1 according to the input voltage.

•

200 W type

•

400 W type

Note

•When cycling the power or plugging/unplugging the connector, turn off the power and wait for 1 minute

or more before doing so.

•Ensure that the connector plugged in securely. Insecure connections may cause malfunction or damage

to the product.

6.2 Inputtingthepower

Turn on the power after connecting as

shown in the gure above.

Display is lit

Indication: Rotation speed

Note

When inputting the power, if the operation switch is set to the RUN side, the

alarm code "

AL46

" (prevention of operation at power-on) is displayed, and

the operation cannot be executed.

Set the operation switch to the STAND-BY side and turn on the power.

Operation switch

*

Refer to p.33 for "prevention of operation at power-on" (alarm code: AL46).

Refer to the next page "6.3 Operating" for how to operate.

Refer to p.12 for the connecting the power supply.

Page 18

Operating by front panel

−18−

6.3 Operating

After turning on the power, operate the product as follows.

䐟 To start running the motor

䐢 To decelerate and stop

the motor

䐠 To adjust the motor rotation

speed

䐡 To determine the setting

of the motor rotation

speed

①

Runningthemotor

Setting the operation switch to the RUN side causes the motor to start rotating.

②

Adjustingthespeed

When turning the setting dial to the right slowly, the rotation speed accelerates by 1 r/min increments. When turning

the setting dial to the left slowly, the rotation speed decelerates by 1 r/min increments.

When turning the setting dial quickly, the amount of the rotation speed change increases.

③

Determiningthespeed

Set

When pressing the setting dial, the rotation speed is determined.

When the display is blinking, the rotation speed has not set yet. Determine it by pressing the setting dial.

(The set data is saved in the operation data No.0. Refer to p.24 for details.)

Conrmation

If the setting dial is pressed while the motor stops, the set speed is displayed blinking (several times).

Operating with the setting dial can be limited by the lock function so that the set rotation speed cannot be changed.

Refer to the p.31 "8.7 Data locking for the set data" for details.

④

Stoppingthemotor

Setting the operation switch to the STAND-BY side causes the motor to decelerate to a stop.

Setting the operation switch again to the RUN side causes the motor to start rotating at the set rotation speed.

[Changing the rotation direction]

Change the rotation direction of the motor (gearhead) using the

rotation direction switch. The rotation direction can be changed

while operating.

With the combination type, the rotation direction of the gearhead

output shaft varies depending on the gear ratio of the gearhead.

Refer to p.22 "7.3 Switching the motor rotation direction" for

details.

Rotation direction

switch

For switching the display or setting, refer to p.23 "8 Convenient functions."

Page 19

Operating by programmable controller

−19−

7 Operatingbyprogrammablecontroller

Motor Driver

AC power

supply

Programmable

controller

The motor can be operated and stopped externally.

7.1 Operating

After connecting the operation input signals (FWD input, REV input) to the CN4, set and operate

the product as follows.

Setting to the

external operation

Change the "external operation

signal input" parameter

Turn the FWD input or REV input ON

Turn OFF the operation input signal

that was turned ON

Power ON

Operation signals

Motor rotates

Motor decelerates to a stop.

[Connecting to the CN4]

· When using a programmable controller

· When using switches and relays

Operation

This operation example is for when the rotation speed is set to the operation data No.0.

Settingthe"Externaloperationsignalinput"parameter

The "external operation signal input" parameter ( ) is required to change the setting when operating or stopping

the motor externally.

The factory setting is "OFF" .

Setting range

oFF

: Operation/standstill using front panel

on

: Operation/standstill using external signals (Front panel operation···Enable)

rE

: Operation/standstill using external signals (Front panel operation···Disable)

【

Front panel operation

】

Operation using the switches and setting dial on the front panel can be set to

"Enable: ○ "

or

"Disable: × ."

Setting

①

Operation switch

②

Rotation direction switch

③

Setting dial

䐟

䐠

䐡

on

○ ○ ○

rE

× ×

×

*

*

The data mode, parameter mode, and the I/O monitor of the monitor mode are enabled

(possible to set).

Connection: p.12

p.16

p.15

Page 20

Operating by programmable controller

−20−

•When the setting is "ON"

Operation by switches on the front panel: Enable

When turning the operation input signal ON while the operation switch is set to the RUN side, the motor rotates.

When the operation switch is set to the "STAND-BY" side, the motor decelerates to a stop even if the operation input

signal is being ON.

Turning the setting dial changes the motor rotation speed.

If the rotation direction switch is changed, the motor rotates in the opposite direction.

•When the setting is "RE"

Operation by switches on the front panel: Disable

If the operation switch or rotation direction switch are operated while setting to "RE," "rE" will be displayed.

Also, if the setting dial is operated while displaying the rotation speed, alarm, or warning in the monitor mode, "

rE

"

will be displayed.

The data mode, parameter mode, and the I/O monitor of the monitor mode are enabled (possible to set).

The display time of "

rE

" varies depending on the switch.

•When setting the operation switch to the "RUN" side, "

rE

" will be displayed continuously.

•When switching the rotation direction switch to "FWD" (or "REV"), or when operating the setting dial, "

rE

" will

be displayed for two seconds.

Exampleoftimingchart

This is an example for when the "external operation signal input" parameter is set to "ON" and the rotation direction

switch is set to the "FWD" side.

CCW

CW CW CW

CCW

OFF

ON

STAND-BY

RUN

OFF

ON

∗

∗

10 ms or more

∗ ∗

Motor operation

50 ms or more

FWD input

Operation switch

REV input

FWD/REV operationRotation speed switching/Stop mode selection

Instantaneous

stop

Deceleration

stop

Deceleration

stop

Deceleration

stop

Deceleration

stop

[Operation input signal]

•The motor rotates when either of the FWD input or REV input is turned ON.

•If the FWD input and REV input are turned ON simultaneously, the motor stops instantaneously.

Page 21

Operating by programmable controller

−21−

7.2 Operatingwithmultiplespeeds

The operation at a speed of two or more can be performed by switching the external input.

Datasettingmethod

[Example:Settherotationspeedto3000r/min(changefrom50r/min)]

→

Power ON

Panel display

Data

mode

Press two times

Data number

selection screen

Data No.0

selection screen

Setting screen

Data No.0:

Operating data

No.0

The display

blinks

The desired operation data

number can be selected from

the operation data No.0 to No.3

(4 data) by pressing .

The desired operation data

can be selected by pressing .

∙ Rotation speed ( )

∙ Acceleration time ( )

∙ Deceleration time ( )

∙ Initialize ( )

Select the other operation data number and set data.

Turn until the number

reaches "3000"

Rotation speed:

50 r/min (Factory setting)

Turn

Setting

The display

blinks

Data determined

Blinks a few times fast

Press once

Press

Setting the

rotation speed

Press Press

Press

F

M

M

F

F

M

F

: Setting dial

: MODE key

: FUNCTION key

For the screen transitions, refer to p.24 "Setting items and panel displays."

Operatingmethod

Operate the motor by selecting any of the operation data No.0 to No.3 based on a combination of ON/OFF status of the M0 and

M1 inputs.

The motor is operated using the rotation speed, acceleration time, and deceleration time in the selected operation data number.

The acceleration time and deceleration time at the factory setting have been set by the acceleration/deceleration time

potentiometer.

[Operation procedure]

(Example: When the "external operation signal input" parameter is set to "ON" )

1. Set the operation switch to the "RUN" side.

2. Select the operation data number using the M0 and M1 inputs.

3. When either of the FWD input or REV input is turned ON, the motor will rotate.

4. Switch the operation data number using the M0 and M1 inputs.

5. When the FWD input or REV input which has been turned ON is turned OFF, the motor will stop.

•Example of operating condition

FWD input

3000 r/min

No.0 No.1 No.2

No.3

1000 r/min

OFF

ON

OFF

ON

M0 input

OFF

ON

M1 input

STAND-BY

RUN

2000 r/min

500 r/min

Motor operation

Operation switch

Operation

data No.

M0 M1

Rotation speed

[r/min]

0 OFF OFF 3000

1 ON OFF 1000

2 OFF ON 2000

3 ON ON 500

When changing from the present speed to the new

speed, the acceleration time and deceleration time

set in the next operation data number are used.

Page 22

Operating by programmable controller

−22−

7.3 Switchingthemotorrotationdirection

When turning the FWD input or REV input ON, the motor rotation direction varies depending on the state of the

rotation direction switch. The rotation direction shown in the gure below is as viewed from the motor output shaft.

Rotation direction switch

External operation input

FWD input REV input

"FWD" side

Motor rotation direction:

Clockwise

Motor rotation direction:

Counterclockwise

CW

CCW

"

REV

" side

Motor rotation direction:

Counterclockwise

Motor rotation direction:

Clockwise

CCW

CW

If the rotation direction switch is changed, the motor will decelerate to a stop and start rotating in the direction being

switched.

If the "external operation signal input" parameter is set to "RE," the rotation direction switch will be disabled.

The rotation direction at which "RE" was set is the same direction as the

"FWD" side

in the gure above.

Combination type • parallel shaft gearhead

The rotation direction of the motor output shaft may vary from that of the gearhead output shaft depending on the

gear ratio of the gearhead.

Gear ratio Rotation direction of gearhead output shaft

5, 10, 15, 20, 100, 200

Same as the motor output shaft

30, 50

Opposite to the motor output shaft

For switching the display or setting, refer to p.23 "8 Convenient functions."

Page 23

Convenient functions

−23−

8 Convenientfunctions

8.1 Functionslist

The following functions are available for this product.

Functions Description

Reference

page

Display

Rotation speed

Displays the rotation speed of the motor output shaft.

28, 26

Displays by converting the motor rotation speed into the

rotation speed of the gearhead output shaft.

Conveyor transfer speed

Displays by converting the motor rotation speed into the

transfer speed of the conveyor drive.

29, 26

Speed increasing

Displays by converting the motor rotation speed into the

increasing speed.

Load factor

Displays the load torque applied on the motor output

shaft as a percentage (%).

28

Operation data No.

Displays the operation data number that is presently

operating.

Alarm

Displays the alarm information by the alarm code.

28, 33

Displays the alarm records.

Warning

Displays the warning information by the waning code.

28, 35

Displays the warning records.

I/O signals

Checks whether a signal is input.

28

Checks whether a signal is output.

Setting

Rotation speed

Sets the motor rotation speed using the setting dial. 18

Sets the motor rotation speed in the operation data. 29

Acceleration time,

deceleration time

Sets using the acceleration/deceleration time

potentiometer.

30

Sets in the operation data. 29

Lock function

Disables an operation with the setting dial so that the set

data cannot be changed.

31

Operation using

programmable controller

Operates by inputting signals externally.

19

Disables an operation with the setting dial on the front

panel.

Operates with multiple speeds. (Up to 4 speeds) 21

Limiting the setting range

of the rotation speed

Sets the upper limit and lower limit of the rotation speed. 31

Slight position-keeping

The load position can be kept at motor standstill. 32

Changing the function for

I/O signals

Changes the functions assigned to the input signals

(5 input signals).

27

Changes the functions assigned to the output signals

(2 output signals).

Initial display at power ON

Changes the display item when turning on the power. 26

Data initialization

Restores the operation data to the factory setting

(initial value).

29

Restores the parameter setting to the factory setting

(initial value).

26

Page 24

Convenient functions

−24−

8.2 Settingitemsandpaneldisplays

M M

M

M

M

M

M

M

M

M

M

M

M

M

FF

F

F

F

M

F

F

F F

F

F

F

F

F

M

F

M

F

M

F

M

F

M

M

M

M

M

F

F

F

M

M

M

M

M

F

M

F

M

F

M

F

M

∗2

∗2

∗2

Speed setting

(blinking display)

Monitor mode

Top screen

Load factor

Operation data No.

Alarm

Warning

Alarm record 1

Return to the "alarm record 1"

Clear alarm

record

∗1

Warning record 1

Clear warning

record

∗1

Alarm

reset

Return to the "warning record 1"

I/O monitor

Return to the

"rotation speed"

Return to the "input monitor"

Input monitor

Output monitor

Data mode

Return to the "rotation speed 0"

Return to the

"operation

data No.0"

Operation

data No.0

Rotation

speed 0

Acceleration

time 0

Deceleration

time 0

Data setting

Data setting

Data setting

Initialize

data 0 Execution

Return to the "rotation speed 3"

Rotation

speed 3

Acceleration

time 3

Deceleration

time 3

Data setting

Data setting

Data setting

Initialize

data 3 Execution

Operation

data No.3

Rotation

speed

Return to the "monitor mode"

Returns to

the display at

power ON

(Only if an alarm

is present)

Power ON

The display for when turning on the power can be changed using the "panel initial view" parameter.

∗1

∗1

Page 25

Convenient functions

−25−

When the front panel is removed

M

F

The characters on the

black screen represents

the indication on the display.

Explanation of graphic symbols

: Turn the setting dial

:

Press the MODE key

:

Press the FUNCTION key

:

Press the setting dial

M

M

M

M

M

F

F

F

F

M

F

M

F

M

F

M

F

M

F

M

F

M

F

M

M

M

M

F

M

M

M

M

M

M

M M

M

M

F

M

F

M

M

M

M

M

F

M

M

M

M

M

M

∗2

∗2

∗2

∗2

∗2

∗2

∗2

M

F

M

∗2

Return to the "monitor mode"

Parameter mode

Execution

Retrun to the

"speed reduction ratio"

Speed

reduction

ratio

Speed

increasing

ratio

Panel initial

view

Data setting

Data setting

Data setting

Data setting

Data setting

Data setting

Data setting

Data setting

Data setting

Data setting

Speed upper

limit

Data setting

Speed lower

limit

Data setting

Data setting

Data setting

Signal

selection 0

Signal

selection 0

Data setting

Signal

selection 4

Data setting

Signal

selection 1

Data setting

External

operation

signal input

∗

2 It cannot be performed while operating.

" " was displayed.

∗

1 When operations are limited by the lock function,

the screen is not displayed.

Prevention of

operation at

power-on

alarm

Reset method

selection for the

prevention of

operation at

power-on

alarm

Analog

acceleration/

deceleration

time

Speed upper

and lower

limit

Slight

position-keeping

selection

Input function

selection

Output

function

selection

Overload alarm

detection time

except when

holding a

shaft

Overload

warning

level

Rotation speed

attainment

band

Initialize the

parameter

mode

∗1

Page 26

Convenient functions

−26−

8.3 Parameterlist

Operation mode: Parameter mode

Item Display Description Setting range

Factory

setting

Speed reduction ratio

Gr-r

Sets the speed reduction ratio

relative to the rotation speed of the

motor output shaft. Displays the

speed calculated based on the speed

reduction ratio on the monitor mode.

If the speed reduction ratio for the

conveyor is calculated and input, the

conveyor transfer speed can also be

displayed.

1.00 to 9999 1.00

Speed increasing ratio

Sp-r

When increasing the motor rotation

speed using the external mechanism

and others, the converted speed can

be displayed.

1.00 to 2.00 1.00

Panel initial view

PDSp

After the power is turned on, the item

displayed on the monitor mode can

be changed.

SpD

Rotation speed (r/min)

SpDtrQ

Load factor (%)

D-no

Operation data No.

Prevention of operation at

power-on alarm

opAL

Sets whether to enable or disable the

"prevention of operation at power-on

alarm."

oFF

Disable

on

on

Enable

Reset method selection for

the prevention of operation

at power-on alarm

oArS

Selects how to reset the prevention

of operation at power-on alarm.

DoFF

Resets by turning the FWD

input or REV input OFF, or by

setting the operation switch to

the STAND-BY side.

DoFF

ArSt

Resets using the

ALARMRESET input or the

alarm reset on the monitor

mode.

Analog acceleration/

deceleration time

tAtD

Changes the setting method of

acceleration/deceleration time.

An

Sets using the acceleration/

deceleration time potentiometer.

(analog)

An

D G

Sets using the operation data.

(digital)

Speed upper

and lower

limit

SPL~n

Speed

upper

limit

H

Sets the upper limit of the rotation

speed.

50 to 4000

4000

Speed

lower

limit

Lo

Sets the lower limit of the rotation

speed.

50

Slight position-keeping

selection

HoLD

The load position can be kept at

motor standstill.

oFF

Disable

oFF

on

Enable

External operation signal

input

oEn

The operation method can be

selected between the front panel and

external input signals.

When operating or stopping the motor

using the external input signals, the

functions of the operation switch,

rotation direction switch, and setting

dial can be set to disable.

oFF

Operation/standstill using

front panel

oFF

on

Operation/standstill using

external signals

(Front panel operation: Enable)

rE

Operation/standstill using

external signals

(Front panel operation: Disable)

IN0 input function selection

n-0

Assigns the input signals to the

external input terminals.

----

Not used

F_wd

FWD

rEu

REV

~n0

M0

~n1

M1

ArSt

ALARM-RESET

E-Er

EXT-ERROR

H-Fr

H-FREE

F_wd

IN1 input function selection

n-1

rEu

IN2 input function selection

n-2

~n0

IN3 input function selection

n-3

~n1

IN4 input function selection

n-4

ArSt

Page 27

Convenient functions

−27−

Item Display Description Setting range

Factory

setting

OUT0 output function

selection

oUt0

Assigns the output signals to the

external output terminals.

----

Not used

AL-1

ALARM-OUT1

Sp

SPEED-OUT

AL-2

ALARM-OUT2

~nouE

MOVE

uA

VA

_wnG

WNG

Sp

OUT1 output function

selection

oUt1 AL-1

Overload alarm detection

time except when holding a

shaft

oLt~n

Sets the time to output the alarm

after detecting the overload condition

when a load up to the limited duty

region exceeding the continuous duty

region was applied.

0.1 to 60.0 s 30.0

Overload warning level

oL-L

Sets the detection level (load factor) for

the overload warning function based

on the rated current being 100%.

50 to 120% 120

Rotation speed attainment

band

uA

Sets the band within which the

rotation speed of the motor is deemed

to have reached the set value.

0 to 400 r/min 200

Initialize the parameter

mode

n

Restores the value set in the

parameter mode to the factory setting.

− −

Note

•Do not turn off the motor power while the initialization is still in progress (= while the display is blinking).

Doing so may damage the data.

•When setting the speed increasing ratio to 1.00, the speed reduction ratio will be effective. When setting the

speed increasing ratio to other than 1.00, the speed increasing ratio will be effective.

•When setting a longer time in the "overload alarm detection time except when holding a shaft" parameter,

an overload status may continue. Repeating this condition may result in shorter service life of the motor and

gearhead.

•If a load exceeding the limited duty region was applied, the "overload alarm detection time except when holding

a shaft" is maximum 5 seconds.

DescriptionofI/Osignals

Signal Terminal Signal name Description

Input

IN0

IN1

IN2

IN3

IN4

FWD

The motor rotates when either of the FWD input or REV input is turned ON. If the FWD

input and REV input are turned ON simultaneously, the motor stops instantaneously.

REV

M0

These signals are used to select the operation data number. If both signals are turned

OFF, the operation data No.0 is selected.

M1

ALARM-RESET This signal is used to reset the alarm. Refer to p.34 for timing chart.

EXT-ERROR

When turning this signal OFF, an alarm generates and the motor stops instantaneously.

Then "

AL6E

" will be shown on the display (normally closed).

H-FREE

The slight position-keeping is released when the H-FREE input is turned ON.

(When the slight position-keeping selection is set to "Enable")

Output

OUT0

OUT1

ALARM-OUT1 This signal is output when an alarm generates (normally closed).

SPEED-OUT

30 pulses are output with each revolution of the motor output shaft synchronously with

the motor operation. The pulse width of output pulse signals is 0.2 ms. You can use the

SPEED-OUT output to calculate the motor speed.

Rotation speed (r/min) = × 60

SPEED-OUT output frequency

30

SPEED-OUT output frequency (Hz) =

1

T

T

0.2 ms

ALARM-OUT2

This signal is output when exceeding the overload warning level.

Or this signal is output when an overload alarm generates (normally closed).

MOVE This signal is output while the motor is operating.

VA

This signal is output when the motor rotation speed becomes equal the value set by the

rotation speed attainment band parameter.

WNG

This signal is output when a warning generates. (The motor will continue to operate.)

When the warning is released, it will automatically turn OFF.

Note

Do not assign the same input signal to multiple input terminals. When the same input signal is assigned to

multiple input terminals, the function will be executed if any of the terminals becomes active.

Page 28

Convenient functions

−28−

8.4 Itemsdisplayedonthedriver

Operation mode: Monitor mode

Item Display Description

Rotation speed

*

0

•Monitors the rotation speed of the motor.

•Monitors the rotation speed of the gear output shaft or conveyor transfer speed

when the "speed reduction ratio" parameter is set.

•When the "speed increasing ratio" parameter is set, the rotation speed being

increased by the external mechanism is displayed.

Load factor

t-

The motor generating torque can be checked. The present load factor is displayed

based on the rated torque being 100%. The load factor is displayed in 1%

increment between 40% and 200%, and "

t-

" is displayed if the load factor is

smaller than 40%.

The display is the load factor on the motor output shaft. It is not for the gearhead

output shaft.

With the combination type product, the permissible torque varies depending on the

gear ratio of the gearhead.

Use the product so that the load does not exceed the permissible torque of the

gearhead output shaft.

When the slight position-keeping is enabled, "

tH

" is displayed.

Operation data No.

opE0

Monitors the operation data No. currently selected.

Alarm

AL00

When an alarm generates, the alarm code is displayed. You can also reset alarms

or check and clear alarm records. Refer to p.33 for alarm type.

Warning

_wn00

When a warning generates, the warning code is displayed. You can also check

and clear warning records. Refer to p.35 for warning type.

I/O monitor

o

You can check the ON/OFF status of each I/O signal of the driver. If the signal is

ON, the corresponding digit is lit. If the signal is OFF, the digit is unlit.

IN0

IN1

IN2

OUT0

OUT1

Input

signals

Output

signals

IN4

IN3

*

For the factory setting, the rotation speed is displayed when the power is turned on.

The display for when turning on the power can be changed using the parameter. "Panel initial view" parameter: p.26

Displayoftherotationspeed

•Displayed digit number when setting the speed reduction ratio or speed increasing ratio

Since the number of signicant gures for the integer part is changed if the speed reduction ratio or speed increasing ratio is set,

the digit number displayed on the panel will also be changed.

Setting value for the speed reduction

ratio and speed increasing ratio

Display on the

monitor mode

1.00 to 9.99 0 to 9999

10.00 to 99.99 0.0 to 999.9

100.0 to 999.9 0.00 to 99.99

1000 or more 0.000 to 9.999

Page 29

Convenient functions

−29−

•Display the conveyor transfer speed

To display the conveyor transfer speed, calculate the conveyor speed reduction ratio by using the formula below and

set to the "speed reduction ratio" parameter.

Conveyor speed reduction ratio =

1

Feed rate per motor revolution

Gearhead gear ratio

Pulley diameter [m] × π

=

When the calculated conveyor speed reduction ratio is used, the conveyor transfer

speed is converted as follows:

Conveyor transfer speed [m/min] =

Motor output shaft rotation speed [r/min]

Conveyor speed reduction ratio

Conveyor transfer

speed

Pulley

diameter